Mechanical properties of basalt fiber reinforced polymer grids reinforced magnesium phosphate cement mortar composite

-

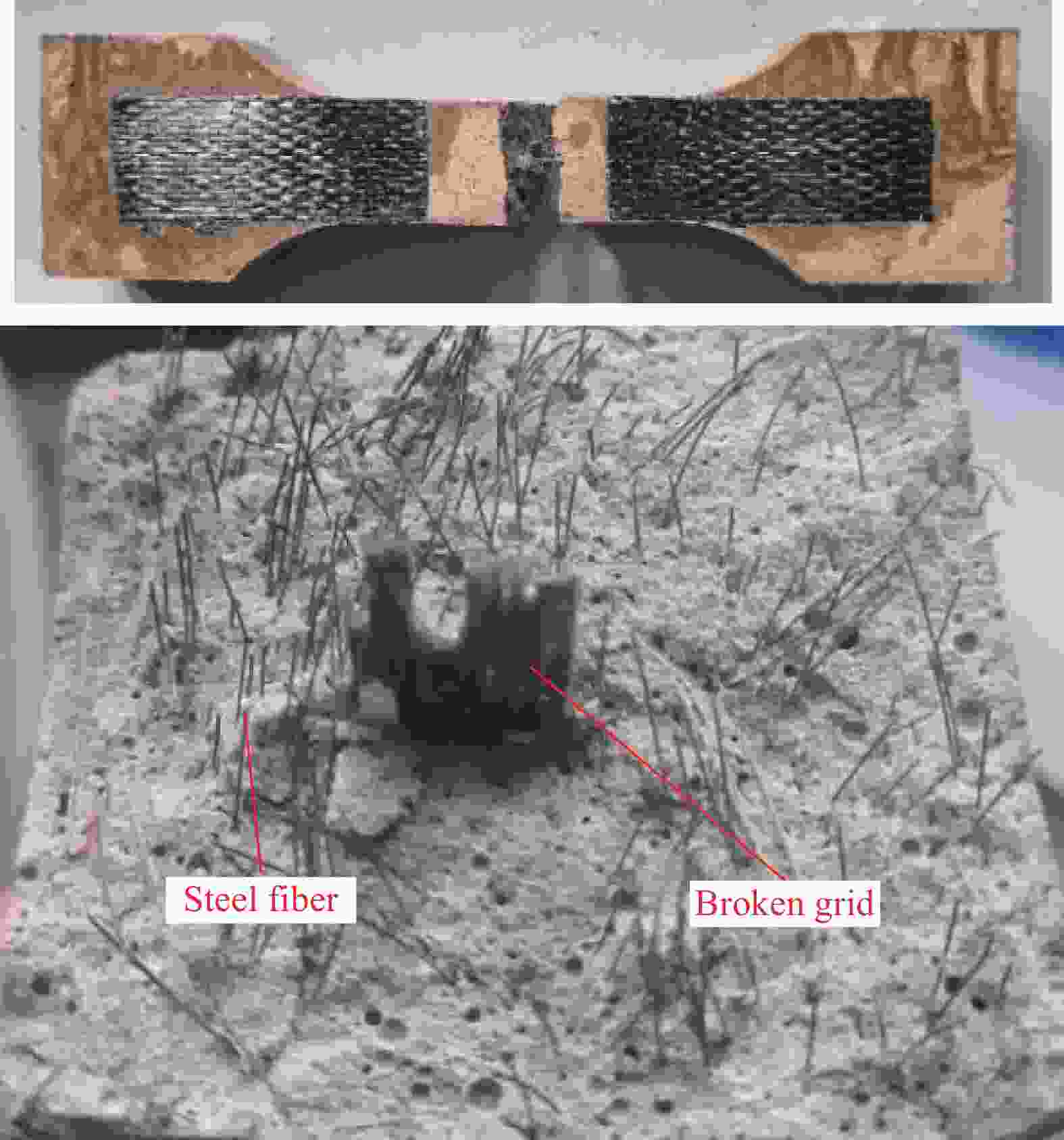

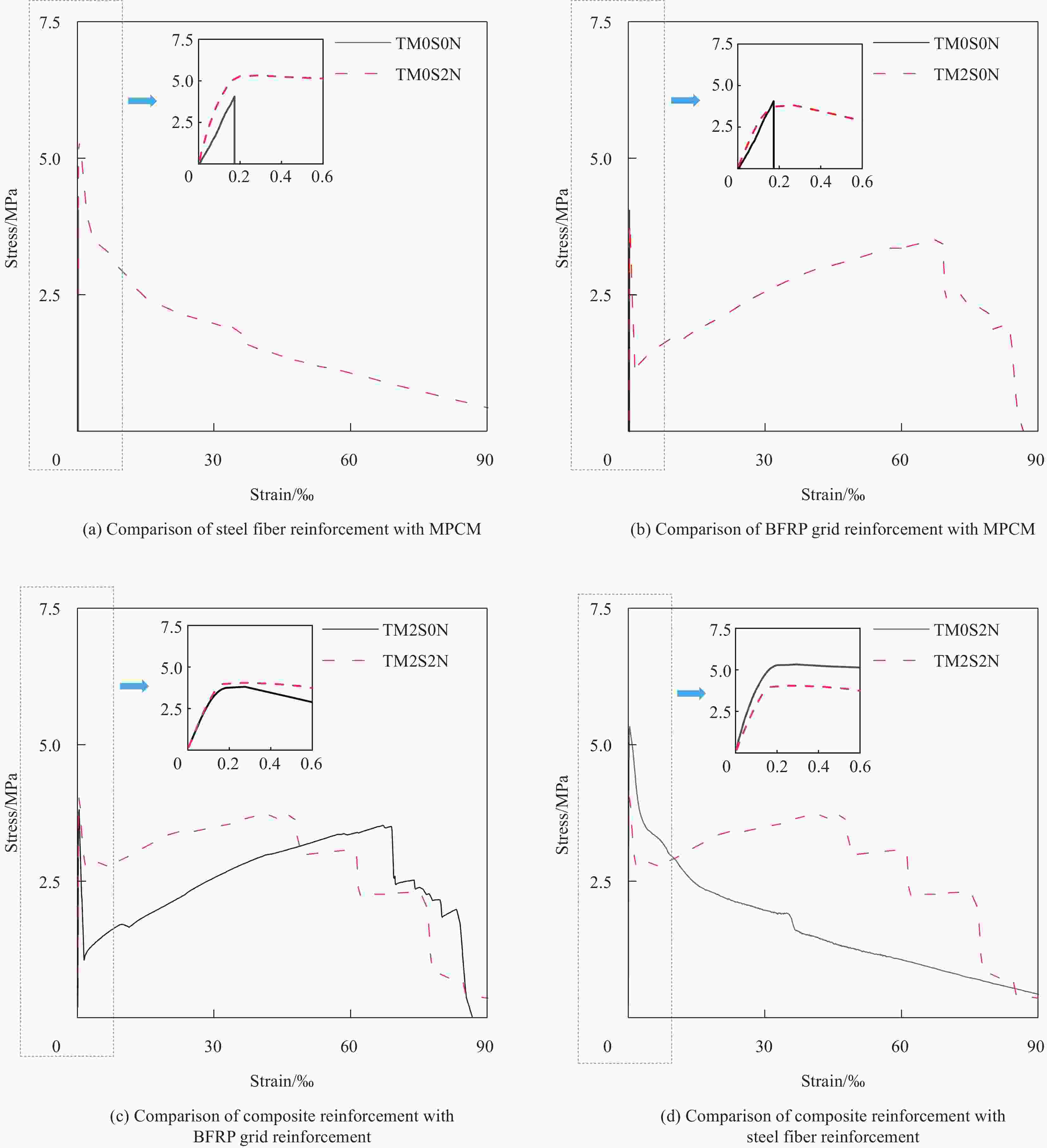

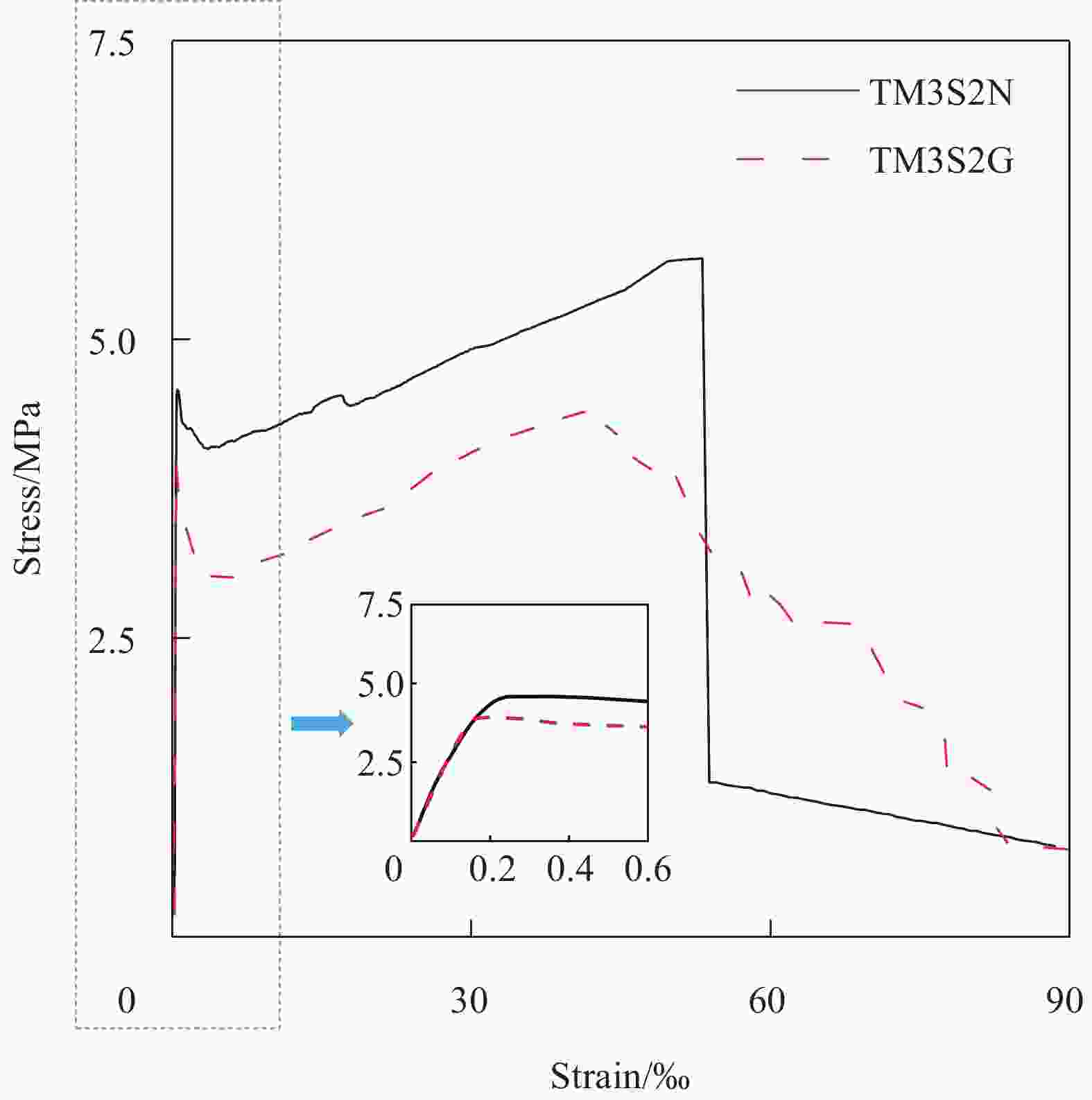

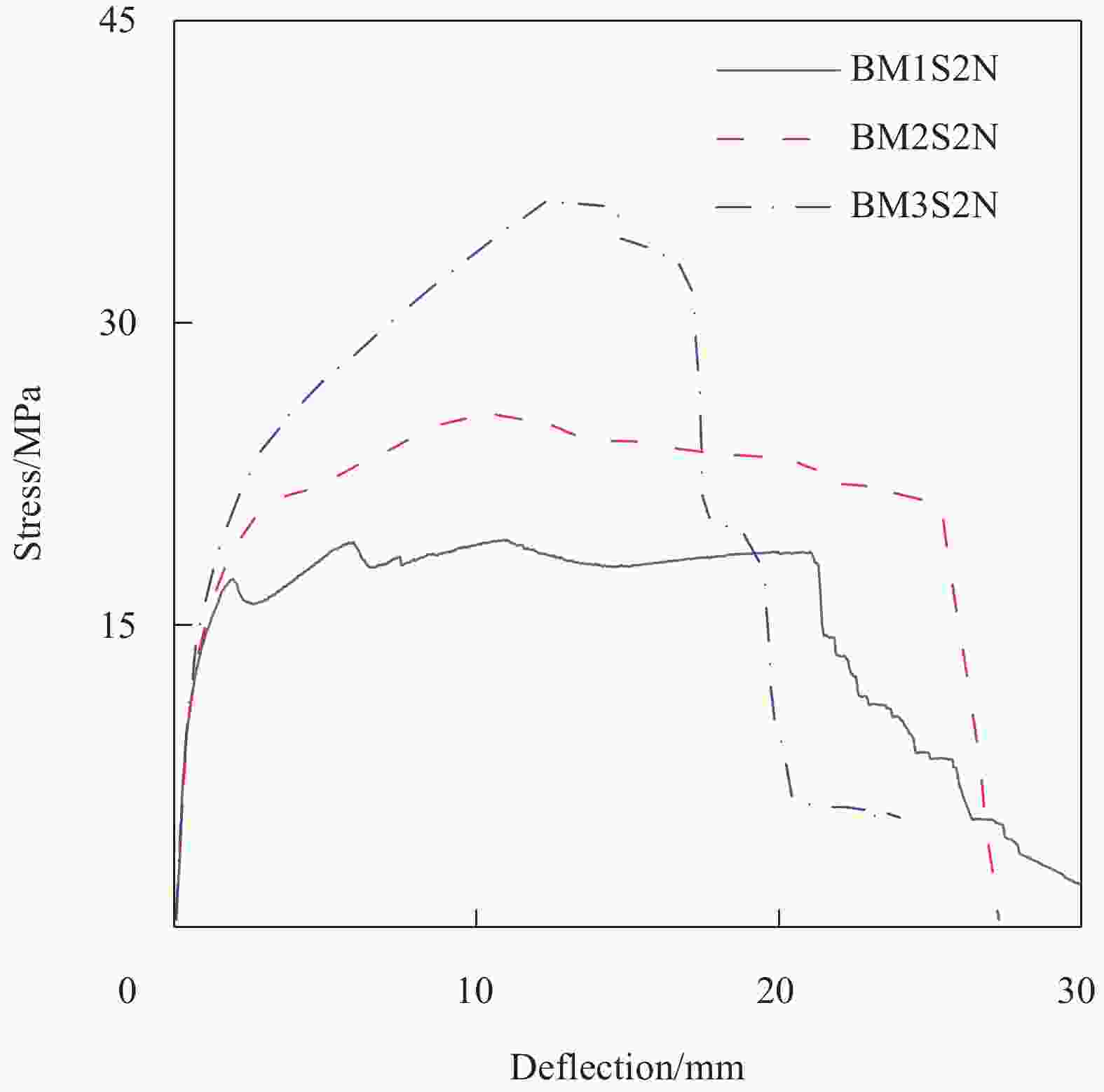

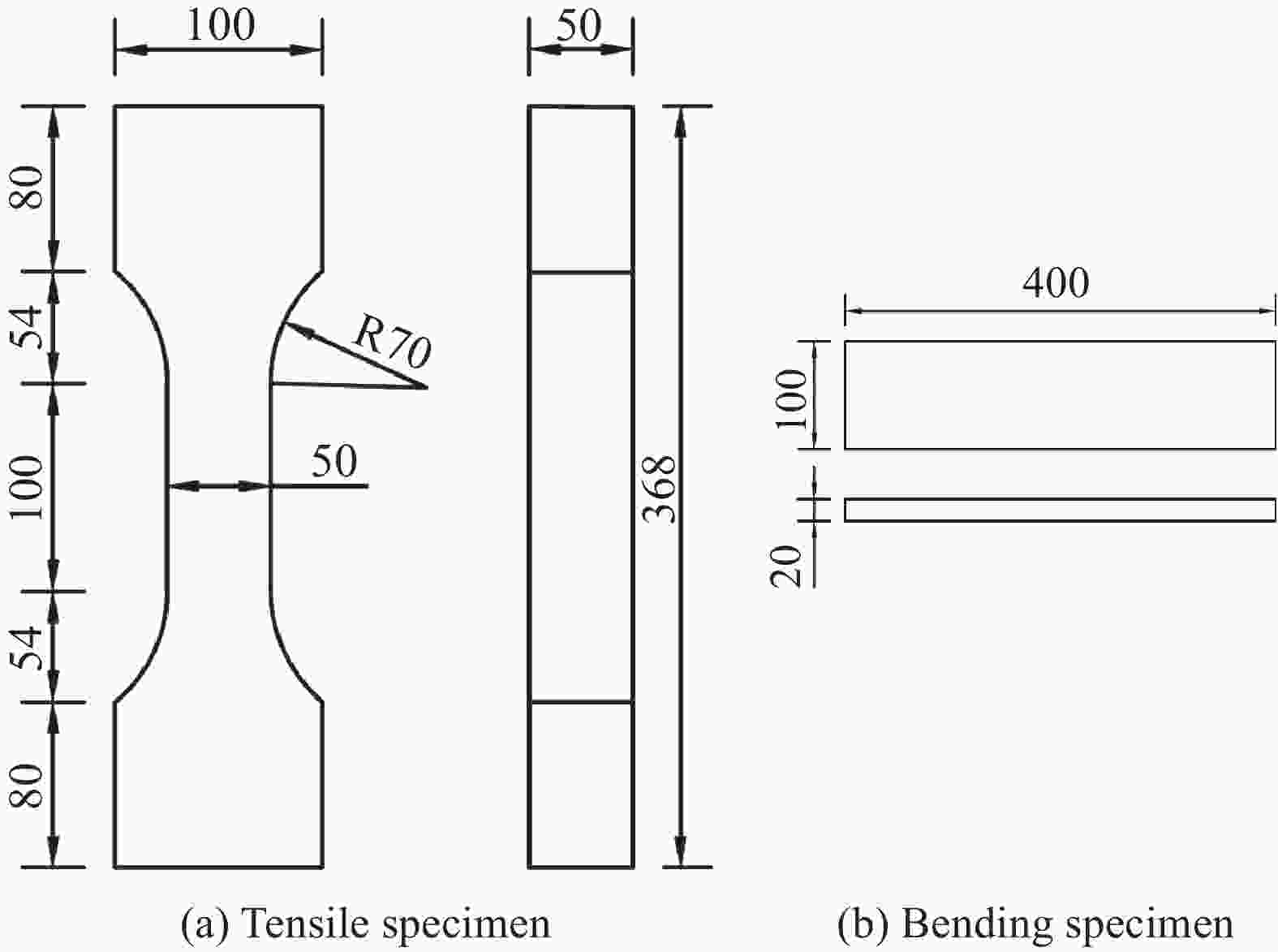

摘要: 为了研究钢纤维与玄武岩纤维(Basalt Fiber Reinforced Polymer,BFRP)网格对磷酸镁水泥砂浆(Magnesium Phosphate Cement Mortar,MPCM)力学性能的增强效果,制备了BFRP网格增强磷酸镁水泥砂浆(Grid Reinforced Magnesium Phosphate Cement Mortar,GRMM)复合材料。通过轴向拉伸试验和四点弯曲试验,研究材料复合方式(钢纤维增强、BFRP网格增强、复合增强)、BFRP网格厚度(1 mm、2 mm、3 mm)和BFRP网格表面形式(未处理、粘砂)对复合材料拉伸应力-应变曲线、弯曲应力-挠度曲线与关键力学参数的影响规律,以及钢纤维、BFRP网格在GRMM中的作用机制。结果表明:钢纤维主要在GRMM受力前期发挥作用,可以有效地抑制裂缝的产生,起到了增强、增韧的作用,钢纤维的掺入使拉伸试件与弯曲试件承载力分别提高了24.23%与215.33%,并提高了两类试件的抗裂性能、变形与耗能能力;BFRP网格作为拉应力的主要承担者,作用于GRMM整个受力过程,使两类试件的峰值变形提升了70倍以上,但试件中BFRP网格与MPCM受力并不协调;两种材料复合增强下,GRMM综合了钢纤维对基体的增强效果与BFRP网格的良好变形性能,其抗裂性能、强度、变形性能及耗能能力均得到提升;随着BFRP网格厚度的增加,GRMM试件强度与耗能能力得到进一步提升;BFRP网格表面进行粘砂处理对GRMM各项性能影响并不明显。Abstract: To investigate the influences of basalt fiber reinforced polymer (BFRP) grid and steel fibers on the mechanical properties of magnesium phosphate cement mortar (MPCM), BFRP grid reinforced magnesium phosphate cement mortar (GRMM) composite was prepared. The effects of material forms (steel fiber reinforced, BFRP grid reinforced and composite reinforced), BFRP grid thicknesses (1mm, 2mm and 3mm), and BFRP grid surface forms (untreated and sand-sticked) on the tensile stress-strain curves, bending stress-deflection curves, and key indexes of GRMM were investigated by the axial tensile test and four-point bending test. Moreover, the roles of steel fibers and BFRP grid in GRMM were also studied. The results show that steel fibers mainly play a role in the early stage, which can effectively inhibit the generation of cracks and improve the strength and toughness of GRMM. The incorporation of steel fibers increases the tensile and bending capacity by 24.23% and 215.33%, respectively, and improves the crack resistance, ductility and energy consumption of both types of specimens. The tensile stress is the mainly borne by BFRP grid, which plays a role throughout the whole loading process of GRMM. The incorporation of the BFRP grid improves the peak deformation of both tests by more than 70 times, but the BFRP grid is not coordinated with the MPCM in the specimen. Combined with the strengthening effects of steel fibers on the matrix and the good deformation of BFRP grid, the cracking resistance, strength, ductility and energy dissipation capacity of MPCM matrix are improved. As the thickness of the BFRP grid increases, the strength and energy dissipation capacity of the GRMM specimens are further improved. Sticking sand on the BRFP grid does not significantly affect the mechanical properties of GRMM.

-

表 1 磷酸镁水泥砂浆(MPCM)配合比及性能

Table 1. Mix proportion and material performance of magnesium phosphate cement mortar (MPCM)

Material Cement-A/

(kg·m−3)Cement-B/

(kg·m−3)Sand/

(kg·m−3)Water/

(kg·m−3)Borax/

(kg·m−3)Rf-3 h/

MPaRf-3 d/

MPaRc-3 h/

MPaRc-3 d/

MPaMPCM 660 660 800 200 26.4 10.3 11.5 49.2 55.7 Notes: Rf and Rc are the flexural strength and the compressive strength, 3 h and 3 d are the ages of MPCM. 表 2 玄武岩纤维网格(BFRP)材料性能

Table 2. Basalt fiber reinforced polymer (BFRP) grids material performance

Tensile strength/MPa Modulus of elasticity/GPa Elongation/% 493 25.37 1.9 表 3 试件参数

Table 3. Specimen parameters

Specimen number Fiber admixture/% Grid thickness/mm Grid surface forms T/BM0S0N-1/2/3 0 0 No treatment T/BM0 S2 N-1/2/3 2 0 T/BM2S0N-1/2/3 0 2 T/BM2 S2 N-1/2/3 2 2 T/BM1 S2 N-1/2/3 2 1 T/BM3 S2 N-1/2/3 2 3 T/BM3 S2 G-1/2/3 2 3 Sand-sticked Notes: In the specimen number, T/B is tensile/bending specimen, M is grid thickness, S is fiber admixture, N/G is grid with no treatment/sand-sticked, 1/2/3 is parallel specimen numbers. 表 4 GRMM拉伸试验结果

Table 4. GRMM tensile test results

Specimen grouping Specimen number σcr/MPa εcr/‰ Es/GPa σsec/MPa εu/‰ TM0S0N TM0S0N-1 4.15 0.17 22.6 - 0.17 TM0S0N-2 4.20 0.19 22.2 - 0.19 TM0S0N-3 3.81 0.16 24.6 - 0.16 Mean 4.05 0.17 23.1 - 0.17 Cov 0.04 0.08 0.05 - 0.08 TM0S2N TM0S2N-1 5.25 0.25 35.8 - 1.15 TM0S2N-3 5.53 0.18 31.1 - 1.67 Mean 5.39 0.22 33.4 - 1.41 Cov 0.03 0.15 0.07 - 0.18 TM2S0N TM2S0N-1 3.74 0.17 29.6 3.68 83.80 TM2S0N-3 3.94 0.18 26.6 3.63 88.93 Mean 3.84 0.18 28.1 3.66 86.37 Cov 0.11 0.03 0.05 0.01 0.07 TM1S2N TM1S2N-1 4.22 0.16 27.6 3.76 57.00 TM1S2N-2 4.48 0.19 26.7 3.67 40.49 TM1S2N-3 4.35 0.18 26.5 3.14 37.77 Mean 4.35 0.18 26.9 3.52 45.09 Cov 0.02 0.07 0.02 0.08 0.19 TM2S2N TM2S2N-2 4.09 0.16 27.3 3.55 43.45 TM2S2N-3 4.02 0.15 27.7 4.35 75.15 Mean 4.05 0.16 27.5 3.95 59.30 Cov 0.01 0.02 0.01 0.10 0.27 TM3S2N TM3S2N-1 4.55 0.21 24.1 5.7 45.36 TM3S2N-3 4.71 0.21 24.9 5.7 62.43 Mean 4.63 0.21 24.5 5.7 53.90 Cov 0.02 0 0.02 0 0.16 TM3S2G TM3S2G-1 4.02 0.16 28.7 4.23 43.08 TM3S2G-2 4.06 0.15 28.1 4.51 47.24 TM3S2G-3 4.37 0.18 27 5.11 60.20 Mean 4.15 0.16 27.9 4.62 50.17 Cov 0.04 0.06 0.03 0.08 0.15 Notes:σcr is cracking stress, εcr is cracking strain, Es is elastic modulus, σsec is peak stress at second rise of the stress-strain curve, εu is ultimate strain. Specimens TM0S2N-2, TM2S0N-2, TM2S2N-1and TM3S2N-2were destroyed outside of the measurement section, their data were not listed in the table, and they were not involved in subsequent data analysis. 表 5 GRMM弯曲试验结果

Table 5. GRMM bending test results

Specimen grouping Specimen number σcr/MPa δcr/mm σmax/MPa δmax/mm BM0S0N BM0S0N-1 6.15 0.39 6.15 0.39 BM0S0N-2 6.07 0.34 6.07 0.34 BM0S0N-3 6.84 0.26 6.84 0.26 Mean 6.36 0.33 6.36 0.33 Cov 0.07 0.20 0.07 0.20 BM0 S2 N BM0 S2 N-1* 9.89 0.33 14.01 0.96 BM0 S2 N-2 9.18 0.35 19.85 2.51 BM0 S2 N-3 10.20 0.35 20.24 2.17 Mean 9.69 0.35 20.05 2.34 Cov 0.07 0 0.014 0.10 BM2S0N BM2S0N-1 5.92 0.21 23.35 26.13 BM2S0N-2 6.00 0.28 29.04 24.32 BM2S0N-3 6.70 0.29 24.44 19.72 Mean 6.20 0.26 25.61 23.39 Cov 0.07 0.17 0.012 0.14 BM1 S2 N BM1 S2 N-1 8.25 0.16 21.88 21.08 BM1 S2 N-2 7.09 0.23 19.15 23.96 BM1 S2 N-3 7.17 0.28 18.99 21.26 Mean 7.50 0.22 20.01 22.10 Cov 0.09 0.27 0.08 0.07 BM2 S2 N BM2 S2 N-1 6.63 0.32 24.60 27.63 BM2 S2 N-2 7.70 0.23 24.29 26.69 BM2 S2 N-3 7.51 0.27 29.89 25.13 Mean 7.28 0.27 26.26 26.48 Cov 0.08 0.16 0.12 0.05 BM3 S2 N BM3 S2 N-1 6.85 0.25 31.53 14.17 BM3 S2 N-2 8.25 0.24 35.34 12.36 BM3 S2 N-3 7.94 0.24 45.78 15.70 Mean 7.68 0.24 37.55 14.08 Cov 0.10 0.02 0.20 0.12 BM3 S2 G BM3 S2 G-1 10.98 0.25 46.95 11.98 BM3 S2 G-2 9.42 0.18 36.12 11.43 BM3 S2 G-3 9.65 0.21 31.30 11.60 Mean 10.02 0.21 38.12 11.67 Cov 0.08 0.16 0.21 0.02 Notes:σcr is cracking stress, δcr is cracking deflection, σmax is bending strength, δmax is ultimate deflection. Since the uneven distribution of steel fibers affected the bending strength of specimen, BM0 S2 N-1 was not involved in the calculation of subsequent analysis. -

[1] 唐亮. 寒区隧道冻害形成机理与防治对策研究 [D]. 重庆: 重庆交通大学, 2011.TANG Liang. Study on the freezing damage mechanism and prevention of tunnels in cold regions [D]. Chongqin: Chongqing Jiaotong University, 2011(in Chinese). [2] 刘德军, 仲飞, 黄宏伟, 等. 运营隧道衬砌病害诊治的现状与发展[J]. 中国公路学报, 2021, 34(11): 178-199.LIU Dejun, ZHONG Fei, HUANG Hongwei, et al. Present status and development trend of diagnosis and treatment of tunnel lining diseases[J]. China Journal of Highway and Transport, 2021, 34(11): 178-199(in Chinese). [3] 秦继辉, 钱觉时, 宋庆, 等. 磷酸镁水泥的研究进展与应用[J]. 硅酸盐学报, 2022, 0(06): 1592-1606.QIN Jihui, QIAN Jueshi, SONG Qing, et al. Research progress on magnesium phosphate cement[J]. Journal of the Chinese ceramic society, 2022, 0(06): 1592-1606 (in Chinese). [4] 谢剑, 李明, 白伟亮. MPC混凝土制备及其力学性能试验研究[J]. 北京工业大学学报, 2020, 46,(8): 948-955.XIE Jian, LI Ming, BAI Weiliang. Experimental study on preparation and mechanical properties of MPC concrete[J]. Journal of Beijing University of Technology, 2020, 46,(8): 948-955 (in Chinese). [5] FENG H, SHEIKH M N, HADI M N S, et al. Pullout behaviour of different types of steel fibres embedded in magnesium phosphate cementitious matrix[J]. International Journal of Concrete Structures and Materials, 2019, 13(1): 33. doi: 10.1186/s40069-019-0344-1 [6] 贾兴文, 连磊, 田昊, 等. 超高性能磷酸镁水泥混凝土的制备和力学性能研究[J]. 功能材料, 2022, 53(6): 6019-6024. doi: 10.3969/j.issn.1001-9731.2022.06.004JIA Xingwen, LIAN Lei, TIAN Hao, et al. The preparation and mechanical properties of ultra high performance magnesium phosphate cement concrete[J]. Journal of Functional Materials, 2022, 53(6): 6019-6024(in Chinese). doi: 10.3969/j.issn.1001-9731.2022.06.004 [7] FENG H, LI L, ZHANG P, et al. Microscopic characteristics of interface transition zone between magnesium phosphate cement and steel fiber[J]. Construction and Building Materials, 2020, (Aug.30): 253. [8] FENG H, CHEN G, GAO D Y, et al. Mechanical properties of steel fiber-reinforced magnesium phosphate cement mortar[J]. Advances in Civil Engineering, 2018, 2018(PT.1): 1-11. [9] 李茂, 岳燕飞, 钱觉时, 等. 钢纤维增强磷酸镁水泥混凝土力学性能研究[J]. 武汉大学学报(工学版), 2022, 55(7): 691-698.LI Mao, YUE Yanfei, QIAN Jueshi, et al. Investigation on the mechanical properties of steel fiber reinforced magnesium phosphate cement concrete[J]. Engineering Journal of Wuhan University, 2022, 55(7): 691-698 (in Chinese). [10] 武芳文, 刘一帆, 何岚清, 等. 钢纤维磷酸镁水泥混凝土梁受弯性能研究[J]. 中国公路学报, 2023, 36(09): 106-118.WU Fangwen, LIU Yifan, HE Lanqiang, et al. Flexural performance of steel fiber magnesium phosphate cement concrete beams[J]. China Journal of Highway and Transport, 2023, 36(09): 106-118(in Chinese). [11] 李振, 秦继辉, 尤超, 等. 渗浆法钢纤维增强磷酸镁水泥基复合材料的力学性能[J]. 硅酸盐学报, 2019, 47(11): 1559-1565.LI Zhen, QIN Jihui, YOU Chao, et al. Mechanical properties of steel fiber reinforced magnesium phosphate cement-based composite by slurry infiltrating[J]. Journal of the Chinese ceramic society, 2019, 47(11): 1559-1565 (in Chinese) [12] 江佳斐, 隋凯. 纤维网格增强超高韧性水泥复合材料加固混凝土圆柱受压性能试验[J]. 复合材料学报, 2019, 36(08): 1957-1967.JIANG Jiafei, SUI Kai. Experimental study of compression performance of concrete cylinder strengthened by textile reinforced engineering cement composites[J]. Acta Materiae Compositae Sinica, 2019, 36(08): 1957-1967(in Chinese). [13] 王庆轩, 丁一宁. 玄武岩纤维网格布增强混凝土板双向弯曲性能试验[J]. 复合材料学报, 2020, 37(05): 1200-1210.WANG Qingxuan, DING Yining. Experiment on biaxial flexural behaviors of basalt fiber textile reinforced concrete slab[J]. Acta Materiae Compositae Sinica, 2020, 37(05): 1200-1210(in Chinese). [14] 邓宗才, 鹿宇浩, 桂营金. 钢丝网或纤维网增强超高性能混凝土双向板弯曲性能[J]. 复合材料学报, 2022, 39(10): 4757-4768.DENG Zongcai, Lu Yuhao, GUI Yingjin. Flexural properties of ultra high performance concrete reinforced with steel wire mesh of fiber mesh[J]. Acta Materiae Compositae Sinica, 2022, 39(10): 4757-4768(in Chinese). [15] 艾珊霞, 尹世平, 徐世烺. 纤维编织网增强混凝土的研究进展及应用[J]. 土木工程学报, 2015, 48(01): 27-40.AI Shanxia, YIN Shiping, XU Shilang. A review on the development of research and application of textile reinforced concrete[J]. China Civil Engineering Journal, 2015, 48(01): 27-40 (in Chinese). [16] 刘赛. 织物增强水泥基复合材料力学行为的试验研究[D]. 长沙: 湖南大学, 2019.LIU Sai. Experimental investigations on mechanical properties of textile reinforced cementitious composite materials [D]. Changsha: Hunan University, 2019 (in Chinese). [17] 周芬, 刘玲玲, 杜运兴. 碳纤维织物增强水泥基复合材料试验研究[J]. 湖南大学学报(自然科学版), 2017, 44(11): 66-72.ZHOU Fen, LIU Lingling, DU Yunxing. Experimental investigations on carbon textile reinforced cementitious composites[J]. Journal of Hunan University (natural sciences), 2017, 44(11): 66-72 (in Chinese). [18] 殷梦缇, 尹世平, 王波. 氯盐环境下纤维编织网增强混凝土拉伸性能[J]. 复合材料学报, 2018, 35(02): 433-440.YIN Mengti, YIN Shiping, WANG Bo. Tensile property of textile reinforced concrete under chloride salt environment[J]. Acta Materiae Compositae Sinica, 2018, 35(02): 433-440(in Chinese). [19] YIN Shiping, XU Shilang, LI Hedong. Improved Mechanical Properties of Textile Reinforced Concrete Thin Plate[J]. Journal of Wuhan University of Technology (Materials Science Edition), 2013, 28(01): 92-98. doi: 10.1007/s11595-013-0647-z [20] 李冬, 丁一宁. 钢纤维对玄武岩纤维编织网增强混凝土板双向弯曲性能的影响[J]. 复合材料学报, 2019, 36(02): 482-490.LI Dong, DING Yining. Effect of steel fiber on biaxial flexural property of textile reinforced with basalt fiber mesh in slab test[J]. Acta Materiae Compositae Sinica, 2019, 36(02): 482-490(in Chinese). [21] 张汉振, 李伟, 谢剑, 等. 碳纤维编织网增强磷酸镁水泥砂浆界面黏结性能研究[J]. 石家庄铁道大学学报(自然科学版), 2023, 36(02): 42-48.ZHANG Hangzhen, LI Wei, XIE Jian, et al. Interfacial bonding performance of carbon fiber textile reinforced magnesium phosphate cement mortar[J]. Journal of Shijiazhuang Tiedao University (natural science edition), 2023, 36(02): 42-48(in Chinese). [22] 中交第一公路勘察设计研究院有限公司. 《公路隧道加固技术规范》JTG/T5440-2018 [S]. 北京: 人民交通出版社, 2019.CCCC First Highway Consultants Co. Technical Specification for Strengthening of Highway Tunnel. JTG/T5440-2018 [S]. Beijing: People's Communications Press, 2019(in Chinese). [23] 秦继辉. 超高强磷酸镁水泥基复合材料制备与力学行为研究 [D]. 重庆: 重庆大学, 2021.QING Jihui. Study on preparation and mechanical behavior of ultra-high strength magnesium phosphate cement composites [D]. Chongqing: Chongqing university, 2021 (in Chinese). [24] 李传秀, 尹世平, 赵俊伶. 纤维编织网增强ECC的拉伸和弯曲性能[J]. 建筑材料学报, 2021, 24(04): 736-741.LI Chuanxiu, YIN Shiping, ZHAO Junling. Tensile and bending properties of textile reinforced ECC[J]. Journal of building materials, 2021, 24(04): 736-741(in Chinese). [25] 中国建筑材料联合会. 超高性能混凝土基本性能与试验方法T/CBMF 37-2018[S]. 北京: 中国建材工业出版社, 2018.China Building Materials Federation. Basic Properties and Test Methods of Ultra High Performance Concrete T/CBMF 37-2018 [S]. Beijing: China Building Material Industry Press, 2018(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 74

- HTML全文浏览量: 43

- 被引次数: 0

下载:

下载: