A method for predicting dome thickness layer by layer of filament wound composite pressure vessel

-

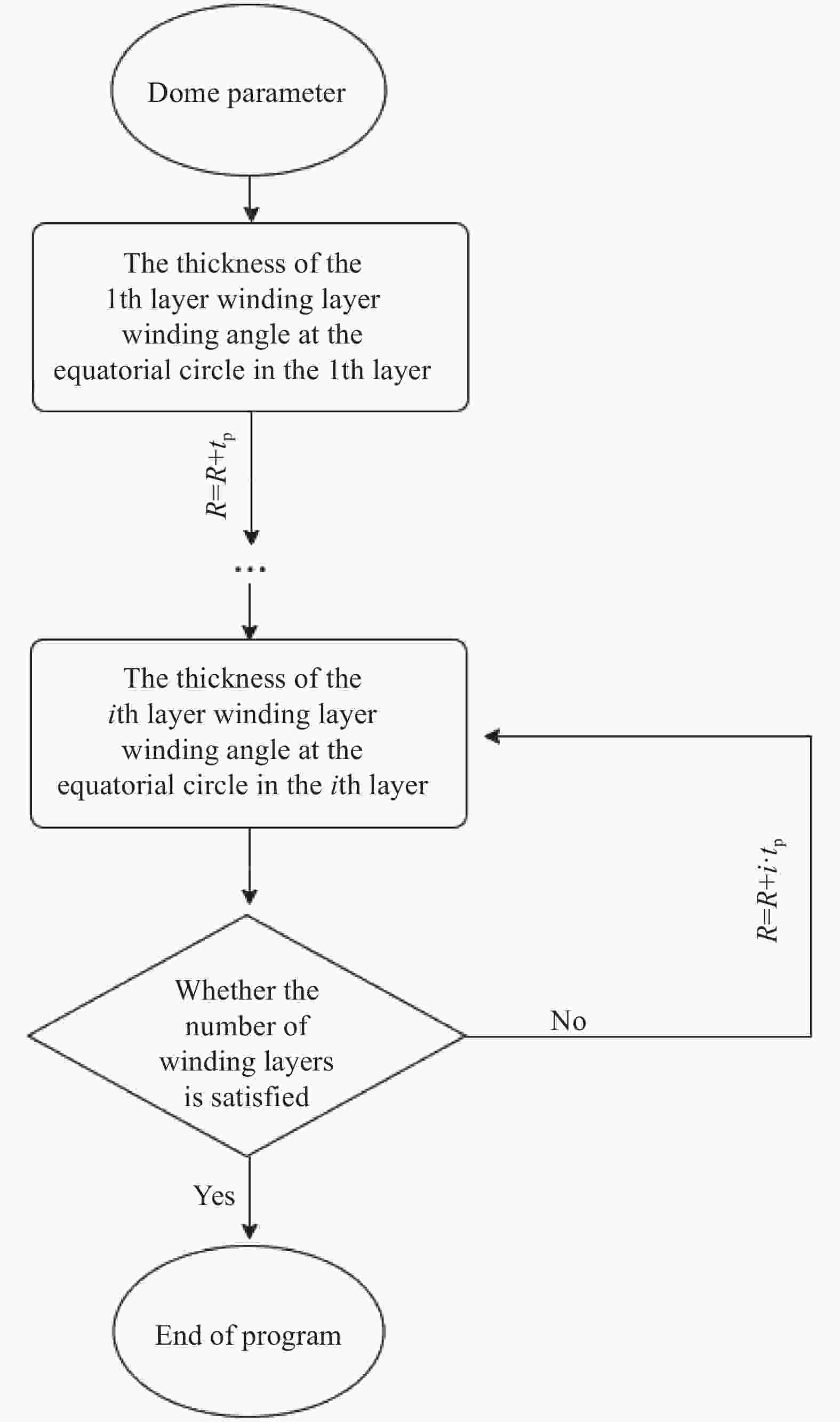

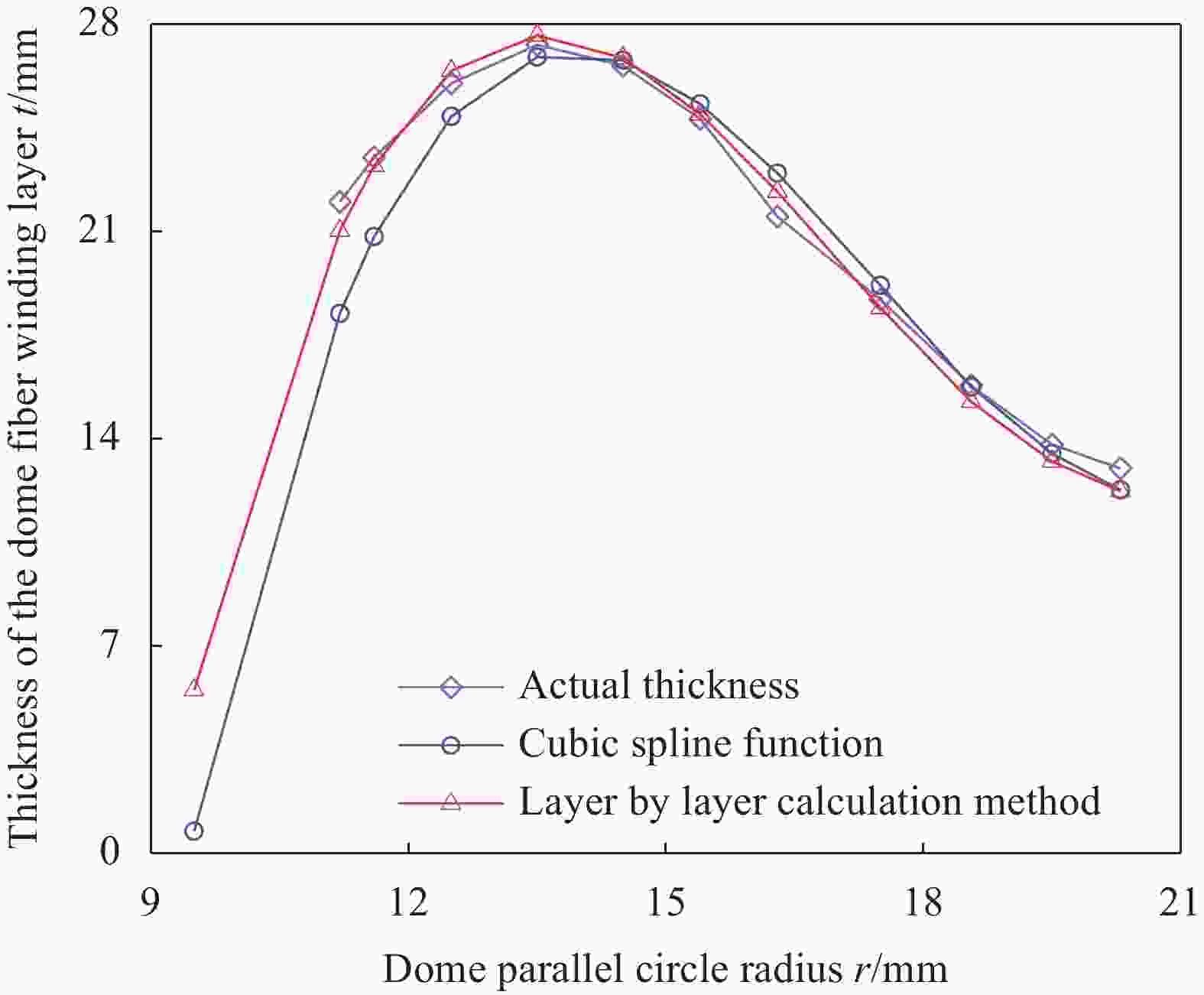

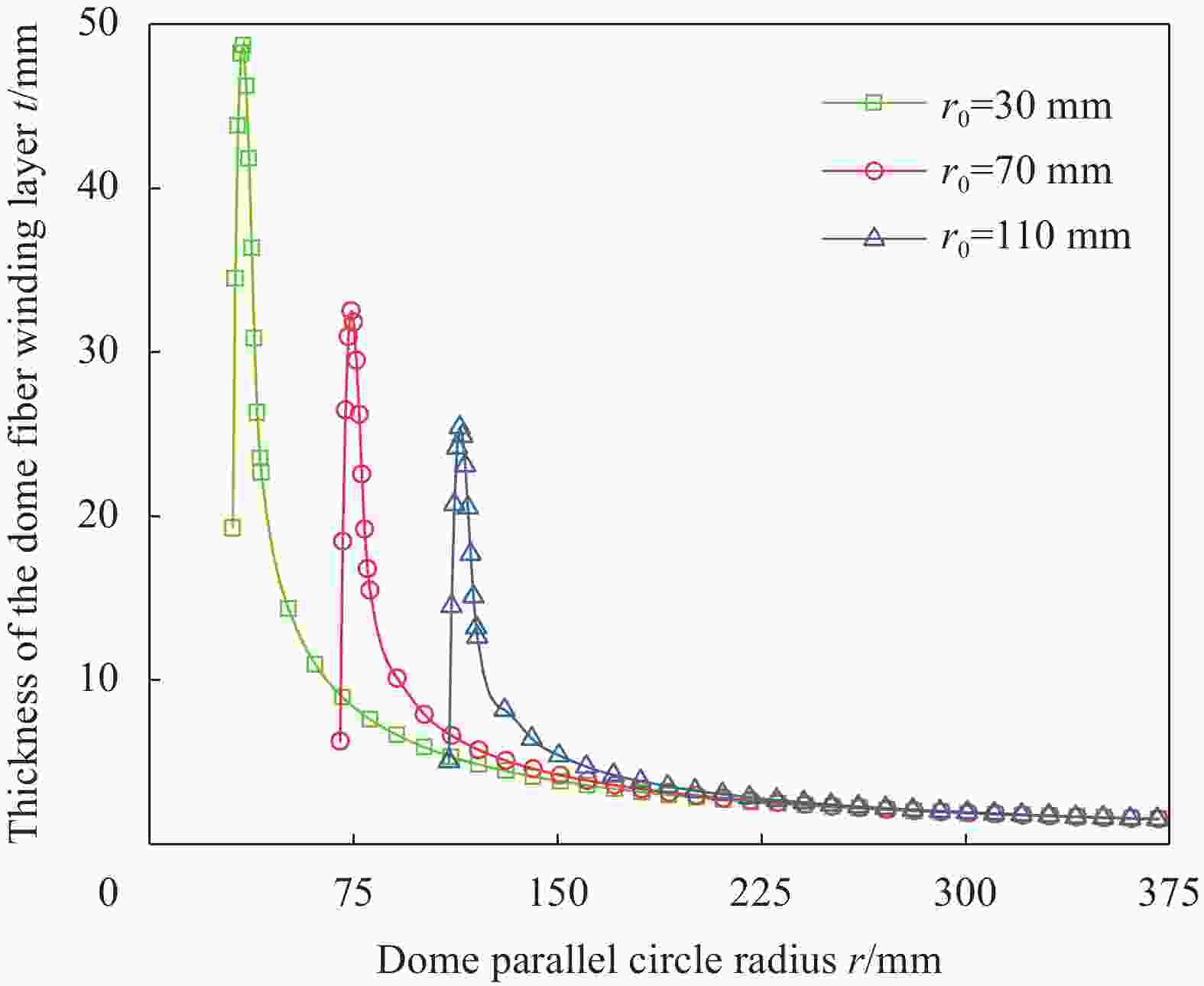

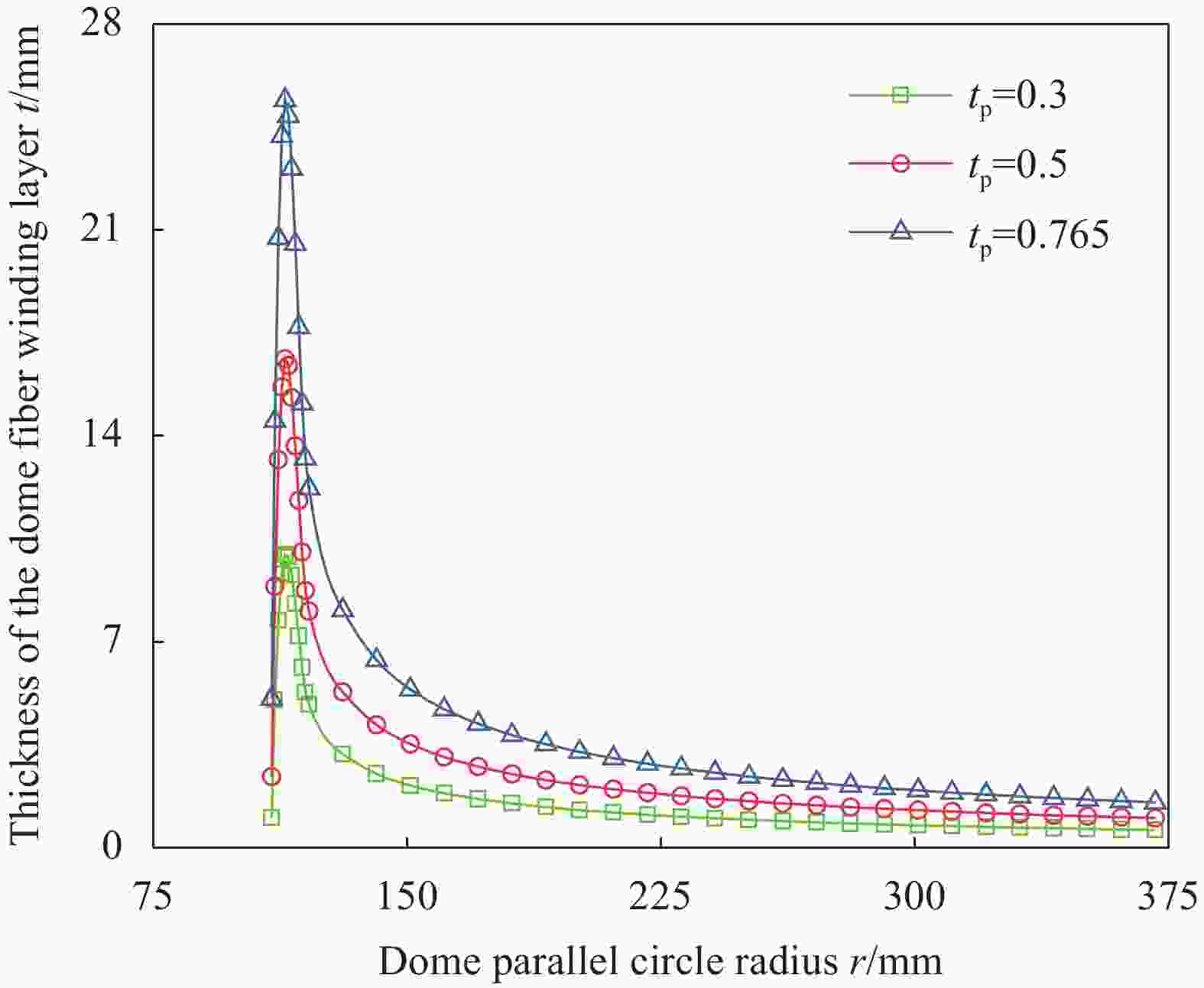

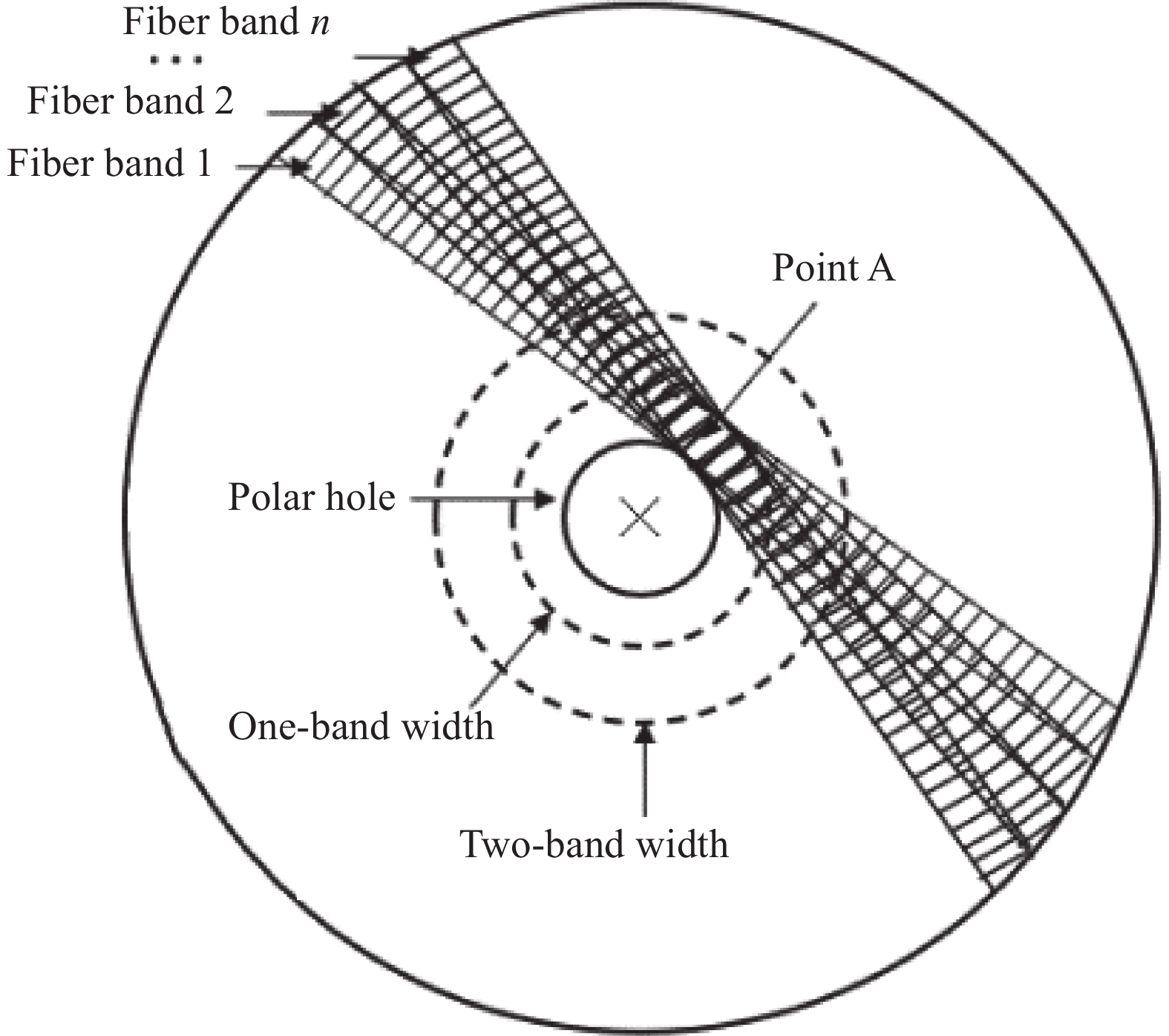

摘要: 受纤维缠绕成型工艺和封头段变曲率/厚度等的影响,复合材料压力容器封头段受力状态较为复杂,实现对封头段缠绕层厚度的逐层精准预测,对于构建高精度有限元模型、指导工程应用具有重要意义。针对上述问题,本文基于双公式法及三次样条函数法,发展了一种复合材料压力容器封头缠绕层厚度逐层预测方法,研究了极孔半径、单层纱带厚度和缠绕层数对封头厚度和赤道圆处缠绕角的影响。结果表明:随着极孔半径增大及单层纱带厚度减小,封头段纤维缠绕层厚度极值逐渐减小,赤道圆处缠绕角度的变化随极孔半径与单层纱带厚度减小逐层减小;进一步地,通过对比封头段每层缠绕层厚度,发现各缠绕层厚度由内层到外层随着平行圆半径增大呈现先变大后减小最终趋于相同的趋势。Abstract: Due to the influence of fiber winding molding process and the variable curvature/thickness of the dome, the stress state of the dome of the composite pressure vessel was relatively complicated. It was of great significance to accurately predict the thickness of the winding layer of the dome, which was of great significance for constructing a high-precision finite element model and guiding engineering applications. In order to solve the above problems, this study developed a layer-by-layer prediction method for the winding layer thickness of composite pressure vessel dome based on the dual formula method and cubic spline function method. The effects of polar hole radius, the thickness of single-layer yarn thickness and number of winding layers on the thickness and winding angle of the dome were studied. The results show that as the polar hole radius increases, the thickness of the single-layer yarn sheet in the dome decreases gradually, the extreme value of the fiber winding layer of the dome gradually decreases, and the variation of winding angle at the equatorial circle decreases with the decrease of the radius of the polar hole and the thickness of single-layer yarn. Furthermore, by comparing the thickness of each layer of the dome, it is found that the thickness of each winding layer from the inner layer to the outer increases first, then decreases, and finally tends to be the same as the radius of parallel circle increases.

-

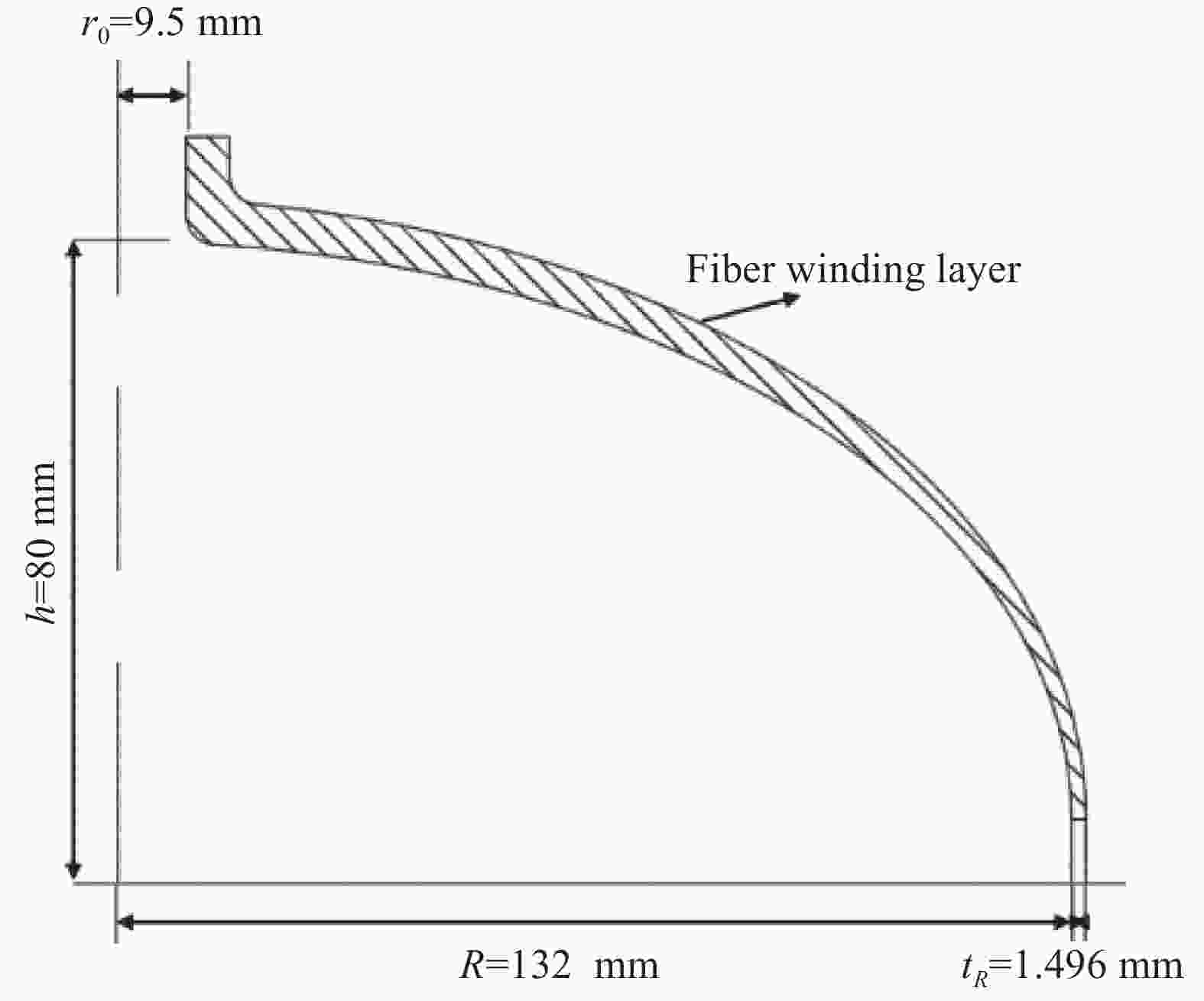

表 1 封头纤维缠绕层参数

Table 1. Parameters of the dome fiber winding layer

r0/mm R/mm tp/mm b/mm h/mm tR/mm 110 372.5 0.765 5.39 213 1.445 Notes: "r0" means the radius of the polar hole, "R" means the radius of the straight barrel section, "tp" means the thickness of the single-layer yarn sheet, "b" means the width of the yarn band, "h" means the height of the dome, "tR" means the thickness of spiral winding layer. 表 2 不同极孔半径时赤道圆处的缠绕角的变化情况

Table 2. Change of winding angle at the equatorial circle with different pole hole radius

Pole radius

r0/mmFirst layer winding angle α/(°) Second layer winding angle α/(°) Winding angle change α/(°) 30 4.6194 4.6099 0.0095 70 10.8314 10.8089 0.0225 110 17.1756 17.1394 0.0363 表 3 不同纱带厚度时赤道圆处缠绕角的变化情况

Table 3. Change of winding angle at the equatorial circle with different thickness of fiber bands

Thickness of a fiber band tp/mm First layer winding angle α/(°) Second layer winding angle α/(°) Winding angle change α/(°) 0.3 17.1756 17.1614 0.0142 0.5 17.1756 17.1519 0.0237 0.765 17.1756 17.1394 0.0363 -

[1] Gramoll K, Onoda J, Namiki F. Dome thcikness of filament wound pressure vessels[J]. Transactions of the Japan Society for Aeronautical and Space Sciences; (Japan), 1990, 33(100): 66-79. [2] 祖磊, 穆建桥, 王继辉, 等. 基于非测地线纤维缠绕压力容器线型设计与优化[J]. 复合材料学报, 2016, 33(5): 1125-1131. doi: 10.13801/j.cnki.fhclxb.20160112.003ZU Lei, MU Jianqiao, WANG Jihui, et al. Pattern design and optimization of filament-winding pressure vessels based on non-geodesics[J]. Acta Materiae Compositae Sinica, 2016, 33(5): 1125-1131(in Chinese). doi: 10.13801/j.cnki.fhclxb.20160112.003 [3] 边文凤, 贾宝贤, 杜善义. 伪弹性合金内衬复合材料压力容器的强度分析[J]. 复合材料学报, 2009, 26(1): 146-149. doi: 10.3321/j.issn:1000-3851.2009.01.025BIAN Wenfeng, JIA Baoxian, DU Shanyi. Anal ysis on the strength of composite pressure vessels with pseudo-elastic inner alloy lining[J]. Acta Materiae Compositae Sinica, 2009, 26(1): 146-149(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.01.025 [4] 沈军, 谢怀勤, 侯涤洋. 纤维缠绕聚合物基复合材料压力容器的可靠性设计[J]. 复合材料学报, 2006, 23(4): 124-128. (in Chinese doi: 10.3321/j.issn:1000-3851.2006.04.022SHEN Jun, XIE Huaiqin, HOU Diyang. Reliabil ity design of fiber wound reinforced plastics pressure vessel[J]. Acta Materiae Compositae Sinica, 2006, 23(4): 124-128(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.04.022 [5] Murthy P, Phoenix S. Designing of a Fleet-Leader Program for Carbon Composite Overwrapped Pressure Vessels[C]// 50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 17th AIAA/ASME/AHS Adaptive Structures Conference 11th AIAA No, 2009: 2517. [6] Che J L, Han M G, Chang S H. Prediction of composite layer thickness for Type III hydrogen pressure vessel at the dome part[J]. Composite Structures, 2021, 271(1-2): 114177. [7] Sato Takuya. Failure Modes and Stresses of Pressure Vessels and Piping (3) : Progressive Deformation Ratcheting and Fatigue Fracture (1)[J]. European Journal of Biochemistry, 2000, 267(24): 7006-7014. [8] 赫晓东, 王荣国, 矫维成, 等. 先进复合材料压力容器[M]. 北京: 科学出版社, 2016.HE Xiaodong, WANG Rongguo, JIAO Weicheng, et al. Advanced composite pressure vessel[M]. Beijing: , Science Press, 2016. (in Chinese) [9] Wang Y, Dai X, You H, et al. Research on the design of hydrogen supply system of 70 MPa hydrogen storage cylinder for vehicles[J]. International Journal of Hydrogen Energy, 2018, 43(41): 19189-19195. doi: 10.1016/j.ijhydene.2018.08.138 [10] Juan, Pedro, Berro, et al. 700 bar type IV high pressure hydrogen storage vessel burst–Simulation and experimental validation[J]. International Journal of Hydrogen Energy, 2015, 40(38): 13183-13192. doi: 10.1016/j.ijhydene.2015.05.126 [11] 左千. 纤维缠绕复合材料压力容器爆破压力研究与优化设计[D]. 浙江大学, 2022.ZUO Qian. Burst pressure study and design opti mization for filament wound composite pressure vessels[D]. Zhejiang University, 2022. (in Chinese) [12] Hartung R F. Planar-wound filamentary pressure vessels[J]. AIAA Journal, 1963, 1(12): 2842-2844. doi: 10.2514/3.2181 [13] Knoell A C. Structural design and stress analysis program for advanced composite filament-wound axisymmetric pressure vessels (COMTANK)[J]. Computer-Aided Design, 1972, 5(4): 267. [14] Gramoll K, Onoda J, Namiki F. Dome thcikness of filament wound pressure vessels[J]. Transactions of the Japan Society for Aeronautical and Space Sciences; (Japan), 1990, 33(100): 66-79. [15] 矫维成, 王荣国, 刘文博, 等. 纤维缠绕复合材料压力容器封头厚度预测[J]. 复合材料学报, 2010, 27(5): 116-121. doi: 10.13801/j.cnki.fhclxb.2010.05.015JIAO Weicheng, WANG Rongguo, LIU Wenbo, et al. Dome thickness prediction of composite pressure vessels[J]. Acta Materiae Compositae Sinica, 2010, 27(5): 116-121(in Chinese). doi: 10.13801/j.cnki.fhclxb.2010.05.015 [16] 顾付伟, 朱晓磊, 陆晓峰, 等. 一种改进的复合材料压力容器封头纤维厚度预测方法: 第十届全国压力容器学术会议[C]. 中国浙江杭州, 2021.GU Fuwei, ZHU Xiaolei, LU Xiaofeng, et la. An improved fiber thickness prediction method for composite pressure vessel dome: 10th National Pressure Vessel Academic Conference [C]. Hangzhou, Zhejiang, China, 2021. (in Chinese) [17] 张桂明, 宋春雨, 祖磊, 等. 纤维缠绕储氢气瓶逐层更新建模方法与性能评估[J]. 复合材料科学与工程, 2023, (2): 60-66. doi: 10.19936/j.cnki.2096-8000.20230228.008ZHANG Guiming, SONG Chunyu, ZU Lei, et la. Modeling method and performance evaluation of filament-wound hydrogen storage cylinder with layer-by-layer renewal[J]. Composite Materials Science and Engineering, 2023, (2): 60-66(in Chinese). doi: 10.19936/j.cnki.2096-8000.20230228.008 [18] 祖磊, 金书明, 张骞, 等. 基于精细化模型的纤维缠绕压力容器失效行为及容积特性影响因素分析[J]. 复合材料科学与工程, 2021, (12): 40-47. doi: 10.19936/j.cnki.2096-8000.20210528.031ZU Lei, JIN Shuming, ZHANG Qian, et la. Failure behavior and influencing factors of volume characteristics of filament wound pressure vessel based on refined model[J]. Composite Materials Science and Engineering, 2021, (12): 40-47(in Chinese). doi: 10.19936/j.cnki.2096-8000.20210528.031 [19] 陈学东, 范志超, 郑津洋, 等. 压力容器绿色制造技术[M]. 北京: 机械工业出版社: 2016.CHEN Xuedong, FAN Zhichao, ZHENG Jinyang, et la. Green manufacturing technology of pressure vessel[M]. Beijing: China Machine Press: 2016. (in Chinese) [20] Wang R, Jiao W, Liu W, et al. A new method for predicting dome thickness of composite pressure vessels[J]. Journal of Reinforced Plastics and Composites, 2010, 29(22): 3345-3352. doi: 10.1177/0731684410376330 [21] 鄢家乐, 陈学东, 范志超, 等. 70MPa车载Ⅳ型储氢气瓶铺层设计与实验验证[J]. 西安交通大学学报, 2022, 56(10): 71-80. doi: 10.7652/xjtuxb202210007YAN Jiale, CHEN Xuedong, FAN Zhichao, et la. Layered Design and Experimental Verification of 70 MPa Vehicle-Mounted Type Ⅳ Hydrogen Storage Cylinder[J]. Journal of Xi 'an Jiaotong University, 2022, 56(10): 71-80(in Chinese). doi: 10.7652/xjtuxb202210007 [22] 李德翔. 氢气瓶缠绕工艺分析及机构设计[D]. 东华大学, 2022.LI Dexiang. Winding process analysis and mechanism design of hydrogen cylinder[D]. Donghua University, 2022. (in Chinese) [23] 缐永兴. 碳纤维全缠绕复合气瓶缠绕方式的设计与选择[D]. 北京工业大学, 2015.XIAN Yongxing. Winding pattern design and se lection of full wrapped composite cylinders[D]. Beijing University of Technology, 2015. (in Chinese) [24] 王迪. 不同缠绕工艺下复合材料气瓶力学性能研究[D]. 大连理工大学, 2017.WANG Di. Study on mechanical properties of composite cylinder under different winding technology[D]. Dalian University of Technology, 2017. (in Chinese) [25] 贾晓龙, 李刚, 薛忠民, 等. 碳纤维/环氧树脂在橡胶内衬表面的全缠绕工艺设计[J]. 玻璃钢/复合材料, 2009, (2): 61-64.JIA Xiaolong, LI Gang, XUE Zhongmin, et la. Winding process design fiber/epoxy on rubber liner[J]. Glass Fiber Reinforced Plastic/ Composite Material, 2009, (2): 61-64(in Chinese). -

下载:

下载: