Dynamic and static mechanical properties and energy dissipation of six polymer materials

-

摘要: 为探究不同高分子材料作为聚能管管材对于聚能爆破的影响,利用电液伺服压力机和直径50 mm的分离式霍普金森压杆分别开展不同高分子材料在准静态下的单轴抗压试验,以及在冲击荷载作用下的单轴压缩试验,对其动静态力学性能、纵波波速、变形特征及能量耗散进行了研究。结果表明,不同高分子材料之间的波阻抗及准静态单轴抗压强度之间最大差值分别达到了42.5%和312.3%;在冲击荷载作用下,不同高分子材料的应力-应变曲线均在曲线末端出现了回弹现象,PVC材料的峰值应力在不同冲击气压下均为6种高分子材料中相对较高的;从对能量的透射、耗散率和单位质量耗散能方面分析,PVC材料的能量透射率是6种高分子材料中最高的,能量耗散和单位质量耗散能是最低的;从岩石爆破角度,引入吸收阻抗比与入射能进行拟合分析,PVC和PC材料的拟合曲线的相关系数相对较高,更符合炸药爆炸时能量传递的描述。最后,综合所有分析认为PVC材料是试验所用的6种高分子材料中最适合作为聚能管管材。

-

关键词:

- 高分子材料 /

- 聚能管 /

- 动态压缩 /

- 吸收阻抗比 /

- 分离式霍普金森压杆(SHPB)

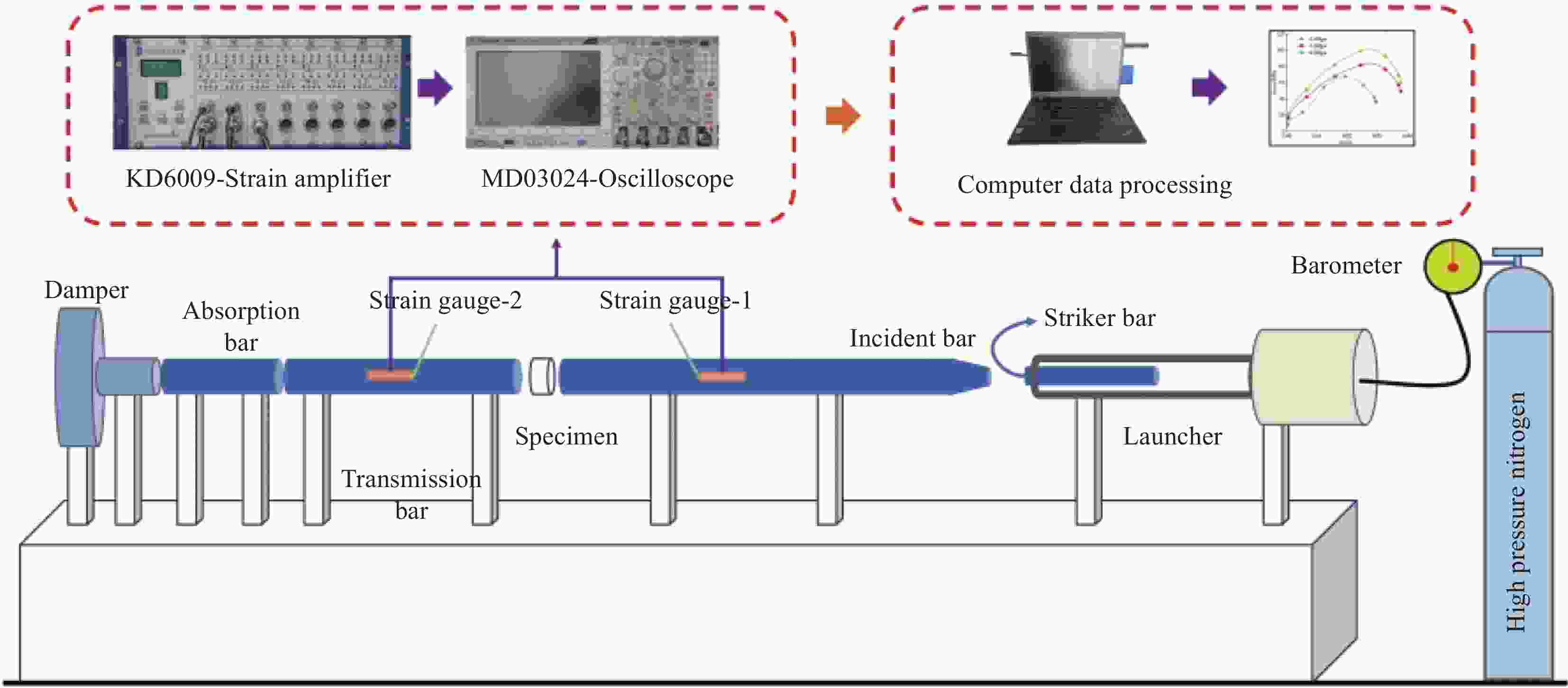

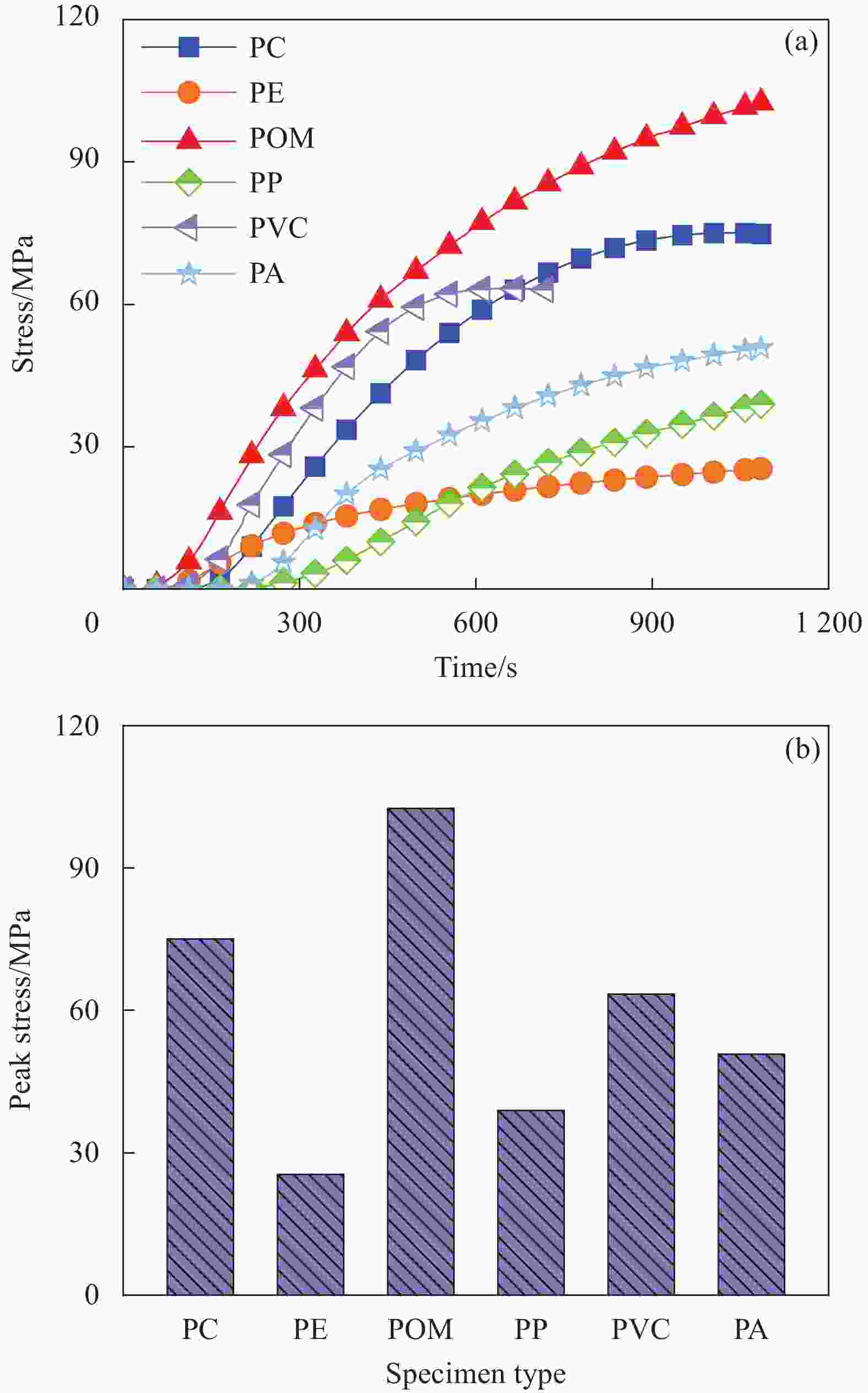

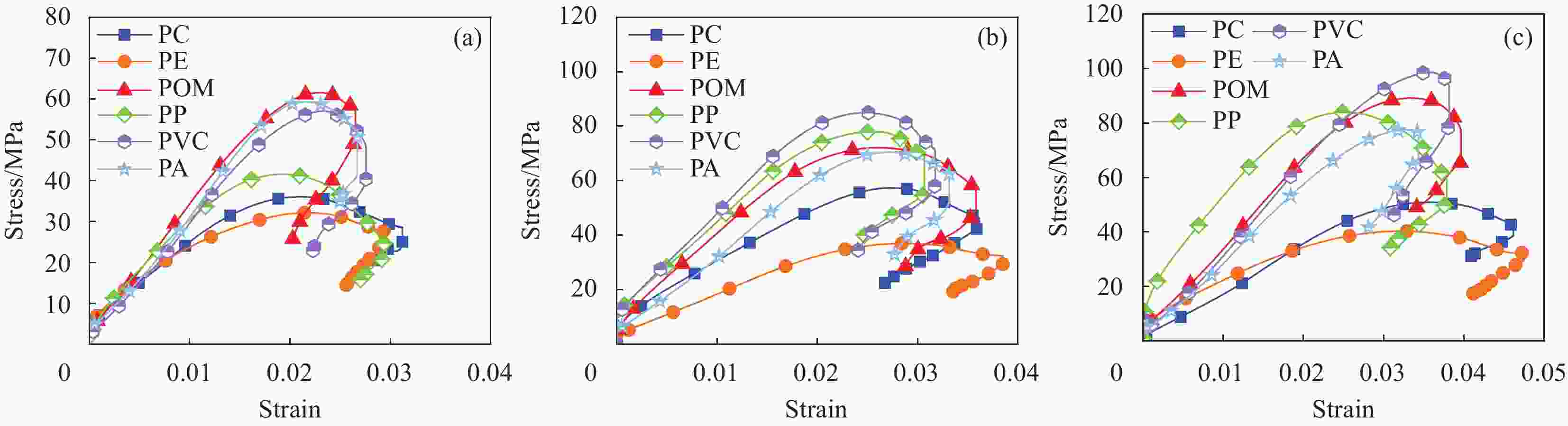

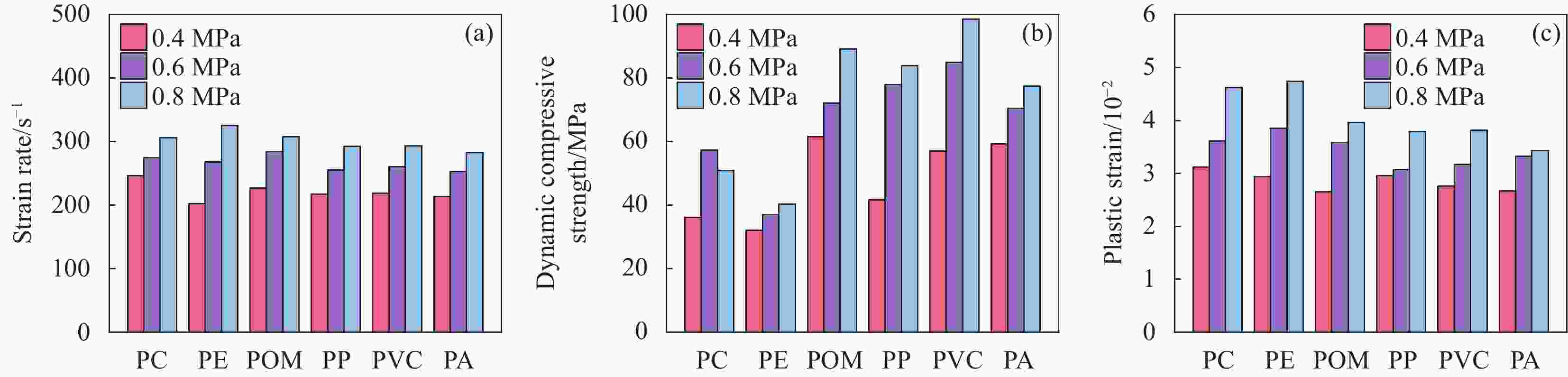

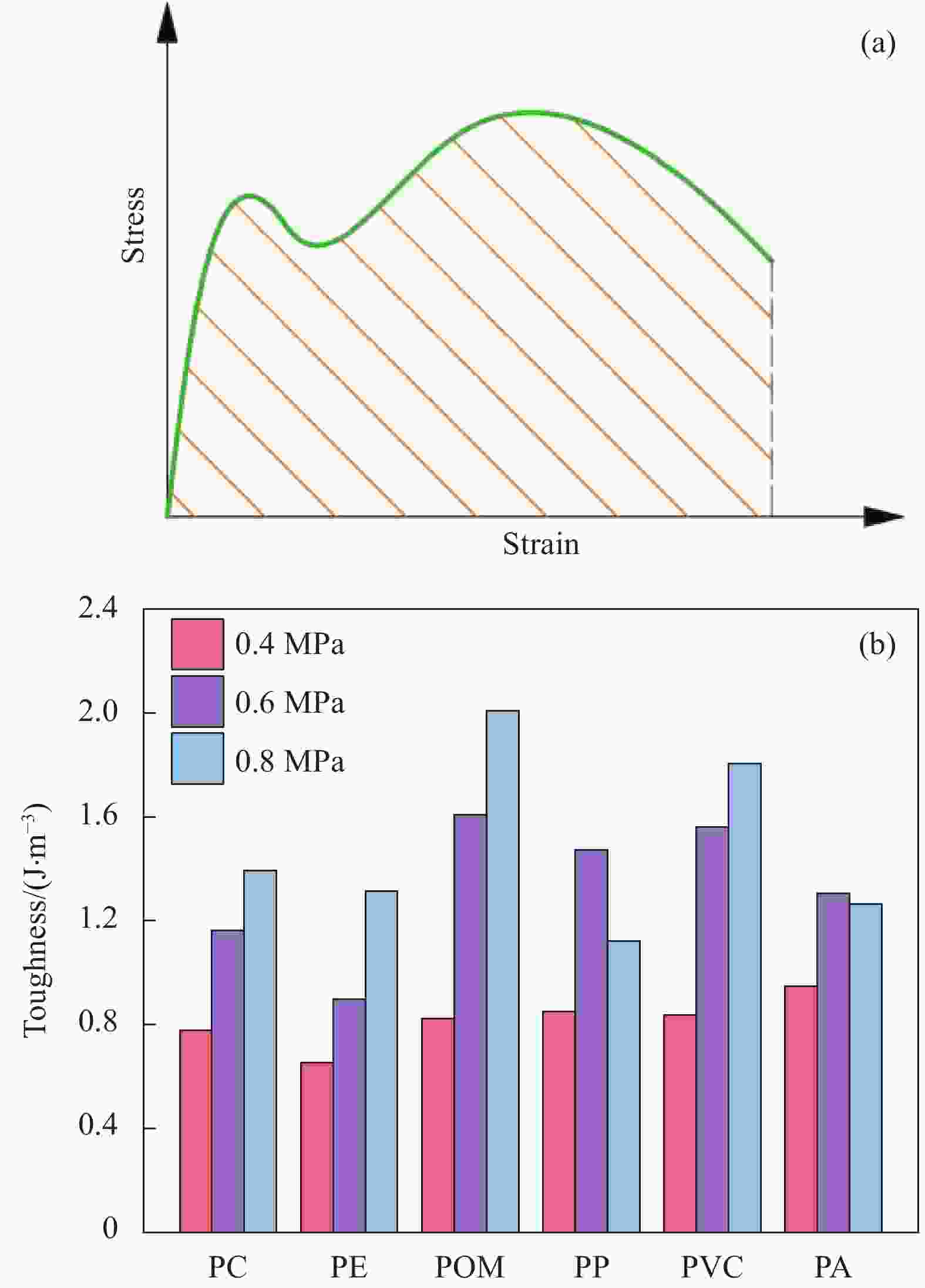

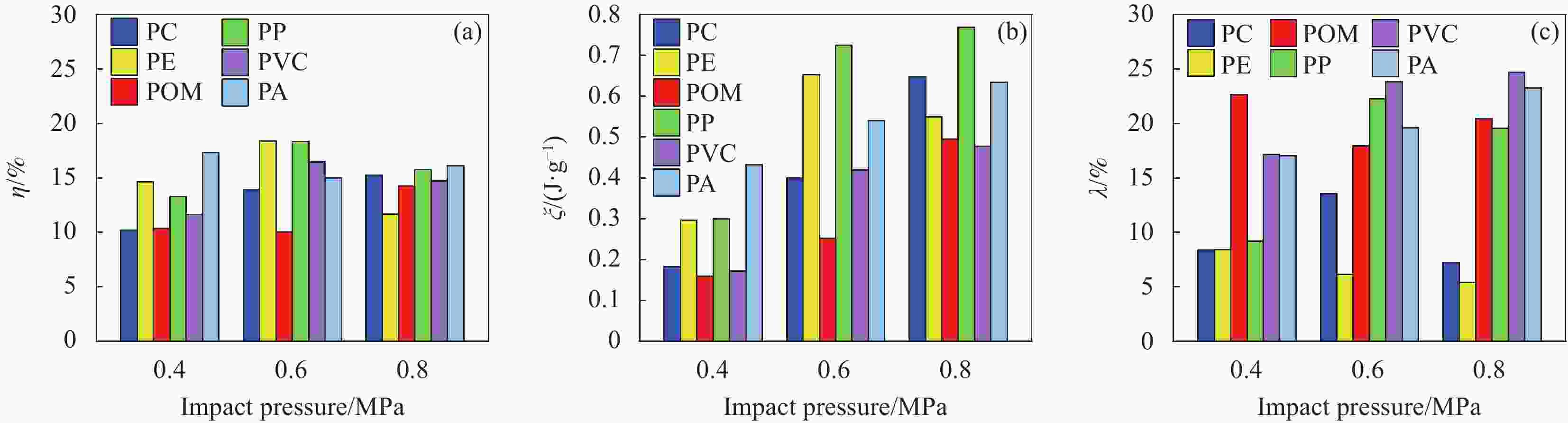

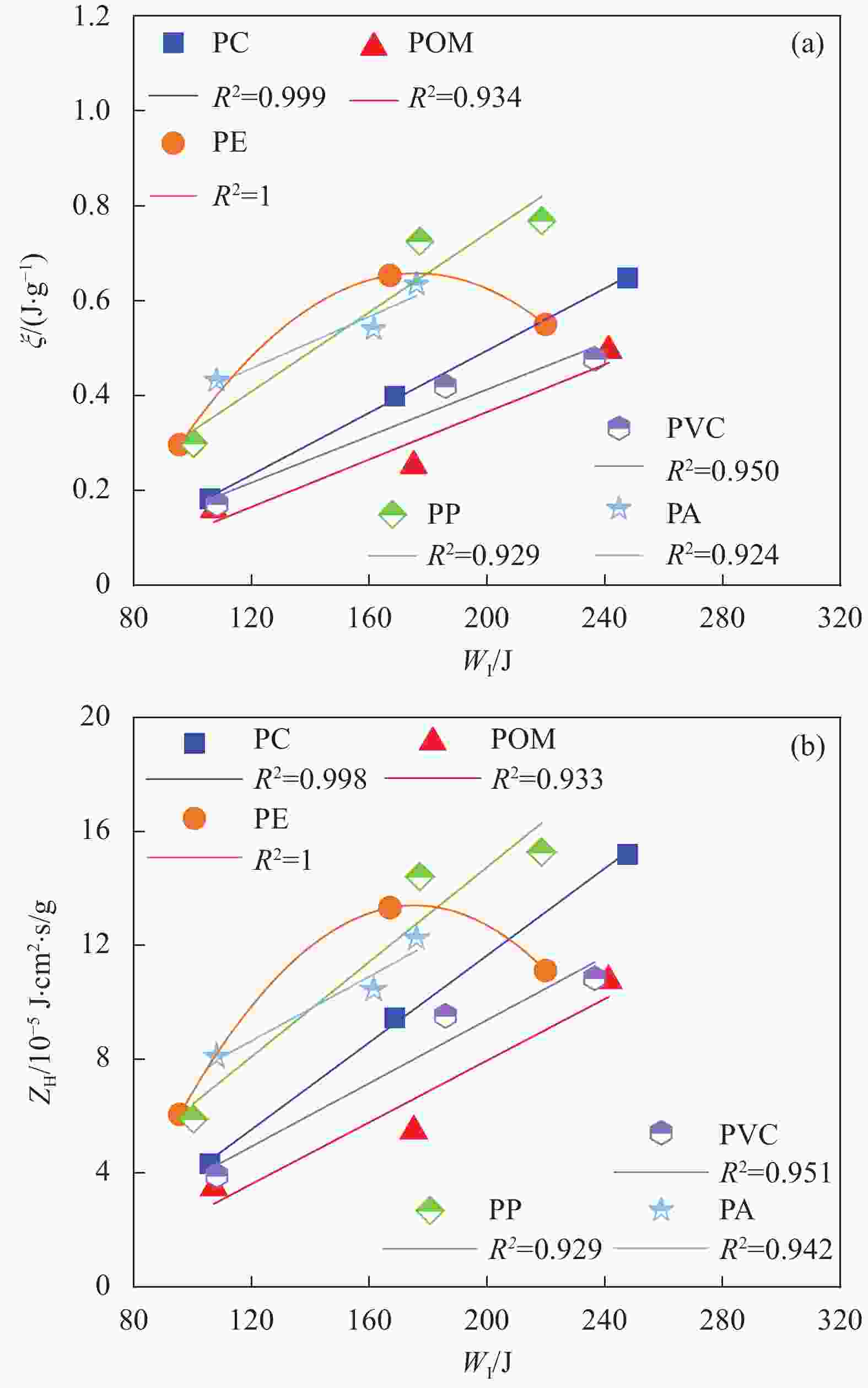

Abstract: In order to investigate the effect of different polymer materials as energy gathering tube tubes on energy gathering blasting, Uniaxial compressive experiments on different polymer materials under quasi-static conditions were conducted using an electro-hydraulic servo press and a 50 mm diameter Split-Hopkinson Pressure Bar. The static and dynamic mechanical properties, longitudinal wave velocity, energy dissipation and the deformation characteristics were studied. The results show that the maximum difference in wave impedance and quasi-static uniaxial compressive strength between different polymer materials reaches 42.5% and 312.3%, respectively. Under the impact load, the stress-strain curves of different polymer materials exhibit rebound phenomenon at the end of the curves, and the peak stress of PVC material is relatively higher among the six polymer materials under different impact pressures. From the analysis of energy transmission, dissipation rate and unit mass dissipation energy, PVC material has the highest energy transmittance among the six polymer materials, while energy dissipation and unit mass dissipation energy are the lowest. From the perspective of rock blasting, the absorption impedance ratio and incident energy are introduced for fitting analysis. The correlation coefficient between the fitting curves of PVC and PC materials is relatively high, which is more in line with the description of energy transfer during explosive explosion. Finally, based on all the analyses, it is believed that PVC material is the most suitable polymer material among the six types used in the experiment as a pipe material for energy gathering tubes. -

表 1 试件的密度和纵波波速测试结果

Table 1. Density and p-wave velocity test results of the specimens

Specimen

nameDensity/

(g·cm−3)P-wave

velocity/(m·s−1)Wave impedance/

(g·cm−2·s−1)PC 1.186 2096 248586 PE 0.952 2421 230479 POM 1.416 2257 319591 PP 0.906 2488 225413 PVC 1.486 2162 321273 PA 0.903 2565 231620 表 2 不同试件加载后的尺寸变化

Table 2. Dimensional changes of different specimens after loading

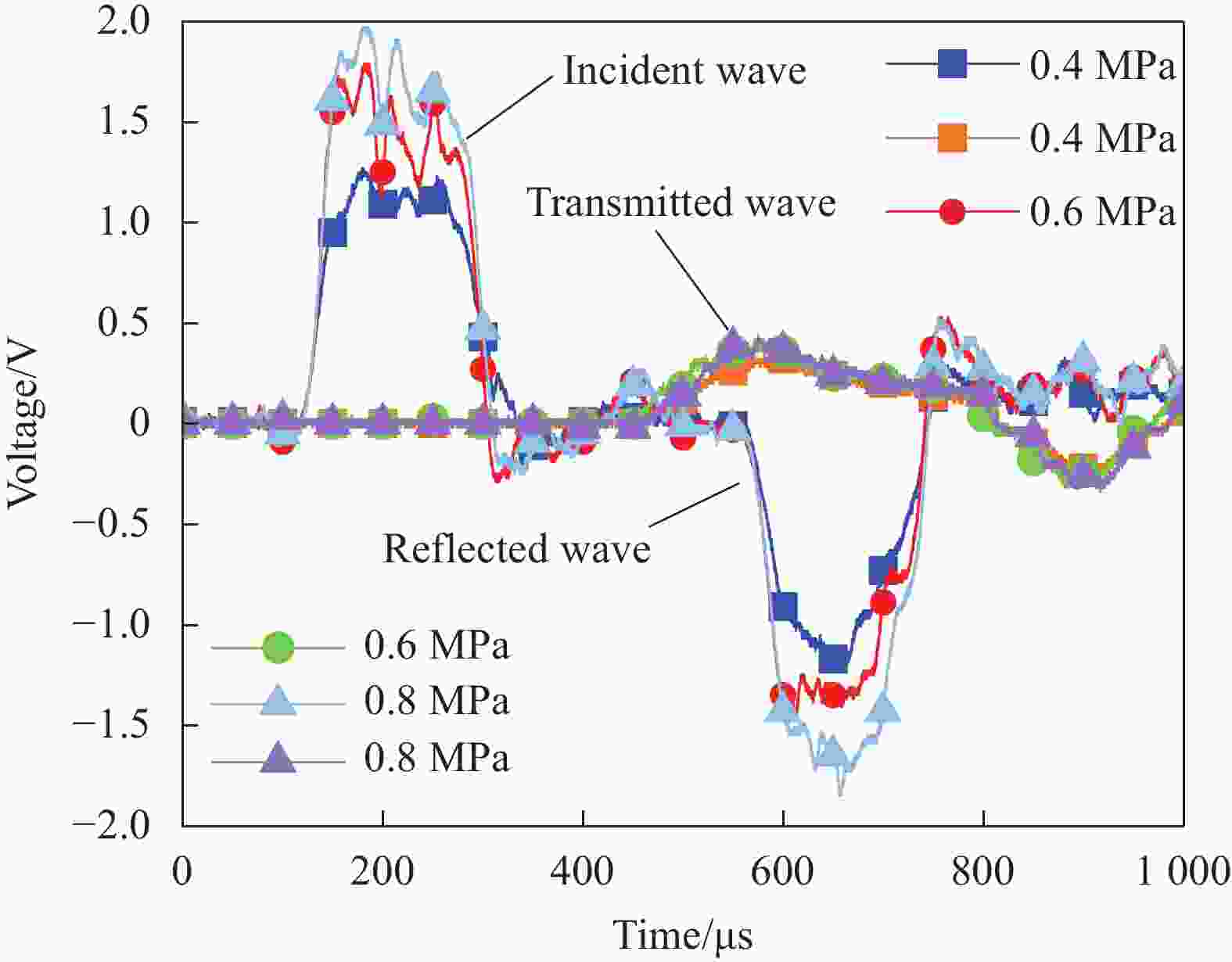

Specimen name PC PE POM PP PVC PA Before the experiment Height/mm 100.12 99.92 100.02 99.92 99.90 99.4 Diameter/mm 49.92 50.02 49.92 50.06 49.98 50.12 After the experiment Height/mm 98.92 95.80 93.78 96.64 99.42 97.06 Diameter/mm 50.02 51.26 52.08 51.68 50.18 51.16 Height difference ΔΗ/mm 1.20 4.12 6.24 3.28 0.48 2.38 Diameter Difference Δd/mm −0.10 −1.24 −2.16 −1.62 −0.20 −1.04 表 3 不同高分子材料冲击试验结果

Table 3. Impact experiment results of different polymer materials

Specimen name Impact

pressure/MPaStrain

rate/s−1Dynamic compressive

strength/MPaPlastic strain Incident energy/J Reflected energy/J Transmitted energy/J Absorbed energy/J PC 0.4 246.2 36.07 3.12 105.79 86.16 8.86 10.77 PC 0.6 274.9 57.39 3.61 168.61 122.24 22.86 23.51 PC 0.8 306.3 50.94 4.62 247.69 192.05 17.86 37.78 PE 0.4 202.5 32.14 2.94 95.60 73.59 8.04 13.97 PE 0.6 267.9 36.95 3.85 167.02 126.09 10.23 30.7 PE 0.8 325.2 40.34 4.74 219.87 182.33 11.92 25.62 POM 0.4 226.5 61.54 2.65 107.23 71.85 24.26 11.12 POM 0.6 284.2 72.12 3.58 175.08 126.13 31.42 17.53 POM 0.8 307.5 89.17 3.96 241.24 157.60 49.27 34.37 PP 0.4 216.9 41.59 2.96 100.23 77.73 9.21 13.29 PP 0.6 255.2 77.97 3.07 177.12 105.19 39.44 32.49 PP 0.8 292.7 83.93 3.79 218.56 141.44 42.69 34.43 PVC 0.4 219.0 57.06 2.76 108.25 77.07 18.59 12.59 PVC 0.6 260.7 85.00 3.17 185.88 111.02 44.26 30.6 PVC 0.8 293.2 98.63 3.82 236.58 143.30 58.43 34.85 PA 0.4 213.4 59.31 2.67 108.08 70.95 18.39 18.74 PA 0.6 253.1 70.46 3.32 161.49 105.63 31.67 24.19 PA 0.8 283.0 77.50 3.43 176.04 106.75 40.94 28.35 -

[1] 何广沂, 张进增, 王树成, 等. 隧道聚能水压光面爆破新技术[M]. 北京: 中国铁道出版社, 2018.HE Guangyi, ZHANG Jinzeng, WANG Shucheng, et al. A new technology of water pressure smooth blasting with concentrated energy in tunnels[M]. Beijing: China Railway Publishing House, 2018(in Chinese). [2] 张铁军, 唐潮, 宋鹏伟, 等. C型聚能管锥角的优化研究[J]. 爆破器材, 2023, 52(5): 30-37. doi: 10.3969/j.issn.1001-8352.2023.05.006ZHANG Tiejun, TANG Chao, SONG Pengwei, et al. Optimization of the cone angle of the C-type shaped charge tube[J]. Explosive Materials, 2023, 52(5): 30-37(in Chinese). doi: 10.3969/j.issn.1001-8352.2023.05.006 [3] 李淮, 孙卫星, 宋鹏伟, 等. 基于C型聚能管的聚能水压光面爆破技术原理及应用[J]. 爆破器材, 2023, 52(1): 50-57.LI Huai, SUN Weixing, Song Pengwei, et al. Principle and application of shaped energy water pressure smooth blastiong technology based on C-shaped energy-concentrating tube[J]. Explosive Materials, 2023, 52(1): 50-57(in Chinese). [4] 张盛, 王小良, 赵文峰, 等. D型聚能爆破管在沿空留巷中应用研究[J]. 煤炭科学技术, 2019, 47(10): 175-182.ZHANG Sheng, WANG Xiaoliang, ZHAO Wenfeng, et al. Study on application of D-type energy gathering blasting tube on gob-side wntry retaining[J]. Coal Science and Technology, 2019, 47(10): 175-182(in Chinese). [5] 郭德勇, 张超, 朱同功, 等. 装药结构对煤层深孔聚能爆破增透的影响[J]. 工程科学学报, 2018, 40(12): 1488-1494.GUO Deyong, ZHANG Chao, ZHU Tonggong, et al. Effective fracture zone under deep-hole cumulative blasting in coal seam[J]. Chinese Journal of Engineering, 2018, 40(12): 1488-1494 (in Chinese). [6] Zhu Feihao, Liu Zegong, Huang An-Chi. Study on the coupling mechanism of shaped blasting and empty hole to crack coal body[J]. Process Safety and Environmental Protection, 2023, 175: 644-653. [7] Guo Huan-Guo, Zheng Yuan-feng, He Suo, et al. Reaction characteristic of PTFE/Al/Cu/Pb composites and application in shaped charge liner[J]. Defence Technology, 2022, 18(9): 1578-1588. [8] Liu Dunwen, Zhang Jianjun, Tang Yu, et al. Damage Analysis of Concrete Structure under Multidirectional Shaped Charge Blasting Using Model Experiment and Ultrasonic Testing[J]. Advances in Civil Engineering, 2021, 2021: 6677041. [9] 杨仁树, 张召冉, 杨立云, 等. 基于硬岩快掘技术的切缝药包聚能爆破试验研究[J]. 岩石力学与工程学报, 2013, 32(2): 317-323. doi: 10.3969/j.issn.1000-6915.2013.02.013YANG Renshu, ZHANG Zhaoran, YANG Liyun, et al. Cumulative blasting experiment study of slotted cartridge based on hard-rock rapid driving technology[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(2): 317-323(in Chinese). doi: 10.3969/j.issn.1000-6915.2013.02.013 [10] 龚元明, 孙志杰, 贺成红, 等. 不同预载/动载下纤维增强环氧树脂复合材料动态粘弹特性[J]. 复合材料学报, 2006, 23(1): 26-30. doi: 10.3321/j.issn:1000-3851.2006.01.004GONG Yuanming, SUN Zhijie, HE Chenghong, et al. Dynamic viscoelasticity of fiber reinforced composites under different proload/dynamic load[J]. Acta Materiae Compositae Sinica, 2006, 23(1): 26-30(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.01.004 [11] 林飞. 新型聚能管在边坡预裂爆破中的研究与应用[J]. 爆破, 2020, 37(2): 115-120. doi: 10.3963/j.issn.1001-487X.2020.02.020LIN Fei. Research and application of new shaped energy gathering tube in presplitting blasting of slope[J]. Blasting, 2020, 37(2): 115-120(in Chinese). doi: 10.3963/j.issn.1001-487X.2020.02.020 [12] 赵鑫, 徐永杰, 郑娜娜, 等. 药型罩侵彻性能仿真与优化[J]. 兵器装备工程学报, 2021, 42(10): 65-71. doi: 10.11809/bqzbgcxb2021.10.011ZHAO Xin, XU Yongjie, ZHENG Nana, et al. Simulation and optimization research of penetration performance of liner[J]. Journal of Ordnance Equipment Engineering, 2021, 42(10): 65-71(in Chinese). doi: 10.11809/bqzbgcxb2021.10.011 [13] 李清, 于强, 朱各勇, 等. 不同药量的切缝药包双孔爆破裂纹扩展规律试验[J]. 岩石力学与工程学报, 2017, 36(9): 2205-2212.LI Qing, YU Qiang, ZHU Geyong, et al. Experiment study of rock propagation under two0hole slotted cartridge blasting with different amounts of charge[J]. Chinese journal of rock mechanics and engineering, 2017, 36(9): 2205-2212(in Chinese). [14] 杨仁树, 王雁冰. 切缝药包不耦合装药爆破爆生裂纹动态断裂效应的试验研究[J]. 岩石力学与工程学报, 2013, 32(7): 1337-1343. doi: 10.3969/j.issn.1000-6915.2013.07.007YANG Renshu, WANG Yanbing. Experiment study of dynamic fracture effect of blasting crack in slotted cratridge decoupling charge blasting[J]. Chinese journal of rock mechanics and engineering, 2013, 32(7): 1337-1343(in Chinese). doi: 10.3969/j.issn.1000-6915.2013.07.007 [15] 王梦想, 汪海波, 宗琦. 煤矿泥岩冲击动态力学特性与破裂破碎特征分析[J]. 振动与冲击, 2019, 38(4): 137-143.WANG Mengxiang, WANG Haibo, ZONG Qi. Analysis dynamic mechanical characteristic and fracture breaking characteristics of coal mine mudstone[J]. Journal of Vibration and Shock, 2019, 38(4): 137-143(in Chinese). [16] 邓华锋, 李建林, 邓成进, 等. 岩石力学试验中试样选择和抗压强度预测方法研究[J]. 岩土力学, 2011, 32(11): 3399-3403.DENG Huafeng, LI Jianlin, DENG Chengjin et al. Analysis of sampling in rock mechanics test and compressive strength prediction methods[J]. Rock and Soil Mechanics, 2011, 32(11): 3399-3403(in Chinese). [17] 徐萧, 金磊, 黄莎玲, 等. 飞片冲击载荷在环氧树脂/印刷电路板/环氧树脂界面处的传递特性[J]. 兵工学报, 2020, 41(9): 1817-1825.XU Xiao, JIN Lei, HUANG Shaling et al. Transmission characteristics of impact load of flying debris at epoxy resin/printed circuit board/epoxy resin interfaces[J]. Acta Armamentarii, 2020, 41(9): 1817-1825(in Chinese). [18] 李夕兵. 岩石动力学基础与应用[M]. 北京: 科学技术出版社, 2014: 278-281.LI Xibing. Foundation and application of rock dynamics[M]. Beijing: Science and Technology Press, 2014(in Chinese). [19] 宋力, 胡时胜. SHPB数据处理中的二波法与三波法[J]. 爆炸与冲击, 2005, (4): 368-373.SONG Li, HU Shisheng. Two-wave and three-wave method in SHPB data processing[J]. Explosion and Shock Waves, 2005, (4): 368-373(in Chinese). [20] 卢芳云, 陈荣, 林玉亮, 等. 霍普金森压杆试验技术[M] . 北京: 科学出版社, 2013.LU Fangyun, CHEN Rong, LIN Yuliang et al. Hopkinson compression bar test technique[M]. Beijing: Science Press, 2013(in Chinese). [21] 平琦, 高祺, 王晨. 不同内径圆环砂岩试件温水耦合动态劈裂力学试验研究[J]. 振动与冲击, 2023, 42(17): 43-51+152.PING Qi, GAO Qi, WANG Chen. Mechanical test study on thermo-water coupled dynamic splitting of annular sandstone specimens with different inner diameters[J]. Journal of Vibration and Shock, 2023, 42(17): 43-51+152(in Chinese). [22] 平琦, 马芹永, 袁璞. 岩石试件SHPB劈裂拉伸试验中能量耗散分析[J]. 采矿与安全工程学报, 2013, 30(03): 401-407.PING Qi, MA Qinyong, YUAN Pu. Energy dissipation analysis of stone specimens in SHPB tensile test[J]. Journal of Mining & Safety Engineering2013, 30(03): 401-407(in Chinese). [23] 杨荣周, 徐颖, 陈佩圆, 等. SHPB劈裂试验下橡胶水泥砂浆的动态力学、能量特性及破坏机理试验研究[J]. 材料导报, 2021, 35(10): 10062-10072.YANG Rongzhou, XU Ying, CHEN Peiyuan et al. Experimental study on dynamic mechanics, energy characteristics, and failure mechanism of rubber cement mortar under SHPB splitting test[J]. Materials Reports, 2021, 35(10): 10062-10072(in Chinese). [24] 王梦想, 汪海波, 宗琦. 冲击荷载作用下煤矿泥岩能量耗散试验研究[J]. 煤炭学报, 2019, 44(6): 1716-1725.WANG Mengxiang, WANG Haibo, ZONG Qi. Experimental study on energy dissipation of mudstone in coal mine im-pact loading[J]. Journal of China Coal Society, 2019, 44(6): 1716-1725(in Chinese). [25] 张华, 郜余伟, 李飞, 等. 高应变率下聚丙烯纤维混凝土动态力学性能和本构模型[J]. 中南大学学报(自然科学版), 2013, 44(8): 3464-3473.ZHANG Hua, GAO Yuwei, LI Fei, et al. Experimental study on dynamic properties and constitutive model of polypropylene fiber concrete under high strain rate[J]. Journal of Central South University(Science and Technology), 2013, 44(8): 3464-3473(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 48

- HTML全文浏览量: 26

- 被引次数: 0

下载:

下载: