Preparation of polyvinylpyrrolidone water-based hybrid coating and its sizing treatment of recycled glass fiber

-

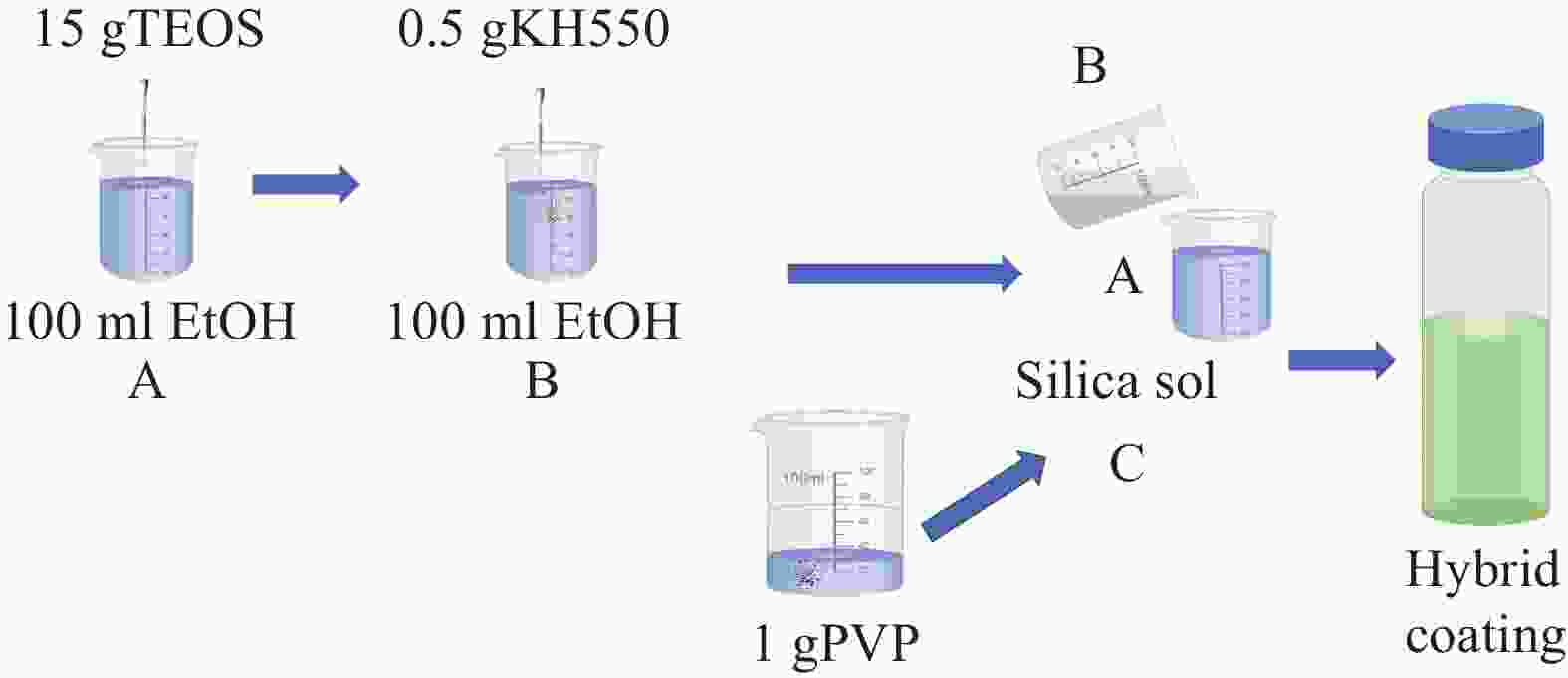

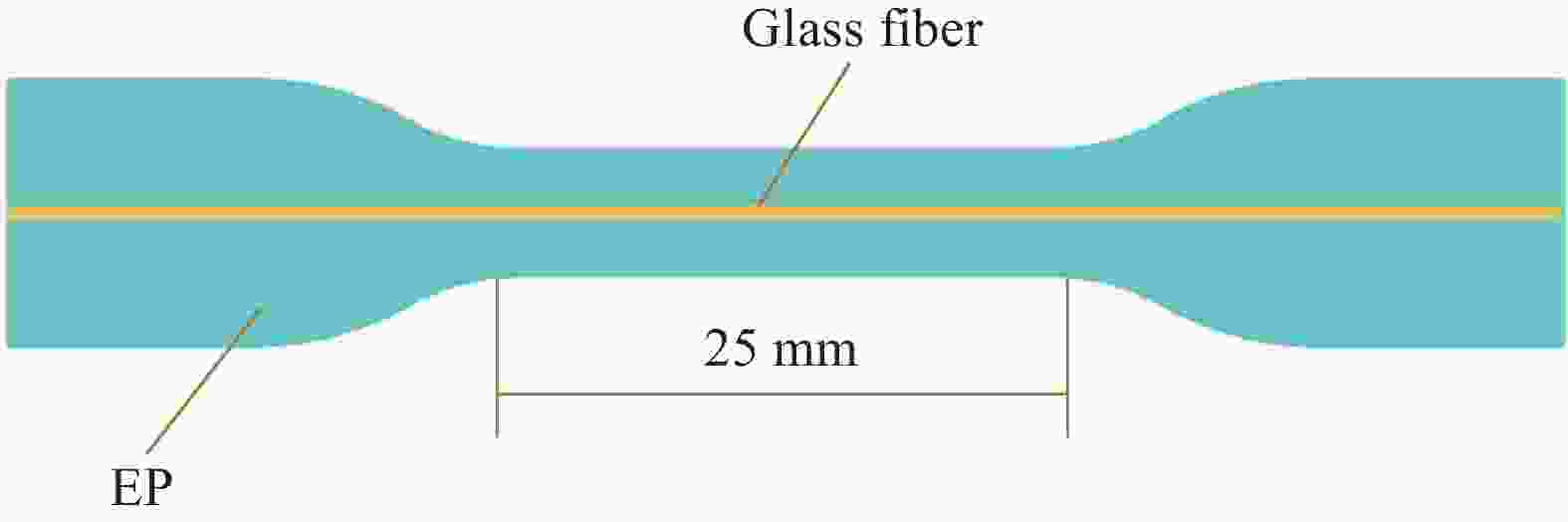

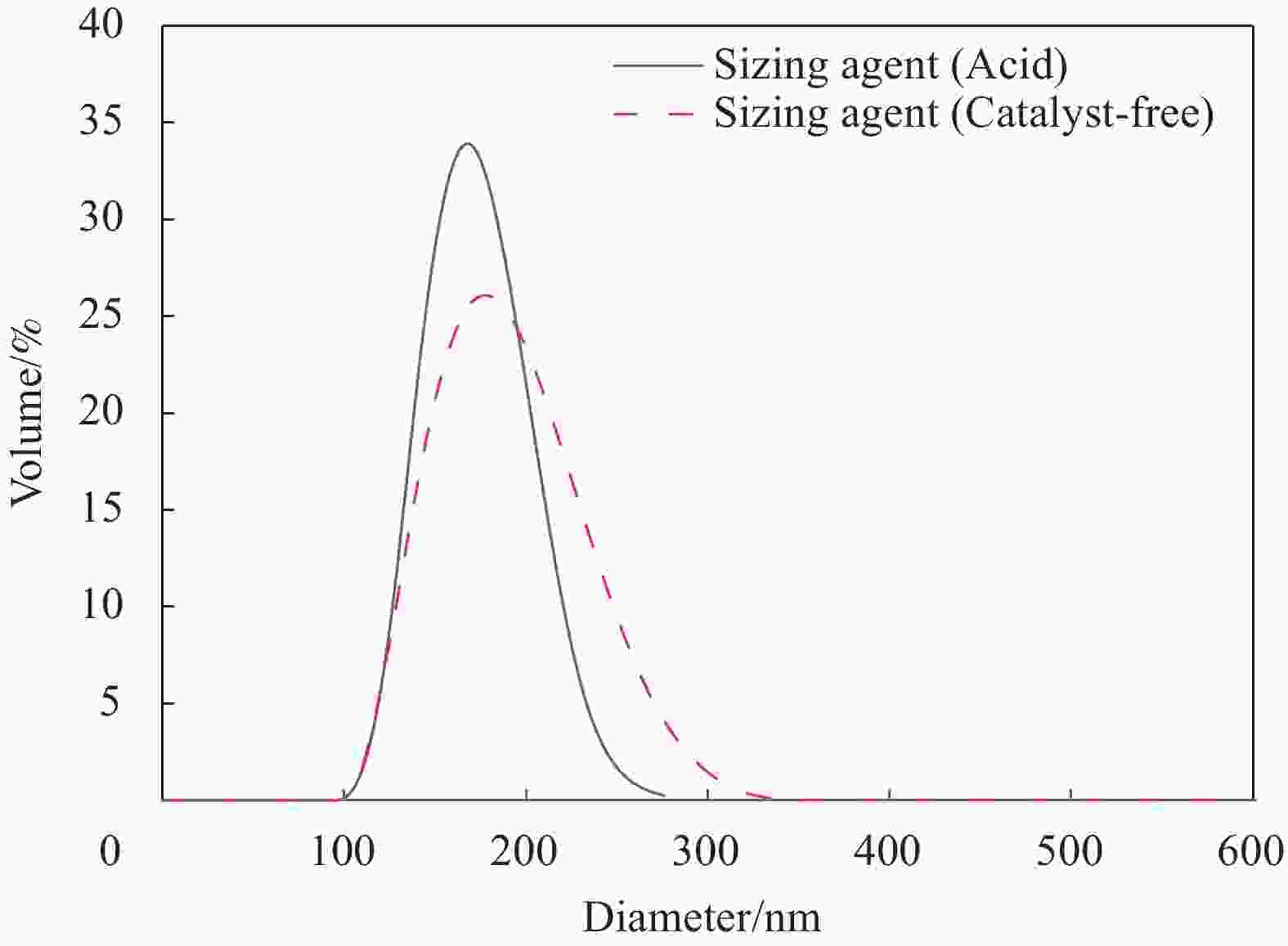

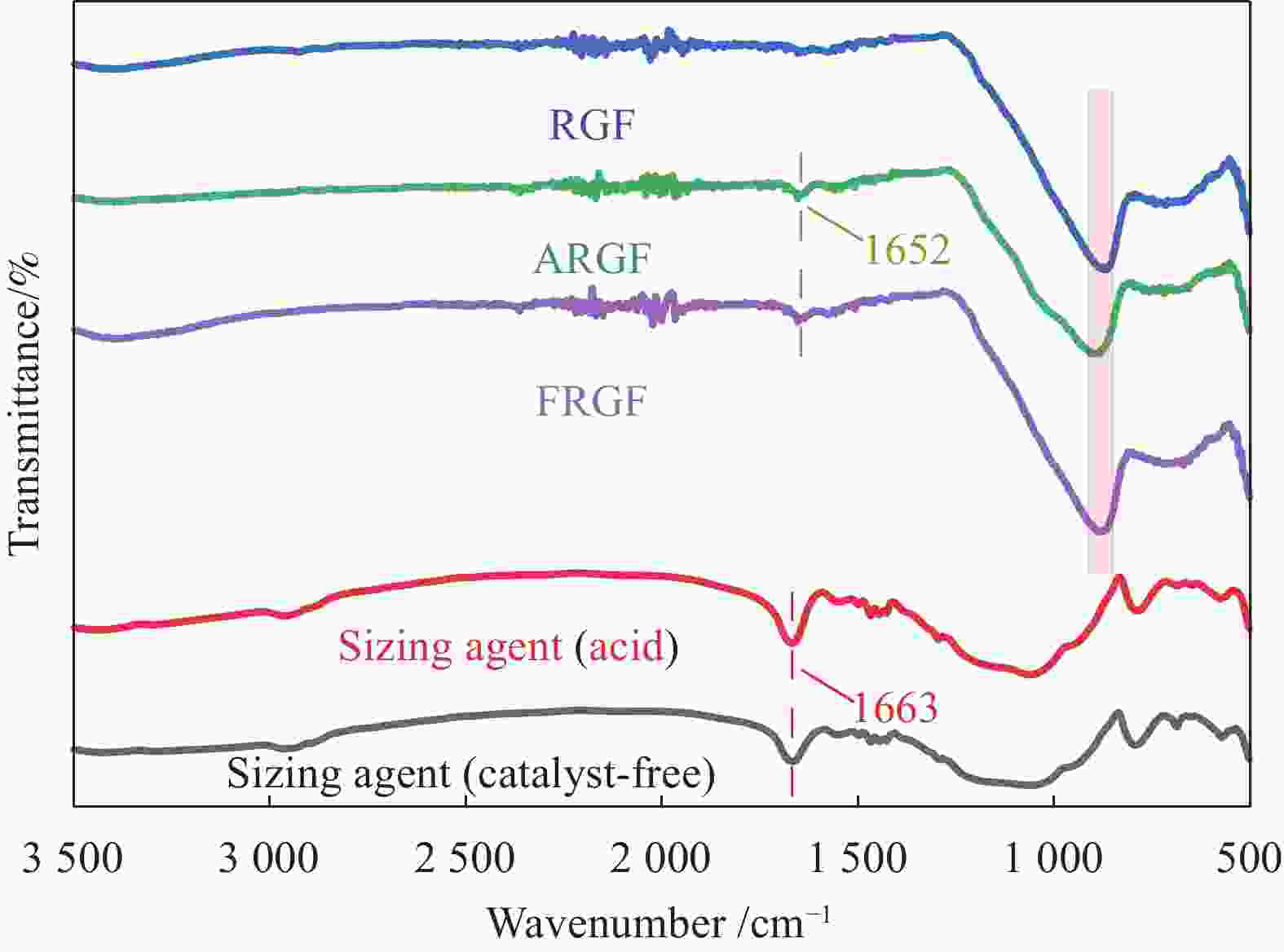

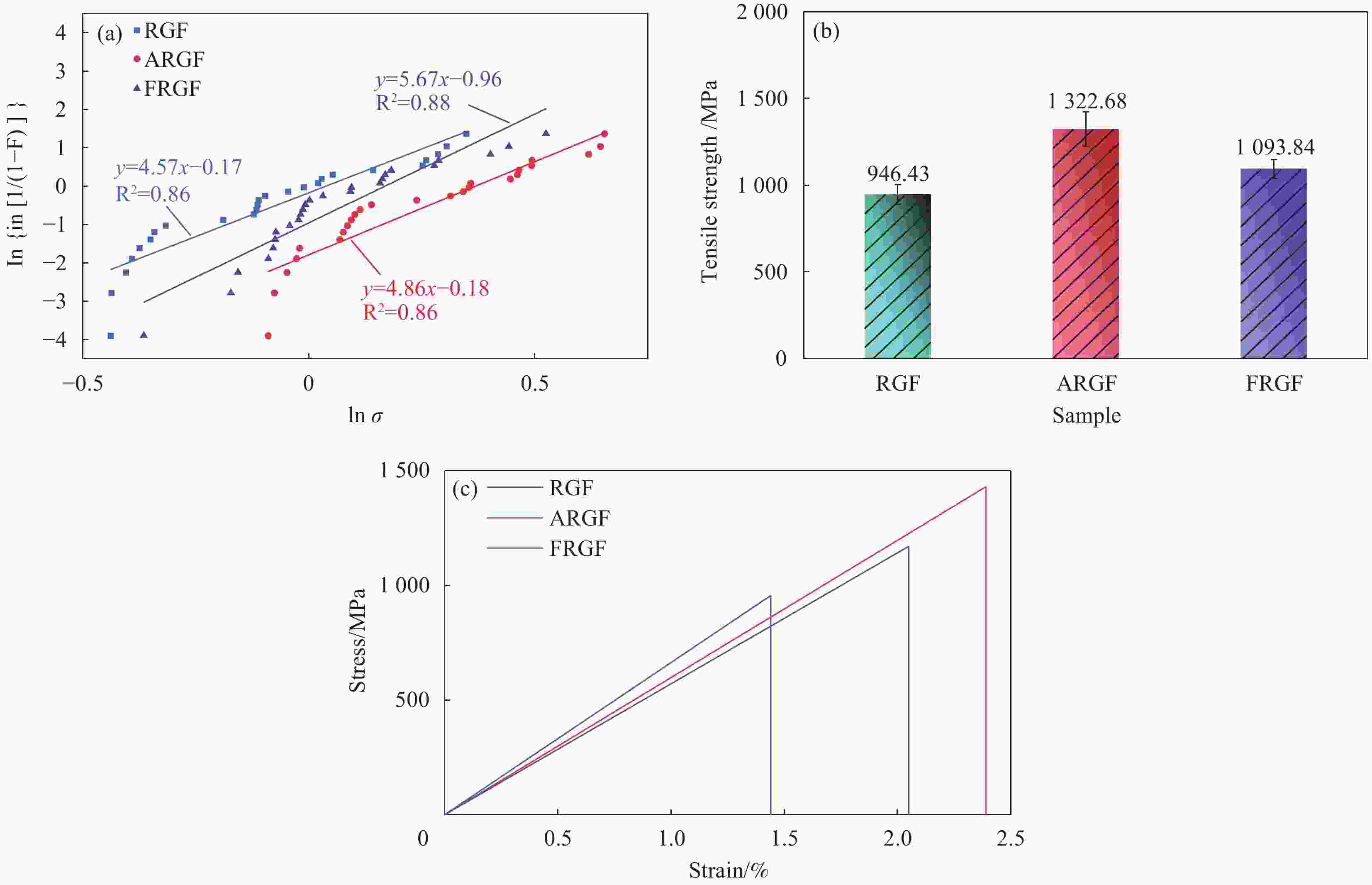

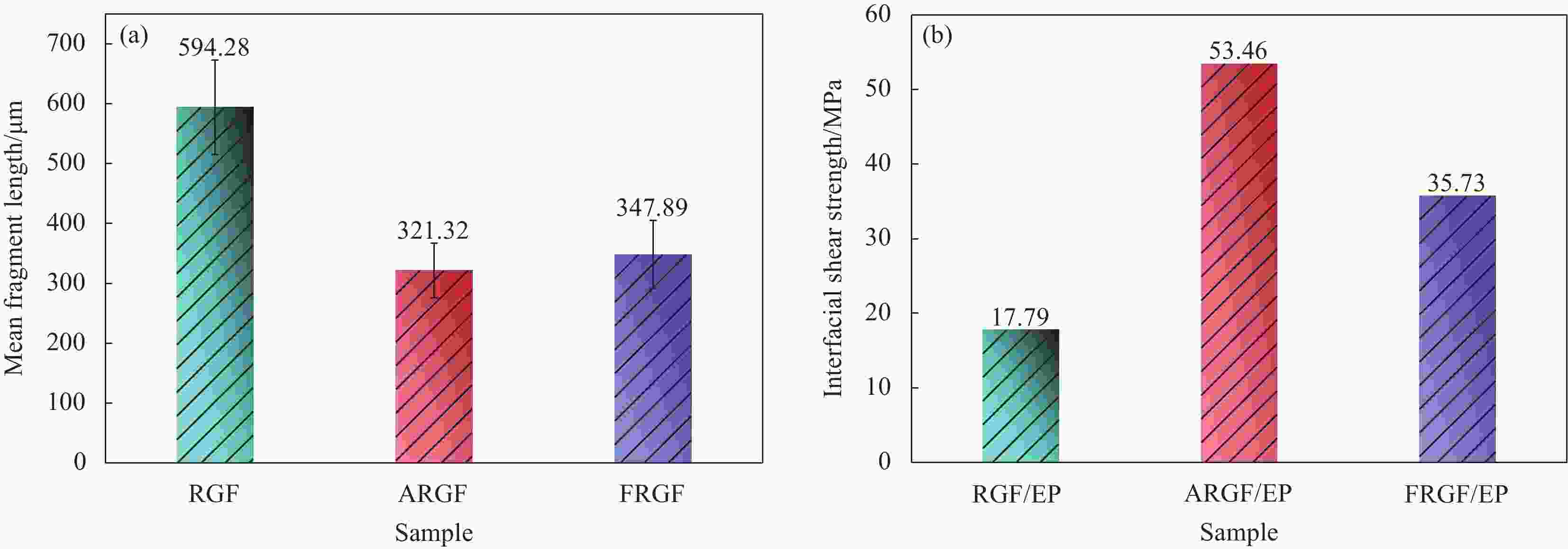

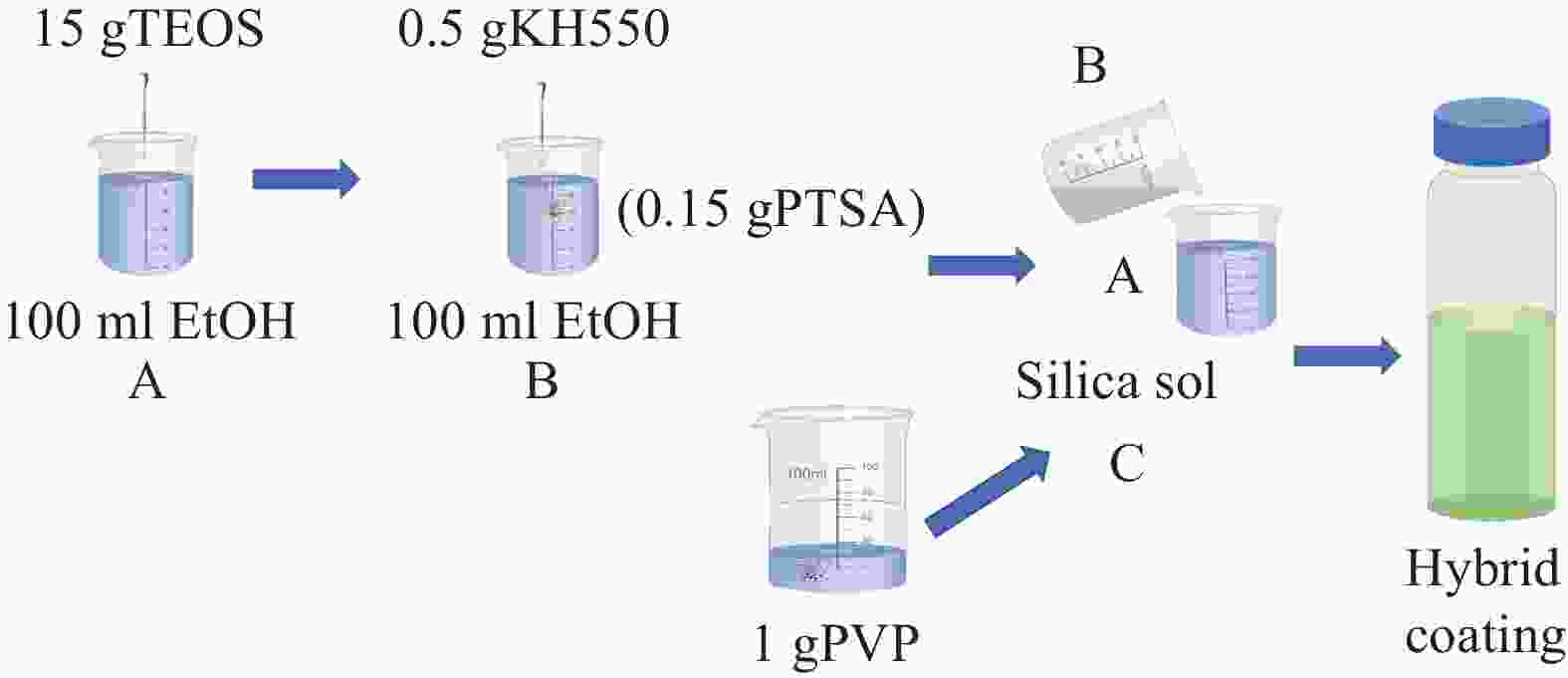

摘要: 为有效利用回收玻璃纤维,以正硅酸乙酯、偶联剂为前驱体,聚乙烯吡咯烷酮为成膜剂,在酸催化和不添加催化剂条件下,合成了两种聚乙烯吡咯烷酮水性杂化涂剂。利用制备的杂化涂剂分别对回收的玻璃纤维进行上浆处理,并对上浆处理后的回收玻璃纤维的性能进行研究。结果表明:与不添加催化剂条件下制备的杂化涂剂相比,经酸催化条件下制备的杂化涂剂上浆处理后的回收玻纤表面粗糙度更大;酸催化条件与不添加催化剂条件制备的杂化涂剂上浆处理后的回收玻璃纤维的单纤维拉伸强度分别为1322.7±98.5 MPa、1093.8±53.8 MPa,相比回收玻璃纤维的单纤维拉伸强度分别提高了39.8%和15.6%。利用单纤维碎断法评价回收玻璃纤维与环氧树脂的界面性能表明,经过酸催化条件与不添加催化条件制备的杂化涂剂上浆处理后的回收玻璃纤维制备的单纤维环氧树脂复合材料的界面剪切强度分别为53.5 MPa、35.7 MPa,比未经过上浆处理的回收玻璃纤维的单纤维环氧树脂复合材料的界面剪切强度分别提高了200.5%与100.8%。显示了在酸催化条件下制备的水性杂化涂剂用于回收玻璃纤维具有可行性。Abstract: In order to effectively utilize recycled glass fiber, two polyvinylpyrrolidone water-based hybrid coatings were synthesized under acid catalysis and without adding catalyst using ethyl orthosilicate and coupling agent as precursors and polyvinylpyrrolidone as film-forming agent. The recycled glass fibers were sized separately using the prepared hybrid coatings. The results showed that the surface roughness of the recycled glass fibers after the sizing treatment of the hybrid coatings prepared under acid-catalyzed conditions was greater compared with that of the hybrid coatings prepared under the condition of no added catalyst; The single-fiber tensile strengths of the recycled glass fibers after sizing treatment of the hybrid coatings prepared under acid-catalyzed conditions and conditions without added catalysts were 1322.7 ± 98.5 MPa and 1093.8 ± 53.8 MPa, which were increased by 39.8% and 15.6%, compared with the single-fiber tensile strengths of the recycled glass fibers. The use of single fiber fragmentation method to evaluate the interfacial properties of recycled glass fiber and epoxy resin shows that single fiber epoxy resin composite materials prepared from recycled glass fiber after sizing with hybrid coating prepared under acid catalytic conditions and without adding catalytic conditions The interfacial shear strengths are 53.5 MPa and 35.7 MPa respectively, which are 200.5% and 100.8% higher than the interfacial shear strengths of single fiber epoxy resin composites of recycled glass fibers without sizing treatment. Aqueous hybrid coatings prepared under acid-catalyzed conditions are shown to be feasible for recycling glass fibers.

-

Key words:

- hybrid coating /

- polyvinylpyrrolidone /

- recycling /

- glass fiber /

- interfacial shear strength /

- composite material

-

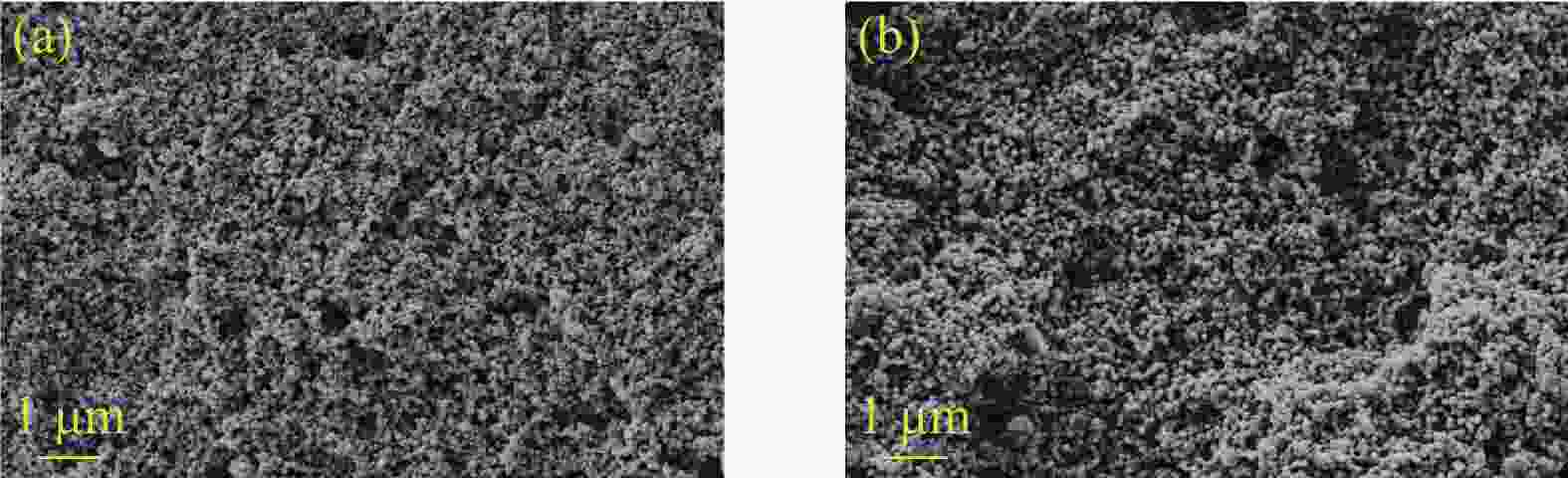

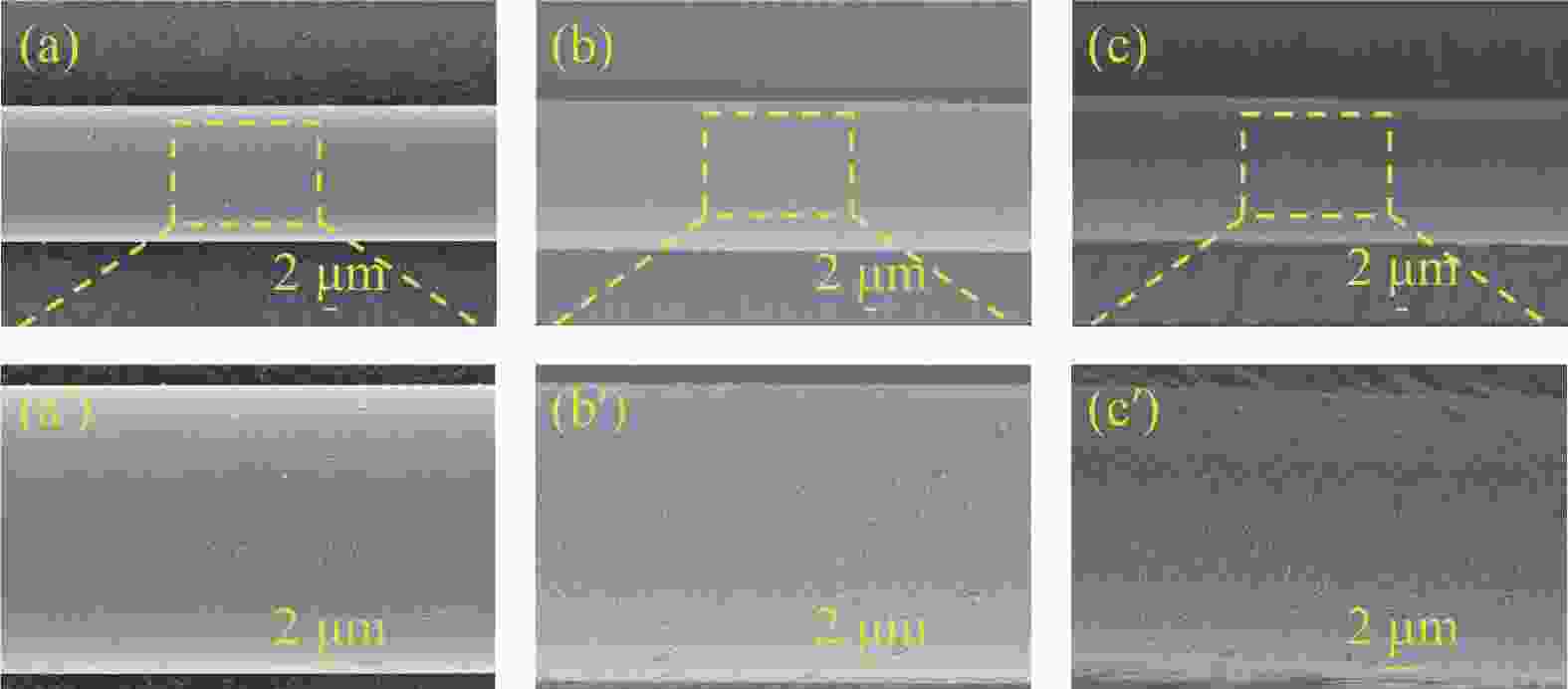

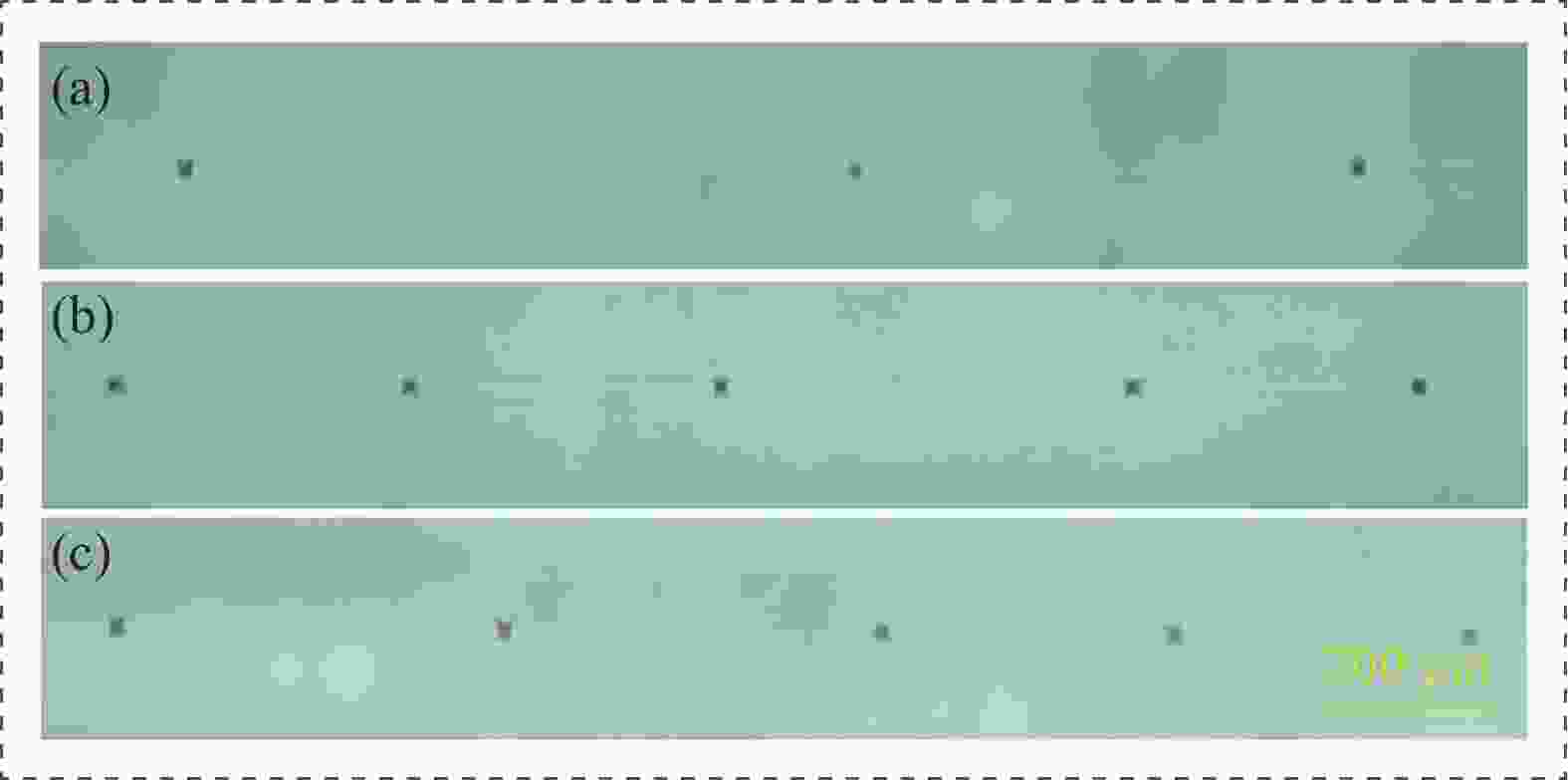

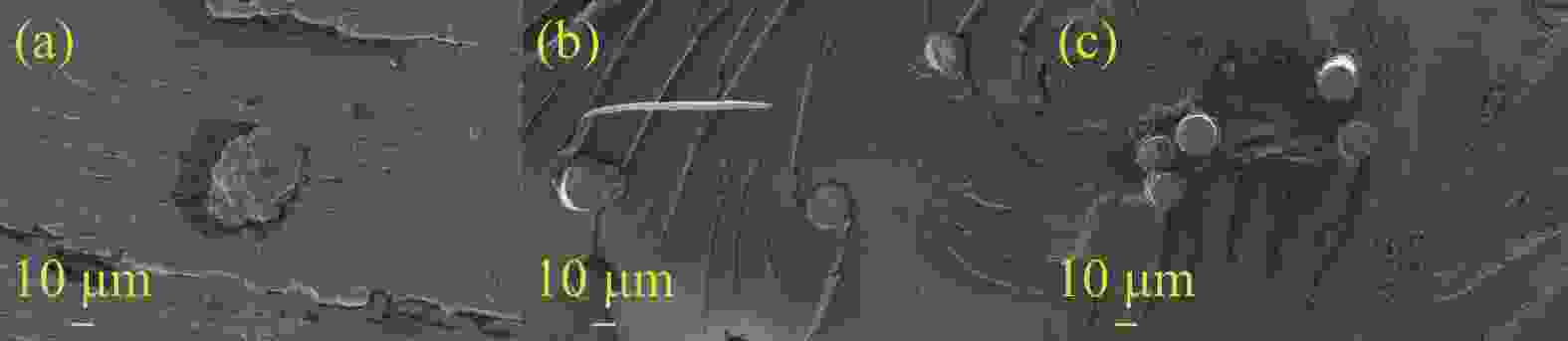

图 11 不同玻纤试样的SEM图: (a-a') 回收玻璃纤维(RGF); (b-b') 酸化涂剂处理的回收玻璃纤维(ARGF); (c-c') 无酸涂剂处理的回收玻璃纤维(FRGF)

Figure 11. SEM images of different glass fiber samples: (a-a') Recycled glass fiber (RGF); (b-b') Acid-coated recycled glass fibers (ARGF); (c-c') Recycled glass fibers treated with acid-free coatings (FRGF)

表 1 不同玻纤试样的单丝拉伸强度、Weibull参数及界面剪切强度评价相关结果

Table 1. Results related to the evaluation of monofilament tensile strength, Weibull parameters and interfacial shear strength of different glass fiber specimens

Sample RGF ARGF FRGF $ {\sigma }_{{\mathrm{f}}} $/MPa 946.43 1322.68 1093.84 $ {d}_{{\mathrm{f}}} $/μm 14 15 15 m 4.57 4.86 5.67 $ \stackrel{-}{l} $/μm 594.28 321.32 347.89 $ {l}_{c} $/μm 792.37 428.43 463.85 $ {\tau }_{{\mathrm{IFSS}}} $/MPa 17.79 53.46 35.73 Notes:$ {\sigma }_{{\mathrm{f}}} $ refers to the average tensile strength of glass fiber at gauge length; $ {d}_{{\mathrm{f}}} $ refers to the glass fiber diameter; m refers to the Weibull shape parameters; $ \stackrel{-}{l} $ refers to the average length of glass fiber in fracture test; $ {l}_{{\mathrm{c}}} $ refers to the critical breaking length of glass fiber; $ {\tau }_{{\mathrm{IFSS}}} $ refers to the interface shear strength. -

[1] NASSER J, STEINKE K, SODANO H. Zno nanostructured interphase for multifunctional and lightweight glass fiber reinforced composite materials under various loading conditions[J]. ACS Applied Nano Materials, 2020, 3(2): 1363-1372. doi: 10.1021/acsanm.9b02216 [2] SUN Q, JIN Q P, GAO Y H, et al. Flexural behavior of PVA-FRC GFRP reinforced concrete beams[J]. Polymer Composites, 2021, 42(7): 3331-3348. doi: 10.1002/pc.26062 [3] ULU A, TUTAR A I, KURKLU A, et al. Effect of excessive fiber reinforcement on mechanical properties of chopped glass fiber reinforced polymer concretes[J]. Construction and Building Materials, 2022, 359: 129486. doi: 10.1016/j.conbuildmat.2022.129486 [4] WU Z H, ZHAO Y, YANG K, et al. Enhancing the mechanical performance of fiber-reinforced polymer composites using carbon nanotubes as an effective nano-phase reinforcement[J]. Advanced Materials Interfaces, 2023, 10(3): 17. [5] ZHANG Y, DUAN L B, LIU X, et al. Distribution law of strain energy density for stiffness design of GFRP, UT/GFRP, and VRB/GFRP hybrid hat-shaped beams[J]. Polymer Composites, 2023, 44(1): 202-228. doi: 10.1002/pc.27039 [6] ZHOU P, LI C G, BAI Y B, et al. Durability study on the interlaminar shear behavior of glass-fibre reinforced polypropylene (GFRPP) bars for marine applications[J]. Construction and Building Materials, 2022, 349: 128694. doi: 10.1016/j.conbuildmat.2022.128694 [7] YANG L, SAEZ E R, NAGEL U, et al. Can thermally degraded glass fibre be regenerated for closed-loop recycling of thermosetting composites?[J]. Composites Part A:Applied Science and Manufacturing, 2015, 72: 167-174. doi: 10.1016/j.compositesa.2015.01.030 [8] KESKISAARI A, KARKI T. Raw material potential of recyclable materials for fiber composites: a review study[J]. Journal of Material Cycles and Waste Management, 2017, 19(3): 1136-1143. doi: 10.1007/s10163-016-0511-2 [9] LIU P, BARLOW C Y. Wind turbine blade waste in 2050[J]. Waste Management, 2017, 62: 229-240. doi: 10.1016/j.wasman.2017.02.007 [10] ASOKAN P, OSMANI M, PRICE A D F. Assessing the recycling potential of glass fibre reinforced plastic waste in concrete and cement composites[J]. Journal of Cleaner Production, 2009, 17(9): 821-829. doi: 10.1016/j.jclepro.2008.12.004 [11] CASTRO A C M, CARVALHO J P, RIBEIRO M C S, et al. An integrated recycling approach for GFRP pultrusion wastes: recycling and reuse assessment into new composite materials using Fuzzy Boolean Nets[J]. Journal of Cleaner Production, 2014, 66: 420-430. doi: 10.1016/j.jclepro.2013.10.030 [12] CUNLIFFE A M, WILLIAMS P T. Characterisation of products from the recycling of glass fibre reinforced polyester waste by pyrolysis[J]. Fuel, 2003, 82(18): 2223-2230. doi: 10.1016/S0016-2361(03)00129-7 [13] MEIRA CASTRO A C, RIBEIRO M C S, SANTOS J, et al. Sustainable waste recycling solution for the glass fibre reinforced polymer composite materials industry[J]. Construction and Building Materials, 2013, 45: 87-94. doi: 10.1016/j.conbuildmat.2013.03.092 [14] TITTARELLI F, SHAH S P. Effect of low dosages of waste GRP dust on fresh and hardened properties of mortars: Part 1[J]. Construction and Building Materials, 2013, 47: 1532-1538. doi: 10.1016/j.conbuildmat.2013.06.043 [15] GEMERT D V, CZARNECKI L, MAULTZSCH M, et al. Cement concrete and concrete–polymer composites: Two merging worlds. A report from 11th ICPIC Congress in Berlin, 2004[J]. Cement and Concrete Composites, 2005, 27(9): 926-933. [16] COOPERMAN A, EBERLE A, LANTZ E. Wind turbine blade material in the United States: Quantities, costs, and end-of-life options[J]. Resources, Conservation and Recycling, 2021, 168: 105439. doi: 10.1016/j.resconrec.2021.105439 [17] OLIVEUX G, DANDY L O, LEEKE G A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties[J]. Progress in Materials Science, 2015, 72: 61-99. doi: 10.1016/j.pmatsci.2015.01.004 [18] BLAZSÓ M. Management, recycling and reuse of waste composites [M]. Sawston: Woodhead Publishing, 2010: 102-121. [19] THOMASON J L, NAGEL U, YANG L, et al. Regenerating the strength of thermally recycled glass fibres using hot sodium hydroxide[J]. Composites Part A:Applied Science and Manufacturing, 2016, 87: 220-227. doi: 10.1016/j.compositesa.2016.05.003 [20] PATEL K, GUPTA R, GARG M, et al. Development of FRC materials with recycled glass fibers recovered from industrial GFRP-Acrylic waste[J]. Advances in Materials Science and Engineering, 2019, 2019: 4149708 [21] 林松, 卫彦, 孙蔚, 等. 玻璃纤维增强光固化树脂基齿科生物复合材料的半互穿网络结构界面的形成及力学性能[J]. 复合材料学报, 2009, 26(6): 85-90.LIN Song, WEI Yan, SUN Wei, et al. Semi-interpenetrating interfacial formation of glass fiber reinforced dental resin bio-composites and its mechanical properties[J]. Acta Materiae Compositae Sinica, 2009, 26(6): 85-90(in Chinese). [22] Chen J, Zhou X R, Ge H Y, et al. Preparation and performance of nano-sio2 stabilized pickering emulsion type sizing agent for glass fiber[J]. Polymer Composites, 2016, 37(2): 334-341. doi: 10.1002/pc.23185 [23] Li M, Ye Y, Zhou X D. A heat-resistant amic acid sizing and its ability to enhance the adhesion between glass fibers and polymer resins[J]. Composite Interfaces, 2020, 27(11): 1007-1021. doi: 10.1080/09276440.2020.1722521 [24] 水兴瑶, 刘猛, 朱曜峰, 等. 水性上浆剂对碳纤维表面及碳纤维/环氧树脂复合材料界面性能的影响[J]. 复合材料学报, 2016, 33(2): 276-279.SHUI Xingyao, LIU Meng, ZHU Yaofeng, et al. Effect of waterborne sizing agent on carbon fiber surface and properties of carbon fiber/epoxy composites interface[J]. Acta Materiae Compositae Sinica, 2016, 33(2): 276-279(in Chinese). [25] 岑浩, 杨洪彬, 傅雅琴. 硅溶胶改性碳纤维对碳纤维/环氧树脂复合材料界面性能影响[J]. 复合材料学报, 2012, 29(12): 32-36.CEN Hao, YANG Hongbin, FU Yaqin. Effect of surface modiffication by silica sol on interfacial properities of canbon fiber/epoxy composite[J]. Acta Materiae Compositae Sinica, 2012, 29(12): 32-36(in Chinese). [26] 徐龙彬. 形状记忆聚氨酯-二氧化硅杂化材料的制备, 表征及应用初探 [D]. 杭州: 浙江理工大学, 2011.Xu Longbin. Preparation, characterization and preliminary study for the application of shape memory polyurethane-silica hybrids. [D]. Hangzhou: Zhejiang Sci-Tech University, 2010(in Chinese). [27] Chen Y, Zhou S, Yang H, et al. Structure and properties of polyurethane/nanosilica composites[J]. Journal of applied polymer science, 2005, 95(5): 1032-1039. doi: 10.1002/app.21180 [28] 焦彩彬. 聚乙烯吡咯烷酮/硅溶胶纳米复合材料的制备及其性能研究 [D]. 武汉: 武汉理工大学, 2015.JIAO Caibin. Synthesis and properties of polyvinylpyrrolidone/silica sol nanocomposites [D]. Wuhan: Wuhan University of Technology, 2015(in Chinese). [29] LIU W, ZHU Y F, QIAN C, et al. Interfacial modification between glass fiber and polypropylene using a novel waterborne amphiphilic sizing agent[J]. Composites Part B:Engineering, 2022, 241: 110029. doi: 10.1016/j.compositesb.2022.110029 [30] SEOUDI R, FOUDA A A, ELMENSHAWY D A. Synthesis, characterization and vibrational spectroscopic studies of different particle size of gold nanoparticle capped with polyvinylpyrrolidone[J]. Physica B:Condensed Matter, 2010, 405(3): 906-911. doi: 10.1016/j.physb.2009.10.012 [31] 毋伟, 贾梦秋, 陈建峰, 等. 硅烷偶联剂对溶胶凝胶法纳米二氧化硅复合材料制备及应用的影响[J]. 复合材料学报, 2004, 21(02): 70-75. doi: 10.3321/j.issn:1000-3851.2004.02.013WU Wei, JIA Mengqiu, CHEN Jianfeng, et al. EFFECT of silane coupling agent on the preparation and application of nano silicon dioxide composite material by sol-gel method[J]. Acta Materiae Compositae Sinica, 2004, 21(02): 70-75(in Chinese). doi: 10.3321/j.issn:1000-3851.2004.02.013 [32] ZHURAVLEV L T. The surface chemistry of amorphous silica. Zhuravlev model[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2000, 173(1): 1-38. [33] DE LANGE P J, MÄDER E, MAI K, et al. Characterization and micromechanical testing of the interphase of aramid-reinforced epoxy composites[J]. Composites Part A:Applied Science and Manufacturing, 2001, 32(3): 331-342. [34] 赵永振. 水性杂化涂层对玻璃纤维/环氧树脂复合材料界面性能的影响 [D]. 杭州: 浙江理工大学, 2017.ZHAO Yongzhen. Effect of water-based hybrid coating on the interfacial properties of glass fiber/epoxy composites [D]. Hangzhou: Zhejiang Sci-Tech University, 2017(in Chinese). [35] ANTHONY D B, SUI X, KELLERSZTEIN I, et al. Continuous carbon nanotube synthesis on charged carbon fibers[J]. Composites Part A:Applied Science and Manufacturing, 2018, 112: 525-538. doi: 10.1016/j.compositesa.2018.05.027 [36] ARNOLD C L, EYCKENS D J, SERVINIS L, et al. Simultaneously increasing the hydrophobicity and interfacial adhesion of carbon fibres: a simple pathway to install passive functionality into composites[J]. Journal of Materials Chemistry A, 2019, 7(22): 13483-13494. doi: 10.1039/C9TA02436K [37] DE LUCA F, CLANCY A J, CARRERO N R, et al. Increasing carbon fiber composite strength with a nanostructured "brick-and-mortar" interphase[J]. Materials Horizons, 2018, 5(4): 668-674. doi: 10.1039/C7MH00917H [38] DE LUCA F, SERNICOLA G, SHAFFER M S P, et al. "Brick-and-Mortar" nanostructured interphase for glass fiber reinforced polymer composites[J]. ACS Applied Materials & Interfaces, 2018, 10(8): 7352-7361. [39] EYCKENS D J, SERVINIS L, SCHEFFLER C, et al. Synergistic interfacial effects of ionic liquids as sizing agents and surface modified carbon fibers[J]. Journal of Materials Chemistry A, 2018, 6(10): 4504-4514. doi: 10.1039/C7TA10516A [40] LIN F, DU X, LI W, et al. Interfacial properties of high failure strain polyimide fiber/epoxy composites analyzed by a modified single fiber fragmentation test[J]. Applied Surface Science, 2020, 513: 145869. doi: 10.1016/j.apsusc.2020.145869 [41] LIU F, SHI Z, DONG Y. Improved wettability and interfacial adhesion in carbon fibre/epoxy composites via an aqueous epoxy sizing agent[J]. Composites Part A:Applied Science and Manufacturing, 2018, 112: 337-345. doi: 10.1016/j.compositesa.2018.06.026 -

点击查看大图

点击查看大图

计量

- 文章访问数: 47

- HTML全文浏览量: 43

- 被引次数: 0

下载:

下载: