Microstructure and high-temperature tensile properties of Ti2AlNb/TA15 laminated composites prepared by vacuum hot pressing

-

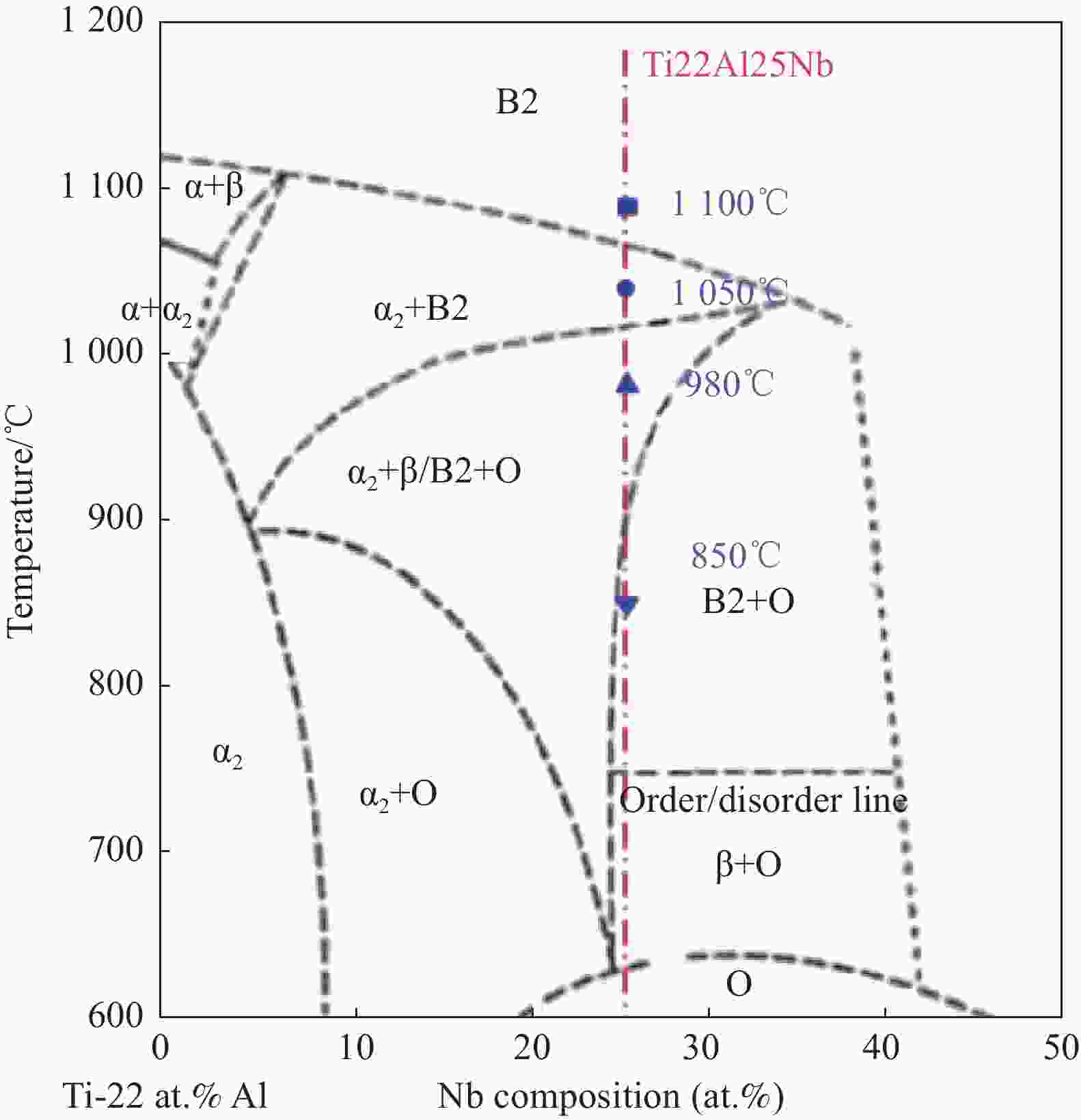

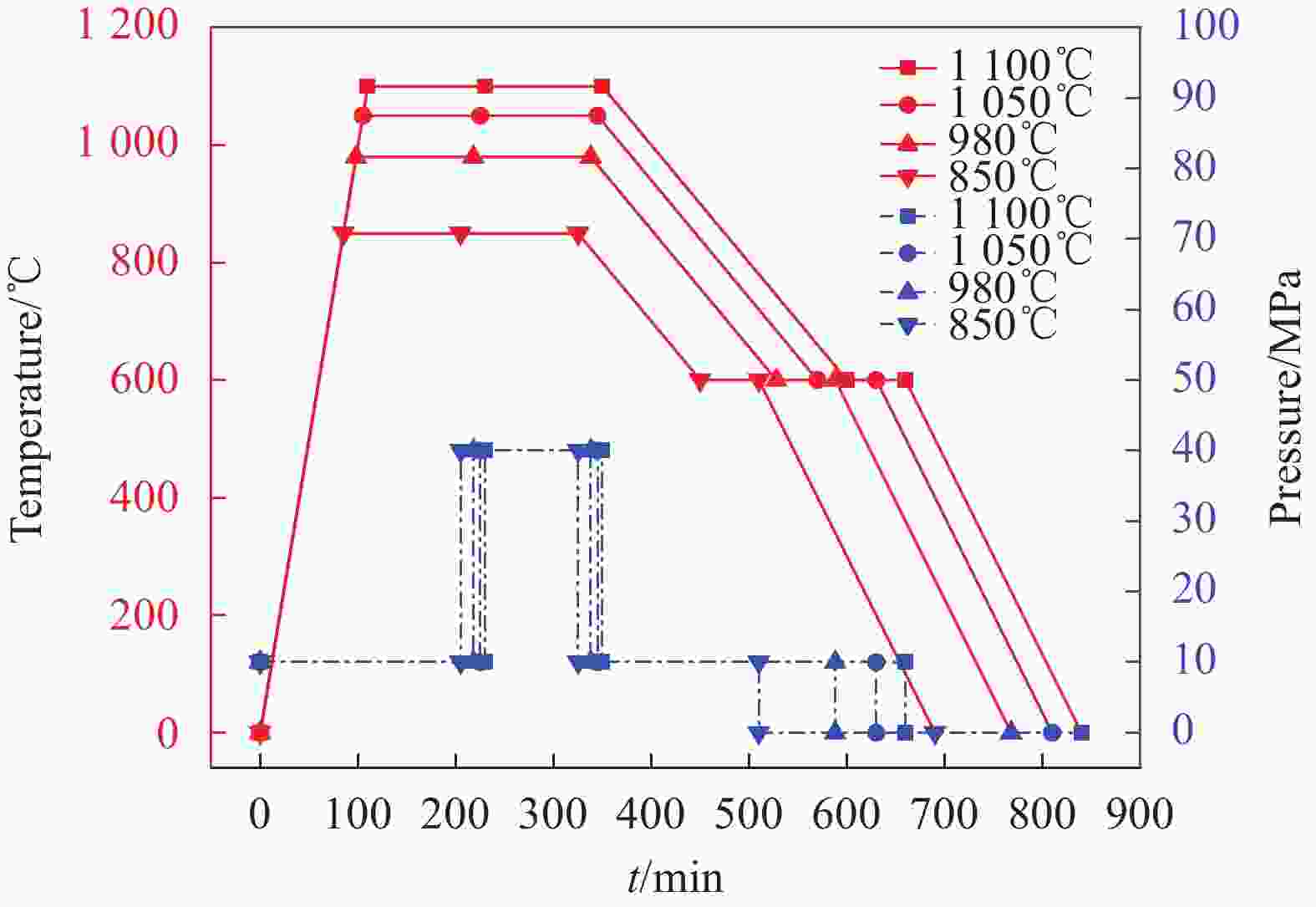

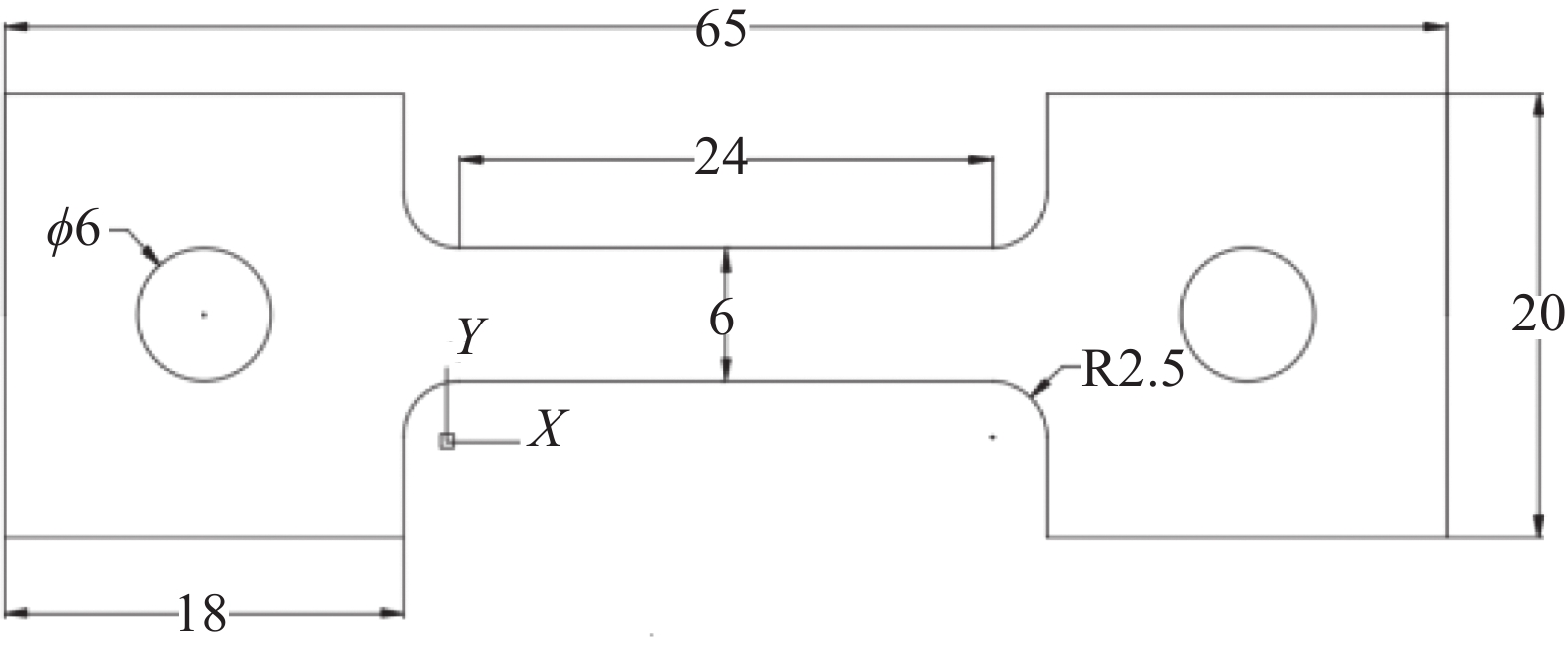

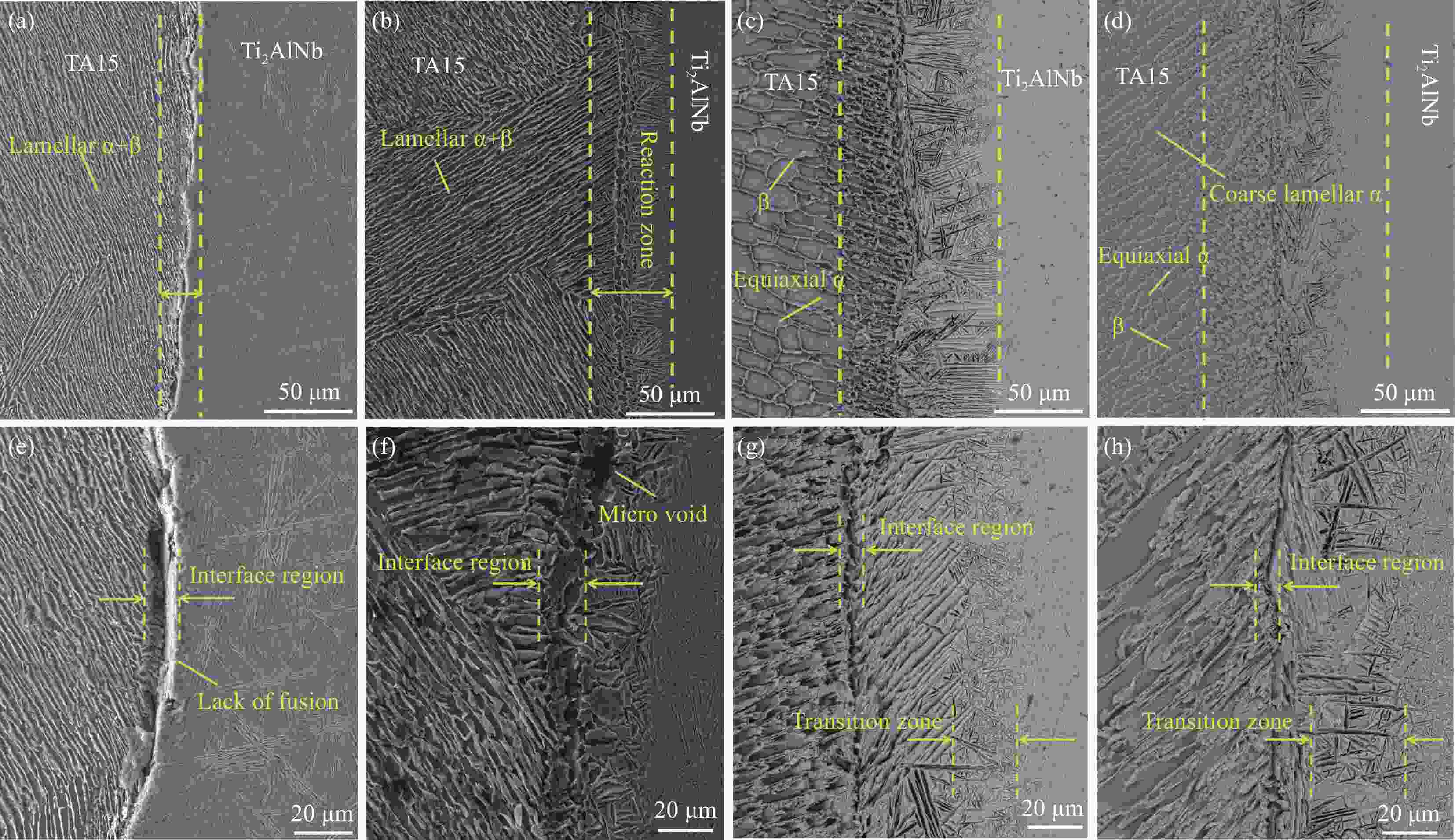

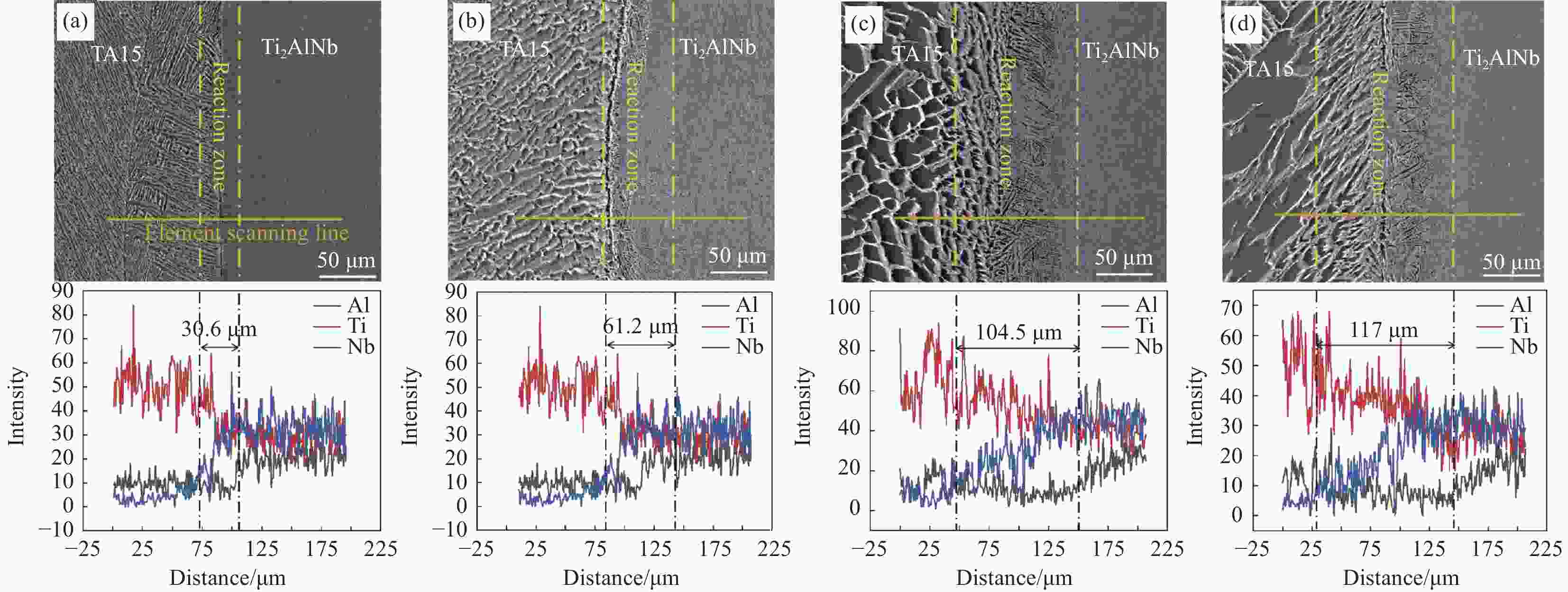

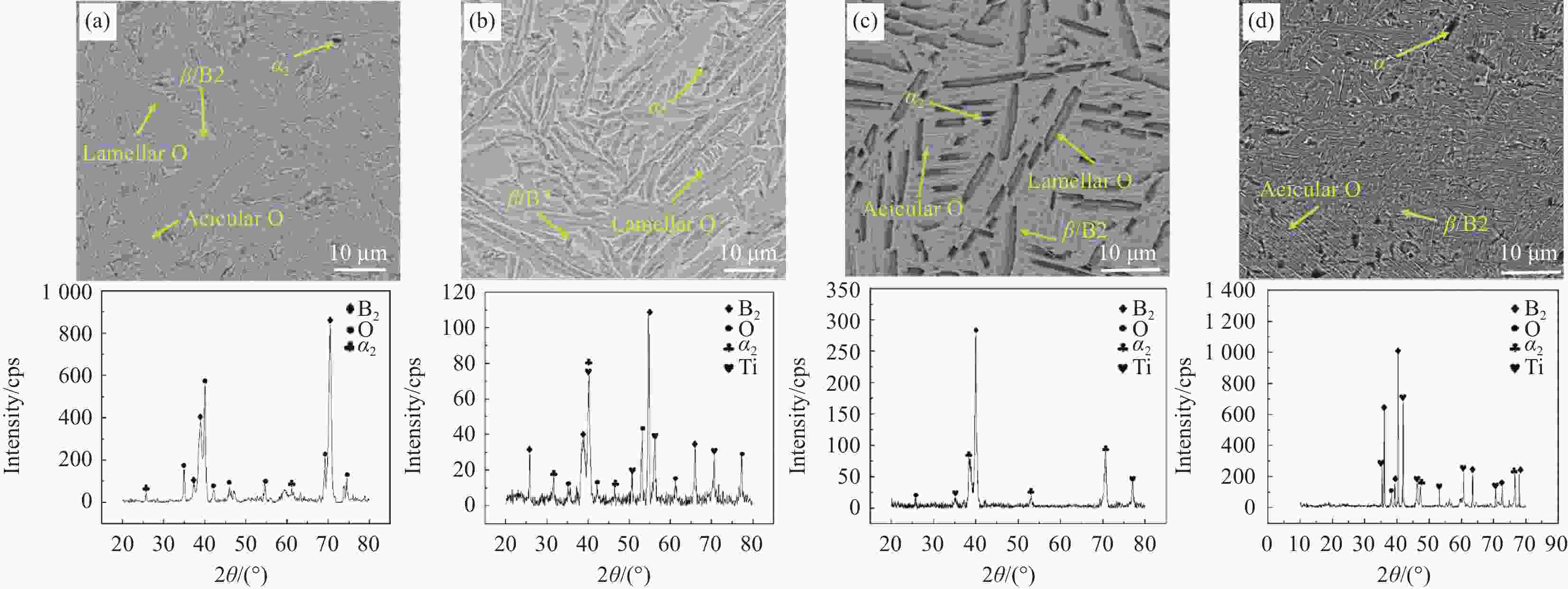

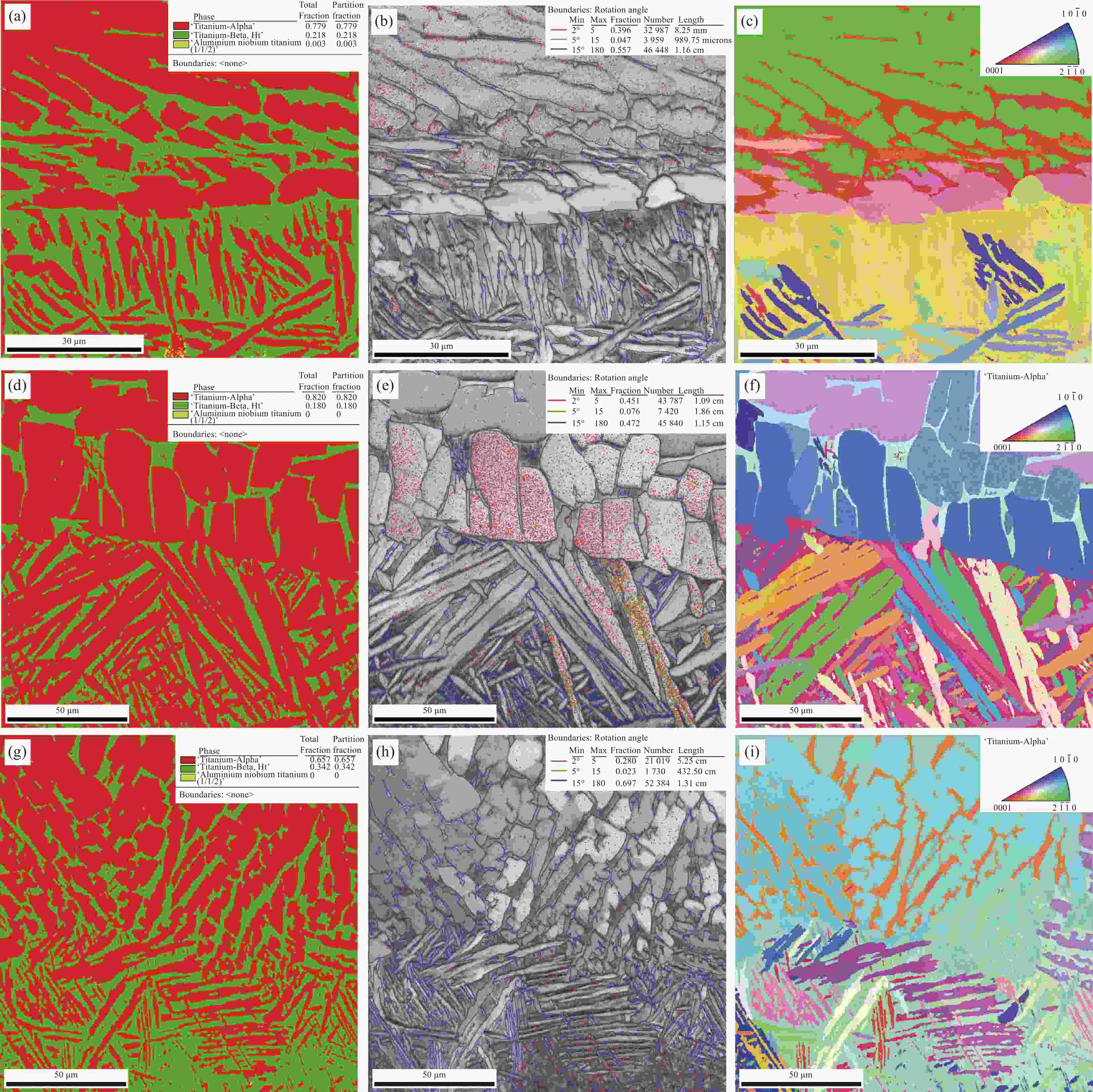

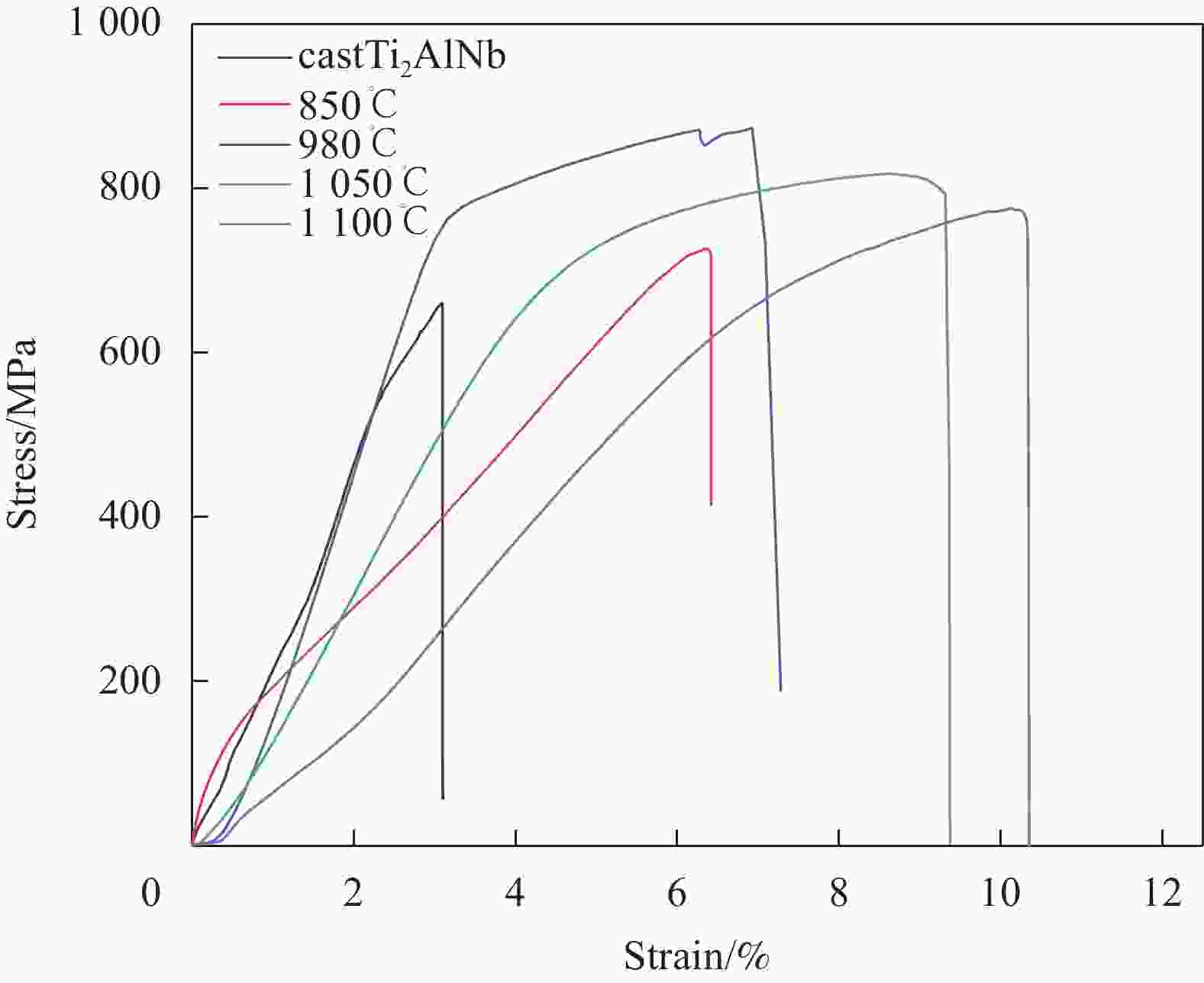

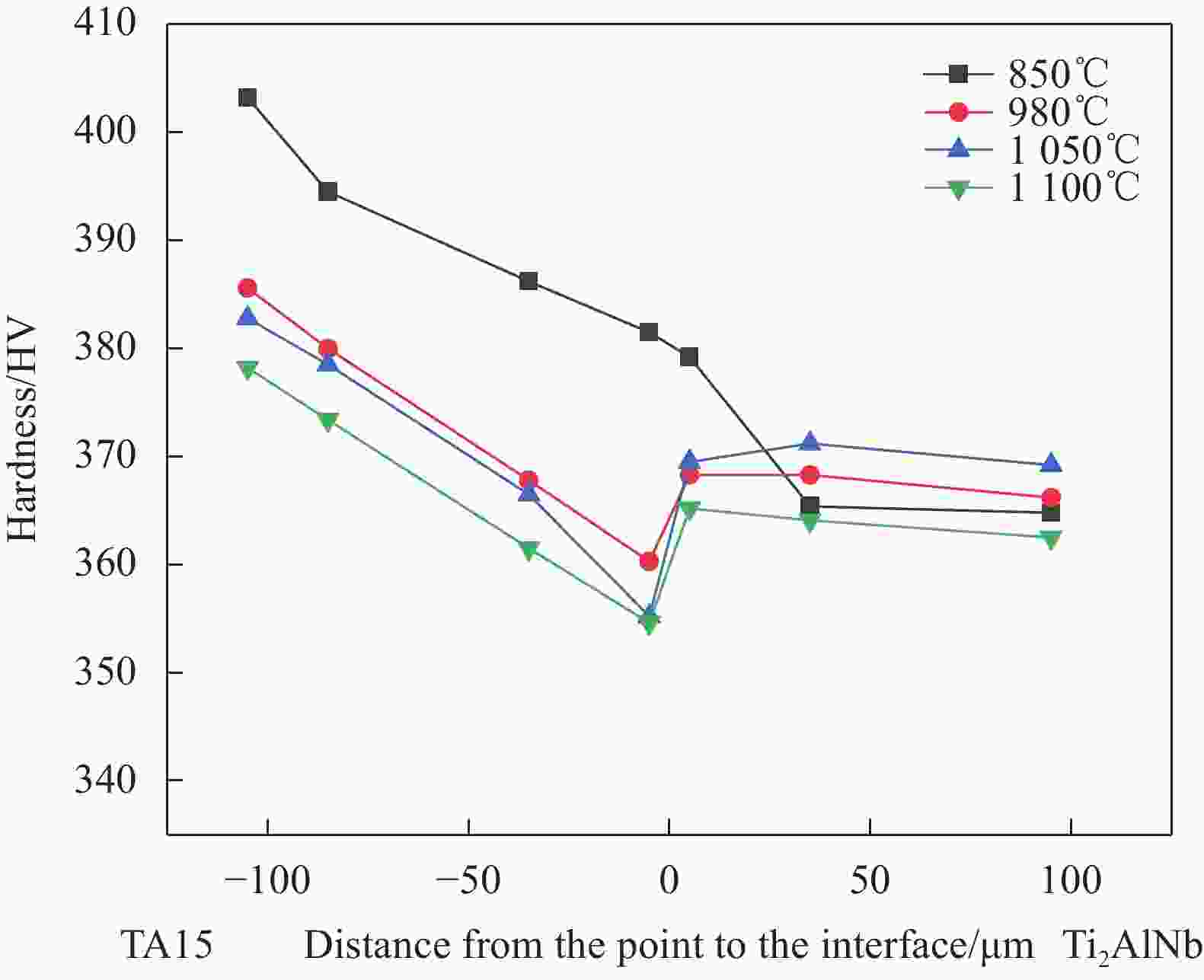

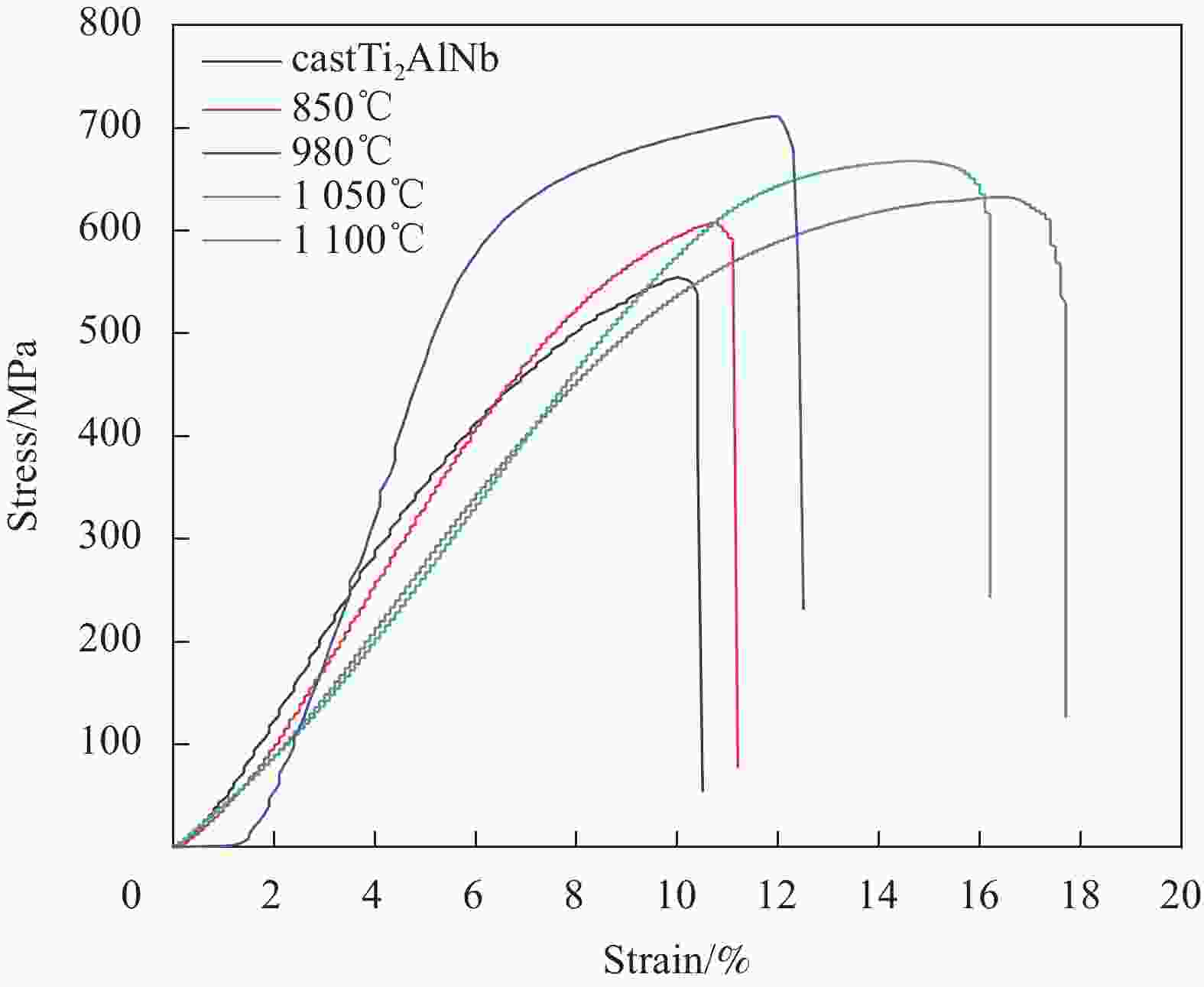

摘要: 为改善Ti2AlNb合金的本征脆性且不牺牲其高温性能,将其与高温钛合金TA15进行复合,采用真空热压法制备了Ti2AlNb/TA15叠层复合材料,研究了不同热压温度对其微观组织及其拉伸性能的影响。研究结果表明,界面层的孔洞缺陷随热压温度的升高逐渐减少,热压温度在1050℃及以上时可以获得无缺陷冶金结合界面。界面反应层厚度随热压温度的升高而增加,且在1050℃及以上的扩散温度条件下,反应区和Ti2AlNb层间形成了一定宽度的过渡层,提升了界面结合性能。拉伸实验结果表明,相较于Ti2AlNb合金,Ti2AlNb/TA15叠层复合材料的室温和高温拉伸性能均有显著的提升。其中1050℃热压温度条件下的叠层复合材料具有较好的综合性能,650℃高温抗拉强度和应变分别为667.85 MPa和16.2%。Abstract: In order to improve the intrinsic brittleness of Ti2AlNb alloy without sacrificing its high-temperature performance, a composite material was prepared by combining it with high-temperature titanium alloy TA15 using vacuum hot pressing. The effects of different hot pressing temperatures on the microstructure and tensile properties of Ti2AlNb/TA15 laminated composite materials were investigated. The results show that the pore defects in the interface layer gradually decrease with the increase of the hot pressing temperature. A defect-free metallurgical bonding interface can be achieved at temperatures of 1050°C and above. The thickness of the interface reaction layer increases with the rise of the hot pressing temperature. Under the diffusion conditions at 1050℃ and above, a transition layer of certain width formed between the reaction zone and the Ti2AlNb layers, which improve the properties of the interface bonding. Tensile tests indicate that the room and high-temperature tensile properties of the Ti2AlNb/TA15 laminated composite material are significantly improved compared with Ti2AlNb alloy. The laminated composite material under the hot pressing temperature condition of 1050℃ exhibits excellent comprehensive performance, with a high-temperature tensile strength and strain of 667.85 MPa and 16.2%, respectively.

-

图 13 Ti2AlNb/TA15叠层复合材料界面区、Ti2AlNb基体和TA15基体断口SEM(SE)图:((a)~(c)) 850℃; ((d)~(f)) 980℃; ((g)~(i)) 1050℃; ((j)~(l))1100℃

Figure 13. SEM (SE) images of Ti2 AlNb/TA15 stacked composite interfacial region, Ti2 AlNb matrix and TA15 matrix fracture: ((a)-(c)) 850℃; ((d)-(f)) 980℃; ((g)-(i)) 1050℃; ((j)-(l))1100℃

表 1 Ti2AlNb和TA15的化学成分

Table 1. Chemical compositions of Ti2AlNb and TA15

Materials Chemical composition TA15/wt% Al: 6.78, Mo: 1.7, V: 2.31, Zr: 2.00, Fe<0.05, Si<0.017, O<0.11, N<0.011, Ti: Bal. Ti2AlNb/at% Al: 22.3, Nb:25.2, Ti: Bal. 表 2 Ti2AlNb/TA15叠层复合材料制备工艺参数

Table 2. Preparation process parameters of Ti2AlNb/TA15 laminated composites

Exp. Phase 1 Phase 2 Phase 3 T1/℃ t1/h P1/MPa T2/℃ t2/h P2/MPa T3/℃ t3/h P3/MPa 1 850 2 10 850 2 40 600 1 10 2 980 2 10 980 2 40 600 1 10 3 1050 2 10 1050 2 40 600 1 10 4 1100 2 10 1100 2 40 600 1 10 Notes:T1, T2 and T3 are the hot-pressing temperature in the first, second and third stage; t1, t2 and t3 are the holding time in the first, second and third stage; P1, P2 and P3 are the hot-pressing pressure in the first, second and third stage. 表 3 Ti2AlNb/TA15叠层复合材料室温拉伸强度和应变

Table 3. Room temperature tensile strength and strain of Ti2AlNb/TA15 laminated composites

Specimens Hot pressing temperature/℃ Tensile strength/MPa Tensile strain/% TA15/Ti2AlNb 850 726.22 6.42 980 873.21 7.28 1050 817.44 9.37 1100 775.79 10.35 Ti2AlNb (as cast) − 660.09 3.10 表 4 Ti2AlNb/TA15叠层复合材料650℃高温拉伸强度和应变

Table 4. 650°C High temperature tensile strength and strain of Ti2AlNb/TA15 laminated composites

Specimens Hot pressing temperature/℃ Tensile strength/MPa Tensile strain/% Ti2AlNb/TA15 850℃ 607.71 11.1 980℃ 711.58 12.5 1050℃ 667.85 16.2 1100℃ 632.76 17.7 Ti2AlNb (as cast) − 555.08 10.5 -

[1] 王兴杰. “爆炸焊接+热处理”制备Ti/Al3Ti叠层复合材料及其性能研究 [D]. 山西: 中北大学, 2022.WANG Xingjie. Research on the preparation and properties of Ti/Al3Ti laminated composites by explosive welding and heat treatment [D]. Shanxi: North University of China, 2022 (in Chinese). [2] 赵赫威, 郭林. 仿贝壳珍珠母层状复合材料的制备及应用[J]. 科学通报, 2017, 62(6): 576-589. doi: 10.1360/N972016-00754ZHAO Hewei, GUO Lin. Synthesis and applications of layered structural composites inspired by nacre[J]. Chinese Science Bulletin, 2017, 62(6): 576-589(in Chinese). doi: 10.1360/N972016-00754 [3] 尹楚藩. 基于爆炸焊接法的Ti/TiAl3叠层复合材料制备技术研究 [D]. 山西: 中北大学, 2020.YIN Chufan. Research on the preparation technology of Ti/TiAl3 laminated composites based on explosion welding method [D]. Shanxi: North University of China, 2020(in Chinese). [4] 曹阳, 朱世范, 果春焕, 等. 新型金属间化合物基层状装甲防护复合材料[J]. 兵器材料科学与工程, 2014, 37(06): 122-128. doi: 10.3969/j.issn.1004-244X.2014.06.039CAO Yang, ZHU Shifan, GUO Chunhuan, et al. Novel metal-intermetallic laminate composite for armor material[J]. Ordnance Material Science and Engineering, 2014, 37(06): 122-128(in Chinese). doi: 10.3969/j.issn.1004-244X.2014.06.039 [5] TRESA M, POLLOCK. Alloy design for aircraft engines[J]. Nature Materials, 2016, 15: 809-815. doi: 10.1038/nmat4709 [6] HAGIWARA M, EMURA S, ARAOKA A, et al. Enhanced mechanical properties of orthorhombic Ti2AlNb-based intermetallic alloy[J]. Metals Materials. International, 2003, 9: 265-272. doi: 10.1007/BF03027045 [7] 冯艾寒, 李渤渤, 沈军. Ti2AlNb基合金的研究进展[J]. 材料与冶金学报, 2011, 10(01): 30-38. doi: 10.3969/j.issn.1671-6620.2011.01.007FENG Aihan, LI Bobo, SHEN Jun. Recent advances on Ti2AlNb-based alloys[J]. Journal of Materials and Metallurgy, 2011, 10(01): 30-38(in Chinese). doi: 10.3969/j.issn.1671-6620.2011.01.007 [8] FRONCZEK D M, WOJEWODA-BUDKA J, CHULIST R, et al. Structural properties of Ti/Al clads manufactured by explosive welding and annealing[J]. Materials & Design, 2016, 91: 80-89. [9] FINDIK F. Recent developments in explosive welding[J]. Materials & Design, 2011, 32(3): 1081-1093. [10] SUN W, FAN H Y, YOU F H, et al. Prediction of interfacial phase formation and mechanical properties of Ti6Al4V-Ti43Al9V laminate composites[J]. Materials Science and Engineering: 2020, 782: 139173. [11] SUN W, YOU F H, KONG F T, et al. Effect of residual stresses on the mechanical properties of Ti-TiAl laminate composites fabricated by hot-pack rolling[J]. Materials Characterization, 2020, 166: 110394. doi: 10.1016/j.matchar.2020.110394 [12] LYU S Y, SUN Y B, LI G D, et al. Effect of layer sequence on the mechanical properties of Ti/TiAl laminates[J]. Materials & Design, 2018, 143: 160-168. [13] SUN W, YOU F H, KONG F T, et, al. Enhanced tensile strength and fracture toughness of a Ti-TiAl metal-intermetallic laminate (MIL) composite[J]. Intermetallics, 2020, 118: 106684. doi: 10.1016/j.intermet.2019.106684 [14] ZHU H F, SUN W, KONG F T, et al. Interfacial characteristics and mechanical properties of TiAl/Ti6Al4V laminate composite (LMC) fabricated by vacuum hot pressing[J]. Materials Science and Engineering:A, 2019, 742: 704-711. doi: 10.1016/j.msea.2018.07.086 [15] 孔凡涛, 陈玉勇. γ-TiA1/TC4复合板材的制备及组织性能研究[J]. 稀有金属材料与工程, 2009, 38(8): 1484-1486. doi: 10.3321/j.issn:1002-185X.2009.08.040KONG Fantao, CHEN Yuyong. Preparation of γ-TiAl/TC4 composite sheet and its microstructure and properties[J]. Rare Metal Materials and Engineering, 2009, 38(8): 1484-1486(in Chinese). doi: 10.3321/j.issn:1002-185X.2009.08.040 [16] 宋志恒. TiAl/Ti合金层状复合材料的制备及组织性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.SONG Zhiheng. Fabrication and microstructure and mechanical properties of TiAl/Ti laminated composities[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [17] FAN M Y, DOMBLESKY J, JIN K, et al. Effect of original layer thicknesses on the interface bonding and mechanical properties of TiAl laminate composites[J]. Materials & Design, 2016, 99: 535-542. [18] 杨蕊鸿, 林飞, 朱岩, 等. TC4/Ti2AlNb异种合金扩散连接接头组织与性能研究[J]. 热加工工艺, 2020, 49(05): 20-24.YANG Ruihong, LIN Fei, ZHU Yan, et al. Microstructure and mechanical properties of diffusion bonded joints of TC4/Ti2AlNb dissimilar alloys[J]. Hot Working Technology, 2020, 49(05): 20-24(in Chinese). [19] LI D H, WANG B B, LUO L S, et al. The interface structure and its impact on the mechanical behavior of TiAl/Ti2AlNb laminated composites[J]. Materials Science and Engineering: 2021, 827: 142095. [20] LI P, JI X H, XUE K M. Diffusion bonding of TA15 and Ti2AlNb Alloys: interfacial microstructure and mechanical properties[J]. Materials Engineering and Performance, 2017, 26(4): 1839-1846. doi: 10.1007/s11665-017-2555-4 [21] LI P, WANG L S, WANG B, et al. Diffusion and mechanical properties of Ti2AlNb and TA15 interface: From experiments to molecular dynamics[J]. Vacuum, 2022, 195: 110637. doi: 10.1016/j.vacuum.2021.110637 [22] LIU Y T, ZHANG Y Z. Microstructure and mechanical properties of TA15-Ti2AlNb bimetallic structures by laser additive manufacturing[J]. Materials Science and Engineering: A, 2020, 795: 140019. doi: 10.1016/j.msea.2020.140019 [23] SUN Z C, YANG H. Microstructure and mechanical properties of TA15 titanium alloy under multi-step local loading forming[J]. Materials Science and Engineering:A, 2009, 523(1-2): 184-192. doi: 10.1016/j.msea.2009.05.058 [24] WEI M, CHEN S, LIANG J, et al. Effect of atomization pressure on the breakup of TA15 titanium alloy powder prepared by EIGA method for laser 3D printing[J]. Vacuum, 2017, 143: 185-194. doi: 10.1016/j.vacuum.2017.06.014 [25] ZHANG K, LEI Z, CHEN Y, et al. Microstructure characteristics and mechanical properties of laser-TIG hybrid welded dissimilar joints of Ti-22Al-27Nb and TA15[J]. Optics & Laser Technology, 2015, 73: 139-145. [26] BOEHLERT C J. The phase evolution and microstructural stability of an orthorhombic Ti-23Al-27Nb alloy[J]. Journal of phase equilibria, 1999, 20(2): 101-108. doi: 10.1007/s11669-999-0007-z [27] ZHANG Y , CAI Q , MA Z , et al. Solution treatment for enhanced hardness in Mo-modified Ti2AlNb-based alloys[J]. Journal of Alloys and Compounds, 2019, 805(15): 1184-1190. [28] WANG J Y, GE Z M, ZHOU B Y. Aeronautical Titanium Alloy [M]. Shanghai: Shanghai scientific and technical publishers, 1985, 120. [29] 曹京霞, 方波, 黄旭, 等. 微观组织对TA15钛合金力学性能的影响[J]. 稀有金属, 2004, (02): 362-364. doi: 10.3969/j.issn.0258-7076.2004.02.018CAO Jingxia, FANG Bo, HUANG Xu, et al. Effects of microstructure on properties of TA15 titanium alloy[J]. Chinese Journal of Rare Metals, 2004, (02): 362-364(in Chinese). doi: 10.3969/j.issn.0258-7076.2004.02.018 [30] ZHAO Y Y, LI J Y, QIU R F, et al. Growth characterization of intermetallic compound at the Ti/Al solid state interface[J]. Materials, 2019, 12(3): 472. doi: 10.3390/ma12030472 [31] ARDELL A J. Microstructural stability at elevated temperatures[J]. Journal European Ceramic Society, 1999, 19: 2217-2231. doi: 10.1016/S0955-2219(99)00094-1 [32] HE B, WU D, PAN J L, et al. Effect of heat treatment on microstructure and mechanical properties of laser deposited TA15/ Ti2AlNb gradient composite structures[J]. Vacuum, 2021, 190: 110309. doi: 10.1016/j.vacuum.2021.110309 [33] STEFANSSO N, SEMIATIN S L. Mechanisms of globularization of Ti-6Al-4V during static heat treatment[J]. Metallurgical and Materials Transaction A, 2003, 34(3): 691-698. doi: 10.1007/s11661-003-0103-3 [34] 郑友平, 曾卫东, 王伟, 等. Ti-22Al-25Nb合金等轴组织演变和拉伸性能[J]. 稀有金属材料与工程, 2017, 46(S1): 200-203.ZHENG Youping, ZENG Weidong , WANG Wei, et al. Equiaxed microstructure evolution and tensile properties of Ti-22Al-25Nb alloy[J]. Rare Metal Materials and Engineering, 2017, 46(S1): 200-203(in Chinese). [35] TANG B, XIAN S Q, KOU H C, et al. Recrystallization behavior at diffusion bonding interface of high Nb containing TiAl alloy[J]. Advanced Engineering Material, 2016, 18(4): 657-664. doi: 10.1002/adem.201500457 [36] ZHANG H, YAN N, LIANG H, et al. Phase transformation and microstructure control of Ti2AlNb-based alloys: A review[J]. Journal of Materials Science & Technology, 2021, 80(21): 203-216. [37] ZHOU Y H, WANG D W, SONG L J, et al. Effect of heat treatments on themicrostructure and mechanical properties of Ti2AlNb intermetallic fabricated by selective laser melting[J]. Materials Science & Engineering, A. Structural Materials: Properties, Misrostructure and Processing, 2021: 817. [38] LI N, ZHAO Z B, SUN H, et al. Effects of heat treatment on microstructure evolution and mechanical properties of Ti-22Al-24Nb-0.5 Mo alloy[J]. Materials Science and Engineering: A, 2022, 857: 144052. doi: 10.1016/j.msea.2022.144052 -

点击查看大图

点击查看大图

计量

- 文章访问数: 114

- HTML全文浏览量: 68

- 被引次数: 0

下载:

下载: