Structure and properties of chitosan enhanced cellulose nanofiber-montmorillonite composite membrane

-

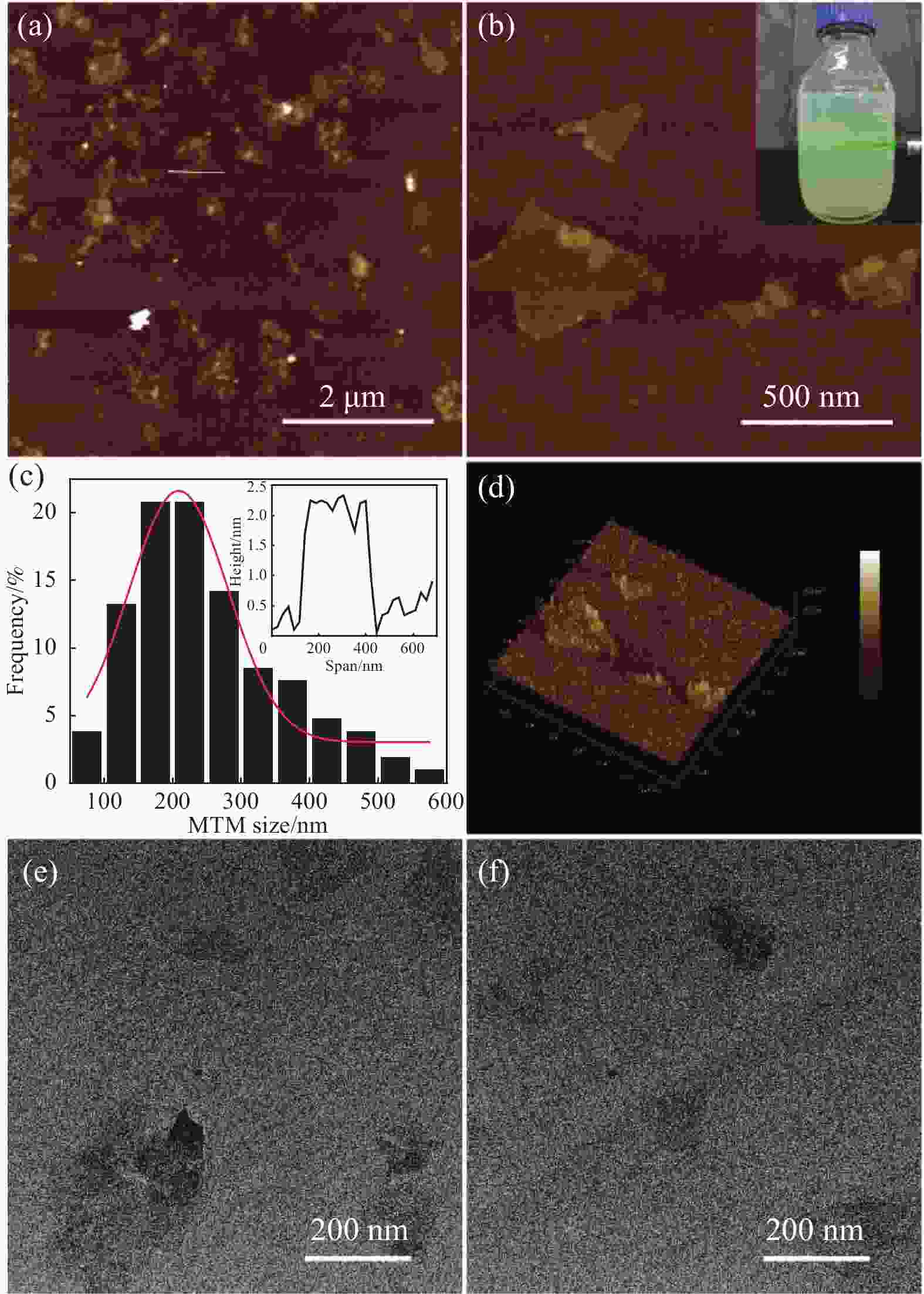

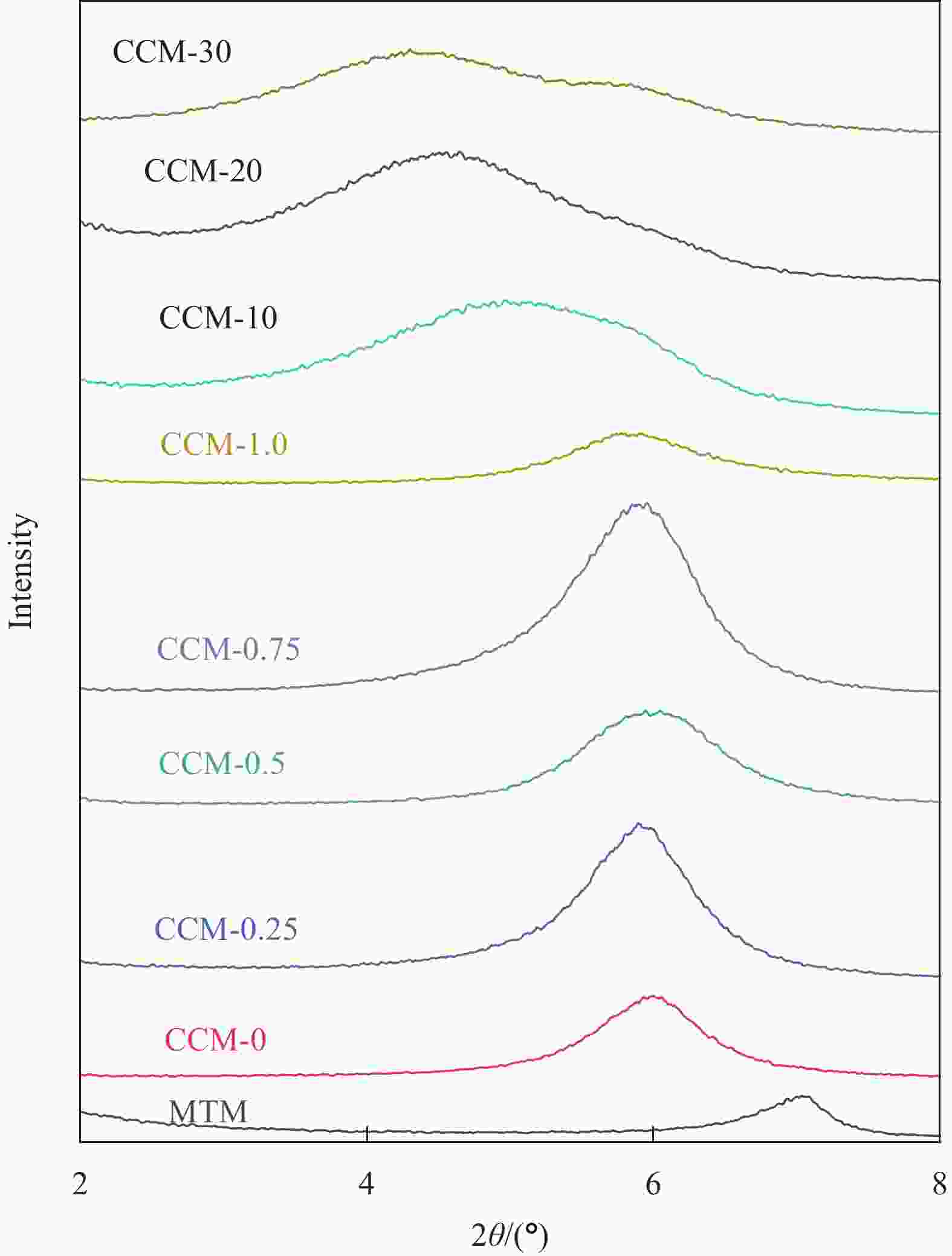

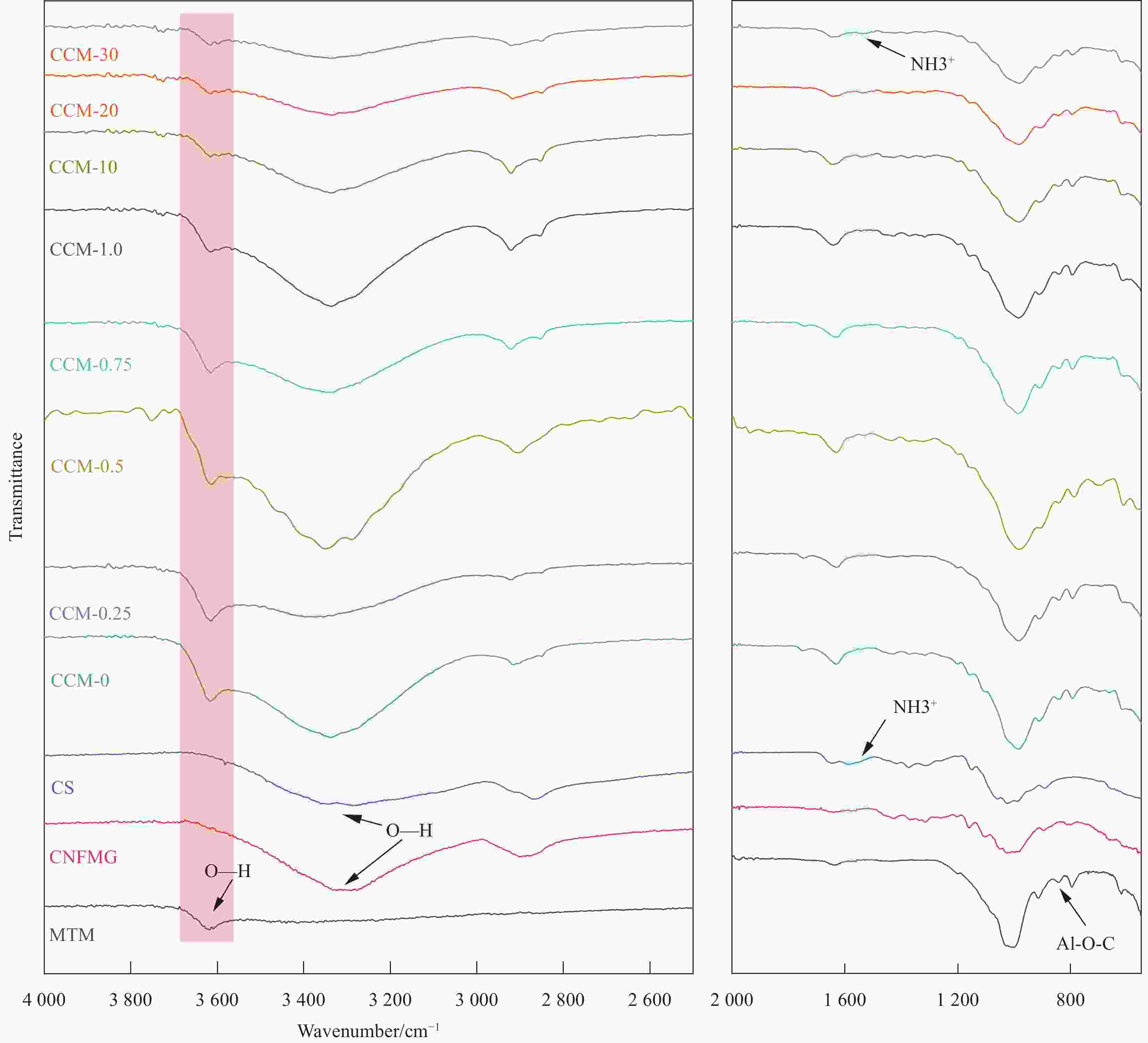

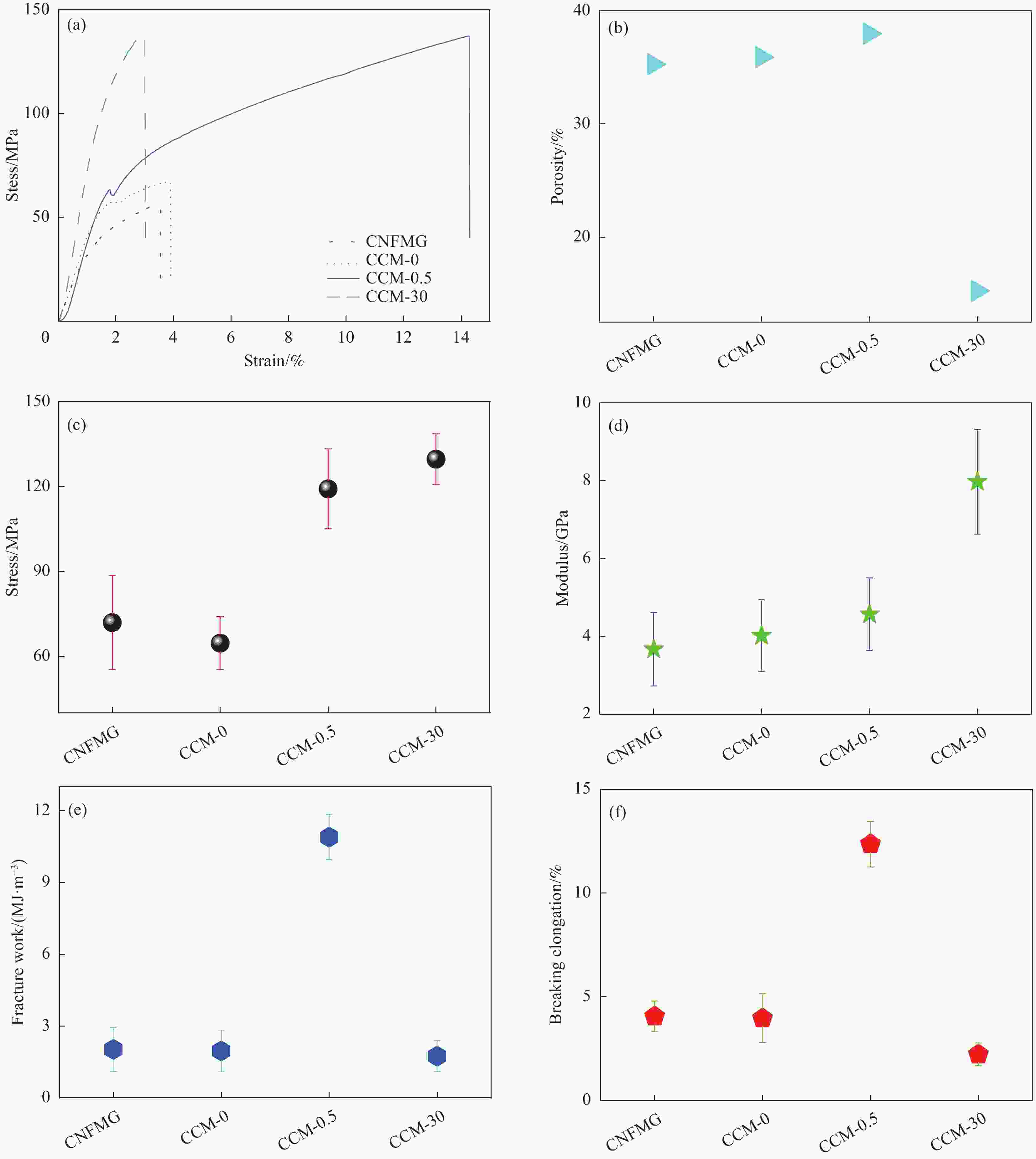

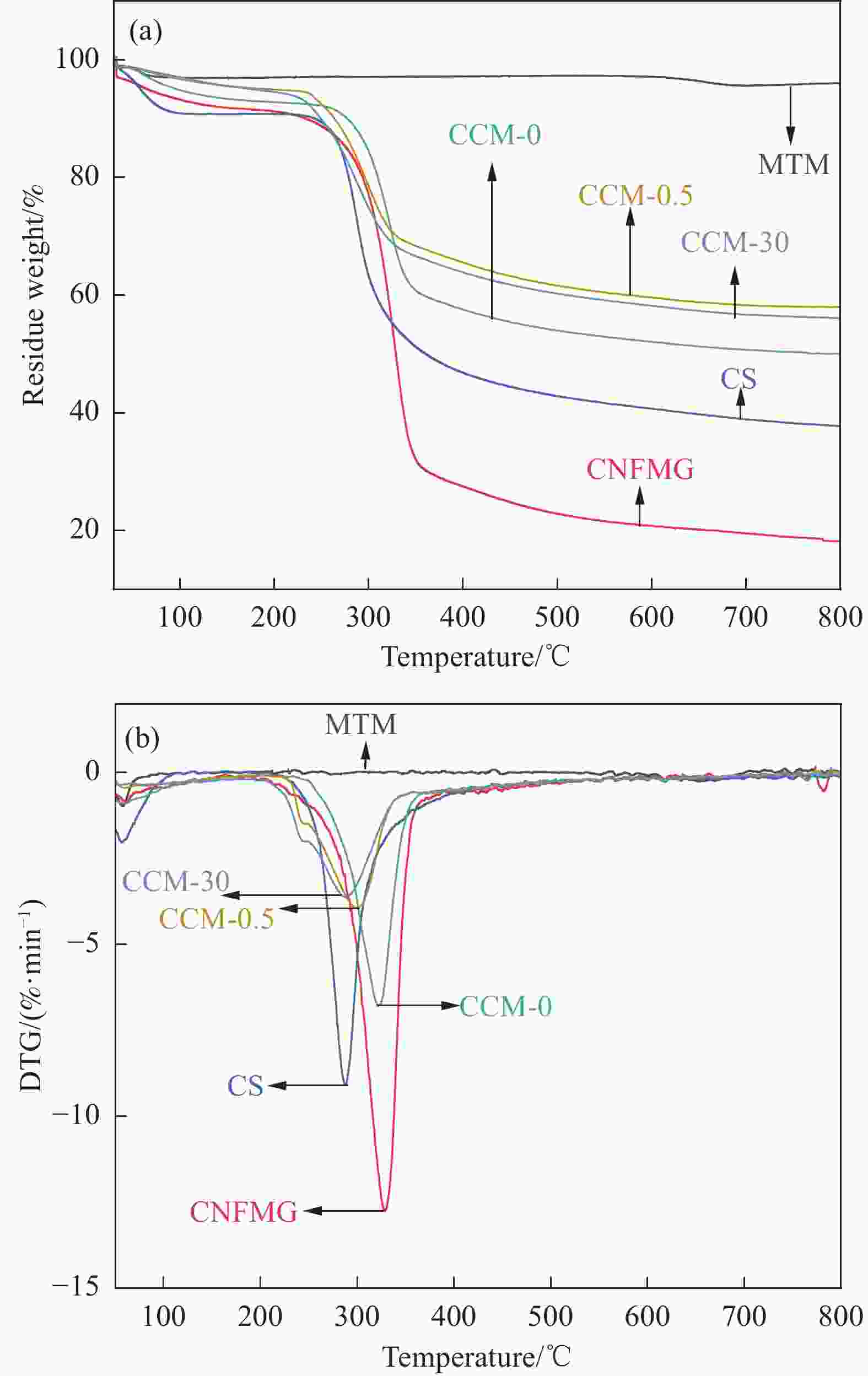

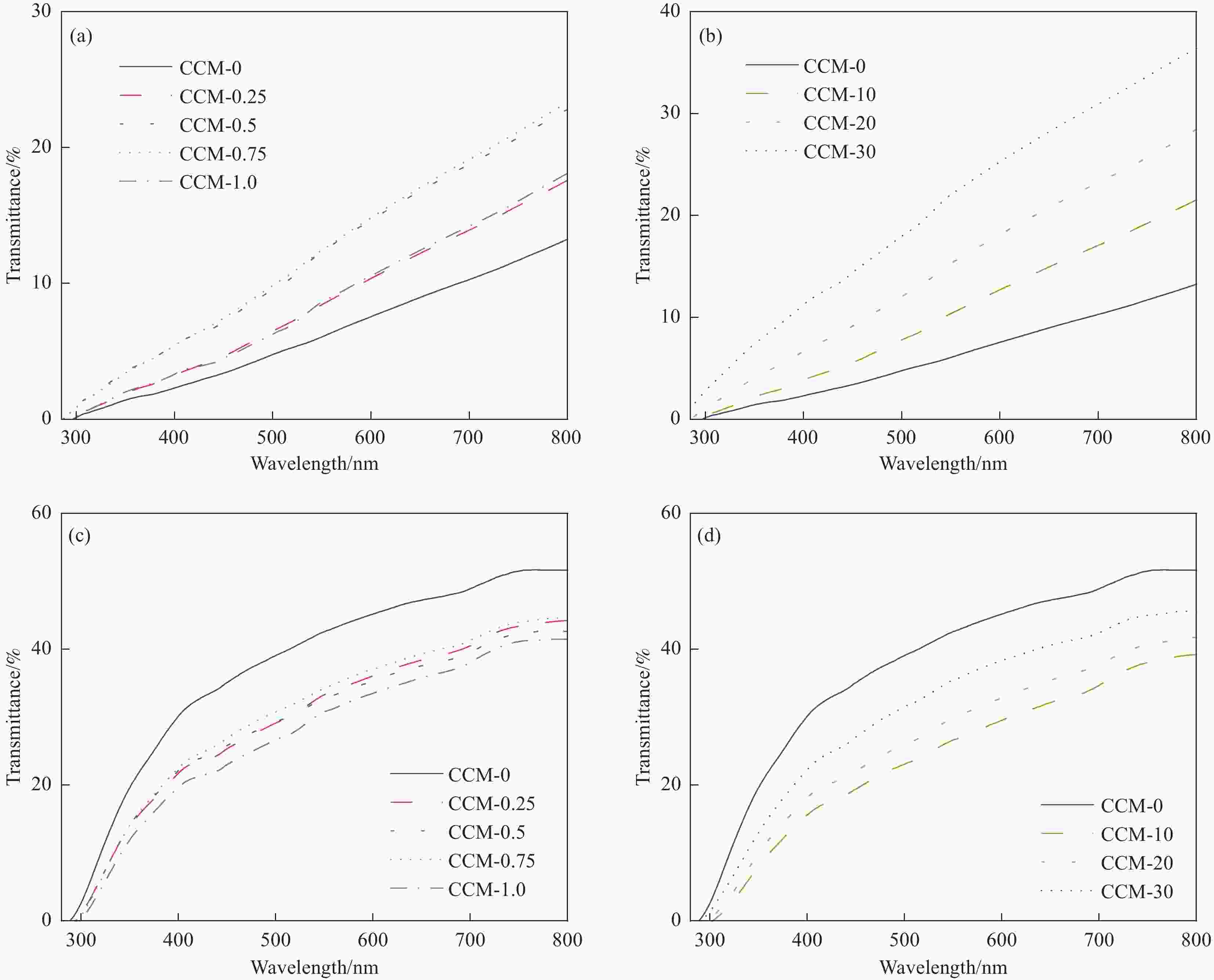

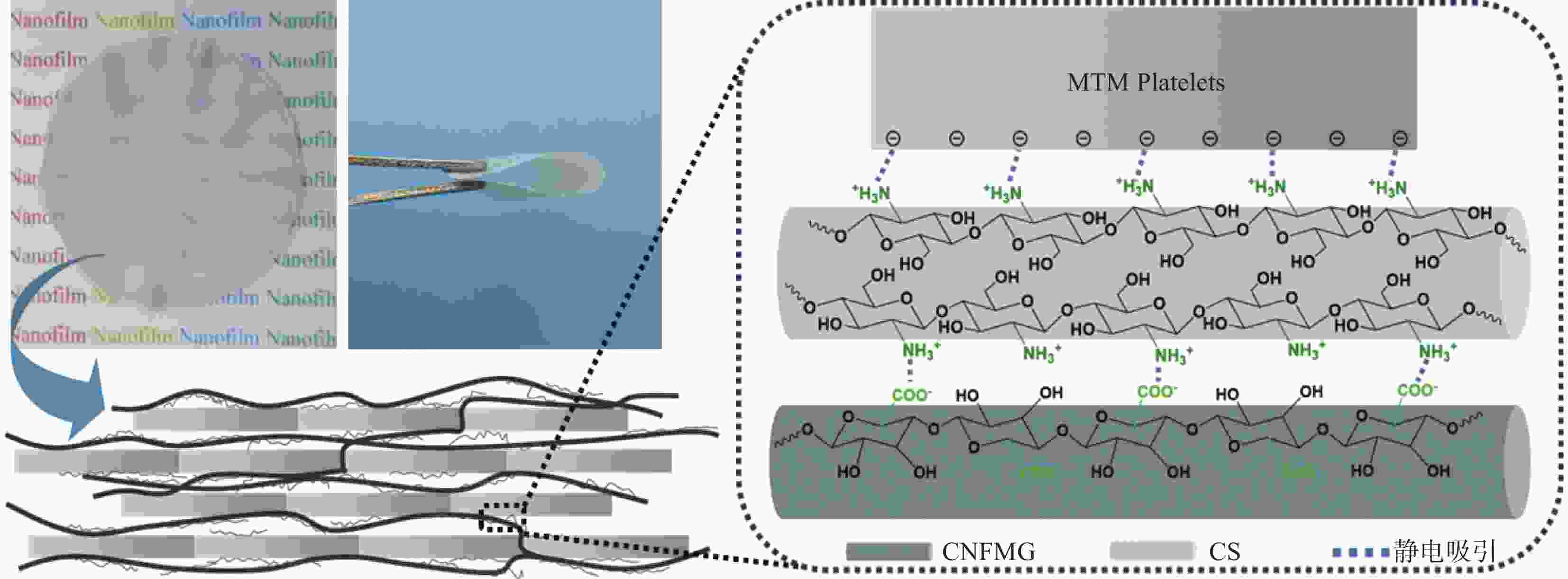

摘要: 利用纤维素和无机物模仿天然贝壳中高度有序的“砖-砂浆”结构制备高强度功能复合材料,是制备绿色包装膜的优秀选择,二者的界面结合是获得理想结构与性能的关键。本文以羧基化纤维素纳米纤维(CNFMG)和蒙脱土(MTM)纳米片制备膜材料,采用壳聚糖(CS)通过静电作用增强界面结合。研究了CS与CNFMG和MTM之间的静电相互作用对纳米复合材料结构、力学性能和热稳定性的影响。结果表明,复合膜中MTM以纳米片状形态有序地分散于CNFMG网络间。与CNFMG-MTM二元膜相比,CS加入后的三元膜拉伸强度达到119.2 MPa,强度提升一倍;断裂能达到10.9 MJ/m3,韧性提升四倍。复合膜为半透明状,具有良好的紫外屏蔽性,CS的加入也提升了复合膜的热稳定性。本文的研究结果可为纤维素基珍珠层仿生材料的研究和应用提供思路。Abstract: The way of mimicking the ordered “brick and mortar” structure in natural shells to prepare high-strength functional composite materials with cellulose and inorganic substances of which the interface bonding is the key to achieving ideal structure and performance is a potential excellent choice for producing naturally degradable packaging films. The single interfacial binding force between nanocellulose and montmorillonite results in insufficient mechanical properties. In this work, carboxymethyl cellulose nanofibers (CNFMG) and montmorillonite (MTM) nanosheets were used to prepare pearl layer films in which chitosan (CS) enhanced interface bonding through electrostatic interaction. The effects of electrostatic interactions between CS, CNFMG, and MTM on the structure, mechanical properties, and thermal stability of nanocomposites were studied. The results indicate that MTM in the composite membrane was orderly dispersed in nanosheet form between CNFMG networks. Compared with the CNFMG-MTM binary film, the tensile strength of the ternary film with the addition of CS reached 119.2 MPa, which doubled the strength. The fracture energy reached 10.9 MJ/m3, and the toughness was increased by four times. The composite film was semitransparent and had good UV shielding properties. The addition of CS also enhanced the thermal stability of the composite film. The research results of this article can provide ideas for the research and application of cellulose based pearl layer biomimetic materials.

-

Key words:

- nanocellulose /

- montmorillonoid /

- chitosan /

- composite membrane /

- biomimetic pearl layer structure

-

图 4 纯 CNFMG膜(a-d);CCM-0.5(e-h)表面和拉伸断面;(j)贝壳 Semicassis bisulcate[1] ;(k)贝壳Fissurella crassa [1]的扫描电子显微镜(SEM)图像,EL(external layer)指外部层,ML 指中间层(middle layer),IL 指内部层(initial layer)

Figure 4. SEM iamges of surface and stretch section of pure CNFMG membrane (a-d); CCM-0.5 (e-h) and facture for Semicassis bisulcate(j) and Fissurella crassa (k), EL, external layer; ES, external surface of the shell; IL, internal layer;ML, middle layer

表 1 试样的配比与命名

Table 1. Naming of membrane with different CS ratio

Name CS/wt% CNFMG/MTM(mass ratio) CNFMG — — CCM-0 0 1∶1 CCM-0.25 0.25 1∶1 CCM-0.5 0.5 1∶1 CCM-0.75 0.75 1∶1 CCM-1.0 1.0 1∶1 CCM-10 10 1∶1 CCM-20 20 1∶1 CCM-30 30 1∶1 Notes: CCM—CS-CNFMG-MTM -

[1] YAO H B, GE J, MAO L B, et al. 25th Anniversary Article: Artificial Carbonate Nanocrystals and Layered Structural Nanocomposites Inspired by Nacre: Synthesis, Fabrication and Applications[J]. Advanced Materials, 2014, 26(1): 163-188. doi: 10.1002/adma.201303470 [2] YANG X, LI L, NISHIYAMA Y, et al. Processing strategy for reduced energy demand of nanostructured CNF/clay composites with tailored interfaces[J]. Carbohydrate Polymers, 2023, 312: 120788 [3] DING F, LIU J, ZENG S, et al. Biomimetic nanocoatings with exceptional mechanical, barrier, and flame-retardant properties from large-scale one-step coassembly[J]. Science Advances, 2017, 3(7): e1701212. doi: 10.1126/sciadv.1701212 [4] MEDINA L, NISHIYAMA Y, DAICHO K, et al. Nanostructure and Properties of Nacre-Inspired Clay/Cellulose Nanocomposites-Synchrotron X-ray Scattering Analysis[J]. Macromolecules, 2019, 52(8): 3131-3140. doi: 10.1021/acs.macromol.9b00333 [5] YAO K, HUANG S, TANG H, et al. Bioinspired Interface Engineering for Moisture Resistance in Nacre-Mimetic Cellulose Nanofibrils/Clay Nanocomposites[J]. Acs Applied Materials & Interfaces, 2017, 9(23): 20169-20178. [6] LIU A, WALTHER A, IKKALA O, et al. Clay Nanopaper with Tough Cellulose Nanofiber Matrix for Fire Retardancy and Gas Barrier Functions[J]. Biomacromolecules, 2011, 12(3): 633-641. doi: 10.1021/bm101296z [7] PODSIADLO P, KAUSHIK A K, ARRUDA E M, et al. Ultrastrong and stiff layered polymer nanocomposites[J]. Science, 2007, 318(5847): 80-83. doi: 10.1126/science.1143176 [8] LIANG K, SPIESZ E M, SCHMIEDEN D T, et al. Bioproduced Polymers Self-Assemble with Graphene Oxide into Nanocomposite Films with Enhanced Mechanical Performance[J]. ACS Nano, 2020, 14(11): 14731-14739. doi: 10.1021/acsnano.0c00913 [9] 梁虎, 张礼兵, 吴婷, et al. 基于醋酸纤维素/MXene复合纤维膜的柔性触觉传感器[J]. 复合材料学报, 2023, 40(11): 6228-6240.LIANG Hu, ZHANG Libing, WU Ting, et al. A flexible tactile sensor based on cellulose acetate/MXene composite fiber membrane[J]. Acta Materiae Compositae Sinica, 2023, 40(11): 6228-6240(in Chinese). [10] 孙泽营, 姜大伟, 孙才英. 石墨烯(碳纳米管)-纤维素/角蛋白复合传感薄膜的制备[J]. 复合材料学报, 2023, 42(0): 1-9.SUN Zeying, JIANG Dawei, SUN Caiying. Preparation of graphene (carbon nanotubes) cellulose/keratin composite sensing thin films [J] Acta Materiae Compositae Sinica, 2023, 42 (0): 1-9(in Chinese). [11] SUN C, FANG Z, QIN F, et al. Insight into the dispersive mechanism of Carboxylated Nanofibrilllated cellulose for individual montmorillonite in water[J]. Composites Part B:Engineering, 2019, 177: 107399. doi: 10.1016/j.compositesb.2019.107399 [12] RONG N, XU Z, ZHAI S, et al. Directional, super-hydrophobic cellulose nanofiber/polyvinyl alcohol/montmorillonite aerogels as green absorbents for oil/water separation[J]. IET Nanobiotechnology, 2021, 15(1): 135-146. doi: 10.1049/nbt2.12008 [13] LUO J, MA X, ZHOU X, et al. Construction of physically crosslinked cellulose nanofibrils/alkali lignin/montmorillonoite/polyvinyl alcohol network hydrogel and its application in methylene blue removal[J]. Cellulose, 2021, 28: 5531-5543. doi: 10.1007/s10570-021-03847-1 [14] JIN B, WANG H, XU H, et al. Bio-inspired nacre-like composites with excellent mechanical properties, gas-barrier function and fire-retardant performances based on self-assembly between hyperbranched poly(amido amine)s and montmorillonite[J]. Rsc Advances, 2023, 13(6): 3661-3668. doi: 10.1039/D2RA07647K [15] YAO H B, TAN Z H, FANG H Y, et al. Artificial Nacre-like Bionanocomposite Films from the Self-Assembly of Chitosan-Montmorillonite Hybrid Building Blocks[J]. Angewandte Chemie-International Edition, 2010, 49(52): 10127-10131. [16] XU D, WANG S, BERGLUND L A, et al. Surface Charges Control the Structure and Properties of Layered Nanocomposite of Cellulose Nanofibrils and Clay Platelets[J]. Acs Applied Materials & Interfaces, 2021, 13(3): 4463-4472. [17] GUO T, GU L, ZHANG Y, et al. Bioinspired self-assembled films of carboxymethyl cellulose-dopamine/montmorillonite[J]. Journal of Materials Chemistry A, 2019, 7(23): 14033-14041. [18] LI W, LIU J, LIANG B, et al. Small molecule hydrogen-bonded toughen nacre-inspired montmorillonite-konjac glucomannan-glycerin film with superior mechanical, transparent and UV-blocking properties[J]. Composites Part B-Engineering, 2021, 204: 108492. [19] SUN C, LI G H, WANG J Y, et al. Transparent montmorillonite/cellulose nanofibril nanocomposite films: the influence of exfoliation degree and interfacial interaction[J]. Cellulose, 2022, 29(13): 7111-7124. [20] MING S, CHEN G, HE J, et al. Highly Transparent and Self-Extinguishing Nanofibrillated Cellulose-Monolayer Clay Nanoplatelet Hybrid Films[J]. Langmuir, 2017, 33(34): 8455-8462. doi: 10.1021/acs.langmuir.7b01665 [21] TORGNYSDOTTER A, WAGBERG L. Influence of electrostatic interactions on fibre/fibre joint and paper strength[J]. Nordic Pulp & Paper Research Journal, 2004, 19(4): 440-447. [22] LI J, SONG X Y, PAN J F, et al. Adsorption and flocculation of bentonite by chitosan with varying degree of deacetylation and molecular weight[J]. International Journal of Biological Macromolecules, 2013, 62: 4-12. doi: 10.1016/j.ijbiomac.2013.08.009 [23] LAUFER G, KIRKLAND C, CAIN A A, et al. Clay-Chitosan Nanobrick Walls: Completely Renewable Gas Barrier and Flame-Retardant Nanocoatings[J]. Acs Applied Materials & Interfaces, 2012, 4(3): 1643-1649. [24] ZHANG X F, ELSAYED I, NAVARATHNA C, et al. Biohybrid Hydrogel and Aerogel from Self-Assembled Nanocellulose and Nanochitin as a High-Efficiency Adsorbent for Water Purification[J]. Acs Applied Materials & Interfaces, 2019, 11(50): 46714-46725. [25] ZHAO C, ZHANG H, ZENG X, et al. Enhancing the inter-fiber bonding properties of cellulosic fibers by increasing different fiber charges[J]. Cellulose, 2016, 23(3): 1617-1628. [26] FU P J, XU K L, SONG H Z, et al. Preparation, stability and rheology of polyacrylamide/pristine layered double hydroxide nanocomposites[J]. Journal of Materials Chemistry, 2010, 20(19): 3869-3876. [27] WU K, FANG J, MA J, et al. Achieving a Collapsible, Strong, and Highly Thermally Conductive Film Based on Oriented Functionalized Boron Nitride Nanosheets and Cellulose Nanofiber[J]. Acs Applied Materials & Interfaces, 2017, 9(35): 30035-30045. [28] LI L, MADDALENA L, NISHIYAMA Y, et al. Recyclable nanocomposites of well-dispersed 2D layered silicates in cellulose nanofibril (CNF) matrix[J]. Carbohydrate Polymers, 2022, 279: 119004. [29] ZHAO H, YUE Y, ZHANG Y, et al. Ternary Artificial Nacre Reinforced by Ultrathin Amorphous Alumina with Exceptional Mechanical Properties[J]. Advanced Materials, 2016, 28(10): 2037-2042. [30] AHNAGRO I, DRZYMALA P, BERENT K, et al. New Crystallographic Relationships in Biogenic Aragonite: The Crossed-Lamellar Microstructures of Mollusks[J]. Crystal Growth & Design, 2016, 16(4): 2083-2093. [31] RAUT H K, SCHWARTZMAN A F, DAS R, et al. Tough and Strong: Cross-Lamella Design Imparts Multifunctionality to Biomimetic Nacre[J]. Acs Nano, 2020, 14(8): 9771-9779. [32] YANG X, LI L, NISHIYAMA Y, et al. Processing strategy for reduced energy demand of nanostructured CNF/clay composites with tailored interfaces[J]. Carbohydrate Polymers, 2023, 312: 120788. [33] ENESCU D, GARDRAT C, CRAMAIL H, et al. Bio-inspired films based on chitosan, nanoclays and cellulose nanocrystals: structuring and properties improvement by using water-evaporation-induced self-assembly[J]. Cellulose, 2019, 26(4): 2389-23401. [34] MARCHESSAULT R H, PEARSON F G, LIANG C Y. Infrared spectra of crystalline polysaccharides. VI. Effect of orientation on the tilting spectra of chitin films[J]. Biochimica et Biophysica Acta, 1960, 45: 499-507. [35] CHEN G G, QI X M, GUAN Y, et al. High Strength Hemicellulose-Based Nanocomposite Film for Food Packaging Applications[J]. Acs Sustainable Chemistry & Engineering, 2016, 4(4): 1985-1993. [36] LIU A, BERGLUND L A. Clay nanopaper composites of nacre-like structure based on montmorrilonite and cellulose nanofibers-Improvements due to chitosan addition[J]. Carbohydrate Polymers, 2012, 87(1): 53-60. -

点击查看大图

点击查看大图

计量

- 文章访问数: 158

- HTML全文浏览量: 106

- 被引次数: 0

下载:

下载: