1D-3D cell coupling simulation of resin flow behavior in perforated sandwich composite materials

-

摘要: 真空辅助树脂灌注工艺(VARI)作为一种高性能、低成本的制造技术,已广泛应用于大型复合材料零部件的制造。穿孔夹芯复合材料具有比强度比模量高、承载能力强等特点,然而,为了准确模拟穿孔夹芯复合材料中树脂的充模过程,需要对芯材内每个孔洞的树脂流动行为进行三维数值计算,尤其是对于大厚度构件而言需要大量的开发成本和生产周期。为了降低仿真计算复杂性和时间成本,本文提出了一种全新的3D-1D有限单元耦合计算方法,利用自开发ANSYS Fluent UDF子程序模拟树脂在芯材孔洞中的流动,避免了对数量巨大的孔洞进行物理建模,成功优化了穿孔夹芯复合材料真空灌注过程的模型构建和仿真计算过程,并通过实尺度的灌注实验验证了仿真模拟的可行性。研究结果表明,数值仿真与实验测得的灌注时间基本吻合,能够较为准确地模拟穿孔夹芯结构成型过程中树脂的流动。

-

关键词:

- 真空辅助树脂灌注工艺 /

- 夹芯复合材料 /

- 芯材孔洞 /

- 单元耦合 /

- 流动仿真

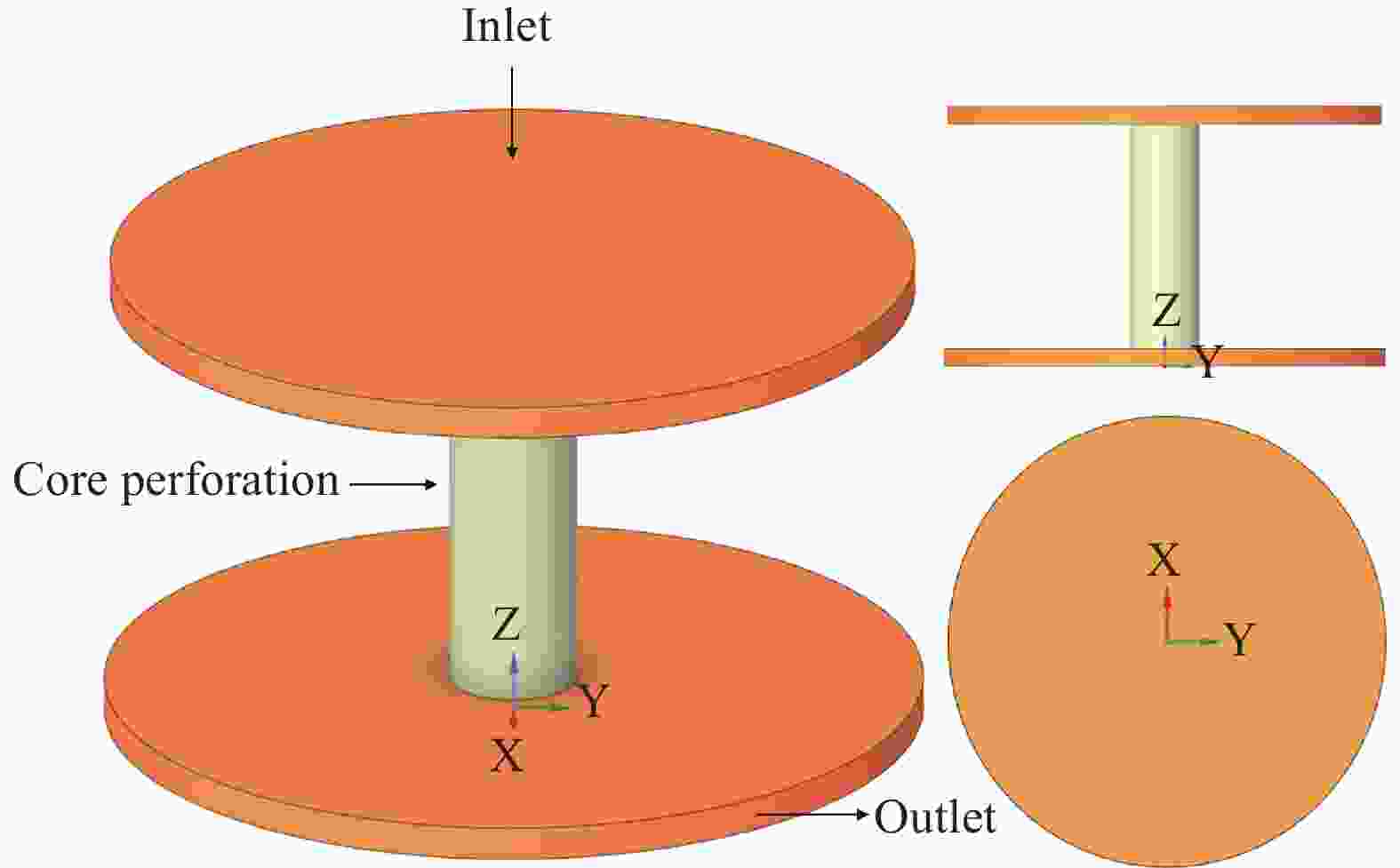

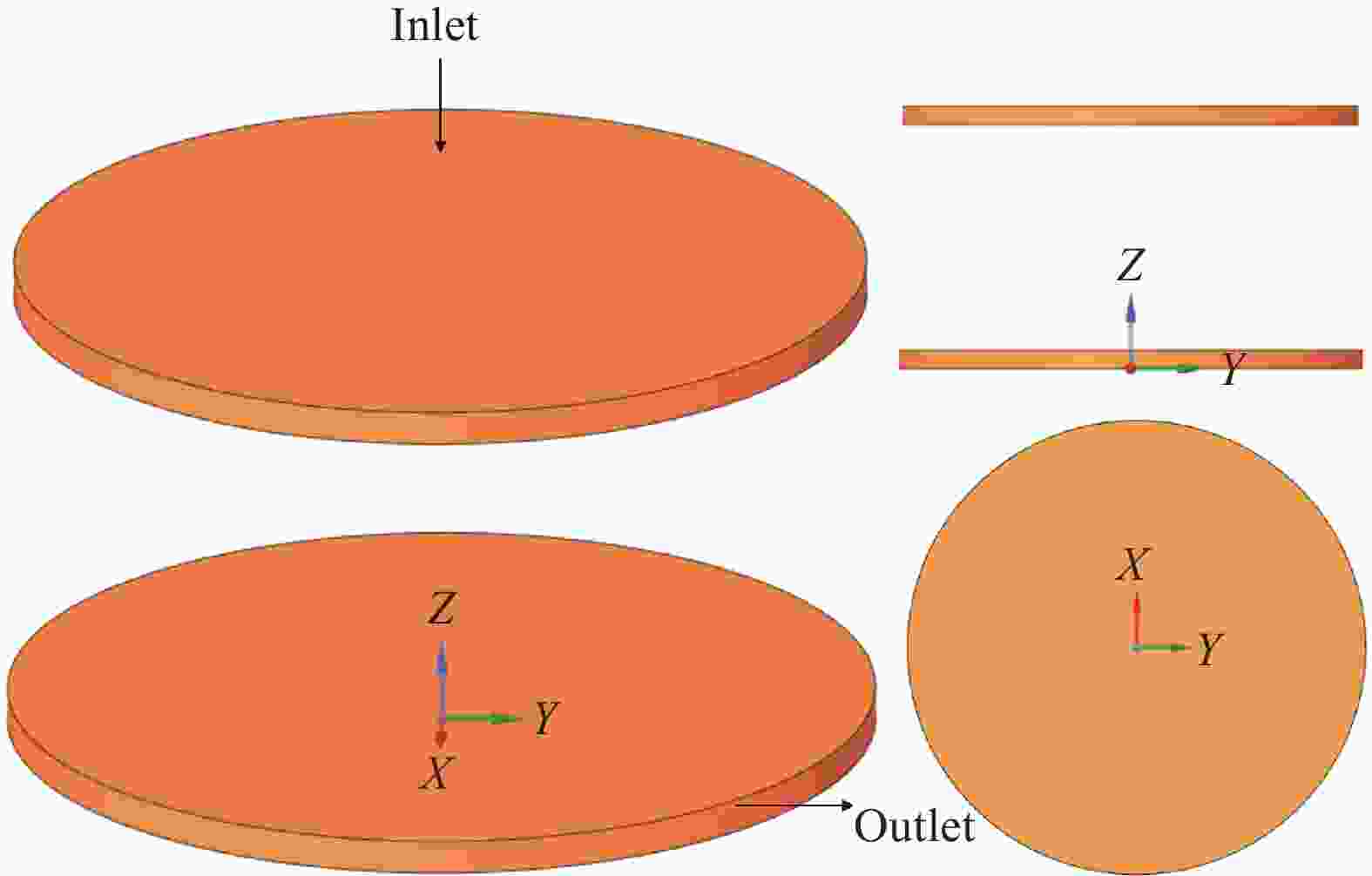

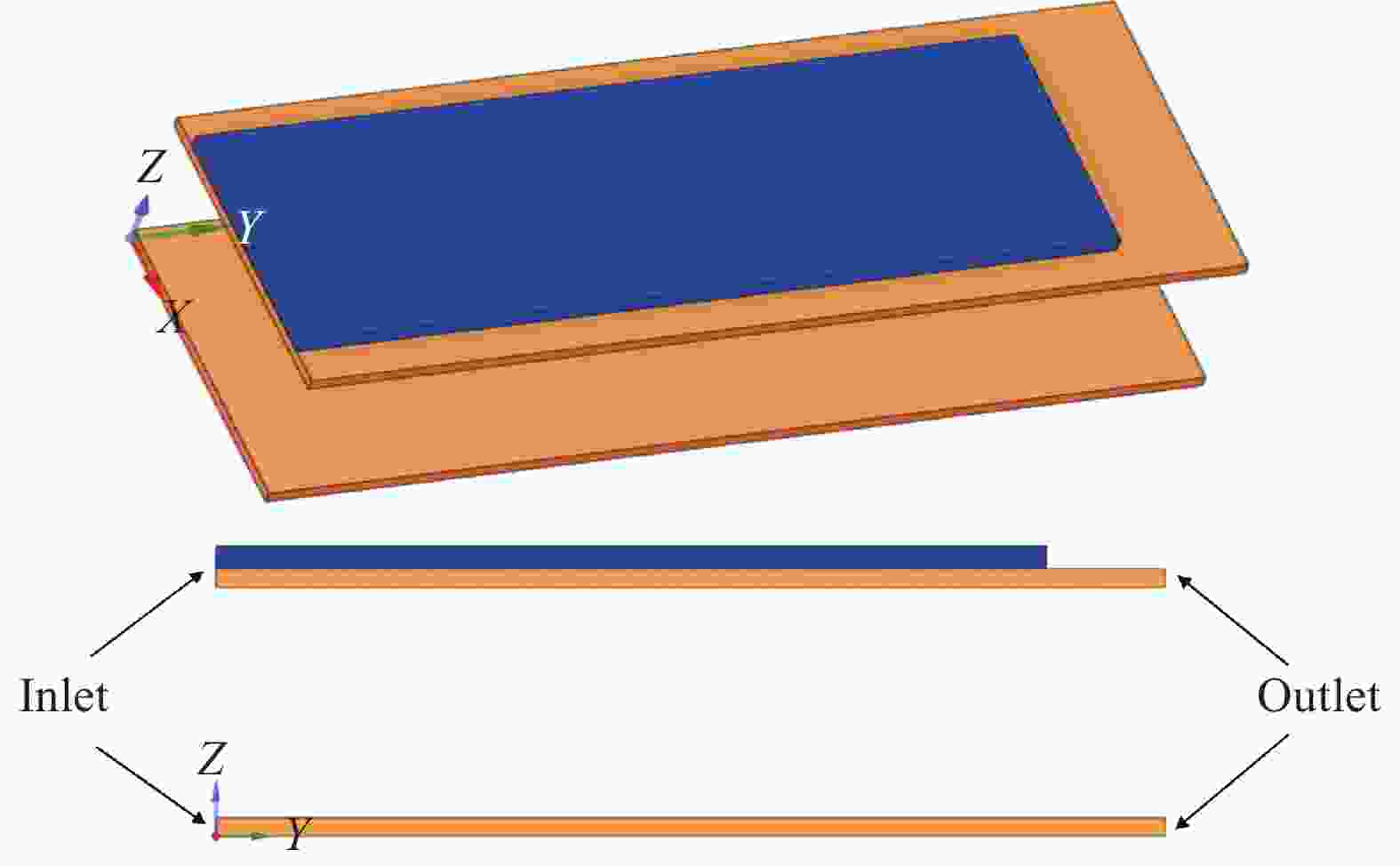

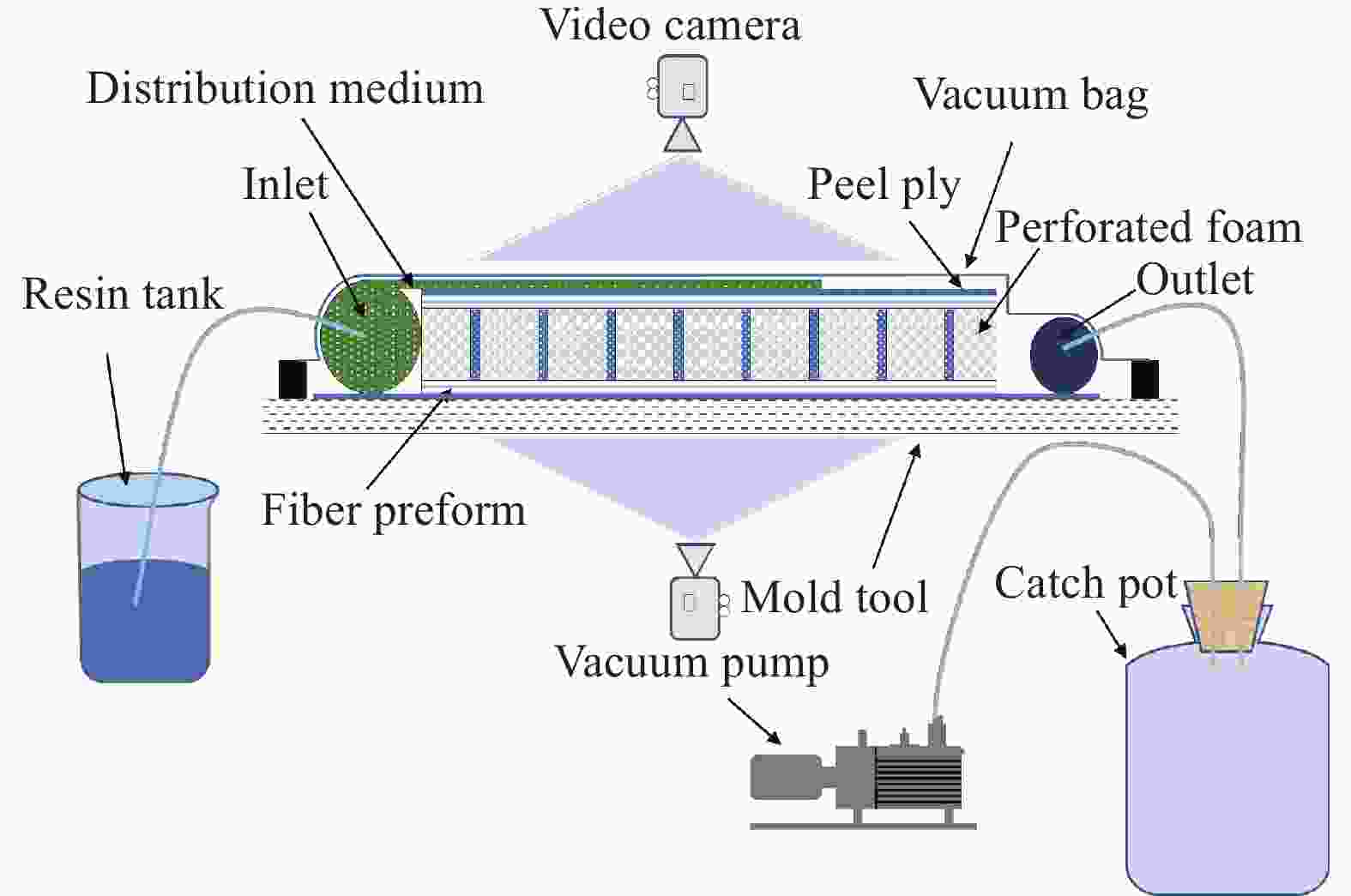

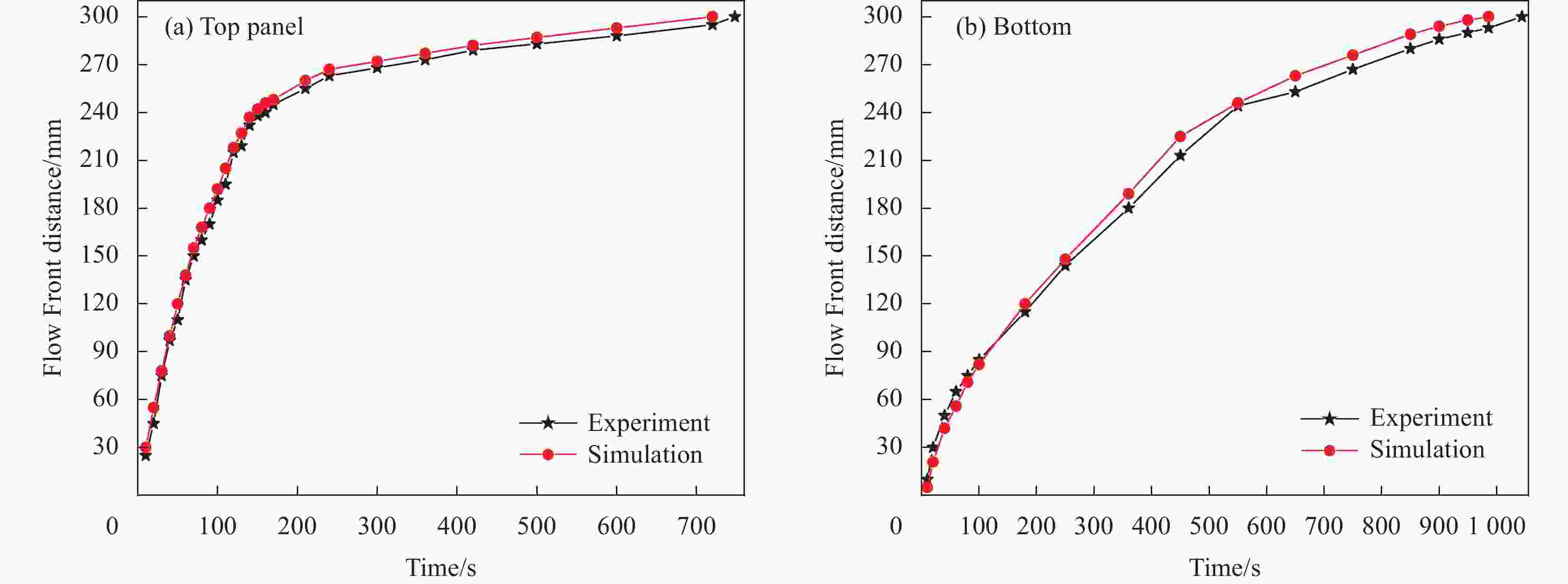

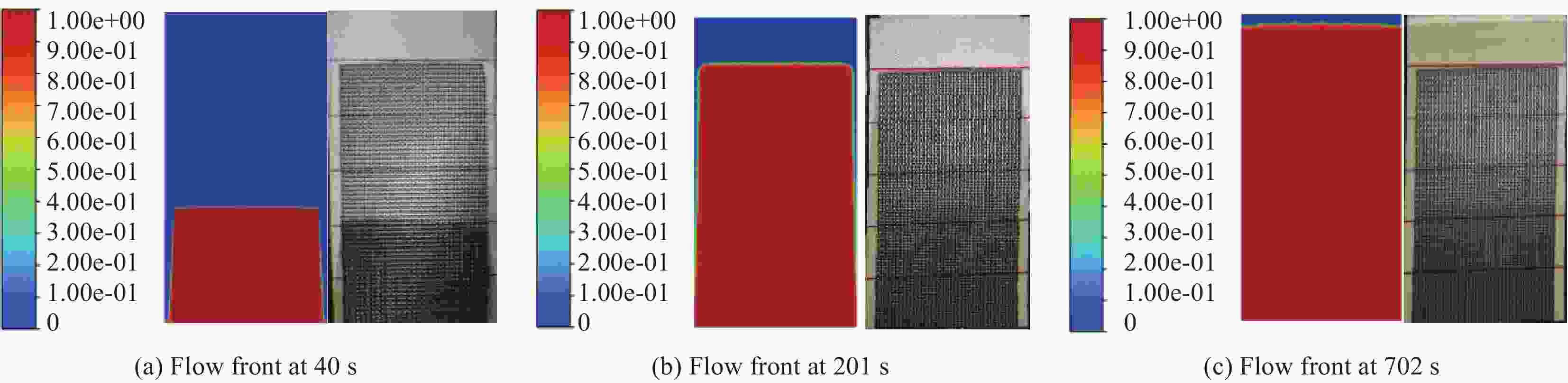

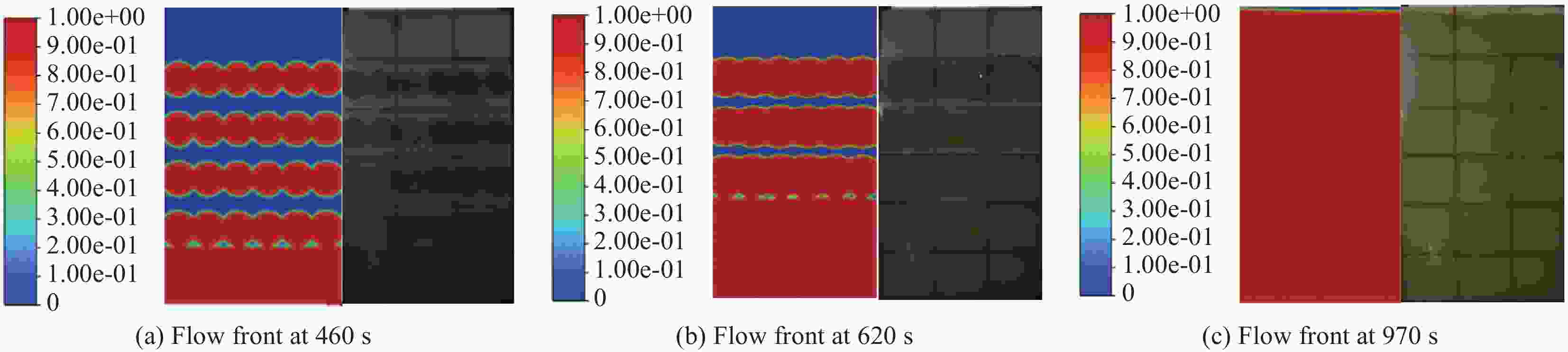

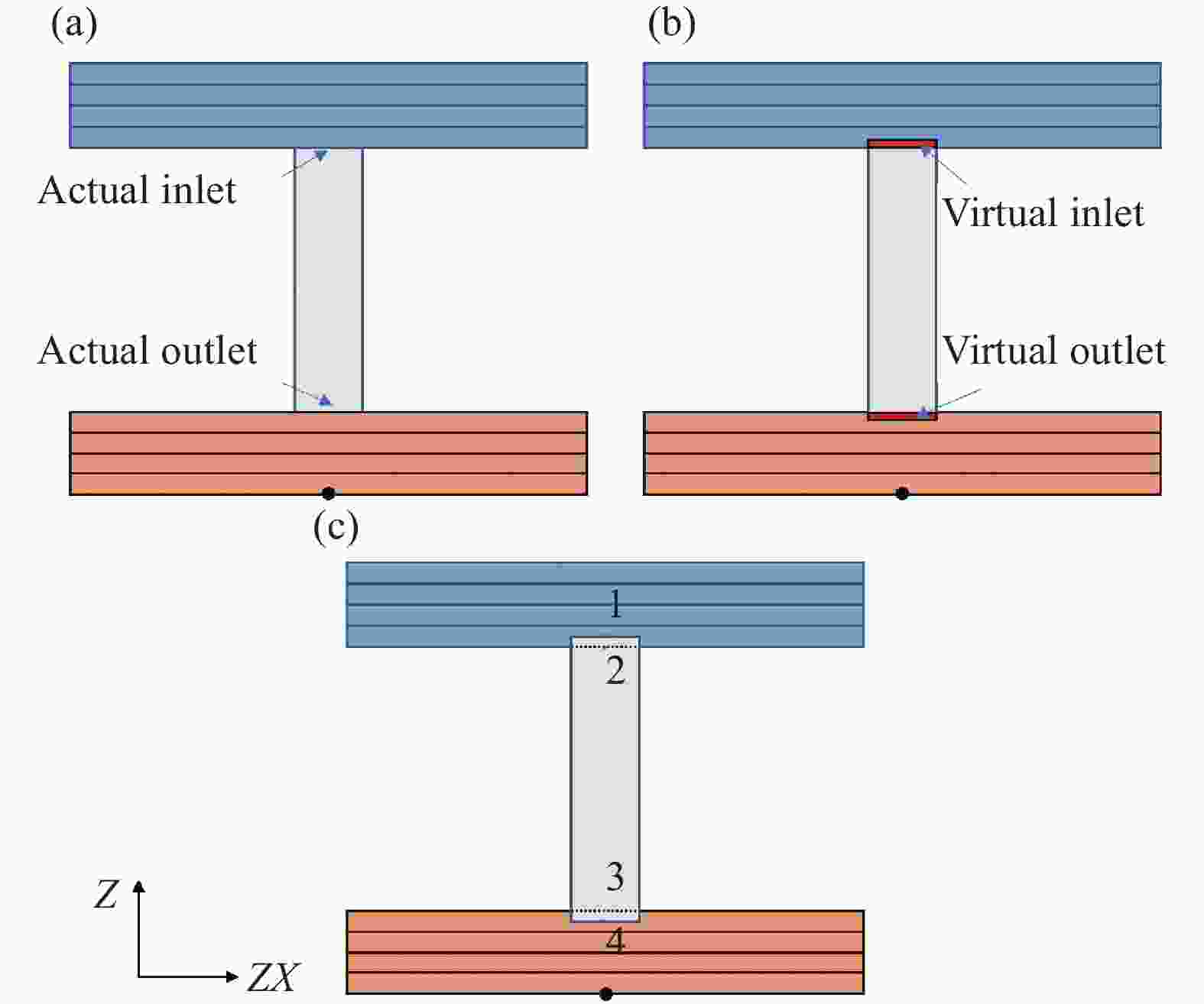

Abstract: The Vacuum Assisted Resin Infusion process (VARI), recognized as a high-performance, cost-effective manufacturing technology, has been widely adopted in the production of large composite material components. Perforated core composite materials exhibit characteristics such as a high strength-to-weight ratio and strong load-bearing capacity. However, to accurately simulate the resin infusion process within perforated core composite materials, three-dimensional numerical calculations of resin flow within each hole of the core material are required, especially for thick components, involving substantial development costs and production cycles. To reduce the complexity and time costs of simulation calculations, this study proposed a novel 3D-1D finite element coupling method. Utilizing a self-developed ANSYS Fluent User-Defined Function (UDF) subroutine to simulate resin flow within the core material holes, the need for physical modeling of a large number of holes is avoided. This approach successfully optimizes the model construction and simulation calculation process of the vacuum infusion process for perforated core composite materials. The feasibility of the simulation was validated through full-scale infusion experiments. The research results indicate that the numerical simulation closely aligns with experimentally measured infusion time, providing a relatively accurate representation of resin flow during the formation process of perforated core structures. -

表 1 材料参数测试结果

Table 1. Test results of material parameters

Material Symbol Value Inlet pressure/Pa $ {P}_{\mathrm{i}\mathrm{n}} $ 0 Outlet pressure/Pa $ {P}_{\mathrm{o}\mathrm{u}\mathrm{t}} $ −101325 Resin viscosity/Pa·s $ {\mu }_{\mathrm{r}} $ 0.25 Resin density/(kg·m−3) $ {\rho }_{\mathrm{r}} $ 1100 Silicone oil viscosity/MPa·s $ {\mu }_{\mathrm{s}} $ 78.4 Silicone oil density/(kg·m−3) $ {\rho }_{\mathrm{s}} $ 963 Fiber volume fraction/vol% $ {V}_{\mathrm{f}} $ 41.1 Permeability/(10−11m2) $ {\mathit{K}}_{\mathit{x}} $ 3.41 $ {\mathit{K}}_{\mathit{y}} $ 3.77 $ {\mathit{K}}_{\mathit{z}} $ 0.2908 Notes: Kx, Ky−In-plan permeability; $ {\mathit{K}}_{{\textit{z}}} $− Permeability in thickness direction. 表 2 不同单元尺寸网格划分方案

Table 2. Meshing scheme of different element sizes

Scheme Upper and lower fiber

panels size/mmCore

size/mmElement/104 a 0.1 0.1 97.2143 b 0.25 0.1 62.4066 c 0.5 0.25 46.4243 d 1 0.5 23.4103 e 1 1 7.8904 -

[1] Irfan S, Siddiqui F. A review of recent advancements in finite element formulation for sandwich plates[J]. Chinese Journal of Aeronautics, 2019, 32(4): 785-798. doi: 10.1016/j.cja.2018.11.011 [2] Patekar V, Kale K. State of the art review on mechanical properties of sandwich composite structures[J]. Polymer Composites, 2022, 43(9): 5820-5830. doi: 10.1002/pc.26989 [3] Galos J, Das R, Sutcliffe M P, et al. Review of balsa core sandwich composite structures[J]. Materials & Design, 2022: 111013. [4] Yang B, Jin T, Bi F, et al. Modeling the resin flow and numerical simulation of the filling stage for vacuum-assisted resin infusion process[J]. Journal of Reinforced Plastics and Composites, 2014, 33(21): 1976-1992. doi: 10.1177/0731684414551039 [5] Gada L A , C. N G S, Akhsin M M . Defect characteristics of unidirectional glass fiber reinforced epoxy manufactured via vacuum assisted resin infusion[J]. Materials Today: Proceedings, 2022, 66 (P5): 2796-2800. [6] Vilà J, González C, LLorca J. Fabric compaction and infiltration during vacuum-assisted resin infusion with and without distribution medium[J]. Journal of Composite Materials, 2017, 51(5): 687-703. doi: 10.1177/0021998316649783 [7] Robinson M J, Kosmatka J B. Analysis of the post-filling phase of the vacuum-assisted resin transfer molding process[J]. Journal of Composite Materials, 2014, 48(13): 1547-1559. doi: 10.1177/0021998313488150 [8] Park C H. Numerical simulation of flow processes in composites manufacturing [M]. Advances in Composites Manufacturing and Process Design. Woodhead Publishing, 2015: 317-378. [9] 施赫荣, 王继辉, 倪爱清等. 穿孔泡沫夹芯复合材料灌注工艺仿真与方案优选[J]. 复合材料学报, 2023, 40(2): 782-793.SHI Herong, WANG Jihui, NI Aiqing, et al. Perforated foam sandwich composite grouting process simulation and scheme optimization[J]. Journal of Composite Materials, 2023, 40(2): 782-793(in Chinese). [10] Shah M, Chaudhary V. Flow modeling and simulation study of vacuum assisted resin transfer molding (VARTM) process: A review[C]. IOP conference series: materials science and engineering. IOP Publishing, 2020, 872(1): 012087. [11] Song Y S, Youn J R. Flow advancement through multi-layered preform with sandwich structure[J]. Composites Part A:Applied Science and Manufacturing, 2007, 38(4): 1082-1088. doi: 10.1016/j.compositesa.2006.04.009 [12] Chao Y, Hailiang W, Xueming R, et al. Experimental and Numerical Study on the Permeation Behavior of Foam-core Sandwich Panels in LCM[J]. Fibers and Polymers, 2021, 22(9). [13] Chao Y, Yishen L, Xia S, et al. Resin Flow Analysis for the Foam Core Sandwich Spoiler by Vacuum-Assisted Resin Injection Process[J]. Materials, 2022, 15(15): 5279-5279. doi: 10.3390/ma15155279 [14] Falaschetti M P, Rondina F, Zavatta N, et al. Material characterization for reliable resin transfer molding process simulation[J]. Applied Sciences, 2020, 10(5): 1814. doi: 10.3390/app10051814 [15] Yan C, Wu H, Ren X, et al. Experimental and Numerical Study on the Permeation Behavior of Foam-core Sandwich Panels in LCM[J]. Fibers and Polymers, 2021, 22(9): 2612-2625. doi: 10.1007/s12221-021-0310-9 [16] Jhan Y T, Lee Y J, Chung C H. Experimental and numerical investigation of the VARTM process with a sandwich structure[J]. Journal of composite materials, 2012, 46(12): 1417-1430. doi: 10.1177/0021998311418703 [17] 王科, 赖家美, 鄢冬冬, 等. 缝合泡沫夹芯结构复合材料VARTM工艺树脂充填模拟及验证[J]. 高分子材料科学与工程, 2015, 31(11): 124-129.WANG Ke, LAI Jiamei, YAN Dongdong, et al. Simulation and verification of resin filling of stitched foam sandwich structure composite VARTM process[J]. Polymer Materials Science and Engineering, 2015, 31 (11): 124-129 28(in Chinese). [18] Poodts E, Minak G, Dolcini E, et al. FE analysis and production experience of a sandwich structure component manufactured by means of vacuum assisted resin infusion process[J]. Composites Part B, 2013, 53. [19] Al Ali A, Arhore E, Ghasemnejad H, et al. Experimental and numerical investigation of multi-layered honeycomb sandwich composites for impact mechanics applications[J]. Results in Engineering, 2024: 101817. [20] Jordaan H, Stephan Heyns P, Hoseinzadeh S. Numerical development of a coupled one-dimensional/three-dimensional computational fluid dynamics method for thermal analysis with flow maldistribution[J]. Journal of Thermal Science and Engineering Applications, 2021, 13(4): 041017. doi: 10.1115/1.4049040 [21] Koekemoer O C, du Toit C G, Niemand P F. Investigation into different 1D/3D co-simulation methodologies applied to a natural circulation loop[J]. Nuclear Engineering and Design, 2022, 390: 111698. doi: 10.1016/j.nucengdes.2022.111698 [22] Zhao H, Zheng Y, Chen X, et al. A one-dimensional code of the passive residual heat removal system for the modular high temperature gas-cooled reactor[J]. Progress in Nuclear Energy, 2019, 110: 374-383. doi: 10.1016/j.pnucene.2018.10.019 [23] Xiyuan C, Jianzhong Y, Tianpeng Y U, et al. A Coupled 1D/3D Co-Simulation Approach in Simulating Aircraft Cabin Temperature Field[J]. International Journal of Simulation--Systems, Science & Technology, 2016, 17(40): 11.1-11.7. [24] Pate S B, Solomon I S M, Dundulis G, et al. Applications of the FEM to pipe whip analysis using coupled modelling technique[J]. Nuclear Engineering and Design, 2024, 418: 112941. doi: 10.1016/j.nucengdes.2024.112941 [25] Zhang P, Cheng Y, Xue S, et al. 1D-3D coupled simulation method of hydraulic transients in ultra-long hydraulic systems based on OpenFOAM[J]. Engineering Applications of Computational Fluid Mechanics, 2023, 17(1): 2229889. doi: 10.1080/19942060.2023.2229889 [26] Yang B, Jin T, Bi F, et al. Modeling the resin flow and numerical simulation of the filling stage for vacuum-assisted resin infusion process[J]. Journal of Reinforced Plastics and Composites, 2014, 33(21): 1976-1992. doi: 10.1177/0731684414551039 [27] Yang B, Jin T, Li J, et al. Simulating the resin flow and stress distributions on mold tools during compression resin transfer molding[J]. Journal of Reinforced Plastics and Composites, 2014, 33(14): 1316-1331. doi: 10.1177/0731684414528831 [28] Hirt C W, Nichols B D. Volume of fluid (VOF) method for the dynamics of free boundaries[J]. Journal of computational physics, 1981, 39(1): 201-225. doi: 10.1016/0021-9991(81)90145-5 [29] Brackbill J U, Kothe D B, Zemach C. A continuum method for modeling surface tension[J]. Journal of computational physics, 1992, 100(2): 335-354. doi: 10.1016/0021-9991(92)90240-Y [30] Průša V. On the influence of boundary condition on stability of Hagen–Poiseuille flow[J]. Computers & Mathematics with Applications, 2009, 57(5): 763-771. [31] 曹鹏军. 基于CT图像的织物渗透率预测及扩张段工艺仿真[D]. 武汉理工大学, 2022.CAO Pengjun. Prediction of Fabric Permeability and Simulation of Expansion Section Process Based on CT Images [D]. Wuhan University of Technology, 2022(in Chinese). [32] 张浩, 李书欣, 王继辉等. 基于新型测试装置的网孔板层开孔率对纤维厚度方向渗透率的影响[J]. 复合材料学报, 2020, 37(5): 1175-1183.ZHANG Hao, LI Shuxin, WANG Jihui, et al. Influence of ratio of hole area for mesh plate layer on through-thickness permeability based on a new designed test bench[J]. Journal of Composite Materials, 2020, 37(5): 1175-1183(in Chinese). [33] Sun X, Li S, Lee L J. Mold filling analysis in vacuum-assisted resin transfer molding. Part I: SCRIMP based on a high-permeable medium[J]. Polymer Composites, 1998, 19(6): 807-817. doi: 10.1002/pc.10155 [34] 戴福洪, 张博明, 杜善义等. RTM工艺注模过程模拟的有限元/控制体积方法和流动分析网络技术比较[J]. 复合材料学报, 2004, 21(2): 92-98. doi: 10.3321/j.issn:1000-3851.2004.02.017DAI Fuhong, ZHANG Boming, DU Shanyi, et al. Comparison of finite element/control volume method and flow analysis network technology for injection molding process simulation of RTM process[J]. Journal of Composite Materials, 2004, 21(2): 92-98(in Chinese). doi: 10.3321/j.issn:1000-3851.2004.02.017 -

点击查看大图

点击查看大图

计量

- 文章访问数: 37

- HTML全文浏览量: 21

- 被引次数: 0

下载:

下载: