Numerical simulation of progressive damage of single-lap CFRP/Al connected by blind rivet under interference condition

-

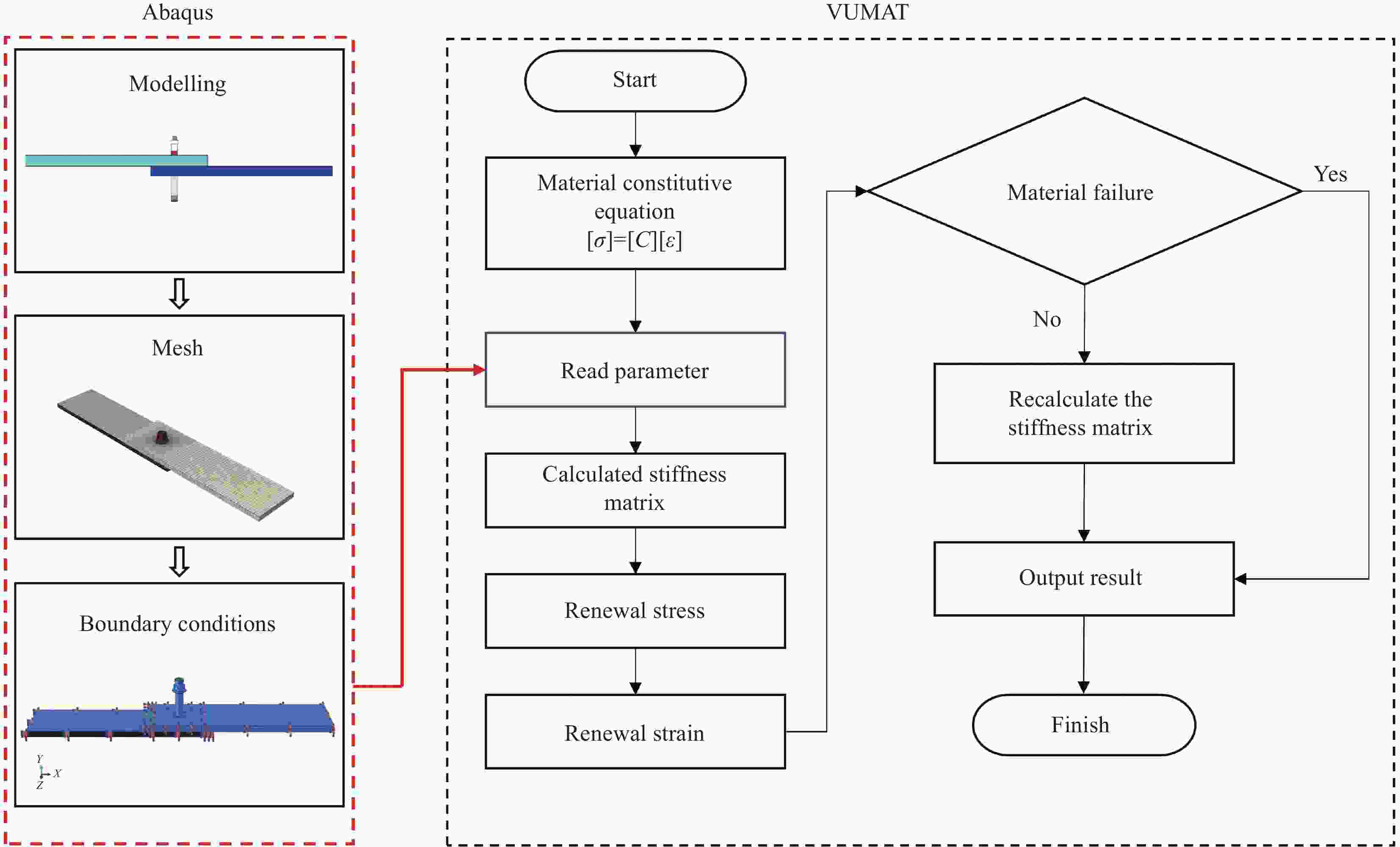

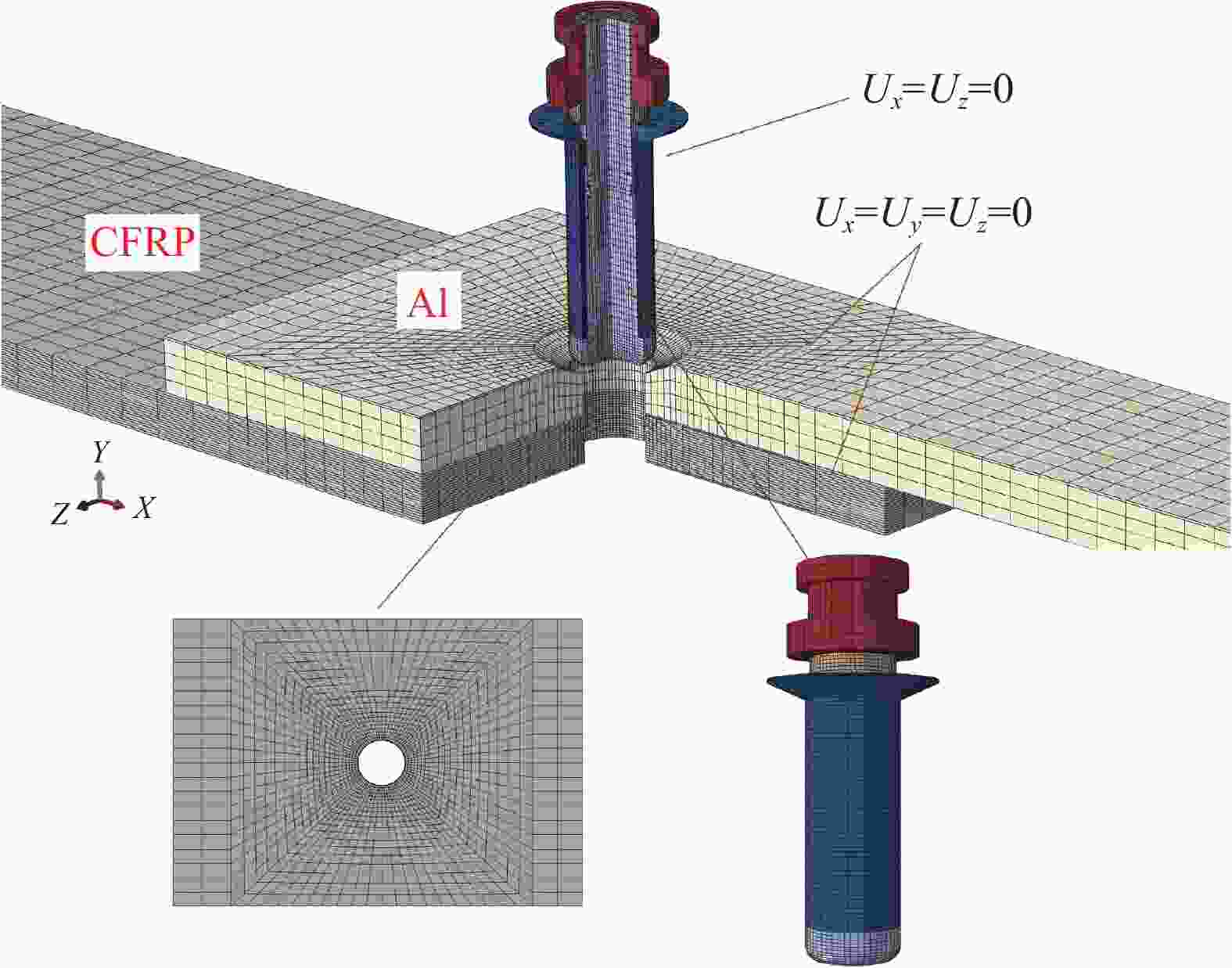

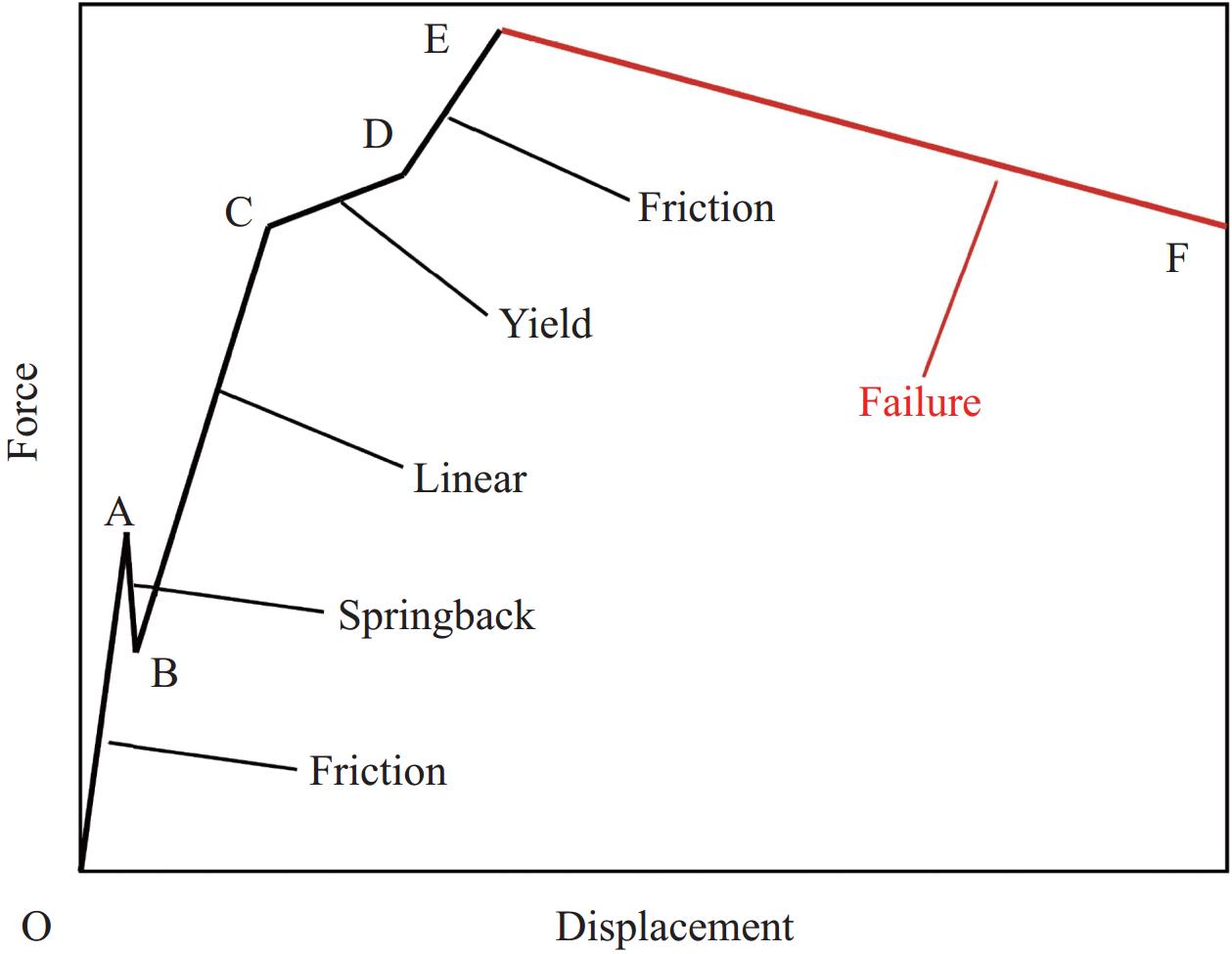

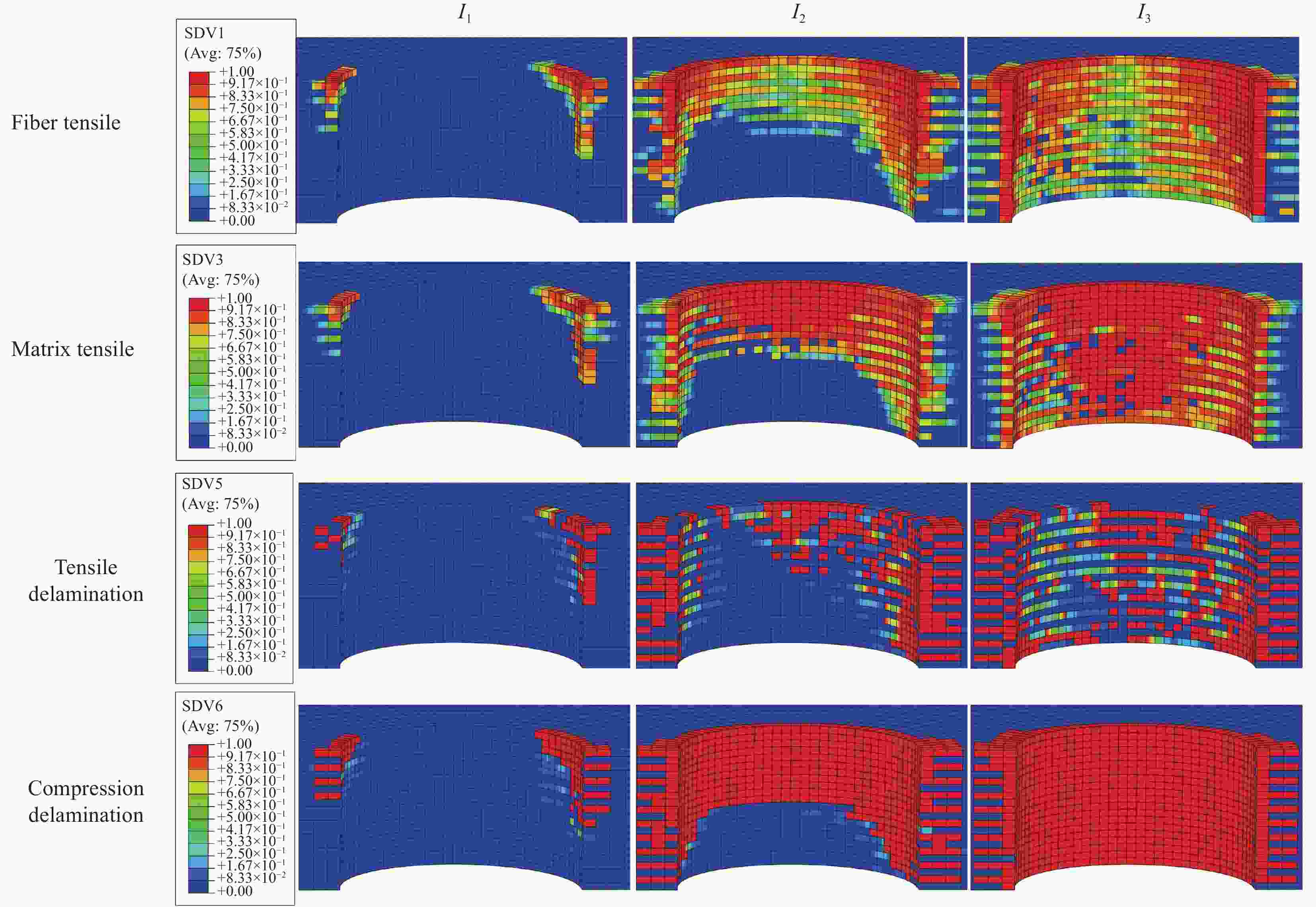

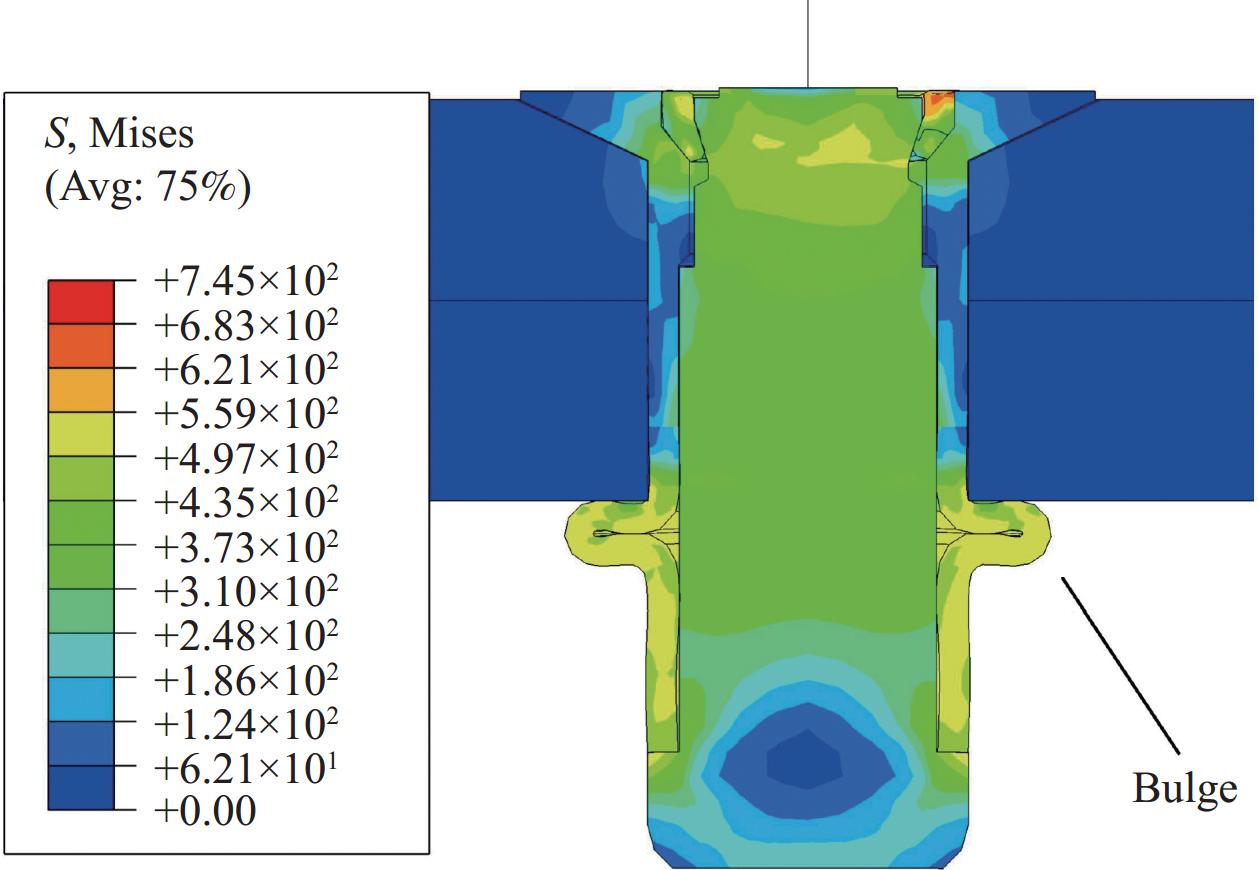

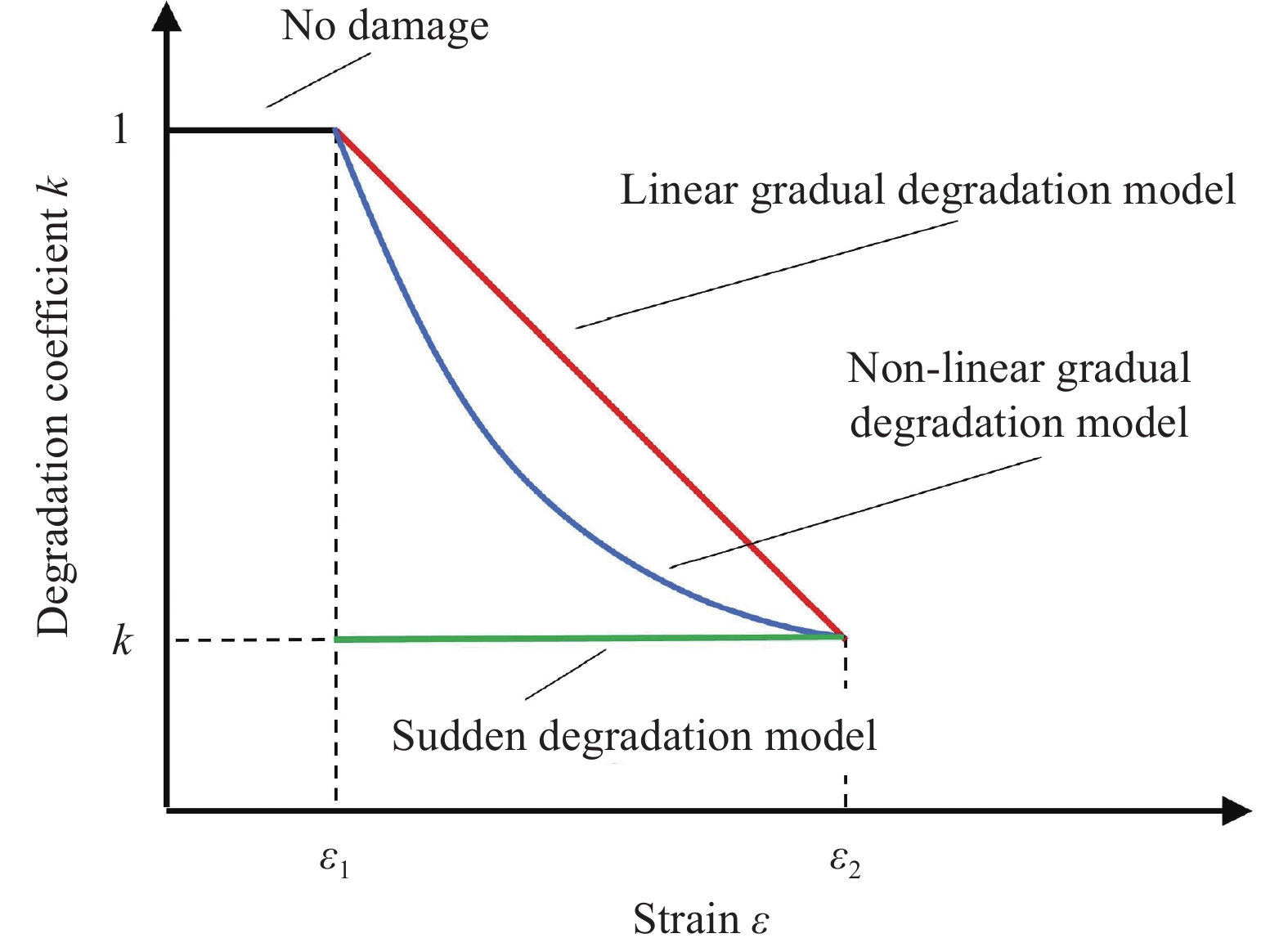

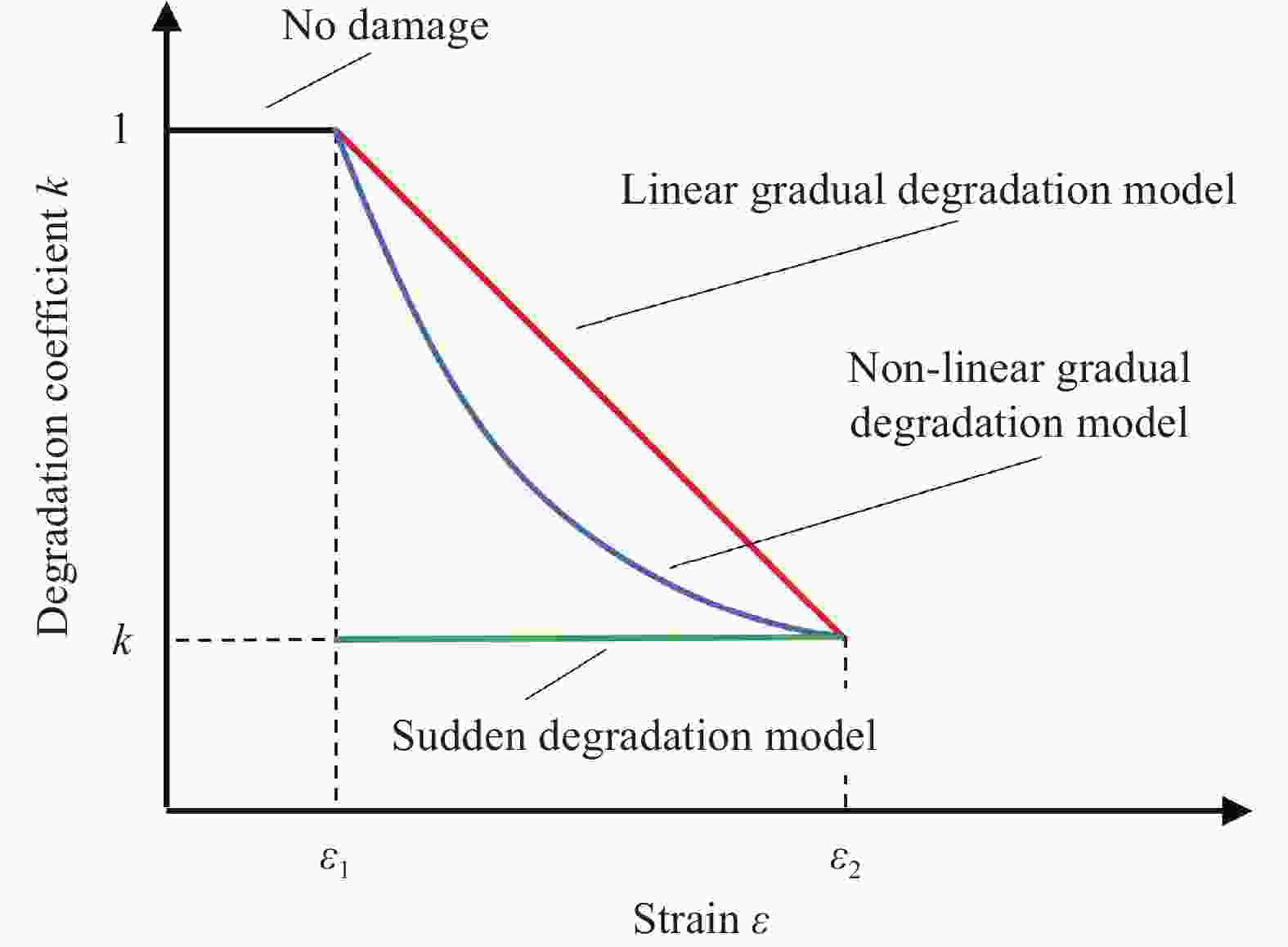

摘要: 干涉配合在改善抽芯铆钉连接复合材料的力学性能方面具有较强优势。然而,干涉配合下抽芯铆钉的安装往往会导致碳纤维增强树脂复合材料(CFRP)层压板的损坏,削弱铆接接头的力学性能。本文采用了完整的抽芯铆钉模型,基于连续损伤力学、扩展的三维破坏准则和应变率效应,通过有限元和Abaqus二次开发相结合的方法,研究了CFRP/Al单剪铆接中抽芯铆钉与连接孔的干涉量和铆钉的安装速度对复合材料损伤的影响。从模拟结果来看受安装速度的影响显著,安装阻力呈现出两个典型的阶段,分别由铝合金板、CFRP板与抽芯铆钉的摩擦产生造成。抽芯铆钉安装在干涉配合情况下,安装速度越大对于降低安装阻力十分有利。然而,过高的安装速度会导致孔壁的损伤增加,尤其在高干涉量下更为明显。抽芯铆钉铆接接头的失效模式以CFRP损伤为主,并受干涉尺寸的影响显著。Abstract: Interference fit has advantages in improving the mechanical performance of blind rivet in connections for composite materials. However, the installation of blind rivets under interference fit leads to the damage of carbon fiber reinforced plastic (CFRP) laminates, weakening the mechanical performance of the joints. In this paper, based on continuous damage mechanics, extended three-dimensional failure criteria and strain rate effect, a complete blind rivet model, which combining finite element method and secondary development of Abaqus was developed to study the effect of interference and installation speed on the damage of composite materials. From the simulation results, the installation resistance force exhibits two typical stages, which are generated by the friction between the aluminum alloy and the CFRP laminate with the blind rivet, respectively. Under interference fit conditions, a higher installation speed is highly advantageous in reducing installation resistance. However, excessive installation speed can lead to increased damage to the hole walls, which is especially noticeable in cases of high interference fit. The failure mode of the joint is mainly caused by CFRP damage and is significantly influenced by the interference size.

-

Key words:

- CFRP /

- blind rivet /

- progressive damage /

- finite element analysis /

- interference fit

-

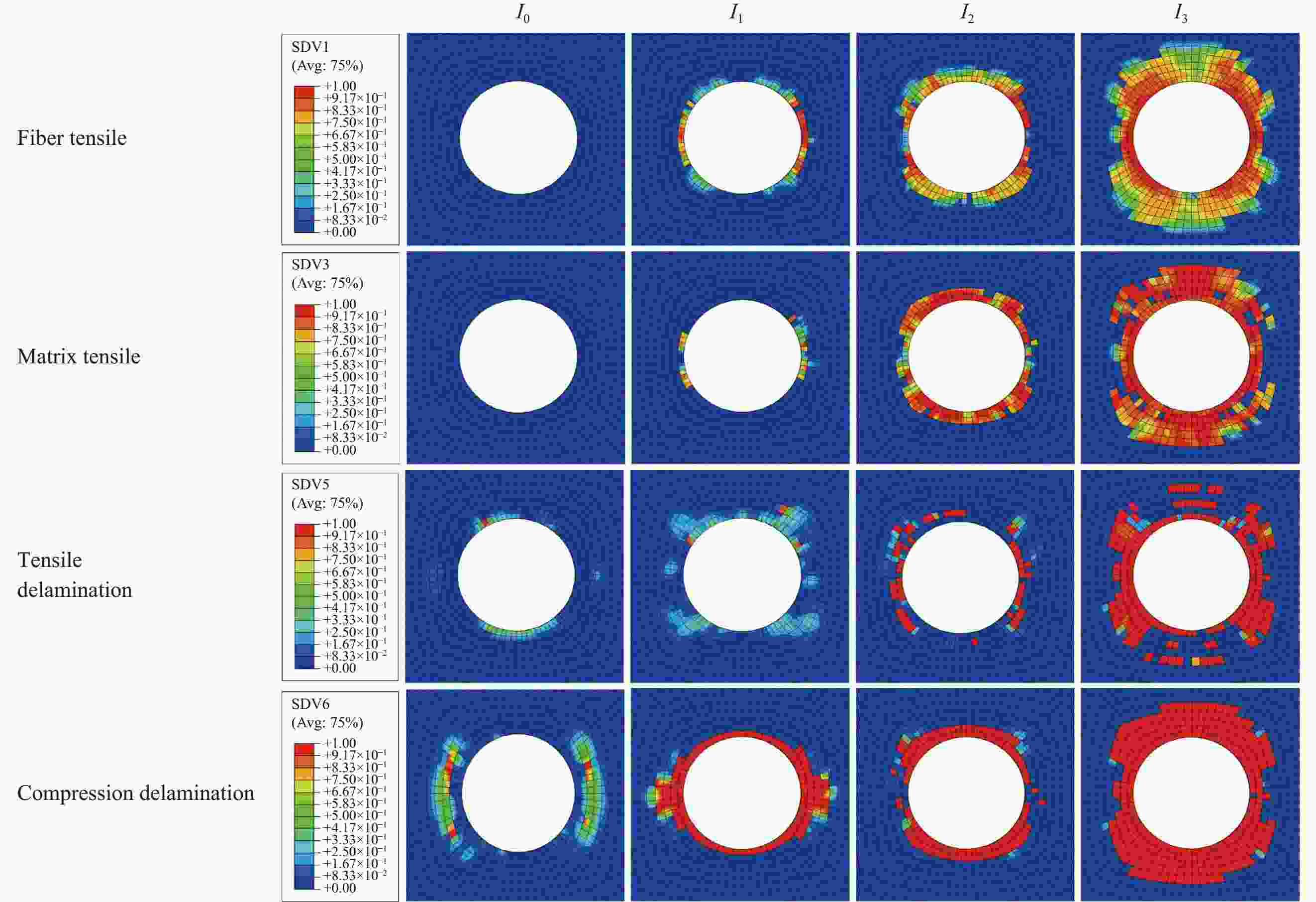

图 8 干涉量I1、I2和I3下1 m/s、5 m/s和10 m/s所对应的CFRP的纤维拉伸损伤、基体拉伸损伤、层合板拉伸损伤和层合板压缩损伤

Figure 8. Fiber tensile damage, matrix tensile damage, laminate tensile damage and laminate compression damage of CFRP corresponding to 1 m/s, 5 m/s and 10 m/s under interference quantities I1, I2 and I3

SDV1—Fiber tensile damage; SDV3—Matrix tensile damage; SDV5—Tensile delamination damage; SDV6—Compressive delamination damage

表 1 T700/M21复合材料属性参数

Table 1. Property parameters of T700/M21 composites

E11/GPa E22/GPa E33/GPa G12/GPa G13/GPa G23/GPa v12/GPa v13/GPa v23/GPa 117 7.7 7.7 4.8 4.8 2.8 0.34 0.34 0.4 Notes: E11, E22, E33—; G12, G13, G23—; v12, v13, v23—. 表 2 T700/M21复合材料层间强度

Table 2. Interlaminar strength of T700/M21 composites

XT/GPa XC/GPa YT/GPa YC/GPa ZT/GPa ZC/GPa S12/GPa S13/GPa S23/GPa 2200 1700 50 300 50 300 95 95 95 Notes: XT, XC—; YT, YC—; ZT, ZC—; S12, S13, S23—. 表 3 抽芯铆钉各零件和铝合金的属性参数

Table 3. Property parameters of each part of blind rivet and aluminum alloy

Name Type Young's modulus/GPa Poisson's ratio Density/(g·cm−3) Sleeve CPTi 100 0.34 4.51 Stem Ti3Al8V6Cr4Mo4Zr 107.8 0.32 4.82 Lock collar A286 2.01 0.305 7.49 Shifting anvil 45A 206 0.269 7.85 Al alloy Al 72 0.33 2.70 表 4 CFRP/Al抽芯铆钉相对干涉量大小

Table 4. Relative interference magnitude of the CFRP/Al blind rivet

Number Interference amount/% Sleeve diameter/mm Aperture/mm $ I $0 0 4.80 4.80 $ I $1 0.42 4.80 4.78 $ I $2 0.84 4.80 4.76 $ I $3 1.30 4.80 4.74 -

[1] LIU Y, XIE J Z, TAFSIROJJAMAN T, et al. CFRP lamella stay-cable and its force measurement based on microwave radar[J]. Case Studies in Construction Materials, 2022, 16: e00824. doi: 10.1016/j.cscm.2021.e00824 [2] DU Y, MA Y, SUN W B, et al. Effect of hygrothermal aging on moisture diffusion and tensile behavior of CFRP composite laminates[J]. Chinese Journal of Aeronautics, 2023, 36(3): 382-392. doi: 10.1016/j.cja.2022.11.022 [3] 王跃全, 童明波, 朱书华. 三维复合材料层合板渐进损伤非线性分析模型[J]. 复合材料学报, 2009, 26(5): 159-166. doi: 10.3321/j.issn:1000-3851.2009.05.026WANG Yuequan, TONG Mingbo, ZHU Shuhua. Progressive damage nonlinear analysis model of three-dimensional composite laminates[J]. Acta Materiae Compositae Sinica, 2009, 26(5): 159-166(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.05.026 [4] DENG B Y, LI L Z, TAN D, et al. Sustainable and cost-effective ultra-lightweight engineered cementitious composite: Design and material characterization[J]. Cement and Concrete Composites, 2023, 136: 104895. doi: 10.1016/j.cemconcomp.2022.104895 [5] WANG H, LI H, FAN J, et al. Numerical analysis of dynamic response: Fatigue behaviour analysis of Al alloy-CFRP riveted single-shear lap joints[J]. International Journal of Fatigue, 2023, 170: 107515. doi: 10.1016/j.ijfatigue.2023.107515 [6] KAPPE F, ZIRNGIBL C, SCHLEICH B, et al. Determining the influence of different process parameters on the versatile self-piercing riveting process using numerical methods[J]. Journal of Manufacturing Processes, 2022, 84: 1438-1448. doi: 10.1016/j.jmapro.2022.11.019 [7] 周金秋, 王振军, 杨思远, 等. 连续石墨纤维增强铝基复合材料准静态拉伸损伤演化与断裂力学行为[J]. 复合材料学报, 2020, 37(4): 907-918.ZHOU Jinqiu, WANG Zhenjun, YANG Siyuan, et al. Quasi-static tensile damage evolution and fracture mechanics behavior of continuous graphite fiber reinforced aluminum matrix composites[J]. Acta Materiae Compositae Sinica, 2019, 37(4): 907-918(in Chinese). [8] SCATTINA A, RONCATO D, BELINGARDI G, et al. Investigation of creep phenomenon on composite material for bolt connections[J]. Composite structures, 2015, 134: 378-383. doi: 10.1016/j.compstruct.2015.08.061 [9] KARATHANASOPOULOS N, MOHR D. Strength and failure of self-piercing riveted aluminum and steel sheet joints: Multi-axial experiments and modeling[J]. Journal of Advanced Joining Processes, 2022, 5: 100107. doi: 10.1016/j.jajp.2022.100107 [10] JIANG H, GAO S, LI G, et al. Structural design of half hollow rivet for electromagnetic self-piercing riveting process of dissimilar materials[J]. Materials & Design, 2019, 183: 108141. [11] HUANG Z C, ZHANG Y K, LIN Y C, et al. Physical property and failure mechanism of self-piercing riveting joints between foam metal sandwich composite aluminum plate and aluminum alloy[J]. Journal of Materials Research and Technology, 2022, 17: 139-149. doi: 10.1016/j.jmrt.2021.12.132 [12] CAO Z Q, ZUO Y J. Electromagnetic riveting technique and its applications[J]. Chinese Journal of Aeronautics, 2020, 33(1): 5-15. doi: 10.1016/j.cja.2018.12.023 [13] MUCHA J, KAŠČÁK L, SPIŠÁK E. The experimental analysis of forming and strength of clinch riveting sheet metal joint made of different materials[J]. Advances in Mechanical Engineering, 2013, 5: 848973. doi: 10.1155/2013/848973 [14] RUSIA A, WEIHE S. Development of an end-to-end simulation process chain for prediction of self-piercing riveting joint geometry and strength[J]. Journal of Manufacturing Processes, 2020, 57: 519-532. doi: 10.1016/j.jmapro.2020.07.004 [15] ABE Y, KATO T, MORI K. Self-piercing riveting of high tensile strength steel and aluminium alloy sheets using conventional rivet and die[J]. Journal of Materials Processing Technology, 2009, 209(8): 3914-3922. doi: 10.1016/j.jmatprotec.2008.09.007 [16] ZHAO J Q, ZHOU H J, SUN X Y, et al. Evaluation on compressive properties of composite laminates with a hole reinforced by metal plate[J]. Composite Structures, 2021, 258: 113423. doi: 10.1016/j.compstruct.2020.113423 [17] KHASHABA U A, SEBAEY T A, ALNEFAIE K A. Failure and reliability analysis of pinned-joints composite laminates: Effects of stacking sequences[J]. Composites Part B: Engineering, 2013, 45(1): 1694-1703. doi: 10.1016/j.compositesb.2012.09.066 [18] LIU Y, LI M, LU X, et al. Pull-out performance and optimization of a novel Interference-fit rivet for composite joints[J]. Composite Structures, 2021, 269: 114041. doi: 10.1016/j.compstruct.2021.114041 [19] LI S, ZHANG S, LI H, et al. Numerical and experimental investigation of fitting tolerance effects on bearing strength of CFRP/Al single-lap blind riveted joints[J]. Composite Structures, 2022, 281: 115022. doi: 10.1016/j.compstruct.2021.115022 [20] ZUO Y J, YUE T, JIANG R, et al. Bolt insertion damage and mechanical behaviors investigation of CFRP/CFRP interference fit bolted joints[J]. Chinese Journal of Aeronautics, 2022, 35(9): 354-365. doi: 10.1016/j.cja.2022.01.027 [21] HU J, ZHANG K, YANG Q, et al. Fretting behaviors of interface between CFRP and coated titanium alloy in composite interference-fit joints under service condition[J]. Materials & design, 2017, 134: 91-102. [22] LI J, ZHANG K, LI Y, et al. Influence of interference-fit size on bearing fatigue response of single-lap carbon fiber reinforced polymer/Ti alloy bolted joints[J]. Tribology International, 2016, 93: 151-162. doi: 10.1016/j.triboint.2015.08.044 [23] LI Q M, MINES R A W, BIRCH R S. Static and dynamic behaviour of composite riveted joints in tension[J]. International Journal of Mechanical Sciences, 2001, 43(7): 1591-1610. doi: 10.1016/S0020-7403(00)00099-0 [24] ZHAO J, PENG Y, SU W, et al. Finite element analysis of the shear capacity of stainless-steel blind-rivet con nections[J]. Journal of Constructional Steel Research, 2021, 179: 106558. doi: 10.1016/j.jcsr.2021.106558 [25] XING P, YU H. Tension-tension fatigue behavior and its modelling for life estimation of rivet-bonding CFRP/CFRP single lap joints[J]. Composite Structures, 2021, 275: 114367. doi: 10.1016/j.compstruct.2021.114367 [26] KELLY B, COSTELLO C. FEA modelling of setting and mechanical testing of aluminum blind rivets[J]. Journal of Materials Processing Technology, 2004, 153: 74-79. [27] ZUO Y, CAO Z, ZHENG G, et al. Damage behavior investigation of CFRP/Ti bolted joint during interference fit bolt dynamic installation progress[J]. Engineering Failure Analysis, 2020, 111: 104454. doi: 10.1016/j.engfailanal.2020.104454 [28] NAKAYASU H, MAEKAWA Z. A comparative study of failure criteria in probabilistic fields and stochastic failure envelopes of composite materials[J]. Reliability Engineering & System Safety, 1997, 56(3): 209-220. [29] 彭亮, 黄文博, 毛伟, 等. 碳纤维增强树脂基层板应变率相关损伤数值研究[J]. 北京航空航天大学学报, 2017, 43(4): 694-700.PENG Liang, HUANG Wenbo, MAO Wei, et al, Numerical study on strain rate-related damage of carbon fiber reinforced resin substrate[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(4): 694-700(in Chinese). [30] NAIK N K, SHRIRAO P. Composite structures under ballistic impact[J]. Composite Structures, 2004, 66(1-4): 579-590. doi: 10.1016/j.compstruct.2004.05.006 [31] ASTM. Standard test method for bearing response of polymer-matrix composite laminates: ASTM D5961/D5961M—05[S]. West Conshohocken: ASTM International, 2005. [32] BERTHE J, BRIEU M, DELETOMBE E, et al. Temperature effects on the time dependent viscoelastic behaviour of carbon/epoxy composite materials: Application to T700GC/M21[J]. Materials & Design, 2014, 62: 241-246. [33] LI S, ZHANG S, LI H, et al. Numerical and experimental investigation of fitting tolerance effects on bearing strength of CFRP/Al single-lap blind riveted joints[J]. Composite Structures, 2022, 281: 115022. doi: 10.1016/j.compstruct.2021.115022 [34] 左杨杰. 复合材料/钛合金结构干涉配合螺栓连接动静态损伤及失效研究[D]. 西安: 西北工业大学, 2018.ZUO Yangjie. Study on dynamic and static damage and failure of bolt connection of composite/titanium alloy structure with interference fit[D]. Xi'an: Northwestern Polytechnical University, 2018(in Chinese). -

下载:

下载: