Extraction of plant long fiber and its application in biodegradable composites

-

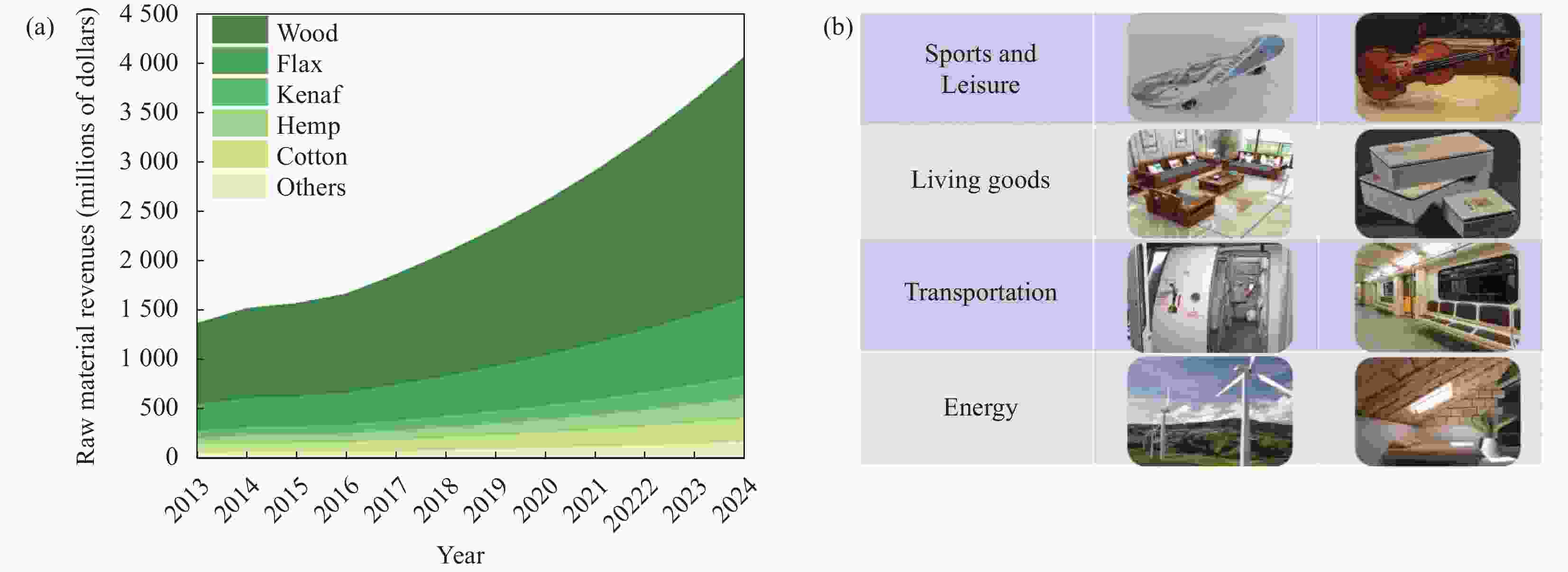

摘要: 植物纤维具有绿色环保、轻质高强、吸声隔热和低碳足迹等优点,与聚合物制备成复合材料后被广泛应用于汽车、航空、建筑和包装运输等领域。本文简述了植物长纤维的种类和提取方法对其物理性能的影响,同时结合纤维取向分布、纤维表面改性、复合材料成型工艺以及拉伸载荷下复合材料的失效模式,概述了植物长纤维作为增强体时对复合材料物理性能的影响,并对植物长纤维增强可降解复合材料的应用进行了总结和展望。Abstract: Plant fibers have the advantages of eco-friendliness, lightweight, high strength, sound and heat insulating, and low carbon footprint, etc. These attributes make them highly sought-after for applications in sectors such as automotive, aerospace, construction, packaging, and transportation, particularly when plant fibers are processed into composites with polymers. This paper briefly describes the effects of the types of plant long fibers and extraction methods on their physical properties, and at the same time outlines the effects of plant long fibers on the physical properties of composites when they are used as reinforcement in combination with the fiber orientation distribution, fiber surface modification, composite molding process, and failure modes under tensile loading, as well as summarizes and looks forward to the application of plant long fiber-reinforced biodegradable composites.

-

Key words:

- Plant long fibers /

- Extraction process /

- Orientation distribution /

- Degradable composites /

- Application

-

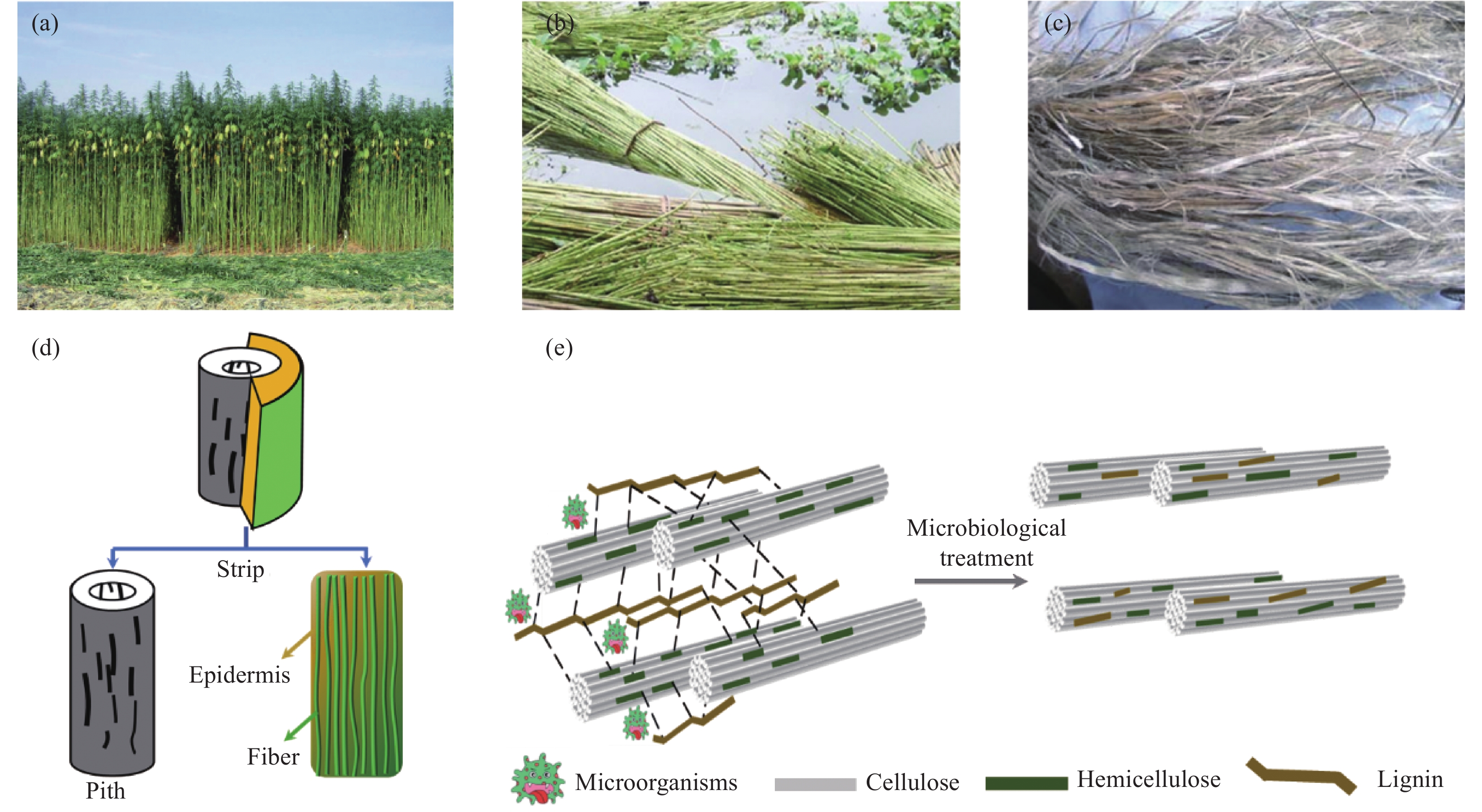

图 1 (a) 人工种植用于提取长纤维的大麻;(b) 自然水沤处理大麻茎秆;(c) 经自然沤制处理后提取的大麻长纤维;(d) 大麻茎秆组织结构示意图;(e) 生物法分离植物纤维的机制示意图

Figure 1. (a) Industrial hemp grown for long fiber production; (b) retting process of hemp stem in the natural environment; (c) long hemp fiber extracted by the retting process; (d) schematic of the tissue structure of hemp stem, and (e) schematic of the mechanism of biological separation of plant fibers

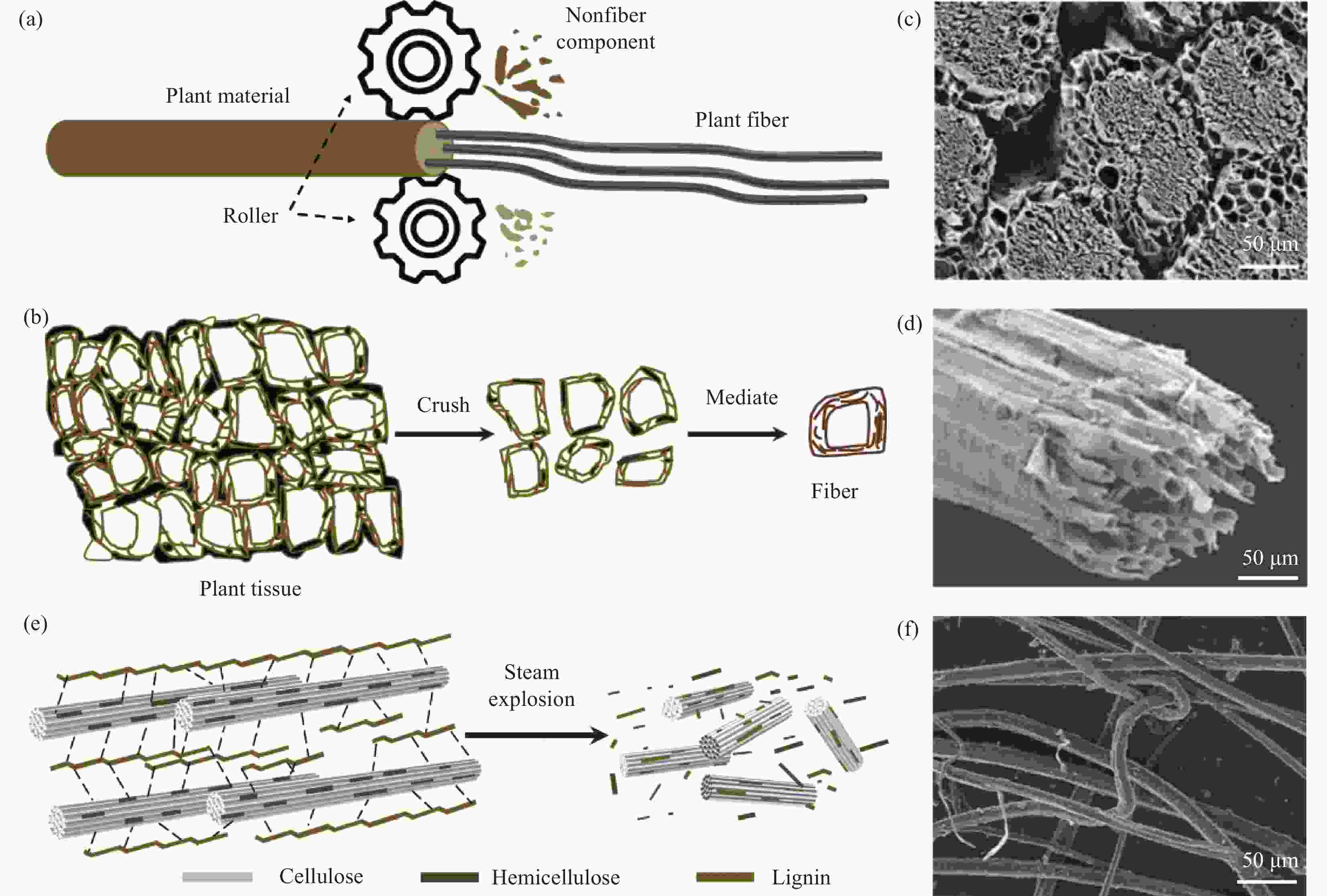

图 2 (a) 机械拆解提取植物纤维示意图;(b) 植物在机械处理过程中的组织结构变化示意图;(c) 天然香蕉茎秆横截面的扫描电镜图;(d) 机械拆解提取的单个香蕉茎秆纤维束的扫描电镜图[25];(e) 蒸汽爆破工艺拆解纤维示意图;(f) 蒸汽爆破法提取的筇竹微纤维的扫描电镜图[28]

Figure 2. (a) Schematic of mechanical extraction of fibers from plants; (b) schematic of structural changes in plant during mechanical treatment; (c) SEM image of cross-section of natural banana stem; (d) SEM image of single fiber bundle mechanically extracted from banana stem[25]; (e) schematic of natural fibers isolated by steam explosion treatment, and (f) SEM image of bamboo microfibers extracted from Qiongzhuea tumidinoda by steam explosion treatment[28]

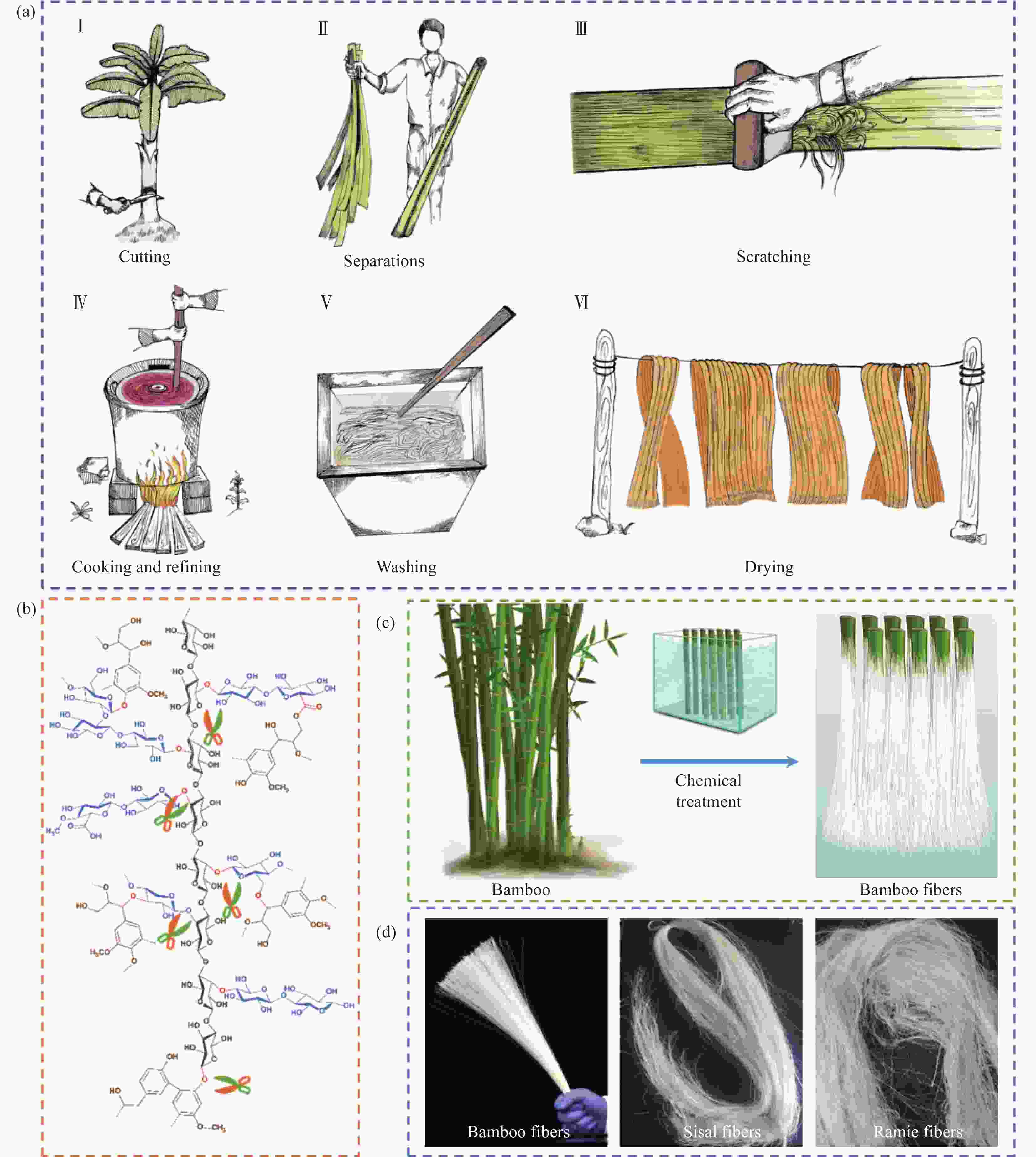

图 3 (a) 传统手工提取香蕉茎秆长纤维的示意图;(b) 化学法处理过程中主要组分连接键断裂示意图;(c) 化学脱木素法提取竹长纤维束示意图;(d) 经化学-机械法提取的部分植物长纤维实物照片

Figure 3. (a) Schematic of traditional manual extraction of long fibers from banana stem; (b) schematic of typical chemical bonding broken during the chemical treatment; (c) schematic of long bamboo fiber bundles extracted by chemical delignification method and (d) photos of long fibers extracted by chemical-mechanical method

图 5 (a) 短纤维在聚合物基体中随机取向分布;(b) 长纤维在基体中单向排列分布;(c) 平纹织物中的长纤维取向分布;(d) 斜纹织物中的长纤维分布;(e) 缎纹织物中的长纤维分布;(f) 三维织物中的长纤维分布

Figure 5. (a) Randomly oriented short fibers in polymer matrix; (b) aligned long fibers in polymer matrix; (c) distribution of long fibers oriented in plain fabrics; (d) distribution of long fibers in twill fabrics; (e) distribution of long fibers in satin fabrics, and (f) distribution of long fibers in three-dimensional fabrics

图 6 (a) 手工层积制备复合材料工艺示意图;(b) 热压成型制备复合材料工艺示意图;(c) 真空辅助成型制备复合材料工艺示意图;(d) 3D打印制备复合材料工艺示意图[104]:单喷嘴打印和双喷嘴打印;(e) 连续纤维热塑性复合材料自动铺放原位成型工艺示意图[105]

Figure 6. (a) Schematic of composites prepared by hand lay-up; (b) schematic of composites prepared by hot-compression molding; (c) schematic of composites prepared by vacuum assisted resin transfer molding; (d) schematic of composites prepared by 3D printing: single-nozzle printing and dual-nozzle printing[104]; (e) schematic of AFP in-situ consolidation technology on continuous fiber reinforced thermoplastic matrix composites[105]

图 7 (a) 随机短纤维增强的复合材料在拉伸载荷下裂纹扩展及受力分析示意图和 (b) 定向长纤维增强的复合材料在拉伸载荷下裂纹的偏转或阻滞及受力分析示意图[106];(c) 裂纹途径纤维二维织物结构时的偏转或阻滞示意图;(d) 裂纹途径定向纤维三维织物结构时产生的偏转或阻滞示意图

Figure 7. Illustrates the following schematics: (a) crack extension and force analysis of composites reinforced with random short fibers under tensile loading and (b) deflection or blocking of cracks and force analysis of composites reinforced with oriented long fibers under tensile loading[106]; (c) deflection or hysteresis in crack pathway oriented to fibers in a two-dimensional fabric structure, and (d) deflection or hysteresis in crack pathway oriented to fibers in a three-dimensional fabric structure

Raw material Plant Cellulose/% Hemicellulose/% Lignin/% Pectin/% Ref. Bast Hemp 70-74 17.9-22.4 3.7-5.7 0.9 [9][10] Flax 71-78 18.6-20.6 2.2 2.3 [9][10] Ramie 68.6-91 5-16.7 0.6-0.7 1.9 [9][11] Leave Sisal 67-78 10-12 8-11 10-14.2 [9][12][13] Agave americana 68.4 15.6 4.85 - [14] Pineapple 70-83 15-20 8-12.7 1.1-4 [9][10][13] Stem Banana 60-85 6-21 5-10 2.5-5 [10][11][13] Bamboo 26-73.8 12.5-30 10.1-26 0.37 [9][10][12] 表 2 经不同方法提取的植物长纤维的物理性能

Table 2. Physical properties of long plant fibers extracted by different methods

Raw plants Length/cm Diameter/μm Tensile strength/MPa Young's modulus/GPa Extraction method Ref. Hemp 6 20-33 683-954 27.5-34.9 Retting [17] Hemp 100 100-230 174-342 8-12 Retting [43] Flax 7.5 64-104 200-400 19-41 Retting [44] Ramie 8 47-51 23-58 5.0-6.0 Enzyme [45] Sisal 5 50-300 530-640 9.4-22 Mechanical [46] Agave americana 180-230 165-333 62-206 0.85-2.84 Retting [47] Pineapple leaf 25-90 50-91 210-695 15-53 Chemical [48][49] Banana stem 30.5 100-400 143 2.1 Retting [50] Banana stem 15 140-180 141-329 10.8-21.8 Enzyme [26] Banana stem 15 56-143 124-296 15.0-38.7 Mechanical [26] Banana stem 15 50-90 241-425 14.8-30.3 Chemical [26] Bamboo 2.5-10 167-550 371-673 11.5-25.7 Mechanical [51] Bamboo 30 50-250 1650-2250 90-120 Chemical [52] 表 3 一些植物长纤维增强聚乳酸复合材料的力学性能

Table 3. Mechanical properties of some plant long fiber reinforced polylactic acid composites

Polymer

matrixFiber type Fiber volume fraction/% Tensile strength/

MPaYoung's modulus/

GPaFlexural strength/

MPaRef. Polylactic

acid (PLA)Unidirectional long sisal fiber 40 164.8 4.9 202.9 [74] Unidirectional long sisal fiber 40 200.4 6.5 216.8 [58] Unidirectional long flax fiber 49.5 151.0 18.5 215.0 [57] Unidirectional long kenaf fiber 70 223 - 254 [75] Hemp twill fabric 20 70 3.5 - [69] Hemp plain fabric 20 60 3.0 - [69] Sisal plain fabric 31 64.1 9.9 - [76] Flax plain fabric 33 45.2 2.1 90.0 [77] Bamboo plain fabric 35 80.6 5.9 143 [78] Jute plain fabric 36 69.3 9.0 - [76] 3D woven ramie fabric 50 - - 74.3 [72] 3D woven ramie fabric 53 91.9 18.1 - [71] -

[1] LI G, ZHAO M, XU F, et al. Synthesis and biological application of polylactic acid[J]. Molecules, 2020, 25(21): 5023. doi: 10.3390/molecules25215023 [2] ANJUM A, ZUBER M, ZIA K M, et al. Microbial production of polyhydroxyalkanoates(PHAs)and its copolymers: A review of recent advancements[J]. International journal of biological macromolecules, 2016, 89: 161-174. doi: 10.1016/j.ijbiomac.2016.04.069 [3] LUO J, XI C, GU Y, et al. Toughening mechanism of SIALON/Si2N2O multiphase ceramics and finite element simulation of stress field at crack tip[J]. Computational Materials Science, 2019, 159: 194-201. doi: 10.1016/j.commatsci.2018.12.005 [4] CHAUDHARY V, AHMAD F. A review on plant fiber reinforced thermoset polymers for structural and frictional composites[J]. Polymer Testing, 2020, 91: 106792. doi: 10.1016/j.polymertesting.2020.106792 [5] BALLA V K, KATE K H, SATYAVOLU J, et al. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects[J]. Composites Part B:Engineering, 2019, 174: 106956. doi: 10.1016/j.compositesb.2019.106956 [6] RÁTHY I, KUKI Á, BORDA J, et al. Preparation and characterization of poly (vinyl chloride)–continuous carbon fiber composites[J]. Journal of applied polymer science, 2012, 124(1): 190-194. doi: 10.1002/app.33617 [7] 宋亚男, 陈绍状, 侯丽华, 等. 植物纤维增强聚乳酸可降解复合材料的研究[J]. 高分子通报, 2011, (9): 111-120.SONG Yanan, CHEN Shaozhuang, HOU Lihua, et al. Research on plant fiber reinforced polylactic acid degradable composites[J]. Polymer Bulletin, 2011, (9): 111-120(in Chinese). [8] LI J, LEMSTRA P J, MA P. Can high-performance fibers be (come) bio-based and also biocompostable?[J]. Advanced Industrial and Engineering Polymer Research, 2022, 5(2): 117-132. doi: 10.1016/j.aiepr.2022.03.002 [9] THANGADURAI D, DABIRE S S, SANGEETHA J, et al. Greener composites from plant fibers: Preparation, structure, and properties[J]. Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications, 2020: 1-19. [10] SANIVADA U K, MÁRMOL G, BRITO F P, et al. PLA composites reinforced with flax and jute fibers—A review of recent trends, processing parameters and mechanical properties[J]. Polymers, 2020, 12(10): 2373. doi: 10.3390/polym12102373 [11] VIGNESHWARAN S, SUNDARAKANNAN R, JOHN K M, et al. Recent advancement in the natural fiber polymer composites: A comprehensive review[J]. Journal of Cleaner Production, 2020, 277: 124109. doi: 10.1016/j.jclepro.2020.124109 [12] BALDA S, SHARMA A, CAPALASH N, et al. Banana fibre: a natural and sustainable bioresource for eco-friendly applications[J]. Clean Technologies and Environmental Policy 2021, 23: 1389-1401. [13] NURUL FAZITA M R, NURNADIA M J, ABDUL KHALIL H P S, et al. Woven natural fiber fabric reinforced biodegradable composite: processing, properties and application[J]. Green Biocomposites: Manufacturing and Properties, 2017: 199-224. [14] MYLSAMY K, RAJENDRAN I. Investigation on physio-chemical and mechanical properties of raw and alkali-treated Agave americana fiber[J]. Journal of Reinforced Plastics and composites, 2010, 29(19): 2925-2935. doi: 10.1177/0731684410362817 [15] MEDDAH M, ROKBI M, ZAOUI M. Extraction and characterization of novel natural lignocellulosic fibers from Malva sylvestris L[J]. Journal of Composite Materials, 2023, 57(5): 897-912. doi: 10.1177/00219983221146355 [16] PANDEY R, JOSE S, SINHA M K. Fiber extraction and characterization from Typha domingensis[J]. Journal of Natural Fibers, 2022, 19(7): 2648-2659. doi: 10.1080/15440478.2020.1821285 [17] LIU M, FERNANDO D, DANIEL G, et al. Effect of harvest time and field retting duration on the chemical composition, morphology and mechanical properties of hemp fibers[J]. Industrial Crops and Products, 2015, 69: 29-39. doi: 10.1016/j.indcrop.2015.02.010 [18] RÉQUILÉ S, MAZIAN B, GRÉGOIRE M, et al. Exploring the dew retting feasibility of hemp in very contrasting European environments: Influence on the tensile mechanical properties of fibres and composites[J]. Industrial Crops and Products, 2021, 164: 113337. doi: 10.1016/j.indcrop.2021.113337 [19] MANIAN A P, CORDIN M, PHAM T. Extraction of cellulose fibers from flax and hemp: a review[J]. Cellulose, 2021, 28(13): 8275-8294. doi: 10.1007/s10570-021-04051-x [20] LIU M, FERNANDO D, MEYER A S, et al. Characterization and biological depectinization of hemp fibers originating from different stem sections[J]. Industrial Crops and Products, 2015, 76: 880-891. doi: 10.1016/j.indcrop.2015.07.046 [21] HOSSAIN M M, SUBBIAH V K, SIDDIQUEE S. Augmented retting effect on kenaf fibers using alkalophilic pectinase-producing bacteria in combination with water solvents[J]. Applied Sciences, 2022, 12(14): 7136. doi: 10.3390/app12147136 [22] LEE C H, KHALINA A, LEE S H, et al. A comprehensive review on bast fibre retting process for optimal performance in fibre-reinforced polymer composites[J]. Advances in Materials Science and Engineering, 2020, 2020: 1-27. [23] 余养伦. 高性能竹基纤维复合材料制造技术及机理研究[D]. 北京: 中国林业科学研究院, 2014.YU Yanglun. Manufacturing technology and mechanism of high performance bamboo-based fiber composites[D]. Beijing: Chinese Academy of Forestry, 2014(in Chinese). [24] 王新洲, 袁朱润, 黄雅茜, 等. 毛竹工艺纤维高温饱和蒸汽-机械分离及其物理力学特性[J]. 复合材料学报, 2021, 38(6): 1905-1913.WANG Xinzhou, YUAN Zhuyun, HUANG Yaxi, et al. Physical and mechanical properties of bamboo fibers extracted by high-temperature saturated steam and mechanical treatment[J]. Acta Materiae Compositae Sinica, 2021, 38(6): 1905-1913(in Chinese). [25] AMUTHA K, SUDHA A, SARAVANAN D. Characterization of natural fibers extracted from banana inflorescence bracts[J]. Journal of Natural Fibers, 2022, 19(3): 872-881. doi: 10.1080/15440478.2020.1764437 [26] XU S, XIONG C, TAN W, et al. Microstructural, thermal, and tensile characterization of banana pseudo-stem fibers obtained with mechanical, chemical, and enzyme extraction[J]. BioResources, 2015, 10(2): 3724-3735. [27] 徐红, 徐勇, 勇强, 等. 蒸汽爆破预处理对红柳木质组分及酶解性能的影响[J]. 林业科学, 2012, 48(11): 92-97. doi: 10.11707/j.1001-7488.20121115XU Hong, XU Yong, YONG Qiang, et al. Woody components and enzymatic hydrolysis property of tamarix ramosissima under various intensity of steam explosion[J]. Scientia Silvae Sinicae, 2012, 48(11): 92-97(in Chinese). doi: 10.11707/j.1001-7488.20121115 [28] LI Q, LUO R, CHEN Y, et al. The Study on bamboo microfibers isolated by steam explosion and their comprehensive properties[J]. Journal of Renewable Materials, 2023, 11(6): 2809-2822. doi: 10.32604/jrm.2023.026184 [29] ZAKIKHANI P, ZAHARI R, SULTAN M T H, et al. Extraction and preparation of bamboo fibre-reinforced composites[J]. Materials & Design, 2014, 63: 820-828. [30] ZHAO W, ZOU Y, ZHANG W, et al. Effect of fiber separation degree on the properties of bamboo fiber composites[J]. European Journal of Wood and Wood Products, 2023, 81(5): 1249-1259. doi: 10.1007/s00107-023-01928-5 [31] LI C, HUANG X, XI J. Steam explosion pretreatment to enhance extraction of active ingredients: current progress and future prospects[J]. Critical Reviews in Food Science and Nutrition, 2023: 1-9. [32] 徐树英, 谭蔚, 张玉苍. 香蕉茎秆纤维化学脱胶工艺及脱胶纤维性能[J]. 农业工程学报, 2015, 31(13): 301-308. doi: 10.11975/j.issn.1002-6819.2015.13.042XU Shuying, TAN Wei, ZHANG Yucang. Process of degumming by chemical for banana pseudostem fibers and characterization of degummed fibers[J]. Journal of Agricultural Engineering, 2015, 31(13): 301-308(in Chinese). doi: 10.11975/j.issn.1002-6819.2015.13.042 [33] LI Z, CHEN C, XIE H, et al. Sustainable high-strength macrofibres extracted from natural bamboo[J]. Nature Sustainability, 2022, 5(3): 235-244. [34] CHEN L Y, MENG X G, YU W W, et al. Efficient separation of cellulose from bamboo by organic alkali[J]. Cellulose, 2023, 30(3): 1369-1379. doi: 10.1007/s10570-022-04969-w [35] HUANG H, TANG Q, LIN G, et al. Anthraquinone-assisted deep eutectic solvent degumming of ramie fibers: evaluation of fiber properties and degumming performance[J]. Industrial Crops and Products, 2022, 185: 115115. doi: 10.1016/j.indcrop.2022.115115 [36] TWEBAZE C, ZHANG M, ZHUANG X, et al. Banana fiber degumming by alkali treatment and ultrasonic methods[J]. Journal of Natural Fibers, 2022, 19(16): 12911-12923. doi: 10.1080/15440478.2022.2079581 [37] LI C, LIU S, SONG Y, et al. A facile and eco-friendly method to extract apocynum venetum fibers using microwave-assisted ultrasonic degumming[J]. Industrial crops and products, 2020, 151: 112443. doi: 10.1016/j.indcrop.2020.112443 [38] ALABDALI R A, GARRISON T F, MAHMOUD M M, et al. Micromechanical characterization of continuous fiber date palm composites[J]. Journal of Natural Fibers, 2023, 20(2): 2280050. doi: 10.1080/15440478.2023.2280050 [39] LIU J, GUAN Z, LI Z. Application of cryogenic and mechanical treatment in degumming of hemp stems[J]. Biosystems Engineering, 2018, 174: 144-152. doi: 10.1016/j.biosystemseng.2018.07.007 [40] SHADHIN M, RAHMAN M, JAYARAMAN R, et al. Natural biomass & waste biomass fibers–structures, environmental footprints, sustainability, degumming methods, & surface modifications[J]. Industrial Crops and Products, 2023, 204: 117252. doi: 10.1016/j.indcrop.2023.117252 [41] LYU P, ZHANG Y, WANG X, et al. Degumming methods for bast fibers—A mini review[J]. Industrial Crops and Products, 2021, 174: 114158. doi: 10.1016/j.indcrop.2021.114158 [42] 开吴珍. 大麻脱胶方法综述[J]. 染整技术, 2019, 41(7): 20-23. doi: 10.3969/j.issn.1005-9350.2019.07.004KAI Wuzhen. Reviews on hemp degumming methods[J]. Textile Dyeing and Finishing Journal, 2019, 41(7): 20-23(in Chinese). doi: 10.3969/j.issn.1005-9350.2019.07.004 [43] MAZIAN B, BERGERET A, BENEZET J C, et al. Influence of field retting duration on the biochemical, microstructural, thermal and mechanical properties of hemp fibres harvested at the beginning of flowering[J]. Industrial crops and products, 2018, 116: 170-181. doi: 10.1016/j.indcrop.2018.02.062 [44] YAN L, CHOUW N, JAYARAMAN K. Flax fibre and its composites–A review[J]. Composites Part B:Engineering, 2014, 56: 296-317. doi: 10.1016/j.compositesb.2013.08.014 [45] ANGELINI L G, SCALABRELLI M, TAVARINI S, et al. Ramie fibers in a comparison between chemical and microbiological retting proposed for application in biocomposites[J]. Industrial Crops and Products, 2015, 75: 178-184. doi: 10.1016/j.indcrop.2015.05.004 [46] SATHISHKUMAR T P, NAVANEETH-AKRISHNAN P, SHANKAR S, et al. Characterization of natural fiber and composites–A review[J]. Journal of Reinforced Plastics and Composites, 2013, 32(19): 1457-1476. doi: 10.1177/0731684413495322 [47] BEZAZI A, BELAADI A, BOURCHAK M, et al. Novel extraction techniques, chemical and mechanical characterisation of agave americana L. natural fibres[J]. Composites Part B:Engineering, 2014, 66: 194-203. doi: 10.1016/j.compositesb.2014.05.014 [48] GEBINO G, MUHAMMED N. Extraction and characterization of ethiopian pineapple leaf fiber[J]. Current Trends in Fashion Technology & Textile Engineering, 2018, 4(4): 77-83. [49] NETO A R S, ARAUJO M A M, SOUZA F V D, et al. Characterization and comparative evaluation of thermal, structural, chemical, mechanical and morphological properties of six pineapple leaf fiber varieties for use in composites[J]. Industrial Crops and Products, 2013, 43: 529-537. doi: 10.1016/j.indcrop.2012.08.001 [50] IKE-EZE I C E, AIGBODION V S, UDE S N, et al. Experimental study on the effects of surface treatment reagents on tensile properties of banana fiber reinforced polyester composites[J]. Journal of Materials and Environmental Science J, 2019, 10(5): 402-410. [51] PHONG N T, FUJII T, CHUONG B, et al. Study on how to effectively extract bamboo fibers from raw bamboo and wastewater treatment[J]. Journal of Materials Science Research, 2012, 1(1): 144. [52] LI Z, CHEN C, XIE H, et al. Sustainable high-strength macrofibres extracted from natural bamboo[J]. Nature Sustainability, 2022, 5(3): 235-244. [53] BAGHERI S, NEJAD M. Fully biobased composite made with epoxidized-lignin, reinforced with bamboo fibers[J]. Polymer Composites, 2023. [54] PANIC V V, SESLIJA S I, POPOVIC I G, et al. Simple one-pot synthesis of fully biobased unsaturated polyester resins based on itaconic acid[J]. Biomacromolecules, 2017, 18(12): 3881-3891. doi: 10.1021/acs.biomac.7b00840 [55] PRABUNATHAN P, ELUMALAI P, DINESH KUMAR G, et al. Antiwetting and low-surface-energy behavior of cardanol-based polybenzoxazine-coated cotton fabrics for oil–water separation[J]. Journal of Coatings Technology and Research, 2020, 17: 1455-1469. doi: 10.1007/s11998-020-00365-w [56] MAYILSWAMY N, KANDASUBRAMANIAN B. Green composites prepared from soy protein, polylactic acid (PLA), starch, cellulose, chitin: a review[J]. Emergent Materials, 2022, 5(3): 727-753. doi: 10.1007/s42247-022-00354-2 [57] AKONDA M, ALIMUZZAMAN S, Shah D U, et al. Physico-mechanical, thermal and biodegradation performance of random flax/polylactic acid and unidirectional flax/polylactic acid biocomposites[J]. Fibers, 2018, 6(4): 98. doi: 10.3390/fib6040098 [58] LIANG Z, WU H, LIU R, et al. Preparation of long sisal fiber-reinforced polylactic acid biocomposites with highly improved mechanical performance[J]. Polymers, 2021, 13(7): 1124. doi: 10.3390/polym13071124 [59] MISRI S, SAPUAN S M, LEMAN Z, et al. Tensile properties of Kenaf yarn fibre reinforced unsaturated polyester composites at different fibre orientations[J]. Applied Mechanics and Materials, 2014, 564: 412-417. doi: 10.4028/www.scientific.net/AMM.564.412 [60] THARAZI I, ABDUL AZAM F A, MUHAMAD N, et al. Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites[J]. Reviews on Advanced Materials Science, 2023, 62(1): 20220275. doi: 10.1515/rams-2022-0275 [61] 王春红, 陈祯, 张青菊. 缝合技术在长竹纤维复合材料制备中的应用研究[J]. 塑料工业, 2016, 44(7): 47-50. doi: 10.3969/j.issn.1005-5770.2016.07.012WANG Chunhong, CHEN Zhen, ZHANG Qingju. Application of stitching technology in fabricating long bamboo fiber-reinforced composites[J]. China Plastics Industry, 2016, 44(7): 47-50(in Chinese). doi: 10.3969/j.issn.1005-5770.2016.07.012 [62] CORBIN A C, SALA B, SOULAT D, et al. Development of quasi-unidirectional fabrics with hemp fiber: A competitive reinforcement for composite materials[J]. Journal of Composite Materials, 2021, 55(4): 551-564. doi: 10.1177/0021998320954230 [63] SAHOO S K, MOHANTY S, NAYAK S K. Mechanical, dynamic mechanical, and interfacial properties of sisal fiber-reinforced composite with epoxidized soybean oil-based epoxy matrix[J]. Polymer Composites, 2018, 39(6): 2065-2072. doi: 10.1002/pc.24168 [64] 谭焕成, 覃文源, 刘升旺, 等. 三维编织复合材料细观几何建模及动态力学性能的研究进展[J]. 机械工程材料, 2021, 45(8): 1-7. doi: 10.11973/jxgccl202108001TAN Huancheng, QIN Wenyuan, LIU Shengwang, et al. Research progress on establishment of meso-scale geometrical model and dynamic mechanical properties of 3D braided composite[J]. Materials for Mechanical Engineering, 2021, 45(8): 1-7(in Chinese). doi: 10.11973/jxgccl202108001 [65] KHAN G M A, TERANO M, GAFUR M A, et al. Studies on the mechanical properties of woven jute fabric reinforced poly (l-lactic acid) composites[J]. Journal of King Saud University-Engineering Sciences, 2016, 28(1): 69-74. doi: 10.1016/j.jksues.2013.12.002 [66] CORBIN A C, SOULAT D, FERREIRA M, et al. Influence of process parameters on properties of hemp woven reinforcements for composite applications: Mechanical properties, bias-extension tests and fabric forming[J]. Journal of Natural Fibers, 2022, 19(2): 714-726. doi: 10.1080/15440478.2020.1761925 [67] ZUO Q, WANG C, LIN L, et al. Layup optimization of ramie fabric reinforced composite: Woven fabric and lamination parameters[J]. Industrial Crops and Products, 2023, 198: 116712. doi: 10.1016/j.indcrop.2023.116712 [68] PORRAS A, MARANON A. Development and characterization of a laminate composite material from polylactic acid(PLA)and woven bamboo fabric[J]. Composites Part B:Engineering, 2012, 43(7): 2782-2788. doi: 10.1016/j.compositesb.2012.04.039 [69] SONG Y S, LEE J T, JI D S, et al. Viscoelastic and thermal behavior of woven hemp fiber reinforced poly (lactic acid) composites[J]. Composites Part B:Engineering, 2012, 43(3): 856-860. doi: 10.1016/j.compositesb.2011.10.021 [70] LI Z, WANG X. Research on the smart fabric interwoven with polylactic acid fiber and ramie based on mechanical properties[C]2021 3rd International Conference on Artificial Intelligence and Advanced Manufacture. 2021: 696-707. [71] ZHOU N, GENG X, YE M, et al. Mechanical and sound adsorption properties of cellular poly (lactic acid) matrix composites reinforced with 3D ramie fabrics woven with co-wrapped yarns[J]. Industrial Crops and Products, 2014, 56: 1-8. doi: 10.1016/j.indcrop.2014.02.029 [72] YANG X, FAN W, GE S, et al. Advanced textile technology for fabrication of ramie fiber PLA composites with enhanced mechanical properties[J]. Industrial Crops and Products, 2021, 162: 113312. doi: 10.1016/j.indcrop.2021.113312 [73] OLHAN S, ANTIL B, KHATKAR V, et al. Mechanical, thermal, and viscoelastic behavior of sisal fibre-based structural composites for automotive applications: Experimental and FEM analysis[J]. Composite Structures, 2023, 322: 117427. doi: 10.1016/j.compstruct.2023.117427 [74] 段俊鹏, 梁行, 兰碧, 等. 取向长剑麻纤维增强聚乳酸层压复合材料力学性能的研究[J]. 塑料工业, 2017, 45(3): 109-113. doi: 10.3969/j.issn.1005-5770.2017.03.016DUAN Junpeng, LIANG Xing, LAN Bi, et al. Research on the mechanical properties of aligned long sisal fiber reinforced laminated polylactide biocomposites[J]. China Plastics Industry, 2017, 45(3): 109-113(in Chinese). doi: 10.3969/j.issn.1005-5770.2017.03.016 [75] OCHI S. Mechanical properties of kenaf fibers and kenaf/PLA composites[J]. Mechanics of materials, 2008, 40(4-5): 446-452. doi: 10.1016/j.mechmat.2007.10.006 [76] KANDOLA B K, MISTIK S I, PORNWANNACHAI W, et al. Natural fibre-reinforced thermoplastic composites from woven-nonwoven textile preforms: Mechanical and fire performance study[J]. Composites Part B:Engineering, 2018, 153: 456-464. doi: 10.1016/j.compositesb.2018.09.013 [77] KANAKANNAVAR S, PITCHAIMANI J. Fabrication and mechanical properties of braided flax fabric polylactic acid bio-composites[J]. The Journal of The Textile Institute, 2022, 113(5): 833-845. doi: 10.1080/00405000.2021.1907958 [78] RAWI N F M, JAYARAMAN K, BHATTACHARYYA D. A performance study on composites made from bamboo fabric and poly (lactic acid)[J]. Journal of Reinforced Plastics and Composites, 2013, 32(20): 1513-1525. doi: 10.1177/0731684413498296 [79] WANG F, YANG M, ZHOU S, et al. Effect of fiber volume fraction on the thermal and mechanical behavior of polylactide-based composites incorporating bamboo fibers[J]. Journal of Applied Polymer Science, 2018, 135(15): 46148. doi: 10.1002/app.46148 [80] FADZULLAH S S M, MUSTAFA Z, RAMLI S N R. The effect of fiber length on the mechanical properties of pineapple leaf (PALF) fiber reinforced PLA biocomposites[J]. Proceedings of Mechanical Engineering Research Day, 2016, 2016: 123-124. [81] GUNGE A, KOPPAD P G, NAGAMADHU M, et al. Study on mechanical properties of alkali treated plain woven banana fabric reinforced biodegradable composites[J]. Composites Communications, 2019, 13: 47-51. doi: 10.1016/j.coco.2019.02.006 [82] RAGOUBI M, BIENAIMÉD, MOLINA S, et al. Impact of corona treated hemp fibres onto mechanical properties of polypropylene composites made thereof[J]. Industrial Crops and Products, 2010, 31(2): 344-349. doi: 10.1016/j.indcrop.2009.12.004 [83] GÜNEY O, BILICI İ, DOĞAN D, et al. Mechanical and thermal properties of recycled polyethylene/surface treated hemp fiber bio-composites[J]. Polymer Composites, 2023, 44(8): 4976-4992. doi: 10.1002/pc.27463 [84] XU X, ZHANG M, QIANG Q, et al. Study on the performance of the acetylated bamboo fiber/PBS composites by molecular dynamics simulation[J]. Journal of Composite Materials, 2016, 50(7): 995-1003. doi: 10.1177/0021998315615690 [85] VINAYAGAMOORTHY R. Influence of fiber surface modifications on the mechanical behavior of vetiveria zizanioides reinforced polymer composites[J]. Journal of Natural Fibers, 2019, 16(2): 163-174. doi: 10.1080/15440478.2017.1410513 [86] TAKEMURA K, TAKADA Y, KATOGI H. Effect of treatment using silane coupling agent on creep properties of jute fiber reinforced composites[J]. WIT Transactions on the Built Environment, 2012, 124: 417-424. [87] 梁晓斌. 汉麻/聚乳酸全降解复合材料的制备和性能研究[D]. 大连: 大连理工大学, 2010.LIANG Xiaobin. Study to the preparation and properties of fully-degradable hemp fiber/polylactic acid composite[D]. Da lian: Dalian University of Technology, 2010(in Chinese). [88] GUPTA U S, TIWARI S, SHARMA U. Cold glow discharge nitrogen plasma treatment of banana and sisal fiber for mechanical and surface characterization improvement[J]. Journal of the Indian Academy of Wood Science, 2023, 20(1): 37-50. doi: 10.1007/s13196-023-00310-5 [89] ZHANG Q, WANG K, CHEN X, et al. Biomass composite based on metallized bamboo fiber for electromagnetic interference shielding, joule heating, and solar heating[J]. Composites Science and Technology, 2023, 243: 110228. doi: 10.1016/j.compscitech.2023.110228 [90] GANDHIMATHI G, NAGAB-HOOSHANAM N, SAMBATH S, et al. Synthesis of microcrystalline cellulose from abaca nonfluorescent flower pistil and its twill weaved fiber-polyester composites: Viscoelastic, fatigue, and mechanical properties[J]. Polymer Com-posites, 2023, 44(7): 3886-3894. doi: 10.1002/pc.27363 [91] 郑茜仁, 邵灵达, 金肖克, 等. 热压成型工艺对竹纤维/PLA复合材料力学性能的影响[J]. 现代纺织技术, 2022, 30(6): 73-79.ZHENG Qianren, SHAO Lingda, JIN Xiaoke, et al. Influence of hot pressing process on mechanical properties of bamboo fiber/PLA composite[J]. Advanced Textile Technology, 2022, 30(6): 73-79(in Chinese). [92] SHI J, ZHANG W, ZHANG J, et al. Mechanical, thermal properties and void characteristics of bamboo fiber-reinforced epoxy resin composites prepared by vacuum-assisted resin transfer molding process[J]. Journal of Natural Fibers, 2023, 20(1): 2187919. doi: 10.1080/15440478.2023.2187919 [93] SHI J, WU Y, ZHANG M, et al. Bamboo fiber-reinforced epoxy composites fabricated by vacuum-assisted resin transfer molding (VARTM): Effect of molding sequence and fiber content[J]. Polymer Composites, 2024, 45(1): 256-266. doi: 10.1002/pc.27774 [94] DICKSON A N, ABOURAYANA H M, Dowling D P. 3D printing of fibre-reinforced thermoplastic composites using fused filament fabrication—A review[J]. Polymers, 2020, 12(10): 2188. doi: 10.3390/polym12102188 [95] KAJBIČ J, FAJDIGA G, KLEMENC J. Material extrusion 3D printing of biodegradable composites reinforced with continuous flax fibers[J]. Journal of Materials Research and Technology, 2023, 27: 3610-3620. doi: 10.1016/j.jmrt.2023.10.148 [96] ZHANG H, LIU D, HUANG T, et al. Three-dimensional printing of continuous flax fiber-reinforced thermoplastic composites by five-axis machine[J]. Materials (Basel), 2020, 13(7). [97] CHENG P, WANG K, CHEN X, et al. Interfacial and mechanical properties of continuous ramie fiber reinforced biocomposites fabricated by in-situ impregnated 3D printing[J]. Industrial Crops and Products, 2021, 170. [98] CHENG P, PENG Y, LI S, et al. 3D printed continuous fiber reinforced composite lightweight structures: A review and outlook[J]. Composites Part B:Engineering, 2023, 250: 110450. doi: 10.1016/j.compositesb.2022.110450 [99] YANG Y, YANG B, CHANG Z, et al. Research status of and prospects for 3D printing for continuous fiber-reinforced thermoplastic composites[J]. Polymers, 2023, 15(17): 3653. doi: 10.3390/polym15173653 [100] 曹丰, 曾志勇, 黄建, 等. 连续纤维增强复合材料的3D打印工艺及应用进展[J]. 中国科学:技术科学, 2023, 53(11): 1815-1833.CAO Feng, ZENG Zhiyong, HUANG Jian, et al. Printing process and application progress of 3D printing continuous fiber reinforced composites[J]. Scientia Sinica(Technologica), 2023, 53(11): 1815-1833(in Chinese). [101] 王凯, 刘寒松, 肇研. 连续纤维增强热塑性树脂基复合材料自动铺放技术研究进展[J]. 航空制造技术, 2021, 64(11): 41-49.WANG Kai, LIU Hansong, ZHAO Yan. Advance in automated fiber placement technology on continuous fiber reinforced thermoplastic resin matrix composites[J]. Aeronautical Manufacturing Technology, 2021, 64(11): 41-49(in Chinese). [102] 王显峰, 段少华, 唐珊珊, 等. 复合材料自动铺放技术在航空航天领域的研究进展[J]. 航空制造技术, 2022, 65(16): 64-77.WANG Xianfeng, DUAN Shaohua, TANG Shanshan, et al. Progress of composite automated placement technology in aviation field[J]. Aeronautical Manufacturing Technology, 2022, 65(16): 64-77(in Chinese). [103] 蒋威, 周悦, 杨飞, 等. 红外辅助自动纤维铺放工艺对连续玻璃纤维增强聚丙烯复合材料结构与性能影响[J]. 复合材料学报, 2023, 40(4): 2015-2025.JIANG Wei, ZHOU Yue, YANG Fei, et al. Infrared-assisted automated fiber placement process on the structure and properties of continuous glass fiber reinforced polypropylene composites[J]. Acta Materiae Compositae Sinica, 2023, 40(4): 2015-2025(in Chinese). [104] 龙昱, 李岩, 付昆昆. 3D打印纤维增强复合材料工艺和力学性能研究进展[J]. 复合材料学报, 2022, 39(9): 4196-4212.LONG Yu, LI Yan, FU Kunkun. Recent advances in 3D printed fiber reinforced composites: processing technique and mechanical performance[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4196-4212(in Chinese). [105] 陈吉平 , 李岩 , 刘卫平, 等. 连续纤维增强热塑性树脂基复合材料自动铺放原位成型技术的航空发展现状[J]. 复合材料学报, 2019, 36(04): 784-794.CHEN Jiping, LI Yan, LIU Weiping, et al. Development of AFP in-situ consolidation technology on continuous fiber reinforced thermoplastic matrix composites in aviation[J]. Acta Materiae Compositae Sinica, 2019, 36(4): 784-794(in Chinese). [106] SONG W, LIU D, PREMPEH N, et al. Fiber alignment and liquid crystal orientation of cellulose nanocrystals in the electrospun nanofibrous mats[J]. Biomacromolecules, 2017, 18(10): 3273-3279. doi: 10.1021/acs.biomac.7b00927 [107] SUKMAWAN R, TAKAGI H, NAKAGAITO A N. Strength evaluation of cross-ply green composite laminates reinforced by bamboo fiber[J]. Composites Part B:Engineering, 2016, 84: 9-16. [108] BONGIORNO F, MILITELLO C, ZUCCARELLO B. Mode I translaminar fracture toughness of high performance laminated biocomposites reinforced by sisal fibers: Accurate measurement approach and lay-up effects[J]. Composites Science and Technology, 2022, 217: 109089. doi: 10.1016/j.compscitech.2021.109089 [109] KANAKANNAVAR S, PITCHAIMANI J. Fracture toughness of flax braided yarn woven PLA composites[J]. International Journal of Polymer Analysis and Characterization, 2021, 26(4): 364-379. doi: 10.1080/1023666X.2021.1892424 [110] SAEED U, NAWAZ M A, AL-TURAIF H A. Wood flour reinforced biodegradable PBS/PLA composites[J]. Journal of Composite Materials, 2018, 52(19): 2641-2650. doi: 10.1177/0021998317752227 [111] ZHANG L, LV S, SUN C, et al. Effect of MAH-g-PLA on the properties of wood fiber/polylactic acid composites[J]. Polymers, 2017, 9(11): 591. doi: 10.3390/polym9110591 [112] PARRES F, PEYDRO M A, JUAREZ D, et al. Study of the properties of a biodegradable polymer filled with different wood flour particles[J]. Polymers, 2020, 12(12): 2974. doi: 10.3390/polym12122974 [113] ABED A, SAMOUH Z, COCHRANCE C, et al. Piezo-resistive properties of bio-based sensor yarn made with sisal fibre[J]. Sensors, 2021, 21(12): 4083. doi: 10.3390/s21124083 [114] MONETTE D, DUMOND P, CHIKHAOUI I, et al. Preliminary material evaluation of flax fibers for prosthetic socket fabrication[J]. Journal of Biomechanical Engineering, 2021, 143(2): 021006. doi: 10.1115/1.4048079 [115] JIANG Y, YARIN A L, Pan Y. Printable highly transparent natural fiber composites[J]. Materials Letters, 2020, 277: 128290. doi: 10.1016/j.matlet.2020.128290 -

下载:

下载: