Study on interfacial compatibility and resilient creep resistance of silane-modified collagen fiber/polyvinyl chloride composites

-

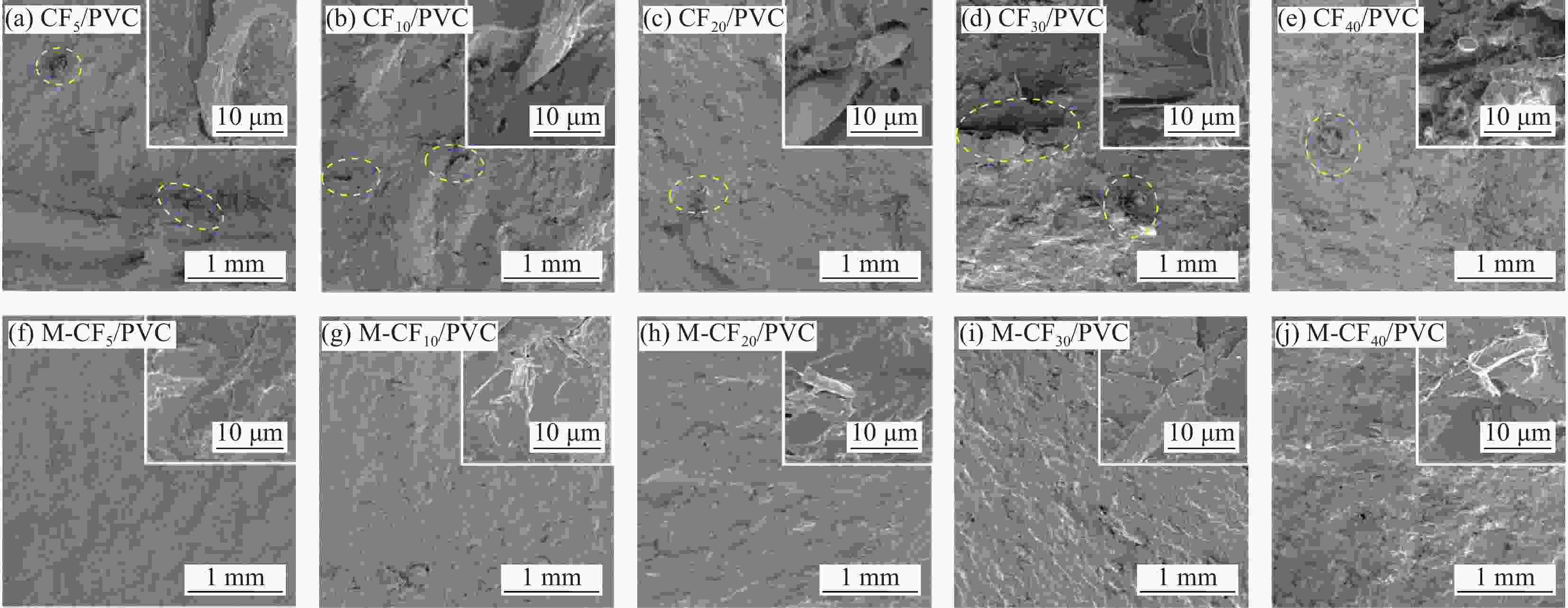

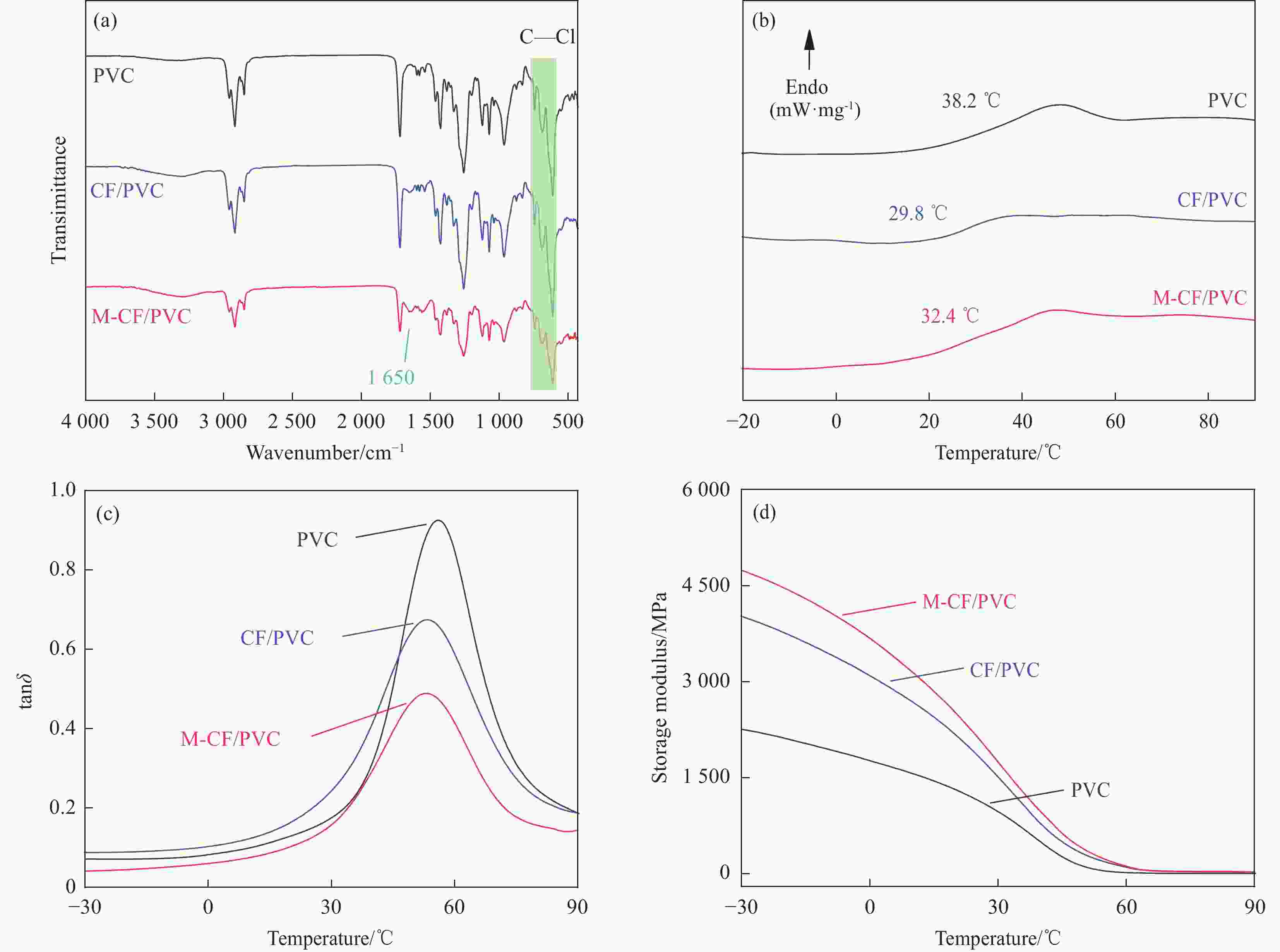

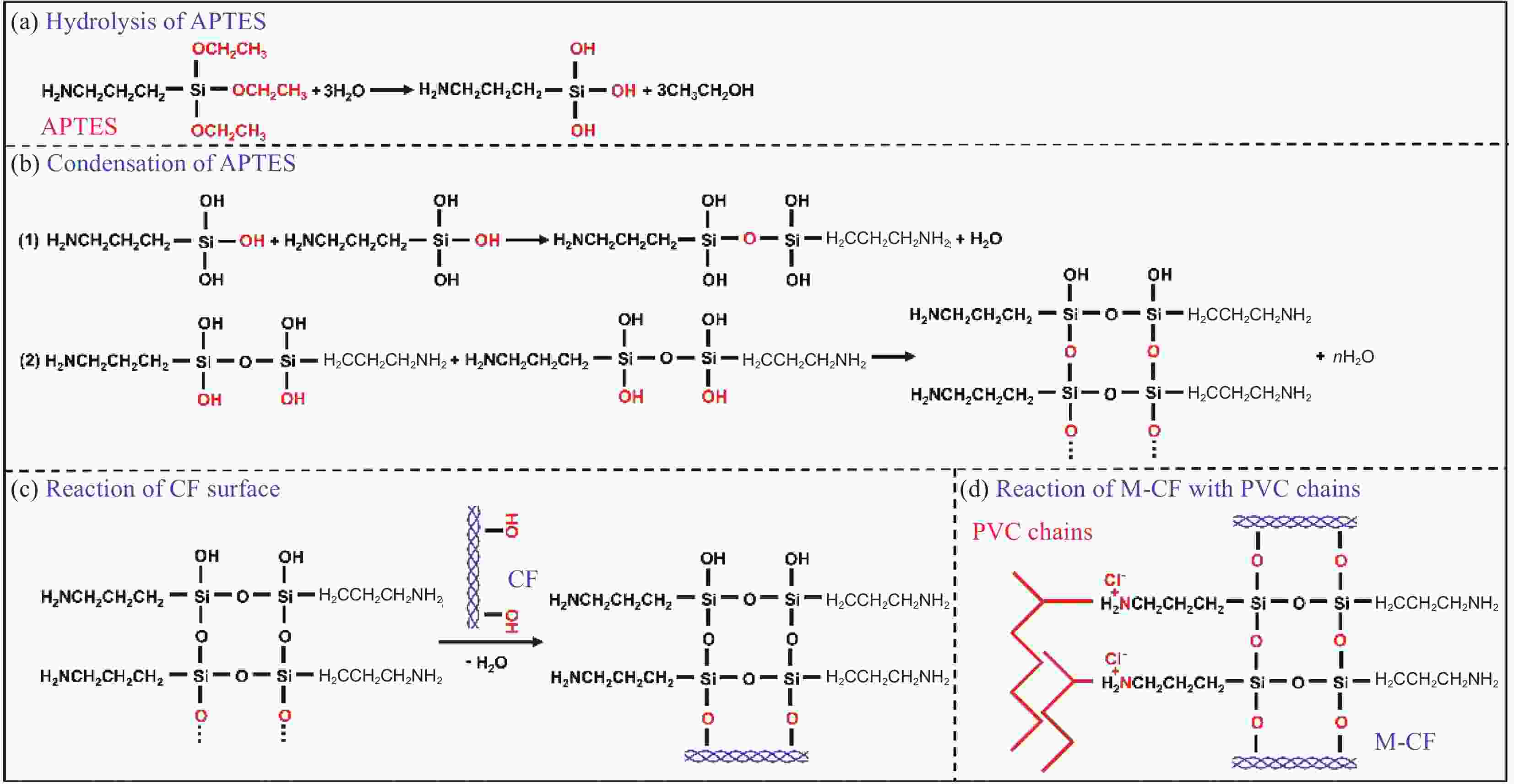

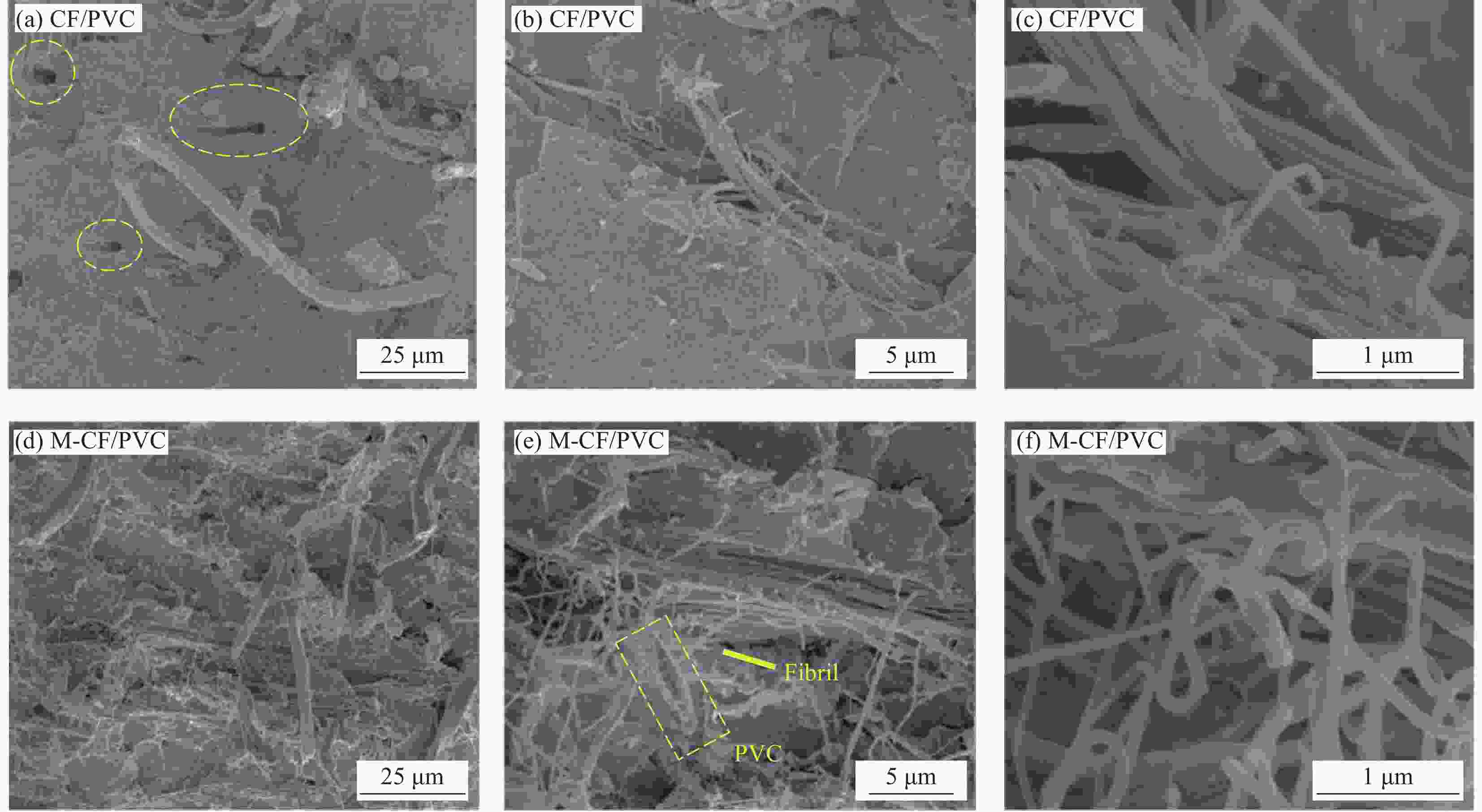

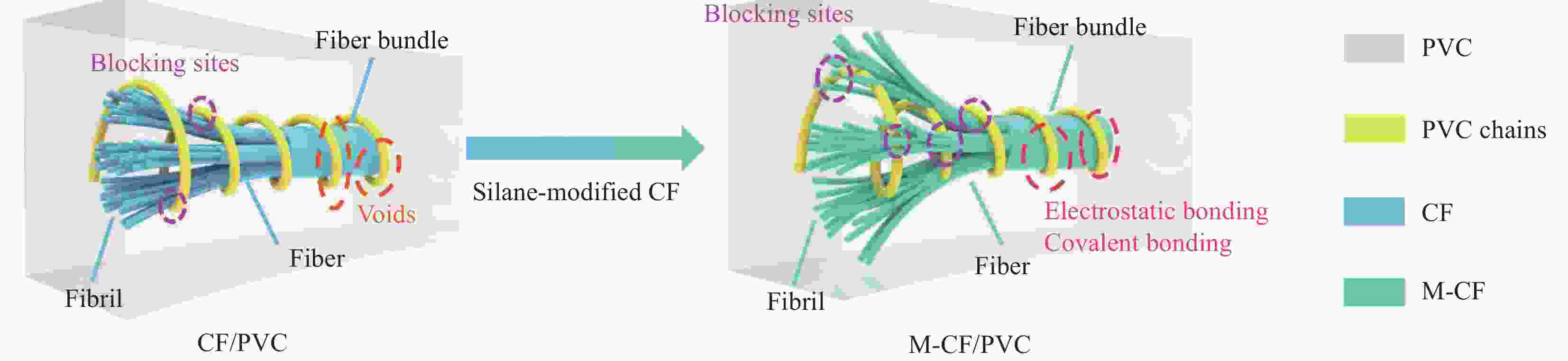

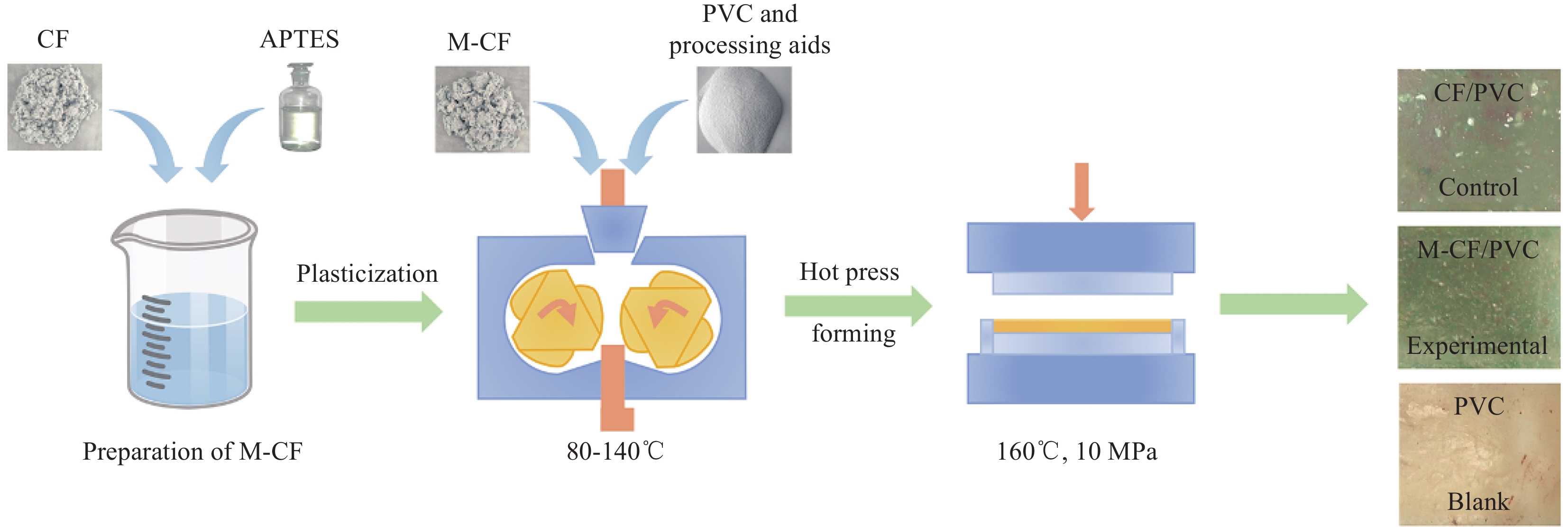

摘要: 胶原纤维(CF)的三维多层级结构具有对聚氯乙烯(PVC)进行高弹抗蠕变改性的天然优势,但亲水性的CF难以与疏水性的PVC有效相容,这限制了CF对PVC的改性效果。文章用氨基硅烷偶联剂(APTES)制备得到改性CF(M-CF),并用FESEM、FTIR和DMA等研究了M-CF的结构转变规律,以及M-CF/PVC的结构、蠕变行为和断裂行为。结果表明,APTES能在提高CF疏水性的同时,与PVC分子链形成离子键和共价键,从而显著改善CF与PVC的界面相容性。此外,APTES改性能充分打开M-CF的三维多层级结构,使PVC更好地渗入M-CF相区,并形成更多的作用位点。由此,PVC分子链的运动受到了明显抑制,M-CF/PVC的形变活化能较纯PVC提高了30.7%,蠕变寿命延长至纯PVC的80.5倍和CF/PVC的2.3倍,且可回复形变(11.50%)增至传统改性PVC的1.4倍以上。综上,CF与PVC相容性的提升使M-CF/PVC表现出了理想的高弹抗蠕变性。Abstract: The three-dimensional hierarchical structure of collagen fiber (CF) has the natural advantage of resilient creep-resistant modification of polyvinyl chloride (PVC), but the hydrophilic CF is difficult to be compatible with the hydrophobic PVC effectively, which limits the modification efficacy of PVC by CF. Modified CF (M-CF) was prepared with amino-silane coupling agent (APTES). The structural transformation pattern of M-CF, and the structure, creep behavior, and fracture behavior of M-CF/PVC were investigated by FESEM, FTIR, and DMA. The results showed that APTES improved the hydrophobicity of CF and formed ionic and covalent bonds with PVC chains, thereby greatly improving the compatibility between CF and PVC. In addition, APTES modification fully opened the three-dimensional hierarchical structure of M-CF, which allowed PVC to better penetrate into the M-CF phase region and form more blocking sites between PVC and M-CF. As a result, the movement of PVC chains was obviously inhibited, the deformation activation energy of M-CF/PVC was increased by 30.7% compared with that of pure PVC, the creep lifetime of M-CF/PVC was extended to 80.5 times that of pure PVC and 2.3 times that of CF/PVC, and the reversible deformation (11.50%) of M-CF/PVC was increased to more than 1.4 times that of the conventional modified PVC. In summary, the improved compatibility between CF and PVC endowed M-CF/PVC with ideal resilient creep-resistance.

-

Key words:

- collagen fiber /

- silane /

- polyvinyl chloride /

- creep resistance /

- resilience

-

图 7 PVC及其复合材料的蠕变-回复曲线(a)、循环蠕变-回复曲线(b)、宾汉模型拟合的蠕变曲线(c)、威布尔分布方程拟合的回复曲线(d)、蠕变柔量主曲线(e)和阿伦尼乌斯方程拟合的活化能曲线(f)

Figure 7. Creep and recovery curves (a), cyclic creep and recovery curves (b), creep fitting curves by Burger’s model (c), recovery fitting curves by Weibull distribution function (d), master curves of creep compliance (e) and activation energy fitting lines by Arrhenius equation (f) of pure PVC and composites

表 1 复合材料的原料配比

Table 1. Formulation of composites

Sample Filler Filler / PVC (Weight ratio) Pure PVC 0 / 100 CF5/PVC CF 5.26 / 100 CF10/PVC CF 11.11 / 100 CF20/PVC CF 25.00 / 100 CF30/PVC CF 42.86 / 100 CF40/PVC CF 66.67 / 100 M-CF5/PVC M-CF 5.26 / 100 M-CF10/PVC M-CF 11.11 / 100 M-CF20/PVC M-CF 25.00 / 100 M-CF30/PVC M-CF 42.86 / 100 M-CF40/PVC M-CF 66.67 / 100 M-GF20/PVC M-GF 25.00 / 100 M-QS20/PVC M-QS 25.00 / 100 表 2 PVC及其复合材料的宾汉模型和威布尔分布方程的模拟参数

Table 2. The simulated parameters of the Burger′s model and the Weibull distribution function with pure PVC and composites

Sample EM/MPa EK/MPa ηK/(MPa·s) ηM/s τ/s ηr/s βr εKV/% ε∞/% εSM/% $ {\text{ε}}_{\text{MAX}}^{\ast } $/% εR/% Pure PVC 2.93 0.14 46.04 3361.34 321.66 158.73 0.59 18.65 6.57 6.06 31.28 24.71 CF/PVC 7.14 0.31 159.10 3703.70 511.12 169.10 0.63 9.27 4.96 1.19 15.42 10.46 M-CF/PVC 7.34 0.35 184.25 8908.69 598.94 172.92 0.65 8.98 2.06 2.52 13.56 11.50 M-GF/PVC 12.45 0.40 308.63 10282.78 765.58 265.61 0.88 5.84 1.80 2.34 9.98 8.18 M-QS/PVC 12.81 0.43 348.45 29090.91 804.94 309.69 0.94 5.38 1.75 1.63 8.76 7.01 Notes: EM, EK, ηK, and ηM are the modulus of the Maxwell spring, the modulus of the Kelvin spring, the viscosity of the Kelvin dashpot, and the viscosity of the Maxwell dashpot, respectively; τ is the relaxation time; ηr and βr are the characteristic life factor and the shape parameters, respectively; εKV, ε∞, and εSM are the delayed elastic (viscoelastic) deformation, the permanent deformation, and the elastic (instantaneous) deformation, respectively; $ {\text{ε}}_{\text{MAX}}^{\ast } $ is the maximum deformation measured by the creep test; εR is the recoverable deformation. -

[1] EL-SEIDY E, CHOUGAN M, SAMBUCCI M, et al. Lightweight alkali-activated materials and ordinary Portland cement composites using recycled polyvinyl chloride and waste glass aggregates to fully replace natural sand[J]. Construction and Building Materials, 2023, 368: 130399. doi: 10.1016/j.conbuildmat.2023.130399 [2] YANG B, YANG Y H, HUO Z T, et al. Advances in research on aging properties of polyvinyl chloride and polyvinylidene fluoride membranes[J]. Construction and Building Materials, 2023, 367: 130292. doi: 10.1016/j.conbuildmat.2023.130292 [3] 陈冬梅, 姜良朋, 刘丁宁, 等. 四种壳类纤维/聚氯乙烯木塑复合材料的蠕变及磨损性能[J]. 复合材料学报, 2018, 35(6): 1464-1471. doi: 10.13801/j.cnki.fhclxb.20170815.001CHEN Dongmei, JIANG Liangpeng, LIU Dingning, et al. Creep and wear properties of four different types of husk fibers/polyvinyl chloride composites[J]. Acta Materiae Compositae Sinica, 2018, 35(6): 1464-1471(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170815.001 [4] 杨丽华, 郑宇, 沈佳斌, 等. 环保型增塑聚氯乙烯的热响应形状记忆性能与机理[J]. 高分子材料科学与工程, 2022, 38(3): 48-55. doi: 10.16865/j.cnki.1000-7555.2022.0052YANG Lihua, ZHEN Yu, SHEN Jiabin, et al. Thermal-responsive shape-memory effect and mechanism of the environment-friendly plasticized poly(vinyl chloride)[J]. Polymer Materials Science & Engineering, 2022, 38(3): 48-55(in Chinese). doi: 10.16865/j.cnki.1000-7555.2022.0052 [5] SRIVABUT C, RATANAWILAI T, HIZIROGLU S. Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubberwood fiber[J]. Construction and Building Materials, 2018, 162: 450-458. doi: 10.1016/j.conbuildmat.2017.12.048 [6] 邱佳, 刘斐, 陈景, 等. 热塑性聚合物复合材料蠕变性能的综述[J]. 高分子通报, 2017, 3: 1-10. doi: 10.14028/j.cnki.1003-3726.2017.03.001QIU Jia, LIU Fei, CHEN Jing, et al. A review on creep of thermoplastic polymer composites[J]. Polymer Bulletin, 2017, 3: 1-10(in Chinese). doi: 10.14028/j.cnki.1003-3726.2017.03.001 [7] YU S M, TANG Z H, WU S W, et al. Use of naturally small molecule as an intelligent interfacial modifier for strengthening and toughening silica-filled rubber composite[J]. Composites Science and Technology, 2022, 227: 109624. doi: 10.1016/j.compscitech.2022.109624 [8] 张尧, 朱四荣, 陆士平, 等. 考虑界面效应的GFRP复合材料蠕变模型[J]. 复合材料学报, 2021, 38(11): 3682-3692. doi: 10.13801/j.cnki.fhclxb.20210119.001ZHANG Yao, ZHU Sirong, LU Shiping, et al. Creep model of GFRP composites considering interface effect[J]. Acta Materiae Compositae Sinica, 2021, 38(11): 3682-3692(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210119.001 [9] BASSO M, PUPURE L, SIMONATO M, et al. Nonlinear creep behaviour of glass fiber reinforced polypropylene: Impact of aging on stiffness degradation[J]. Composites Part B:Engineering, 2019, 163: 702-709. doi: 10.1016/j.compositesb.2019.01.052 [10] 井德胜, 白晓宇, 王海刚, 等. 玻璃纤维增强聚合物锚杆蠕变性能研究进展[J]. 复合材料科学与工程, 2022, 2: 119-128. doi: 10.19936/j.cnki.2096-8000.20220228.019JIN Desheng, BAI Xiaoyu, WANG Haigang, et al. Research progress on creep property of glass fiber reinforced polymer anchors[J]. Composites Science and Engineering, 2022, 2: 119-128(in Chinese). doi: 10.19936/j.cnki.2096-8000.20220228.019 [11] SUN Z, GUO F L, LI Y Q, et al. Effects of carbon nanotube-polydopamine hybridization on the mechanical properties of short carbon fiber/polyetherimide composites[J]. Composites Part B:Engineering, 2022, 236: 109848. doi: 10.1016/j.compositesb.2022.109848 [12] 邵笑, 何春霞, 姜彩昀. 木质纤维/PVC复合材料的蠕变和热稳定性[J]. 材料科学与工程学报, 2019, 37(6): 991-995. doi: 10.14136/j.cnki.issn1673-2812.2019.06.023SHAO Xiao, HE Chunxia, JIANG Caiyun. Study on creep and thermal stability of wood fiber/PVC composites[J]. Journal of Materials Science and Engineering, 2019, 37(6): 991-995(in Chinese). doi: 10.14136/j.cnki.issn1673-2812.2019.06.023 [13] 段国燕, 何春霞, 杨星星, 等. 碳化硅对聚氯乙烯/竹粉复合材料性能影响[J]. 工程塑料应用, 2023, 51(1): 128-132. doi: 10.3969/j.issn.1001-3539.2023.01.023DUAN Guoyan, HE Chunxia, YANG Xingxing, et al. Effect of SiC on properties of polyvinyl chloride/bamboo powder composites[J]. Engineering Plastics Application, 2023, 51(1): 128-132(in Chinese). doi: 10.3969/j.issn.1001-3539.2023.01.023 [14] IHEZE C C, OKAFOR C E, ONWURAH U O, et al. Modelling creep responses of plantain fibre reinforced HDPE (PFRHDPE) for elevated temperature applications[J]. Advanced Industrial and Engineering Polymer Research, 2023, 6(1): 49-61. doi: 10.1016/j.aiepr.2022.06.001 [15] HE X X, OU D, WU S Y, et al. A mini review on factors affecting network in thermally enhanced polymer composites: Filler content, shape, size, and tailoring methods[J]. Advanced Composites and Hybrid Materials, 2021, 5(1): 21-38. [16] NADEEM A, BROWN E A, RADFORD M J, et al. Improved resilience and uniformity in polysulfone blends from an accelerated grafting ring-opening polymerization reaction with benzoxazine[J]. Macromolecules, 2021, 54(21): 10017-10030. doi: 10.1021/acs.macromol.1c01613 [17] XU J, HOWARD M J, MITTAL V, et al. Block copolymer micelle toughened isotactic polypropylene[J]. Macromolecules, 2017, 50(17): 6421-6432. doi: 10.1021/acs.macromol.7b01656 [18] ZHONG L Y, HAO Y X, ZHANG J H, et al. Closed-loop recyclable fully bio-based epoxy vitrimers from ferulic acid-derived hyperbranched epoxy resin[J]. Macromolecules, 2022, 537: 148013. [19] ZUO H M, LI D S, JIANG L. Experimental study on compressive fatigue behavior and failure mechanism of 3D five-directional braided composites[J]. Composites Part A:Applied Science and Manufacturing, 2020, 139: 106097. doi: 10.1016/j.compositesa.2020.106097 [20] KHATKAR V, BEHERA B. Experimental investigation of textile structure reinforced composite leaf spring for their cyclic flexural and creep behaviour[J]. Composite Structures, 2021, 258: 113439. doi: 10.1016/j.compstruct.2020.113439 [21] REN H P, OUYANG Y W, XIAO S L, et al. Shape memory property and mechanism of the knitting-fabric reinforced epoxy composites subjected to tensile loading[J]. Composites Science and Technology, 2022: 109764. [22] XU W X, WU X T, SHI B. Toughening agent for melamine formaldehyde resin: A new method for recycling chrome shavings[J]. Polymer, 2022, 253: 124979. doi: 10.1016/j.polymer.2022.124979 [23] 李昊, 王亚平, 闫林萍, 等. 碘化铯/天然皮革复合可穿戴X射线屏蔽材料的制备及性能[J]. 复合材料学报, 2023, 40(7): 3853-3862. doi: 10.13801/j.cnki.fhclxb.20220922.005LI Hao, WANG Yaping, YAN Linping, et al. Preparation and performance of cesium iodide/natural leather wearable X-ray shielding composites[J]. Acta Materiae Compositae Sinica, 2023, 40(7): 3853-3862(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220922.005 [24] 许维星, 雷超, 曾运航, 等. 抗蠕变复合材料及其制备方法[P]. 中国专利, ZL 202111494567.5, 2022–02–25.XU Weixing, LEI Chao, ZENG Yunhang, et al. Creep-resistant composites and their preparation method[P]. Chinese patent, ZL 202111494567.5, 2022–02–25(in Chinese). [25] XU W, WU X, WEN Q, et al. Effects of collagen fiber addition on the combustion and thermal stability of natural rubber[J]. Journal of Leather Science and Engineering, 2020, 2(1): 27. doi: 10.1186/s42825-020-00040-1 [26] LI C, LI R H, LYU P, et al. The fabrication of thermoplastic polyurethane/leather powder composite film with excellent mechanical property[J]. Composites Communications, 2021, 25: 100694. doi: 10.1016/j.coco.2021.100694 [27] 欧荣贤, 姚开泰, 孙理超, 等. 木塑复合材料蠕变特性及预测方法的研究进展[J]. 复合材料学报, 2021, 38(6): 1734-1753. doi: 10.13801/j.cnki.fhclxb.20210302.005OU Rongxian, YAO Kaitai, SUN Lichao, et al. State-of-the-art of the creep characteristics of wood-plastic composite and its prediction methods[J]. Acta Materiae Compositae Sinica, 2021, 38(6): 1734-1753(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210302.005 [28] JIA H, LIU C, QIAO Y, et al. Enhanced interfacial and mechanical properties of basalt fiber reinforced poly (aryl ether nitrile ketone) composites by amino-silane coupling agents[J]. Polymer, 2021, 230: 124028. doi: 10.1016/j.polymer.2021.124028 [29] 别依诺, 朱四荣, 贺攀, 等. 纳米SiO2-硅烷协同改性对玄武岩纤维/环氧树脂复合材料力学性能及蠕变性能的影响[J]. 复合材料学报, 2022, 39(8): 3723-3732.BIE Yinuo, ZHU Sirong, HE Pan, et al. Effect of nano-SiO2 particles-silane synergistic modification on mechanical properties and creep properties of basalt fiber/epoxy composites[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 3723-3732(in Chinese). [30] PHIRI R, RANGAPPA S M, SIENGCHIN S, et al. Development of sustainable biopolymer-based composites for lightweight applications from agricultural waste biomass: A review[J]. Advanced Industrial and Engineering Polymer Research, 2023, 6(4): 436-450. doi: 10.1016/j.aiepr.2023.04.004 [31] SEPE R, BOLLINO F, BOCCARUSSO L, et al. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites[J]. Composites Part B:Engineering, 2018, 133: 210-217. doi: 10.1016/j.compositesb.2017.09.030 [32] LIU Y, GUO L M, WANG W H, et al. Modifying wood veneer with silane coupling agent for decorating wood fiber/high-density polyethylene composite[J]. Construction and Building Materials, 2019, 224: 691-699. doi: 10.1016/j.conbuildmat.2019.07.090 [33] LI S Y, WANG Y P, XU W X, et al. Natural rubber-based elastomer reinforced by chemically modified multiscale leather collagen fibers with excellent toughness[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(13): 5091-5099. [34] DONG J, MEI C T, HAN J Q, et al. 3D printed poly(lactic acid) composites with grafted cellulose nanofibers: Effect of nanofiber and post-fabrication annealing treatment on composite flexural properties[J]. Additive Manufacturing, 2019, 28: 621-628. doi: 10.1016/j.addma.2019.06.004 [35] GHOSH S K, PRUSTY R K, RATHORE D K, et al. Creep behaviour of graphite oxide nanoplates embedded glass fiber/epoxy composites: Emphasizing the role of temperature and stress[J]. Composites Part A:Applied Science and Manufacturing, 2017, 102: 166-177. doi: 10.1016/j.compositesa.2017.08.001 [36] SEN B, HIREMATH M M, PRUSTY R K, et al. Enhanced creep resistance of GFRP composites through interpenetrating polymer network[J]. International Journal of Mechanical Sciences, 2021, 212: 106728. doi: 10.1016/j.ijmecsci.2021.106728 [37] XU S, XIAO H, SHI B. The improvement of dispersity, thermal stability and mechanical properties of collagen fibers by silane modification: an exploration for developing new leather making technology[J]. Journal of Leather Science and Engineering, 2022, 4(1): 26. doi: 10.1186/s42825-022-00100-8 [38] WEN Z P, XU C, QIAN X, et al. A two-step carbon fiber surface treatment and its effect on the interfacial properties of CF/EP composites: The electrochemical oxidation followed by grafting of silane coupling agent[J]. Applied Surface Science, 2019, 486: 546-554. doi: 10.1016/j.apsusc.2019.04.248 [39] MATUANA L M, WOODHAMS R T, BALATINECZ J J, et al. Influence of interfacial interactions on the properties of PVC/cellulosic fiber composites[J]. Polymer Composites, 1998, 19(4): 446-455. doi: 10.1002/pc.10119 [40] ORNAGHI H L, MONTICELI F M, NEVES R M, et al. Effect of stacking sequence and porosity on creep behavior of glass/epoxy and carbon/epoxy hybrid laminate composites[J]. Composites Communications, 2020, 19: 210-219. doi: 10.1016/j.coco.2020.04.006 [41] 刘燕燕, 盛宝璐, 黄东升, 等. 集成竹拉伸蠕变性能加速试验研究[J]. 复合材料学报, 2024, 41(0): 1-11. doi: 10.13801/j.cnki.fhclxb.20230625.003LIU Yanyan, SHENG Baolu, HUANG Dongsheng, et al. Accelerated creep testing of tensile properties of glued laminated bamboo[J]. Acta Materiae Compositae Sinica, 2024, 41(0): 1-11 (in Chinese). doi: 10.13801/j.cnki.fhclxb.20230625.003 -

下载:

下载: