Preparation of flake Ca-Mg composite carbonate by ultrasonic assisted method and its effect on the properties of PBAT composites

-

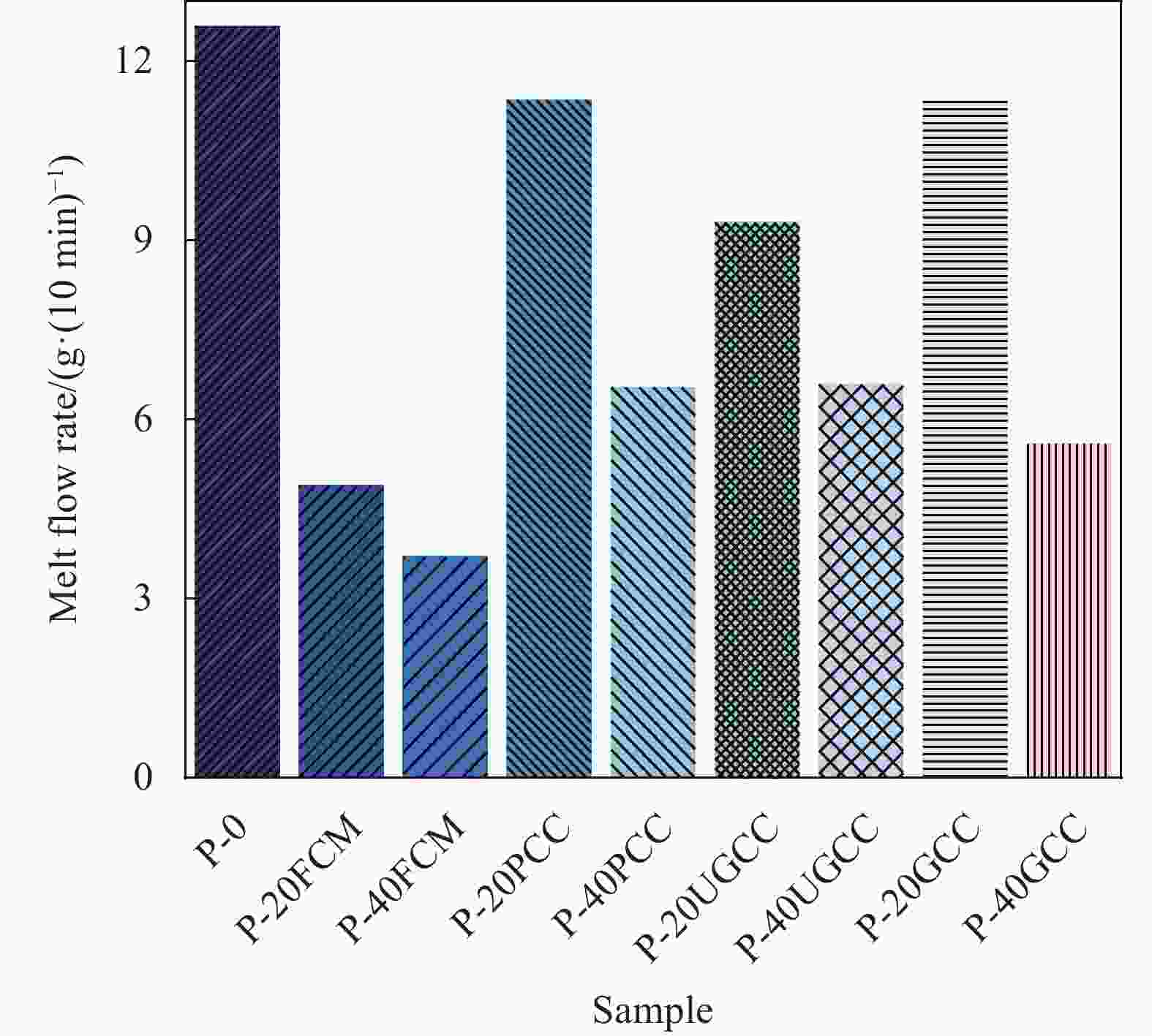

摘要: 片状碳酸盐类材料凭借无毒、价廉和原料来源丰富等优点已成为重要的热塑性聚合物增强增刚无机填料,但其制备工艺复杂,难以实现量产。本文结合石灰石产业中低品位石灰石附加值不高的问题,以含Mg的石灰石为原料,采用超声辅助碳化法制备了片状Ca-Mg复相碳酸盐(FCM)。探究了不同Mg含量、不同碳化反应温度、不同超声功率等工艺参数对产物形貌的影响。在此基础之上,将活性FCM与聚对苯二甲酸-己二酸丁二醇酯(PBAT)树脂共混挤出造粒后加工成复合材料,对比研究了添加不同种类的填料和不同配比对复合材料性能影响。结果表明,Mg含量、超声功率、反应温度对Ca-Mg复相碳酸盐的形貌有显著的影响,随着Mg含量提升到20.61wt%、反应温度提升至70℃、超声功率提升到400 W,得到了具有大量片状结构、比表面积为23.5 m2/g的Ca-Mg复相碳酸盐产物;添加了活性FCM的复合材料展现出优异的力学性能,当活性FCM添加量为20wt%时,复合材料的冲击强度、弯曲强度和弯曲模量分别较纯PBAT提升1倍、2倍和2.8倍;当添加量为40wt%时,这些性能指标进一步提升,分别比纯PBAT提升了1.2倍、2.6倍和4.8倍;更重要的是,添加了活性FCM的复合材料土壤降解率显著提高,这将有效促进复合材料在使用后降解,使其在完成服役使命后能够迅速融入自然环境,进一步体现其环保和可持续的特性。Abstract: Flaky carbonate materials have become important thermoplastic polymer reinforced rigid inorganic fillers due to their advantages of non-toxicity, low cost and abundant raw materials. However, their preparation process is complex and difficult to achieve mass production. In this paper, combined with the problem of low added value of low-grade limestone in limestone industry, flaky Ca-Mg complex carbonates (FCM) were prepared by ultrasonic-assisted carbonization method using Mg-containing limestone as raw material. The effects of process parameters such as different Mg content, different carbonization reaction temperature and different ultrasonic power on the morphology of the product were investigated. On this basis, the active FCM and poly (butylene adipate-co-terephthalate) (PBAT) resin were blended and extruded into composites. The effects of different kinds of fillers and different ratios on the properties of composites were compared. The results show that Mg content, ultrasonic power and reaction temperature have a significant effect on the morphology of Ca-Mg composite carbonate. With the increase of Mg content to 20.61wt%, reaction temperature to 70℃ and ultrasonic power to 400 W, Ca-Mg composite carbonate products with a large number of flake structures and a specific surface area of 23.5 m2/g were obtained. The composites with active FCM showed excellent mechanical properties. When the content of active FCM was 20wt%, the impact strength, flexural strength and flexural modulus of the composites were 1 time, 2 times and 2.8 times higher than those of pure PBAT, respectively. When the addition amount is 40wt%, these performance indexes are further improved, which are 1.2 times, 2.6 times and 4.8 times higher than that of pure PBAT, respectively. More importantly, the soil degradation rate of the composite material added with the active FCM is significantly improved, which will effectively promote the degradation of the composite material after use, so that it can quickly integrate into the natural environment after completing the service mission, further reflecting its environmental protection and sustainable characteristics.

-

图 2 不同制备工艺所得Ca-Mg复相碳酸盐的XRD图谱以及局部放大图

(a) 不同Mg含量、不同碳化反应温度、不同超声功率制备的Ca-Mg复相碳酸盐的XRD图谱; (b) 局部放大图

Figure 2. XRD patterns and local magnification of Ca-Mg composite carbonates obtained by different preparation processes

(a) XRD patterns of Ca-Mg composite carbonates prepared with different Mg contents, different carbonization reaction temperatures and different ultrasonic powers; (b) Local enlargement

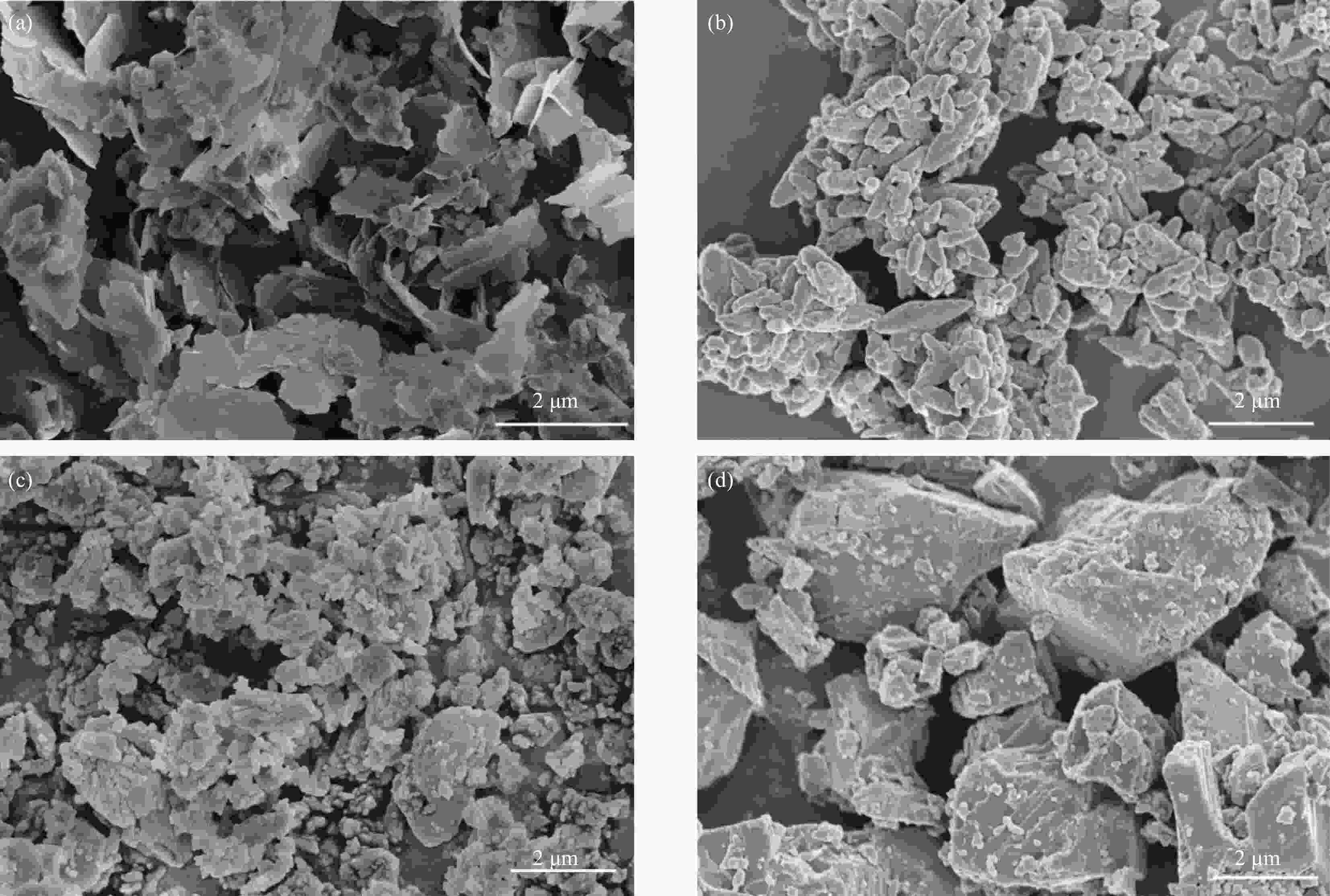

图 3 不同制备工艺所得Ca-Mg复相碳酸盐的微观形貌图及Ca-Mg-20.61的EDS面谱图

(a) Ca-Mg-0.459, (b) Ca-Mg-4.89, (c) Ca-Mg-14.05, (d) Ca-Mg-20.61, (e) 200 W-Ca-Mg-20.61, (f) 0 W-Ca-Mg-20.61, (g) RT-Ca-Mg-20.61, (h) Ca-Mg-20.61的EDS面谱图

Figure 3. SEM images of Ca-Mg composite carbonate obtained by different preparation processes and the EDS spectra of Ca-Mg-20.61 were obtained

(a) Ca-Mg-0.459, (b) Ca-Mg-4.89, (c) Ca-Mg-14.05, (d) Ca-Mg-20.61, (e) 200 W-Ca-Mg-20.61, (f) 0 W-Ca-Mg-20.61, (g) RT-Ca-Mg-20.61, (h) EDS elemental mapping of Ca-Mg-20.61

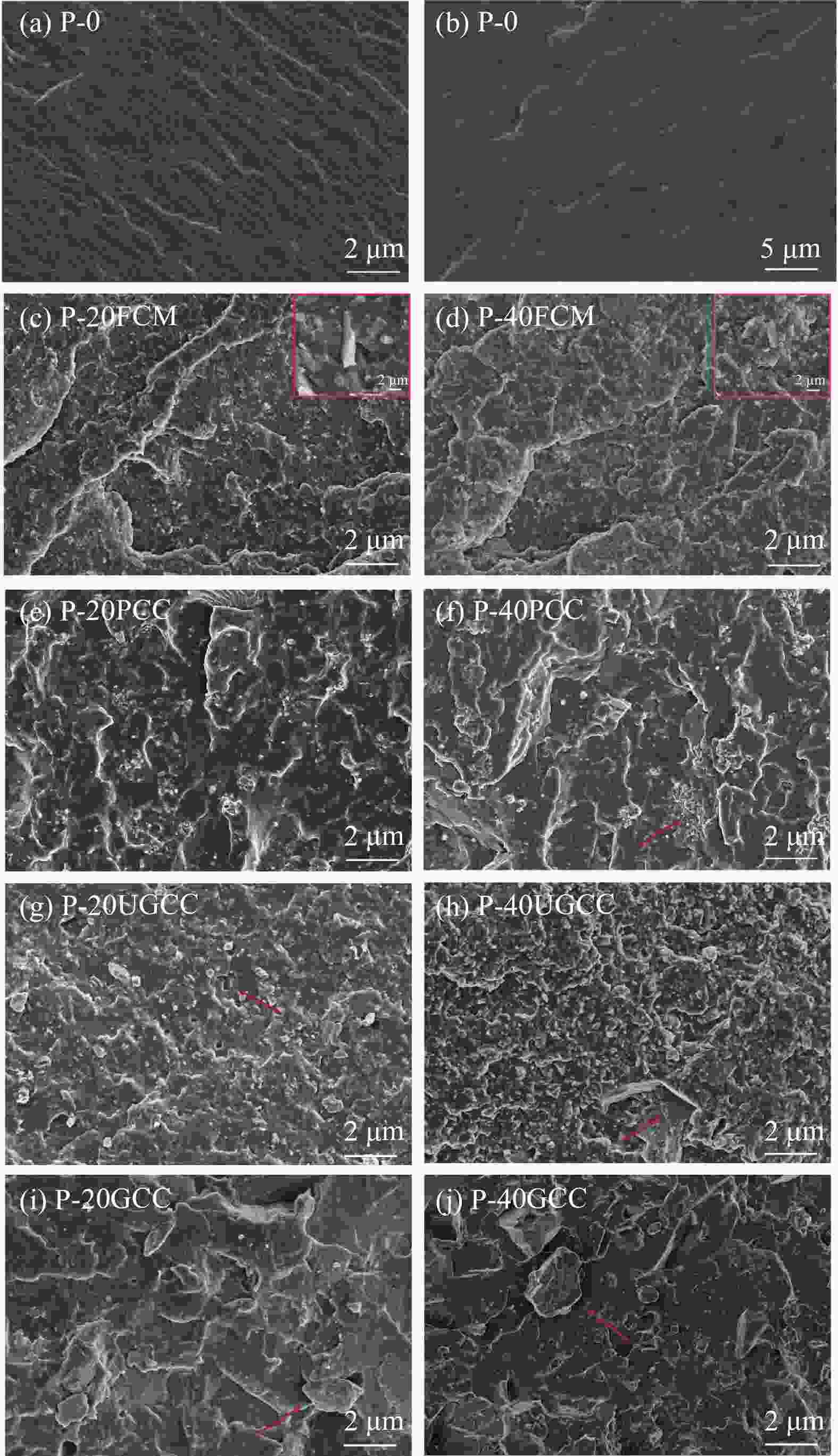

图 6 PBAT复合材料的微观形貌图

(a, b) P-0, (c) P-20 FCM, (d) P-40 FM, (e) P-20 PCC, (f) P-40 GCC, (g) P-20 UGCC, (h) P-40 UGCC, (i) P-20 GCC, (j) P-40 GCC

Figure 6. The SEM Morphology of PBAT matrix composites

(a, b) P-0, (c) P-20 FCM, (d) P-40 FM, (e) P-20 PCC, (f) P-40 GCC, (g) P-20 UGCC, (h) P-40 UGCC, (i) P-20 GCC, (j) P-40 GCC

图 7 不同填充量、不同填料对PBAT力学性能的影响

(a) 复合材料的拉伸强度和冲击强度图, (b) 复合材料的弯曲强度和弯曲模量图

Figure 7. The effect of different filling amounts and inorganic filler on the mechanical properties of PBAT

(a) Tensile strength and impact strength diagram of the composite material, (b) Flexural strength and flexural modulus diagram of the composite material

表 1 石灰石的主要成分及含量(wt%)

Table 1. Main components and content of limestone (wt%)

Sample CaO MgO SiO2 Al2O3 Loss on ignition Ca-0.459 54.99 0.459 0.353 0.108 44.09 Ca-4.89 48.87 4.89 0.658 0.233 45.349 Ca-14.05 37.56 14.05 1.16 0.414 46.816 Ca-20.61 34.65 20.61 1.08 0.387 43.273 表 2 Ca-Mg复相碳酸盐反应条件

Table 2. Reaction conditions of Ca-Mg composite calcium carbonate

Sample Mg content (MgOwt%) Ultrasonic power /W Reaction temperature /℃ Ca-Mg-0.459 0.459 400 70 Ca-Mg-4.89 4.89 400 70 Ca-Mg-14.05 14.05 400 70 Ca-Mg-20.61 20.61 400 70 200 W-Ca-Mg-20.61 20.61 200 70 0 W-Ca-Mg-20.61 20.61 0 70 RT- Ca-Mg-20.61 20.61 400 30 Note: Mg content was used as the pronoun of MgO content detected by X-ray fluorescence spectrometer 表 3 复合材料的加工配方比例

Table 3. Processing formula ratio of composite materials

Sample Type of fillers Filler/wt% PBAT/wt% Assistant/wt% P-0 / / 95 5 P-20FCM Active FCM 20 75 5 P-40FCM Active FCM 40 55 5 P-20PCC Active PCC 20 75 5 P-40PCC Active PCC 40 55 5 P-20UGCC Active UGCC 20 75 5 P-40UGCC Active UGCC 40 55 5 P-20GCC Active GCC 20 75 5 P-40GCC Active GCC 40 55 5 Notes: PCC—Precipitated Calcium Carbonate; GCC—Ground Calcium Carbonate; UGCC—Ultrafine Ground Calcium Carbonate. 表 4 不同种类填料性能测试

Table 4. Performance test of different kinds of fillers

Sample Type Oil absorption

value/%Whiteness/% Degree of

activation/%Contact angle /(°) specific surface

area /(m2·g−1)Active FCM PCC 59.7 97.5 99.9 122.1 23.5 Active PCC PCC 24.8 94.3 99.8 119.6 7.1 Active UGCC GCC 20.0 96.2 99.9 120.1 9.8 Active GCC GCC 15.6 90.0 99.7 116.8 3.6 表 5 活性FCM添加量为50wt%时PBAT复合材料的配方比例及力学性能测试结果

Table 5. Formula ratio and mechanical properties of the PBAT composites with 50wt% active FCM addition were tested

Sample FCM addition

amount/wt%PBAT/wt% assistant/wt% Mechanical property Tensile

strength /MPaImpact strength/

(kJ·m−2)Flexural strength/

MPaFlexural Modulus/

MPaP-50 FCM 50 45 5 3.57 12.85 11.81 498.73 3.68 11.15 12.78 481.35 3.40 12.43 14.90 486.91 3.76 9.32 10.67 497.66 3.31 10.78 10.09 500.10 3.54(Average) 11.30(Average) 12.05(Average) 492.95(Average) -

[1] XIE J X. Effect of mixing strategy on thermal and mechanical properties of poly(butylene adipate-co-terephthalate)/poly(lactic acid) incorporated with CaCO3 fillers[J]. Journal of Polymer Research, 2023, 30(6): 229. doi: 10.1007/s10965-023-03618-5 [2] ARIFFIN A, MANSOR A S, JIKAN S S, et al. Evaluation of hybridizing talc and surface-treated kaolin on the properties of PP hybrid composites[J]. Journal of Reinforced Plastics and Composites, 2010, 29(23): 3429-3441. doi: 10.1177/0731684410386272 [3] LI M, CHEN Y, WU L, et al. A novel polypropylene composite filled by kaolin particles with -nucleation[J]. Journal of Thermal Analysis and Calorimetry, 2019, 135(4): 2137-2145. doi: 10.1007/s10973-018-7294-8 [4] 彭国志, 张琦伟, 周杨, 等. PP/改性高岭土复合材料的制备及性能[J]. 现代塑料加工应用, 2023, 35(3): 29-32.PENG G Z, ZHANG Q W, ZHOU Y, et al. Preparation and properties of polyethylene/modified kaolin Composite[J]. Modern Plastics Processing and Applications, 2023, 35(3): 29-32(in Chinese). [5] 朱丹彤, 吴倩, 李文斐, 等. 高岭土接枝流滴剂/聚乙烯复合材料的制备及性能[J]. 复合材料学报, 2020, 37(1): 35-41.ZHU D T, WU Q, LI W F, et al. Preparation and properties of kaolin grafted alkyl amine type dripping agent/polyethylene composites[J]. Acta Materiae Compositae Sinica, 2020, 37(1): 35-41(in Chinese). [6] 李娜, 栾晓波. 碳酸钙和滑石粉对硬质PVC性能的影响[J]. 聚氯乙烯, 2023, 51(7): 11-13.LI N, LUAN X B. The effect of calcium carbonate and talcum powder on the properties of hard PVC[J]. Polyvinyl Chloride, 2023, 51(7): 11-13(in Chinese). [7] 熊煦, 李娜, 冯潮, 等. PBAT/滑石粉复合材料的制备与性能[J]. 塑料, 2023, 52(4): 50-53+136.XIONG X, LI N, FENG C, et al. Structure and property of PBAT / talc powder composite[J]. Plastic, 2023, 52(4): 50-53+136(in Chinese). [8] OMAR M F, AKIL H M, RASYID M F A, et al. Thermal properties of polypropylene/muscovite layered silicate composites: effects of organic modifications and compatibilisers[J]. Journal of Composite Materials, 2014, 49(10): 1195-1209. [9] SEBASTIEN L, JANNICK D, JEAN F, et al. Effect of Ionic Liquid Modified Synthetic Layered Silicates on Thermal and Mechanical Properties of High Density Polyethylene Nanocomposites[J]. Macromolecular Symposia, 2014, 342(1): 46-55. doi: 10.1002/masy.201300228 [10] 王铎, 雷泽一川, 周京. 表面改性滑石粉填充对PP管材性能的影响[J]. 应用化工, 2023, 50(3): 33-35.WANG D, LEI Z Y C, ZHOU J. Study of surface modifiers on talc filled with PP type[J]. Applied Chemical Industry, 2023, 50(3): 33-35(in Chinese). [11] 田鹏杰. 含石棉型滑石矿浮选除杂技术研究[D]. 沈阳: 东北大学, 2011.TIAN P J. Study on flotation impurity removal technology of asbestos-bearing talc ore[D]. Shenyang: Northeastern University, 2011(in Chinese). [12] 王晓茹, 陈支泽. 乳酸低聚物改性的纳米碳酸钙对聚乳酸性能的影响[J]. 复合材料学报, 2021, 38(9): 2786-2794.WANG X R, CHEN Z Z. Effect of nano-calcium carbonate modified by lactic acid oligomers on the properties of polylactic acid[J]. Acta Materiae Compositae Sinica, 2021, 38(9): 2786-2794(in Chinese). [13] 刘艳新. 新型片状碳酸钙在喷墨打印纸涂料中的应用[J]. 造纸化学品, 2004, (6): 60-62.LIU Y X. Application of new flake calcium carbonate in ink-jet printing paper coatings[J]. Paper Chemicals, 2004, (6): 60-62(in Chinese). [14] 赵丽娜, 孔治国, 王秀艳. 自组装片状纳米碳酸钙的制备及表面改性[J]. 化工进展, 2010, 29(12): 2346-2350.ZHAO L, KONG Z , WANG X Y. Preparation and surface modification of self-assembled plate-shaped nanometer calcium carbonate[J]. Chemical Industry and Enginering Progress, 2010, 29(12): 2346-2350(in Chinese). [15] 袁爱群. 一种片状文石型超细碳酸钙颗粒的制备方法[P]. 中国专利, CN 201510670840.3, 2015-10-15.YUAN A Q. A preparation method of flake aragonite type ultrafine calcium carbonate particles[P]. China Patent, CN 201510670840.3, 2015-10-15(in Chinese). [16] WEI H, SHEN Q, ZHAO Y, et al. Erratum to "Crystallization habit of calcium carbonate in the presence of sodium dodecyl sulfate and/or polypyrrolidone"[J]. Journal of Crystal Growth, 2004, 26010(82): 511-516. [17] 蒋凌云, 杨振祥, 章苏, 等. 造纸专用片状沉淀碳酸钙的制备[J]. 无机盐工业, 2004, (2): 41-43.JIANG L Y, YANG Z X, ZHANG S, et al. The preparation of flake precipitated calcium carbonate for paper coating[J]. Inorganic Chemicals Industry, 2004, (2): 41-43(in Chinese). [18] 余玉翔, 陈雪梅. 石灰石中镁含量对纳米碳酸钙制备及性能的影响[J]. 无机盐工业, 2015, 47(12): 43-46.YU Y X, CHEN X M. Effects of magnesium content in limestone on preparation and property of nano-sized CaCO3[J]. Inorganic Chemicals Industry, 2015, 47(12): 43-46(in Chinese). [19] 杨天雷. 高镁石灰石在水泥生产中的应用[J]. 中国水泥, 2022, (9): 82-84.YANG T L. Application of high magnesium limestone in cement production[J]. China Cement, 2022, (9): 82-84(in Chinese). [20] HE L Q, MO S Y, SUN L, et al. Nonclassical and Classical Crystallization: The Formation of Spindle-Shaped CaCO3 Covered with Abundant Nanoscale Rhombic Calcite Subunits[J]. Crystal Growth & Design, 2023. [21] RAUTARAY D, KASTURE M, SASTRY M. Role of Mg ions in modulating the morphology and structure of CaCO3 crystals grown in aqueous foams[J]. Crystengcomm, 2005, 7: 469-475. doi: 10.1039/b501420b [22] TAKAHIRO O, SEI S, KOHEI M, et al. Preparation of petaloid microspheres of basic magnesium carbonate[J]. Langmuir:The ACS Journal of Surfaces and Colloids, 2007, 23(11): 5872-5874. doi: 10.1021/la7002782 [23] 中国国家标准化管理委员会. 碳酸钙分析方法: GB/T 19281-2014[S]. 北京: 中国标准出版社, 2014.SAC. Analysis method of calcium carbonate: GB/T 19281-2014[S]. Beijing: Standards Press of China, 2014(in Chinese). [24] ASTM. Melt Flow Rates of Thermoplastics by Extrusion Plastometer: ASTM D1238-13[S]. Weat Conshohocken: ASTM, 2013. [25] 中国国家标准化管理委员会. 塑料拉伸性能的测定: GB/T 1040.2-2006[S]. 北京: 中国标准出版社, 2006.SAC. Determination of tensile properties of plastics: GB/T 1040.2-2006[S]. Beijing: Standards Press of China, 2006(in Chinese). [26] 中国国家标准化管理委员会. 塑料弯曲性能的测定: GB/T 9341-2008[S]. 北京: 中国标准出版社, 2008.SAC. Determination of bending properties of plastics: GB/T 9341-2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [27] 中国国家标准化管理委员会. 塑料简支梁冲击性能的测定: GB/T 1043.1-2008[S]. 北京: 中国标准出版社, 2008.SAC. Determination of water absorption of plastics: GB/T 1034-2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [28] MELDRUM F C, HYDE S T. Morphological influence of magnesium and organic additives on the precipitation of calcite[J]. Journal of Crystal Growth, 2001, 231(4): 544-558. doi: 10.1016/S0022-0248(01)01519-6 [29] 钱鹏, 唐国翌, 宋国林. 超声波辅助制备分散性良好的球形花瓣状氢氧化镁[J]. 功能材料, 2014, 45(1): 1117-1121.QIAN P, TANG G Y, SONG G L. Ultrasonic-assisted preparation of well-dispersed spherical petal-like magnesium hydroxide[J]. Journal of Functional Materials, 2014, 45(1): 1117-1121(in Chinese). [30] 陈建铭, 牛晓红, 王晓彤, 等. 采用定-转子碳化反应器制备高活性氧化镁[J]. 无机盐工业, 2016, 48(12): 40-43.CHEN J M, NIU X H, WANG X T, et al. Preparation of highly active magnesium oxide by rotor-stator reactor(RSR)[J]. Inorganic Chemicals Industry, 2016, 48(12): 40-43(in Chinese). [31] 赵彩云, 徐艳, 王潮霞. 聚氨酯-聚乳酸共混物的制备及性能[J]. 复合材料学报, 2017, 34(9): 2030-2037.ZHAO C Y, XU Y, WANG C X. Preparation and properties of thermoplastic polyurethane-polylactic acid blends[J]. Acta Materiae Compositae Sinica, 2017, 34(9): 2030-2037(in Chinese). [32] 杜兴, 何天亮, 张飞燕, 等. PBAT/高岭土/艾草抗菌可降解薄膜的制备及性能[J]. 塑料科技, 2022, 50(2): 59-62.DU X, HE T L, ZHANG F Y, et al. Preparation and properties of PBAT/Kaolin/Wormwood antibacterial degradable Film[J]. Plastics Science and Technology, 2022, 50(2): 59-62(in Chinese). [33] 李璐瑶, 高建峰, 徐鼐, 等. 多元环氧扩链剂改性PLA/PBAT薄膜的制备与性能表征[J]. 工程塑料应用, 2023, 51(8): 8-14.LI L Y, GAO J F, XU N, et al. Preparation and Properties of PLA/PBAT Films Modified with Multiple Epoxy Extenders[J]. Engineering Plastics Application, 2023, 51(8): 8-14(in Chinese). [34] 孙岭, 罗文倩, 何丽秋, 等. CaCO3形貌对LLDPE/HDPE/CaCO3复合材料性能的影响[J]. 塑料科技, 2023, 51(4): 1-5.SUN L, LUO W Q, HE L Q, et al. Effect of CaCO3 morphology on properties of LLDPE/HDPE/CaCO3 Composites[J]. Plastics Science and Technology, 2023, 51(4): 1-5(in Chinese). [35] XIA M S, YAO Z T, GE L Q, et al. A potential bio-filler: The substitution effect of furfural modified clam shell for carbonate calcium in polypropylene[J]. Journal of Composite Materials, 2015, 49(7): 807-816. doi: 10.1177/0021998314525981 [36] LIN S, GUO W, CHEN C, et al. Mechanical properties and morphology of biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends compatibilized by transesterification[J]. Materials & Design, 2012, 36: 604-608. [37] 宁平, 陈明月, 肖运鹤. 淀粉填充改性PBAT的结构与性能研究[J]. 化工新型材料, 2010, 38(7): 116-119.NING P, CHEN M Y, XIAO Y H. Study on starches filled degradable poly(butylene adipate-co-terephthalate) modified by compatibilizers[J]. New Chemical Materials, 2010, 38(7): 116-119(in Chinese). [38] 马祥艳, 王翔宇, 李莉, 等. PLA/PBAT/纳米碳酸钙三元复合材料的微观形貌与性能[J]. 塑料, 2017, 46(5): 93-97.MA X Y, WANG X Y, LI L, et al. Morphologies and properties of PLA/PBAT/nano-CaCO3 ternary composite[J]. Plastics, 2017, 46(5): 93-97(in Chinese). [39] LEE J B, KIM D Y, NAM K, et al. Compatibility and Impact Properties of Poly(lactic acid)/Poly(butylene adipate-co-terephthalate) Blend Using Poly(butyl acrylate)[J]. Polymer Korea, 2020, 44(5): 689-694. doi: 10.7317/pk.2020.44.5.689 [40] 深圳市高分子行业协会. 聚对苯二甲酸-己二酸丁二酯/碳酸钙薄膜专用料: T/SGX 011-2021[S]. 深圳: 深圳市高分子行业协会, 2021.SZPRA. Poly ( butylene adipate-co-terephthalate )/calcium carbonate film special material. Shenzhen: T/SGX 011-2021[S]. SZPRA, 2021(in Chinese). [41] 谢良科, 黄骏成, 龚泽威, 等. 不同生物质纤维及其添加量对PBAT复合材料结构与性能的影响[J]. 包装工程, 2022, 43(23): 25-33.XIE L K, HUANG J C, GONG Z W, et al. Effects of different biomass fibers and their content on the structure and properties of PBAT composites[J]. Packaging Engineering, 2022, 43(23): 25-33(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 23

- HTML全文浏览量: 21

- 被引次数: 0

下载:

下载: