Optimization of mixture ratio and microstructure influence mechanism of composite filling slurry based on response surface method

-

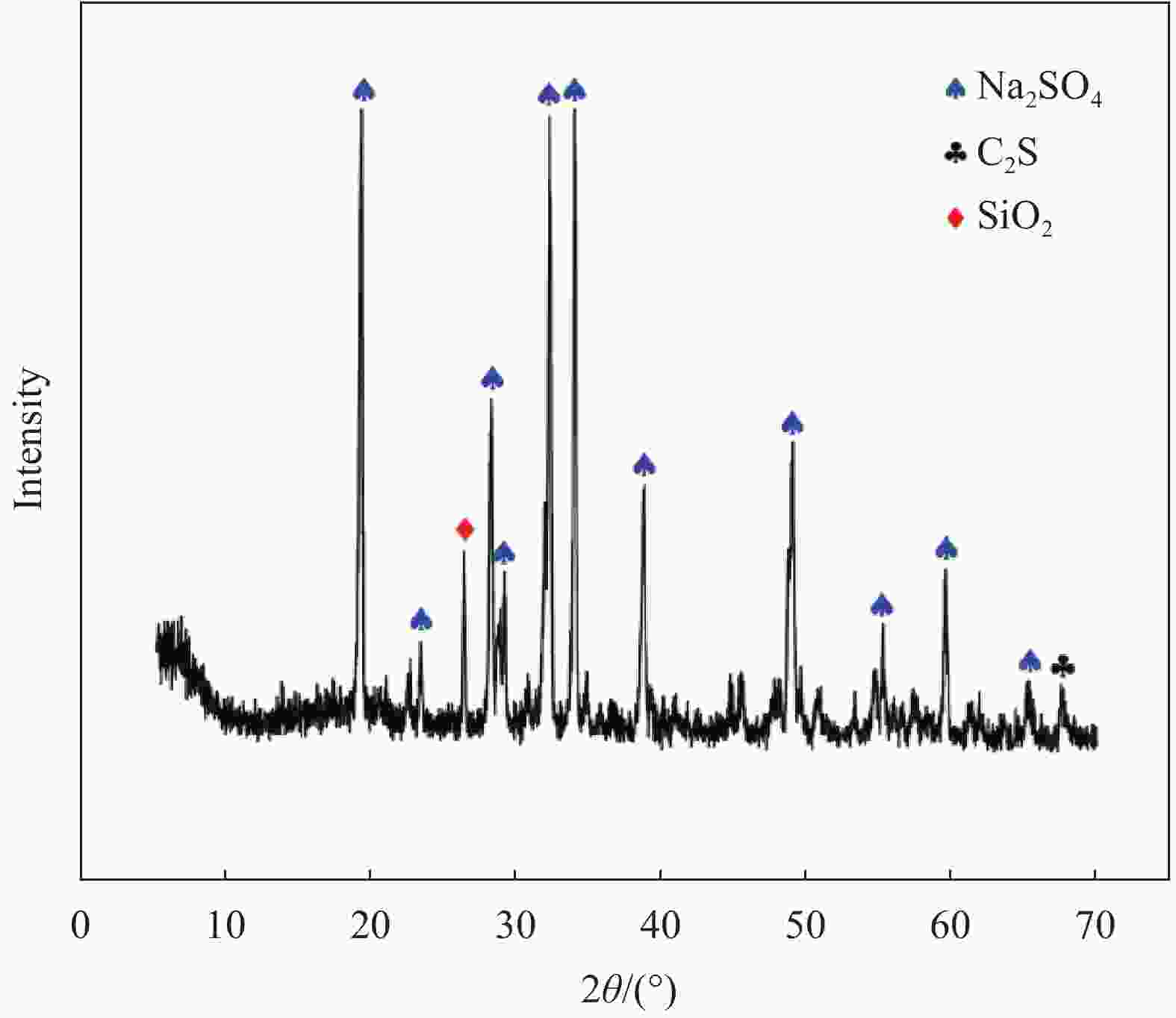

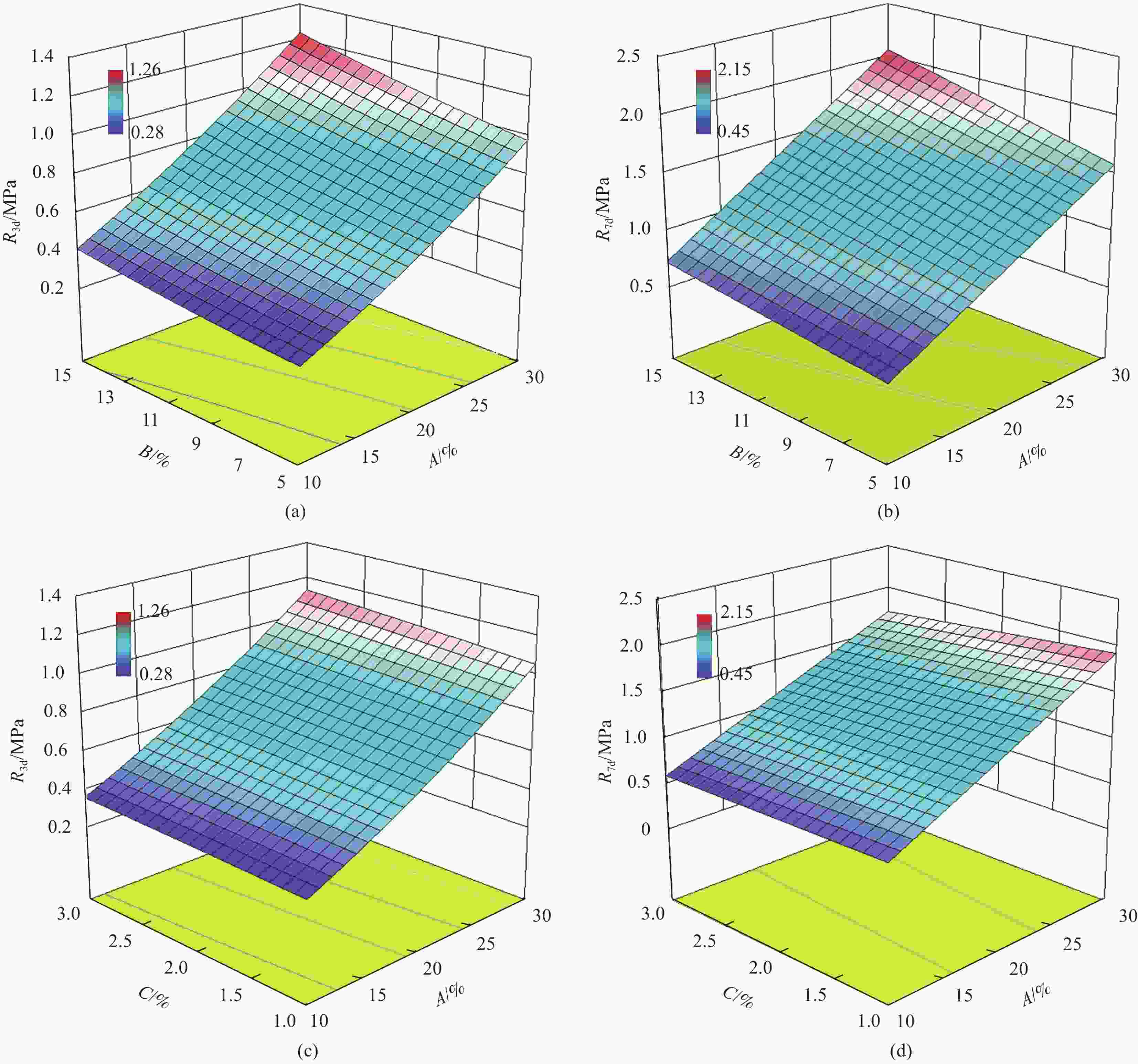

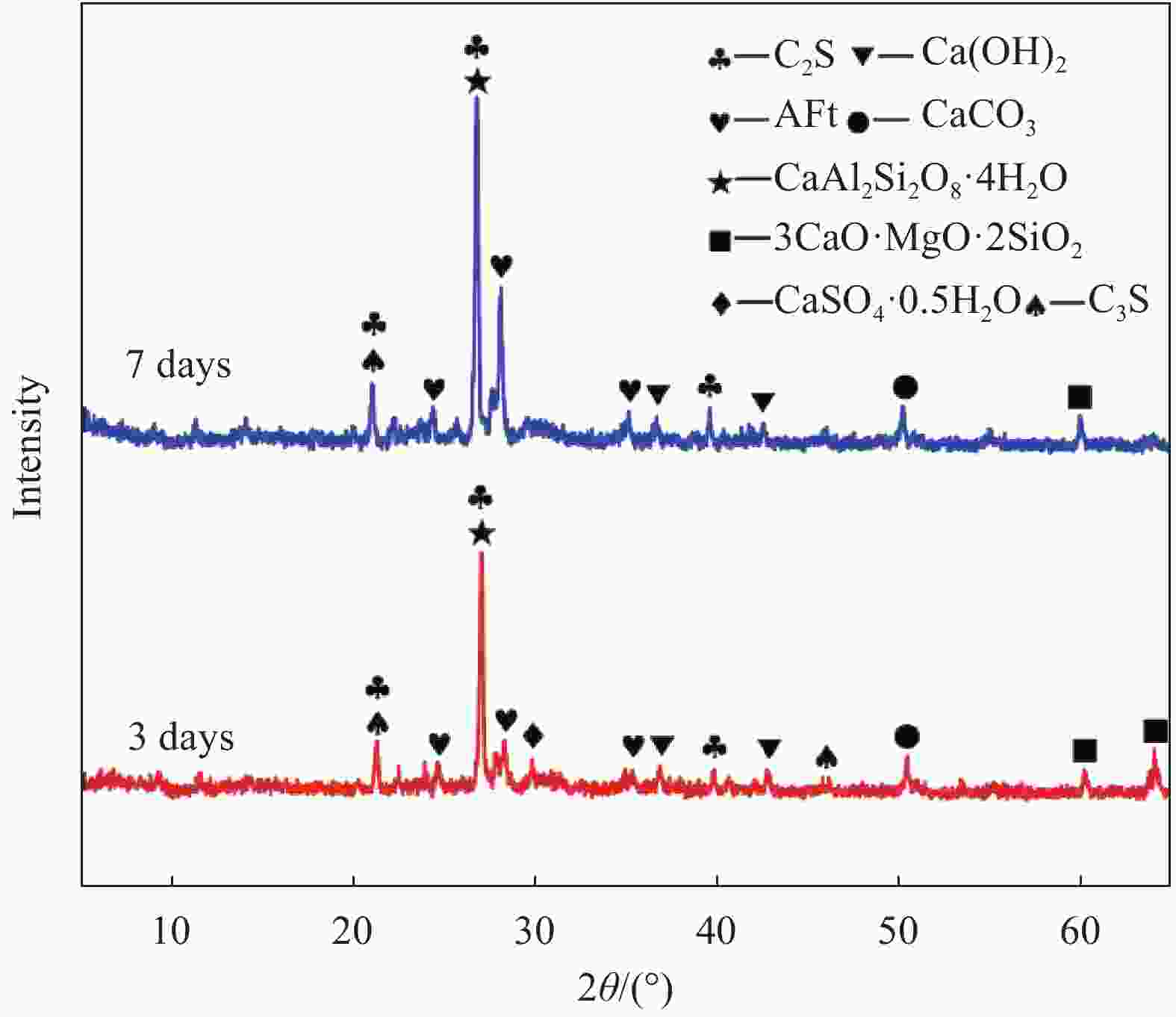

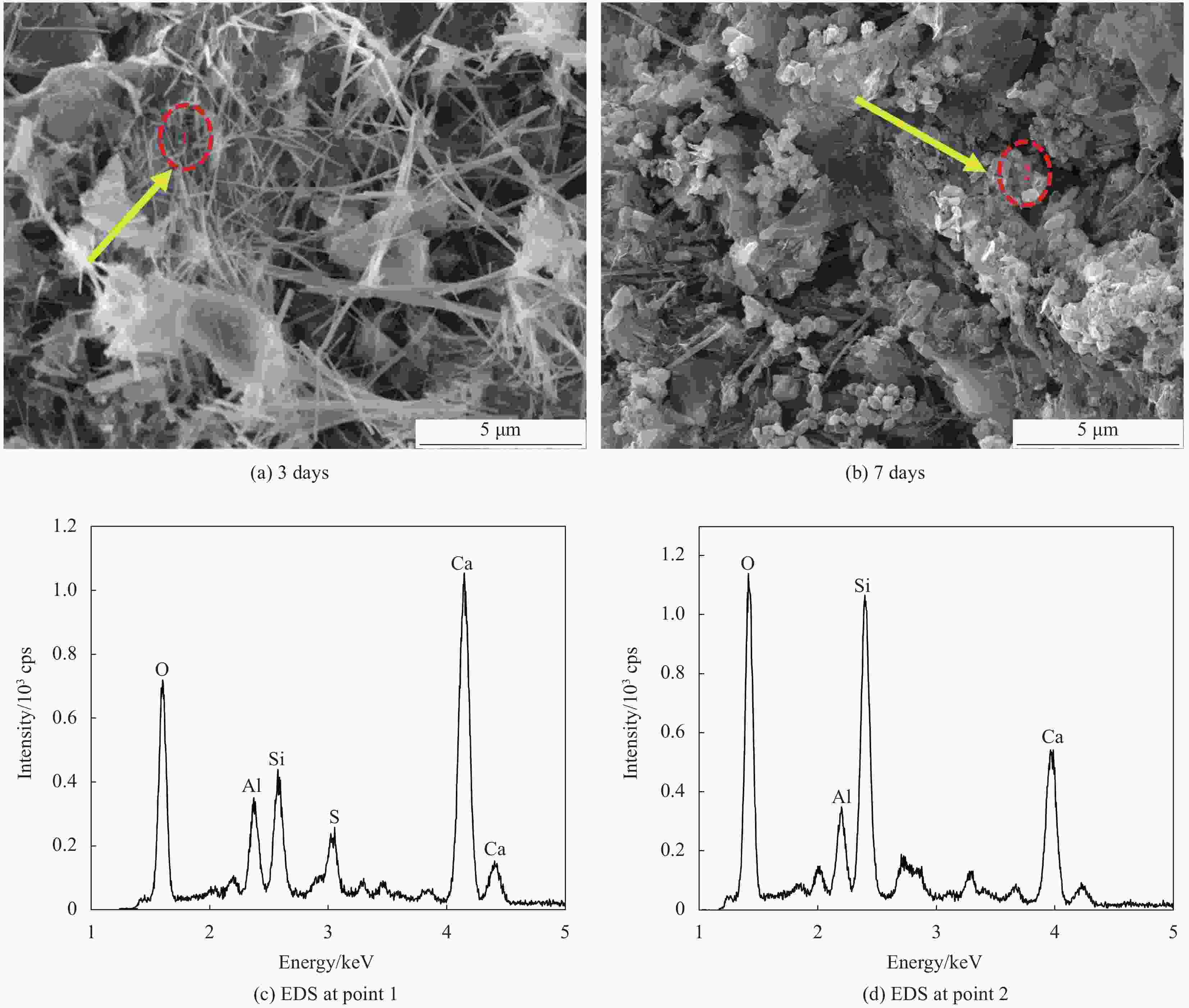

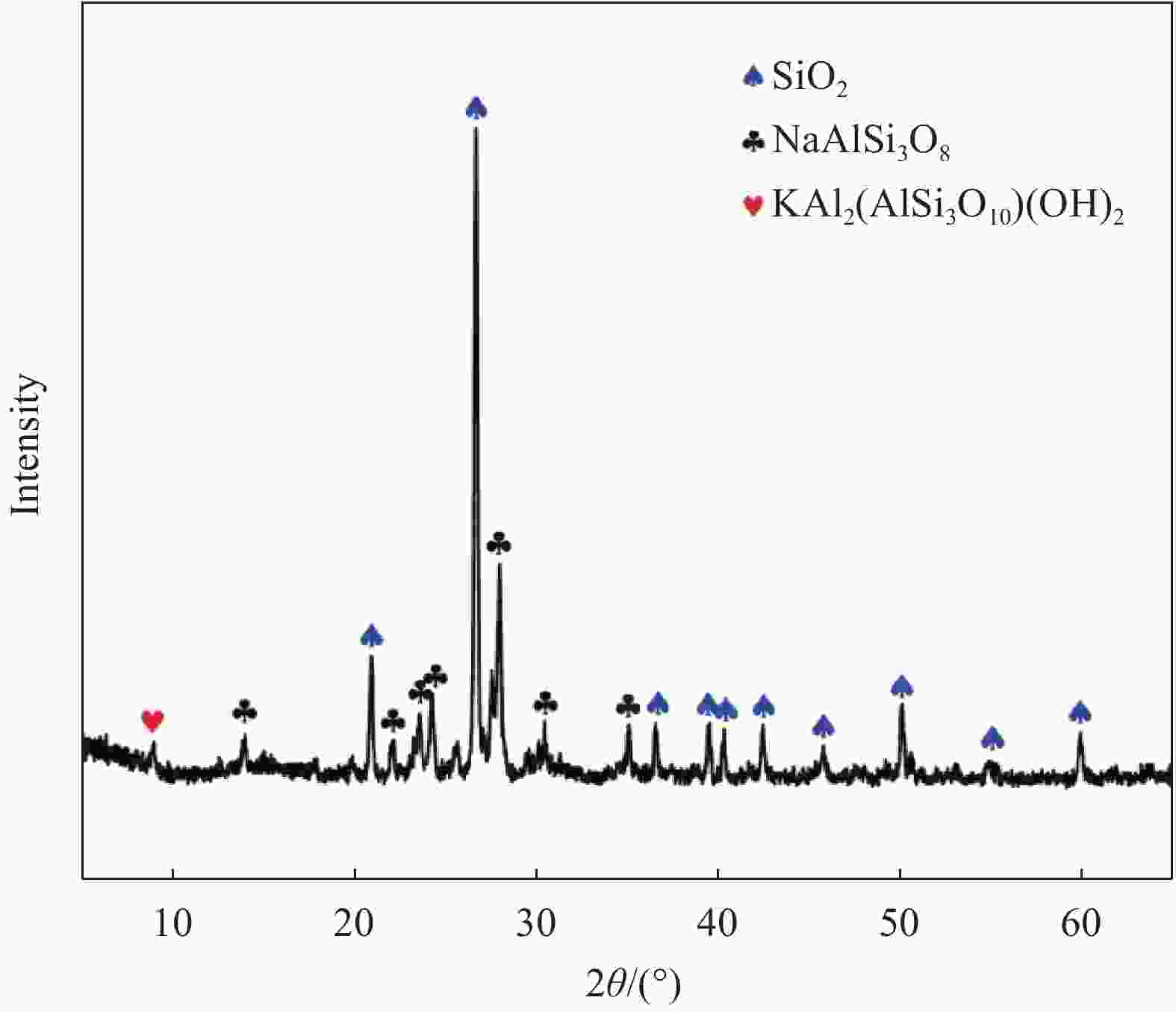

摘要: 为探明因素间交互作用对充填体强度性能的影响机制及揭示胶凝材料水化产物作用机制,以水泥、石灰、石膏添加量为自变量影响因子,胶结体抗压强度为响应目标值,采用Box-Behnken响应面法(RSM)设计试验,建立二次多项式回归模型,结合Numencial功能优化模型自变量参数。最后,利用XRD、SEM、EDS分析手段,探讨净浆试样水化产物组成及微观结构形貌。研究结果表明∶方差分析及模型响应曲面共同诠释了水泥和石灰添加量的交互作用是影响充填体强度性能的关键性因素。对复合充填料浆配合比寻优可得,在水泥∶石灰∶石膏∶矿渣∶甲酸钙=30∶15∶1∶50∶4最优条件下,胶结体3天和7天抗压强度为1.19 MPa和2.17 MPa,模型验证试验相对误差为3.25%和0.93%,表明模型精确度高,可靠性强。复合胶凝体系水化产物主要为钙矾石(AFt)和C-S-H凝胶,随着龄期的延长,AFt和C-S-H凝胶交错生长,紧密搭接,形成致密的三维空间网络结构支撑体系,是胶结充填体具备强度性能的主要来源。Abstract: To explore how the interaction among factors influences the strength of filling body, and reveal the action mechanism of hydration products from cement materials, a test was designed by Box-Behnken response surface methodology (RSM) for establishing a quadratic polynomial regression model in combination with independent variable parameters of numencial function optimization model. In the design, the added quantities of cement, lime and gypsum were taken as independent variable influence factors, and the compressive strength of cement body as the response target values. Finally, XRD, SEM and EDS analysis methods were utilized to discuss the composition and microstructure morphology of the hydration products from paste samples. The results show that the ANOVA and the response surface of the model jointly explain that the interaction between cement and lime quantities added is the critical factor influencing the strength of filling body. After optimizing the mixture ratio of the composite filling slurry, when the ratio of cement∶lime∶gypsum∶slag∶calcium formate is optimal as 30∶15∶1∶50∶4, the 3 days and 7 days compressive strength values of the cement body are 1.19 MPa and 2.17 MPa, respectively. The relative errors of the model validation tests are 3.25% and 0.93%, which indicates that the model is precise and reliable. The main hydration products of the composite cementitious system are AFt and C-S-H gels, which stagger and overlap closely with age, thus forming a dense 3D spatial network structure support system as the main source of strength for the cemented filling body.

-

Key words:

- response surface method /

- interaction /

- regression model /

- compressive strength /

- optimal ratio /

- microstructure

-

表 1 尾砂主要化学成分组成

Table 1. Main chemical composition of tailings

Test No. Chemical component Mass fraction/wt% 1 SiO2 62.60 2 Al2O3 15.20 3 CaO 2.31 4 K2O 5.86 5 Na2O 3.10 6 Fe2O3 1.16 7 TiO2 0.22 8 MgO 0.90 9 SO3 0.40 10 P2O5 0.09 11 MnO 0.03 12 Others 8.13 表 2 胶结剂主要化学成分组成

Table 2. Main chemical composition of cement

Chemical

componentMass fraction/wt% Slag Cement Lime Gypsum CaO 43.80 45.80 95.50 46.40 Al2O3 16.50 15.50 0.43 0.17 SiO2 26.90 25.50 1.75 1.26 Na2O 0.39 0.72 0.10 0.09 MgO 7.10 3.94 1.28 3.24 Fe2O3 0.58 2.88 0.35 0.18 SO3 2.87 3.56 0.30 48.10 Others 1.86 2.10 0.29 0.56 表 3 响应面因素设计与水平编码

Table 3. Response surface factor design and horizontal coding

Level A/wt% B/wt% C/wt% −1 10 5 1 0 20 10 2 1 30 15 3 Notes:A—Cement; B—Lime; C—Gypsum. 表 4 复合充填料浆响应面试验设计与测试结果

Table 4. Response surface test design and test results of composite filling slurry

Test No. Coded value R3d/MPa R7d/MPa A/wt% B/wt% C/wt% Actual value Predicted value Actual value Predicted value 1 0 0 0 0.68 0.68 1.26 1.22 2 0 0 0 0.68 0.68 1.27 1.22 3 0 −1 −1 0.58 0.58 1.11 1.11 4 0 1 1 0.82 0.82 1.33 1.34 5 −1 −1 0 0.28 0.30 0.45 0.51 6 0 0 0 0.68 0.68 1.26 1.22 7 1 −1 0 0.99 0.98 1.63 1.59 8 1 0 −1 1.05 1.06 1.84 1.93 9 0 0 0 0.69 0.68 1.27 1.22 10 0 0 0 0.68 0.68 1.25 1.22 11 1 0 1 1.12 1.14 1.61 1.73 12 −1 0 −1 0.34 0.32 0.65 0.64 13 1 1 0 1.26 1.24 2.15 2.07 14 0 −1 1 0.63 0.62 1.02 0.99 15 0 1 −1 0.74 0.75 1.42 1.46 16 −1 1 0 0.41 0.42 0.71 0.73 17 −1 0 1 0.37 0.36 0.58 0.60 Notes:R3d—Uniaxial compressive strength of 3rd day; R7d—Uniaxial compressive strength of 7th day. 表 5 响应面回归模型方差分析

Table 5. Analysis of variance of response surface regression model

Curing age/day Source Sum of square DF Mean square F-value P-value Significance 3 Model 1.23 9 0.14 545.22 <0.0001 *** A 1.14 1 1.14 4 547.21 <0.0001 *** B 0.070 1 0.070 280.45 <0.0001 *** C 6.613×10−3 1 6.613×10−3 26.37 0.0013 ** AB 4.900×10−3 1 4.900×10−3 19.54 0.0031 ** AC 4.000×10−4 1 4.000×10−4 1.60 0.2470 * BC 2.250×10−4 1 2.250×10−4 0.90 0.3750 * A2 6.821×10−3 1 6.821×10−3 27.21 0.0012 ** B2 6.845×10−4 1 6.845×10−4 2.73 0.1425 * C2 2.132×10−5 1 2.132×10−5 0.085 0.7791 * Residual 1.755×10−3 7 2.507×10−4 — — — Lack of fit 1.675×10−3 3 5.583×10−4 27.92 0.0038 ** Pure error 8.000×10−5 4 2.000×10−5 — — — Cor total 1.23 16 — — — — R2=0.9986 RAdj2=0.9967 RPred2=0.9781 CV=2.24% Source Sum of square DF Mean square F-value P-value Significance 7 Model 3.23 6 0.54 120.23 <0.0001 *** A 2.93 1 2.93 654.91 <0.0001 *** B 0.25 1 0.25 54.80 <0.0001 *** C 0.029 1 0.029 6.44 0.0295 ** AB 0.017 1 0.017 3.78 0.0805 * AC 6.400×10−3 1 6.4×10−3 1.43 0.2591 * BC 0.000 1 0.000 0.000 1.000 * Residual 0.045 10 4.471×10−3 — — — Lack of fit 0.044 6 7.405×10−3 105.79 0.0002 ** Pure error 2.800×10−4 4 7.000×10−5 — — — Cor total 3.27 16 — — — — R2=0.9863 RAdj2=0.9781 RPred2=0.9389 CV=5.46% Notes:DF—Degree freedom; F-value—Ratio of the mean square to the residual term; P-value—Influence degree value of each factor; ***—Significant in [-∞,0.0001]; **—Significant in [0.0001,0.05]; *—Significant in [0.05,+∞]; R2—Complex correlation coefficient; RAdj2—Correction correlation coefficient; RPred2—Predictive correlation coefficient; CV—Coefficient of variation. 表 6 胶结体响应面预测模型验证试验结果

Table 6. Response surface prediction model verification test results of cement

Curing age 3 days 7 days Predicted value/MPa 1.19 2.17 Actual value/MPa 1.25 2.17 1.23 2.16 1.20 2.14 1.26 2.15 1.21 2.14 Average value/MPa 1.23 2.15 Error/% 3.25 0.93 -

[1] 兰文涛, 吴爱祥, 王贻明. 凝水膨胀充填复合材料的配比优化与形成机制[J]. 复合材料学报, 2019, 36(6):1536-1545.LAN Wentao, WU Aixiang, WANG Yiming. Formulation optimization and formation mechanism of condensate expansion and filling composites[J]. Acta Materiae Compositae Sinica,2019,36(6):1536-1545(in Chinese). [2] 杨云鹏, 高谦. 尾砂新型复合胶结材料实验研究[J]. 岩石力学与工程学报, 2012, 31(S1):2906-2911.YANG Yunpeng, GAO Qian. Experimental study of a new commenting material using tailings[J]. Chinese Journal of Rock Mechanics and Engineering,2012,31(S1):2906-2911(in Chinese). [3] LI H, WU A X, WANG H J. Evaluation of short-term strength development of cemented backfill with varying sulphide contents and the use of additives[J]. Journal of Environmental Management,2019,239:279-286. [4] YIN S H, SHAO Y J, WU A X, et al. A systematic review of paste technology in metal mines for cleaner production in China[J]. Journal of Cleaner Production,2020,247:1-21. [5] 付自国, 乔登攀, 郭忠林, 等. 基于RSM-BBD的废石-风砂胶结体配合比与强度试验研究[J]. 煤炭学报, 2018, 43(3):694-703.FU Ziguo, QIAO Dengpan, GUO Zhonglin, et al. Experimental research on mixture proportion and strength of cemented hydraulic fill with waste rock and eolian sand based on RSM-BBD[J]. Journal of China Coal Society,2018,43(3):694-703(in Chinese). [6] 侯永强, 尹升华, 曹永, 等. 基于RSM-BBD 的混合骨料胶结充填体强度增长规律分析[J]. 材料导报, 2020, 34(7):14063-14069.HOU Yongqiang, YIN Shenghua, CAO Yong, et al. Analysis of strength growth law of mixed aggregate cemented backfill based on BBD response surface method[J]. Materials Reports,2020,34(7):14063-14069(in Chinese). [7] 王有团, 杨志强, 李茂辉, 等. 全尾砂-棒磨砂新型胶凝充填材料的制备[J]. 材料研究学报, 2015, 29(4):291-298. doi: 10.11901/1005.3093.2014.404WANG Youtuan, YANG Zhiqiang, LI Maohui, et al. Preparation of new backfill cementitious materials with unclassified tailings-rod milling sands[J]. Chinese Journal of Materials Research,2015,29(4):291-298(in Chinese). doi: 10.11901/1005.3093.2014.404 [8] 李立涛, 高谦, 陈得信, 等. 石膏-熟料质量比对矿渣充填胶凝材料性能的影响及应用[J]. 中南大学学报(自然科学版), 2020, 51(2):490-498.LI Litao, GAO Qian, CHEN Dexin, et al. Effect of gypsum-clinker mass ratios on properties of slag filling cementitious material and its application[J]. Journal of Central South University (Science and Technology),2020,51(2):490-498(in Chinese). [9] 尹升华, 刘家明, 邵亚建, 等. 全尾砂-粗骨料膏体早期抗压强度影响规律及固化机理[J]. 中南大学学报(自然科学版), 2020, 51(2):478-488. doi: 10.11817/j.issn.1672-7207.2020.02.021YIN Shenghua, LIU Jiaming, SHAO Yajian, et al. Influence rule of early compressive strength and solidification mechanism of full tailings paste with coarse aggregate[J]. Journal of Central South University (Science and Technology),2020,51(2):478-488(in Chinese). doi: 10.11817/j.issn.1672-7207.2020.02.021 [10] 温震江, 高谦, 王永定, 等. 基于模糊综合评判的复合胶凝材料开发及料浆配比优化[J]. 中国有色金属学报, 2020, 30(3):698-707. doi: 10.11817/j.ysxb.1004.0609.2020-37561WEN Zhenjiang, GAO Qian, WANG Yongding, et al. Development of composite cementitious material and optimization of slurry proportion based on fuzzy comprehensive evaluation[J]. The Chinese Journal of Nonferrous Metals,2020,30(3):698-707(in Chinese). doi: 10.11817/j.ysxb.1004.0609.2020-37561 [11] 姜关照, 吴爱祥, 王贻明, 等. 生石灰对半水磷石膏充填胶凝材料性能影响[J]. 硅酸盐学报, 2020, 48(1):86-93.JIANG Guanzhao, WU Aixiang, WANG Yiming, et al. Effect of lime on properties of filling cementitious material prepared by hemihydrate phosphogypsum[J]. Journal of the Chinese Ceramic Society,2020,48(1):86-93(in Chinese). [12] 兰文涛, 吴爱祥, 王贻明, 等. 半水磷石膏充填强度影响因素试验[J]. 哈尔滨工业大学学报, 2019, 51(8):128-135. doi: 10.11918/j.issn.0367-6234.201804082LAN Wentao, WU Aixiang, WANG Yiming, et al. Experimental study on influencing factors of the filling strength of hemihydrate phosphogypsum[J]. Journal of Harbin Institute of Technology,2019,51(8):128-135(in Chinese). doi: 10.11918/j.issn.0367-6234.201804082 [13] 李颖, 吴保华, 倪文, 等. 矿渣-钢渣-石膏体系早期水化反应中的协同作用[J]. 东北大学学报(自然科学版), 2020, 41(4):581-586.LI Ying, WU Baohua, NI Wen, et al. Synergies in early hydration reaction of slag-steel slag-gypsum system[J]. Journal of Northeastern University (Natural Science),2020,41(4):581-586(in Chinese). [14] 杨啸, 杨志强, 高谦, 等. 混合充填骨料胶结充填强度试验与最优配比决策研究[J]. 岩土力学, 2016, 37(S2):636-641.YANG Xiao, YANG Zhiqiang, GAO Qian, et al. Cemented filling strength test and optimal proportion decision of mixed filling aggregate[J]. Rock and Soil Mechanics,2016,37(S2):636-641(in Chinese). [15] 张钦礼, 李谢平, 杨伟. 基于BP网络的某矿山充填料浆配比优化[J]. 中南大学学报(自然科学版), 2013, 44(7):2867-2874.ZHANG Qinli, LI Xieping, YANG Wei. Optimization of filling slurry ratio in a mine based on back-propagation neural network[J]. Journal of Central South University (Science and Technology),2013,44(7):2867-2874(in Chinese). [16] QI C C, FOURIE A, CHEN Q S, et al. A strength prediction model using artificial intelligence for recycling waste tailings as cemented paste backfill[J]. Journal of Cleaner Production,2018,183:566-578. doi: 10.1016/j.jclepro.2018.02.154 [17] FALL M, POKHAREL M. Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill[J]. Cement & Concrete Composites,2010,32:819-828. [18] MOHAMMED B S, FANG O C, HOSSAIN K M. A, et al. Mix proportioning of concrete containing paper mill residuals using response surface methodology[J]. Construction and Building Materials,2012,35:63-68. doi: 10.1016/j.conbuildmat.2012.02.050 [19] 付自国, 乔登攀, 郭忠林, 等. 超细尾砂胶结充填体强度计算模型及应用[J]. 岩土力学, 2018, 39(9):3147-3156.FU Ziguo, QIAO Dengpan, GUO Zhonglin, et al. A model for calculating strength of ultra-fine tailings cemented hydraulic fill and its application[J]. Rock and Soil Mechanics,2018,39(9):3147-3156(in Chinese). [20] 中国建材联合会. 用于水泥中的粒化高炉矿渣: GB/T 203—2008[S]. 北京: 中国标准出版社, 2008.China Building Materials Federation. Granulated blastfurnace slag used for cement production: GB/T 203—2008[S]. Beijing: China Standard Press, 2008(in Chinese). [21] 赵冰冰, 方艳, 武康, 等. 蓝藻粉-青霉素菌渣/低密度聚乙烯复合材料配方的响应面法优化设计和验证[J]. 复合材料学报, 2020, 37(8):1894-1903.ZHAO Bingbing, FANG Yan, WU Kang, et al. Optimization design and validation of algae powder-penicillin residue/low density polyethylene composites formulation by response surface methodology[J]. Acta Materiae Compositae Sinica,2020,37(8):1894-1903(in Chinese). [22] 郭策, 江小婷, 邹稳蓬, 等. 仿甲虫鞘翅轻质结构及其参数优化设计[J]. 复合材料学报, 2015, 32(3):856-863.GUO Ce, JIANG Xiaoting, ZOU Wenpeng, et al. A lightweight structure inspired by beetle’s elytra and its optimum design of parameters[J]. Acta Materiae Compositae Sinica,2015,32(3):856-863(in Chinese). [23] 张磊, 杨柳, 桑国臣, 等. 基于响应面法的石灰-矿渣/生土复合材料热湿综合性能[J]. 复合材料学报, 2017, 34(5):1095-1102.ZHANG Lei, YANG Liu, SANG Guochen, et al. Heat & moisture comprehensive property for lime-slag/soil compo-sites based on response surface methodology[J]. Acta Materiae Compositae Sinica,2017,34(5):1095-1102(in Chinese). [24] 高谦, 杨晓炳, 温震江, 等. 基于RSM-BBD的混合骨料充填料浆配比优化[J]. 湖南大学学报(自然科学版), 2019, 46(6):47-55.GAO Qian, YANG Xiaobing, WEN Zhenjiang, et al. Optimization of proportioning of mixed aggregate filling slurry based on BBD response surface method[J]. Journal of Hunan University (Natural Sciences),2019,46(6):47-55(in Chinese). [25] 史耀耀, 俞涛, 何晓东, 等. 复合材料带缠绕成型工艺参数耦合机制及优化[J]. 复合材料学报, 2015, 32(3):831-839.SHI Yaoyao, YU Tao, HE Xiaodong, et al. Mechanism and optimization of process parameters coupling for compo-site tape winding[J]. Acta Materiae Compositae Sinica,2015,32(3):831-839(in Chinese). [26] 马致远, 刘勇, 周吉奎, 等. 响应曲面法优化废催化剂中微波浸出钒的工艺[J]. 中国有色金属学报, 2019, 29(6):1308-1315.MA Zhiyuan, LIU Yong, ZHOU Jikui, et al. Optimization of microwave assisted leaching of vanadium from spent catalyst based on response surface methodology[J]. The Chinese Journal of Nonferrous Metals,2019,29(6):1308-1315(in Chinese). [27] 国家建筑材料工业局. 水泥胶砂强度检验方法(ISO法): GB/T 17671—1999 [S]. 北京: 中国标准出版社, 1999.State Administration of Building Materials Industry. Method of testing cements-determination of strength: GB/T 17671—1999 [S]. Beijing: China Standard Press, 1999(in Chinese). [28] 洪旗, 史耀耀, 路丹妮, 等. 基于灰色关联分析和响应面法的复合材料缠绕成型多目标工艺参数优化[J]. 复合材料学报, 2019, 36(12):2822-2832.HONG Qi, SHI Yaoyao, LU Danni, et al. Multi-response parameter optimization for the composite tape winding process based on grey relational analysis and response surface methodology[J]. Acta Materiae Compositae Sinica,2019,36(12):2822-2832(in Chinese). [29] 诸利一, 吕文生, 杨鹏, 等. 基于响应面法外场作用下全尾砂浓密沉降试验[J]. 中国有色金属学报, 2018, 28(9):1908-1917.ZHU Liyi, LV Wensheng, YANG Peng, et al. Thickening sedimentation of unclassified tailings under influence of external field based on response surface method[J]. The Chinese Journal of Nonferrous Metals,2018,28(9):1908-1917(in Chinese). [30] 林天扬, 王春红, YOUSFANI S H S, 等. 碱处理提取竹黄纤维的响应曲面优化[J]. 复合材料学报, 2018, 35(4):876-884.LIN Tianyang, WANG Chunhong, YOUSFANI S H S, et al. Study on extraction technology of bamboo fiber by response surface[J]. Acta Materiae Compositae Sinica,2018,35(4):876-884(in Chinese). [31] 张浩, 黄新杰, 宗志芳, 等. 基于热湿综合性能的棕榈醇-棕榈酸-月桂酸/SiO2复合材料制备方案的响应面法优化[J]. 复合材料学报, 2017, 34(1):203-209.ZHANG Hao, HUANG Xinjie, ZONG Zhifang, et al. Optimization of preparation program for hexadecanol-palmitic acid-lauric acid/SiO2 composite materials by response surface methodology based on heat & moisture comprehen-sive property[J]. Acta Materiae Compositae Sinica,2017,34(1):203-209(in Chinese). [32] 劳德平, 丁书强, 倪文, 等. 含铝铁硅固废制备PSAF混凝剂RSM优化与结构表征[J]. 中国环境科学, 2018, 38(10):3720-3728. doi: 10.3969/j.issn.1000-6923.2018.10.015LAO Deping, DING Shuqiang, NI Wen, et al. Preparation polysilicate aluminum ferric coagulant from solid waste which containing aluminum, iron and silicon: Response surface method optimization and microstructure characterization[J]. China Environmental Science,2018,38(10):3720-3728(in Chinese). doi: 10.3969/j.issn.1000-6923.2018.10.015 -

下载:

下载: