Low-frequency broadband sound absorption performance of butterfly-like arc resonant cavity acoustic metamaterials

-

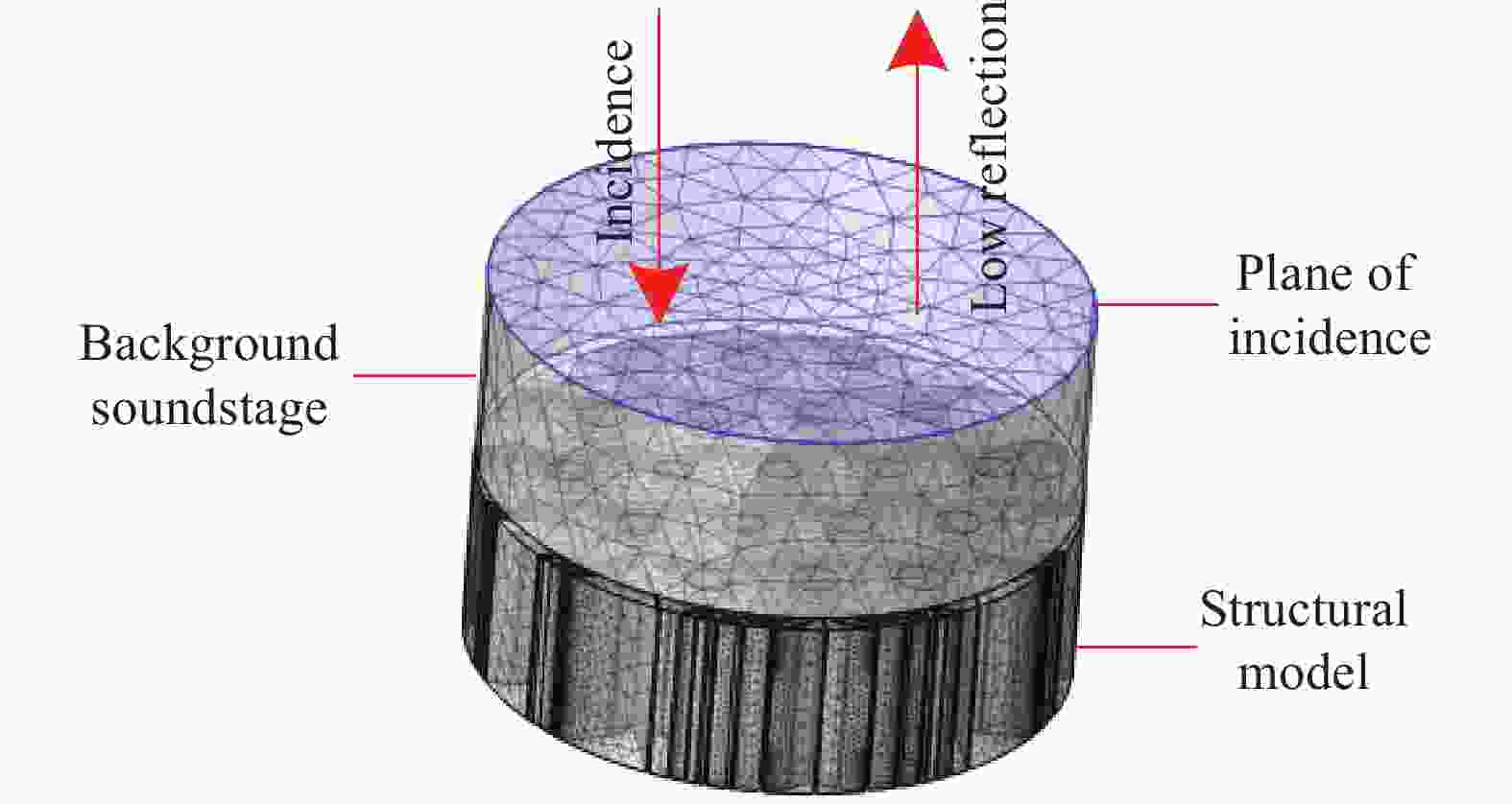

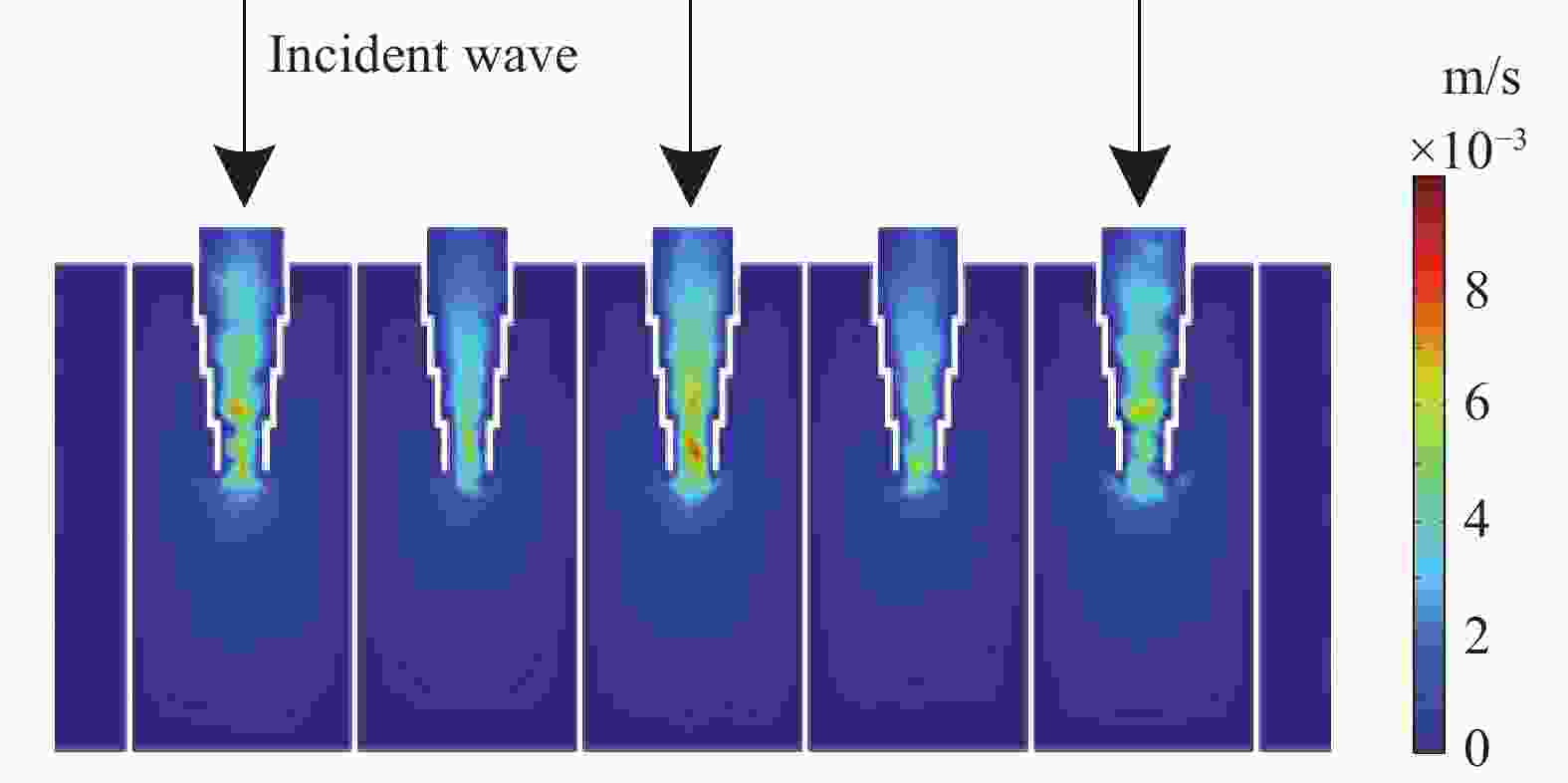

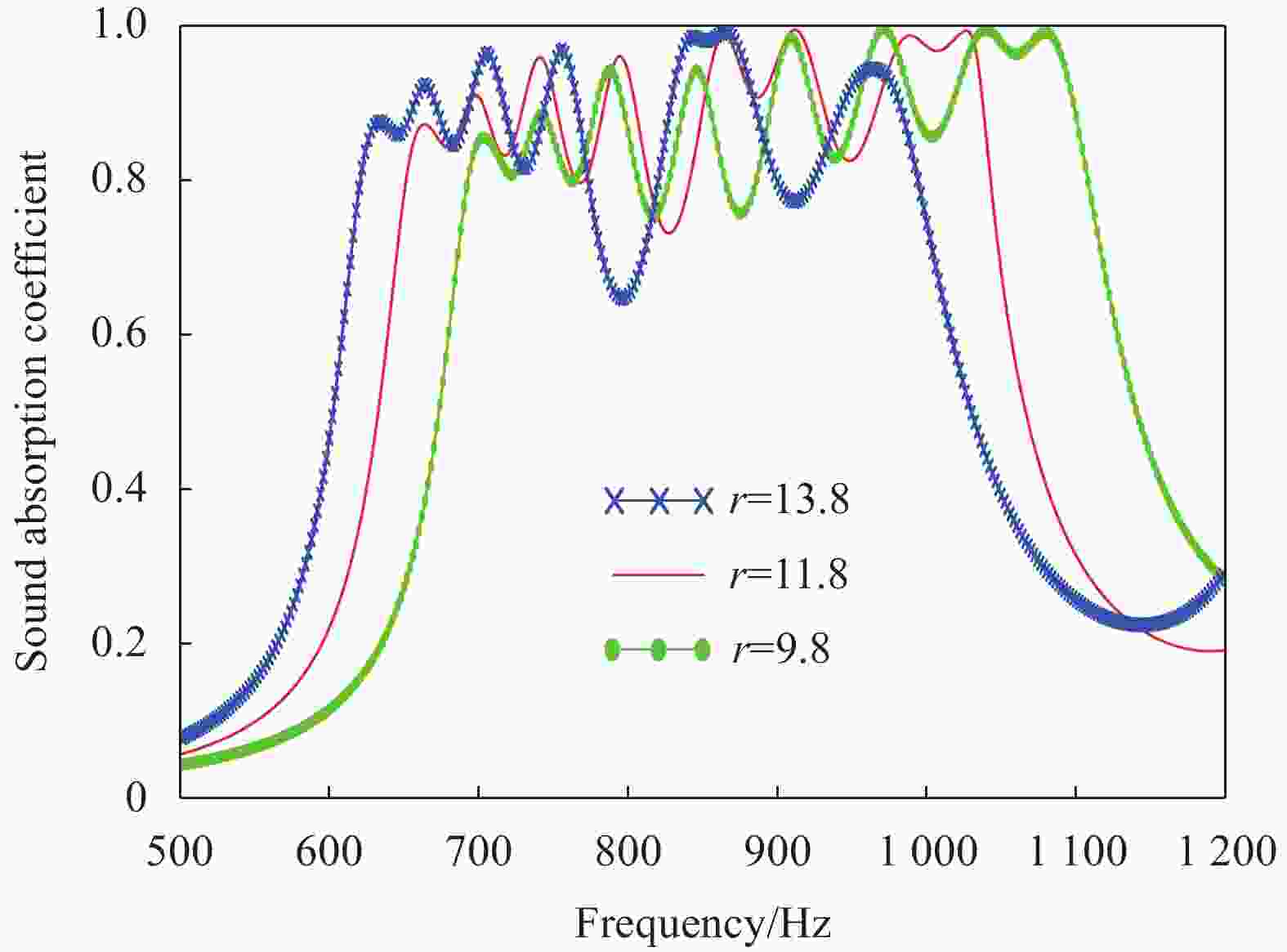

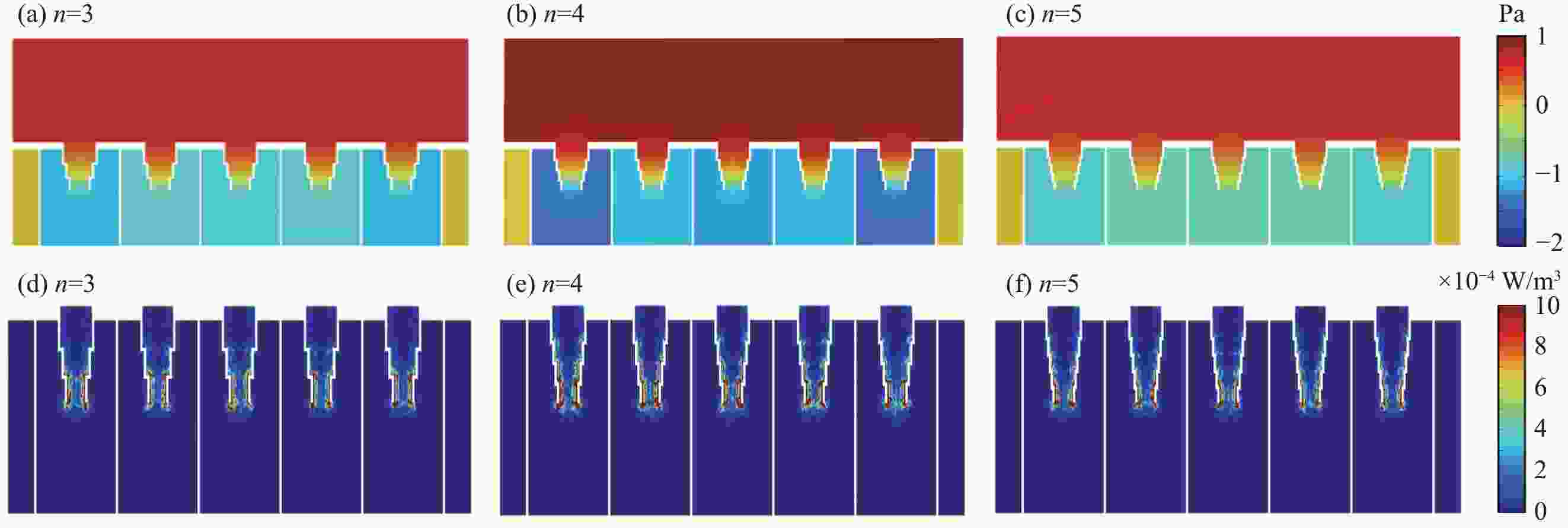

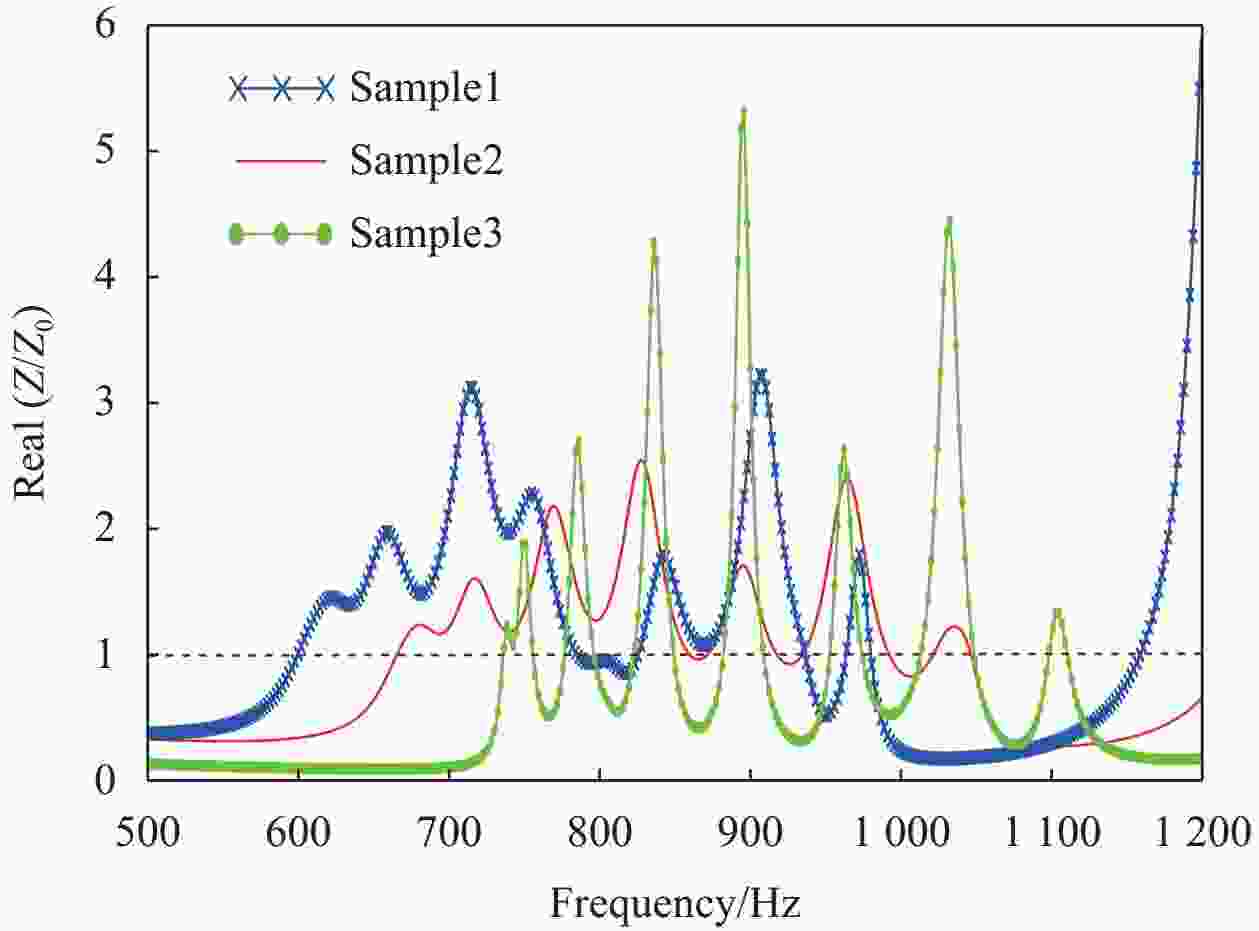

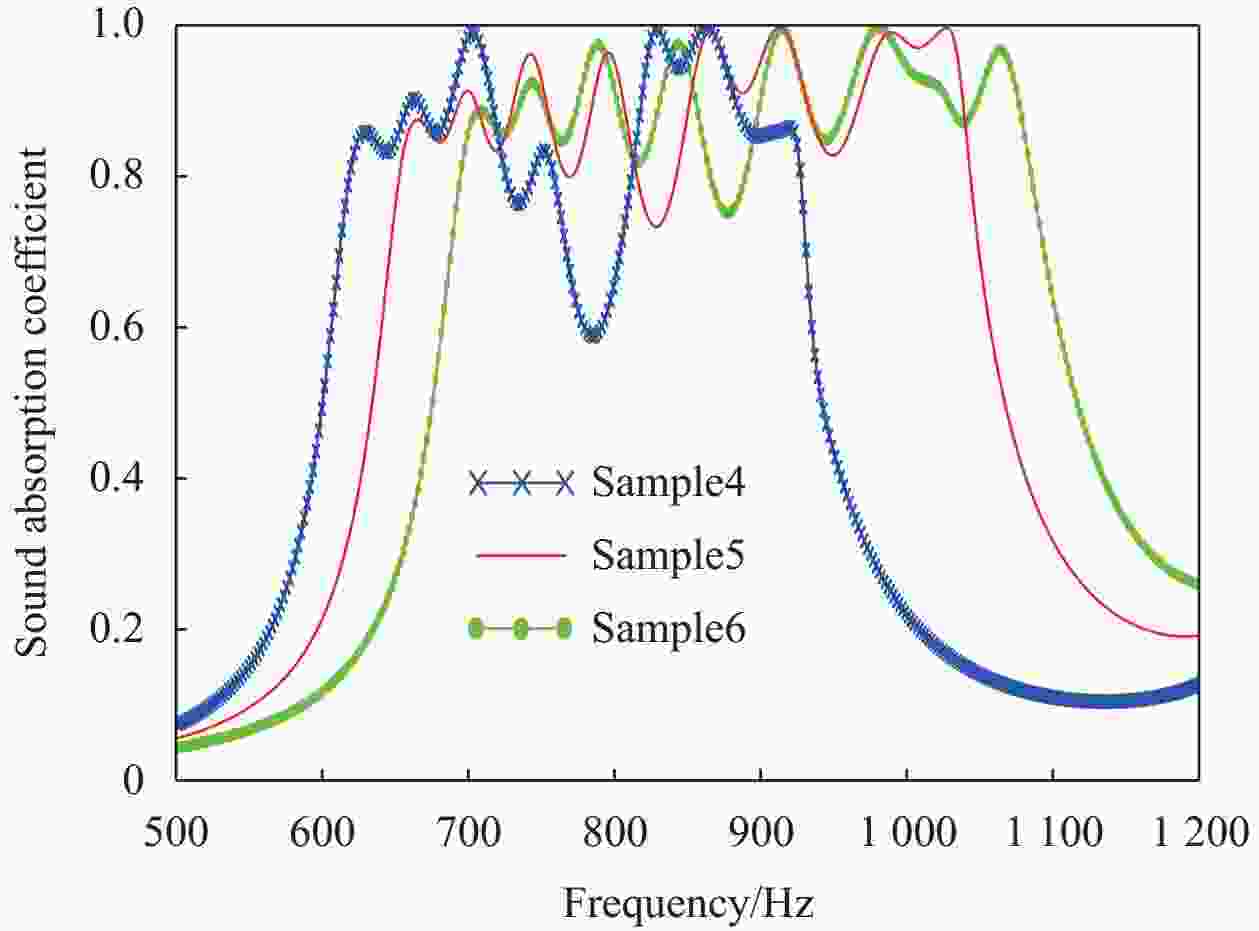

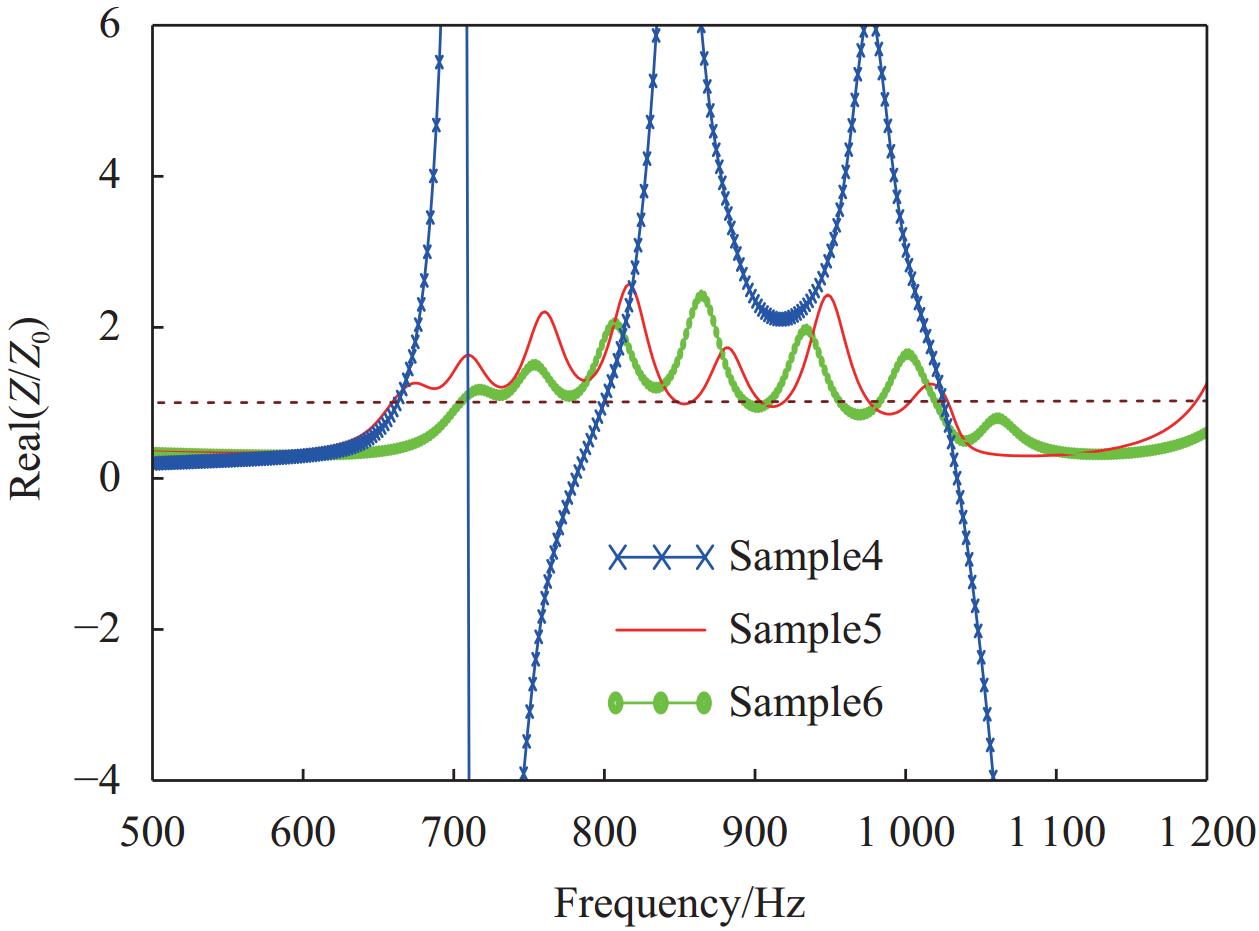

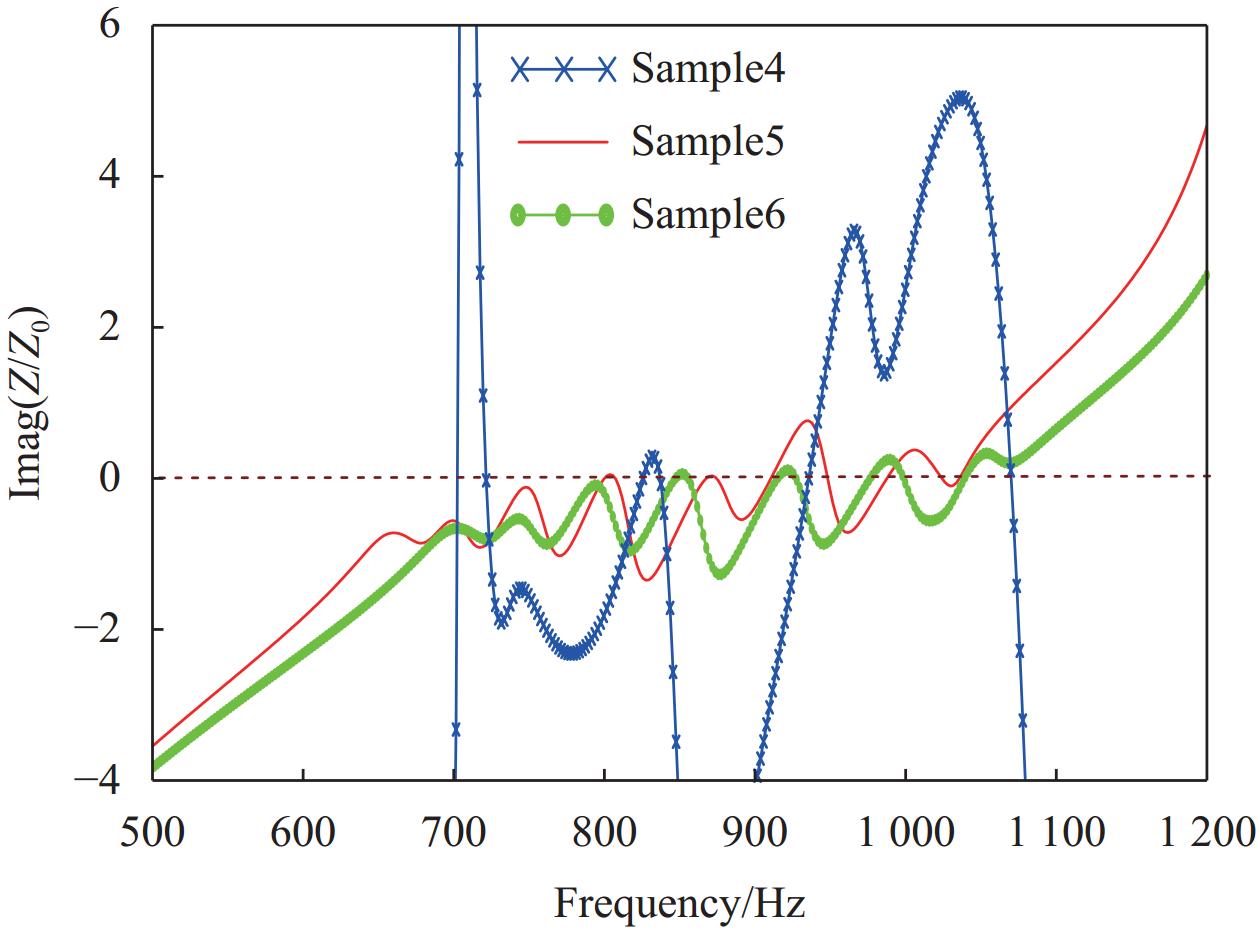

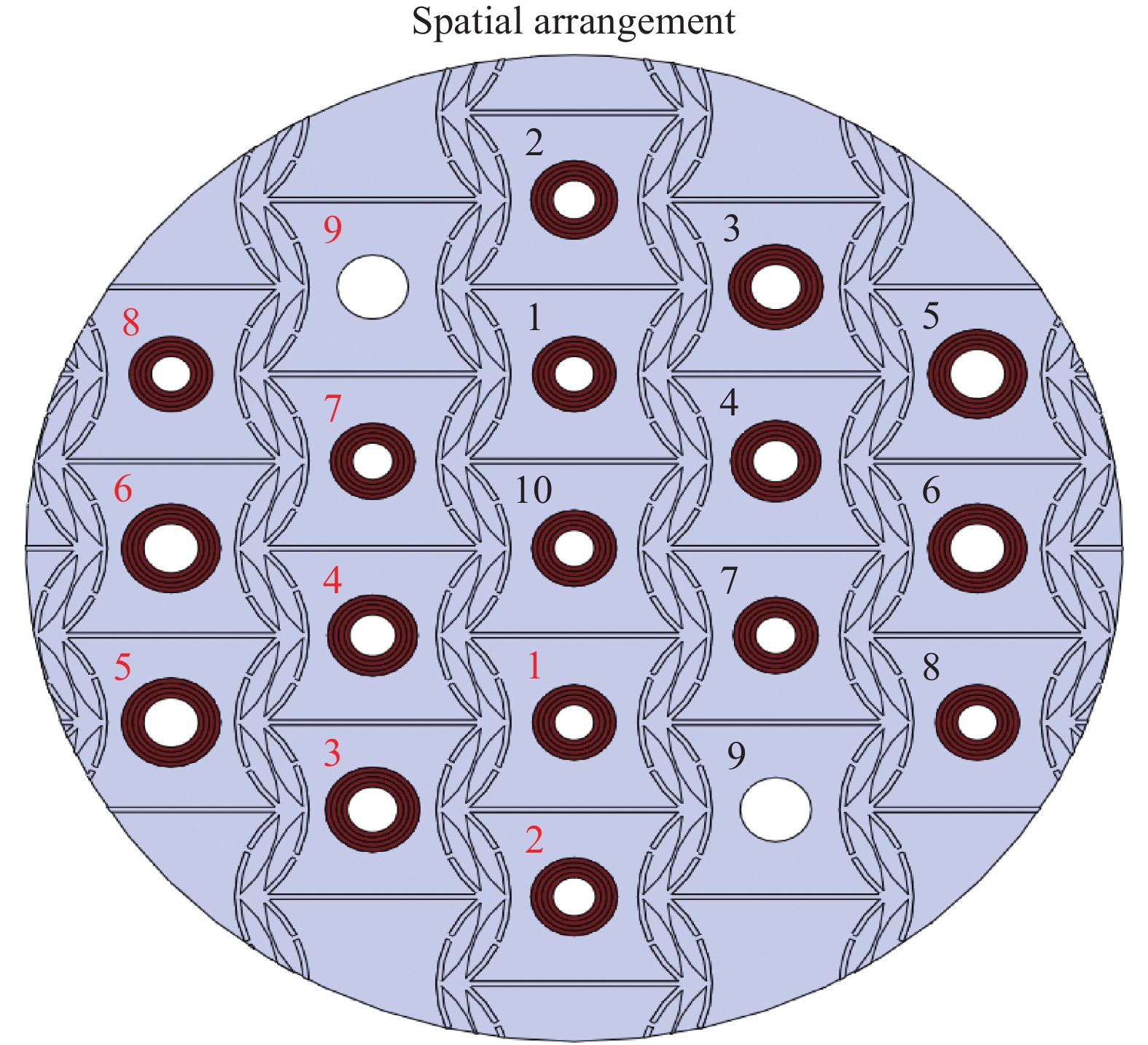

摘要: 针对目前亥姆霍兹共振器低频吸声效果不理想的问题,提出了一种仿蝴蝶弧形共振腔型声学超材料结构,将阶梯式圆孔引入亥姆霍兹共振器的颈管,同时改变传统的负泊松比内凹夹芯结构,使结构在不改变整体尺寸的前提下,有效地为吸声器提供低频吸声所需的声阻抗,从而降低共振频率。利用有限元软件COMSOL 6.1对结构进行了仿真并通过驻波管吸声测试实验进行了验证,实验与仿真的结果具有较高的一致性。结果表明:仿蝴蝶弧形共振腔型声学超材料结构可以有效降低亥姆霍兹共振器的吸收峰值频率,使得该结构在650~1050 Hz频率范围内有着优秀的吸声性能,平均吸声系数大于0.9,实现了对声波的准完美吸收。吸声结构在740 Hz共振吸收系数峰值为0.962509,此时结构的厚度仅为吸收峰频率对应波长的1/15,体现了其深亚波长尺寸的特征。当结构的高度为30 mm时,仍有一个较宽的吸声频带,带宽比为62% (吸声系数>0.5)。不同仿蝴蝶弧形负泊松比的胞元参数对吸声性能也有一定的影响,当弧形胞元的圆弧半径r为11.8 mm、阶梯式圆孔的阶梯数n为4,以及阶梯式圆孔管径da和管长la为试件尺寸时,可以使亥姆霍兹共振器在低频宽带条件下有着优秀的吸声性能。Abstract: A novel acoustic metamaterial structure, inspired by the shape of butterfly arc, is proposed to address the issue of low-frequency absorption performance in Helmholtz resonators. In this paper, a butterfly-like arc resonance cavity acoustic metamaterial structure is proposed, and a stepped round hole is introduced into the neck tube of the Helmholtz resonator, and the traditional negative Poisson's ratio concave sandwich structure is changed, so that the structure can effectively provide the acoustic impedance required for low-frequency sound absorption for the sound absorber without changing the overall size, so as to reduce the resonance frequency. The structure was numerically simulated using COMSOL 6.1 finite element software and validated through a standing wave tube absorption test experiment, showing a high level of consistency between the experimental and simulated results. The results demonstrate that butterfly-like arc resonance cavity acoustic metamaterial structure can effectively reduce the absorption peak frequency of Helmholtz resonators, achieving excellent sound absorption performance in the frequency range of 650~1050 Hz, with an average sound absorption coefficient greater than 0.9. The structure achieves near-perfect absorption of sound waves. At the resonance absorption peak of 740 Hz, the structure thickness is only 1/15 of the corresponding wavelength, highlighting its deep subwavelength characteristics. Even at a height of 30 mm, the structure still exhibits a wide absorption bandwidth with a bandwidth ratio of 62% (Sound absorption coefficient > 0.5). The sound absorption performance is also influenced by different parameters of the butterfly arc-shaped negative Poisson's ratio unit cell. When the circular arc radius (r) of the arc-shaped cell is 11.8 mm, the number of steps (n) in the step-like circular hole is 4, and the diameter (da) and length (la) of the step-like circular hole correspond to the specimen size, the Helmholtz resonator exhibits excellent sound absorption performance over a wide low-frequency band.

-

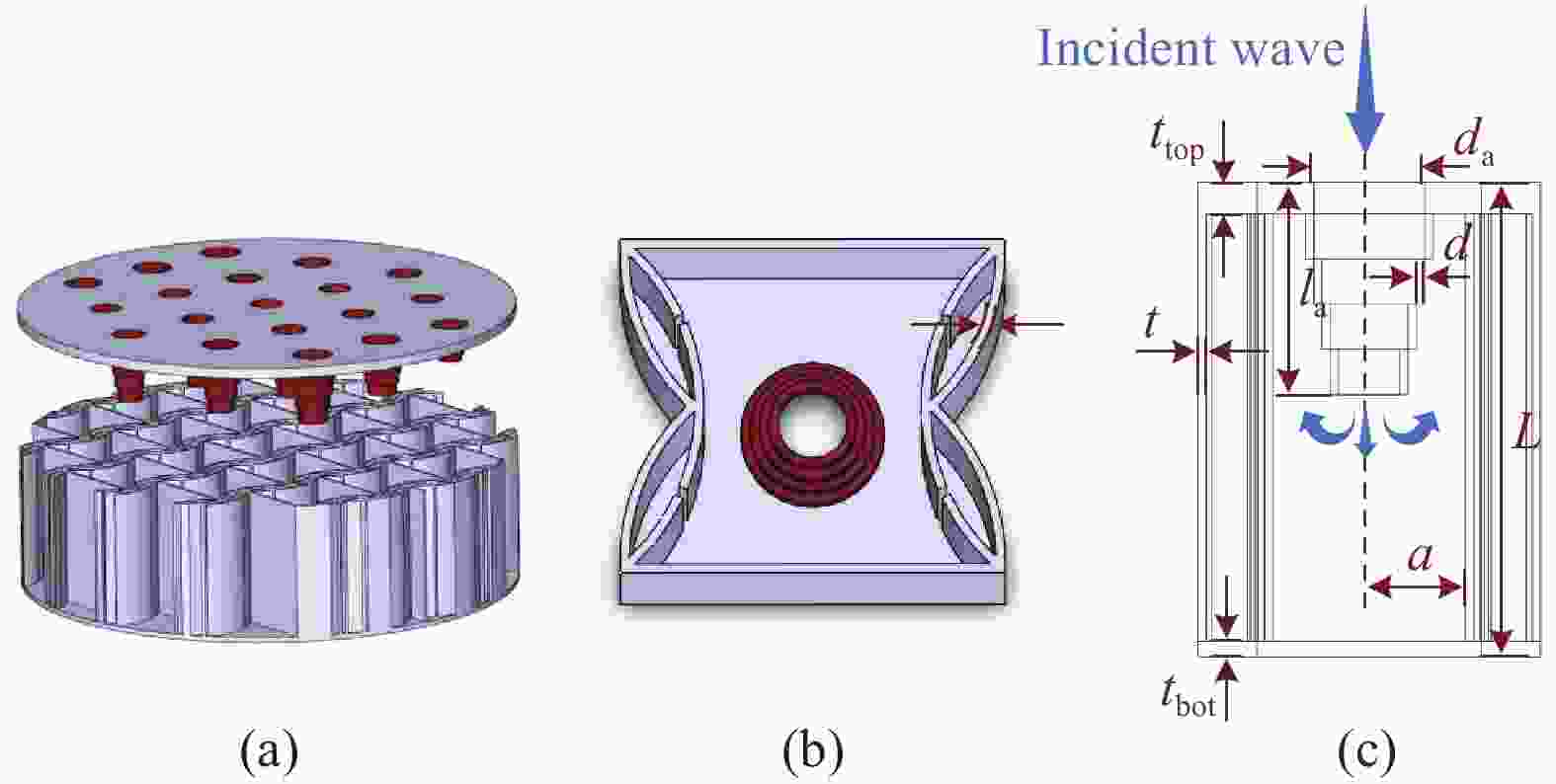

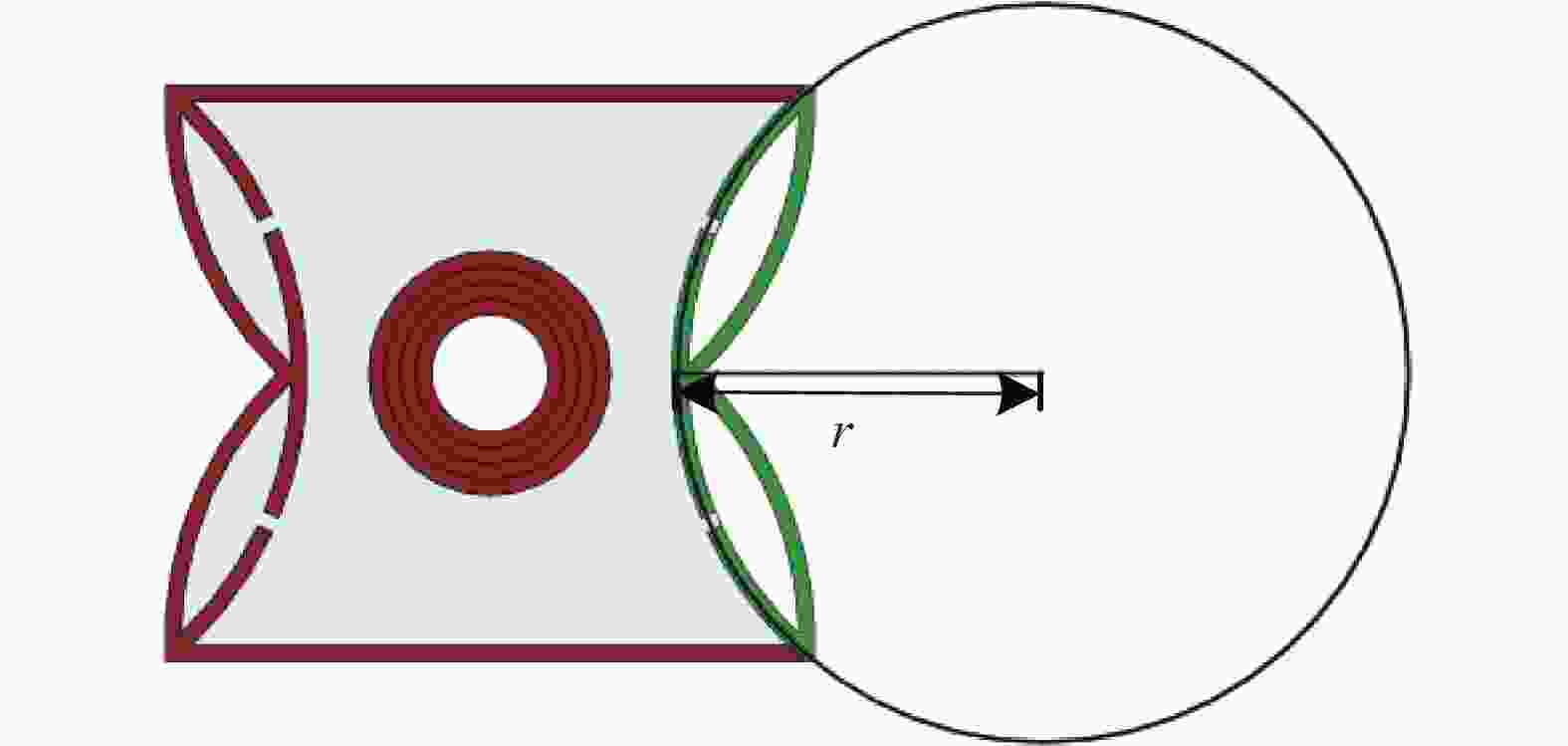

图 2 仿蝴蝶弧形共振腔型声学超材料结构示意图:(a) 整体结构;(b) 胞元结构示意图;(c) 胞元截面示意图

Figure 2. Schematic diagram of the structure of an acoustic metamaterial in an arc-like resonant cavity imitation butterfly: (a) Overall structure; (b) Cell structure; (c) Cell cross-section

ttop—Thickness of the microperforated plat; tbot—Thickness of the lower panel; t—Wall thickness of the cavity; a—Distance from the central axis of the inner extension tube to the concave wall; d—Stepped decreasing thickness; L—Cavity height; da—Diameter of the extension tube; la—Length of the extension tube.

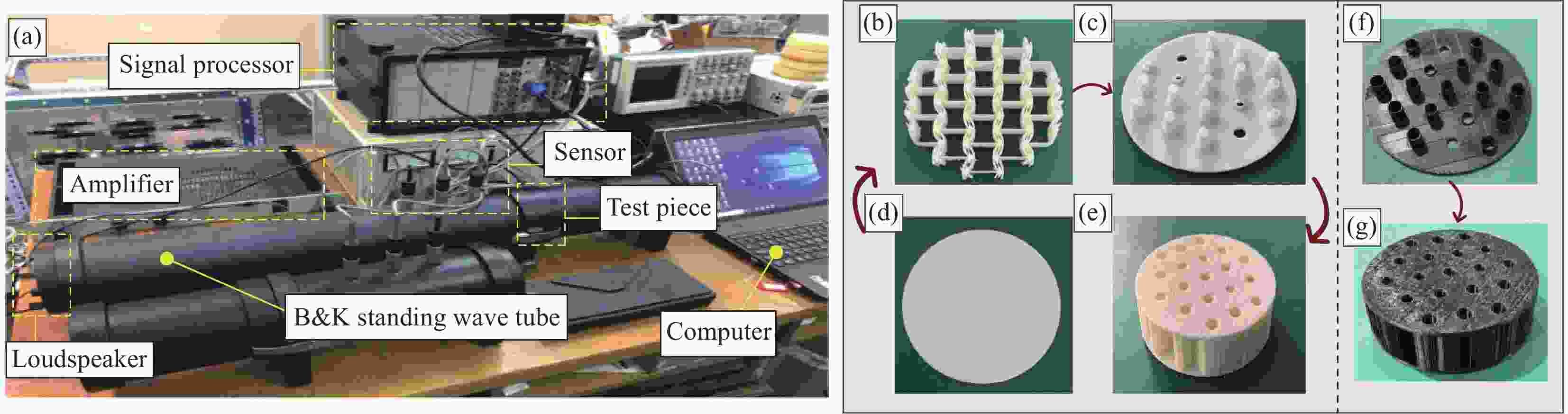

图 6 (a) B&K驻波管测量设备;仿蝴蝶弧形共振腔型声学超材料结构实验样品结构制备流程:(b) 仿蝴蝶弧形夹芯层;(c) 含阶梯式圆孔内嵌管的微穿孔板; (d) 下面板;(e) 具有嵌入阶梯式圆孔的实验样品;(f) 含传统直管式内嵌管的微穿孔板;(g) 具有传统直管式内嵌管的实验样品

Figure 6. (a) B&K VSWT measurement equipment; Fabrication process of experimental samples for a resonator-type acoustic metamaterial with a mimicked butterfly-shaped: (b) Mimicked butterfly-shaped sandwich layer; (c) Micro-perforated plate with stepped round bore inline tubes; (d) Lower panel; (e) Experimental sample with embedded stepped round holes; (f) Micro-perforated plate with traditional straight inline tubes; (g) Experimental sample with traditional straight tubes

表 1 试件参数

Table 1. Specimen parameters

$ {{t}}_{\text{top}} $/mm $ {{t}}_{\text{bot}} $/mm $ {t} $/mm $ {d} $/mm $ {L} $/mm $ {a} $/mm $ {r} $/mm $ {n} $ (piece) 2 1 0.5 0.5 30 5.8 11.8 4 Notes: $ {r} $—Radius of the arc; $ {n} $—Number of steps. 表 2 试件内延伸管的直径$ {{d}}_{\text{a}} $和管长$ {{l}}_{\text{a}} $参数

Table 2. Parameters of diameter $ {{d}}_{\text{a}} $ and length $ {{l}}_{\text{a}} $of the extension tube in the specimen

Unit $ {{d}}_{\text{a}} $/mm $ {{l}}_{\text{a}} $/mm 1 5.6 11.5 2 5.9 11.5 3 6.6 11.5 4 6.2 11.5 5 7 11.5 6 7 8.9 7 5.7 1.4 8 6.6 5.3 9 5.5 0 10 5.7 11.5 表 3 仿蝴蝶弧形共振腔型声学超材料不同阶梯式圆孔管径da的参数(mm)

Table 3. Parameters of different stepped circular hole diameter da of butterfly-like arc resonant cavity acoustic metamaterials (mm)

Unit 1 2 3 4 5 6 7 8 9 10 Sample1 5.2 5.5 6.2 5.8 6.6 6.6 5.3 6.2 5.1 5.3 Sample2 5.6 5.9 6.6 6.2 7.0 7.0 5.7 6.6 5.5 5.7 Sample3 6.0 6.3 7.0 6.6 7.4 7.4 6.1 7.0 5.9 6.1 表 4 仿蝴蝶弧形共振腔型声学超材料不同阶梯式圆孔管长la的参数(mm)

Table 4. Parameters of different stepped round hole tube length la of butterfly-like arc resonant cavity acoustic metamaterials (mm)

Unit 1 2 3 4 5 6 7 8 9 10 Sample4 13.5 13.5 13.5 13.5 13.5 10.9 3.4 7.3 2.0 13.5 Sample5 11.5 11.5 11.5 11.5 11.5 8.9 1.4 5.3 0.0 11.5 Sample6 9.5 9.5 9.5 9.5 9.5 6.9 1.4 3.3 0.0 9.5 -

[1] 宁方立, 张畅通, 宁舜山, 等. 多孔材料对空腔噪声抑制效果研究[J]. 振动与冲击, 2020, 39(11): 31-37.NING Fangli, ZHANG Changtong, NING Shunshan, et al. Study on the effect of porous materials on cavity noise suppression[J]. Journal of Vibration and Shock, 2020, 39(11): 31-37(in Chinese). [2] 陈林, 李磊, 张航, 等. 声学材料表面铺层对船舶舱室噪声影响研究[J]. 舰船科学技, 2021, 43(17): 74-79.CHEN Lin, LI Lei, ZHANG Hang, et al. Study on the effect of surface layup of acoustic materials on ship cabin noise[J]. Journal of Ship Science and Technology, 2021, 43(17): 74-79(in Chinese). [3] SUN W H, PAN B R, SONG X, et al. A novel sound absorber design of nanofibrous composite porous material[J]. Materials & Design, 2022, 214: 110418. [4] 纪双英, 郝巍, 刘杰. 共振吸声结构在航空发动机上的应用进展[J]. 航空工程进展, 2019, 10(3): 302-308.JI Shuangying, HAO Wei, LIU Jie. Progress in the application of resonant sound-absorbing structures in aero engines[J]. Progress in Aeronautical Engineering, 2019, 10(3): 302-308(in Chinese). [5] 张磊. 微穿孔-蜂窝吸声结构在船舶舱室噪声控制中的应用[D]. 哈尔滨: 哈尔滨工业大学, 2022.ZHANG Lei. Application of microperforation-honeycomb sound-absorbing structure in ship cabin noise control[D]. Harbin: Harbin Institute of Technology, 2022(in Chinese). [6] 俞悟周, 王晨, 毛东兴, 等. 高速铁路动车组列车的噪声特性[J]. 环境污染与防治, 2009, 31(1): 74-77.YU Wuzhou, WANG Chen, MAO Dongxing, et al. Noise characteristics of high-speed railway EMU trains[J]. Environmental Pollution and Prevention, 2009, 31(1): 74-77(in Chinese). [7] KIM H S, MA P S, KIM B K, et al. Low-frequency sound absorption of elastic micro-perforated plates in a parallel arrangement[J]. Journal of Sound and Vibration, 2019, 460: 114884. doi: 10.1016/j.jsv.2019.114884 [8] LI X, LIU B L, CHANG D Q. An acoustic impedance structure consisting of perforated panel resonator and porous material for low-to-mid frequency sound absorption[J]. Applied Acoustics, 2021, 180: 108069. doi: 10.1016/j.apacoust.2021.108069 [9] MENG H, GALLAND M A, ICHCHOU M, et al. Small perforations in corrugated sandwich panel significantly enhance low frequency sound absorption and transmission loss[J]. Composite Structures, 2017, 182: 1-11. [10] 侯九霄, 朱海潮, 袁苏伟. 耦合条件下微穿孔板吸声特性研究[J]. 振动与冲击, 2020, 39(15): 156-162.HOU Jiuxiao, ZHU Haichao, YUAN Suwei. Study on sound absorption characteristics of microperforated plates under coupling conditions[J]. Journal of Vibration and Shock, 2020, 39(15): 156-162(in Chinese). [11] MOSA A I, PUTRA A, RAMLAN R, et al. Theoretical model of absorption coefficient of an inhomogeneous MPP absorber with multi-cavity depths[J]. Applied Acoustics, 2019, 146: 409-419. doi: 10.1016/j.apacoust.2018.11.002 [12] MOSA A I, PUTRA A, RAMLAN R, et al. Wideband sound absorption of a double-layer microperforated panel with inhomogeneous perforation[J]. Applied Acoustics, 2020, 161: 107167. doi: 10.1016/j.apacoust.2019.107167 [13] 田文昊, 吴锦武, 李威等. 双层串联微穿孔板吸声体吸声特性研究[J]. 噪声与振动控制, 2019, 39(4): 32-35.TIAN Wenhao, WU Jinwu, LI Wei, et al. Study on sound absorption characteristics of sound absorbers in double-layer tandem microperforated plates[J]. Noise and Vibration Control, 2019, 39(4): 32-35(in Chinese). [14] NING J F, GENG Q, MP A, et al. Wide absorption bandwidth of a light composite absorber based on micro-perforated sandwich panel[J]. Applied Acoustics, 2021, 174: 107735. doi: 10.1016/j.apacoust.2020.107735 [15] MENG H, GALLAND M A, ICHCHOU M , et al. On the low frequency acoustic properties of novel multifunctional honeycomb sandwich panels with micro-perforated faceplates[J]. Applied Acoustics, 2019, 152: 31-40. [16] LI L, ZHANG Z F, HUANG Q B, et al. A sandwich anechoic coating embedded with a micro-perforated panel in high-viscosity condition for underwater sound absorption[J]. Composite Structures, 2020, 235: 111761. doi: 10.1016/j.compstruct.2019.111761 [17] BOCCACCIO M, BUCCIARELLI F, FIERRO G P M, et al. Microperforated panel and deep subwavelength archimedean-inspired spiral cavities for multi-tonal and broadband sound absorption[J]. Applied Acoustics, 2021, 176: 107901. doi: 10.1016/j.apacoust.2020.107901 [18] ZHANG X, WU J W, MAO Q B, et al. Design of a honeycomb-microperforated panel with an adjustable sound absorption frequency[J]. Applied Acoustics, 2020, 164: 107246. doi: 10.1016/j.apacoust.2020.107246 [19] XIE S C, WANG D, FENG Z J, et al, Sound absorption performance of microperforated honeycomb metasurface panels with a combination of multiple orifice diameters[J]. Applied Acoustics, 2020, 158: 107046. [20] HUANG S, FANG X, WANG X, et al. Acoustic perfect absorbers via Helmholtz resonators with embedded apertures[J]. The Journal of the Acoustical Society of America, 2019, 145(1): 254-262. doi: 10.1121/1.5087128 [21] LEE D, JANG Y, PARK J, et al. Underwater stealth metasurfaces composed of split-orifice-conduit hybrid resonators[J]. Journal of Applied Physics, 2021, 129(10): 105103. doi: 10.1063/5.0042246 [22] LI S, YANG J S, WU L Z. Vibration behavior of metallic sandwich panels with Hourglass truss cores[J]. Marine Structures, 2019, 63: 84-98. doi: 10.1016/j.marstruc.2018.09.004 [23] 高玉魁. 负泊松比超材料和结构[J]. 材料工程, 2021, 49(5): 38-47.GAO Yukui. Metamaterials and structures with negative Poisson's ratio[J]. Materials Engineering, 2021, 49(5): 38-47(in Chinese). [24] 任鑫, 张相玉, 谢亿民. 负泊松比材料和结构的研究进展[J]. 力学学报, 2019, 51(3): 656-687.REN Xin, ZHANG Xiangyu, XIE Yimin. Research progress on materials and structures with negative Poisson's ratio[J]. Chinese Journal of Mechanics, 2019, 51(3): 656-687(in Chinese). [25] LIU S, WANG K F, WANG B L. Buckling and vibration characteristic of anisotropic sandwich plates with negative Poisson's ratio based on isogeometric analysis[J/OL]. Mechanics of Advanced Materials and Structures, 2023: 1-16. https://doi.org/10.1080/15376494.2023.2222280. [26] SHEN J B, GE J R, XIAO J H, et al. In-plane impact dynamics of honeycomb structure containing curved reentrant sides with negative Poisson's ratio effect[J]. Mechanics of Advanced Materials and Structures, 2022, 29(10): 1489-1497. doi: 10.1080/15376494.2020.1824285 [27] ZHANG Z J, ZHANG L A, DONG Y Y, et al. Mechanical properties of negative Poisson's ratio metamaterial units and honeycomb structures with cosine-like re-entrant structure[J]. Materials Letters, 2023, 331: 13345. [28] 马芳武, 梁鸿宇, 赵颖等. 内凹三角形负泊松比材料的面内冲击动力学性能[J]. 振动与冲击, 2019, 38(17): 81-87.MA Fangwu, LIANG Hongyu, ZHAO Ying, et al. In-plane impact dynamics of concave triangular negative Poisson's ratio materials[J]. Vibration and Shock, 2019, 38(17): 81-87(in Chinese). [29] FU T, HU X C, YANG C, Impact response analysis of stiffened sandwich functionally graded porous materials doubly-curved shell with re-entrant honeycomb auxetic core[J]. Applied Mathematical Modelling. 2023, 124: 553-575. -

下载:

下载: