A cyclic plasticity-damage model for predicting ratcheting behavior of composite materials

-

摘要: 构建循环塑性本构模型并揭示其微观机制,目前仍然是复合材料力学研究富有挑战性的课题。本文提出了一种循环塑性-损伤模型,用以预测在循环载荷作用下纤维增强复合材料的应力-应变响应。该模型是在作者前期提出的描述非线性滞后行为的弹塑性本构模型的基础上的进一步扩展。它可以预测加载时的非线性响应、卸载和重加载时的迟滞行为及大量循环下的棘轮现象。作为基准问题验证,将Kawai等的实验数据与本文模型的数值预测进行了比较。结果表明,该模型能够模拟碳纤维/环氧树脂单向复合材料在偏轴循环加载下的棘轮行为。

-

关键词:

- 纤维增强聚合物复合材料 /

- 循环塑性 /

- 迟滞行为 /

- 棘轮效应 /

- 疲劳损伤

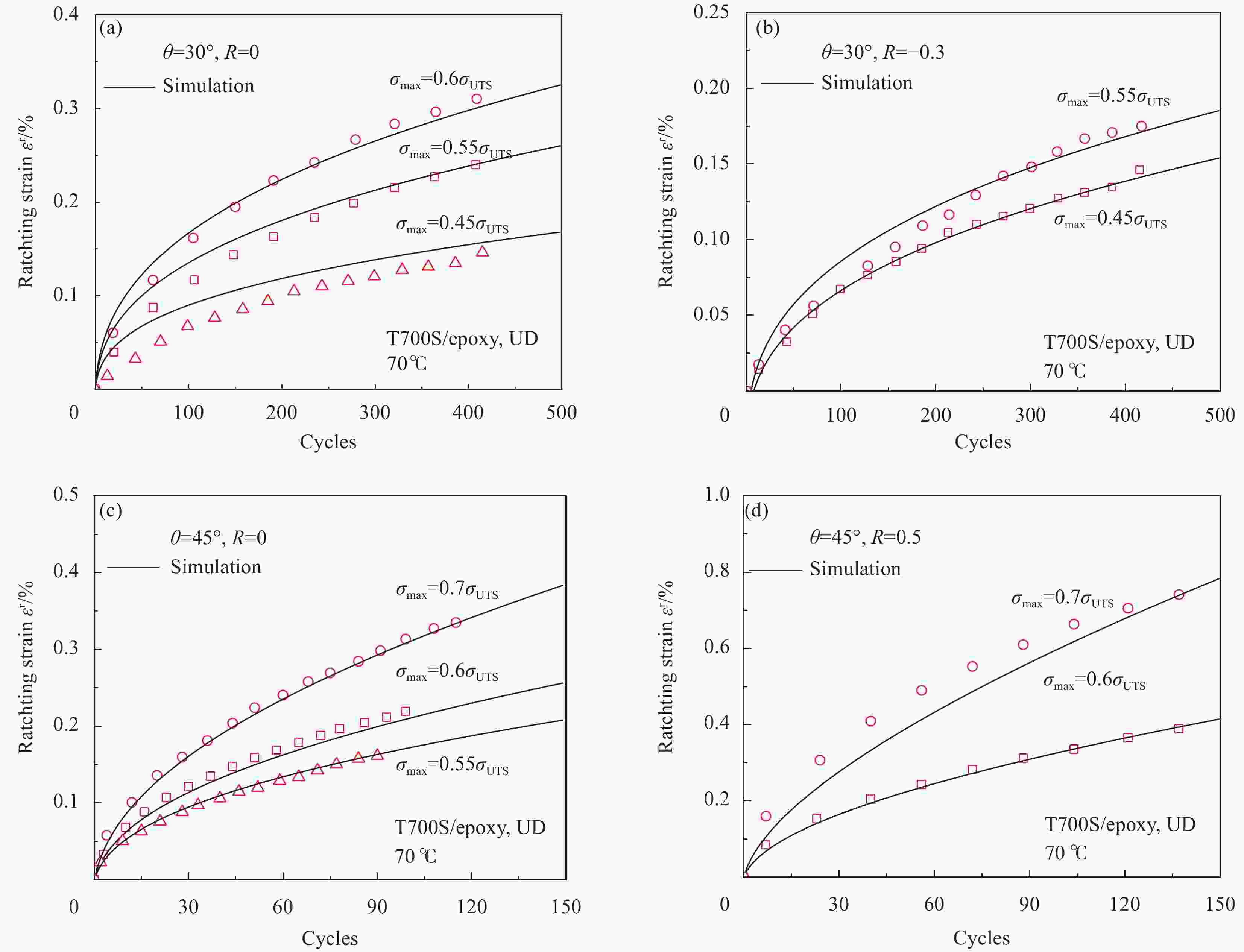

Abstract: It is still a challenging problem to establish a constitutive model for cyclic plasticity and reveal its microscopic mechanism. A cyclic plasticity-damage model was proposed in this study to predict the stress-strain response of fiber reinforced polymer under cyclic loading. This model is a further extension of the elastic-plastic constitutive model to describe the nonlinear hysteresis behavior proposed by the authors. It can predict the nonlinear responses during loading, hysteresis behavior during unloading and reloading and the ratcheting phenomena under a large number of cycles. As a benchmark problem verification, the experimental data by Kawai et al, were compared with the numerical prediction of the model in this paper. The results show that the model can simulate the ratcheting behavior of carbon fiber/epoxy unidirectional composite under off-axis cyclic loading.-

Key words:

- fiber reinforced polymer /

- cyclic plasticity /

- hysteresis behavior /

- ratcheting effects /

- fatigue damage

-

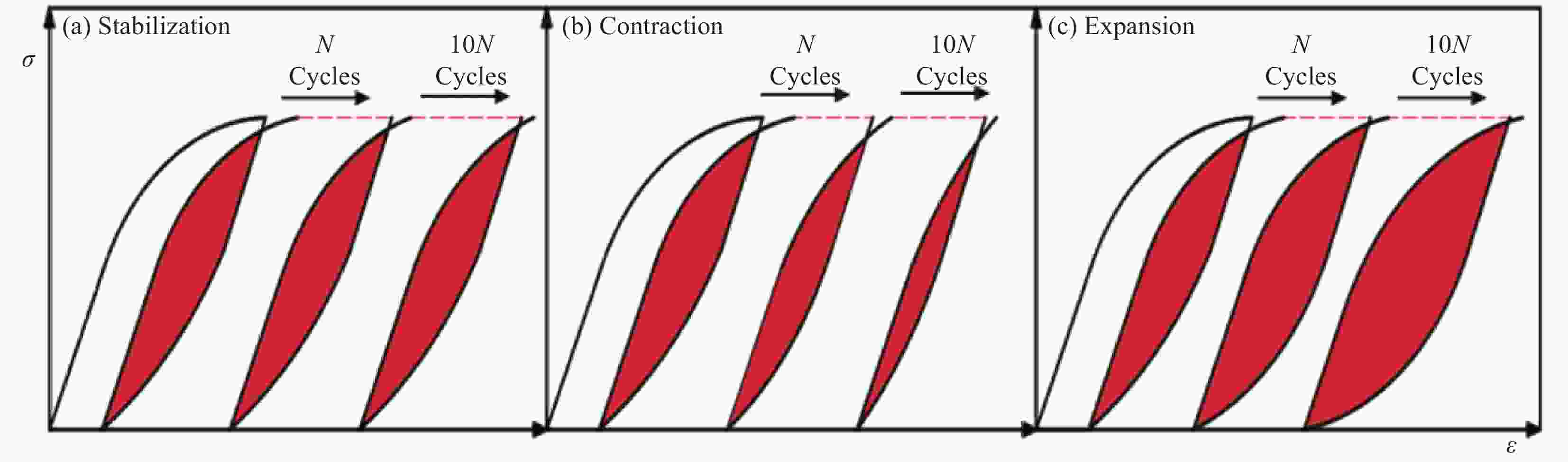

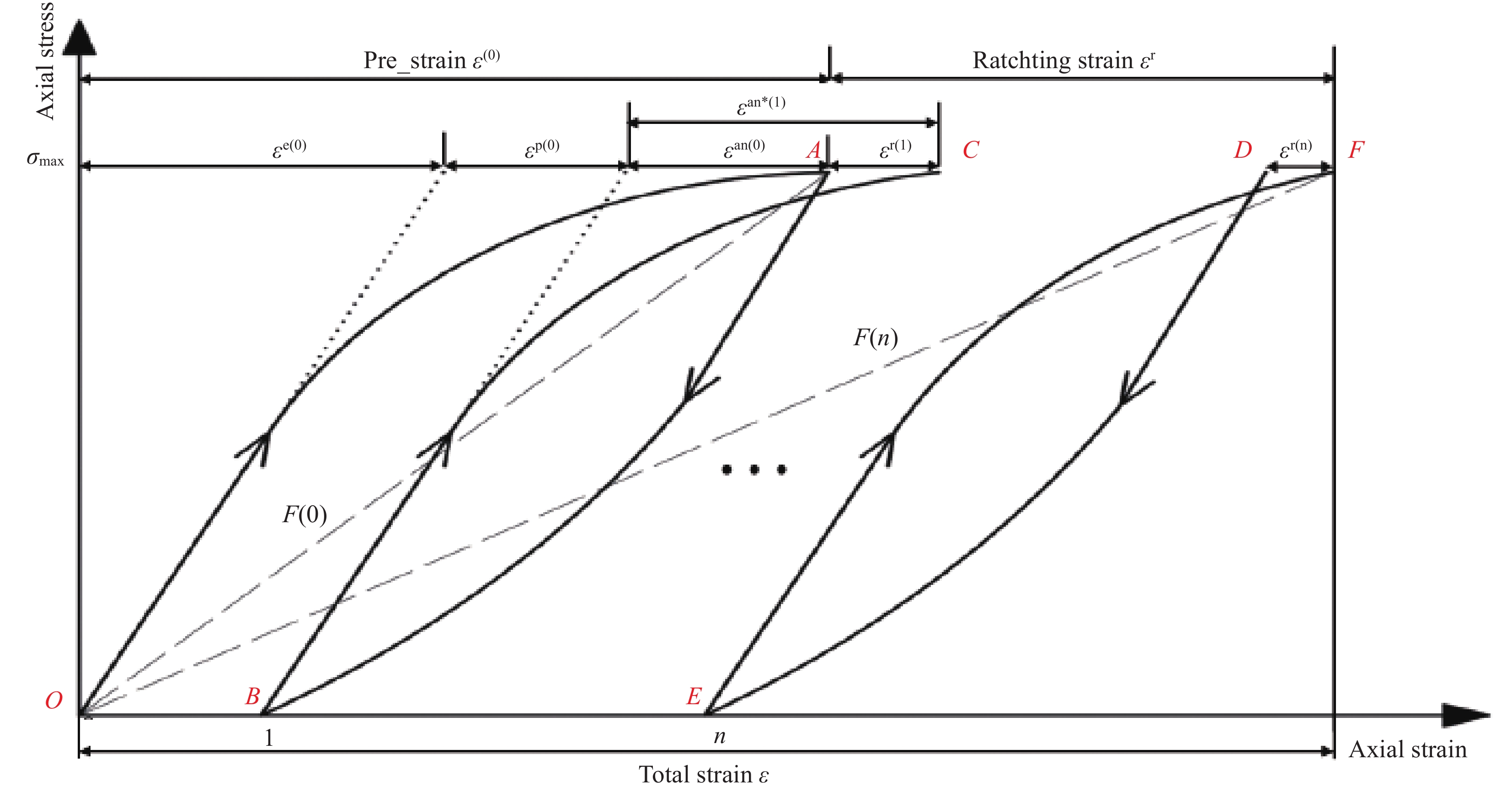

图 1 单向纤维增强聚合物复合材料(FRP)在偏轴循环载荷下应力-应变曲线的典型特征

Figure 1. Typical features of stress-strain curves for unidirectional fiber reinforced polymer (FRP) laminates under off-axis cycle loading

σmax—Maximum stress; ε, εe, εp, εan, εr, εan*—Total, elastic, plastic, anelastic, ratcheting and sum of anelastic and ratcheting strain; F(n)—Fatigue modulus

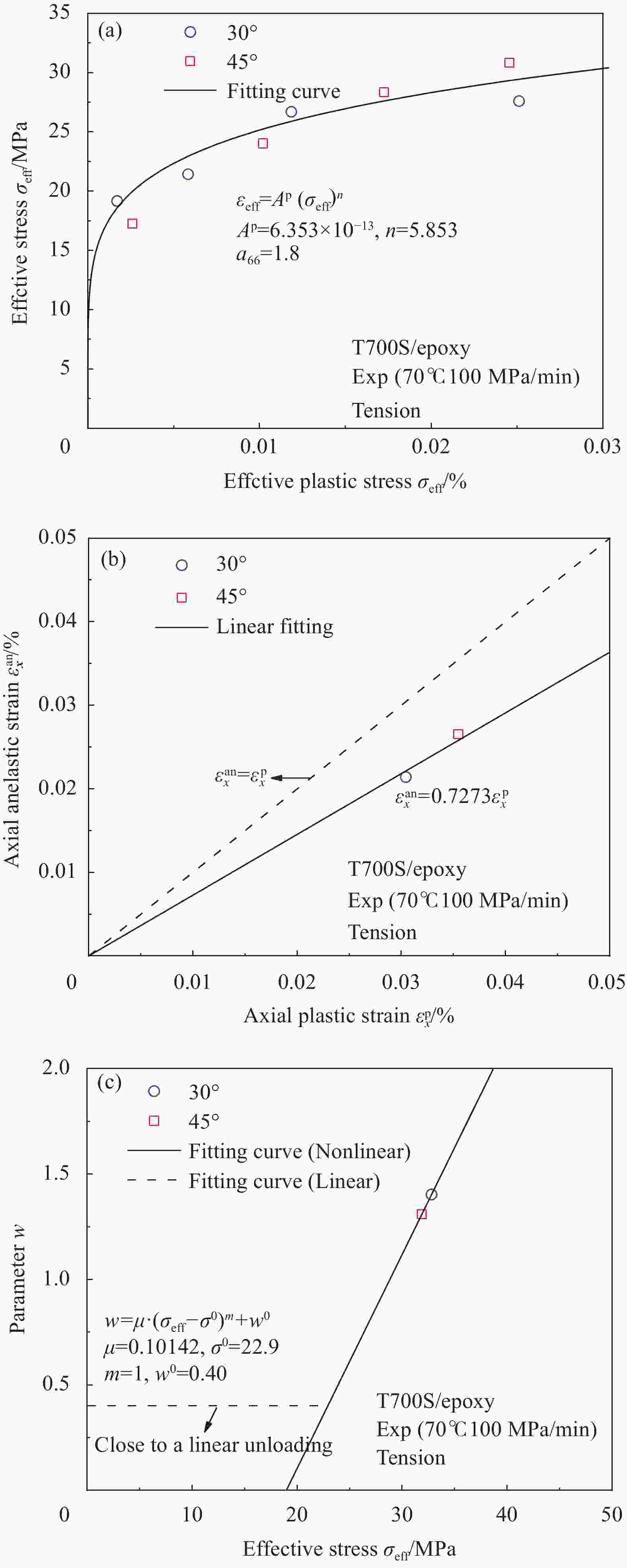

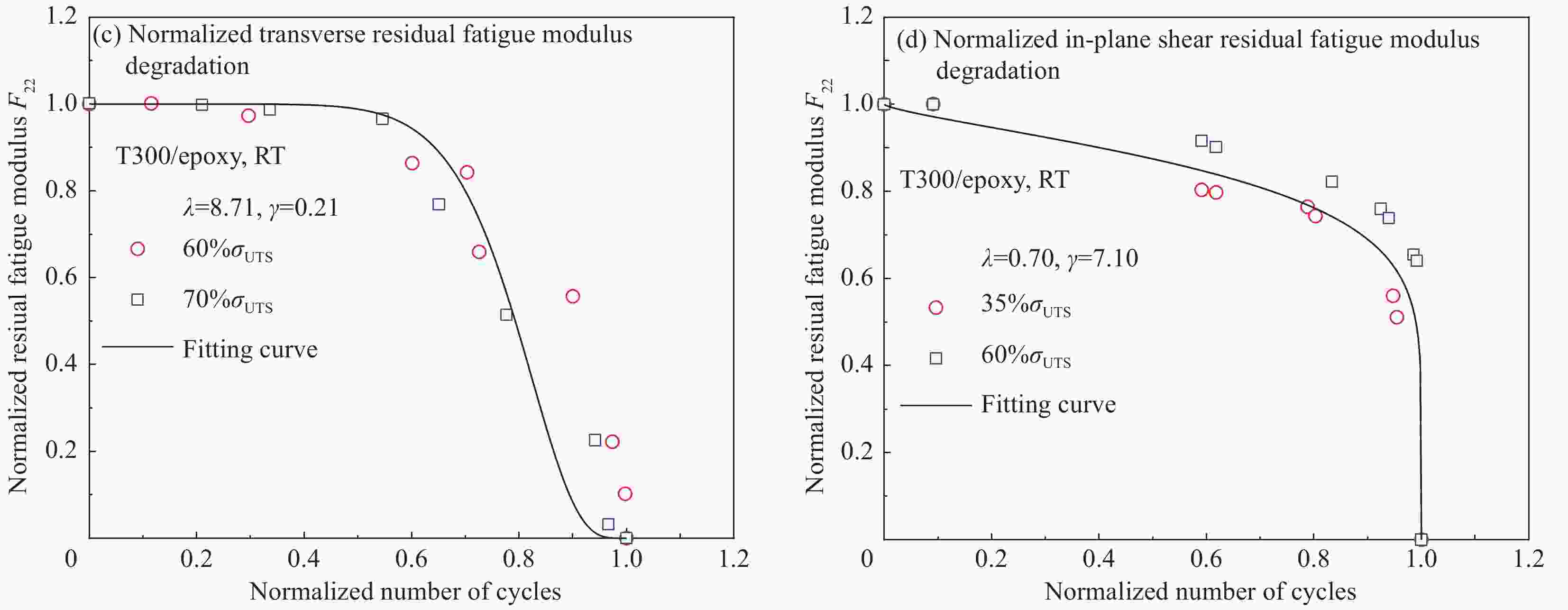

表 1 碳纤维/环氧树脂复合材料性能和模型参数(70 ℃)

Table 1. Properties and model parameters of carbon fiber/epoxy composites (70℃)

Material property Model parameter Cycle plastic Fatigue damage E1/GPa 124 a66 1.8 λ22 1.62 E2/GPa 7.93 Ap 6.35×10−13 γ22 0.21 G12/GPa 3.74 Aan 4.62×10−13 λ12 0.70 μ12 0.35 n 5.853 γ12 7.10 YT/MPa 33.4 μ 0.10142 A22 0.787 *YC/MPa 123 m 1 B22 0.244 S12/MPa 24.1 σ0 22.9 A12 −0.124 w0 0.40 B12 0.251 Notes:E1—Longitudinal modulus; E2—Transverse modulus; G12—Shear modulus; u12—Poisson’s ratio; YT—Transverse tensile strength; *YC—Transverse compress strength, from the data of our research group; S12—Shear strength;

a66—Shear/transverse plasticity ratio; Ap, Aan, n—Plasticity and anelasticity during initial loading; μ, m, σ0, w0—Hysteresis loop;

λ22, γ22—Transverse fatigue modulus degradation; λ12, γ12—In-plane shear fatigue modulus degradation; A22, B22—Transverse fatigue life; A12,B12—In-plane shear fatigue life. -

[1] 罗祖道, 王震鸣. 复合材料力学进展[M]. 北京: 北京大学出版社, 1992.LUO Z D, WANG Z M. Progress in composite material mechanics[M]. Beijing: Peking University Press, 1992(in Chinese). [2] FALLAHI H, TAHERI-BEHROOZ F, ASADI A. Nonlinear mechanical response of polymer matrix composites: A review[J]. Polymer Reviews,2020,60(1):42-85. doi: 10.1080/15583724.2019.1656236 [3] KAWAI M, ZHANG J Q, XIAO Y, et al. Modeling of tension-compression asymmetry in off-axis nonlinear rate-dependent behavior of unidirectional carbon/epoxy composites[J]. Journal of Composite Materials, 2010, 44(1): 75-94. [4] WANG J, XIAO Y. Some improvements on Sun–Chen’s one-parameter plasticity model for fibrous composites-Part I: Constitutive modelling for tension-compression asymmetry response[J]. Journal of Composite Materials,2017,51(3):405-418. doi: 10.1177/0021998316644853 [5] WANG J, XIAO Y, KAWAI M. Parameter identification problem in one-parameter plasticity model for fibrous compo-sites[J]. Advanced Composite Materials,2019,28:29-51. [6] DROZDOV A D. Cyclic thermo-viscoplasticity of high density polyethylene[J]. International Journal of Solids and Structures,2010,47(11-12):1592-1602. doi: 10.1016/j.ijsolstr.2010.02.021 [7] WANG J, XIAO Y, INOUE K, et al. Modeling of nonlinear response in loading-unloading tests for fibrous composites under tension and compression[J]. Composite Structures,2019,207:894-908. doi: 10.1016/j.compstruct.2018.09.054 [8] 薛康, 肖毅, 王杰, 等. 单向纤维增强聚合物复合材料压缩渐进破坏[J]. 复合材料学报, 2019, 36(6):1398-1412.XUE K, XIAO Y, WANG J, et al. Compression progressive failure of unidirectional fiber reinforced polymer compo-sites[J]. Acta Materiae Compositae Sinica,2019,36(6):1398-1412(in Chinese). [9] LV J X, XIAO Y, ZHOU Y, et al. Characterization and modeling of the creep behavior of fiber composites with tension and compression asymmetry[J]. International Journal of Mechanical Sciences,2020,170:105340. doi: 10.1016/j.ijmecsci.2019.105340 [10] OHNO N. Recent topics in constitutive modeling of cyclic plasticity and viscoplasticity[J]. Applied Mechanics Reviews, 1990, 43(11): 283-295. [11] OHNO N. Recent progress in constitutive modeling for ratchetting[J]. Journal of the Society of Materials Science Japan,1997,46(3Appendix):1-9. doi: 10.2472/jsms.46.3Appendix_1 [12] 陈旭, 焦荣, 田涛. 棘轮效应预测及其循环本构模型研究进展[J]. 力学进展, 2003, 33(4):461-470. doi: 10.3321/j.issn:1000-0992.2003.04.003CHEN X, JIAO R, TIAN T. Research advances of ratcheting effects and cyclic constitutive models[J]. Advances in Mechanics,2003,33(4):461-470(in Chinese). doi: 10.3321/j.issn:1000-0992.2003.04.003 [13] KANG G Z. Ratchetting: Recent progresses in phenomenon observation, constitutive modeling and application[J]. International Journal of Fatigue,2008,30(8):1448-1472. doi: 10.1016/j.ijfatigue.2007.10.002 [14] FREDERICK C O, ARMSRRONG P J. A mathematical representation of the multiaxial Bauschinger effect[J]. High Temperature Technology, 1998, 24(1): 1-26. [15] BOWER A F. Cyclic hardening properties of hard-drawn copper and rail steel[J]. Journal of the Mechanics and Physics of Solids,1989,37(4):455-470. doi: 10.1016/0022-5096(89)90024-0 [16] CHABOCHE J L. On some modifications of kinematic hardening to improve the description of ratchetting effects[J]. International Journal of Plasticity,1991,7(7):661-678. doi: 10.1016/0749-6419(91)90050-9 [17] OHNO N, WANG J D. Kinematic hardening rules with critical state of dynamic recovery, Part I: Formulation and basic features for ratchetting behavior[J]. International Journal of Plasticity,1993,9(3):375-390. doi: 10.1016/0749-6419(93)90042-O [18] OHNO N, WANG J D. Kinematic hardening rules with critical state of dynamic recovery, Part II: Application to experiments of ratchetting behavior[J]. International Journal of Plasticity,1993,9(3):391-403. doi: 10.1016/0749-6419(93)90043-P [19] JIANG Y, SEHITOGLU H. Multiaxial cyclic ratchetting under multiple step loading[J]. International Journal of Plasticity,1994,10(8):849-870. doi: 10.1016/0749-6419(94)90017-5 [20] KANG G Z, GUO S, DONG C. Numerical simulation for uniaxial cyclic deformation of discontinuously reinforced metal matrix composites[J]. Materials Science & Engineering A,2006,426(1-2):66-76. [21] VOYIADJIS G Z, THIAGARAJAN G. A cyclic anisotropic-plasticity model for metal matrix composites[J]. International Journal of Plasticity,1995,12(1):69-91. [22] 王艳锋, 康国政, 刘宇杰, 等. 玻璃长纤维增强树脂基复合材料的单轴时间相关棘轮行为实验研究[J]. 复合材料学报, 2009, 26(6):161-166. doi: 10.3321/j.issn:1000-3851.2009.06.027WANG Y F, KANG G Z, LIU Y J, et al. Experimental study on uniaxial time-dependent ratcheting of continuous glass fiber reinforced polymer composites[J]. Acta Materiae Compositae Sinica,2009,26(6):161-166(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.06.027 [23] 刘煦, 朱志武, 康国政, 等. 碳纤维增强 PEEK 树脂基复合材料的单轴时相关循环特性实验研究[J]. 复合材料学报, 2012, 29(1):28-34.LIU X, ZHU Z W, KANG G Z, et al. Experimental study on uniaxial time-dependent cyclic character of carbon fiber reinforced PEEK resin matrix composite[J]. Acta Materiae Compositae Sinica,2012,29(1):28-34(in Chinese). [24] SAKAI M, UDA N, KUNOO K. Experimental observation on low cycle fatigue behavior of symmetric angle-ply CFRP laminate[J]. Journal of the Japan Society for Aeronautical and Space Sciences, 2006, 54(635): 555-562 [25] KAWAI M, KIGURE T, SUZUKI T. Off-axis ratcheting behavior of unidirectional CFRP laminate at high temperature and its phenomenological modeling[J]. Journal of the Japan Society for Composite Materials, 2011, 37(2): 46-57. [26] SUZUKI T, KAWAI M. Off-axis ratcheting behavior of unidirectional carbon/epoxy laminate under asymmetric cyclic loading at high temperature[C]// Proceedings of the 12th Japan International SAMPE Symposium & Exhibition (JISSE-12), Tokyo, 2011. [27] RUI Y, SUN C T. Cyclic plasticity in AS4/PEEK composite laminates[J]. Journal of Thermoplastic Composite Materials,1993,6(4):312-322. [28] ZHU C, SUN C T. Micromechanical characterization of cyclic plasticity of IM7/5260 composite at various temperatures[J]. Journal of Reinforced Plastics and Composites,1998,17(3):184-204. doi: 10.1177/073168449801700301 [29] ZHU C, SUN C T. A viscoplasticity model for characterizing loading and unloading behavior of polymeric composites[M]//Time dependent and nonlinear effects in polymers and composites. West Conshohocken: ASTM International, 2000. [30] SHOKRIEH M M, LESSARD L B. Multiaxial fatigue behaviour of unidirectional plies based on uniaxial fatigue experiments I—Modelling[J]. International Journal of Fatigue, 1997, 19(3): 201-207. [31] LEE L J, YANG J N, SHEU D Y. Prediction of fatigue life for matrix-dominated composite laminates[J]. Composites Science and Technology,1993,46(1):21-28. doi: 10.1016/0266-3538(93)90077-T [32] 沈媛臻, 肖毅. 微动损伤对复合材料螺栓连接预紧力松弛的影响[J]. 复合材料学报, 2019, 36(2):400-409.SHEN Y Z, XIAO Y. Effects of fretting damage on pre load relaxation in bolted composite joints[J]. Acta Materiae Composite Sinica,2019,36(2):400-409(in Chinese). [33] 成磊. 复合材料疲劳损伤的定量评估[D]. 上海: 同济大学, 2018.CHENG L. Quantitative assessment on fatigue damage of composite materials[D]. Shanghai: Tongji University, 2018(in Chinese). -

下载:

下载: