Mechanism of fiber grid reinforced with end self-locking anchorage

-

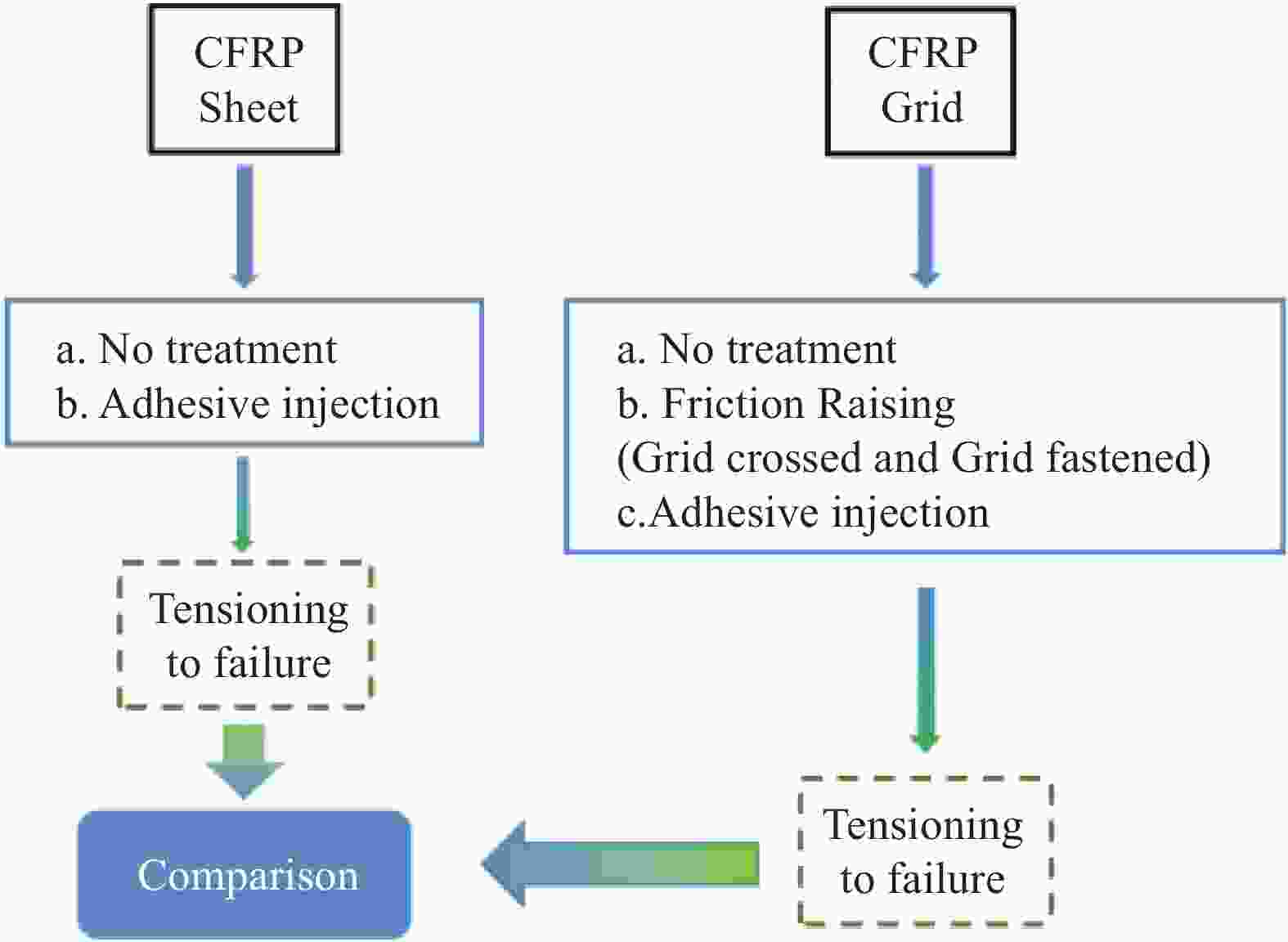

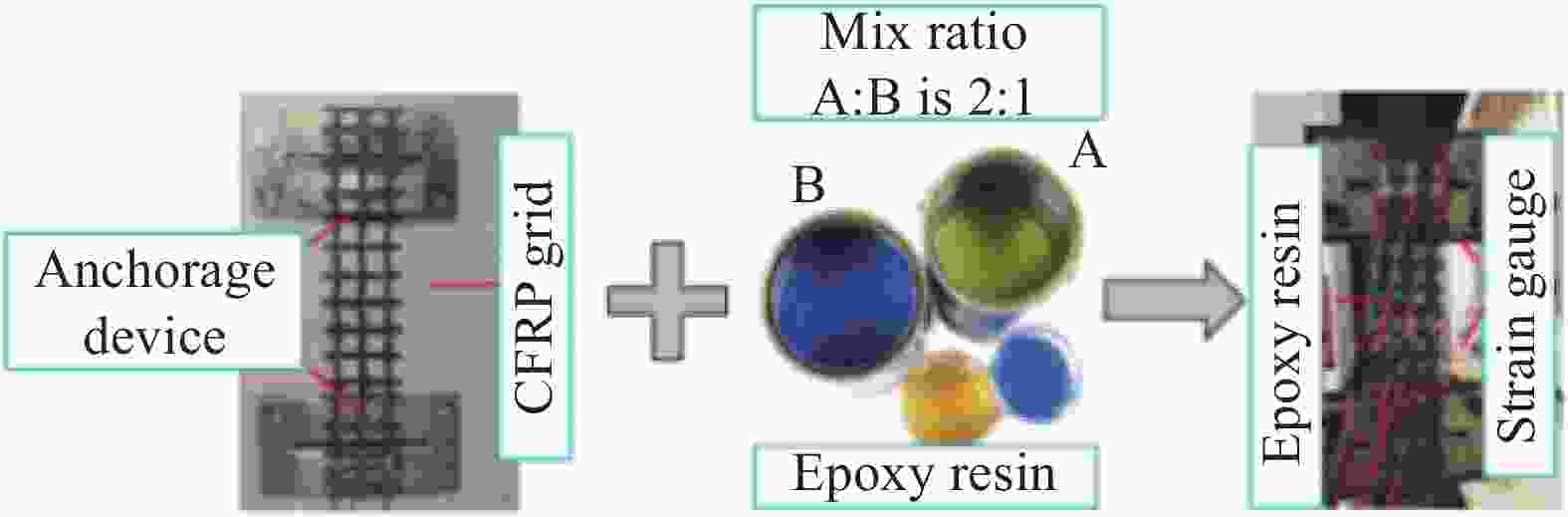

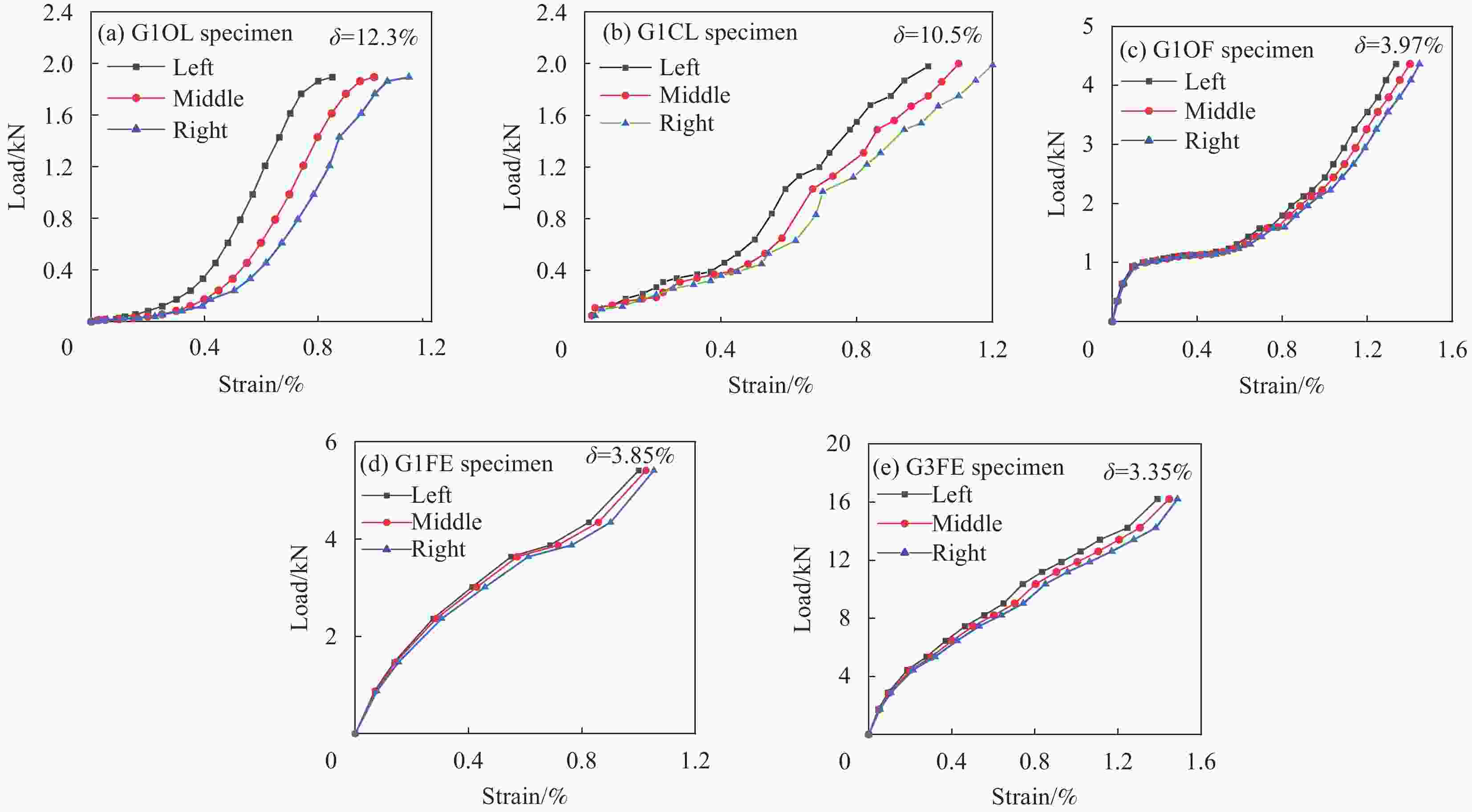

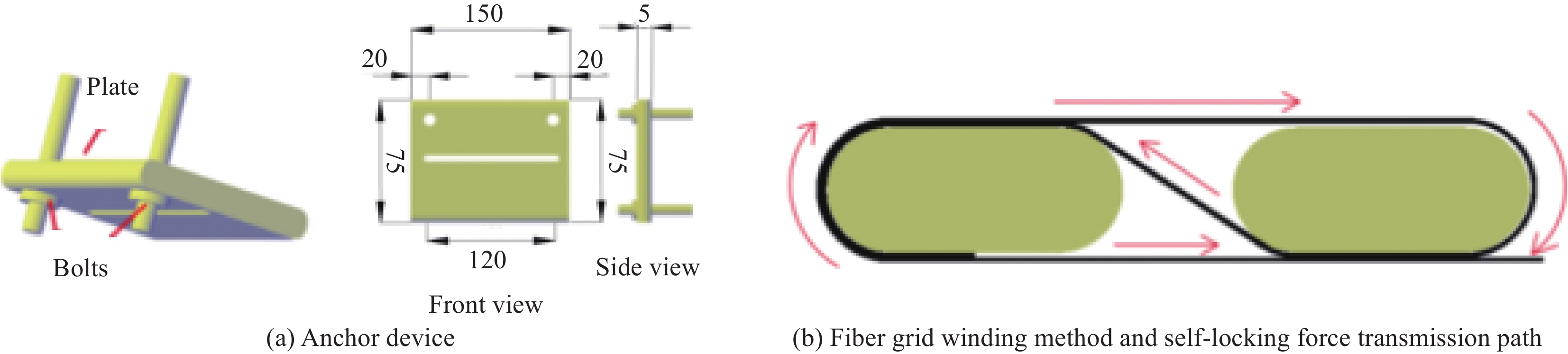

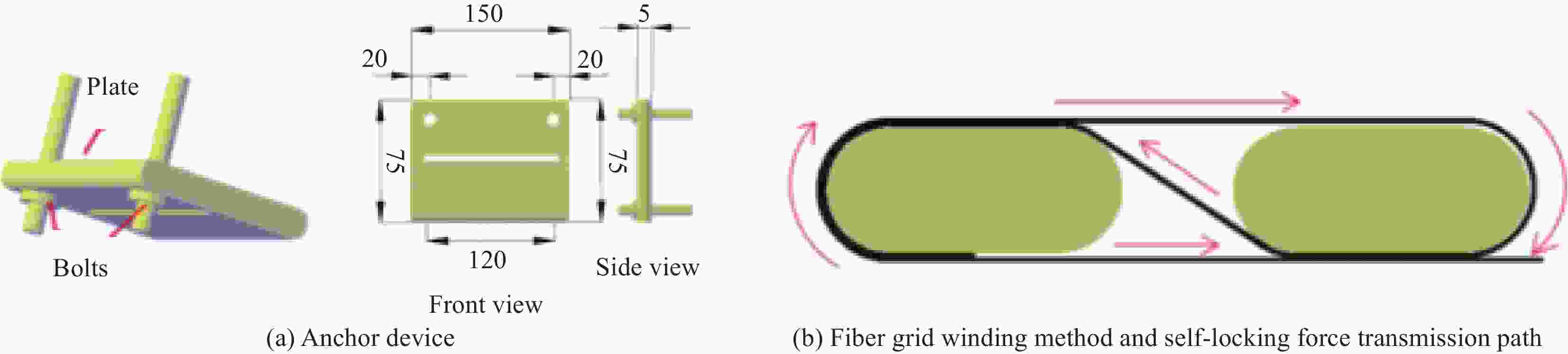

摘要: 为解决织物增强混凝土(Textile Reinforced Concrete,TRC)加固混凝土梁结构界面端部剥离问题,拟采用端部自锁技术将TRC板锚固在梁底。得益于该技术提供的端部锚固作用,即使发生界面剥离,TRC板仍能继续承载。但与纤维布相比,纤维网格由于各纤维束之间间隙大得多,协同受力性能较差,在不做处理的情况下能否实现自锁尚存疑问。为了提高纤维网格强度利用率,本文通过端部自锁锚固的纤维网格拉伸试验对其端锚自锁增强效应进行了研究。对纤维网格采取增大物理摩擦或增加化学粘结等措施,进而拉伸至破坏,分析比较了各试件的破坏模式、荷载-应变曲线,提出了纤维网格增强后承载力计算公式。试验结果表明:纤维网格端部自锁锚固时的强度利用率最大提升了60.66%,通过与端部锚板的有效结合,三层网格的抗拉承载力能够达到与单层纤维布相近的水平,应用自锁锚固技术有望在TRC加固混凝土梁中解决端部界面剥离问题,提升材料利用率,改善加固效果。所提出的纤维网格增强后承载力计算公式可为相关工程实践提供有益参考。Abstract: In order to solve the problem of interface end peeling of textile reinforced concrete (TRC) reinforced concrete beam structures, an end self-locking technique was proposed to anchor the TRC slabs at the bottom of the beams. Thanks to the end anchorage provided by this technique, the TRC slab can continue to carry the load even if interfacial spalling occurs. However, compared with the fiber cloth, the fiber mesh has poor synergistic stress performance due to much larger gaps between the fiber bundles, and it is doubtful whether self-locking can be achieved without treatment. In order to improve the utilization of fiber mesh strength, this paper investigates the end-anchor self-locking enhancement effect through the end self-locking anchored fiber mesh tensile test. Measures such as increasing physical friction or adding chemical bonding to the fiber grid are taken to stretch it to failure. The failure modes and load-strain curves of each specimen are analyzed and compared, and a formula for calculating the bearing capacity of the fiber grid after enhancement is proposed. The results show that even if the size of the fiber grid is limited, the strength utilization rate of the fiber grid under end anchoring is increased by 60.66% by reinforcement measures, and the tensile bearing capacity of the three-layer grid can be similar to that of the fiber sheet. The application of the self-locking anchorage technology is expected to solve the problem of end-interface spalling in TRC-reinforced concrete beams, enhance the material utilization, and improve the reinforcement effect. The proposed formula for calculating the bearing capacity after fiber mesh reinforcement can provide a useful reference for related engineering practice.

-

Key words:

- fiber grid /

- end anchored /

- self locking /

- tensile test

-

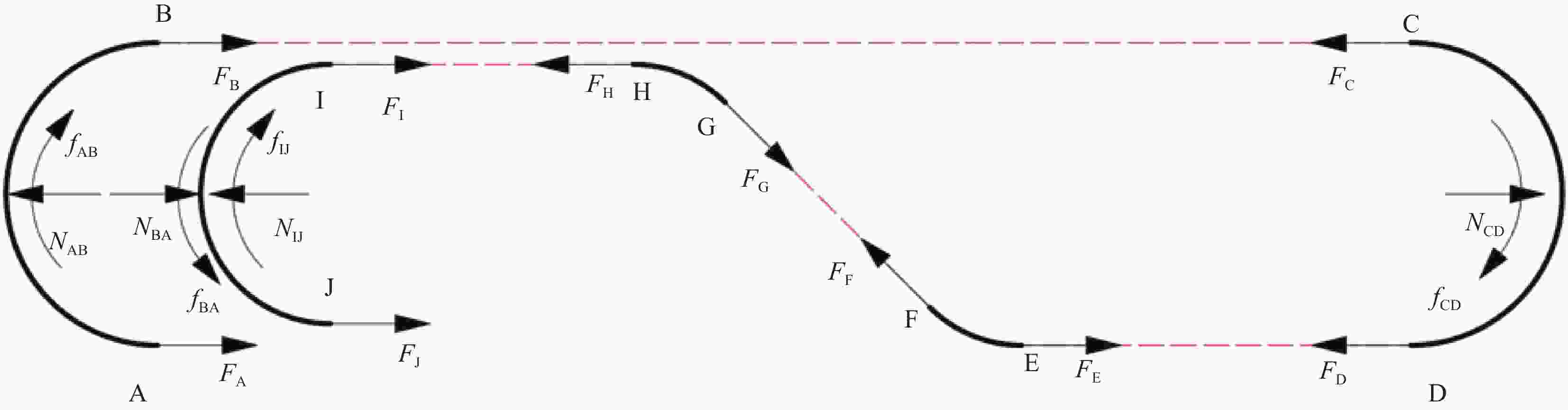

图 6 自锁情况网格缠绕部分力学模型[24]

Figure 6. Mechanical model of mesh winding in self-locking condition[24]

NIJ represents the equivalent normal force of each section of the strip; fIJ represents the tangential friction force of each section of the strip; FI represents the axial force at positions I of the strip. For example, FA and FH respectively represent the axial forces at the ends A and H of the strip

表 1 试件概况汇总、试验结果对比

Table 1. Summary of specimens and comparison of test results

Specimen

numberExperimental parameters Performance parameters Layers Whether increased

contact treatmentClamp loosened/

fastenedWhether epoxy

impregnationUltimate loads /kN Ultimate

strength/

MPaMaterial

strength/

MPaIntensity utilization/

%Theoretical/experimental

values of ultimate

loads/(kN·kN-1)G1OL 1 No loosened No 1.9 719 2169 33.18 - G1CL Yes 2 757 2169 34.93 - G1OF No fastened 4.5 1704 2169 78.59 4.4/4.5=0.98 G1FE Yes 5.4 2035 2169 94.3 5.3/5.4=0.98 G3 FE 3 16.2 2043 2169 94.3 15.9/16.2=0.98 SE 1 21.2 3173 3319 95.62 21.6/21.2=1.02 SN 15.2 2275 3319 68.56 —— Notes: G (Grid) represents fiber grid, S (CFRP sheet) represents CFRP sheet; O (Overlapped) represents no treatment, i.e., the grid is overlapped vertically; C (Crossed) represents increased contact of the grid, i.e., the grid is staggered vertically; L (Loosened) represents no external force fastening, i.e., loose; F (Fastened) represents fastening with external force, i.e., tight; E (Epoxy) represents epoxy resin impregnated adhesive, N (Not) represents not impregnated. The number represents the number of layers of fiber grid. Example: G3 FE represents 3 layers of fiber grid impregnated with epoxy resin and fastened with external force. Ultimate strength = ultimate load/cross-sectional area, intensity utilization = ultimate strength/material strength × 100%. 表 2 材料性能参数

Table 2. Properties of selected materials

Material Kind Density /(kg·m−2) Theoretical

thickness/mmElastic

modulus/GPaTensile

strength/MPaUltimate

strain/µεFiber sheet T700SC12K/0500 300 0.167 230 3319 14430 Fiber grid CFN200/200 - 0.047 124 2169 17520 Epoxy resin CFSR−A/B - - 4.0 55 - 表 3 不同工况试件拉伸破坏失效模式

Table 3. Failure modes of different specimens

Material No processing increasing

contact areaClamp

clamping1 layer&

epoxy impregnation3 layers&

epoxy impregnationFiber grid

Fiber sheet

—————

———— -

[1] 冯鹏, 陆新征, 叶列平. 纤维增强复合材料建设工程应用技术[M]. 中国建筑工业出版社, 2011.FENG Peng, LU Xinzheng, YE Lieping. Application technology of fiber reinforced composite material construction engineering[M]. China Building Industry Press, 2011(in Chinese). [2] RAHIMI H, HUTCHINSON A. Concrete beams strengthened with externally bonded FRP plates[J]. Composite Construction, 2001, 5(1): 44-56. doi: 10.1061/(ASCE)1090-0268(2001)5:1(44) [3] CROMWELL JR, HARRIES KA, SHAHROOZ BM. Environmental durability of externally bonded FRP materials intended for repair of concrete structures[J]. Construction and Building Materials, 2011, 25(5): 2528-2539. doi: 10.1016/j.conbuildmat.2010.11.096 [4] AKTAS M, KARAKUZU R. Determination of Mechanical Properties of Glass-Epoxy Composites in High Temperatures[J]. Polymer Composites, 2009, 30(10): 1437-1441. doi: 10.1002/pc.20708 [5] JCPH G, AL-MAHAIDI R, WONG M B. Bond characteristics of CFRP plated concrete members under elevated temperatures[J]. Composite Structures, 2006, 75: 199-205. doi: 10.1016/j.compstruct.2006.04.068 [6] XIE Jianhe, LU Zhongyu, GUO Yongchang, et al. Durability of CFRP Sheets and Epoxy Resin Exposed to Natural Hygrothermal or Cyclic Wet−Dry Environment[J]. Polymer Composites, 2019, 40(2): 553-567. doi: 10.1002/pc.24687 [7] PATRÍCIA S, PEDRO F, FERNANDO C. Effects of different environmental conditions on the mechanical characteristics of a structural epoxy[J]. Polymer Composites, 2016, 88: 55-63. [8] LETTIERI M, FRIGIONE M. Effects of humid environment on thermal and mechanical properties of a cold-curing structural epoxy adhesive[J]. Construction and Building Materials, 2012, 30: 753-760. doi: 10.1016/j.conbuildmat.2011.12.077 [9] AL-LAMI K, D'ANTINO T, COLOMBI P. Durability of FabricReinforced Cementitious Matrix (FRCM) Composites: A Review[J]. Applied sciences-bacel, 2020, 10(5): 1714. doi: 10.3390/app10051714 [10] AYGORMEZ Y, CANPOLAT O, AL-MASHHADANI MM. Assessment of geopolymer composites durability at one year age[J]. Journal of Building Engineering, 2020, 32. [11] SAHMARAN M, LI VC. Durability of mechanically loaded engineered cementitious composites under highly alkaline environments[J]. Cement Concrete Composites, 2008, 30(2): 72-81. doi: 10.1016/j.cemconcomp.2007.09.004 [12] LIU Hezhi, ZHANG Qian, Li V, et al. Durability study on engineered cementitious composites (ECC) under sulfate and chloride environment[J]. Construction and Building Materials, 2017, 133: 171-181. doi: 10.1016/j.conbuildmat.2016.12.074 [13] ZHU Miaochang, ZHU Jihua, TAMON U. Bond behavior of carbon fabric reinforced cementitious matrix (FRCM) composites considering matrix impregnation[J]. Composite Structures, 2021, 262. [14] RAOOF SM, KOUTAS LN, BOURNAS DA. Textile−reinforced mortar (TRM) versus fiber−reinforced polymers (FRP) in flexural strengthening of RC beams[J]. Composite Part B−Engineering, 2015, 77: 338-348. doi: 10.1016/j.compositesb.2015.03.055 [15] PAPANICOLAOU CG, PAPANTONIOU IC. Mechanical Behavior of Textile Reinforced Concrete (TRC)/Concrete Composite Elements[J]. Journal of Advanced Concrete Technology, 2010, 8(1): 35-47. doi: 10.3151/jact.8.35 [16] KONG K, MESTICOU Z, MICHEL M, et al. Comparative characterization of the durability behavior of textile−reinforced concrete (TRC) under tension and bending[J]. Composite. Structures, 2017, 179: 107-123. doi: 10.1016/j.compstruct.2017.07.030 [17] 徐世烺, 尹世平, 蔡新华. 纤维编织网增强混凝土加固钢筋混凝土梁受弯性能研究[J]. 土木工程学报, 2011, 44(04): 23-34.XU Shiyi, YIN Shiping, CAI Xinhua. Study on bending performance of reinforced concrete beams reinforced with fiber woven mesh[J]. China Civil Engineering Journal, 2011, 44(04): 23-34(in Chinese). [18] YIN Shiping, LI Yao, LI Shichang, et al. Seismic Performance of RC Columns Strengthened with Textile−Reinforced Concrete in Chloride Environment[J]. Journal of Composite Construction, 2020, 24(1): 04019062. doi: 10.1061/(ASCE)CC.1943-5614.0000992 [19] 张勤. 织物增强混凝土(TRC)加固RC梁正截面抗弯性能试验研究[D]. 江苏大学, 2009.ZHANG Qin. Experimental study on bending performance of positive section RC beam reinforced with fabric reinforced concrete (TRC)[D]. Jiangsu University, 2009(in Chinese). [20] ZHOU Chaoyang, YU Yanan, XIE Enli. Strengthening RC beams using externally bonded CFRP sheets with end self−locking[J]. Composite Structures, 2020, 241. [21] 周朝阳, 于亚男, 熊造, 等. CFRP布端绕双杆自锁加固凝土窄梁抗弯试验[J]. 复合材料学报, 2018, 35(08): 2216-2221.ZHOU Chaoyang, YU Yanan, XIONG Zao, et al. Bending resistance test of CFRP cloth end around double rod self-locking reinforced concrete narrow beam[J]. AMCS, 2018, 35(08): 2216-2221(in Chinese). [22] GHAHSAREH FM, MOSTOFINEJAD D. Groove classification in EBROG FRP-to-concrete joints. Construction and Building Materials 275 (2021) 122169 [23] 中国国家标准局. 定向纤维增强塑料拉伸性能试验方法GB/T 3354−1999[S]. 北京: 中国标准出版社, 2011.National Institute of Standards and Technology of the People’s Republic of China. Test method for tensile properties of directional fiber reinforced plastics GB/T 3354−1999 [S]. Beijing: China Standards Press, 2011(in Chinese). [24] 刘君. U形碳纤维带预应力技术及其抗剪加固持载钢筋混凝土梁的性能与设计[D]. 中南大学LIU Jun. Performance and design of U-shaped carbon fiber with prestressing technology and its shear reinforcement reinforced concrete beam [D]. Central South University(in Chinese). [25] 尹世平, 徐世烺. 纤维编织网增强混凝土的拉伸力学模型[J]. 复合材料学报, 2012, 29 ( 5) : 222−229.YIN Shiping, XU Shiyi, Tensile Mechanics Model of Fiber Braided Mesh Reinforced Concrete[J]. Journal of Composites, 2012, 29 ( 5): 222−229(in Chinese). -

下载:

下载: