Research progress on the application of lignin-based functional materials in barrier packaging paper

-

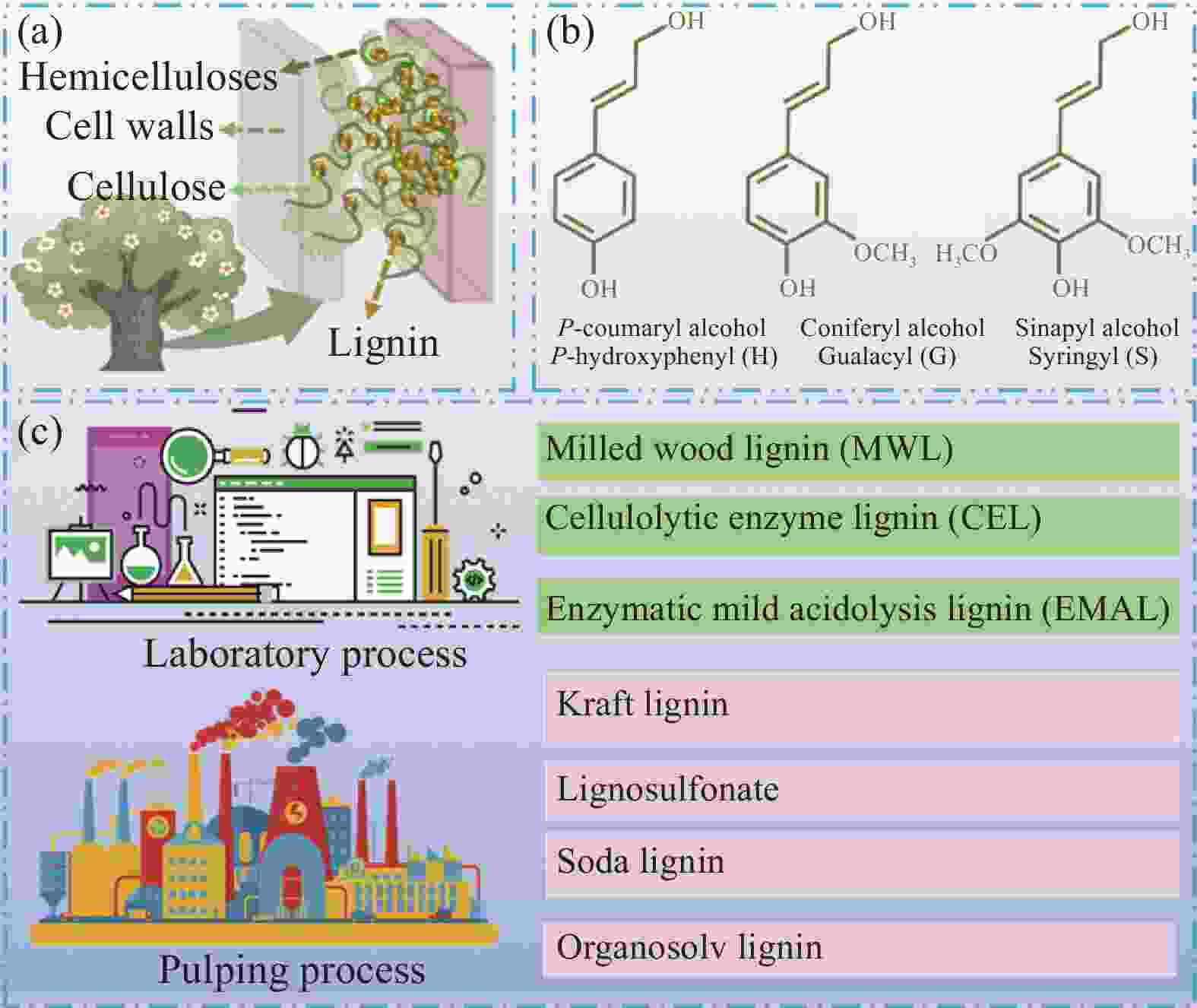

摘要: 随着石油资源的逐渐枯竭,生物质基阻隔包装材料作为传统石油基塑料包装的绿色替代品受到越来越多重视。木质素作为自然界中第二丰富的天然高分子聚合物,也是唯一富含重复苯环结构单元的可再生资源,具有生物可降解性、生物相容性和出色的加工性等优势。现阶段,大部分木质素仍作为工业副产物被焚烧处理,其高值化利用程度较低。虽然木质素独特的化学结构和耐水、耐溶剂、抗老化、抗紫外等功能特性,使其在制备生物基阻隔材料方面具有巨大潜力。但木质素的结构、木质素基阻隔材料的多重阻隔性能、构效关系及应用场景仍需深入思考。鉴于此,本文对木质素基功能材料在阻隔包装纸中的应用研究进展进行了系统总结和全面评述。首先,简述了木质素的结构和来源。其次,详细概括了木质素基功能材料在阻隔包装纸上的应用现状,重点介绍了木质素基功能材料在包装纸阻隔水、气体、油脂、紫外线以及阻燃方面的应用进展。最后,探讨了木质素基功能材料在阻隔包装纸应用中面临的主要挑战和未来的发展方向。本文将为木质素基功能材料在制备具有单一或多重阻隔性能包装纸的应用研究领域提供理论参考,对工业化生产木质素基高附加值产品具有实际意义。Abstract: With the gradual depletion of petroleum resources, bio-based barrier packaging materials have garnered growing attention as an eco-friendly alternative to conventional petroleum-based plastic packaging. Lignin, the second most abundant natural polymer and the only renewable resource rich in repetitive benzene ring structural units, possesses biodegradability, biocompatibility and excellent processability. Currently, the majority of lignin is still disposed of through incineration as industrial by-products, resulting in limited utilization and low added value. Due to its unique chemical structure, water resistance, solvent resistance, aging resistance, and UV resistance, lignin exhibits significant potential in the development of bio-based barrier materials. However, further consideration is required regarding the structural characteristics of lignin, its multifaceted barrier properties in material applications, the establishment of structure-property relationships, and exploration of diverse application scenarios. Therefore, the present review provides a systematic and comprehensive review of the application of lignin-based functional materials in barrier packaging paper. Firstly, the structure and origin of lignin are briefly elucidated. A comprehensive overview of the current status of the application of lignin-based functional materials in barrier packaging papers is then provided, with particular emphasis on the advances in the use of lignin-based functional materials for water, gas, oil, ultraviolet radiation and flame retardancy properties in packaging paper. Finally, the primary challenges and future prospects for the development of lignin-based functional materials in barrier packaging paper applications are discussed. This review will provide a theoretical foundation for the utilization of lignin-based functional materials in the production of paper with single or multiple barrier properties, thereby providing practical significance for the industrial-scale manufacturing of value-added products derived from lignin.

-

Key words:

- Lignin /

- Barrier packaging materials /

- Functional paper /

- High value utilization /

- Biomass

-

图 3 (a) 木质素的长效紫外线阻隔机制,SQ自由基生成、转化和稳定结构[43]。(b) 紫外-可见透射光谱、说明性数码照片和透射率雾度值[44]。(c) LCNP的制备示意图[45]。(d). LPANPs制备方案、光学雾度和紫外阻隔示意图[46]

Figure 3. (a) Long-lasting UV-blocking mechanism of lignin, SQ radical generation, transformation and stabilization of structures [43]. (b) UV-Vis transmission spectra, illustrative digital photographs and transmittance haze values. [44]. (c) Schematic diagram of LCNP preparation [45]. (d) Schematic of LPANPs preparation scheme, optical haze and UV blocking [46].

图 5 (a) 植物性纤维素-木质素增强复合材料示意图,纤维素-木质素复合吸管的照片[54]。(b) 木质素-纤维素复合材料的制造示意图[55]。(c) 麦草中木质素的提取和含木质素的纤维素涂布纸制备流程示意图[56]

Figure 5. (a) Schematic diagram of plant-based cellulose-lignin reinforced composites, photos of cellulose-lignin composite straws [54]. (b) Schematic diagram of the fabrication of lignin-cellulose composites [55]. (c) Schematic diagram of the process of extraction of lignin from wheatgrass and preparation of lignin-containing cellulose-coated paper [56]

图 6 (a) 改性微纤化纤维素及木质素沉积纸制备过程示意图[6]。(b) 涂布纸张制备示意图及纸张渗水期间信号强度的变化曲线[58]

Figure 6. (a) Schematic diagram of the preparation process of modified microfibrinated cellulose and lignin-deposited paper [6]. (b) Schematic diagram of coated paper preparation, variation curve of signal intensity during paper bleeding [58].

图 7 (a) LCNF涂层纸折叠形成碗状,纸碗五个月后容纳植物油数码照片[60]。(b1) 未改性的对照滤器、(b2) 2.44 g·m−2湿滤器、(b3) 8.34 g·m−2湿滤器和(b4) 8.22 g·m−2干滤器过滤前(i)和过滤后(ii)油水乳液的数码照片和显微镜成像[63]

Figure 7. (a) LCNF coating paper folding form bowl, paper bowl after five months for vegetable oil digital photos [60]. (b) Digital photographs and microscopic imaging of oil-water emulsions before (i) and after (ii) filtration through (b1) unmodified control filter, (b2) 2.44 g·m−2 wet filter, (b3) 8.34 g·m−2 wet filter and (b4) 8.22 g·m−2 dry filter [63].

图 8 (a) GnP/CNT/木质素涂层纸的制造和火焰测试示意图[67]。(b) 热处理(在225℃、20和60 min,在1和75 v/v%的水蒸气气氛中)与UB、OD和FB纸浆片的初始ISO亮度之间的关系曲线图,及对于UB、OD和FB纸浆片材,经过热处理(在225℃,20和60 min,在1和75 v/v%的水蒸气气氛中)与初始光吸收系数k之间的关系曲线图[68]

Figure 8. (a) Schematic of manufacturing and flame testing of GnP/CNT/lignin coated paper [67]. (b) Plot of the relationship between heat treatment (at 225℃, 20 and 60 min, in a water vapor atmosphere of 1 and 75 v/v%) and the initial ISO brightness of UB, OD and FB pulp sheets, and for UB, OD and FB pulp sheets, after heat treatment (at 225℃, 20 and 60 min, P < 0.05). Between 1 and 75 v/v) % of water vapor atmosphere and the relationship between the initial light absorption coefficient k graph [68]

-

[1] LACHANCE A M, HOU Z, FAROOQUI M M, et al. Polyolefin films with outstanding barrier properties based on one-step coassembled nanocoatings[J]. Advanced Composites and Hybrid Materials, 2022, 5(2): 1067-1077. [2] PARK J H, KOO M S, CHO S H, et al. Comparison of thermal and optical properties and flowability of fossil-based and bio-based polycarbonate[J]. Macromolecular Research, 2017, 25(11): 1135-1144. [3] The fate of all of our plastics[J]. Nature, 2017, 547(7664): 382. [4] JANG Y-C, LEE G, KWON Y, et al. Recycling and management practices of plastic packaging waste towards a circular economy in South Korea[J]. Resources, Conservation and Recycling, 2020, 158: 104798. [5] WU Y, YU X, DING W, et al. Fabrication, performance, and potential environmental impacts of polysaccharide-based food packaging materials incorporated with phytochemicals: A review[J]. Int J Biol Macromol, 2023, 249: 125922. [6] WWANG W, GU F, DENG Z, et al. Multilayer surface construction for enhancing barrier properties of cellulose-based packaging[J]. Carbohydrate Polymers, 2021, 255: 117431. [7] RASTOGI V, SAMYN P. Bio-Based Coatings for Paper Applications[J]. Coatings, 2015, 5(4): 887-930. [8] HUANG H B, MAO L, WANG W, et al. A facile strategy to fabricate antibacterial hydrophobic, high-barrier, cellulose papersheets for food packaging[J]. International Journal of Biological Macromolecules, 2023, 236: 123630. [9] YOOK S, PARK H, PARK H, et al. Barrier coatings with various types of cellulose nanofibrils and their barrier properties[J]. Cellulose, 2020, 27(8): 4509-4523. [10] RODIONOVA G, LENES M, ERIKSEN Ø, et al. Surface chemical modification of microfibrillated cellulose: improvement of barrier properties for packaging applications[J]. Cellulose, 2010, 18(1): 127-134. [11] PERESIN M S, KAMMIOVIRTA K, HEIKKINEN H, et al. Understanding the mechanisms of oxygen diffusion through surface functionalized nanocellulose films[J]. Carbohydr Polym, 2017, 174: 309-317. [12] SOLALA I, BORDES R, LARSSON A. Water vapor mass transport across nanofibrillated cellulose films: effect of surface hydrophobization[J]. Cellulose, 2017, 25(1): 347-356. [13] SAMYN P. Wetting and hydrophobic modification of cellulose surfaces for paper applications[J]. Journal of Materials Science, 2013, 48(19): 6455-6498. [14] SHOREY R, MEKONNEN T H. Sustainable paper coating with enhanced barrier properties based on esterified lignin and PBAT blend[J]. International Journal of Biological Macromolecules, 2022, 209: 472-484. [15] VAEZI K, ASADPOUR G, SHARIFI S H. Effect of coating with novel bio nanocomposites of cationic starch/cellulose nanocrystals on the fundamental properties of the packaging paper[J]. Polymer Testing, 2019, 80: 106080. [16] TIAN X W, WU M, WANG Z W, et al. A high-stable soybean-oil-based epoxy acrylate emulsion stabilized by silanized nanocrystalline cellulose as a sustainable paper coating for enhanced water vapor barrier[J]. Journal of Colloid and Interface Science, 2022, 610: 1043-1056. [17] REN L, YAN X, ZHOU J, et al. Influence of chitosan concentration on mechanical and barrier properties of corn starch/chitosan films[J]. Int J Biol Macromol, 2017, 105(Pt 3): 1636-1643. [18] WANG W, GUO T, SUN K, et al. Lignin Redistribution for Enhancing Barrier Properties of Cellulose-Based Materials[J]. Polymers (Basel), 2019, 11(12): 1929. [19] LIU Z H, LI B Z, YUAN J S, et al. Creative biological lignin conversion routes toward lignin valorization[J]. Trends Biotechnol, 2022, 40(12): 1550-1566. [20] YOU X Y, WANG X L, ZHANG H J, et al. Supertough Lignin Hydrogels with Multienergy Dissipative Structures and Ultrahigh Antioxidative Activities[J]. Acs Applied Materials & Interfaces, 2020, 12(35): 39892-39901. [21] AZADI P, INDERWILDI O R, FARNOOD R, et al. Liquid fuels, hydrogen and chemicals from lignin: A critical review[J]. Renewable and Sustainable Energy Reviews, 2013, 21: 506-523. [22] LISý A, HáZ A, NADáNYI R, et al. About Hydrophobicity of Lignin: A Review of Selected Chemical Methods for Lignin Valorisation in Biopolymer Production[J]. Energies, 2022, 15(17): 6213. [23] WANG D, GU Y, FENG S, et al. Lignin-containing biodegradable UV-blocking films: a review[J]. Green Chemistry, 2023, 25(22): 9020-9044. [24] YANG H, YU B, XU X, et al. Lignin-derived bio-based flame retardants toward high-performance sustainable polymeric materials[J]. Green Chemistry, 2020, 22(7): 2129-2161. doi: 10.1039/D0GC00449A [25] MEI Q, SHEN X, LIU H, et al. Selectively transform lignin into value-added chemicals[J]. Chinese Chemical Letters, 2019, 30(1): 15-24. [26] LIU C, LUAN P, LI Q, et al. Biopolymers Derived from Trees as Sustainable Multifunctional Materials: A Review[J]. Adv Mater, 2021, 33(28): e2001654. doi: 10.1002/adma.202001654 [27] DOHERTY W O S, MOUSAVIOUN P, FELLOWS C M. Value-adding to cellulosic ethanol: Lignin polymers[J]. Industrial Crops and Products, 2011, 33(2): 259-276. doi: 10.1016/j.indcrop.2010.10.022 [28] WANG M, WANG F. Lignin: Catalytic Scissoring of Lignin into Aryl Monomers[J]. Advanced Materials, 2019, 31(50): 1901866. doi: 10.1002/adma.201901866 [29] SUN Z, FRIDRICH B, DE SANTI A, et al. Bright Side of Lignin Depolymerization: Toward New Platform Chemicals[J]. Chem Rev, 2018, 118(2): 614-678. [30] FIGUEIREDO P, LINTINEN K, HIRVONEN J T, et al. Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications[J]. Progress in Materials Science, 2018, 93: 233-269. [31] XIONG F, HAN Y, WANG S, et al. Preparation and formation mechanism of size-controlled lignin nanospheres by self-assembly[J]. Industrial Crops and Products, 2017, 100: 146-152. [32] WEN J L, SUN S L, XUE B L, et al. Structural elucidation of inhomogeneous lignins from bamboo[J]. Int J Biol Macromol, 2015, 77(250-259). [33] RAJ A, DEVENDRA L P, SUKUMARAN R K. Comparative evaluation of laccase mediated oxidized and unoxidized lignin of sugarcane bagasse for the synthesis of lignin-based formaldehyde resin[J]. Industrial Crops and Products, 2020, 150: 112385. [34] BASBASAN A, JR. , HARARAK B, WINOTAPUN C, et al. Emerging challenges on viability and commercialization of lignin in biobased polymers for food packaging: A review[J]. Food Packaging and Shelf Life, 2022, 34: 100969. doi: 10.1016/j.fpsl.2022.100969 [35] TOPUZ F, UYAR T. Antioxidant, antibacterial and antifungal electrospun nanofibers for food packaging applications[J]. Food Res Int, 2020, 130: 108927. [36] HU X, LU C, TANG H, et al. Active Food Packaging Made of Biopolymer-Based Composites[J]. Materials (Basel), 2022, 16(1): 16010279. [37] CHEN Z, WAN C. Biological valorization strategies for converting lignin into fuels and chemicals[J]. Renewable and Sustainable Energy Reviews, 2017, 73: 610-621. [38] 袁振宏, 雷廷宙, 庄新姝, et al. 我国生物质能研究现状及未来发展趋势分析[J]. 太阳能, 2017, (2): 12-19.YUAN Z H, LEI T Z, ZHUANG Z S, et al. The current research on biomass energy in China and the future development trend analysis[J]. Solar Energy, 2017, (2): 12-19(in Chinese). [39] 邢献军, 李涛, 马培勇, et al. 欧盟与中国生物质成型燃料产业发展现状对比[J]. 安徽科技, 2015, (1): 38-41.XING X J, LI T, MA P Y, et al. The European Union and the comparison between the present situation of the development of Chinese biomass fuel molding industry[J]. Anhui Science and Technology, 2015, (1): 38-41(in Chinese). [40] 吕豪豪, 刘玉学, 杨生茂, et al. 生物质炭化技术及其在农林废弃物资源化利用中的应用[J]. 浙江农业科学, 2015, 56(1): 19-22.LYU H H, LIU Y X, YANG S M, et al. Biomass carbonization technology and its application in resource utilization of agricultural and forestry waste[J]. Zhejiang agricultural science, 2015, 56(1): 19-22(in Chinese). [41] SUN R-C. Lignin Source and Structural Characterization[J]. ChemSusChem, 2020, 13(7): 4385-4393. [42] NGUYEN L T, PHAN D-P, SARWAR A, et al. Valorization of industrial lignin to value-added chemicals by chemical depolymerization and biological conversion[J]. Industrial Crops and Products, 2021, 161: 113219. doi: 10.1016/j.indcrop.2020.113219 [43] FU Y, XIAO Y, CHEN X, et al. Long-lasting UV-blocking Mechanism of Lignin: Origin and Stabilization of Semiquinone Radicals[J]. Small Methods, 2024, 2301783. [44] JIANG Y, WANG Z, ZHOU L, et al. Highly efficient and selective modification of lignin towards optically designable and multifunctional lignocellulose nanopaper for green light-management applications[J]. Int J Biol Macromol, 2022, 206: 264-276. doi: 10.1016/j.ijbiomac.2022.02.147 [45] ZHANG Y, WEI Y, QIAN Y, et al. Lignocellulose Enabled Highly Transparent Nanopaper with Tunable Ultraviolet-Blocking Performance and Superior Durability[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(46): 17033-17041. [46] LI X, ZHANG X, WANG N, et al. Range-Broadening Ultraviolet-Blocking Regulation of Cellulose Nanopaper via Surface Self-Absorption with Poly(methyl methacrylate)/Avobenzone[J]. ACS Applied Polymer Materials, 2019, 1(11): 2981-2989. doi: 10.1021/acsapm.9b00686 [47] SANI M A, AZIZI-LALABADI M, TAVASSOLI M, et al. Recent Advances in the Development of Smart and Active Biodegradable Packaging Materials[J]. Nanomaterials (Basel), 2021, 11(5): 1331. doi: 10.3390/nano11051331 [48] ZHANG N, LIU P, YI Y, et al. Application of Polyvinyl Acetate/Lignin Copolymer as Bio-Based Coating Material and Its Effects on Paper Properties[J]. Coatings, 2021, 11(2): 192. doi: 10.3390/coatings11020192 [49] SIRVIö J A, ISMAIL M Y, ZHANG K, et al. Transparent lignin-containing wood nanofiber films with UV-blocking, oxygen barrier, and anti-microbial properties[J]. Journal of Materials Chemistry A, 2020, 8(16): 7935-7946. doi: 10.1039/C9TA13182E [50] WINESTRAND S, JÄRNSTRÖM L, JÖNSSONET L J, et al. Fractionated Lignosulfonates for Laccase-Catalyzed Oxygen-Scavenging Films and Coatings[J]. Molecules, 2021, 26: 6322. doi: 10.3390/molecules26206322 [51] LIU Chao, LUAN Pengcheng, LI Qiang, et al. Biopolymers Derived from Trees as Sustainable Multifunctional Materials: A Review[J]. Advanced Materials, 2021, 7: 2001654. [52] LIU Chao, LUAN Pengcheng, LI Qiang, et al. Biodegradable, Hygienic, and Compostable Tableware from Hybrid Sugarcane and Bamboo Fibers as Plastic Alternative[J]. Matter, 2020, 3: 2066-2079. doi: 10.1016/j.matt.2020.10.004 [53] SZLISZKA E, CZUBA Z P, DOMINO M, et al. Ethanolic extract of propolis (EEP) enhances the apoptosis- inducing potential of TRAIL in cancer cells[J]. Molecules, 2009, 14(2): 738-754. doi: 10.3390/molecules14020738 [54] WANG X, XIA Q, JING S, et al. Strong, Hydrostable, and Degradable Straws Based on Cellulose-Lignin Reinforced Composites[J]. Small, 2021, 17(18): e2008011. doi: 10.1002/smll.202008011 [55] JIANG B, CHEN C, LIANG Z, et al. Lignin as a Wood-Inspired Binder Enabled Strong, Water Stable, and Biodegradable Paper for Plastic Replacement[J]. Advanced Functional Materials, 2019, 30(4): 1906307. [56] SINGH S S, ZAITOON A, SHARMA S, et al. Enhanced hydrophobic paper-sheet derived from Miscanthus x giganteus cellulose fibers coated with esterified lignin and cellulose acetate blend[J]. Int J Biol Macromol, 2022, 223(Pt A): 1243-1256. [57] HULT E-L, ROPPONEN J, POPPIUS-LEVLIN K, et al. Enhancing the barrier properties of paper board by a novel lignin coating[J]. Industrial Crops and Products, 2013, 50: 694-700. doi: 10.1016/j.indcrop.2013.08.013 [58] LAVRIC G, ZAMLJEN A, GRKMAN J J, et al. Organosolv Lignin Barrier Paper Coatings from Waste Biomass Resources[J]. Polymers, 2021, 13(24): 4443. doi: 10.3390/polym13244443 [59] NAIR S S, CHEN H, PENG Y, et al. Polylactic Acid Biocomposites Reinforced with Nanocellulose Fibrils with High Lignin Content for Improved Mechanical, Thermal, and Barrier Properties[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(8): 10058-10068. [60] A H T, TAJVIDI M, BOUSFIELD D. Paper-Based Oil Barrier Packaging using Lignin-Containing Cellulose Nanofibrils[J]. Molecules, 2020, 25(6): 1344. doi: 10.3390/molecules25061344 [61] YI C, YUAN T, REN H, et al. Fabrication of food-safe, degradable and high-barrier air frying paper by chitosan, zein and LCNF coatings[J]. Cellulose, 2023, 30(4): 2441-2452. doi: 10.1007/s10570-022-05032-4 [62] GHAFFARI S, ALIOFKHAZRAEI M, BARATI DARBAND G, et al. Review of superoleophobic surfaces: Evaluation, fabrication methods, and industrial applications[J]. Surfaces and Interfaces, 2019, 17: 100340. doi: 10.1016/j.surfin.2019.100340 [63] MITTAG A, RAHMAN M M, HAFEZ I, et al. Development of Lignin-Containing Cellulose Nanofibrils Coated Paper-Based Filters for Effective Oil-Water Separation[J]. Membranes (Basel), 2022, 13(1): 1 doi: 10.3390/membranes13010001 [64] KIM J-Y, OH S, HWANG H, et al. Structural features and thermal degradation properties of various lignin macromolecules obtained from poplar wood (Populus albaglandulosa)[J]. Polymer Degradation and Stability, 2013, 98(9): 1671-1678. doi: 10.1016/j.polymdegradstab.2013.06.008 [65] BERTELLA1, LUTERBACHER, 钱孙逸豪, et al. 木质素功能化在新材料生产中的应用[J]. 腐植酸, 2023, 4: 27-35.BERTELLA1, LUTERBACHER, QIAN S Y M, et al. The application of lignin functionalization in the production of new materials[J]. humic acid, 2023, 4: 27-35(in Chinese). [66] BREBU M, TAMMINEN T, SPIRIDON I. Thermal degradation of various lignins by TG-MS/FTIR and Py-GC-MS[J]. Journal of Analytical and Applied Pyrolysis, 2013, 104: 531-539. doi: 10.1016/j.jaap.2013.05.016 [67] SONG K, GANGULY I, EASTIN I, et al. Lignin-Modified Carbon Nanotube/Graphene Hybrid Coating as Efficient Flame Retardant[J]. Int J Mol Sci, 2017, 18(11): 2368. doi: 10.3390/ijms18112368 [68] VäNSKä E, VIHELä T, PERESIN M S, et al. Residual lignin inhibits thermal degradation of cellulosic fiber sheets[J]. Cellulose, 2015, 23(1): 199-212. -

点击查看大图

点击查看大图

计量

- 文章访问数: 58

- HTML全文浏览量: 28

- 被引次数: 0

下载:

下载: