Construction of Se@TiO2 nanostructures on polyester surface and investigation of the photocatalytic and antibacterial properties

-

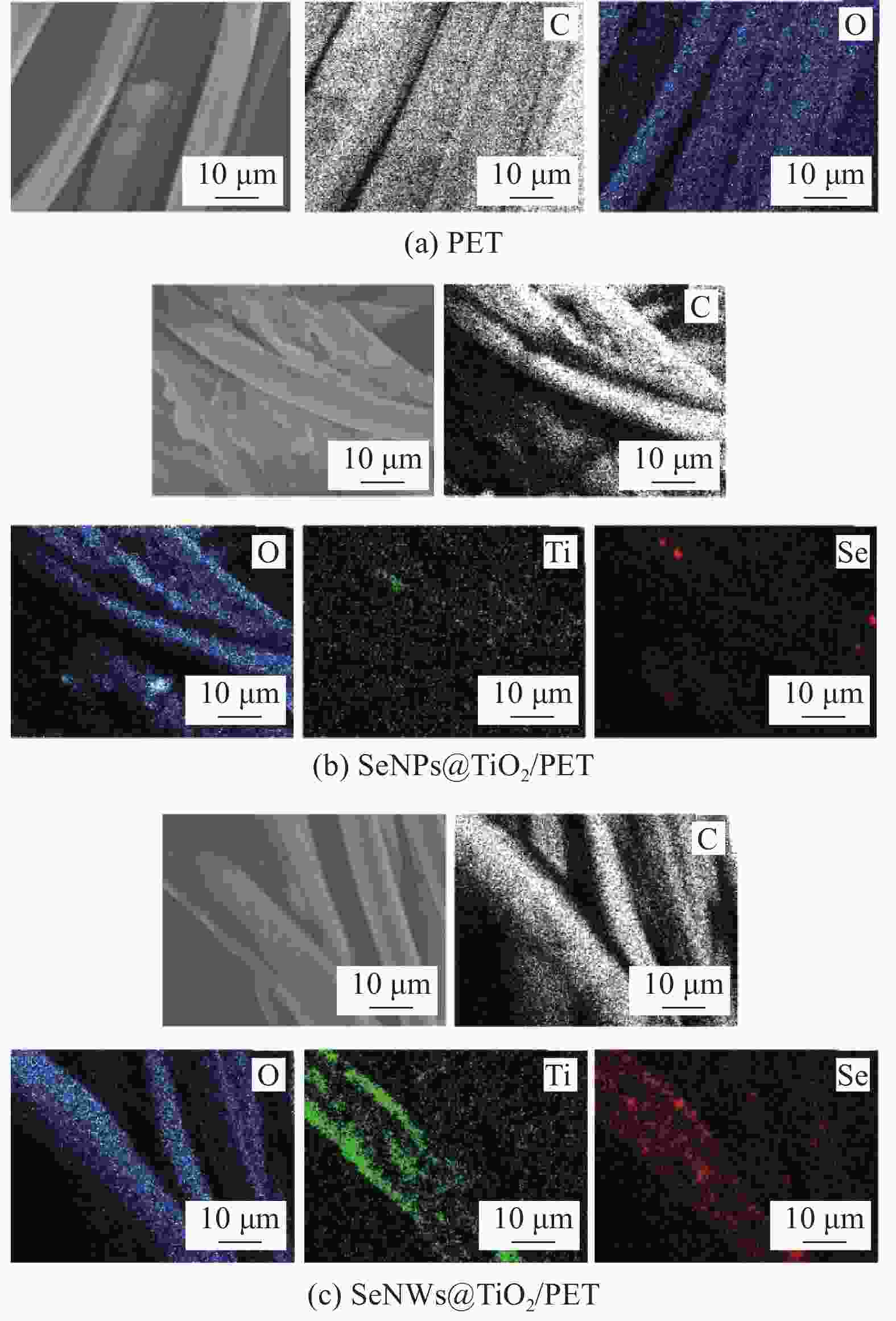

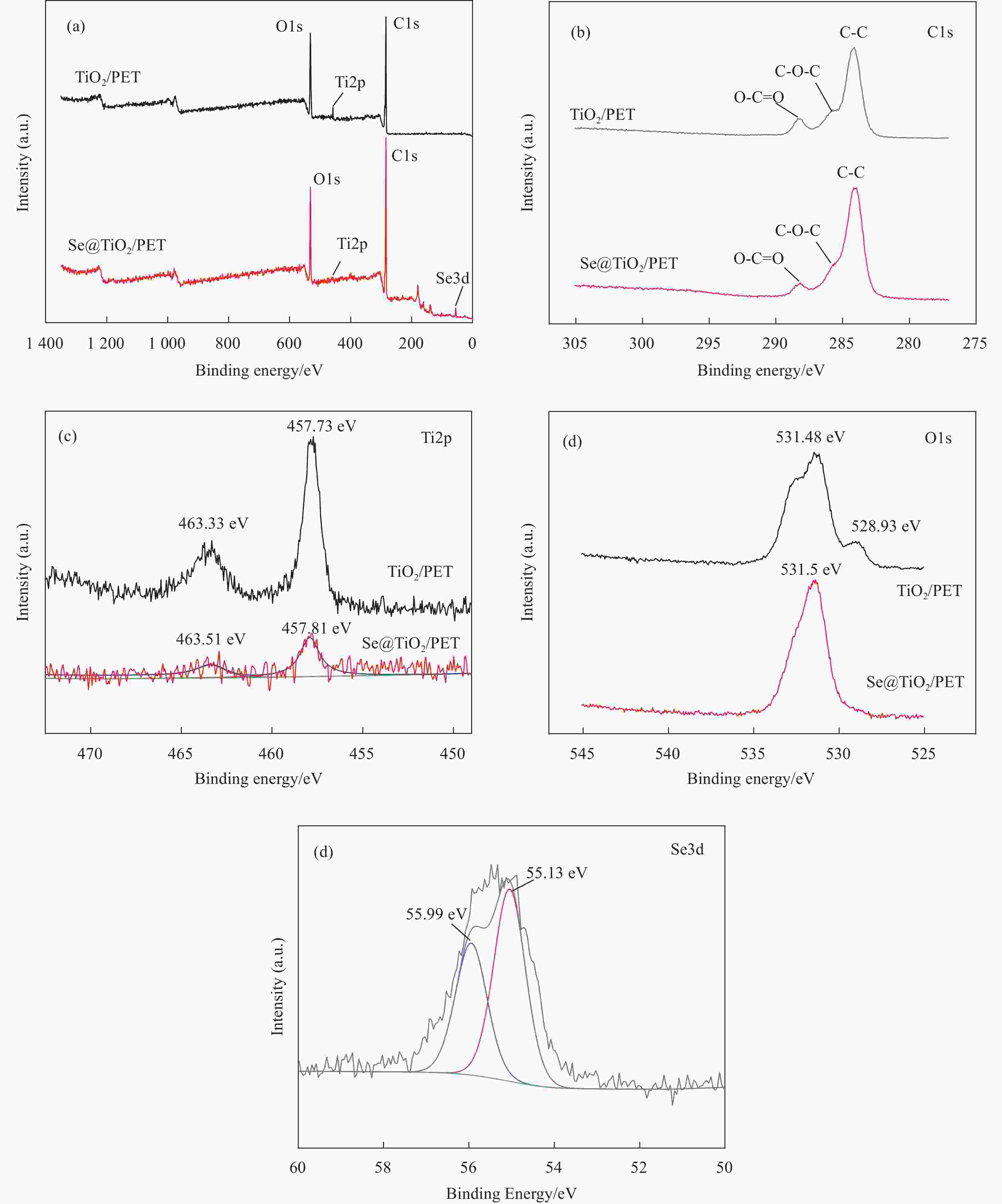

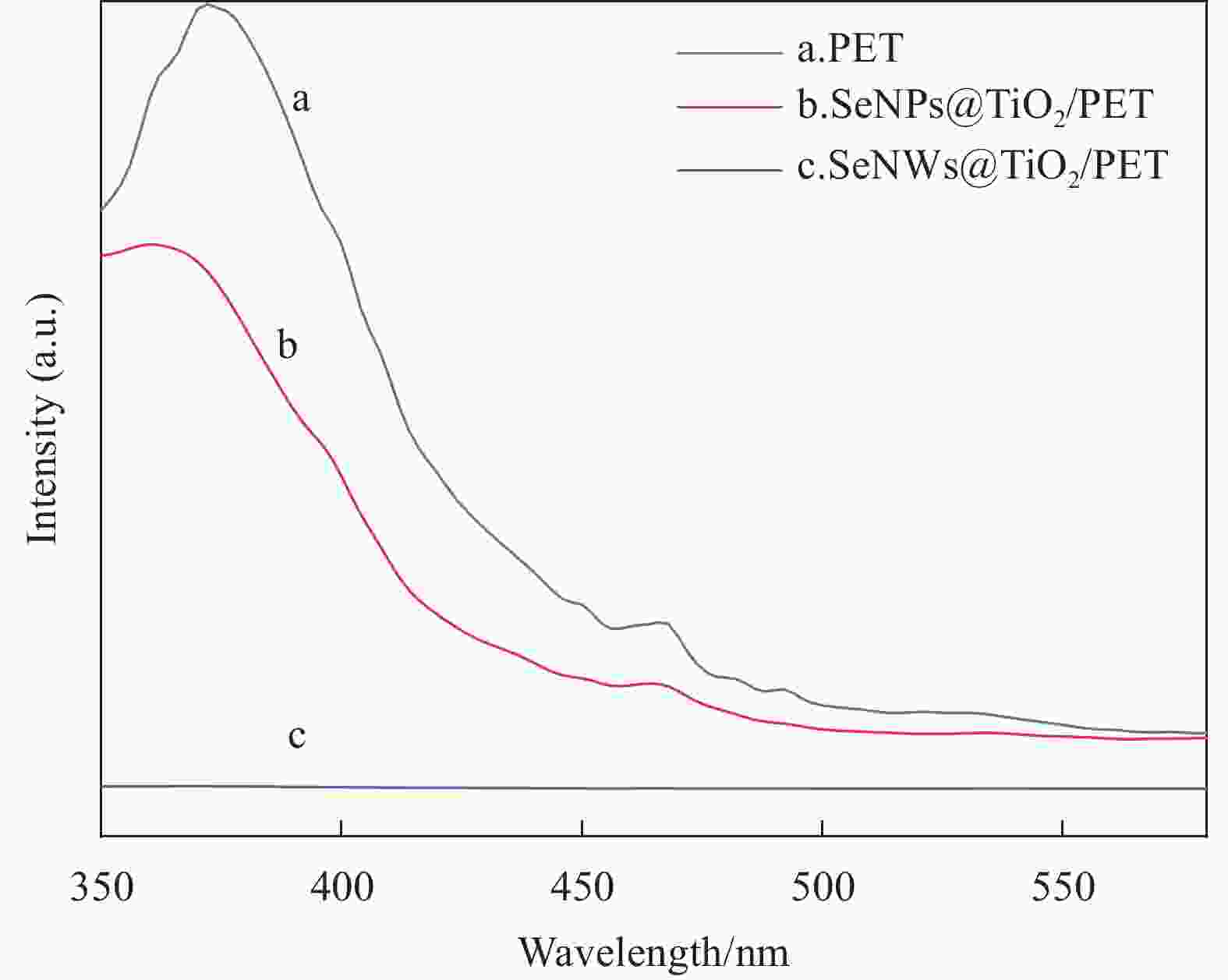

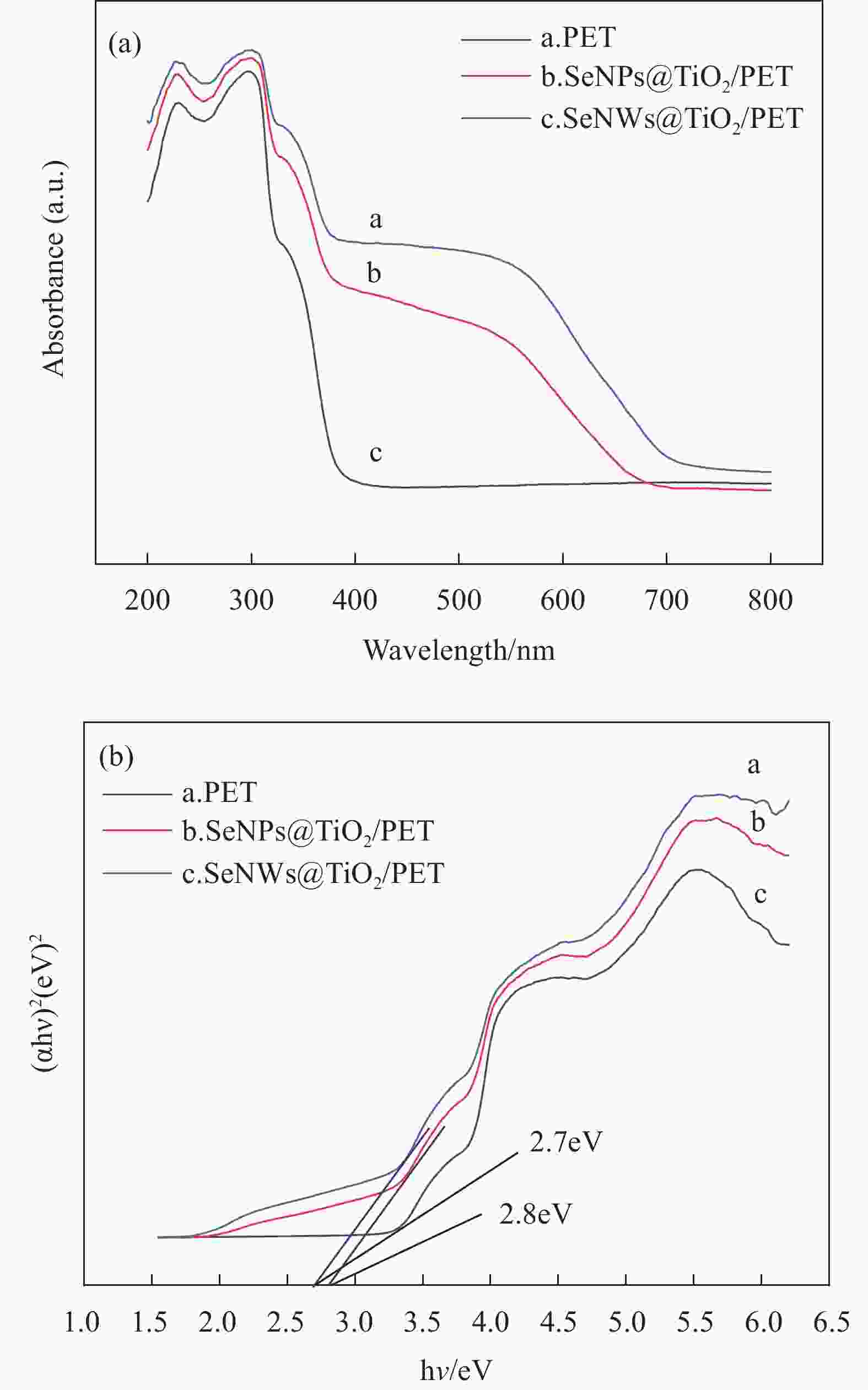

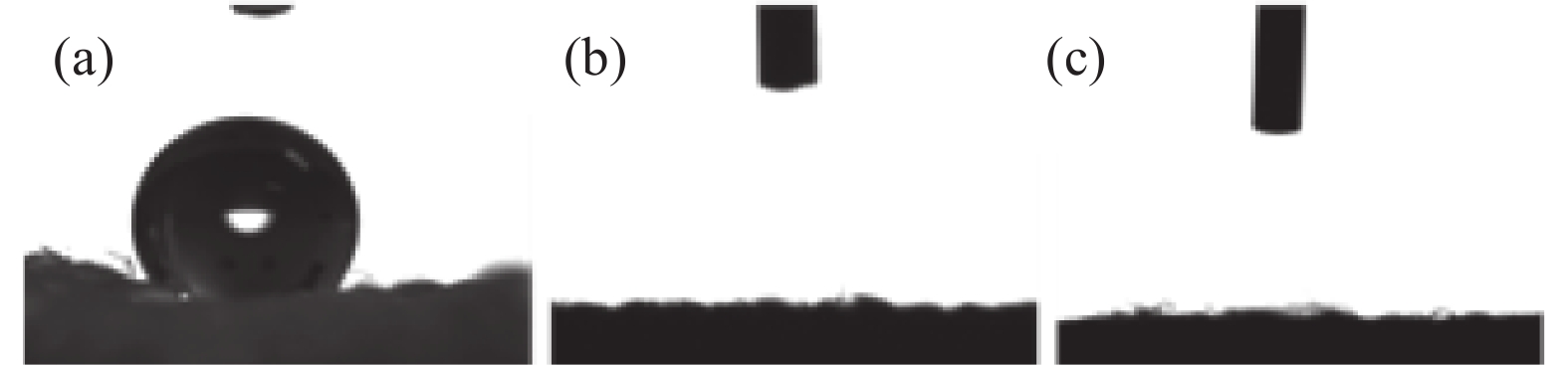

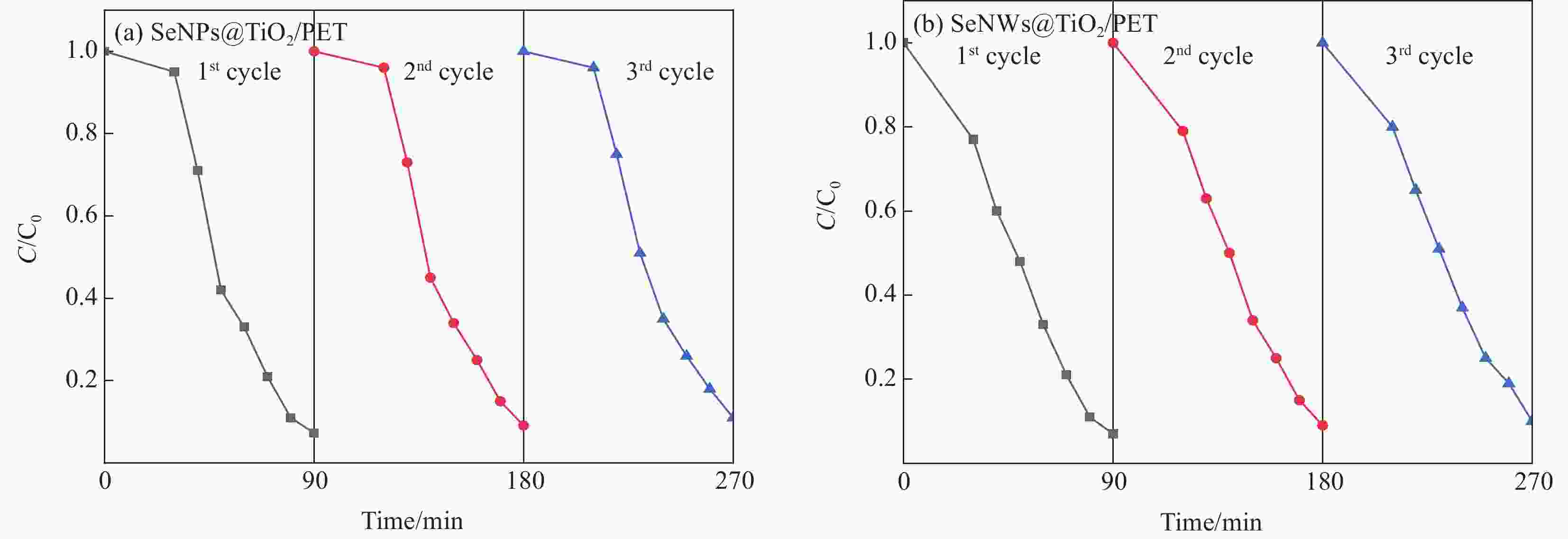

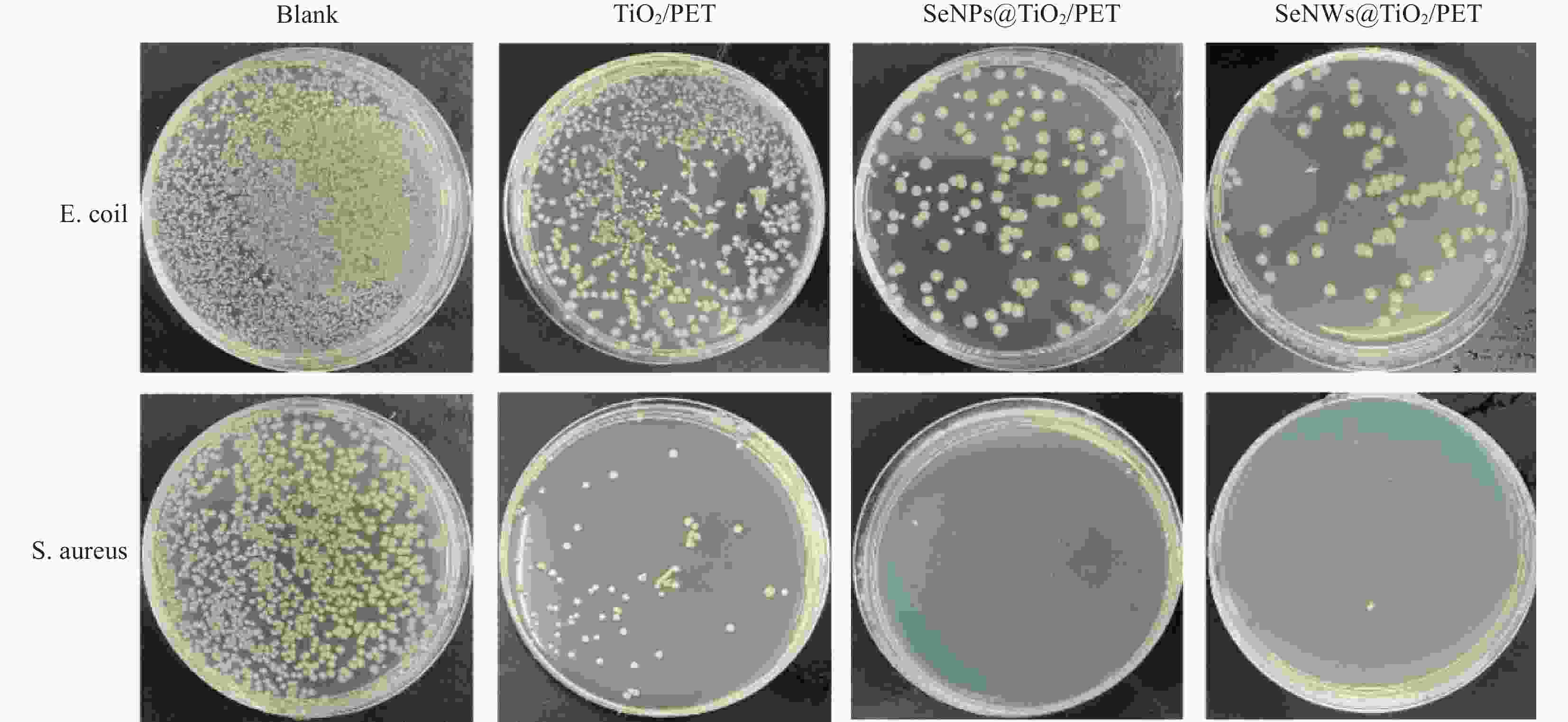

摘要: 采用等离子体技术对涤纶织物进行表面预处理,在涤纶织物表面负载纳米TiO2,然后通过分子组装法在TiO2/聚对苯二甲酸乙二醇酯(PET)表面生长Se纳米球(SeNPs)和Se纳米线(SeNWs),在涤纶织物表面构筑Se@TiO2二元复合结构(SeNPs@TiO2/PET和SeNWs@TiO2/PET)。通过扫描电镜(SEM)、X射线衍射(XRD)、X射线光电子能谱(XPS)、紫外-可见吸收光谱(UV-vis)、光致发光光谱(PL)及光催化和抗菌实验对材料的晶体结构、表面形态、化学组成、光催化性能及抗菌性能等进行表征。通过接触角测试对复合光催化材料的表面润湿性能进行表征。光催化降解实验表明SeNWs@TiO2/PET在模拟太阳光下具有更高的降解率,其对模型污染物亚甲基蓝降解90 min后,降解率达到98.3%。PL光谱表明SeNWs@TiO2/PET电子-空穴对的分离率高于SeNPs@TiO2/PET。UV-vis光谱表明SeNPs@TiO2/PET和SeNWs@TiO2/PET的相对禁带宽度分别为2.8 eV和2.7 eV。两种复合材料对金黄色葡萄球菌和大肠杆菌的抑菌率分别可达到99%和90%以上。Abstract: Surface pretreatment of polyester fabric was carried out using plasma technology. Nano-TiO2 was loaded on the surface of the polyester fabric, and then Se nanospheres (SeNPs) and Se nanowires (SeNWs) were grown on the surface of the TiO2/ Polyethylene terephthalate (PET) through molecular assembly method. Se@TiO2 binary composite structure was constructed on the surface of the PET(SeNPs@TiO2/PET and SeNWs@TiO2/PET). The crystal structure, surface morphology, chemical composition, photocatalytic and antibacterial properties of the material were characterized by SEM, XRD, XPS, UV vis, PL, and photocatalytic and antibacterial experiments. Characterize the wetting performance of composite photocatalytic materials through contact angle testing. The results indicate that SeNPs@TiO2/PET and SeNWs@TiO2/PET composite photocatalytic materials have been successfully prepared. The photocatalytic degradation experiment shows that SeNWs@TiO2/PET has a higher degradation rate under sunlight simulation. After 90 minutes of degradation of the model pollutant methylene blue, the degradation rate reached 98.3%. PL spectrum indicates SeNWs@TiO2/PET separation rate of electron hole pairs is higher than SeNPs@TiO2/PET. The UV-vis spectrum indicates that relative bandgap widths of SeNPs@TiO2/PET and SeNWs@TiO2/PET are 2.8 eV and 2.7 eV, respectively. The antibacterial rates of composite materials against S.aureus and E.coli can reach over 99% and 90%, respectively.

-

Key words:

- TiO2 /

- Se /

- photocatalysis /

- antibacterial /

- PET /

- polyester fabric

-

表 1 材料表面各元素的相对含量

Table 1. Relative content of elements on the surface of materials

Sample Relative content of element/

wt%C O Ti Se PET 67.79 32.21 - - SeNPs@TiO2/PET 60.83 37.47 0.69 1.01 SeNWs@TiO2/PET 61.44 34.82 2.83 0.91 表 2 材料的接触角及吸水时间

Table 2. Contact angle and water absorption time of materials

Sample Contact angle Water

absorption timePET 126.4° n/a SeNPs@TiO2/PET 0° >1 s SeNWs@TiO2/PET 0° >1 s 表 3 SeNPs@TiO2/PET和SeNWs@TiO2/PET对大肠杆菌和金黄色葡萄球菌的抑菌率

Table 3. Antibacterial rates of SeNPs@TiO2/PET and SeNWs@TiO2/PET against E.coli and S.aureus

Sample E. coli colony/

(CFU·mL−1)Bacteriostatic rate S. aureus colony/(CFU·mL−1) Bacteriostatic

rateBlank 1.73×106 n/a 0.95×106 n/a TiO2/PET 7.06×105 59.19% 0.84×105 91.16% SeNPs@TiO2/PET 1.38×105 92.03% 1 99.99% SeNWs@TiO2/PET 0.92×105 94.68% 1 99.99% -

[1] 邓佳雯, 郭颖, 徐利云, 等. 低气压等离子体工艺参数对制备超疏水涤纶织物的影响[J]. 上海纺织科技, 2019, 47(10): 51-66.DENG Jiawen, GUO Yin, XV Liyun, et al. Prepration of super-hydrophobic polyester fabric by low pressure plasma[J]. Shanghai Textile Science and Technology, 2019, 47(10): 51-66(in Chinese). [2] 邵灵达, 申晓, 金肖克, 等. 涤纶纤维表面复合改性对其亲水性的影响[J]. 丝绸, 2020, 57(02): 19-24.SHAO Linda, SHEN Xiao, JIN Xiaoke, et al, Effect of surface modification of polyester fiber on its properties. Silk, 2020, 57(02): 19-24. (in Chinese) [3] RASHID M M, SIMONCIC B, TOMSIC B. Recent advances in TiO2-functionalized textile surfaces[J]. Surf Interfaces, 2021, 22. [4] 朱文怡. 纳米N/TiO2负载涤纶非织造材料的制备及其降解甲醛的研究 [D]. 江南大学, 2021.ZHU Wenyi. Study on the polyester nonwovens Supported N-doped Nano-TiO, Compositing Material And Degradation of formaldehyde[D]. Jiangnan University, 2021. (in Chinese) [5] 梁慧, 张光先, 张凤秀, 等. 紫外线纳米二氧化钛改性高亲水涤纶织物的制备[J]. 纺织学报, 2013, 34(03): 82-86.LIANG Hui, ZHANG Guangguang, ZHANG Fengxiu, et al, Prepration of highly hydrophilic polyester fabrics via UV irradiation/nano-TiO2 modification. Journal of Textile Research, 2013, 34(03): 82-86. (in Chinese) [6] GAO Y, CRANSTON R. Recent advances in antimicrobial treatments of textiles[J]. Text Res J, 2008, 78(1): 60-72. doi: 10.1177/0040517507082332 [7] MIHAILOVIC D, SAPONJIC Z, RADOICIC M, et al. Functionalization of polyester fabrics with alginates and TiO2 nanoparticles[J]. Carbohydr Polym, 2010, 79(3): 526-532. doi: 10.1016/j.carbpol.2009.08.036 [8] FUJISHIMA A, RAO T N. Recent advances in heterogeneous TiO2 photocatalysis[J]. J Chem Sci, 1997, 109(6): 471-486. doi: 10.1007/BF02869207 [9] SáNCHEZ-RODRíGUEZ D, MEDRANO M G M, REMITA H, et al. Photocatalytic properties of BiOCl-TiO2 composites for phenol photodegradation[J]. J Environ Chem Eng, 2018, 6(2). [10] 王建强, 黄菊梅, 马玉龙, 等. 改性二氧化钛光催化技术在水污染治理中的研究进展[J]. 现代盐化工, 2021, 48(06): 9-11. doi: 10.3969/j.issn.1005-880X.2021.06.005WANG Jianqiang, HUANG Jumei, MA Yulong, et al. Research progress of modified titanium dioxide photocatalytic technology in water pollution control[J]. Modern Salt and Chemical Industry, 2021, 48(06): 9-11(in Chinese). doi: 10.3969/j.issn.1005-880X.2021.06.005 [11] MU J, LUO D, MIAO H, et al. Synergistic wide spectrum response and directional carrier transportation characteristics of Se/SnSe2/TiO2 multiple heterojunction for efficient photoelectrochemical simultaneous degradation of Cr (VI) and RhB[J]. Appl Surf Sci, 2021, 542. [12] LIU W W, GOLSHAN N H, DENG X L, et al. Selenium nanoparticles incorporated into titania nanotubes inhibit bacterial growth and macrophage proliferation[J]. Nanoscale, 2016, 8(34): 15783-15794. doi: 10.1039/C6NR04461A [13] WANG T T, LI L H, YIN Z L, et al. Selenium-sensitized TiO2 p-n heterojunction thin films with high resistance to oxidation and moisture for self-driven visible-light photodetection[J]. Thin Solid Films, 2023, 774. [14] 张建花. 不同形貌和粒度纳米硒的制备及其相变热力学性质的研究 [D]; 太原理工大学, 2018.ZHANG Jianhua. Researches into preparation of nano-Se with different morphologies and sizes and its thermodynamics properties of phase transitions[D]. Taiyuan University of Technology, 2018(in Chinese) [15] 徐林, 任煜, 张红阳, 等. 涤纶织物表面TiO2/氟硅烷超疏水层构筑及其性能[J]. 纺织学报, 2019, 40(12): 86-92.XU Lin, REN Yu, ZHANG Hongyang, et al. Construction and properties of superhydrophobic layer of titania/fluorosilane on polyester fabric surface[J]. Journal of Textile Research, 2019, 40(12): 86-92. [16] D'AMATO C A, GIOVANNETTI R, ZANNOTTI M, et al. Band Gap Implications on Nano-TiO2 Surface Modification with Ascorbic Acid for Visible Light-Active Polypropylene Coated Photocatalyst[J]. Nanomaterials, 2018, 8(8): [17] 喻波. 纳米硒的形貌调控、功能化及其抗肿瘤活性研究 [D]; 暨南大学, 2011.YU Bo. Morphological modulation, functionalization and anticancer activities of selenium nanoparticles[D]. Jinan University, 2011(in Chinese) [18] 赵渺. 硒纳米/微米材料的制备及研究 [D]; 广东工业大学, 2011.ZHAO Miao. Research and Preparation of selenium nano/micro materials[D]. Guangdong University of Technology, 2011(in Chinese) [19] WU C Y, CORRIGAN N, LIM C H, et al. Guiding the Design of Organic Photocatalyst for PET-RAFT Polymerization: Halogenated Xanthene Dyes[J]. Macromolecules, 2019, 52(1): 236-248. doi: 10.1021/acs.macromol.8b02517 [20] WU S X, MA Z, QIN Y N, et al. XPS study of copper doping TiO2 photocatalyst[J]. Acta Phys Chim Sin, 2003, 19(10): 967-969. doi: 10.3866/PKU.WHXB20031017 [21] 王法国. Cu-TiO2基光催化材料的设计、制备及光催化性能研究 [D]; 北京科技大学, 2023.WANG Faguo. Design, Synthesis and Photocatalytic properties of Cu-TiO2 based Photocatalysts[D]. University of Science and Technology Beijing, 2021(in Chinese) [22] ROCKAFELLOW E M, HAYWOOD J M, WITTE T, et al. Selenium-Modified TiO2 and Its Impact on Photocatalysis[J]. Langmuir, 2010, 26(24): 19052-19059. doi: 10.1021/la1026569 [23] ZHANG Y, ZHANG C, GUO Y, et al. Selenium vacancy-rich CoSe2 ultrathin nanomeshes with abundant active sites for electrocatalytic oxygen evolution[J]. J Mater Chem A, 2019, 7(6): 2536-2540. doi: 10.1039/C8TA11407B [24] ZHANG H Y, YU H, DAI J D, et al. Microstructure, photoluminescence and photocatalytic activity of ZnO-MoS2-TiO2 composite[J]. Chin J Phys, 2018, 56(6): 3053-3061. doi: 10.1016/j.cjph.2018.10.015 [25] KANSAL S K, LAMBA R, MEHTA S K, et al. Photocatalytic degradation of Alizarin Red S using simply synthesized ZnO nanoparticles[J]. Mater Lett, 2013, 106(385-389). [26] KIBOMBO H S, WEBER A S, WU C-M, et al. Effectively dispersed europium oxide dopants in TiO2 aerogel supports for enhanced photocatalytic pollutant degradation[J]. J Photochem Photobiol, A, 2013, 269(49-58). [27] RAO Z P, SHI G S, WANG Z, et al. Photocatalytic degradation of gaseous VOCs over Tm3+-TiO2: Revealing the activity enhancement mechanism and different reaction paths[J]. Chem Eng J, 2020, 395. [28] MURUGESAN R, SIVAKUMAR S, KARTHIK K, et al. Structural, optical and magnetic behaviors of Fe/Mn-doped and co-doped CdS thin films prepared by spray pyrolysis method[J]. Appl Phys A, 2019, 125(4): 281. doi: 10.1007/s00339-019-2577-x [29] CHIOU Y-D, HSU Y-J. Room-temperature synthesis of single-crystalline Se nanorods with remarkable photocatalytic properties[J]. Applied Catalysis B-Environmental, 2011, 105(1-2): 211-219. doi: 10.1016/j.apcatb.2011.04.019 [30] YUN H J, LEE H, JOO J B, et al. Influence of Aspect Ratio of TiO2 Nanorods on the Photocatalytic Decomposition of Formic Acid[J]. The Journal of Physical Chemistry C, 2009, 113(8): 3050-3055. doi: 10.1021/jp808604t [31] HENRIKSEN-LACEY M, CARREGAL-ROMERO S, LIZ-MARZáN L M. Current Challenges toward In Vitro Cellular Validation of Inorganic Nanoparticles[J]. Bioconjugate Chem, 2017, 28(1): 212-221. doi: 10.1021/acs.bioconjchem.6b00514 [32] HORIE M, SUGINO S, KATO H, et al. Does photocatalytic activity of TiO2 nanoparticles correspond to photo-cytotoxicity? Cellular uptake of TiO2 nanoparticles is important in their photo-cytotoxicity[J]. Toxicol Mech Methods, 2016, 26(4): 284-294. doi: 10.1080/15376516.2016.1175530 [33] BILEK O, FOHLEROVA Z, HUBALEK J. Enhanced antibacterial and anticancer properties of Se-NPs decorated TiO2 nanotube film[J]. PLoS One, 2019, 14(3). [34] GUISBIERS G, WANG Q, KHACHATRYAN E, et al. Inhibition of E. coli and S. aureus with selenium nanoparticles synthesized by pulsed laser ablation in deionized water[J]. Int J Nanomed, 2016, 11(3731-3736). -

点击查看大图

点击查看大图

计量

- 文章访问数: 69

- HTML全文浏览量: 44

- 被引次数: 0

下载:

下载: