Experimental and simulational study on tensile mechanical property of carbon nanotubes/epoxy resin composite

-

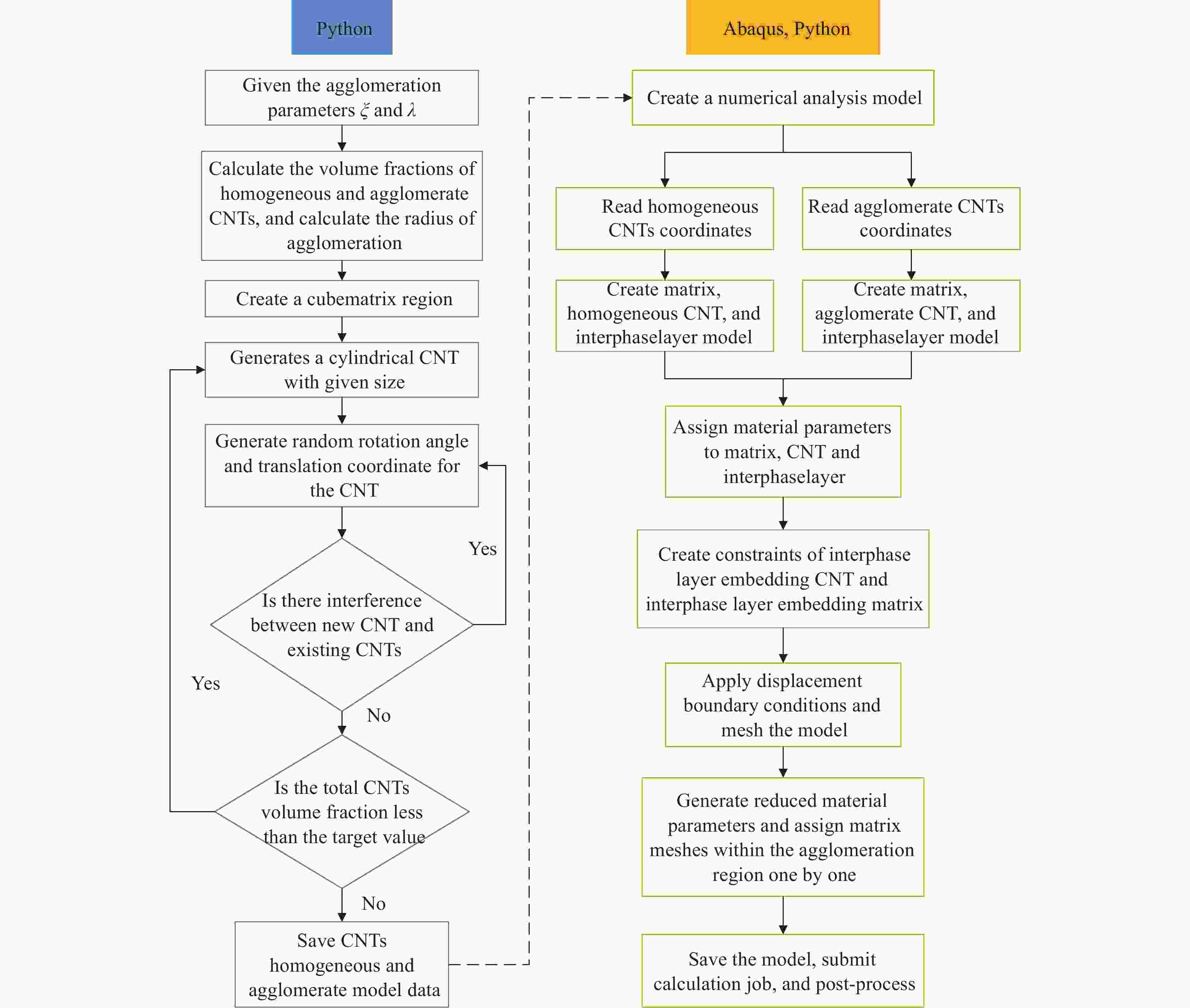

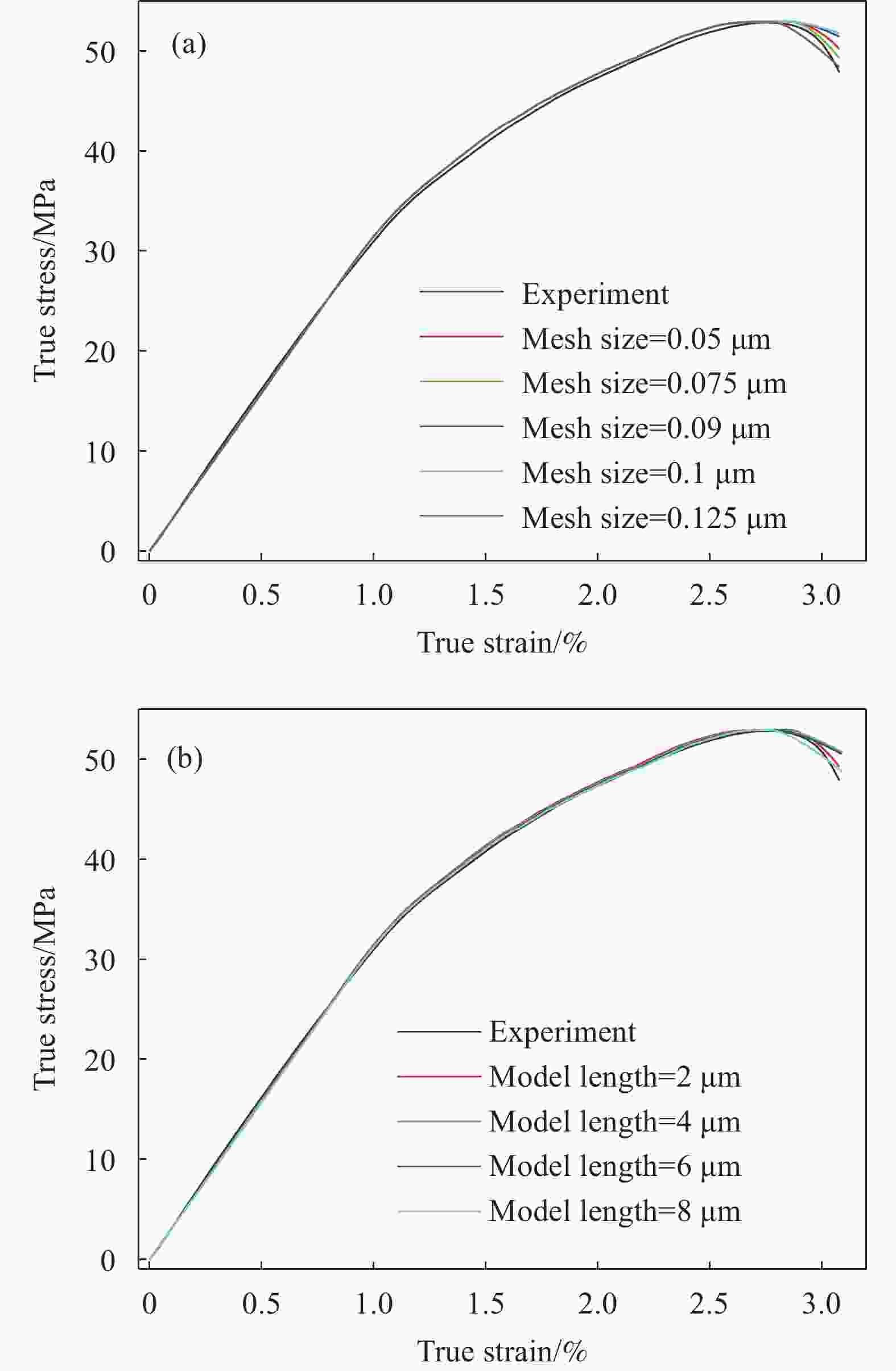

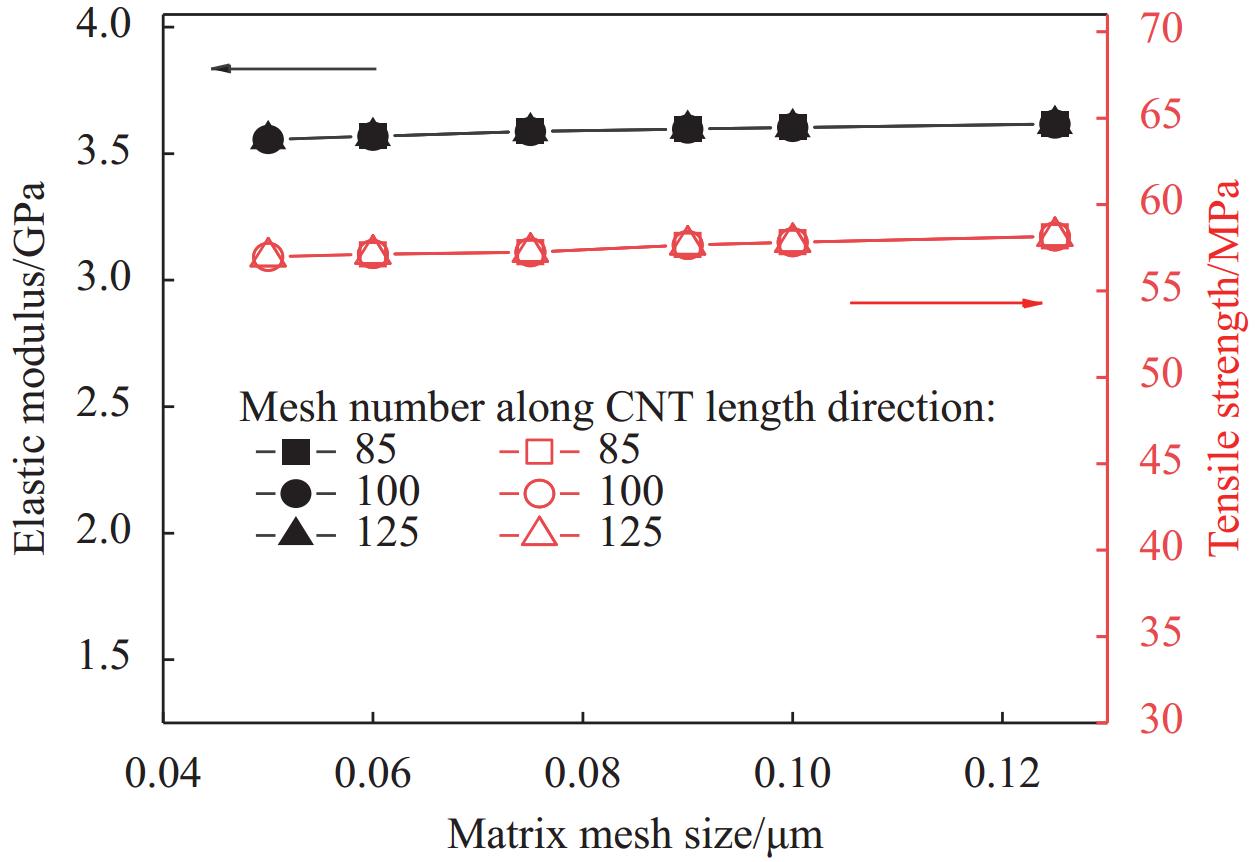

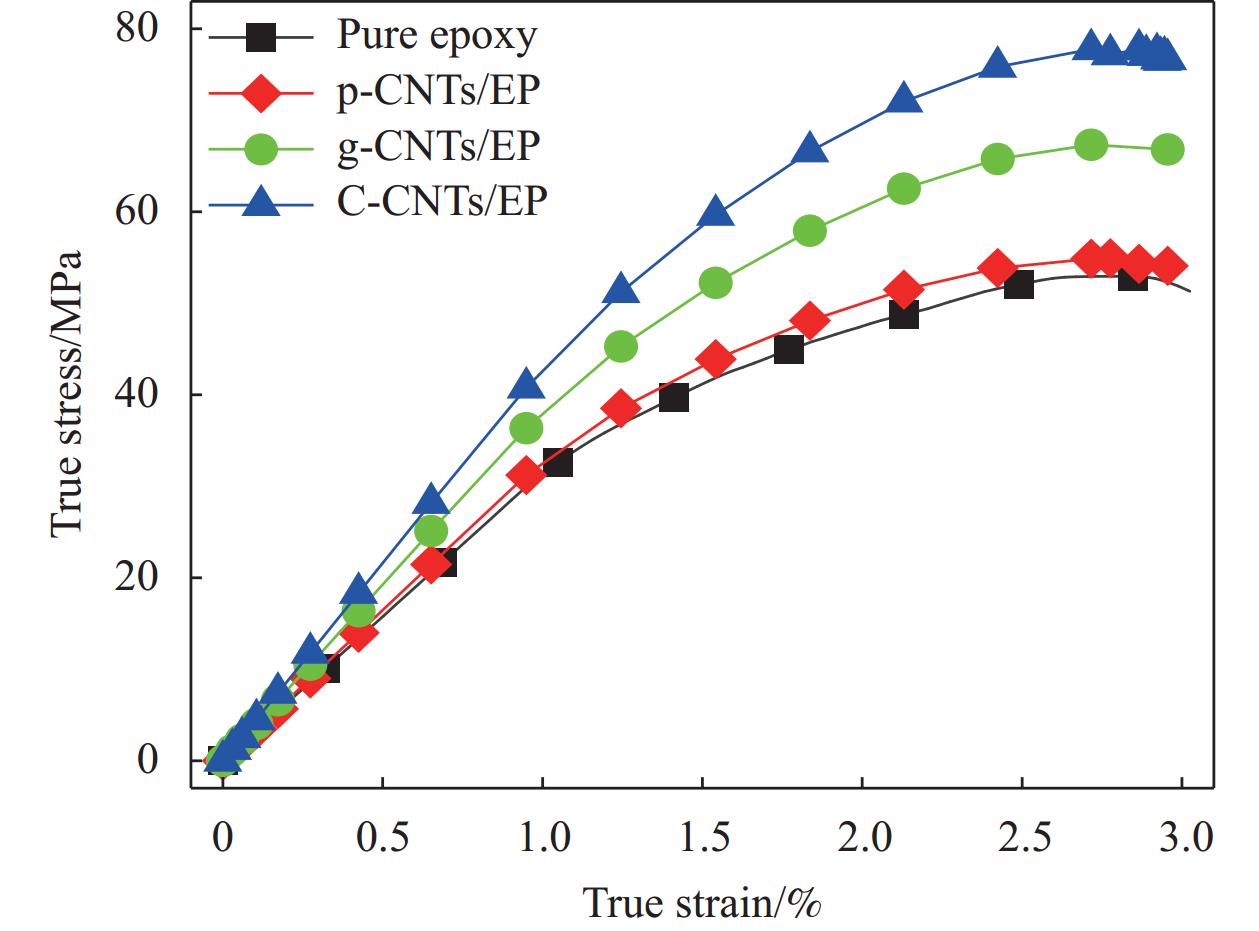

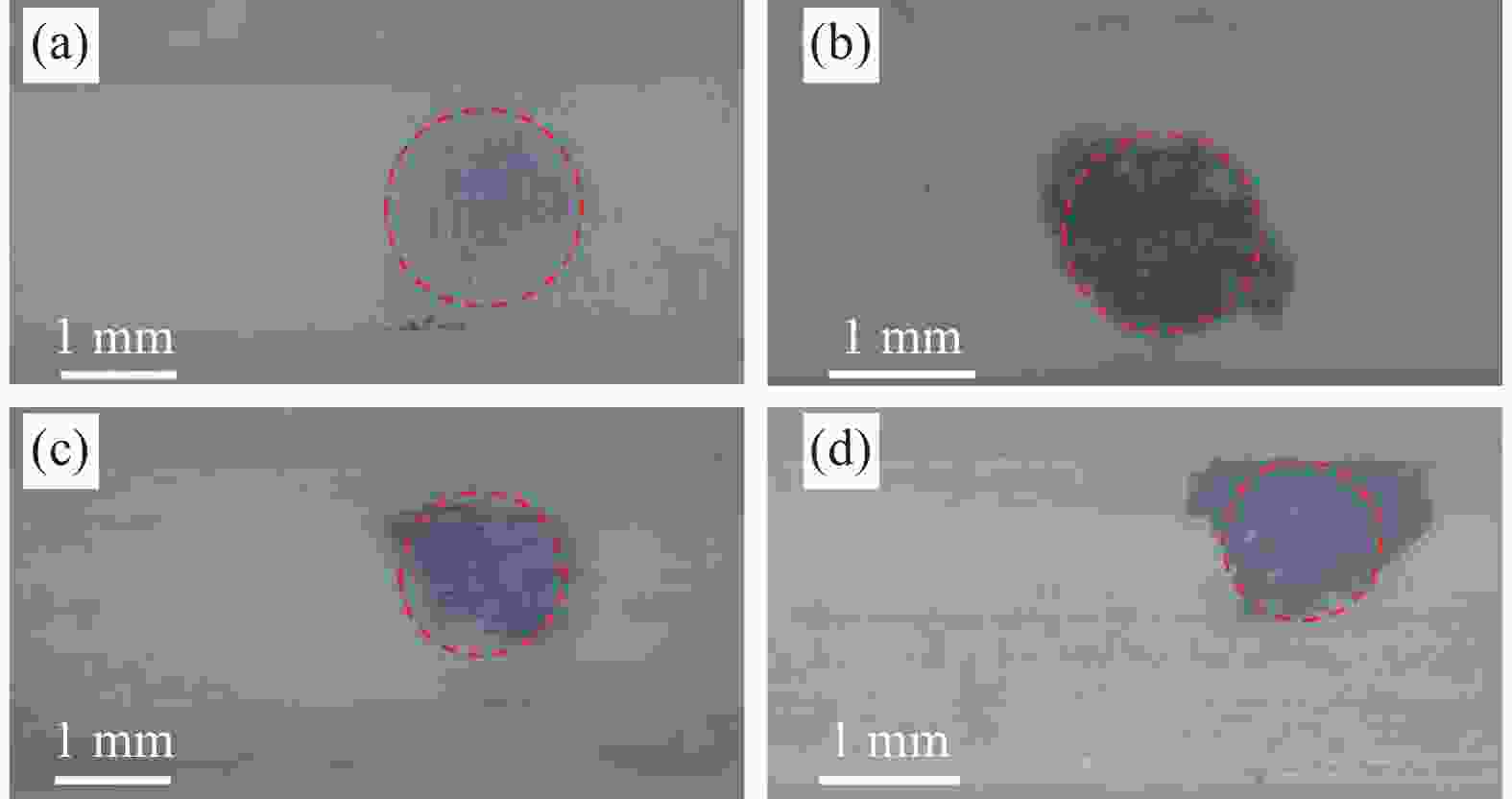

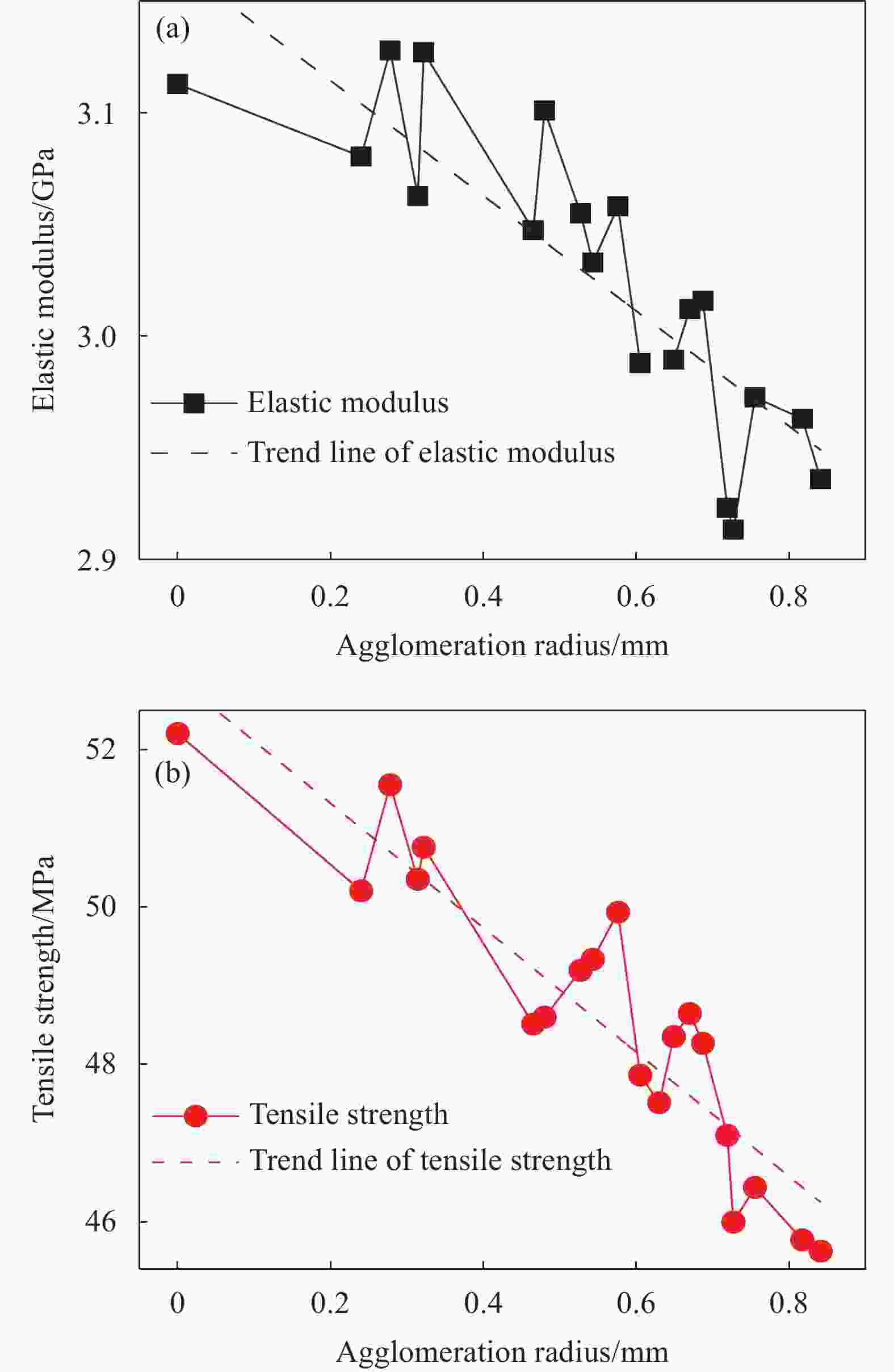

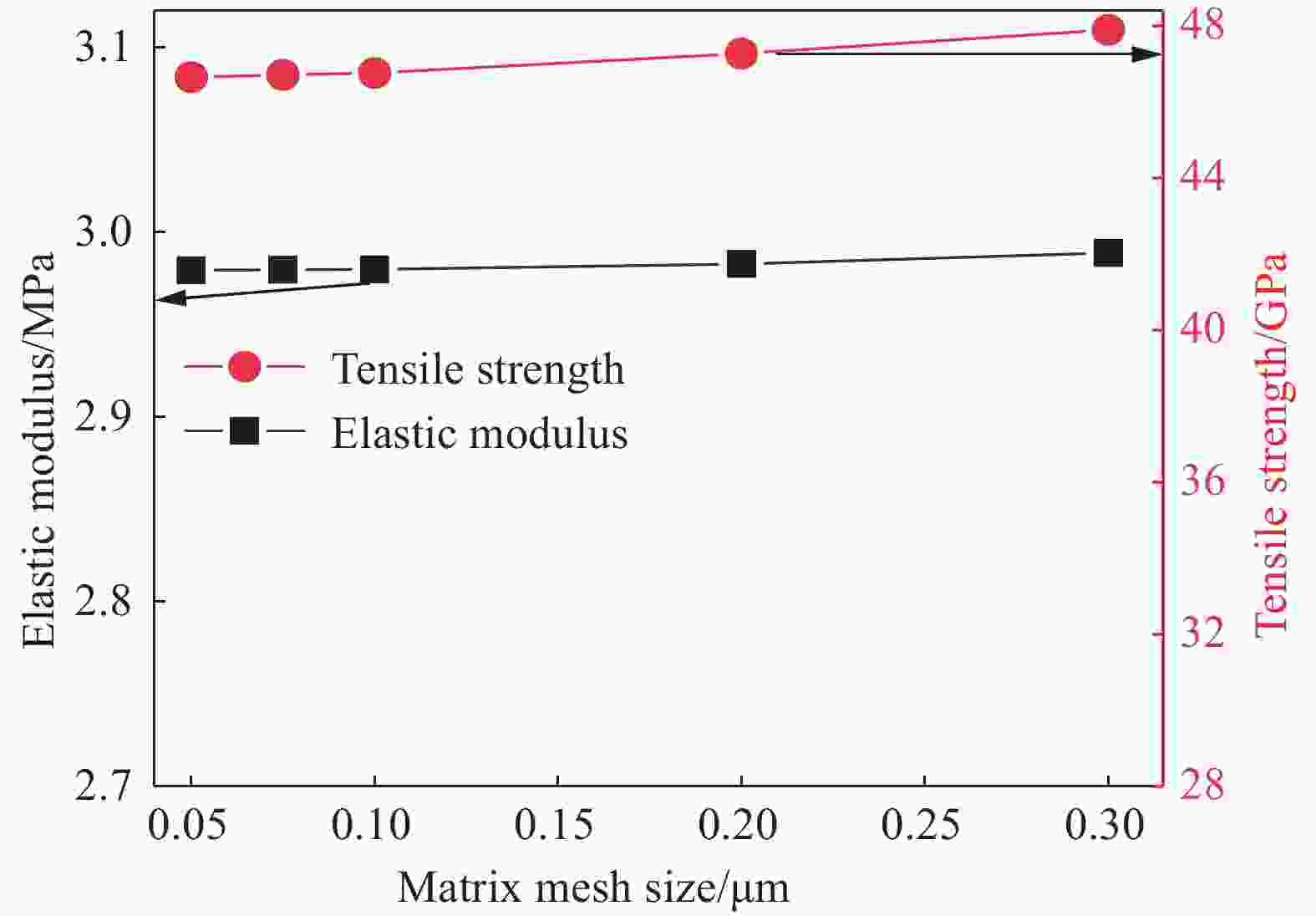

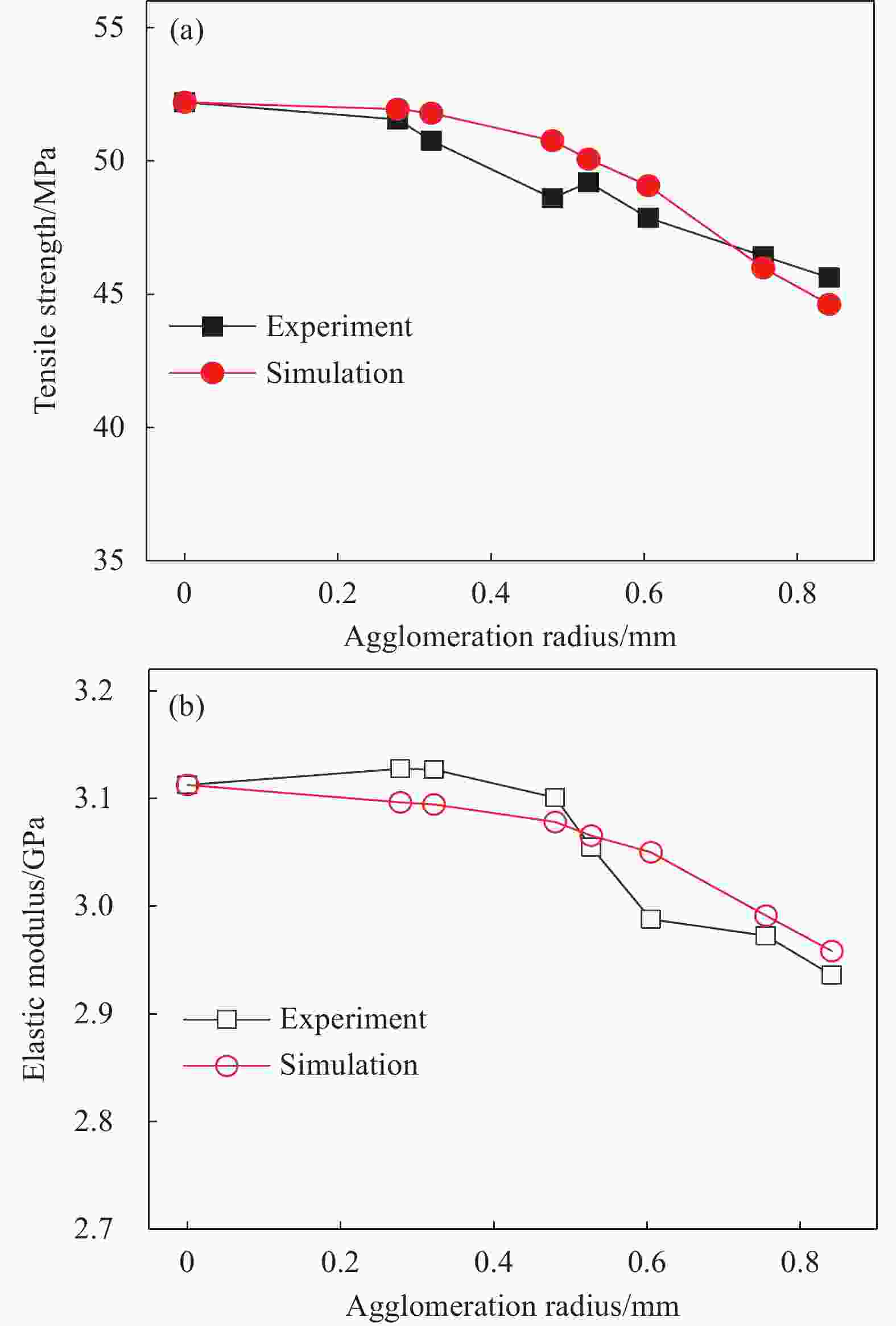

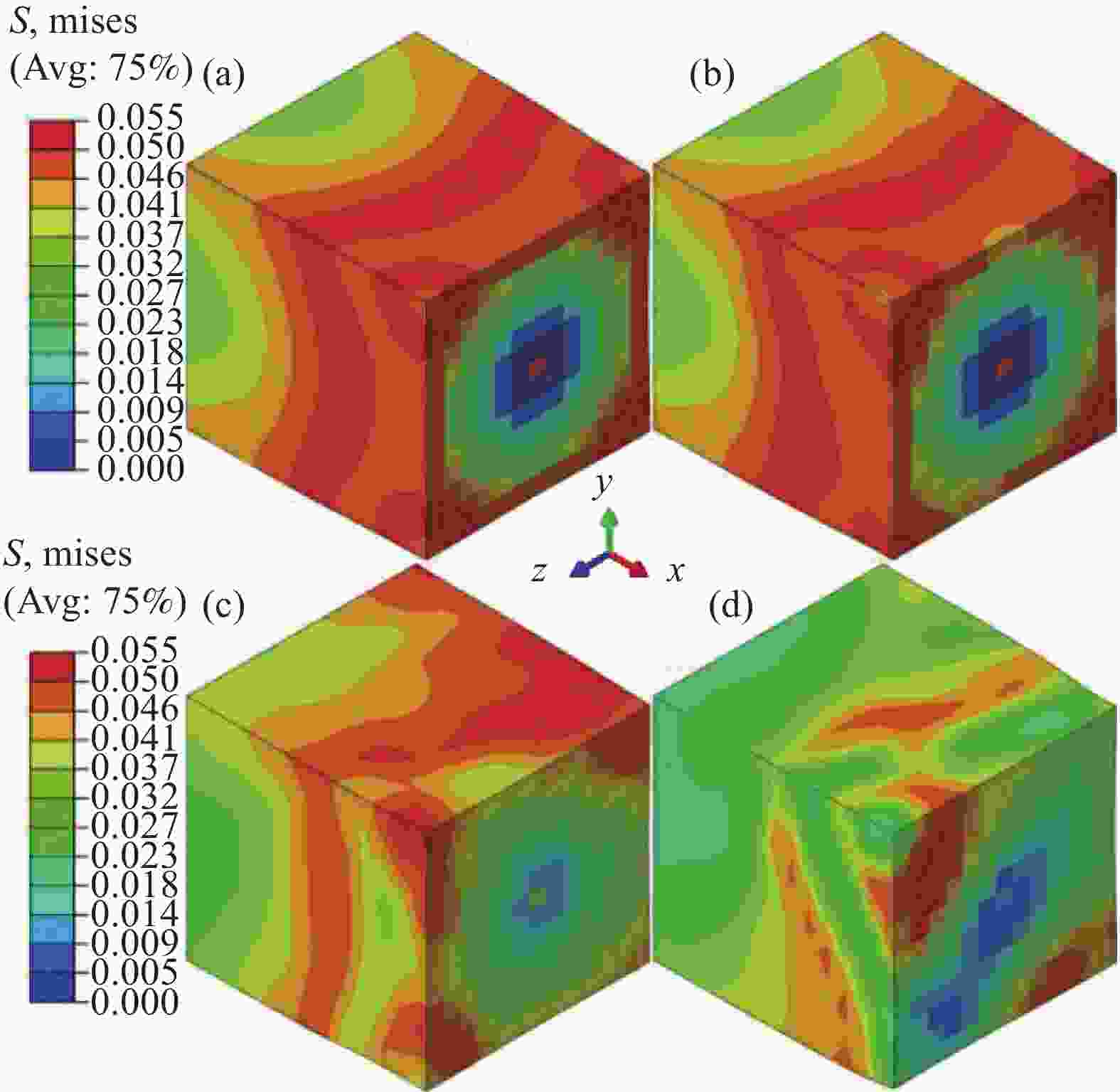

摘要: 由于具有优异的力学、电学和热学性能,碳纳米管(Carbon nanotubes,CNTs)被广泛用于高性能复合材料制备研究。然而,CNTs具有高长径比、高比表面能和强范德华力,在制备过程中易团聚,在高填料浓度下导致复合材料力学性能的降低。为了准确表征碳纳米管增强环氧树脂纳米复合材料(CNTs enhanced epoxy nanocomposite,CNTs/EP)的拉伸力学性能,通过实验和有限元模拟分析,表征了不同类型CNTs增强的CNTs/EP的拉伸力学性能。在考虑团聚对环氧树脂材料参数影响的情况,提出了折减团聚区域树脂材料参数的方法,改进了团聚分布数值分析方法。结果表明,在0.5wt%的低含量下,均匀分布数值分析方法可以准确预测CNTs/EP的拉伸强度和弹性模量;团聚分析方法准确预测了CNTs/EP在1.5wt%高浓度下的拉伸力学性能,弹性模量和拉伸强度的预测误差不超过5%。Abstract: Due to the excellent mechanical, electrical and thermal properties, carbon nanotubes (CNTs) are widely used in the research and preparation of high-performance composite. However, with the high aspect ratio, high specific surface energy and strong van der Waals force, CNTs intend to form agglomeration during the preparation process, causing a decrease in the mechanical property of the composite material at high concentration. In order to accurately characterize the tensile mechanical property of CNTs enhanced epoxy nanocomposite (CNTs/EP) nanocomposite, the tensile mechanical properties of different kinds of CNTs/EP were characterized by experiment and finite element analysis. Considering the influence of agglomeration on the material parameter of epoxy, a method for reducing the materials parameter of epoxy in the agglomeration region was proposed to improve the numerical analysis method of agglomeration distribution model. The results show that the uniform distribution numerical analysis method can accurately predict the tensile strength and elastic modulus of CNTs/EP at a low content of 0.5wt%. The agglomeration analysis method accurately predicts the tensile mechanical property, the error of elastic modulus and tensile strength of CNTs/EP are no more than 5% at a high concentration of 1.5wt%.

-

Key words:

- carbon nanotubes /

- epoxy resin /

- dispersion property /

- mechanical property /

- finite element method

-

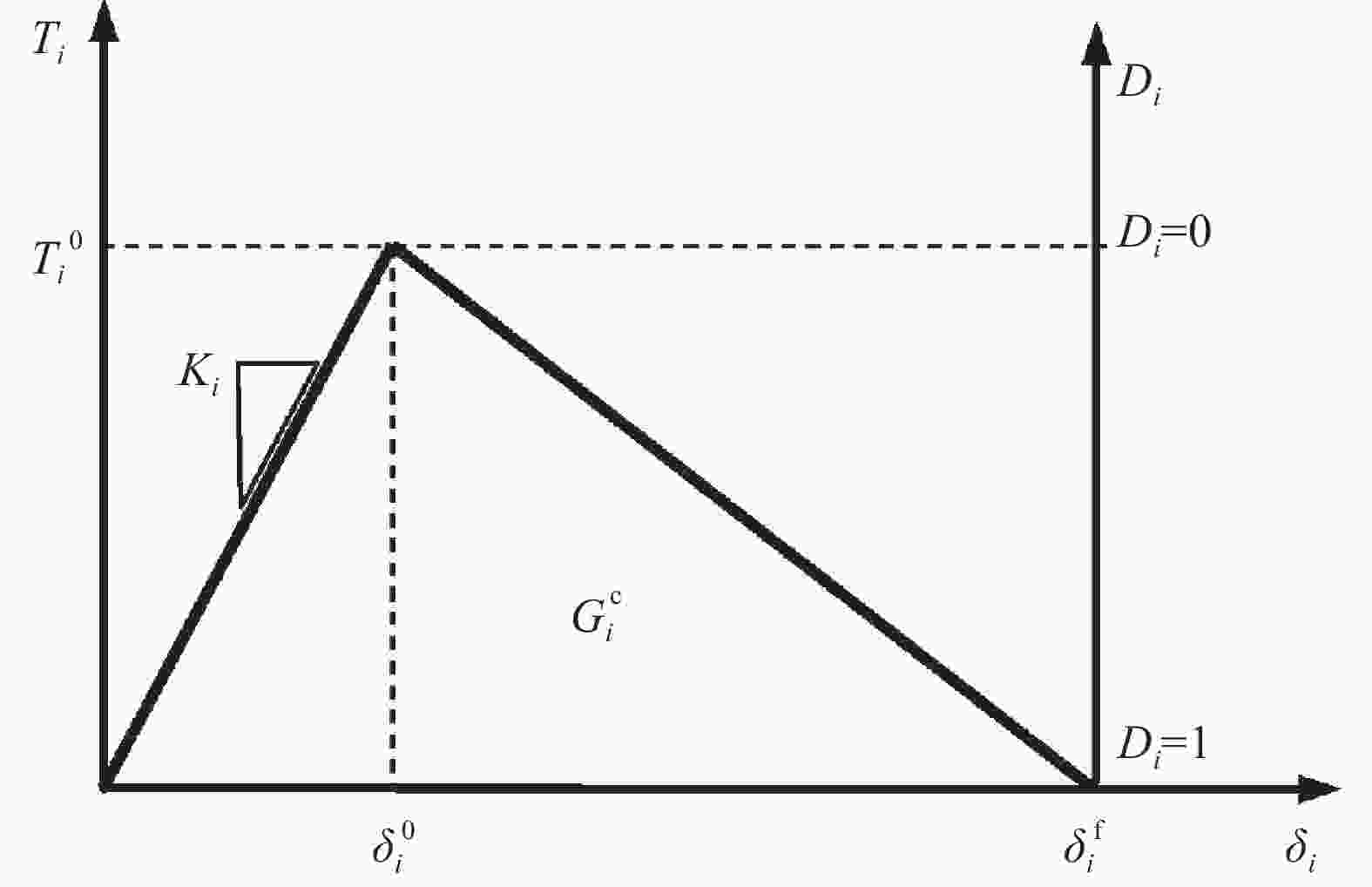

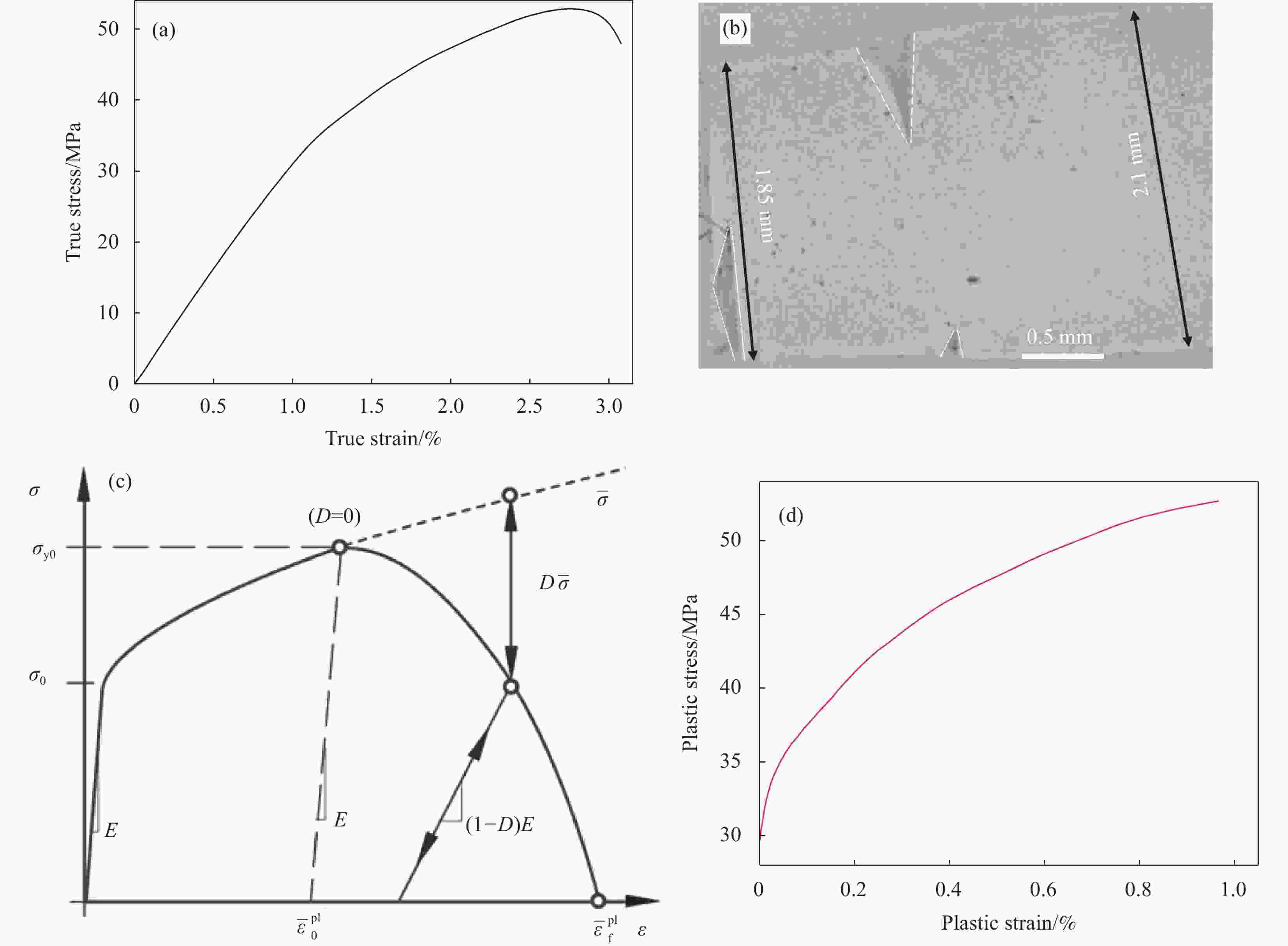

图 3 EP轴拉伸性能:(a)应力-应变曲线;(b)断裂图;(c)延性材料;(d)塑性参数

Figure 3. Uniaxial tensile property of pure EP: (a) Stress-strain curve; (b) Fracture image; (c) Ductile material; (c) Plasticity parameter

$ \bar \varepsilon _0^{{\text{pl}}} $—Equivalent plastic strain at the onset of damage; $ \bar \varepsilon _0^{{\text{pl}}} $—Equivalent plastic strain at failure; $ {\sigma _0} $—Elastic limit for tension; $ {\sigma _{{\text{y}}0}} $—Yield stress; $ E $—Elastic modulus; $ D $—Damage variable; $ \bar \sigma $—Stress without damage

Material Modulus

/GPaPoisson's ratio Strength/GPa EP 3.112 0.3 0.0524 CNT 1000 0.2 20 表 2 纳米材料界面参数

Table 2. Interface parameters of nanomaterials

Nanomaterial Stiffness/

(GPa·μm−1)Interfacial strength/GPa Fracture energy/

(10−4 GPa·μm)C-CNTs 3000 0.3 7.5 g-CNTs 1000 0.1 2.5 p-CNTs 360 0.036 9.0 Notes: C-CNTs—Carboxylated carbon nanotubes; g-CNTs—Gelatin functionalized CNTs; p-CNTs—Pristine CNT -

[1] LIU S, CHEVALI V S, XU Z, et al. A review of extending performance of epoxy resins using carbon nanomaterials[J]. Composites Part B: Engineering, 2018, 136: 197-214. doi: 10.1016/j.compositesb.2017.08.020 [2] WATTERS A, CUADRA J, KONTSOS A, et al. Processing-structure–property relationships of SWNT–epoxy composites prepared using ionic liquids[J]. Composites Part A: Applied Science and Manufacturing, 2015, 73: 269-276. doi: 10.1016/j.compositesa.2015.03.019 [3] MAGHSOUDLOU M A, BARBAZ ISFAHANI R, SABER-SAMANDARI S, et al. Effect of interphase, curvature and agglomeration of SWCNTs on mechanical properties of polymer-based nanocomposites: Experimental and numerical investigations[J]. Composites Part B: Engineering, 2019, 175: 107119. doi: 10.1016/j.compositesb.2019.107119 [4] YAZDANPARAST R, RAFIEE R. Investigating the influence of pull-out speed on the interfacial properties and the pull-out behavior of CNT/polymer nanocomposites[J]. Composite Structures, 2023, 316: 117049. doi: 10.1016/j.compstruct.2023.117049 [5] 廖向娜, 贺雍律, 张鉴炜, 等. CNTs-纤维增强树脂基复合材料纳米-介观尺度数值模拟研究进展[J]. 材料工程, 2020, 48(12): 1-11. doi: 10.11868/j.issn.1001-4381.2020.000154LIAO Xiangna, HE Yonglv, ZHANG Jianwei, et al. Research pro-gress in nano-meso scale modelling of carbon nanotube reinforced FRP composites[J]. Journal of Materials Engineering, 2020, 48(12): 1-11(in Chinese). doi: 10.11868/j.issn.1001-4381.2020.000154 [6] 庄茁. 基于abaqus的有限元分析和应用[M], 北京: 清华大学出版社, 2009.ZHUANG Zhuo. Finite element analysis and application based on ABAQUS[M]. Beijing: Tsinghua University Press, 2009(in Chinese). [7] ROMANOV V S, LOMOV S V, VERPOEST I, et al. Modelling evidence of stress concentration mitigation at the micro-scale in polymer composites by the addition of carbon nanotubes[J]. Carbon, 2015, 82: 184-194. doi: 10.1016/j.carbon.2014.10.061 [8] LIU Q, LOMOV S V, GORBATIKH L. The interplay between multiple toughening mechanisms in nanocomposites with spatially distributed and oriented carbon nanotubes as revealed by dual-scale simulations[J]. Carbon, 2019, 142: 141-149. doi: 10.1016/j.carbon.2018.10.005 [9] ZENG L, TAO W, ZHAO J, et al. Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement[J]. Nanotechnology Reviews, 2022, 11(1): 625-636. doi: 10.1515/ntrev-2022-0040 [10] American Society for Testing and Materials. Standard Test Method for Tensile Properties of Plastics: ASTM-D638—14[S], Philadelphia: ASTM international, 2014. [11] YOUSEFI E, SHEIDAEI A, MAHDAVI M, et al. Effect of nanofiller geometry on the energy absorption capability of coiled carbon nanotube composite material[J]. Composites Science and Technology, 2017, 153: 222-231. doi: 10.1016/j.compscitech.2017.10.025 [12] RAFIEE R, SAHRAEI M. Characterizing delamination toughness of laminated composites containing carbon nanotubes: Experimental study and stochastic multi-scale modeling[J]. Composites Science and Technology, 2021, 201: 108487. doi: 10.1016/j.compscitech.2020.108487 [13] RAFIEE R, GHORBANHOSSEINI A. Investigating interaction between CNT and polymer using cohesive zone model[J]. Polymer Composites, 2018, 39(11): 3903-3911. doi: 10.1002/pc.24428 [14] ARAIN M F, WANG M, CHEN J, et al. Experimental and numerical study on tensile behavior of surface modified PVA fiber reinforced strain-hardening cementitious composites (PVA-SHCC)[J]. Construction and Building Materials, 2019, 217: 403-415. doi: 10.1016/j.conbuildmat.2019.05.083 [15] SATO M, KOYANAGI J, LU X, et al. Temperature dependence of interfacial strength of carbon-fiber-reinforced temperature-resistant polymer composites[J]. Composite Structures, 2018, 202: 283-289. doi: 10.1016/j.compstruct.2018.01.079 [16] LI D, YANG Q S, LIU X, et al. Experimental and cohesive finite element investigation of interfacial behavior of CNT fiber-reinforced composites[J]. Composites Part A: Applied Science and Manufacturing, 2017, 101: 318-325. doi: 10.1016/j.compositesa.2017.06.033 [17] LIU Q, GORBATIKH L, LOMOV S V. A combined use of embedded and cohesive elements to model damage development in fibrous composites[J]. Composite Structures, 2019, 223: 110921. doi: 10.1016/j.compstruct.2019.110921 [18] YANG L, YAN Y, LIU Y, et al. Microscopic failure mechanisms of fiber-reinforced polymer composites under transverse tension and compression[J]. Composites Science and Technology, 2012, 72(15): 1818-1825. doi: 10.1016/j.compscitech.2012.08.001 [19] WAGNER H D, LOURIE O, FELDMAN Y, et al. Stress-induced fragmentation of multiwall carbon nanotubes in a polymer matrix[J]. Applied Physics Letters, 1998, 72(2): 188-190. doi: 10.1063/1.120680 [20] PAPANIKOS P, NIKOLOPOULOS D D, TSERPES K I. Equivalent beams for carbon nanotubes[J]. Computational Materials Science, 2008, 43(2): 345-352. doi: 10.1016/j.commatsci.2007.12.010 [21] PENG J, WU J, HWANG K C, et al. Can a single-wall carbon nanotube be modeled as a thin shell?[J]. Journal of the Mechanics and Physics of Solids, 2008, 56(6): 2213-2224. doi: 10.1016/j.jmps.2008.01.004 [22] ZACCARDI F, SANTONICOLA M G, LAURENZI S. Role of interface bonding on the elastic properties of epoxy-based nanocomposites with carbon nanotubes using multiscale analysis[J]. Composite Structures, 2021, 255: 113050. doi: 10.1016/j.compstruct.2020.113050 [23] ARORA G, PATHAK H. Modeling of transversely isotropic properties of CNT-polymer composites using meso-scale FEM approach[J]. Composites Part B:Engineering, 2019, 166: 588-597. doi: 10.1016/j.compositesb.2019.02.061 [24] RAFIEE R, ZEHTABZADEH H. Predicting the strength of carbon nanotube reinforced polymers using stochastic bottom-up modeling[J]. Applied Physics A, 2020, 126(8): 595. doi: 10.1007/s00339-020-03784-z [25] JIAN W, LAU D. Understanding the effect of functionalization in CNT-epoxy nanocomposite from molecular level[J]. Composites Science and Technology, 2020, 191: 108076. doi: 10.1016/j.compscitech.2020.108076 [26] GANESAN Y, PENG C, LU Y, et al. Interface Toughness of Carbon Nanotube Reinforced Epoxy Composites[J]. ACS Applied Materials & Interfaces, 2011, 3(2): 129-134. [27] BARBER A H, COHEN S R, WAGNER H D. Measurement of carbon nanotube–polymer interfacial strength[J]. Applied Physics Letters, 2003, 82(23): 4140-4142. doi: 10.1063/1.1579568 [28] LIU Q, LOMOV S V, GORBATIKH L. When does nanotube grafting on fibers benefit the strength and toughness of composites?[J]. Composites Science and Technology, 2020, 188: 107989. doi: 10.1016/j.compscitech.2020.107989 [29] COOPER C A, COHEN S R, ET AL, WAGNER H D. Detachment of nanotubes from a polymer matrix[J]. Applied Physics Letters, 2002, 81(20): 3873-3875. doi: 10.1063/1.1521585 [30] ZAMAN I, KUAN H-C, DAI J, et al. From carbon nanotubes and silicate layers to graphene platelets for polymer nanocomposites[J]. Nanoscale, 2012, 4(15): 4578-4586. doi: 10.1039/c2nr30837a [31] WANG Q, SHI W, ZHU B, et al. An effective and green H2O2/H2O/O3 oxidation method for carbon nanotube to reinforce epoxy resin[J]. Journal of Materials Science & Technology, 2020, 40: 24-30. [32] KHARITONOV A P, KHARITONOV A P, TKACHEV A G, et al. Handbook of Composites from Renewable Materials [M]. Beverly: Scrivener Publishing LLC, 2017: 381-408. [33] MORI T, TANAKA K. Average stress in matrix and average elastic energy of materials with misfitting inclusions[J]. Acta Metallurgica, 1973, 21(5): 571-574. doi: 10.1016/0001-6160(73)90064-3 [34] KAMARIAN S, SALIM M, DIMITRI R, et al. Free vibration analysis of conical shells reinforced with agglomerated Carbon Nanotubes[J]. International Journal of Mechanical Sciences, 2016, 108-109: 157-165. doi: 10.1016/j.ijmecsci.2016.02.006 [35] MEHRABADI S J, SOBHANI ARAGH B. Stress analysis of functionally graded open cylindrical shell reinforced by agglomerated carbon nanotubes[J]. Thin-Walled Structures, 2014, 80: 130-141. doi: 10.1016/j.tws.2014.02.016 [36] 潘静, 复合材料细观力学模型及相关材料性能研究[D]. 燕山大学, 2019.PAN Jing. A study on Micromechanics model of composite materials and related properties of materials[D]. Yanshan University, 2019(in Chinese). [37] LIU Q, LU Z, HU Z, et al. Finite element analysis on tensile behaviour of 3D random fibrous materials: Model description and meso-level approach[J]. Materials Science and Engineering: A, 2013, 587: 36-45. doi: 10.1016/j.msea.2013.07.087 [38] YUAN Z, LU Z. Numerical analysis of elastic–plastic properties of polymer composite reinforced by wavy and random CNTs[J]. Computational Materials Science, 2014, 95: 610-619. doi: 10.1016/j.commatsci.2014.08.031 [39] LUO Y, ZHAO Y, CAI J, et al. Effect of amino-functionalization on the interfacial adhesion of multi-walled carbon nanotubes/epoxy nanocomposites[J]. Materials & Design, 2012, 33: 405-412. [40] HUANG X, LI R, ZENG L, et al. A multifunctional carbon nanotube reinforced nanocomposite modified via soy protein isolate: A study on dispersion, electrical and mechanical properties[J]. Carbon, 2020, 161: 350-358. doi: 10.1016/j.carbon.2020.01.069 [41] RAI A, SUBRAMANIAN N, CHATTOPADHYAY A. Investigation of damage mechanisms in CNT nanocomposites using multiscale analysis[J]. International Journal of Solids and Structures, 2017, 120: 115-124. doi: 10.1016/j.ijsolstr.2017.04.034 [42] ESBATI A H, IRANI S. Effect of functionalized process and CNTs aggregation on fracture mechanism and mechanical properties of polymer nanocomposite[J]. Mechanics of Materials, 2018, 118: 106-119. doi: 10.1016/j.mechmat.2018.01.001 -

下载:

下载: