Preparation of curved carbon/carbon honeycomb and its mechanical properties under uniform load

-

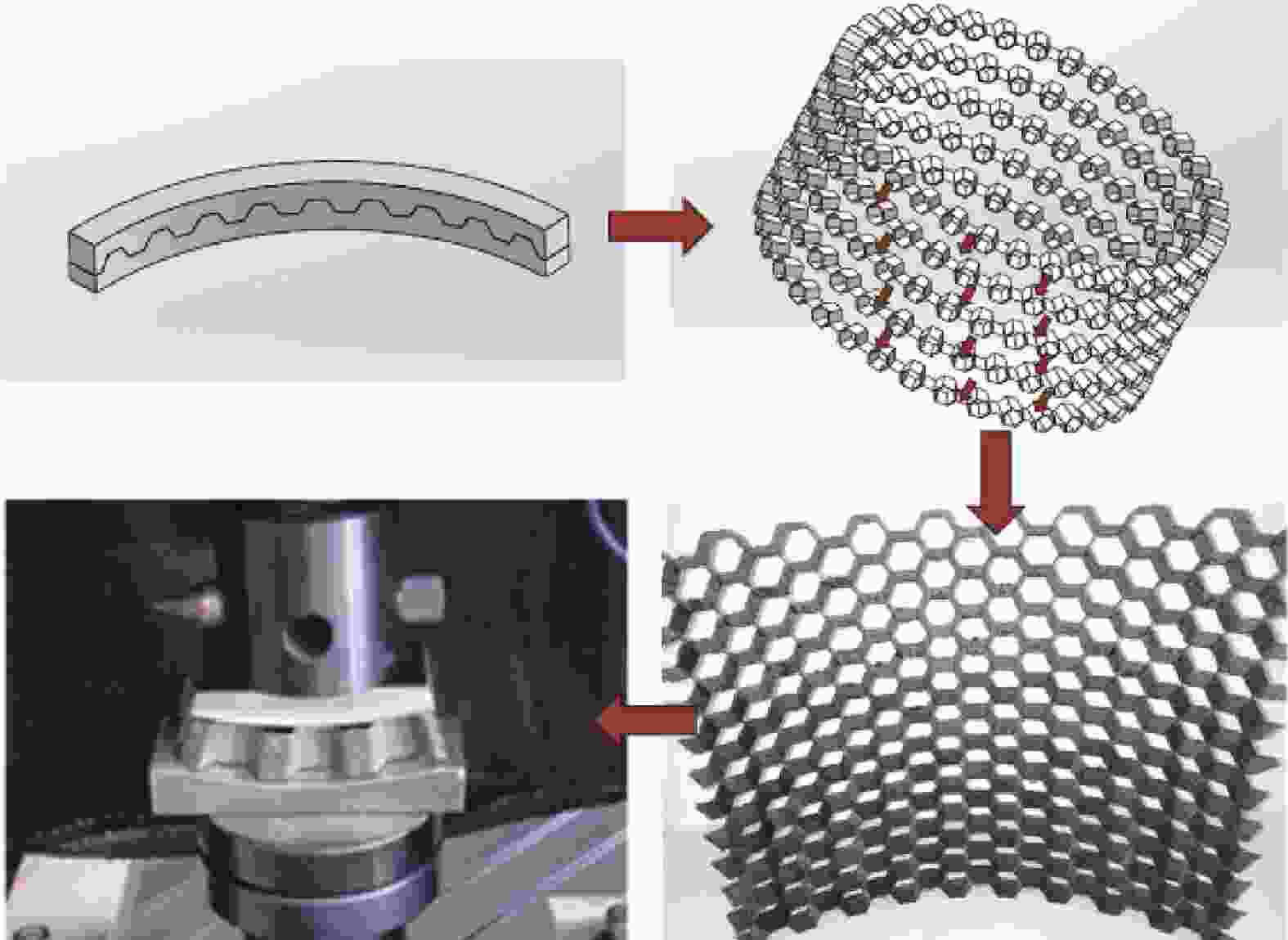

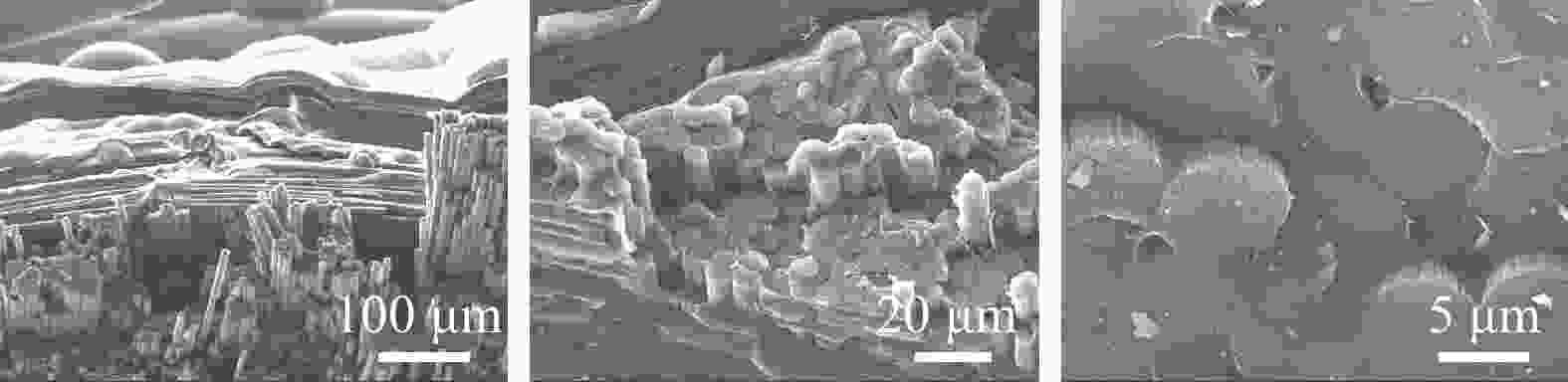

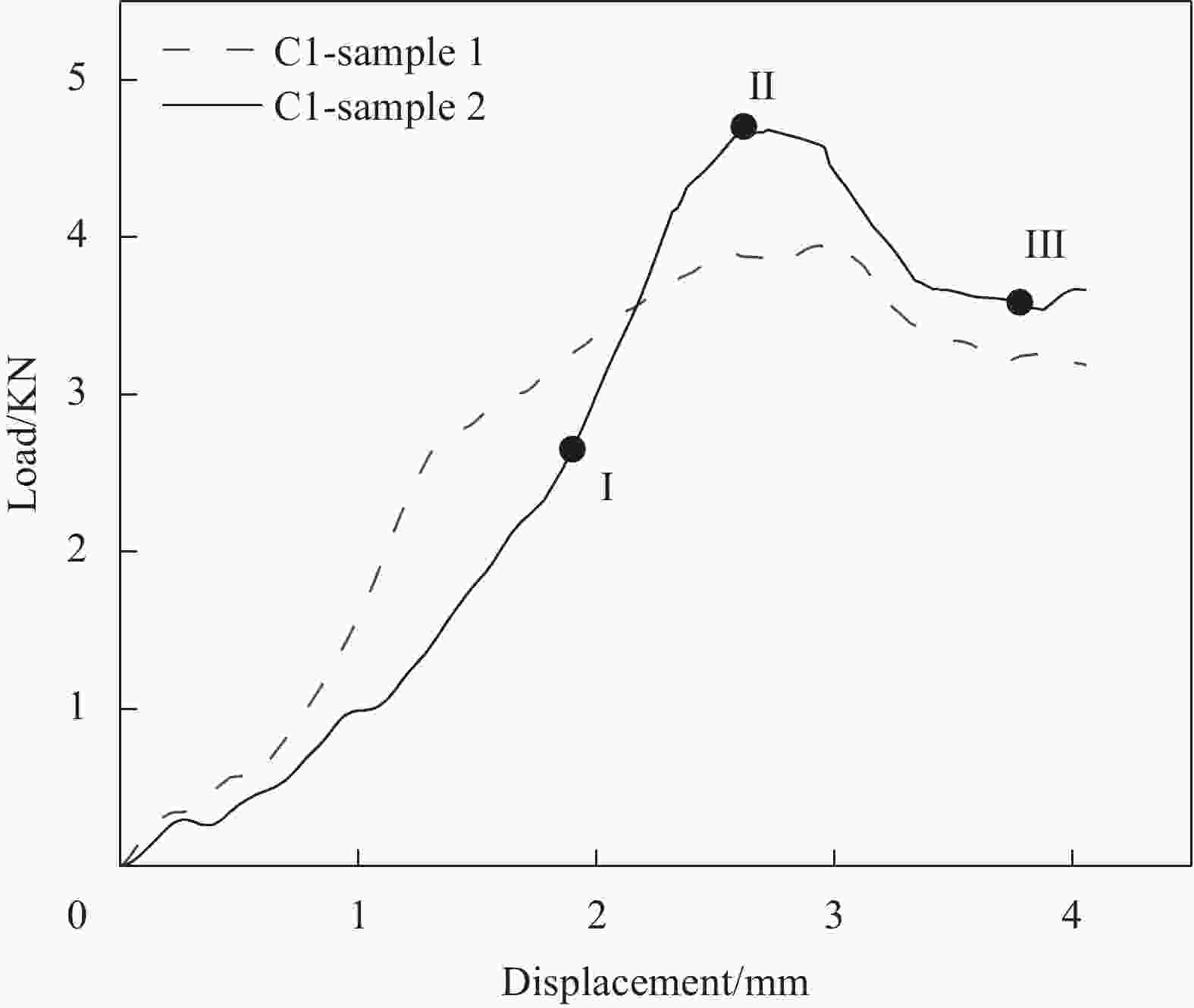

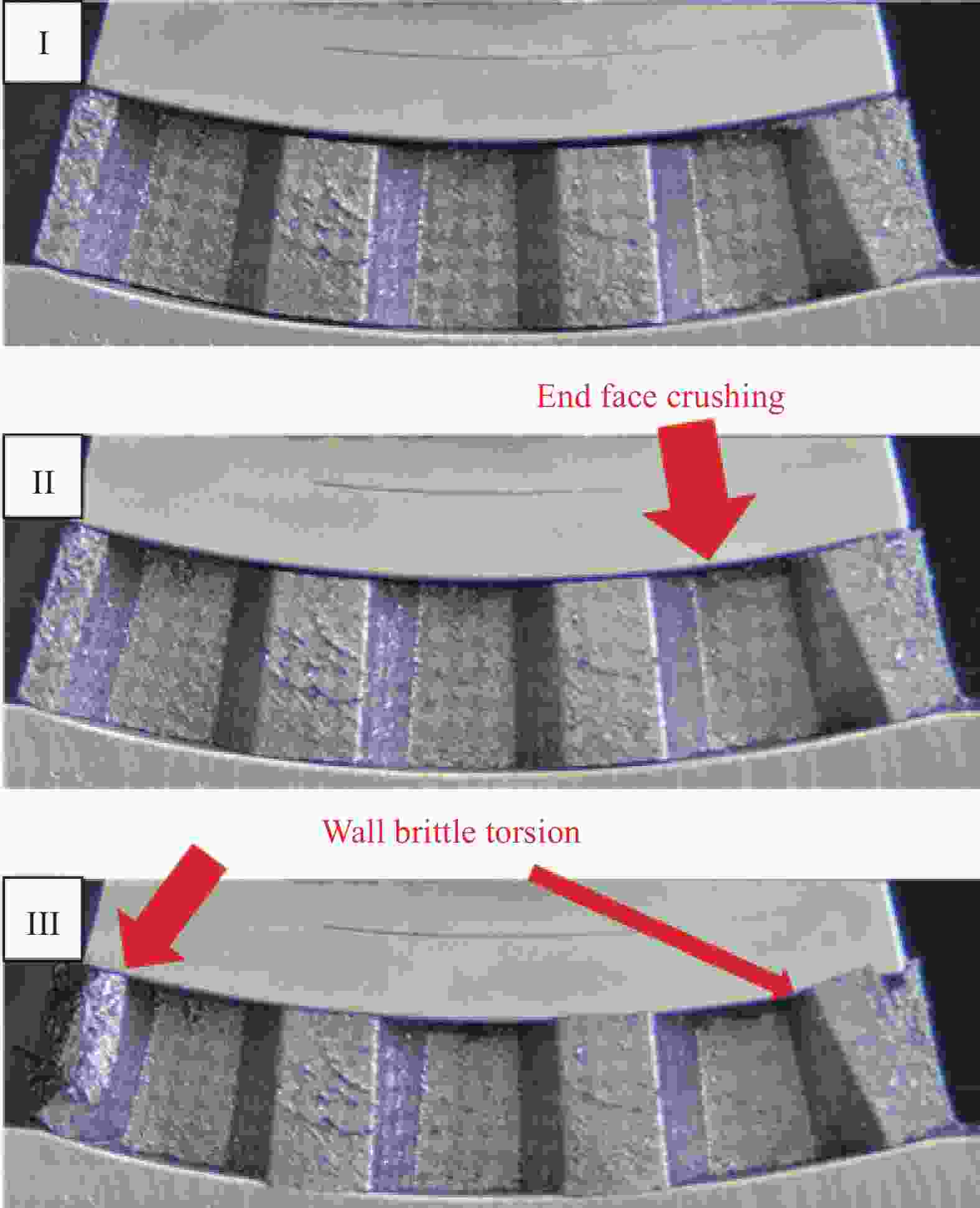

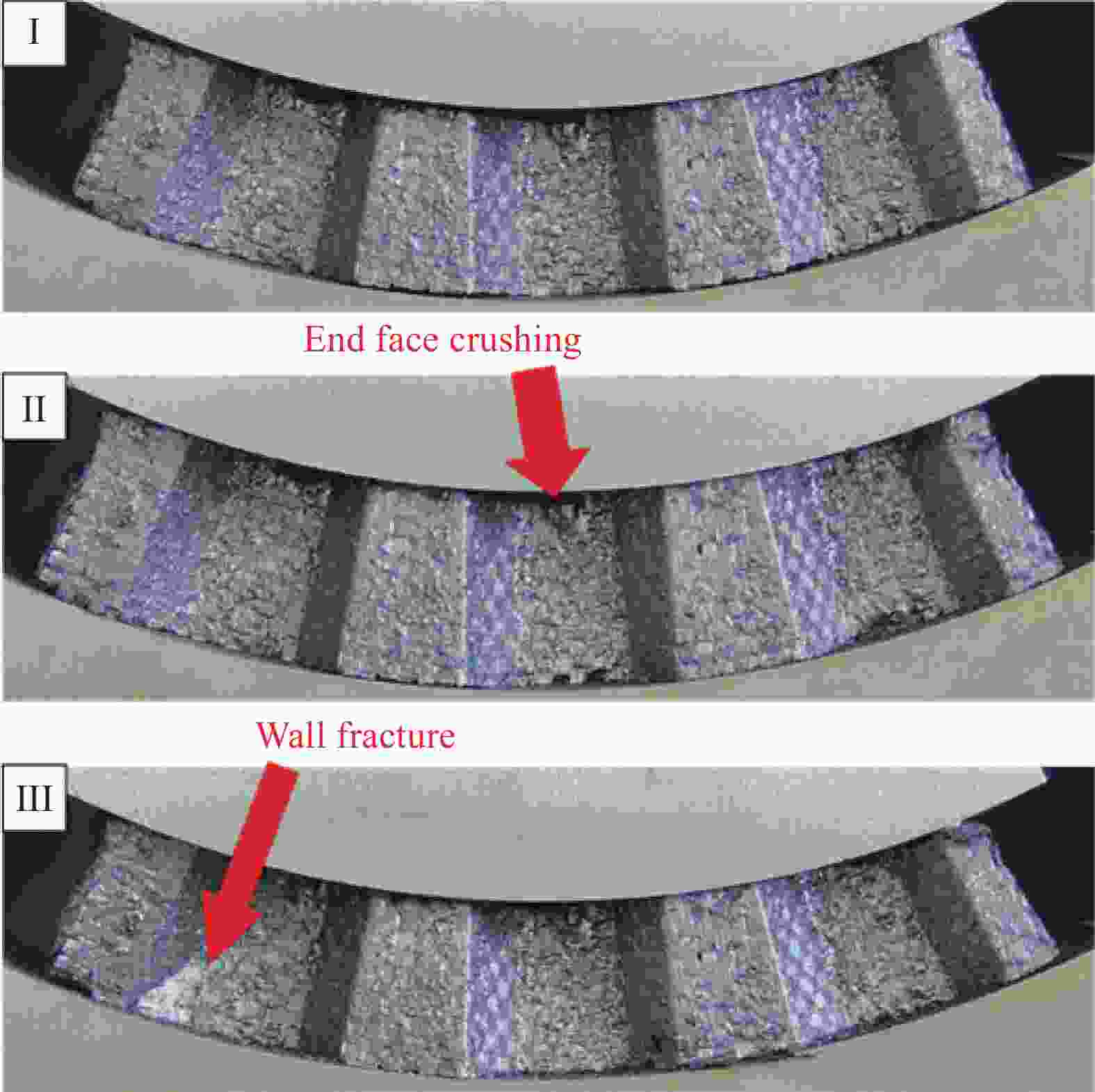

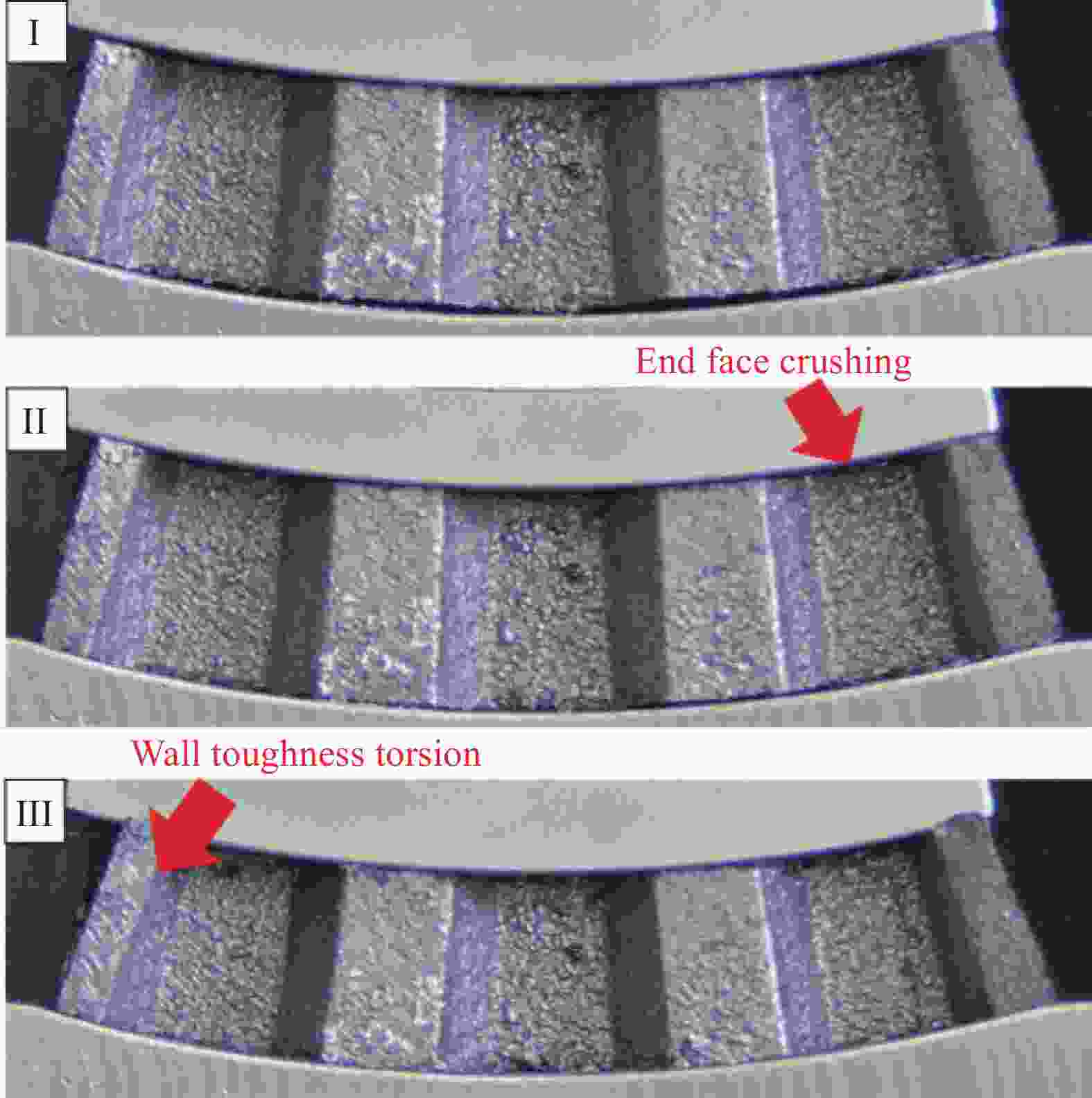

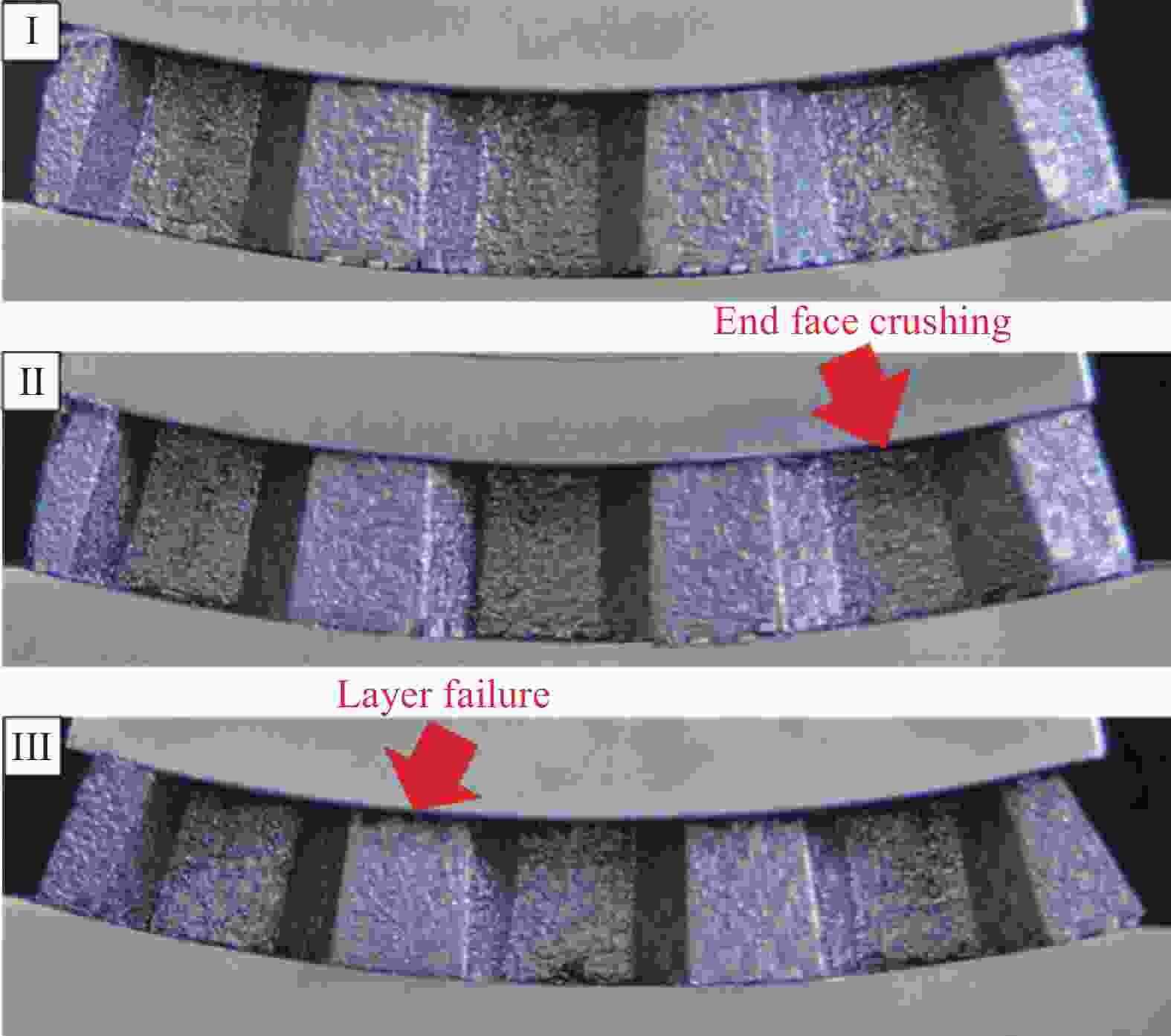

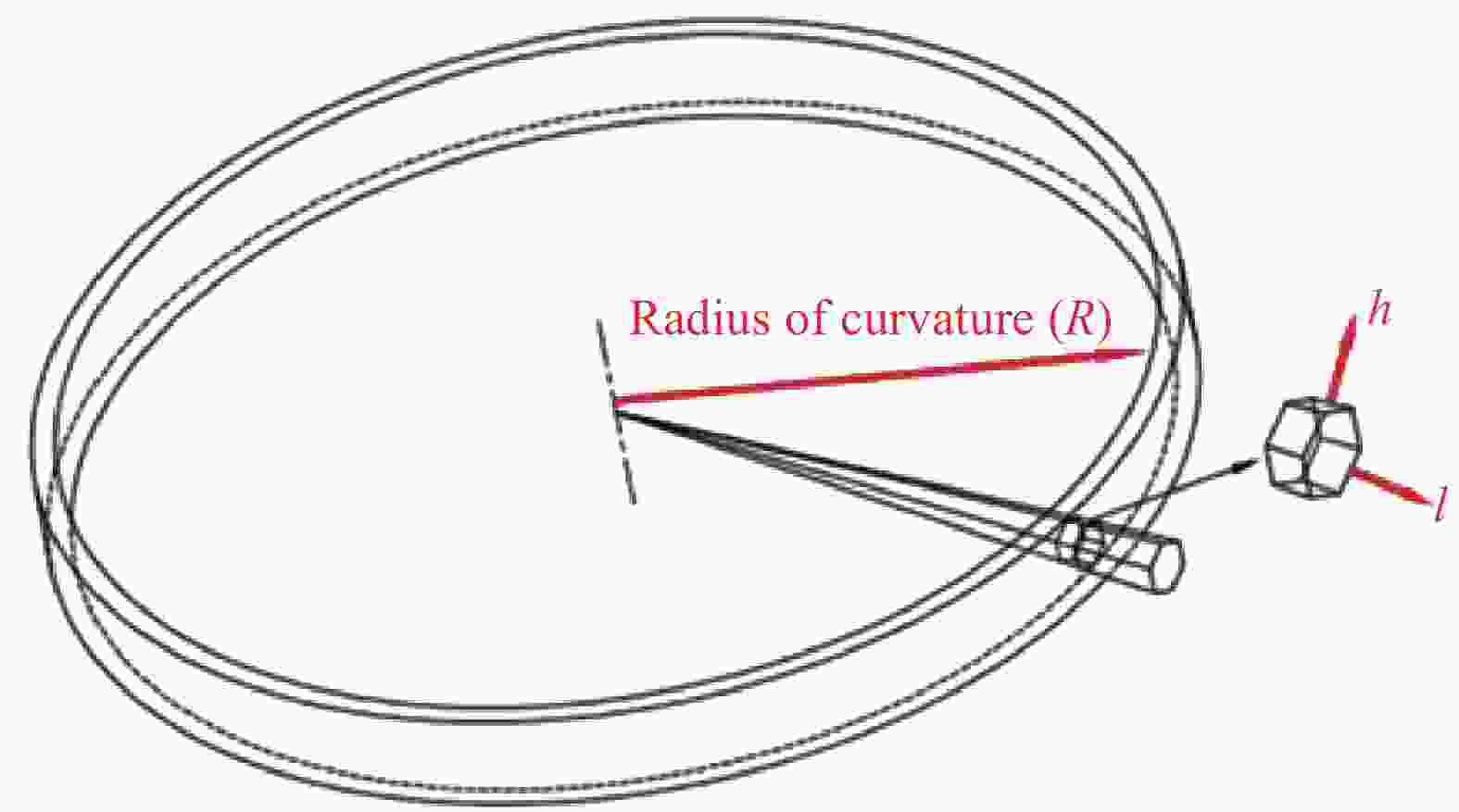

摘要: 精密仪器对承载平台结构的要求不断提高,蜂窝结构由于其轻质和超高稳定性的特点而受到广泛关注。为了满足异形复合材料承载平台的需求,本文采用热压成型和树脂浸渍碳化-化学气相沉积(CVD)相结合的工艺制备了不同规格曲面碳/碳蜂窝结构试样,而后,根据曲面蜂窝的结构特点和服役环境,设计了均布载荷的测试方法对不同试样进行压缩试验,分析了蜂窝厚度、铺层角度、曲率半径等因素对曲面蜂窝力学性能的影响规律。结果表明,当蜂窝的径向厚度增大时,蜂窝壁屈曲程度增大,蜂窝双层壁处所受载荷增大,胶粘面开裂倾向更加显著;当蜂窝纤维取向由0°至45°转变蜂窝壁皱曲转变方式为不皱曲-韧性皱曲-塑性皱曲;当曲面蜂窝的曲率半径减小时,其破坏模式逐渐由双层壁脱粘开裂向蜂窝壁的屈曲断裂转变。本文制备的曲面碳/碳蜂窝压缩强度达到1.48 MPa,具备良好的力学性能,可以满足日益复杂化的航天结构承载需求。Abstract: With the increasing demand of precision instruments on the bearing platform structure, honeycomb structure has been widely concerned because of its light weight and ultra-high stability. In order to meet the requirements of the special-shaped composite bearing platform, this paper uses the combination of hot pressing and resin impregnation carbonization and chemical vapor deposition (CVD) to prepare the curved carbon/carbon honey-comb structure samples of different specifications. Then, according to the structural characteristics of curved honeycomb and the service environment, a test method of uniform load is designed to conduct compression tests on different samples. The influences of honeycomb thickness, layering angle and curvature radius on the mechanical properties of curved honeycomb were analyzed. The results show that when the radial thickness of honeycomb increases, the bending degree of honeycomb wall increases, the load on honeycomb double-walled space increases, and the cracking tendency of adhesive surface becomes more obvious. When the orientation of honeycomb fiber changes from 0° to 45°, the bending mode of honeycomb wall changes to non-buckling, ductile buckling and plastic buckling. When the curvature radius of curved honeycomb decreases, the failure mode gradually changes from decudation cracking to buckling fracture of honeycomb wall. The curved carbon/carbon honeycomb prepared in this paper has a compressive strength of 1.48 MPa, and has good mechanical properties, which can meet the requirements of increasingly complex aerospace structures.

-

Key words:

- carbon/carbon composite materials /

- curved honeycomb /

- uniform load /

- destruction mode

-

表 1 不同设计参数下样品的规格与编号

Table 1. Sample specification and number under different design parameters

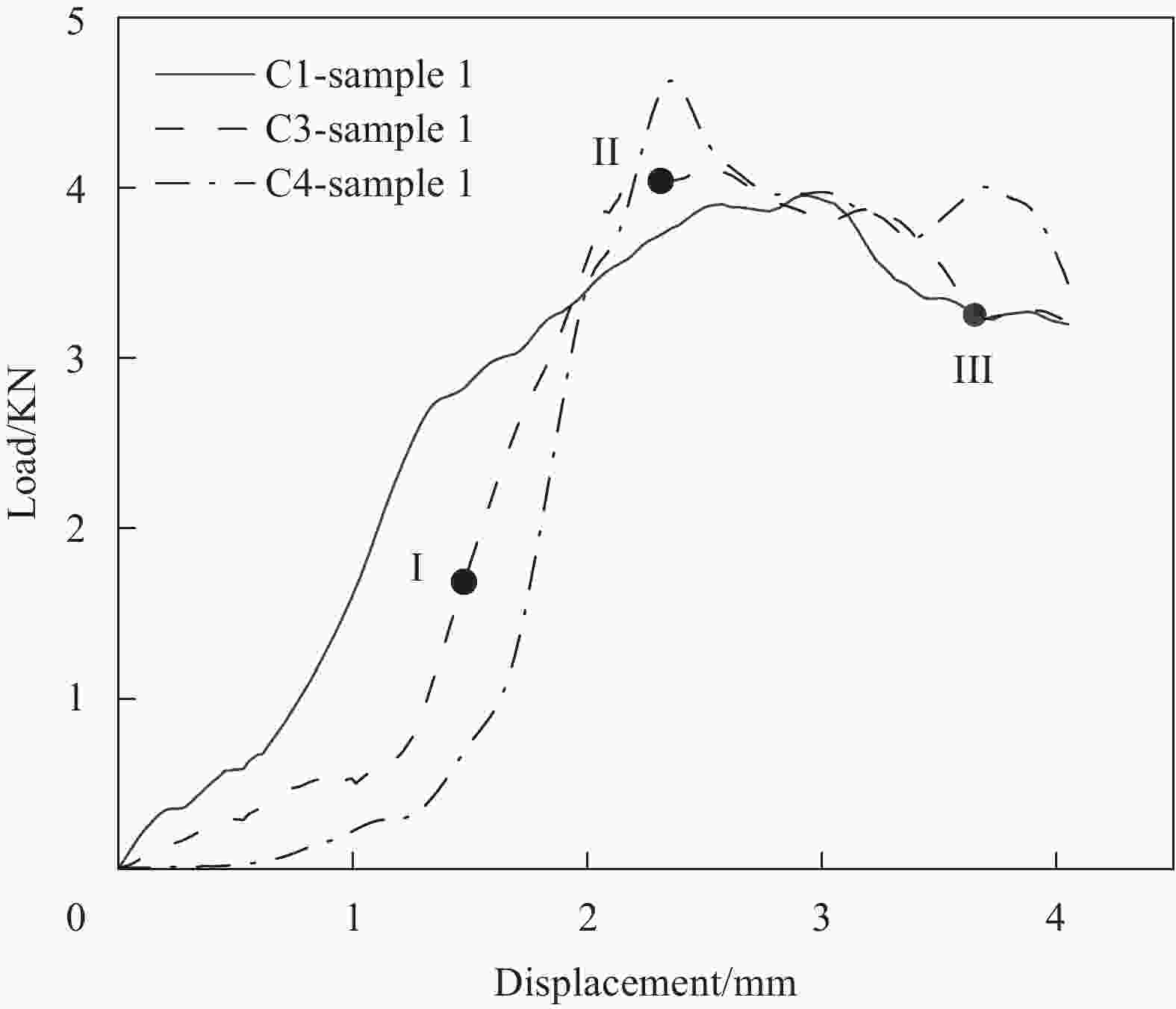

Specification number Radius of curvature /mm Radial thickness /mm Fiber orientation weight /g density /(g·cm−3) C1 180 20 0°/90° 8.73 0.380 C2 180 15 0°/90° 5.68 0.334 C3 180 20 30°/−60° 7.74 0.337 C4 180 20 45°/−45° 8.11 0.353 C5 150 20 0°/90° 8.66 0.373 C6 120 20 0°/90° 8.49 0.360 表 2 不同曲面径向厚度曲面蜂窝的压缩强度

Table 2. Compressive strength of curved honeycomb with different axial thickness

Specification number Radial thickness /mm Compressive strength /MPa Dispersion ratio /% C1 20 1.157 4.15 C2 15 1.422 3.47 表 3 不同纤维取向曲面蜂窝的压缩强度

Table 3. Compressive strength of honeycomb with different fiber orientation curved surfaces

Specification number Fiber orientation Compressive strength /MPa Dispersion ratio /% C1 0°/90° 1.157 4.15 C3 30°/−60° 1.476 7.79 C4 45°/−45° 1.366 6.81 表 4 不同曲率半径曲面蜂窝的压缩强度

Table 4. Compressive strength of curved honeycomb with different curvature radius

Specification number Radius of curvature /mm Compressive strength /MPa Dispersion ratio /% C1 180 1.157 4.15 C5 150 1.237 7.11 C6 120 1.322 1.29 -

[1] Li F, Ruan P, Li T, et al. Application of car-bon-carbon composite for loading-carrying cylinder in lunar optical telescope[C]. SPIE-The International Society for Optical Engi-neering, Beijing, China, May 24, 2011. [2] Krumweide D E, Wonacott G D, Woida P M, et al. Carbon-carbon mirrors for exoatmospheric and space applications[C]//Optical Materials and Structures Technologies III. International Society for Optics and Photonics, 2007, 6666: 66660H. [3] Yao S, Xiao X, Xu P, et al. The impact performance of honeycomb-filled structures under eccentric loading for subway vehicles[J]. Thin-Walled Structure, 2018, 123: 360-70. doi: 10.1016/j.tws.2017.10.031 [4] Wang J, Shi C, Yang N, et al. Strength, stiffness, and panel peeling strength of carbon fiber-reinforced composite sandwich structures with aluminum honeycomb cores for vehicle body[J]. Composite Structure, 2018, 184: 1189-96. doi: 10.1016/j.compstruct.2017.10.038 [5] Bailly B, Cornu J L, Capdepuy B, et al. High stability carbon/carbon telescope structure[C]//Proc. of SPIE Vol. 2018, 10570: 105701T-1. [6] Bailly B, Cornu J, Capdepuy B, et al. Dimensionally stable structures. Spacecraft Structures[J]. Materials and Mechanical Engineering, 1996, 386: 361. [7] Panin, Fabio, Martine Lutz-Nivet, et al. Development of carbon-carbon sandwich panels[J]. EUROPEAN SPACE AGENCY-PUBLICATIONS-ESA SP, 2003, (540): 81-86. [8] Lutz M, Cornillon L, Vitupier Y, et al. Evaluation of ultrastable carbon/carbon sandwich structures joined with ceramic cement[C]//61st International Astronautical Congress, Prague, CZ. 2010: 1-4. [9] M. Salvo, V. Casalegno, Y. Vitupier, et al. Study of joining of carbon/carbon composites for ultra stable structures[J]. Journal of the European Ceramic Society 2010, (30): 1751-1759. [10] 刘宇峰, 张中伟, 许正辉, 等. 空间高稳定碳/碳蜂窝夹层结构制备及性能[J]. 宇航学报, 2020, 41(8): 1067-1075.Liu Yufeng, Zhang Zhongwei, Xu Zhenghui, et al. Preparation and performance of highly stable carbon/carbon honeycomb sandwich structures in space[J]. Journal of Astronautics, 2020, 41(8): 1067-1075(in Chinese). [11] 杨玉平, 张中伟, 李玮洁, 等. 碳/碳蜂窝制备工艺及压缩与剪切行为[J]. 复合材料学报, 2023, 40(12): 6639-6648.Yang Yuping, Zhang Zhongwei, Li Weijie, et al. Preparation process and compression and shear behavior of carbon/carbon honeycomb [J/OL][J]. Acta Materiae Compositae Sinica, 2023, 40(12): 6639-6648. [12] Guo L, Wang H, Li W, et al. Multi-scale damage modeling and out-of-plane shear behavior of carbon/carbon honeycomb structure[J]. Thin-Walled Structures, 2023, 192: 111103. doi: 10.1016/j.tws.2023.111103 [13] Guo L, Wang H, Yang Y, et al. A multi-scale damage model and mechanical behavior for novel light-weight C/C honeycomb sandwich structure[J]. Journal of Materials Research and Technology, 2023, (25): 2097-2111. [14] Shi Y, Dileep P, Heidenreich B, et al. Determination and modeling of bending properties for continuous fiber reinforced C/C-SiC sandwich structure with grid core[J]. Composite Structures, 2018, 204: 198-206. doi: 10.1016/j.compstruct.2018.07.086 [15] Feng Yixiong, Qiu Hao, Gao Yicong, et al. Creative design for sandwich structures: A review[J]. International Journal of Advanced Robotic Systems 2020(17.3): 1729881420921327. [16] Li Wanxin, Sun Fangfang, Wang Peng, et al. A novel carbon fiber reinforced lattice truss sandwich cylinder: Fabrication and experiments[J]. Composites Part A:Applied Science and Manufacturing, 2016, (81): 313-322. [17] Li Z, Gao Y, Xue P, et al. Fabrication and failure mechanisms of all-composite honeycomb sandwich cylinder under the axial compression[J]. Composites Part A:Applied Science and Manufacturing, 2022, 161: 107075. doi: 10.1016/j.compositesa.2022.107075 [18] Mark K. Pryor, Hygrothermal stability of laminated CFRP composite mirrors, Proc. SPIE 4013, UV, Optical, and IR Space Telescopes and Instruments: 655-662. [19] 熊健, 李志彬, 韦兴宇, 等. 一种复合材料曲面蜂窝的制备方法[P]. 黑龙江省: CN114055825A, 2022-02-18.Xiong Jian, Li Zhibin, Wei Xingyu, et al. A preparation method for composite material curved honeycomb [P] Heilongjiang Province: CN114055825A, 2022-02-18 (in Chinese). [20] Saito K, Pellegrino S, Nojima T. Manufacture of arbitrary cross-section composite honeycomb cores based on origami techniques[J]. Journal of Mechanical Design, 2014, 136(5): 051011. doi: 10.1115/1.4026824 [21] Marinucci G, Taniguchi C. Development of Non-Plane Honeycomb Sandwich Composite for Structural Use[J]. Moving Forward With 50 Years of Leadership in Advanced Materials, 1994, 39: 457-468. [22] 郑德利. 蜂窝材料大型不规则曲面数字化加工技术[D]. 大连: 大连理工大学, 2009.Zheng Deli. Digital Processing Technology for Large Irregular Curved Surface of Honeycomb Materials [D]. Dalian: Dalian University of Technology, 2009 (in Chinese). [23] 刘禹峰. 蜂窝芯复杂曲面六轴超声切削刀具路径规划研究[D]. 大连: 大连交通大学, 2017.Liu Yufeng. Research on Tool Path Planning for Six Axis Ultrasonic Cutting of Honeycomb Core Complex Curved Surface [D]. Dalian: Dalian Jiaotong University, 2017 (in Chinese). [24] Wei X, Xiong J, Wang J, et al. New advances in fiber-reinforced composite honeycomb materials[J]. Science China Technological Sciences, 2020, 63(8): 1348-1370. doi: 10.1007/s11431-020-1650-9 [25] Du B, Chen L, Wu W, et al. A novel hierarchical thermoplastic composite honeycomb cylindrical structure: fabrication and axial compressive properties[J]. Composite Science and Technology, 2018, 164: 136-45. doi: 10.1016/j.compscitech.2018.05.021 [26] Liu H, Chen L, Cao J, et al. Axial compression deformability and energy absorption of hierarchical thermoplastic composite honeycomb graded structures[J]. Composite Structure, 2020, 254: 112851. doi: 10.1016/j.compstruct.2020.112851 [27] Guo Y, Chen L, Zhu C, et al. Fabrication and axial compression test of thermoplastic composite cylindrical sandwich structures with hierarchical honeycomb core[J]. Composite Structure, 2021, 275: 114453. doi: 10.1016/j.compstruct.2021.114453 [28] Liu H, Chen L, Zhou Y, et al. Repeated energy absorption and multiple compressive responses of thermoplastic composite hierarchical cylindrical structures[J]. Composite Science and Technology, 2022, 221: 109306. doi: 10.1016/j.compscitech.2022.109306 -

点击查看大图

点击查看大图

计量

- 文章访问数: 53

- HTML全文浏览量: 27

- 被引次数: 0

下载:

下载: