Friction and wear properties of TC4 titanium alloy with high-speed nitriding treatment

-

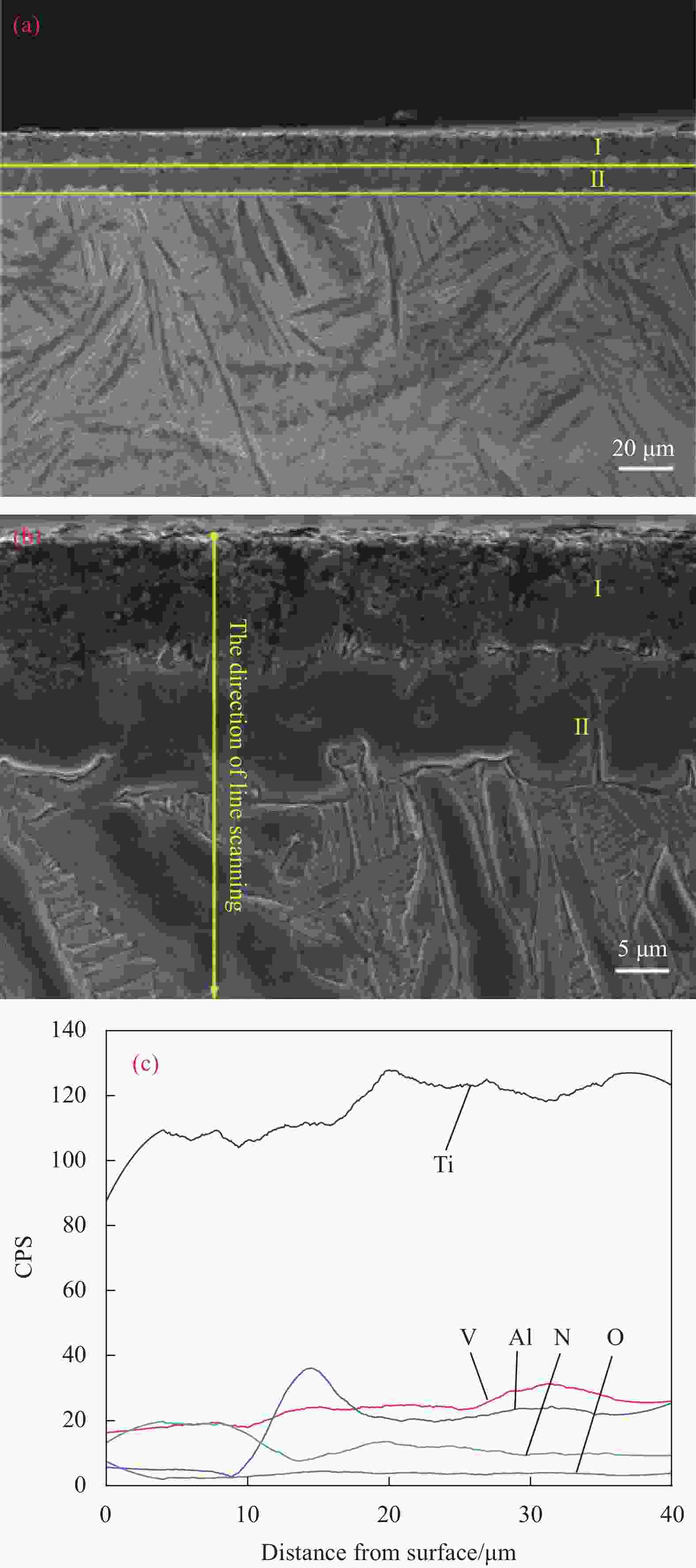

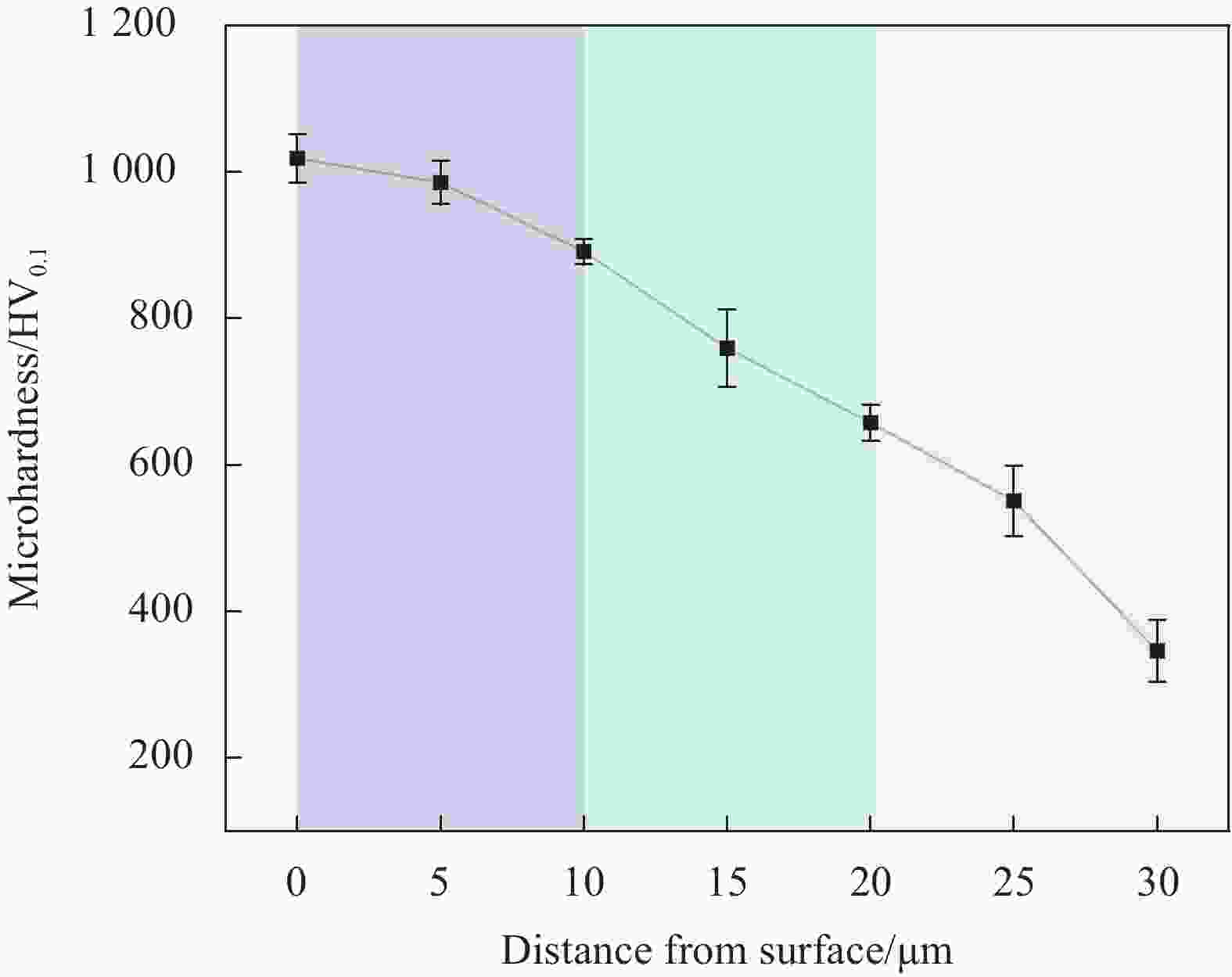

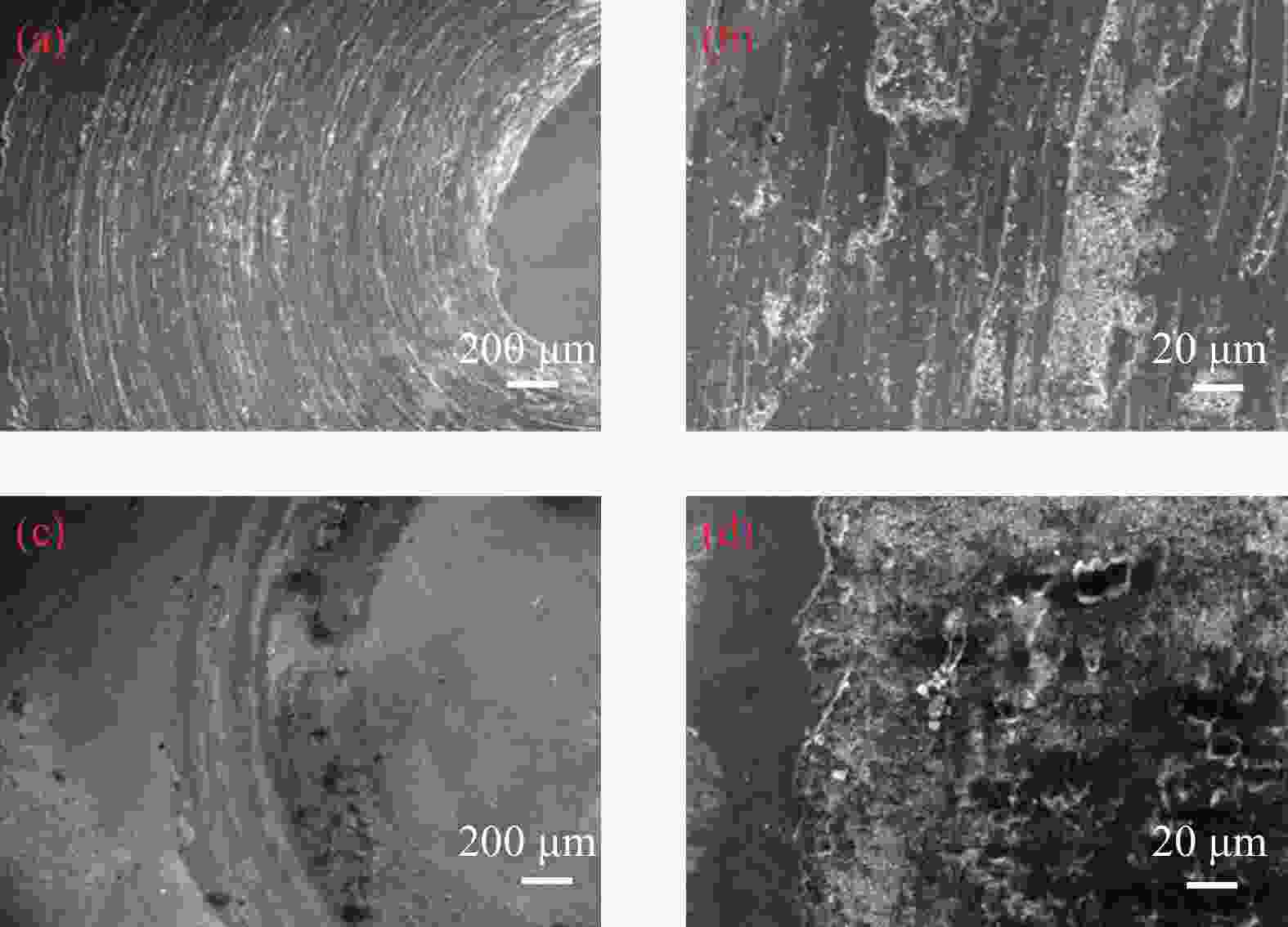

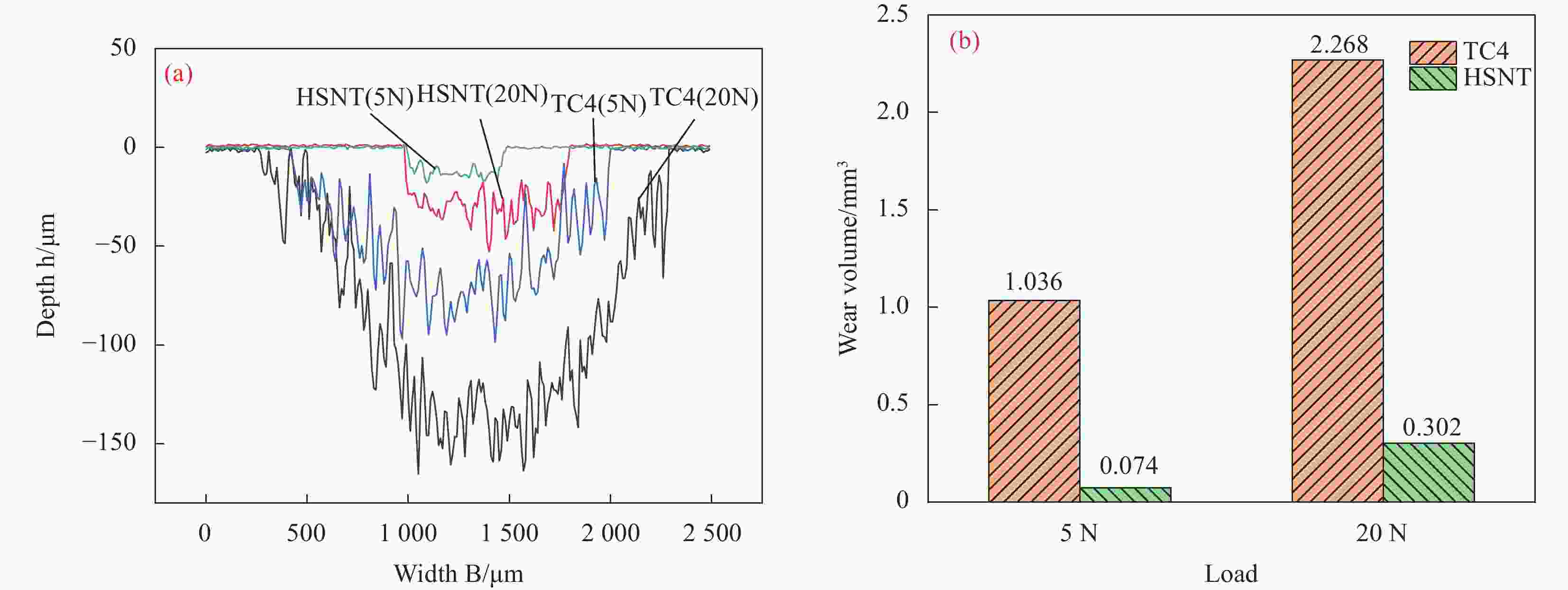

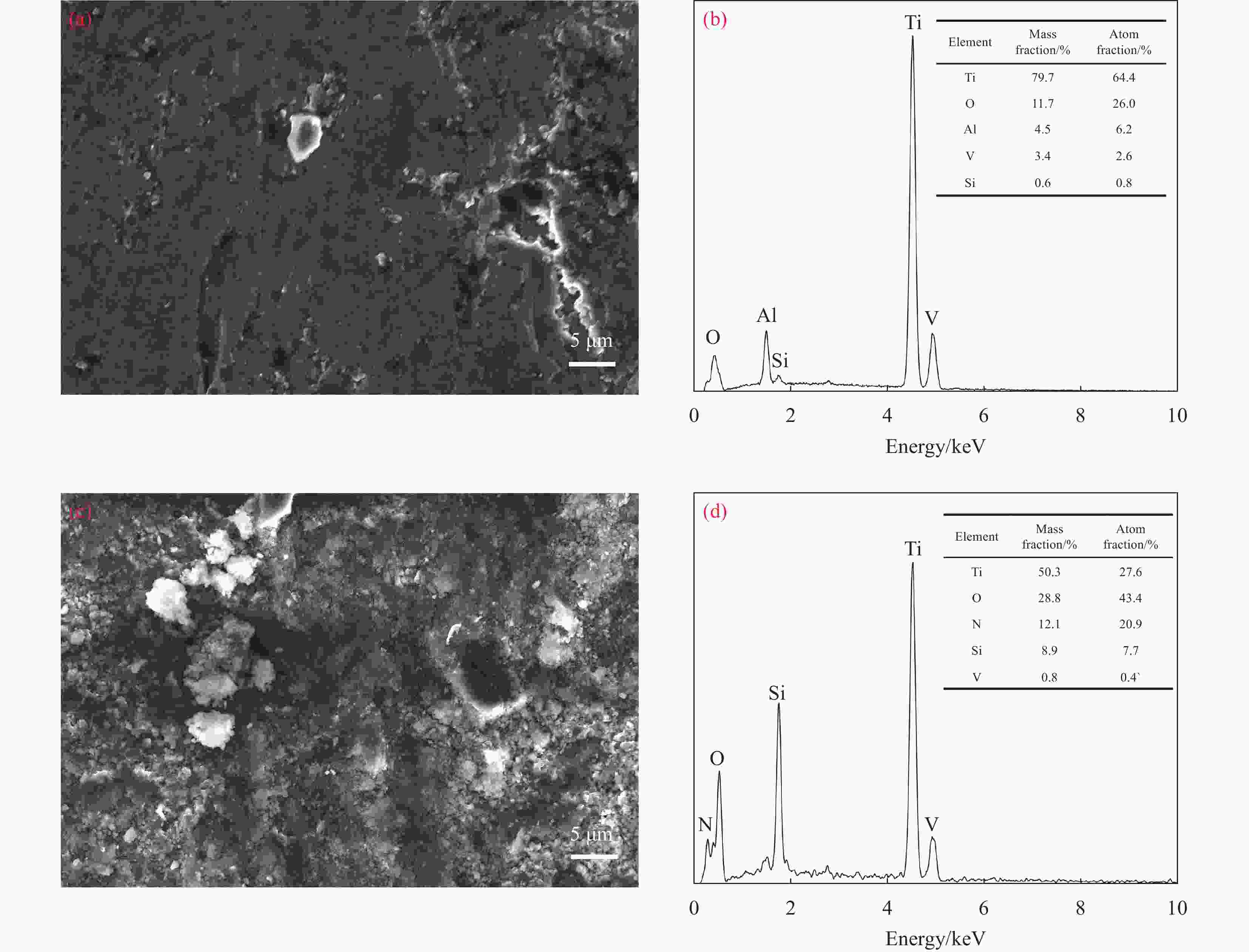

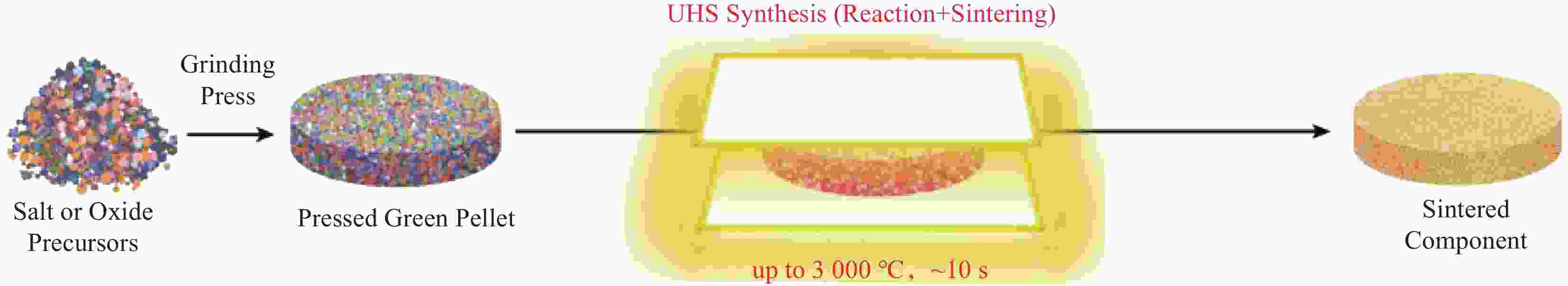

摘要: 为了改善TC4钛合金表面硬度、耐磨性较差的缺点,本文提出了基于超快高温烧结(UHS)工艺的快速渗氮处理(HSNT)表面处理方法。对TC4钛合金表面进行HSNT,利用X射线衍射仪和扫描电子显微镜研究试样的微观组织,采用维氏显微硬度计和摩擦磨损试验装置对试样进行力学性能测试。2 min即可在TC4钛合金表面形成改性层,改性层由两部分组成,最表层为氮化物层,厚度10 μm,平均显微硬度为973.55 HV0.1,主要成分为TiN;次表层为渗氮层,厚度10 μm,平均显微硬度为774.53 HV0.1,截面显微硬度整体呈现出阶梯分布的趋势。摩擦磨损试验发现,在20 N载荷下,经过HSNT的TC4的摩擦系数为0.406,降低了24.4%,经过HSNT的TC4的磨损体积为0.302 mm3,降低了86.7%。不同载荷下经过HSNT的TC4的摩擦系数和磨损体积始终小于TC4钛合金,且均随着载荷的增加而增大。在20 N载荷下,TC4的磨损机制主要表现为磨粒磨损和氧化磨损,经过HSNT的TC4的磨损机制主要表现为粘着磨损和氧化磨损。经过HSNT的TC4钛合金的性能得到了明显的改善,弥补了TC4硬度低,耐磨性差的缺点。Abstract: In order to improve the surface hardness and wear resistance of TC4 titanium alloy, a high-speed nitriding treatment (HSNT) based on Ultrafast High-temperature Sintering (UHS) process was proposed. HSNT was ap-plied to the surface of TC4 titanium alloy, and the microstructure of the sample was studied by X-ray diffractometer and scanning electron microscope. The mechanical properties of the sample were tested by Vickers microhardness tester and friction and wear test device. The modified layer can be formed on the surface of TC4 titanium alloy in 2 min. The modified layer consists of two parts. The outermost layer is the nitride layer, the thickness is about 10 μm, the average microhardness is 973.55 HV0.1, and the main component is TiN. The sub-surface layer is nitriding layer, the thickness is also about 10 μm, the average microhardness is 774.53 HV0.1, the cross-section microhardness overall shows a trend of ladder distribution. The friction and wear test shows that under 20 N load, the friction coefficient of TC4 with HSNT is 0.406, which is reduced by 24.4%, and the wear volume of TC4 with HSNT is 0.302 mm3, which is reduced by 86.7%. The friction coefficient and wear volume of TC4 with HSNT under different loads are always smaller than that of TC4 titanium alloy, and all increase with the increase of load. Under 20 N load, the wear mechanism of TC4 is mainly abrasive wear and oxidative wear, while the wear mechanism of TC4 with HSNT is mainly adhesive wear and oxidative wear. The performance of TC4 titanium alloy with HSNT has been significantly improved, making up for the shortcomings of low hard-ness and poor wear resistance of TC4.

-

Key words:

- TC4 titanium alloy /

- High-speed Nitriding Treatment /

- microstructure /

- microhardness /

- friction and wear

-

表 1 TC4钛合金的元素成分(wt%)

Table 1. Elemental compositions of TC4 titanium alloy(wt%)

Ti Alloying element Impurity element Al V Fe Si C N H O Bal. 5.5~6.8 3.5~4.5 ≤0.30 ≤0.10 ≤0.10 ≤0.05 <0.015 <0.015 表 2 摩擦磨损试验参数

Table 2. Parameters of frictional wear test

Load/N Friction pair Temperature/℃ Rotate speed/(r·min−1) Time/min Radius/mm 5

20Si3N4 20 500 30 2 -

[1] FENG X, ZHAO Y, NING W. Application of the Titanium Alloy in Civil Aviation[J]. Baosteel Technical Research, 2011, 5(4): 25-35. [2] DING R, GUO Z X. Microstructural evolution of a Ti–6Al–4V alloy during β-phase processing: experimental and simulative investigations[J]. Materials Science and Engineering:A, 2004, 365(2): 172-179. [3] 应扬, 李磊, 赵彬, 等. 钛合金的摩擦磨损性能及其改善方法[J]. 有色金属材料与工程, 2019, 40(3): 49-54.YING Y, LI L, ZHAO B. Friction and Wear Properties of Titanium Alloys and the Improving Methods[J]. Nonferrous Metal Materials and Engineering, 2019, 40(3): 49-54 (in Chinese). [4] 衣晓红, 樊占国, 张景垒, 等. TC4钛合金的固体渗硼[J]. 稀有金属材料与工程, 2010, 39(9): 1631-1635.YI X H, FAN Z G, ZHANG J L, et al. Solid-State Pack Boronizing of TC4 Titanium Alloy[J]. Rare Metal Materials and Engineering, 2010, 39(9): 1631-1635(in Chinese). [5] ZUO S, MIAO Q, LIANG W, et al. Effects of Pretreatment on Borocarburized of TC4 Titanium Alloy[J]. Materials Research Express, 2019, 6(5): 056505. doi: 10.1088/2053-1591/ab0070 [6] MENG Y G, BAI J, JIANG X J, et al. Effect of Zr on Isothermal Oxidation Behavior of TC4 Alloy at 600℃[J]. Vacuum, 2023, 213: 112112. doi: 10.1016/j.vacuum.2023.112112 [7] RASTKAR A R, SHOKRI B, BELL T. Structural and Mechanical Evaluation of the Effect of Oxygen Boost Diffusion on a Gamma Based Titanium Aluminide of Ti–45Al–2Nb–2Mn–1B[J]. Surface and Coatings Technology, 2008, 202(24): 6038-6048. doi: 10.1016/j.surfcoat.2008.07.001 [8] ÜSTEL F, ZEYTIN S. Growth Morphology and Phase Analysis of Titanium-based Coating Produced by Thermochemical Method[J]. Vacuum, 2006, 81(3): 360-365. doi: 10.1016/j.vacuum.2006.06.011 [9] 谭金花, 孙荣禄, 牛伟等. TC4合金激光熔覆材料的研究现状[J]. 材料导报, 2020, 34(15): 15132-15137.TAN J H, SUN R L, NIU W, et al. Research Status of TC4 Alloy Laser Cladding Materials[J]. Materials Reports, 2020, 34(15): 15132-15137(in Chinese). [10] KANYANE L R, ADESINA O S, POPOOLA A P, et al. Microstructural Evolution and Corrosion Properties of Laser Clad Ti-Ni on Titanium Alloy (Ti6Al4V)[J]. Procedia Manufacturing, 2019, 35: 1267-1272. doi: 10.1016/j.promfg.2019.06.086 [11] FENG J, WANG J, YANG K, et al. Microstructure and Performance of YTaO4 Coating Deposited by Atmospheric Plasma Spraying on TC4 Titanium Alloy Surface[J]. Surface and Coatings Technology, 2022, 431: 128004. doi: 10.1016/j.surfcoat.2021.128004 [12] WANG X, WANG X, SUN X, et al. Microstructure and Properties Evolution of Plasma Sprayed Al2O3-Y2O3 Composite Coatings during High Temperature and Thermal Shock Treatment[J]. Journal of Rare Earths, 2021, 39(6): 718-727. doi: 10.1016/j.jre.2020.09.008 [13] LIN B, CHEN X, CHEN J, et al. Facile Synthesis of Homogeneously Dispersed Carbon Nanotubes on TC4 Alloy Powder by in-situ CVD and its Growth Behavior[J]. Journal of Materials Research and Technology, 2023, 24: 9928-9938. doi: 10.1016/j.jmrt.2023.05.127 [14] SHI H, WANG Z, REN H, et al. The Research on Tool Wear of High Speed Milling Titanium Alloy TC4[C]// Seventh International Conference on Electronics and Information Engineering. SPIE, 2017, 10322: 882-88. [15] 杨闯, 刘静, 马亚芹, 等. TC4钛合金表面低压渗氮层的显微组织与耐磨性能[J]. 机械工程材料, 2016, 40(6): 98-101. doi: 10.11973/jxgccl201606021YANG C, LIU J, MA Y Q, et al. Microstructure and Wear Resistance of Low Pressure Nitrided Layer on TC4 Titanium Alloy Surface[J]. Materials for Mechanical Engineering, 2016, 40(6): 98-101(in Chinese). doi: 10.11973/jxgccl201606021 [16] ZHU X S, FU Y D, LI Z F, et al. Wear Resistance of TC4 by Deformation Accelerated Plasma Nitriding at 400℃[J]. Journal of Central South University, 2016, 23(11): 2771-2776. doi: 10.1007/s11771-016-3339-y [17] YANG Y L, ZHAO G J, ZHANG D, et al. Improving the Surface Property of TC4 Alloy by Laser Nitriding and Its Mechanism[J]. Acta Metallurgica Sinica, 2006, 19(2): 151-156. [18] WEN K, ZHANG C, GAO Y. Influence of Gas Pressure on the Low-temperature Plasma Nitriding of Surface-nanocrystallined TC4 Titanium Alloy[J]. Surface and Coatings Technology, 2022, 436: 128327. doi: 10.1016/j.surfcoat.2022.128327 [19] LIU G, LENG K, HE X, et al. Microstructure Evolution of Ti–6Al–4V under Cold Rolling + Low Temperature Nitriding Process[J]. Progress in Natural Science:Materials International, 2022, 32(4): 424-432. doi: 10.1016/j.pnsc.2022.06.004 [20] WANG C, PING W, BAI Q, et al. A General Method to Synthesize and Sinter Bulk Ceramics in Seconds[J]. Science, 2020, 368(6490): 521-526. doi: 10.1126/science.aaz7681 [21] DONG J, POUCHLY V, BIESUZ M, et al. Thermally-insulated ultra-fast high temperature sintering (UHS) of zirconia: A master sintering curve analysis[J]. Scripta Materialia, 2021, 203: 114076. doi: 10.1016/j.scriptamat.2021.114076 [22] BIESUZ M, GALOTTA A, MOTTA A, et al. Speedy bioceramics: Rapid densification of tricalcium phosphate by ultrafast high-temperature sintering[J]. Materials Science and Engineering:C, 2021, 127: 112246. doi: 10.1016/j.msec.2021.112246 [23] GUO R F, MAO H R, ZHAO Z T, et al. Ultrafast high-temperature sintering of bulk oxides[J]. Scripta Materialia, 2021, 193: 103-107. doi: 10.1016/j.scriptamat.2020.10.045 [24] LI L H, CHEN Y. Atomically Thin Boron Nitride: Unique Properties and Applications[J]. Advanced Functional Materials, 2016, 26(16): 2594-2608. doi: 10.1002/adfm.201504606 [25] 王培, 叶源盛. 钛合金表面激光熔覆h-BN固体润滑涂层[J]. 表面技术, 2015, 44(8): 44-48.WANG P, YE Y S. Solid Self-Lubricating Coatings on TC4 Titanium Alloy by Laser Cladding with h-BN[J]. Surface Technology, 2015, 44(8): 44-48(in Chinese). [26] 杨闯, 彭晓东, 刘静, 等. TC4钛合金低压真空渗氮处理[J]. 真空科学与技术学报, 2014, 34(11): 1146-1149.YANG C, PENG X D, LIU J, et al. Surface Modification of TC4 Titanium Alloy by Low Pressure Nitriding[J]. Chinese Journal of Vacuum Science and Technology, 2014, 34(11): 1146-1149(in Chinese). [27] 胡林泉, 缪强, 梁文萍, 等. 载荷对经氧-氮共渗的TC4钛合金摩擦学性能的影响[J]. 热处理, 2019, 34(3): 1-10.HU L Q, MIAO Q, LIANG W P, et al. Effect of Loads on Tribological Characteristics of Oxynitrided TC4 Titanium Alloy[J]. Heat Treatment, 2019, 34(3): 1-10(in Chinese). [28] LEE H, KANG H, KIM J, et al. Inward diffusion of Al and Ti3Al compound formation in the Ti–6Al–4V Alloy during high temperature gas nitriding[J]. Surface and Coatings Technology, 2014, 240: 221-225. doi: 10.1016/j.surfcoat.2013.12.027 [29] AICH S, RAVI CHANDRAN K S. TiB whisker coating on titanium surfaces by solid-state diffusion: Synthesis, microstructure, and mechanical properties[J]. Metallurgical and Materials transactions A, 2002, 33: 3489-3498. doi: 10.1007/s11661-002-0336-6 [30] ZHANG H, CUI H, MAN C, et al. The tribocorrosion resistance of TiN+ TiB/TC4 composite coatings and the synergistic strengthening effects of multi-level reinforcements[J]. Corrosion Science, 2023, 219: 111224. doi: 10.1016/j.corsci.2023.111224 [31] XIAO H, LIU X, LU Q, et al. Promoted low-temperature plasma nitriding for improving wear performance of arc-deposited ceramic coatings on Ti6Al4V alloy via shot peening pretreatment[J]. Journal of Materials Research and Technology, 2022, 19: 2981-2990. doi: 10.1016/j.jmrt.2022.06.067 [32] 李景阳, 王文波, 秦林, 等. TD3钛合金离子渗氮层的摩擦磨损性能[J]. 金属热处理, 2021, 46(9): 258-261.LI J Y, WANG W B, QIN L, et al. Friction and Wear Properties of Nitrided Layer of TD3 Titanium Alloy[J]. Heat Treatment of Metals, 2021, 46(9): 258-261(in Chinese). [33] CHEN W, ZHENG J, LIN Y, et al. Comparison of AlCrN and AlCrTiSiN coatings deposited on the surface of plasma nitrocarburized high carbon steels[J]. Applied Surface Science, 2015, 332: 525-532. doi: 10.1016/j.apsusc.2015.01.212 -

点击查看大图

点击查看大图

计量

- 文章访问数: 128

- HTML全文浏览量: 56

- 被引次数: 0

下载:

下载: