Research progress of electrospinning flame retardant nanofiber

-

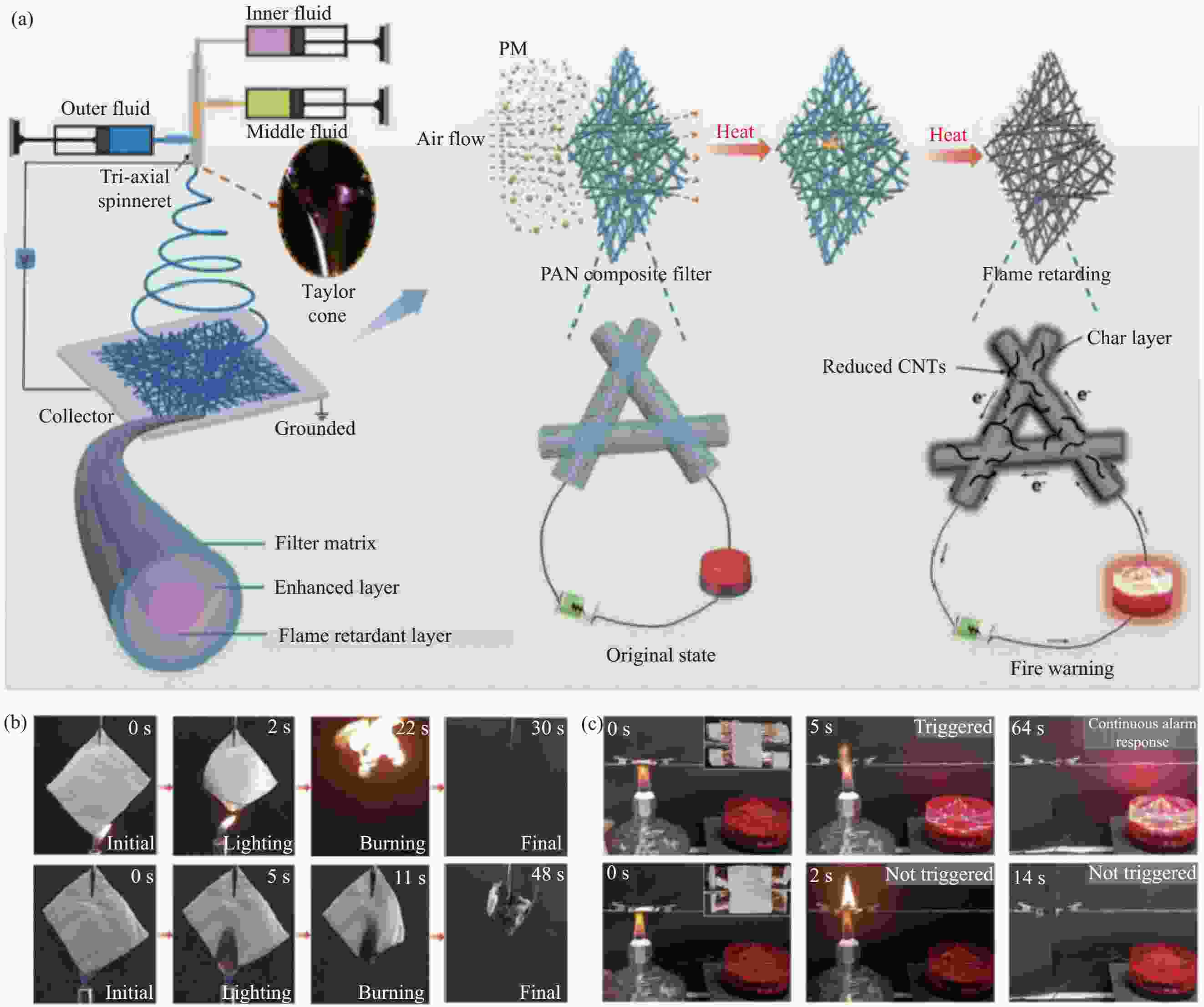

摘要: 静电纺丝纳米纤维具有可调控的纤维直径和分布、相互连通的孔结构、高孔隙率、高比表面积、可控纤维堆积密度等优点,成为近年来研究的热点。阻燃性是高分子材料的重要特性,阻燃纤维相较普通纤维具有使用安全性高的特点,研发具有阻燃特性的纳米纤维具有重要意义。静电纺丝技术提供了将纳米颗粒结合到聚合物溶液中并获得具有多种功能复合纤维材料的可能性。基于此,本文综述了采用静电纺丝技术制备阻燃纳米纤维的研究进展,特别是对静电纺丝阻燃纳米纤维的结构进行了分类,主要包括共混结构、核-壳结构、并列结构和多孔结构,并总结了不同结构阻燃纳米纤维的优缺点。然后对静电纺丝阻燃纳米纤维在锂离子电池隔膜、空气过滤、火灾报警传感、防护材料等领域的应用进行了归纳,最后对静电纺丝阻燃纳米纤维未来的发展方向进行了展望。Abstract: Electrospinning nanofiber exhibits several advantages, such as adjustable fiber diameter and distribution, interconnected pore structure, high porosity, high specific surface area, and controllable fiber packing density, which is a prominent research hot spot in recent years. Flame-retardant is an important characteristic of polymer materials, and flame-retardant fibers have the characteristic of higher safety in use compared to ordinary fibers. The development of nanofibers with flame-retardant properties is of great significance. Electrospinning technology refers to the jet spinning of polymer solutions or melts under strong electric fields, providing technical support for constructing nanofibers with special functions. It not only provides the possibility of combining functional fillers into polymers, but also provides the possibility of uniform dispersion of functional fillers within the polymer, which helps to more conveniently produce nanocomposites with special properties in situ. Based on this, this review introduced the development of flame-retardant nanofibers via electrospinning technology. Specially, the structure of electrospinning flame-retardant nanofibers was discussed, mainly including blend structure, core-shell structure, side-by-side structure, and porous structure. Their advantages and disadvantages were also emphasized. Moreover, the application status of flame-retardant nanofibers in lithium-ion battery separators, air filtration systems, fire alarm sensors, and protective materials were introduced. Finally, the future development directions of electrospinning flame-retardant nanofibers were foreseen.

-

Key words:

- electrospinning /

- flame retardant /

- nanofiber /

- structure /

- application

-

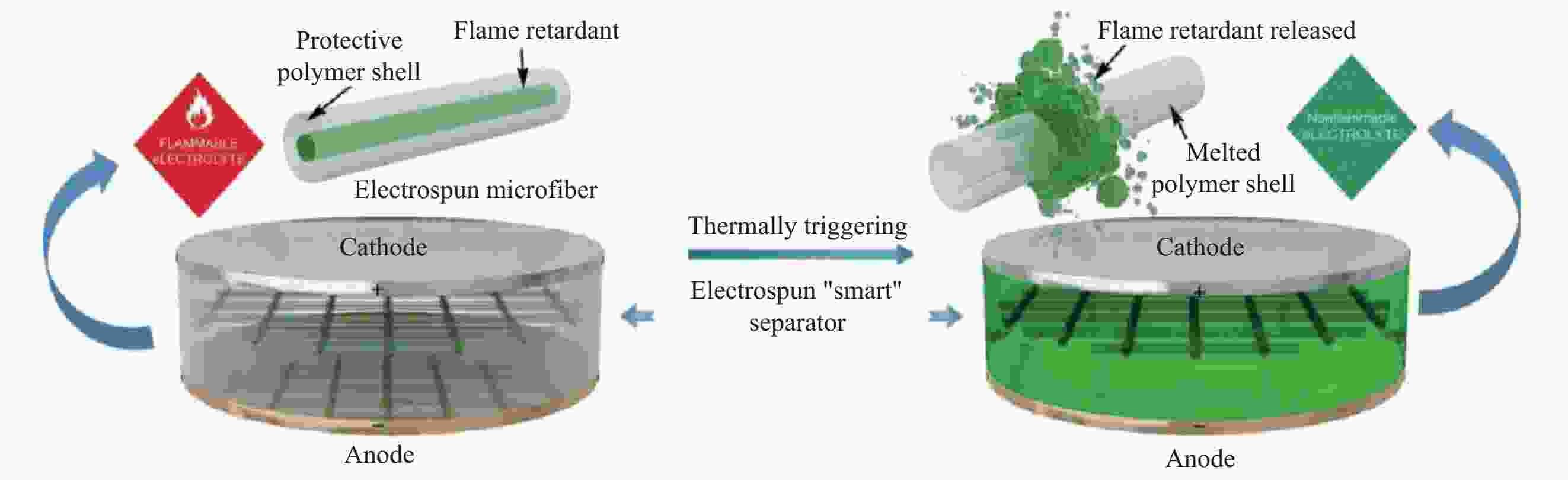

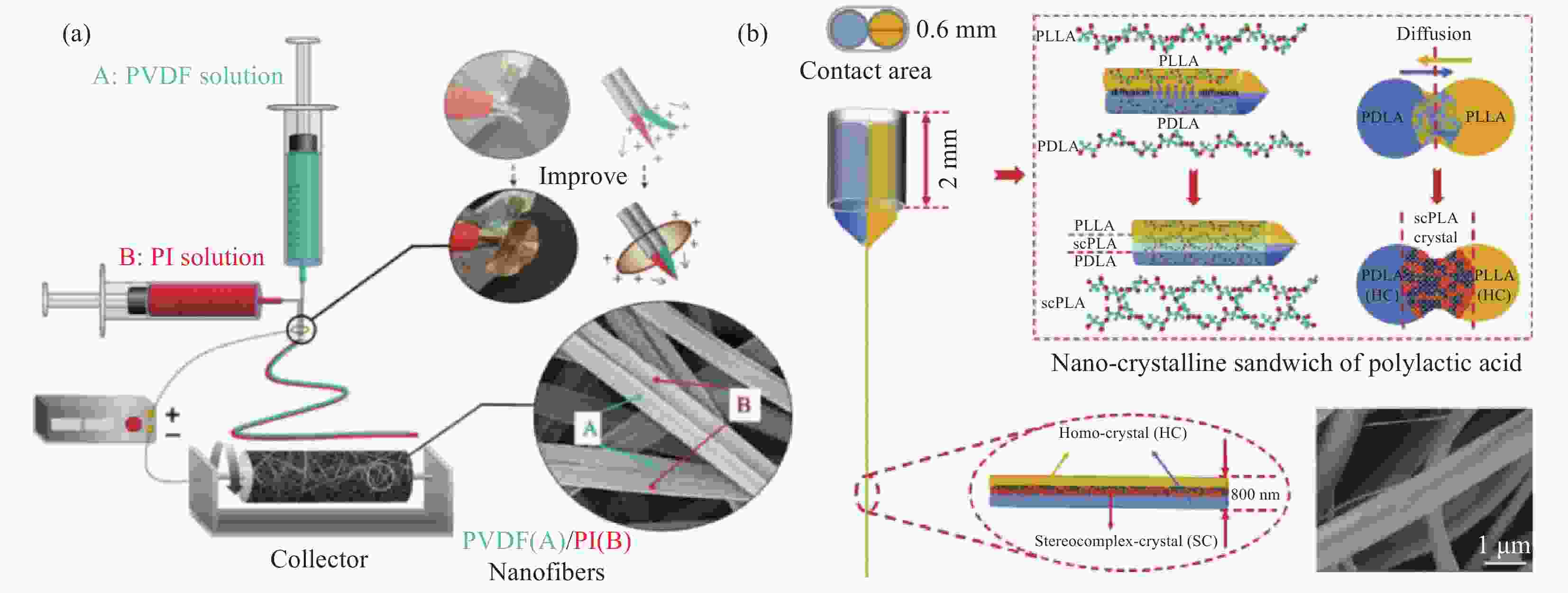

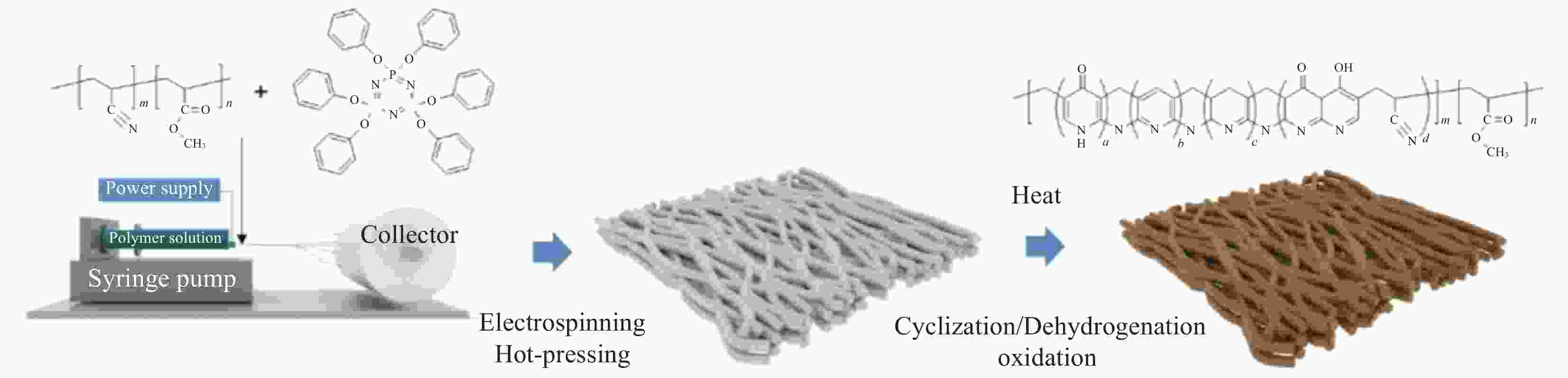

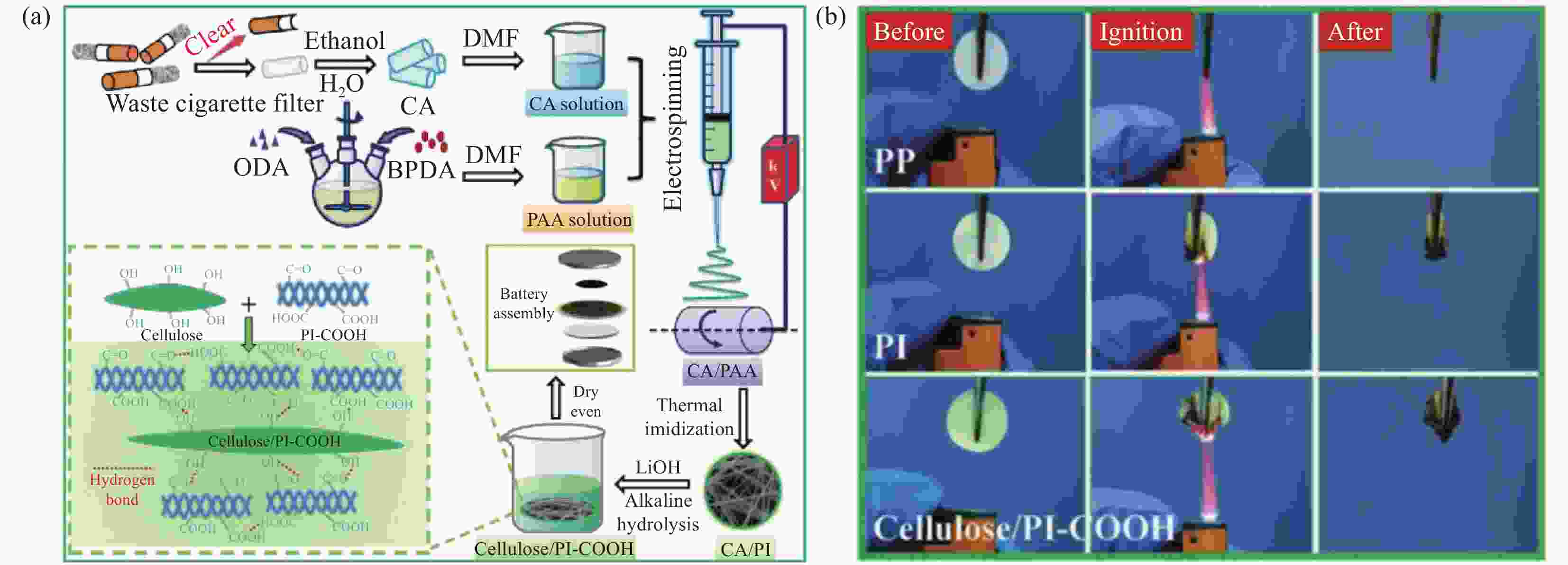

图 5 (a)氢键交联纤维素/羧基化PI纳米纤维复合隔膜的制备工艺;(b) PP、PI和纤维素/羧基化PI隔膜的阻燃性能[15]

Figure 5. (a) Preparation process of hydrogen-bonded cellulose/PI-COOH composite separator; (b) Flame retardancy of PP, PI andcellulose/PI-COOH separator [15]

BPDA—4, 4′-biphthalic anhydride; ODA—4, 4′-diiminodiphenylether; DMF—N, N-dimethylformamide; PAA—Poly(amic acid); PP—Polypropylene

表 1 静电纺丝技术构建阻燃纳米纤维的结构及性能

Table 1. Structure and properties of flame-retardant nanofiber builted by electrospinning technology

Structure Name of

nanomaterialSelf-extinguish-

mentTmax/℃ Char residue/wt% Advantage Disadvantage ref Blend PEN-PCDA - 506 42 Optimize flame retardant performance through synergistic regulation among components The compatibility between flame retardants and polymers is generally poor [40] PEEK-PI Yes 414 64 [41] PVDF-PVP - 400 26 [42] PAN/PU Yes 275 - [43] Core-shell PI/PVDF-HFP Yes 450 42 There is no need to consider the compatibility of the spinning solution, and the introduction of flame retardants is greater The miscibility of the solution greatly affects the electrospinning process [28] TPP@PVDF-HFP Yes 420 - [29] Bi@C - 400 18 [44] Gelatin-gum arabic - 250 10 [45] CA/Gel-Eg - 310 22 [46] Side-by-side PI/PVDF-HFP Yes 460 50 Composite fibers can fully utilize the advantages of both components and achieve synergistic flame retardant effects Difficulty in practical operation [33] PVDF/PI - 230 - [32] Porous NiO/CB/PLA Yes 340 8 It can significantly improve the reflection effect of thermal radiation, reduce convective heat transfer, and enhance the flame retardant performance of the material May cause shrinkage and fracture of nanofibers [38] SiO2-TiO2 Yes - - [37] HPCTP-PAN Yes 230 - [39] Notes:PEN—Polyarylene ether nitriles; PCDA—10, 12-pentacosadiynoic acid; PEEK—Poly(ether-ether-ketone); PVP—Polyvinylpyrrolidone; PU—Polyurethane; PVDF-HFP—Poly(vinylidene fluoride)-co-hexafluoropropylene; TPP—Triphenyl phosphate; CA—Acetate; Gel—Gelatin; Eg—Eugenol; CB—Carbon black; PLA—Polylactic acid 表 2 静电纺丝阻燃纳米纤维的应用

Table 2. Application of flame retardant nanofiber builted by electrostatic spinning technology

Application area Material LOI Char residue/

wt%ref Separator forlithium-ion battery material Cellulose/PI-COOH 33.6% 59 [15] PI/PVDF-HFP 27.7% 42 [28] PI/PVDF-HFP - 50 [33] PI/PS/PAA - 10 [22] PAN/DOPO - 35 [20] PCM-TEP@SiO2/PP - 56.2 [70] Air filter material OPAN/PVP/SnO2/SnCl2 - 22 [57] BaTiO3@PU/PSA - 30 [55] Phase change material IL/AlN/CoPA - 10.5 [68] Fire alarm material PAN/APP/A-CNTs 30.9% 68.7 [61] CA/CNFs - 43.1 [60] SMPU/MXene - 70.79 [62] Flame retardant material PMIA - 40 [71] Notes:PS—Polystyrene; PAA—Poly(amic acid); PCM-Phase change materials; TEP—Triethyl phosphate; OPAN—Oxidized polyacrylonitrile; PU—Polyurethane; PSA—Polysulfonamidefibre; IL—Ionic liquid; CoPA—Copolyamides; A-CNTs—Amino-functionalizedcarbon nanotube; SMPU—Shape memory thermoplastic polyurethane; PMIA—Poly(m-phenylene isophtalamide) -

[1] SHIE C Y, CHEN C C, CHEN H F, et al. Flexible and self-powered thermal sensor based on graphene-modified intumescent flame-retardant coating with hybridized nanoge-nerators[J]. ACS Applied Nano Materials, 2023, 6: 2429-2437. doi: 10.1021/acsanm.2c04700 [2] BADDAM Y, IJAOLA A O, ASMATULU E. Fabrication of flame-retardant and superhydrophobic electrospun nano-fibers[J]. Surfaces and Interfaces, 2021, 23: 101017. doi: 10.1016/j.surfin.2021.101017 [3] 鲍艳, 许佳琛, 郭茹月, 等. 基于微纳结构的高灵敏度柔性压力传感器[J]. 化学进展, 2023, 35(05): 709-720.BAO Yan, XU Jiachen, GUO Ruyue, et al. High-sensitivity flexible pressure sensor based on micro-nano structure[J]. Progress in Chemistry, 2023, 35(05): 709-720(in Chinese). [4] WANG S X, YAP C C, HE J, et al. Electrospinning: A facile technique for fabricating functional nanofibers for environmental applications[J]. 2016, 5: 51-73. [5] 曾倩. 静电纺丝制备阻燃聚丙烯腈纳米纤维的研究[D]. 天津: 天津工业大学, 2018.ZENG Qian. Study on the preparation of flame-retardant polyacrylonitrile nanofibers by electrospinning[D]. Tianjin: Tiangong University, 2018(in Chinese) [6] BAKAR S S S, FONG K C, ELEYAS A, et al. Effect of voltage and flow rate electrospinning parameters on polyacrylonitrile electrospun fibers[J]. IOP Conference Series:Materials Science and Engineering, 2018, 318: 012076. doi: 10.1088/1757-899X/318/1/012076 [7] DING Y, HOU H, ZHAO Y, et al. Electrospun polyimide nanofibers and their applications[J]. Progress in Polymer Science, 2016, 61: 67-103. doi: 10.1016/j.progpolymsci.2016.06.006 [8] YU M, CHU Y, XIE W, et al. An interlayer flame retardant method to effectively fire retardant and reinforce CF/EP composites by nanofiber film intercalation[J]. Chemical Engineering Journal, 2023, 467: 143545. doi: 10.1016/j.cej.2023.143545 [9] HAN C, XING W, ZHOU K, et al. Self-assembly of two-dimensional supramolecular as flame-retardant electrode for lithium-ion battery[J]. Chemical Engineering Journal, 2022, 430: 132873. doi: 10.1016/j.cej.2021.132873 [10] SUN F, GUO J, LIU Y, et al. Preparation, characterizations and properties of sodium alginate grafted acrylonitrile/polyethylene glycol electrospun nanofibers[J]. International Journal of Biological Macromolecules, 2019, 137: 420-425. doi: 10.1016/j.ijbiomac.2019.06.185 [11] LIU R, HOU L, YUE G, et al. Progress of fabrication and applications of electrospun hierarchically porous nanofibers[J]. Advanced Fiber Materials, 2022, 4: 604-630. doi: 10.1007/s42765-022-00132-z [12] CAO L, LIU Q, REN J, et al. Electro-blown spun silk/graphene nanoionotronic skin for multifunctional fire protection and alarm[J]. Advanced Materials, 2021, 33: 2102500. doi: 10.1002/adma.202102500 [13] VAHABI H, WU H, SAEB M R, et al. Electrospinning for developing flame retardant polymer materials: Current status and future perspectives[J]. Polymer, 2021, 217: 123466. doi: 10.1016/j.polymer.2021.123466 [14] MIN T, ZHOU L, SUN X, et al. Electrospun functional polymeric nanofibers for active food packaging: A review[J]. Food Chemistry, 2022, 391: 133239. doi: 10.1016/j.foodchem.2022.133239 [15] DENG J, CAO D, YANG X, et al. Cross-linked cellulose/carboxylated polyimide nanofiber separator for lithium-ion battery application[J]. Chemical Engineering Journal, 2022, 433: 133934. doi: 10.1016/j.cej.2021.133934 [16] RUI J, LI J, LI Y, et al. Preparation of C–SiC/ZrSi x O y C z core-shell fibers by coaxial electrospinning and the high-temperature performance[J]. Ceramics International, 2022, 48: 2625-2631. doi: 10.1016/j.ceramint.2021.10.045 [17] GAO D, ZHAO R, YANG X, et al. Bicomponent PLA nanofiber nonwovens as highly efficient filtration media for particulate pollutants and pathogens[J]. Membranes, 2021, 11(11): 819. doi: 10.3390/membranes11110819 [18] ZHANG W, HE Z, HAN Y, et al. Structural design and envi-ronmental applications of electrospun nanofibers[J]. Composites Part A: Applied Science and Manufacturing, 2020, 137: 106009. doi: 10.1016/j.compositesa.2020.106009 [19] SERBEZEANU D, HAMCIUC C, VLAD-BUBULAC T, et al. Electrospun nanofibers based on polymer blends with tunable high-performance properties for innovative fire-resistant materials[J]. Polymers, 2022, 14(24): 5501. doi: 10.3390/polym14245501 [20] YUSUF A, AVVARU V S, DIRICAN M, et al. Low heat yielding electrospun phosphenanthrene oxide loaded polyacrylonitrile composite separators for safer high energy density lithium-ion batteries[J]. Applied Materials Today, 2020, 20: 100675. doi: 10.1016/j.apmt.2020.100675 [21] CHEN Y, QIU L, MA X, et al. Electrospun cellulose polymer nanofiber membrane with flame resistance properties for lithium-ion batteries[J]. Carbohydrate Polymers, 2020, 234: 115907. doi: 10.1016/j.carbpol.2020.115907 [22] WANG Y, GUO M, FU H, et al. Thermotolerant separator of cross-linked polyimide fibers with narrowed pore size for lithium-ion batteries[J]. Journal of Membrane Science, 2022, 662: 121004. doi: 10.1016/j.memsci.2022.121004 [23] WANG Y, WANG S, FANG J, et al. A nano-silica modified polyimide nanofiber separator with enhanced thermal and wetting properties for high safety lithium-ion batteries[J]. Journal of Membrane Science, 2017, 537: 248-254. doi: 10.1016/j.memsci.2017.05.023 [24] TRUPP F, BARELLA M, CIBILS R, et al. In situ syringe rotation system for heavy microparticle suspension stability in electrospinning technique[J]. Review of Scientific Instruments, 2023, 94: 033906. doi: 10.1063/5.0131947 [25] CHENG Y, ZHU W, LU X, et al. Recent progress of electrospun nanofibrous materials for electromagnetic interference shielding[J]. Composites Communications, 2021, 27: 100823. doi: 10.1016/j.coco.2021.100823 [26] XIE Z, LI W C, SUN X M, et al. Effect of post-treatment on mechanical and biological properties of coaxial electrospun core–shell structured poly(lactic-co-glycolic acid)/gelatin methacrylamide fibrous scaffolds[J]. ACS Applied Polymer Materials, 2022, 4: 987-998. doi: 10.1021/acsapm.1c01442 [27] PRESLEY K F, REINSCH B M, CYBYK D B, et al. Oxygen sensing performance of biodegradable electrospun nanofibers: Influence of fiber composition and core-shell geometry[J]. Sensors and Actuators B: Chemical, 2021, 329: 129191. doi: 10.1016/j.snb.2020.129191 [28] YANG K, LIU Z, CHAI J, et al. High performance polyimide-based separator for 4.5V high voltage LiCoO2 battery with superior safety[J]. Materials Chemistry and Physics, 2022, 282: 125975. doi: 10.1016/j.matchemphys.2022.125975 [29] LIU K, LIU W, QIU Y, et al. Electrospun core-shell microfiber separator with thermal-triggered flame-retardant properties for lithium-ion batteries[J]. Science Advances, 3: e1601978. [30] MA L, SHI X, ZHANG X, et al. Electrospinning of polycaprolacton/chitosan core-shell nanofibers by a stable emulsion system[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2019, 583: 123956. doi: 10.1016/j.colsurfa.2019.123956 [31] WANG M L, YU D G, BLIGH S W A, Progress in preparing electrospun janus fibers and their applications[J]. Applied Materials Today, 2023, 31: 101766. [32] CAI M, HE H, ZHANG X, et al. Efficient synthesis of PVDF/PI side-by-side bicomponent nanofiber membrane with enhanced mechanical strength and good thermal stability[J]. Nanomaterials (Basel), 2018, 9(1): 39. doi: 10.3390/nano9010039 [33] CAI M, YUAN D, ZHANG X, et al. Lithium ion battery separator with improved performance via side-by-side bicomponent electrospinning of PVDF-HFP/PI followed by 3D thermal crosslinking[J]. Journal of Power Sources, 2020, 461: 228123. doi: 10.1016/j.jpowsour.2020.228123 [34] ZHAO R, HE H, CAI M, et al. Nano-crystalline sandwich formed in polylactic acid fibers[J]. Macromol Rapid Commun, 2019, 40: e1900492. doi: 10.1002/marc.201900492 [35] DILAMIAN M, JOGHATAEI M, ASHRAFI Z, et al. From 1D electrospun nanofibers to advanced multifunctional fibrous 3D aerogels[J]. Applied Materials Today, 2021, 22: 100964. doi: 10.1016/j.apmt.2021.100964 [36] WANG P, LV H, CAO X, et al. Recent progress of the prepa-ration and application of electrospun porous nanofibers[J]. Polymers (Basel), 2023, 15(4): 921. doi: 10.3390/polym15040921 [37] WANG Y, HUANG H, ZHAO Y, et al. Self-assembly of ultralight and compressible inorganic sponges with hierarchi-cal porosity by electrospinning[J]. Ceramics International, 2020, 46: 768-774. doi: 10.1016/j.ceramint.2019.09.031 [38] ZHANG L, LIU W, WEN X, et al. Electrospun submicron nio fibers combined with nanosized carbon black as reinforcement for multi-functional poly(lactic acid) composites[J]. Composites Part A:Applied Science and Manufacturing, 2020, 129: 105662. doi: 10.1016/j.compositesa.2019.105662 [39] KANG S H, JANG J K, JEONG H Y, et al. Polyacrylonitrile/phosphazene composite-based heat-resistant and flame-retardant separators for safe lithium-ion batteries[J]. ACS Applied Energy Materials, 2022, 5: 2452-2461. doi: 10.1021/acsaem.1c03948 [40] WANG P, LIU X, YOU Y, et al. Fabrication of high-perfor-mance colorimetric membrane by incorporation of polydiacetylene into polyarylene ether nitriles electrospinning nanofibrous membranes[J]. Nanomaterials (Basel), 2022, 12(24): 4379. doi: 10.3390/nano12244379 [41] SERBEZEANU D, HAMCIUC C, VLAD-BUBULAC T, et al. Electrospun nanofibers based on polymer blends with tunable high-performance properties for innovative fire-resis-tant materials[J]. Polymers (Basel), 2022, 14(24): 5501. doi: 10.3390/polym14245501 [42] SUN L, GU Q, WANG H, et al. Anhydrous proton conducti-vity of electrospun phosphoric acid-doped PVP-PVDF nano-fibers and composite membranes containing MOF fillers[J]. RSC Advance, 2021, 11: 29527-29536. doi: 10.1039/D1RA04307B [43] ZAINAB G, WANG X, YU J, et al. Electrospun polyacrylonitrile/polyurethane composite nanofibrous separator with electrochemical performance for high power lithium ion batteries[J]. Materials Chemistry and Physics, 2016, 182: 308-314. doi: 10.1016/j.matchemphys.2016.07.037 [44] FU H, SHI C, NIE J, et al. Bi2O3 nanospheres coated in electrospun carbon spheres derived Bi@C used as anode materials for lithium-ion batteries[J]. Journal of Alloys and Compounds, 2022, 918: 165666. doi: 10.1016/j.jallcom.2022.165666 [45] ZHANG C, LI Y, WANG P, et al. Core-shell nanofibers electrospun from O/W emulsions stabilized by the mixed monolayer of gelatin-gum arabic complexes[J]. Food Hydrocolloids, 2020, 107: 105980. doi: 10.1016/j.foodhyd.2020.105980 [46] SHI Y, CAO X, ZHU Z, et al. Fabrication of cellulose ace-tate/gelatin-eugenol core-shell structured nanofiber films for active packaging materials[J]. Colloids Surf B Biointerfaces, 2022, 218: 112743. doi: 10.1016/j.colsurfb.2022.112743 [47] COSTA C M, LEE Y H, KIM J H, et al. Recent advances on separator membranes for lithium-ion battery applications: From porous membranes to solid electrolytes[J]. Energy Storage Materials, 2019, 22: 346-375. doi: 10.1016/j.ensm.2019.07.024 [48] LIU X, ZHANG B, WU Y, et al. The effects of polybenzi-midazole nanofiber separator on the safety and perfor-mance of lithium-ion batteries: Characterization and analysis from the perspective of mechanism[J]. Journal of Power Sources, 2020, 475: 228624. doi: 10.1016/j.jpowsour.2020.228624 [49] WANG Q, YU Y, MA J, et al. Electrospun melamine resin-based multifunctional nonwoven membrane for lithium ion batteries at the elevated temperatures[J]. Journal of Power Sources, 2016, 327: 196-203. doi: 10.1016/j.jpowsour.2016.07.063 [50] MIAO Y E, ZHU G N, HOU H, et al. Electrospun polyimide nanofiber-based nonwoven separators for lithium-ion batteries[J]. Journal of Power Sources, 2013, 226: 82-86. doi: 10.1016/j.jpowsour.2012.10.027 [51] ARIFEEN W U, CHOI J, YOO K, et al. A nano-silica/polyacrylonitrile/polyimide composite separator for advanced fast charging lithium-ion batteries[J]. Chemical Engineering Journal, 2021, 417: 128075. doi: 10.1016/j.cej.2020.128075 [52] WANG L, WANG Z, SUN Y, et al. Sb2O3 modified PVDF-CTFE electrospun fibrous membrane as a safe lithium-ion battery separator[J]. Journal of Membrane Science, 2019, 572: 512-519. doi: 10.1016/j.memsci.2018.11.041 [53] WEI Z, WU Z, SU Q, et al. A novel high-performance and outstanding flame retardancy polysulfonamide nano-fibrous filter for the high-efficiency PM2.5 filtration[J]. Separation and Purification Technology, 2022, 287: 120355. doi: 10.1016/j.seppur.2021.120355 [54] VATANPOUR V, DEHQAN A, PAZIRESH S, et al. Polylactic acid in the fabrication of separation membranes: A review[J]. Separation and Purification Technology, 2022, 296: 121433. doi: 10.1016/j.seppur.2022.121433 [55] YANG X, PU Y, ZHANG Y, et al. Multifunctional composite membrane based on BaTiO3@PU/PSA nanofibers for high-efficiency PM2.5 removal.[J]. Journal of Hazardous Materials, 2020, 391: 122254. doi: 10.1016/j.jhazmat.2020.122254 [56] ZHOU Y, LIU Y, ZHANG M, et al. Electrospun nanofiber membranes for air filtration: A review[J]. Nanomaterials (Basel), 2022, 12(7): 1077. doi: 10.3390/nano12071077 [57] KANG Y, CHEN J, FENG S, et al. Efficient removal of high-temperature particulate matters via a heat resistant and flame retardant thermally-oxidized PAN/PVP/SnO2 nano-fiber membrane[J]. Journal of Membrane Science, 2022, 662: 120985. doi: 10.1016/j.memsci.2022.120985 [58] HUA Y, LI Y, JI Z, et al. Dual-bionic, fluffy, and flame resis-tant polyamide-imide ultrafine fibers for high-tempera-ture air filtration[J]. Chemical Engineering Journal, 2023, 452: 139168. doi: 10.1016/j.cej.2022.139168 [59] MAO M, YU K X, CAO C F, et al. Facile and green fabrication of flame-retardant Ti3C2T x MXene networks for ultrafast, reusable and weather-resistant fire warning[J]. Chemical Engineering Journal, 2022, 427: 131615. doi: 10.1016/j.cej.2021.131615 [60] ZHENG H, HAN X, WEI Q, et al. Biomass-based flexible fire warning sensor with excellent flame retardancy and sensi-tivity[J]. Chemical Engineering Journal, 2022, 437: 135412. doi: 10.1016/j.cej.2022.135412 [61] ZHAO T, TENG D, XU Y, et al. Multi-functional air filters with excellent flame retardancy and fire-warning capabi-lity[J]. Journal of Colloid and Interface Science, 2022, 617: 236-245. doi: 10.1016/j.jcis.2022.03.003 [62] ZHANG L, HUANG Y, DONG H, et al. Flame-retardant shape memory polyurethane/MXene paper and the appli-cation for early fire alarm sensor[J]. Composites Part B:Engineering, 2021, 223: 109149. doi: 10.1016/j.compositesb.2021.109149 [63] SHAHID UL I, SHAHID M, MOHAMMAD F. Perspectives for natural product based agents derived from industrial plants in textile applications–a review[J]. Journal of Cleaner Production, 2013, 57: 2-18. doi: 10.1016/j.jclepro.2013.06.004 [64] LI J, XU G, YIN J, et al. Electrospun silica-based fiber for developing multifunctional protective clothing[J]. Materials Science and Engineering: B, 2023, 289: 116259. doi: 10.1016/j.mseb.2023.116259 [65] DRAKOPOULOS S X, YANG J, VRYONIS O, et al. Flexible polymer-based nanodielectrics reinforced with electrospun composite nanofibers for capacitive energy storage[J]. ACS Applied Polymer Materials, 2022, 4: 8203-8215. doi: 10.1021/acsapm.2c01162 [66] AYTAC Z, HUANG R, VAZE N, et al. Development of biodegradable and antimicrobial electrospun zein fibers for food packaging[J]. ACS Sustainable Chemistry & Engineering, 2020, 8: 15354-15365. [67] ZHAO L, WU H, JIAO W, et al. Superelastic, lightweight, and flame-retardant 3D fibrous sponge fabricated by one-step electrospinning for heat retention[J]. Composites Communications, 2021, 25: 100681. doi: 10.1016/j.coco.2021.100681 [68] LIN C, LI W, YAN Y, et al. Ultrafine electrospun fiber based on ionic liquid/AlN/copolyamide composite as novel form-stable phase change material for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2021, 223: 110953. doi: 10.1016/j.solmat.2020.110953 [69] ZONG X, CAI Y, SUN G, et al. Fabrication and characterization of electrospun SiO2 nanofibers absorbed with fatty acid eutectics for thermal energy storage/retrieval[J]. Solar Energy Materials and Solar Cells, 2015, 132: 183-190. doi: 10.1016/j.solmat.2014.08.030 [70] LIU Z, PENG Y, MENG T, et al. Thermal-triggered fire-extinguishing separators by phase change materials for high-safety lithium-ion batteries[J]. Energy Storage Materials, 2022, 47: 445-452. doi: 10.1016/j.ensm.2022.02.020 [71] MAZZOCCHETTI L, BENELLI T, MACCAFERRI E, et al. Poly-m-aramid electrospun nanofibrous mats as high-performance flame retardants for carbon fiber reinforced composites[J]. Composites Part B:Engineering, 2018, 145: 252-260. doi: 10.1016/j.compositesb.2018.03.036 -

下载:

下载: