Classification, absorbing mechanism and research progress of biomass-derived carbon-based composite absorbing materials

-

摘要: 为解决电子信息技术带来的电磁波污染问题,碳基复合吸波材料受到了广泛的关注。生物质衍生碳复合材料不仅具有优异的电磁波吸收能力,还具有密度小、来源广泛和成本低等优点。本文首先阐述了生物质衍生碳的制备方法及过程;其次,依据生物科学分类法系统归纳了植物界类、真菌类、原生生物界类的三种生物质衍生碳的结构形貌特征,对生物质衍生碳基复合吸波材料近些年的研究成果进行了总结与综述;接着,对不同分类的吸波材料的结构形貌与电磁波吸收性能进行了对比,并分析了各类材料的吸波机制。最后,分析了目前生物质衍生碳基复合材料的吸波性能及其缺点,并对未来发展方向进行展望。本文为推进非动物类生物质衍生碳复合吸波材料的研究,提供了较全面的归纳、分类、分析与理论支持,为其未来发展提供了思路。Abstract: In order to solve the electromagnetic wave pollution caused by electronic information technology, carbon-based composite absorbing materials have received extensive attention. Biomass-derived carbon composites not only have excellent electromagnetic wave absorption ability, but also have the advantages of low density, wide source and low cost. Firstly, the preparation method and process of biomass derived carbon are described. Secondly, the structural and morphological characteristics of three kinds of biomass-derived carbon, including plant kingdom, fungus kingdom and protista kingdom, were systematically summarized, and the research results of biomass-derived carbon-based composite absorbing materials in recent years were summarized. Then, the structural morphology and electromagnetic wave absorption properties of different kinds of absorbing materials are compared, and the absorbing mechanism of various materials is analyzed. Finally, the current wave absorbing properties and disadvantages of biomass-derived carbon matrix composites are analyzed, and the future development direction is prospected. This paper provides comprehensive induction, classification, analysis and theoretical support for promoting the research of non-animal biomass derived carbon composite absorbing materials, and provides ideas for its future development.

-

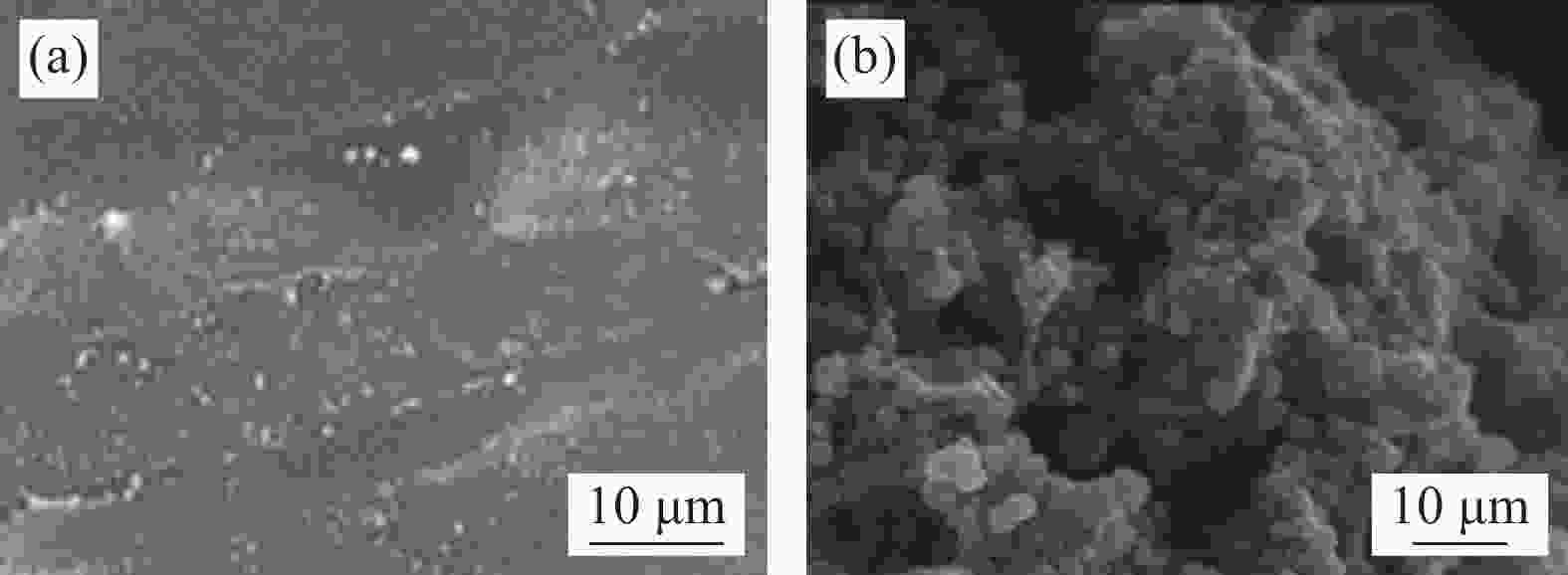

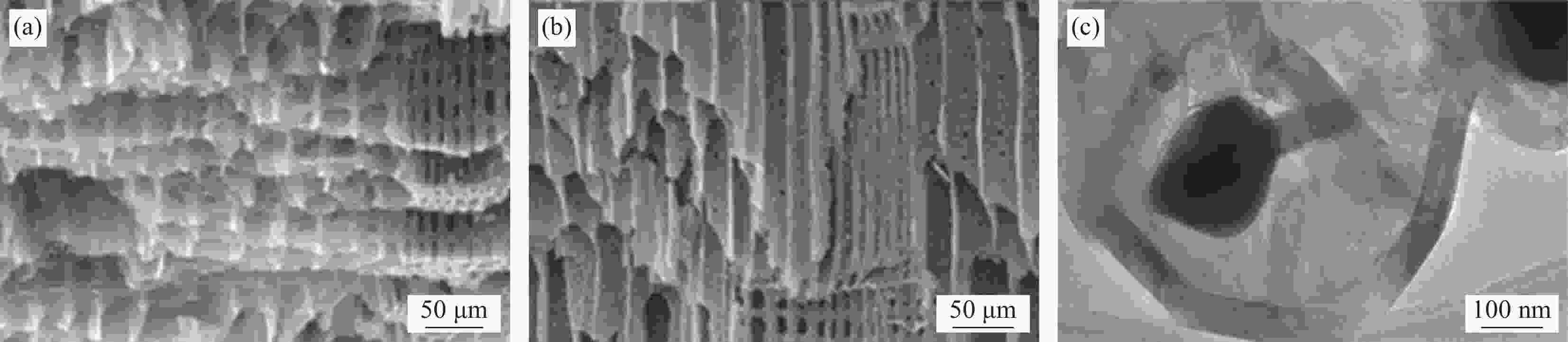

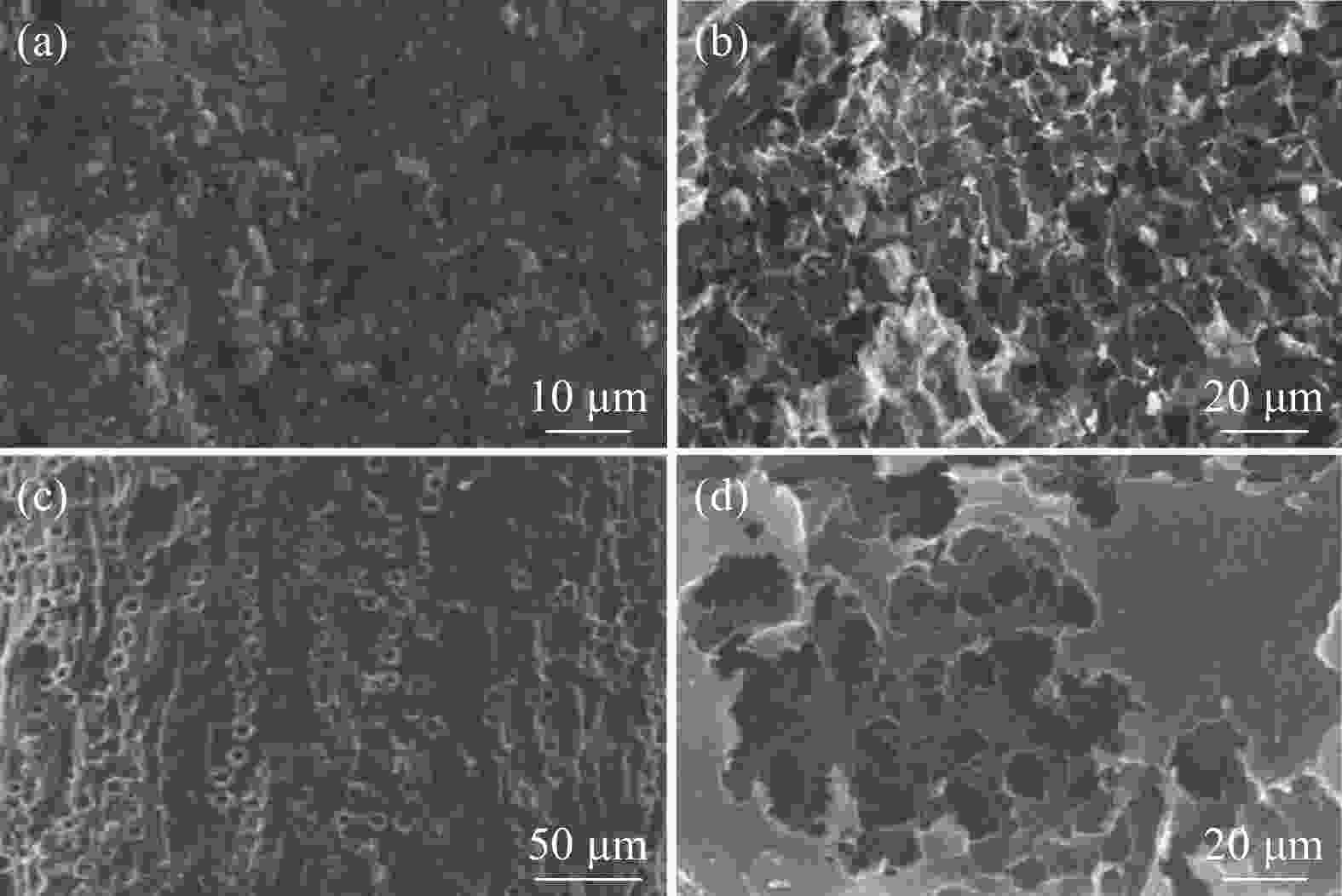

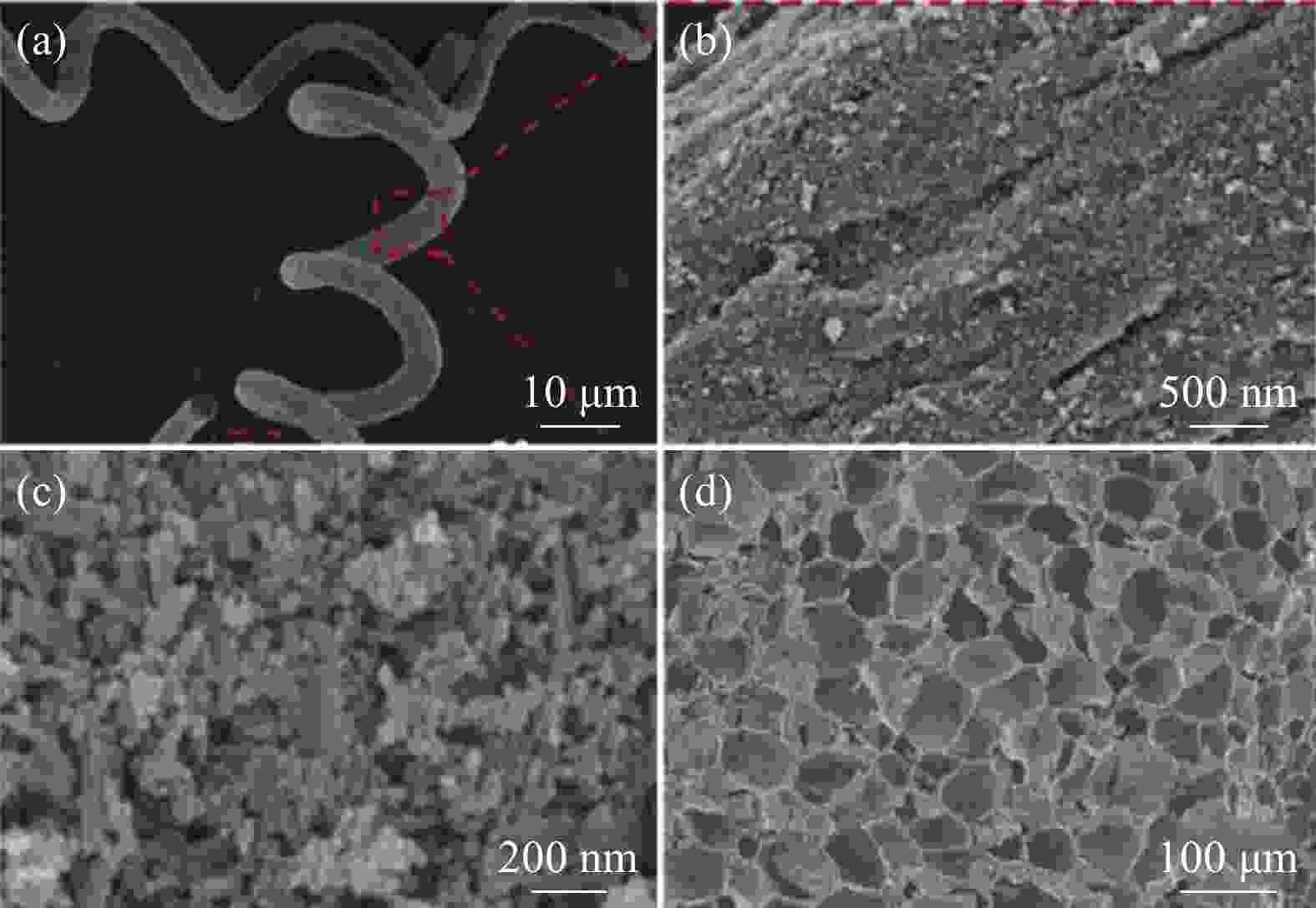

表 1 真菌类生物质的结构与成分

Table 1. Structure and composition of fungal biomass

Biomass species Mushroom Agaric Yeast Heteroelement element/(μg·g−1) P: 0.63-1.05

Fe: 27.5-215

Zn: 49.4-85.8P: 1305.35-2430.59

Fe: 83.76-110.62

Zn: 26.58-51.76P: 1.6-3.5% (wt%)

Fe: 90-350

Zn: 100-160Structural molecule Chitin, cellulose, hemicellulose Pore size scope /μm Tissue holes:10-200 μm

Cell wall pit 0.9-2.7 μmPlasmodesma:

30-60 nmPorosity/% 59.0 62.9 — 表 2 部分真菌类生物质衍生碳复合材料的结构与成分

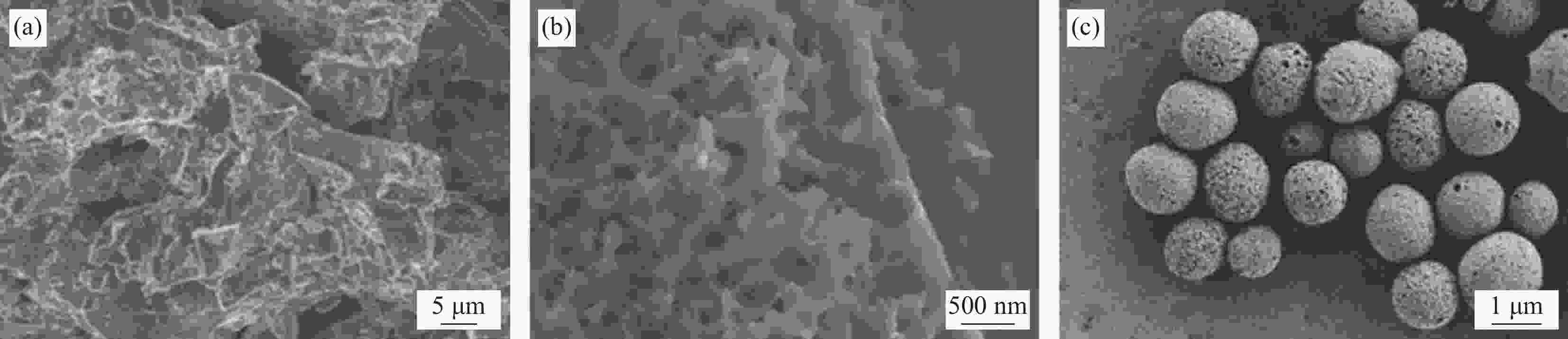

Table 2. Structure and composition of partial fungal biomass derived carbon composites

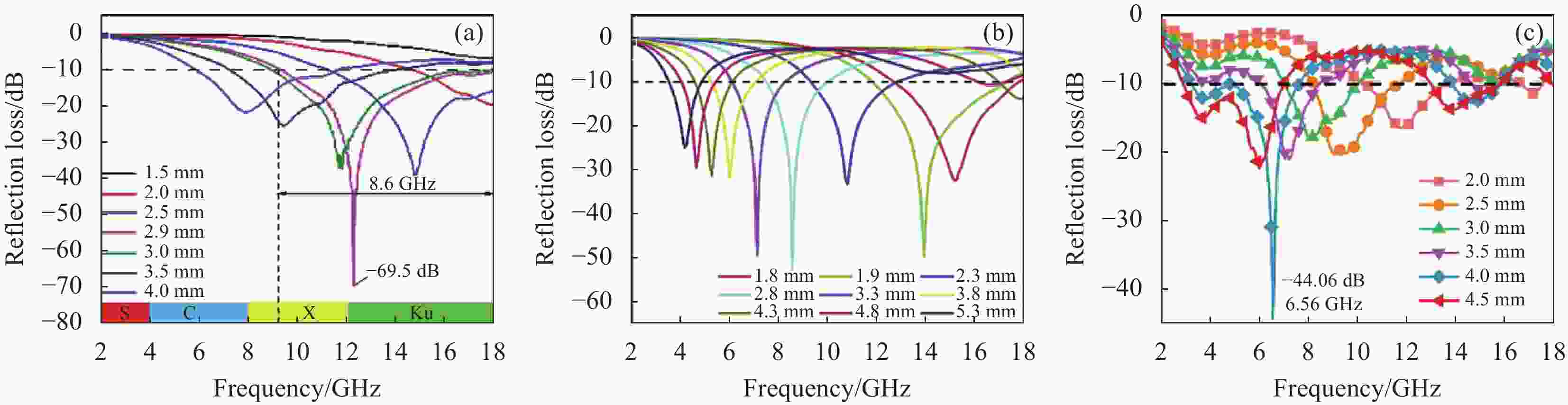

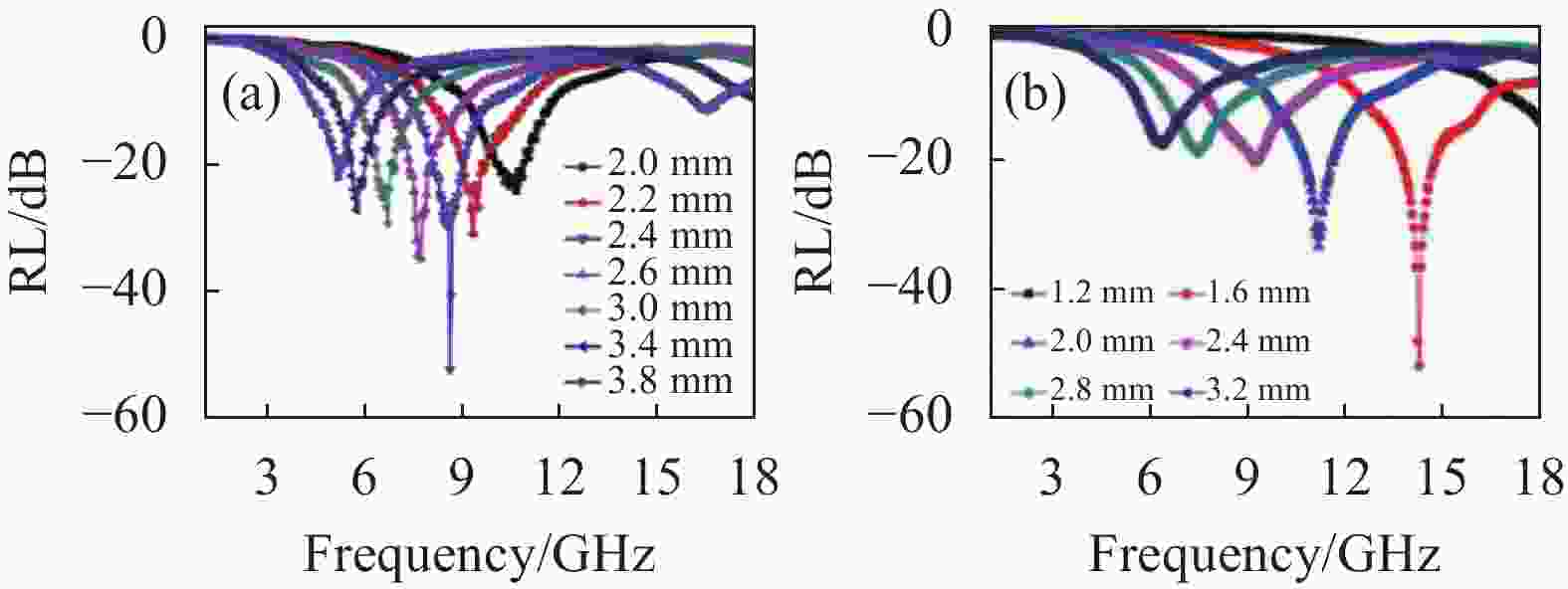

BDC species Mushroom Agaric Yeast Heteroelement species P、Fe Fe Carbonization temperature /℃ 700 800 800 800 800 800 800 900 900 ID/IG 0.92 0.97 — 1.02 1.06 0.89 2.95 0.92 1.05 Pore size scope /nm — 9.10 5.27 5.60 3.93 — 2.6-5.0 6.90 — BET surface area/(m2/g) — 81.6 1631 193 173 — 571 89.6 — Pore volume/(cm3/g) — 0.22 0.07 0.25 — — 0.33 0.04 — Ref. [24] [25] [21] [26] [27] [28] [22] [29] [30] Notes: BDC—Biomass Derived Carbon; BET—Brunauer Emmett Teller 表 3 真菌生物质衍生碳基复合吸波材料的微波吸收性能

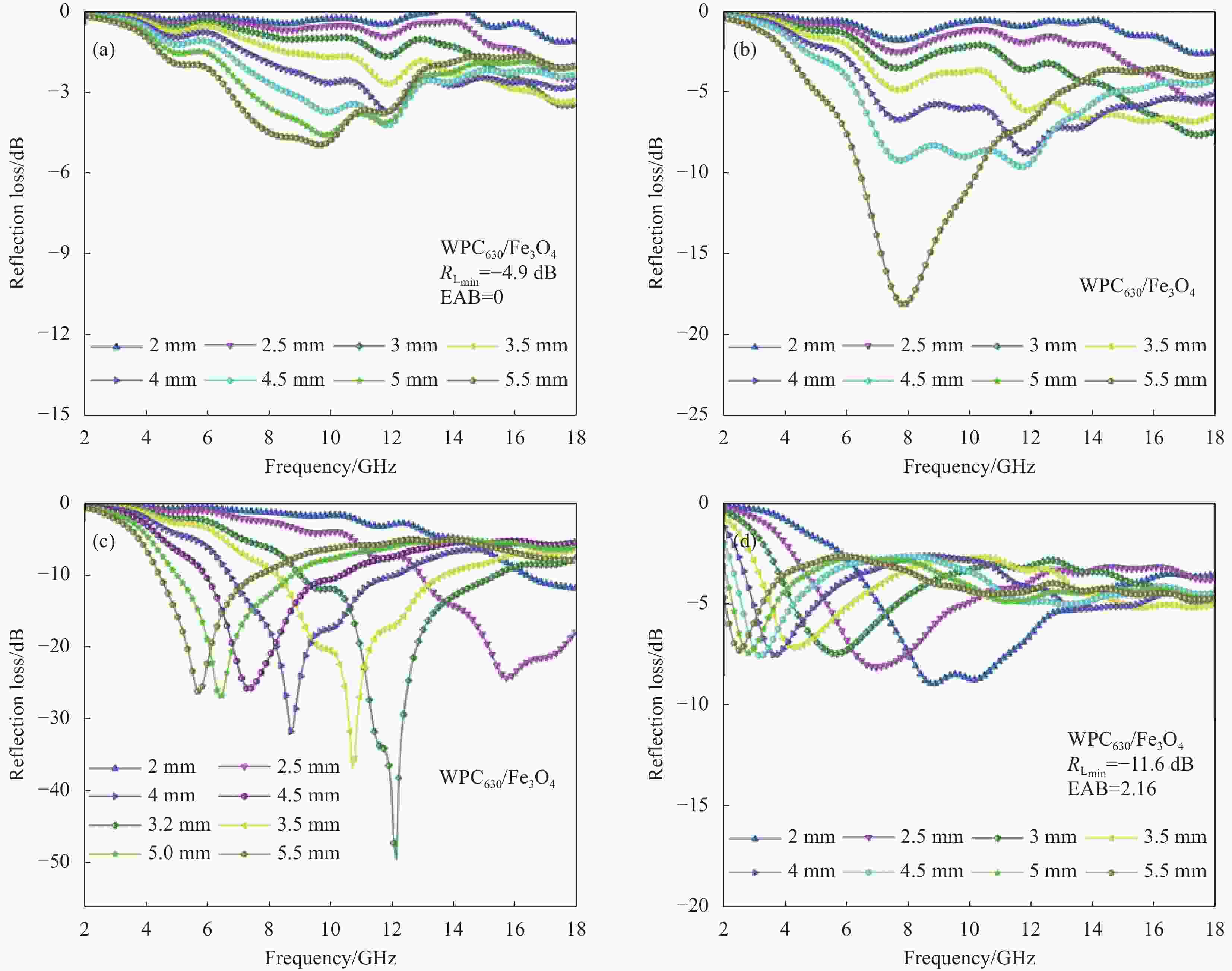

Table 3. Microwave absorption performance of fungal biomass derived carbon-based composite absorbing materials

Precursor material Amount of fill /wt% Abosobers Thickness/

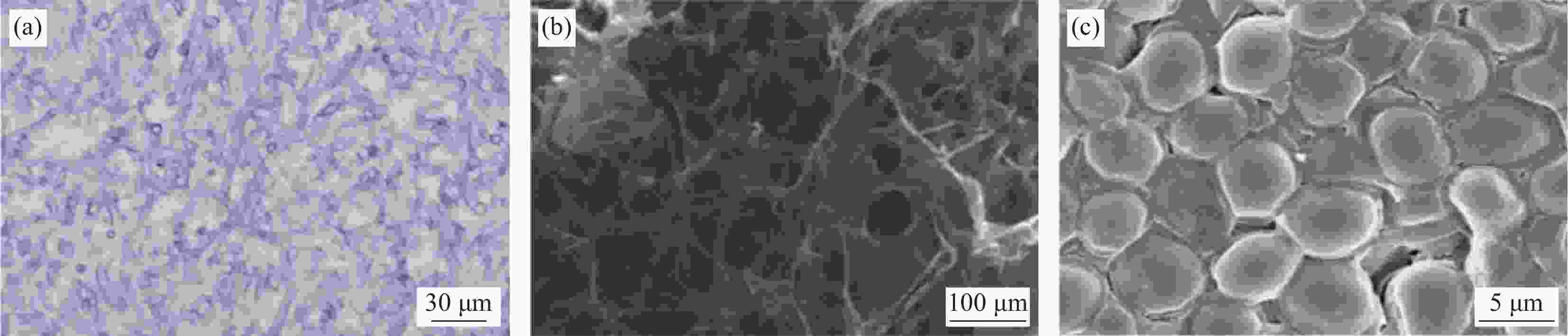

mmFrequence/

GHzRLmin/

dBEAB/

GHzDistribution area of

EAB/GHzRef. Mushroom 50% Fe/Fe4N/BDC 5

44.8 −30.3

6.64

4.00-10.64[24] FeCo@C@BDC 2.9 12.2 −69.5 8.6 9.4-18 [25] Agaric 30% Co/BDC 2.8 8.56 −52.6 5.44 11.84-17.28 [26]

[27]50% BDC@NCO 4.09 −54.6 1.85 5.7 9.9-15.6 50% Fe/Fe3O4/BDC 2.06 9.63 −30.4 2.45 9.58-12.37 [28] Yeast 20% CoNiO2@BDC 4 6.56 −44.0 4.5 7.04 [29] 40% Mo2C@N/P 2.5 12.4 −50.6 5.4 10.5-15.9 [30] Notes: RLmin—Reflection Loss Minimum; EAB—Effective absorption bandwidth. 表 4 植物类生物质的结构与成分

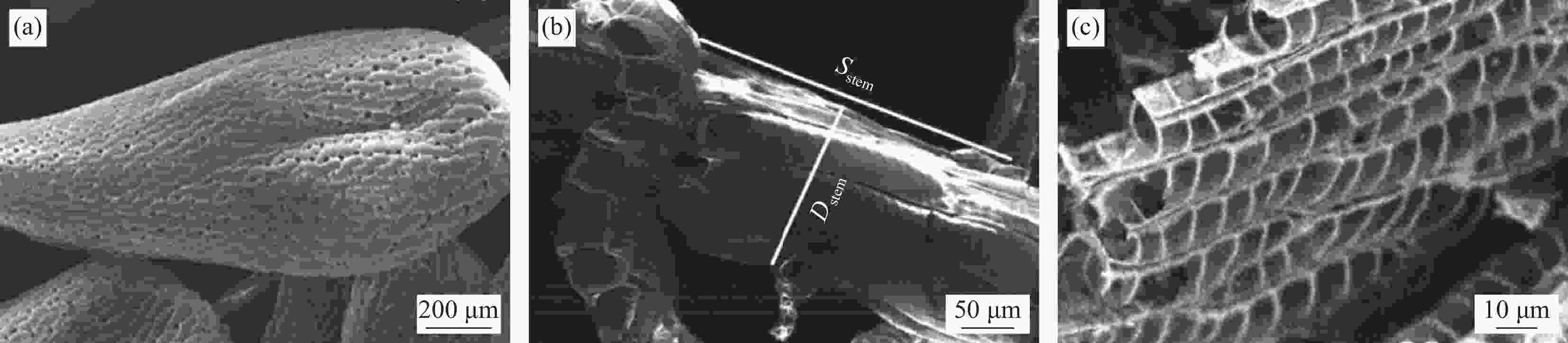

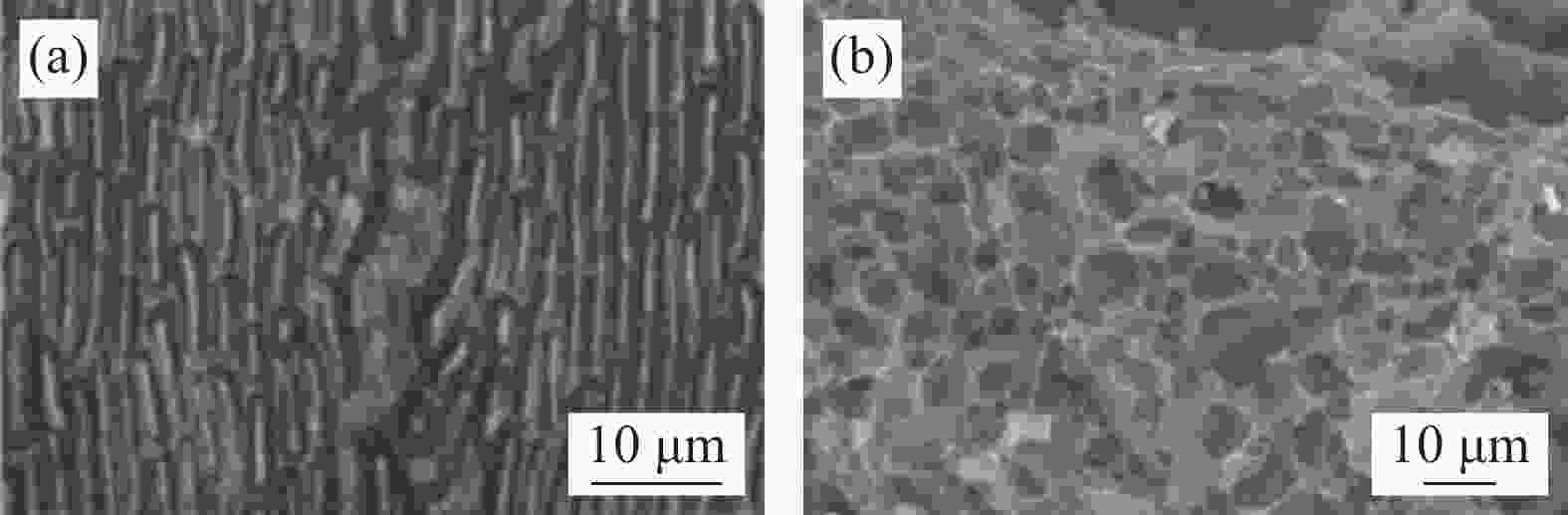

Table 4. Structure and composition of plant biomass

Biomass Heteroelement element/(μg/g) Structural molecule Pore size scope Porosity/% Part Species Leaf Ginkgo Fe: 340; Zn: 30; P: 250 Lignin

Cellulose

HemicelluloseCell pit 1.2 μm

Capillary: 0.1-25 μm— Peatmoss P: 1.04; Zn: 415.8; — Shell Pinecone N: 3.78%(wt%) Cell pit 1.2 μm

Pore: 2.41 nm— Rice-hull P: 289; Fe: 37;

Zn: 14; Si: 40— Stems Fir N:0.1~0.2% (wt%)

Ash content:0.2~1.7(wt%)26.03 μm 58.46 Pine Capillary:1-10 nm

Cell pit: 0.1-0.7 μm

average:1.466 nm78.39 Wheat-straw N:1.12% (wt%)

S:0.25% (wt%)14.79 nm 27.2 Purslane Fe: 154.5; Zn: 177.1 Cell pit 1.2 μm — 表 5 植物类生物质衍生碳复合材料的结构与成分

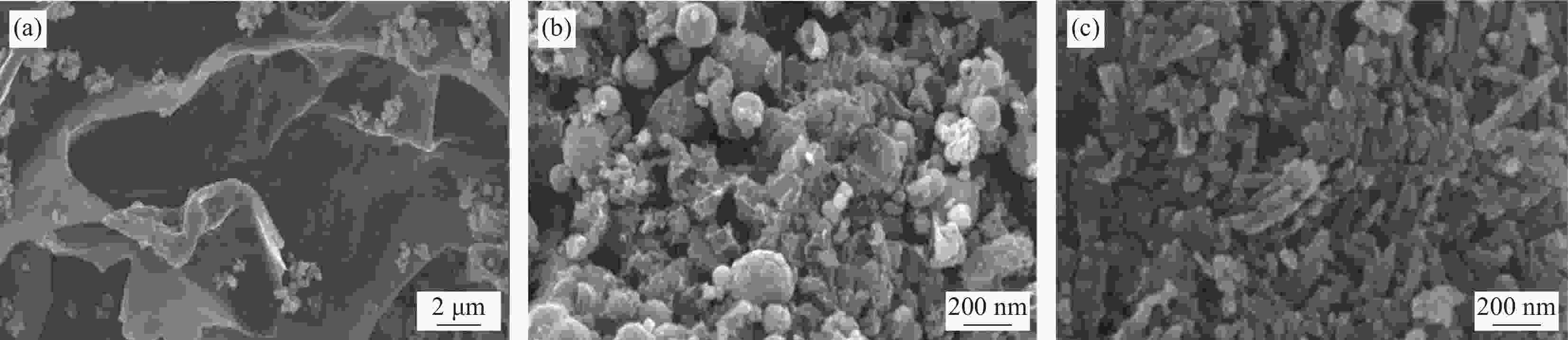

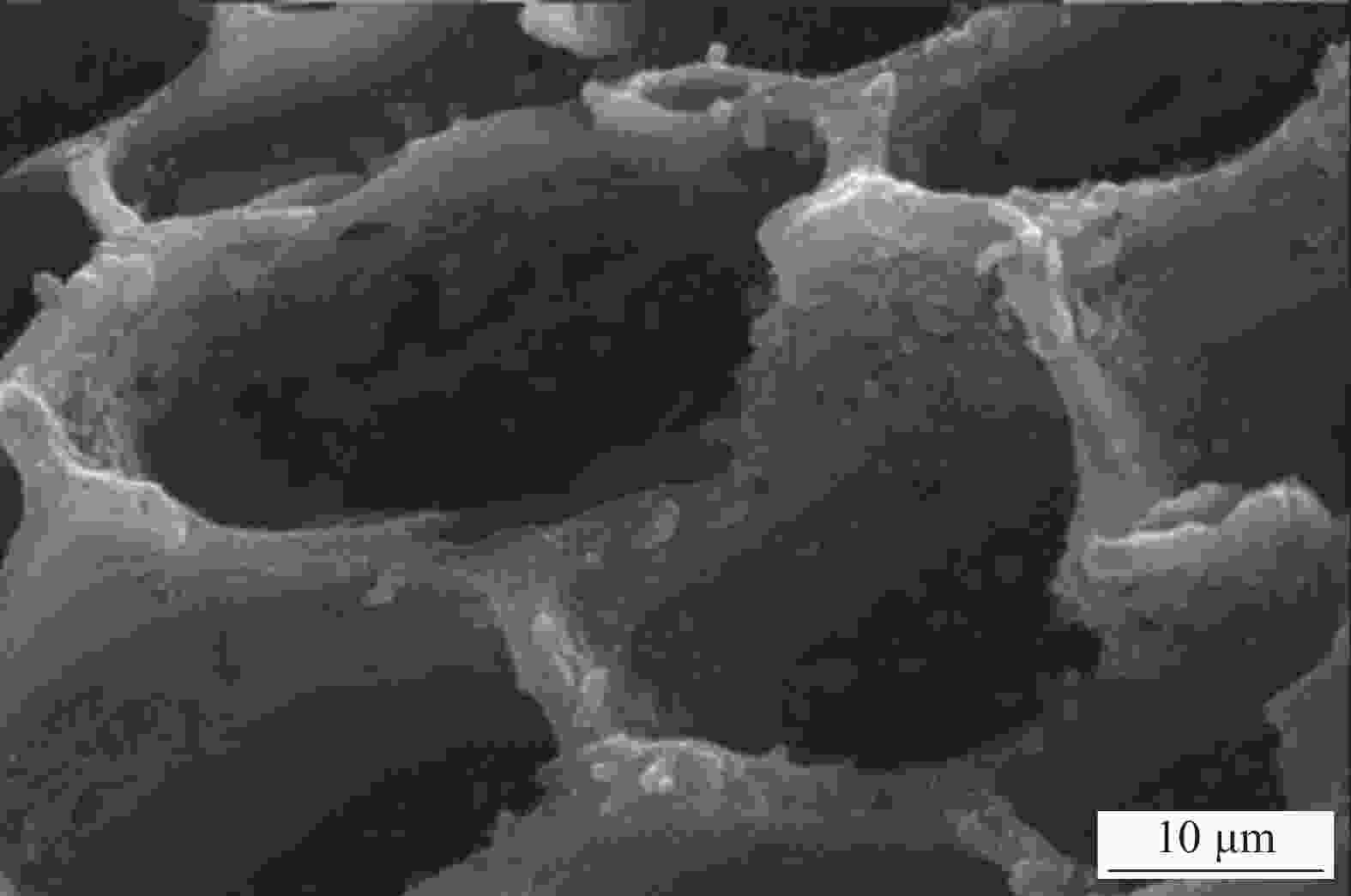

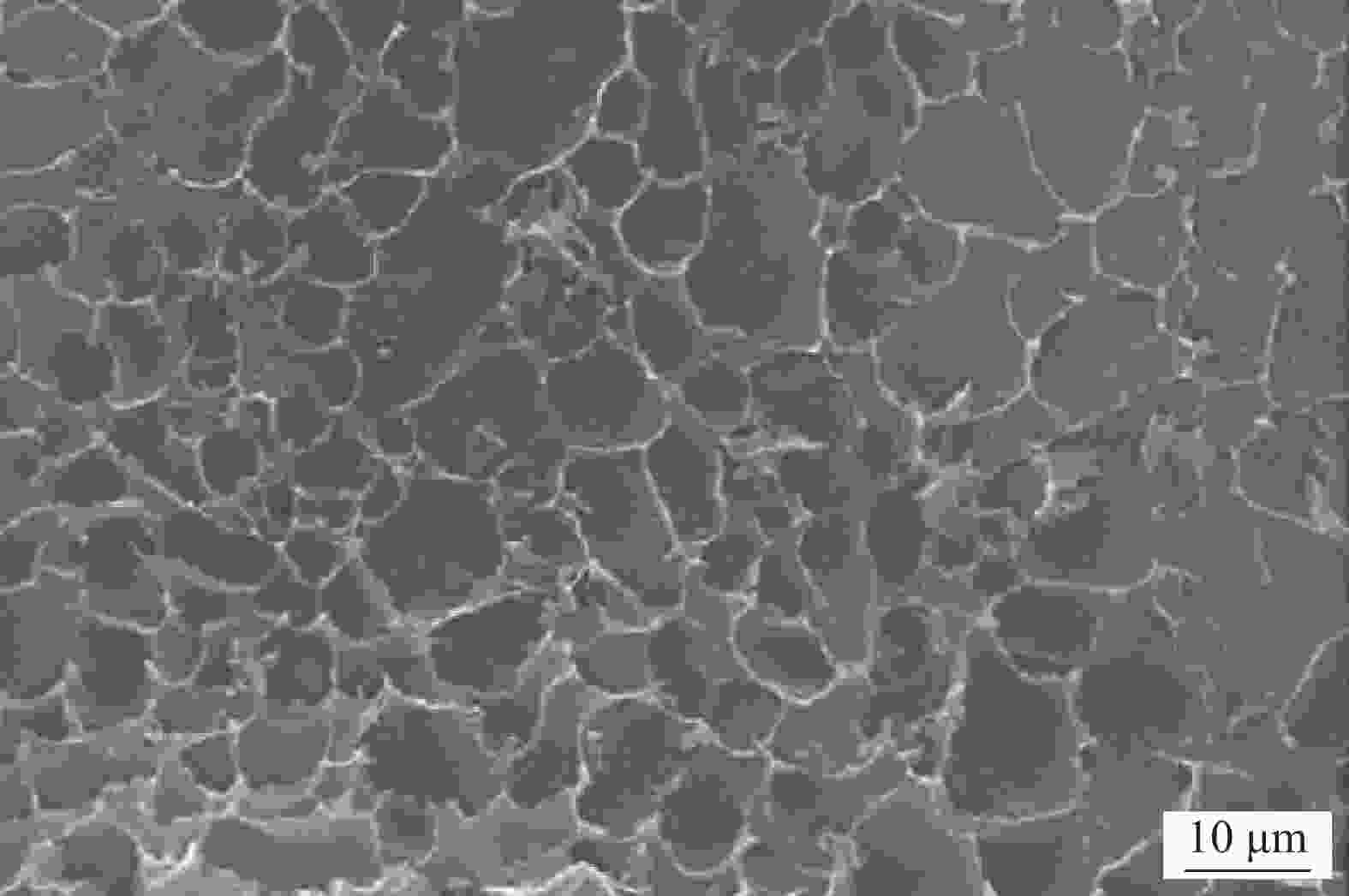

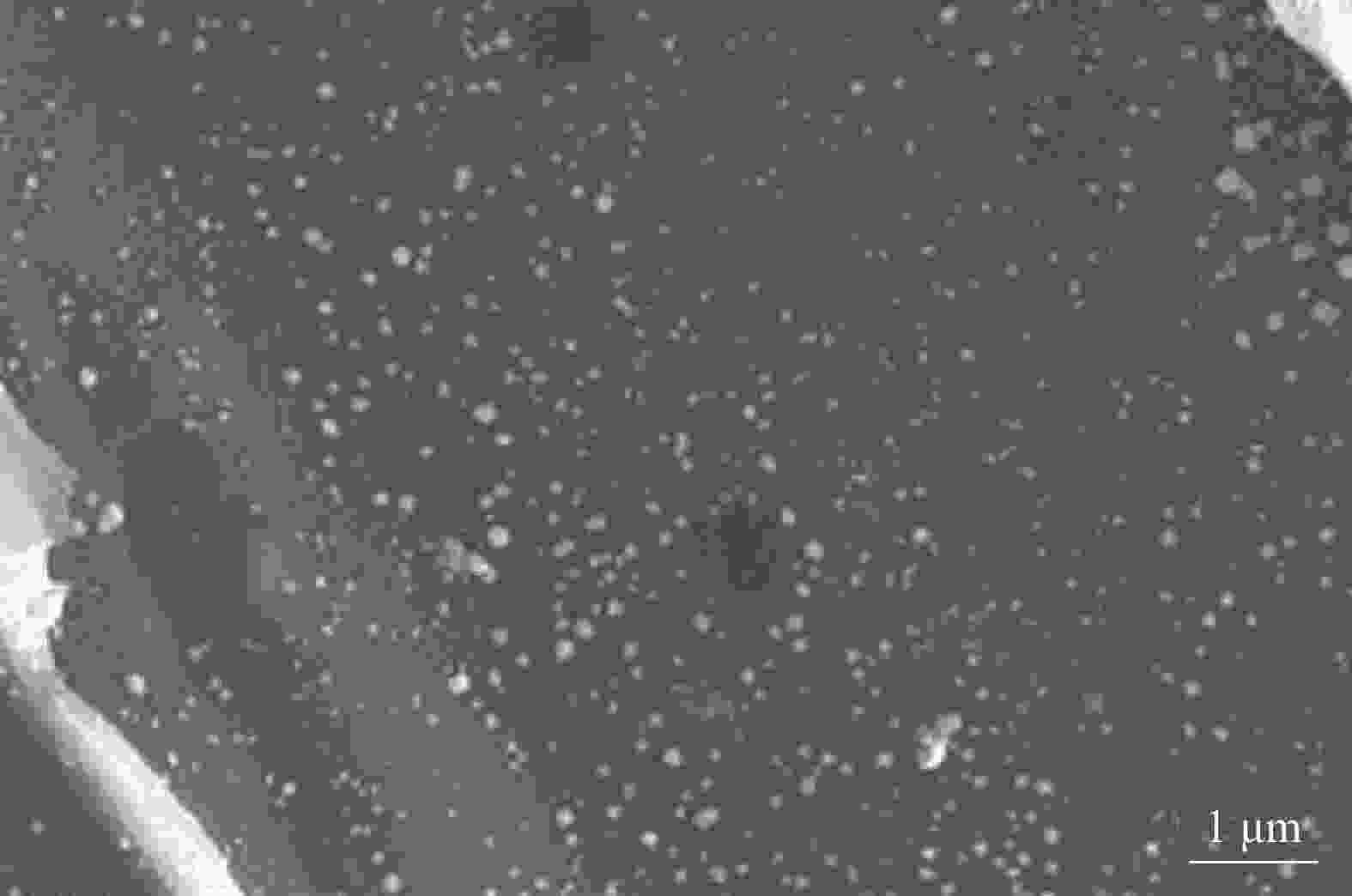

Table 5. Structure and composition of plant biomass derived carbon composites

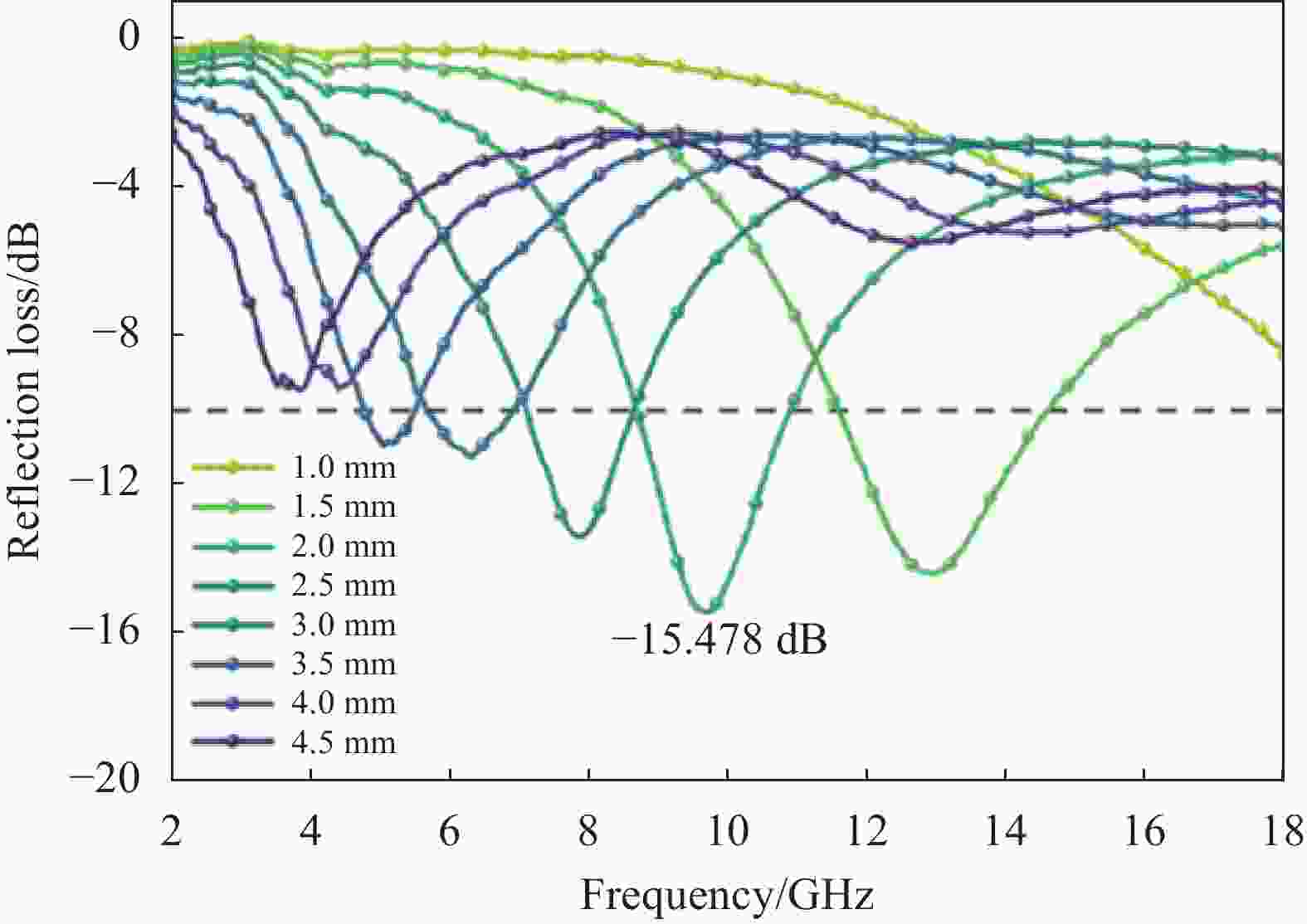

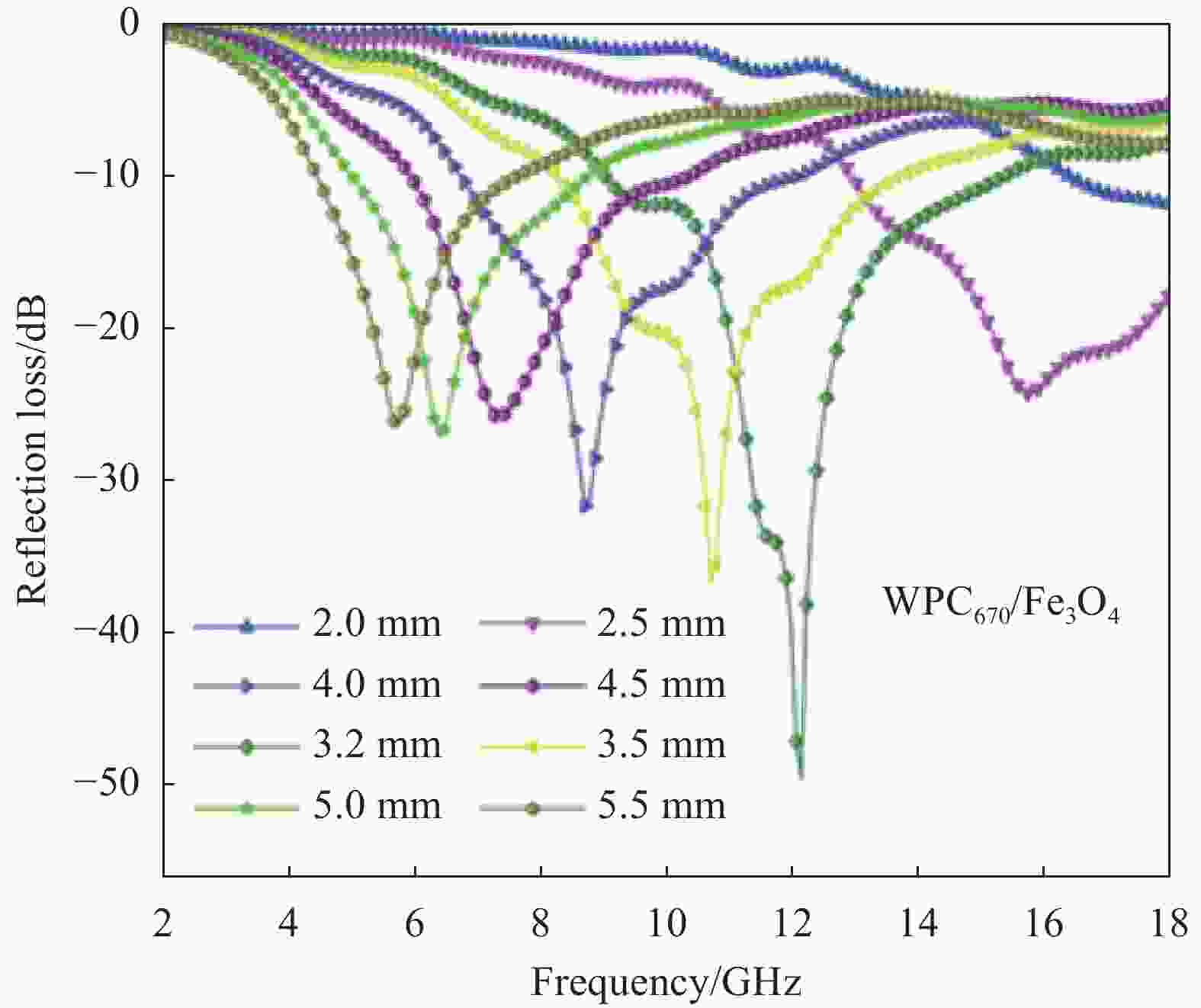

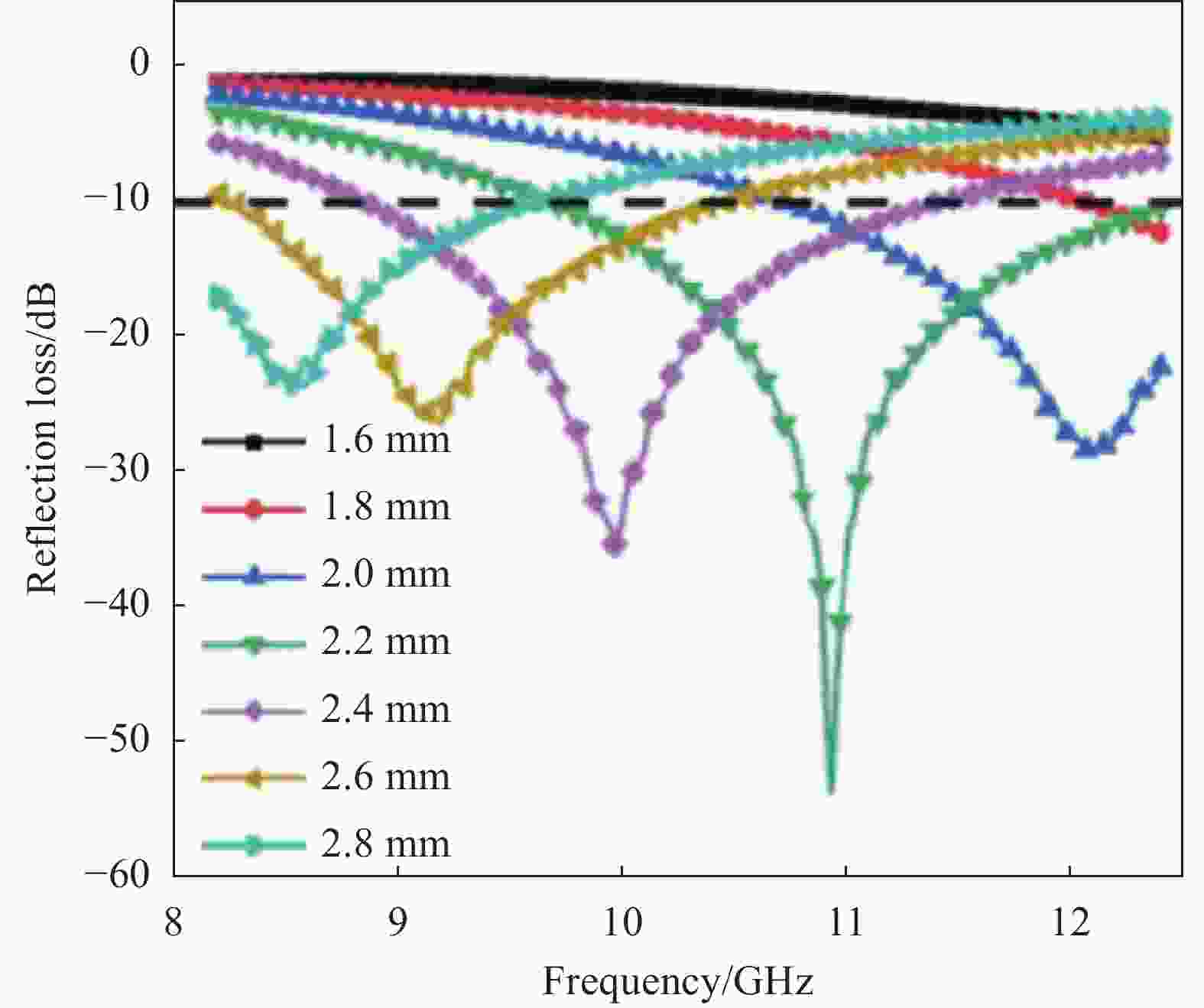

BDC Heteroelement element Carbonization

temperature /℃ID/IG Pore size

scope/nmBET surface

area/(m2/g)Ref. Part Species Leaf Ginkgo S

P700 1.08 — — [36] 800 1.10 1.4-1.6

/2.2/42103 [35] Peatmoss Fe

Zn:

P800 1.01 1.1/1.7-3.5 350 [32] 800 0.98 5/7/15/25 1861 [33] Shell Pinecone N 800 0.85 1.07 — [45] Rice-hull P 600 — 1.7-2.6/4 941.98 [53] 600 0.41 4-10 82.23 [54] 600 1.75 3.5 666.14 [56] Stems Fir N 1000 1.66 19.2-24.8μm — [41] 1000 1.01 — [42] 900 1.06 — 681.63 [37] Pine 670 — 10-20μm — [40] 1400 1.58 2 — [43] Purslane Fe、Zn 650 1.82 — — [49] Wheat-straw N 600 0.95 12.5–30 654.23 [48] 表 6 植物生物质衍生碳基复合吸波材料的微波吸收性能

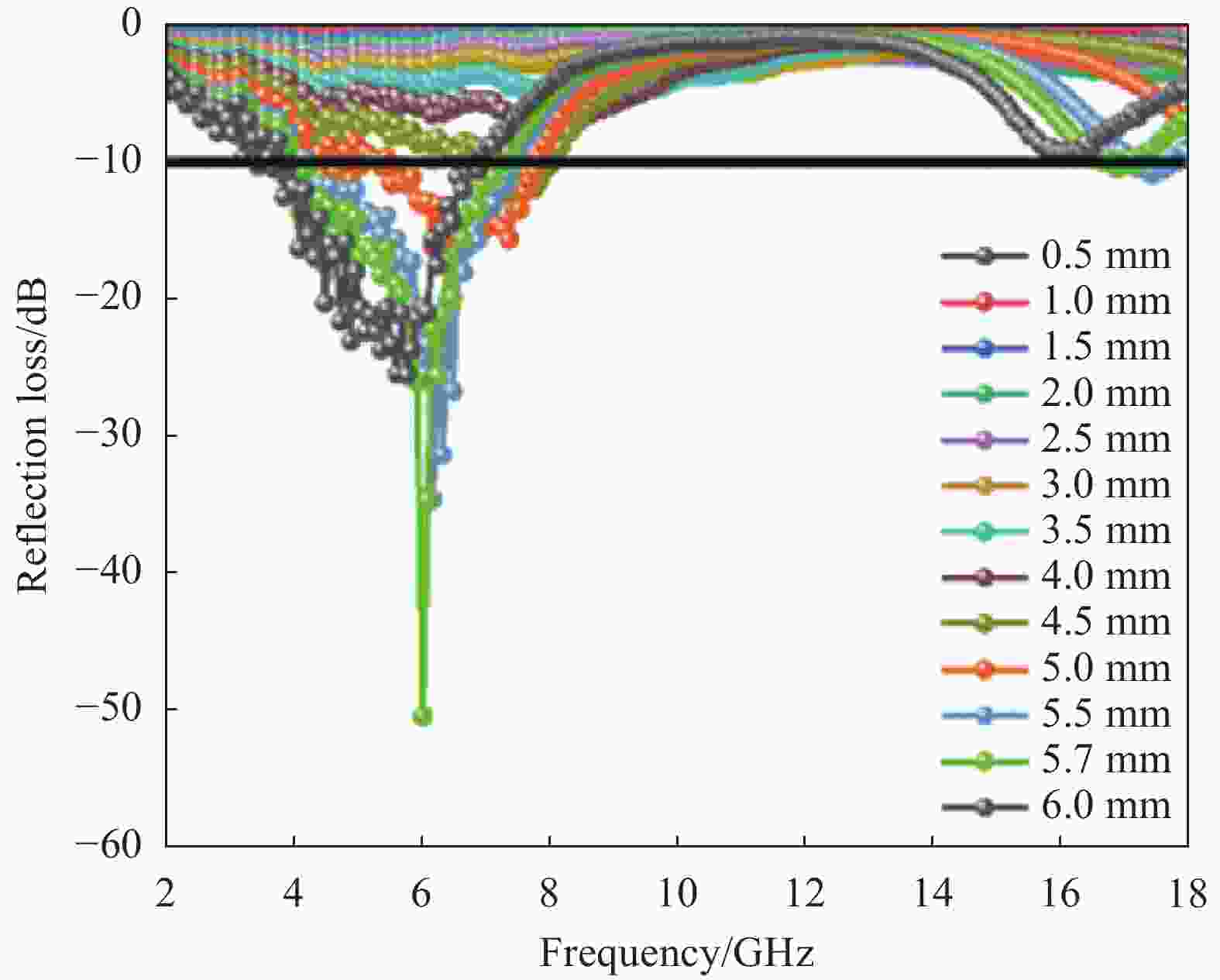

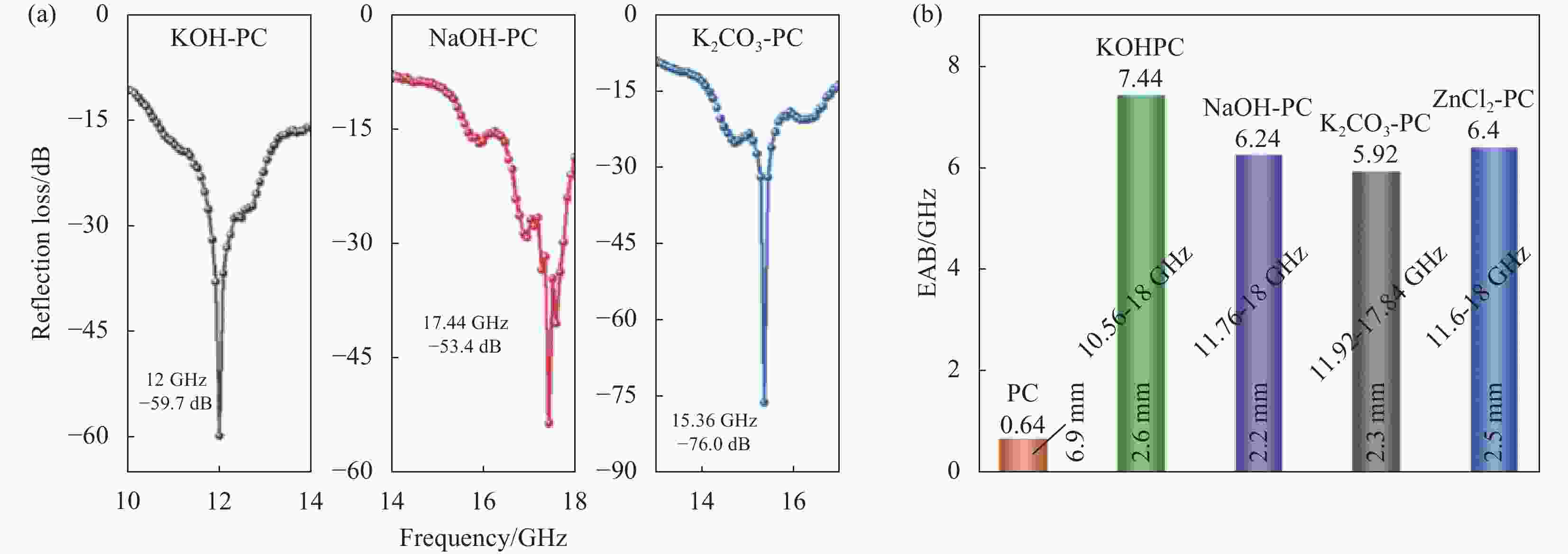

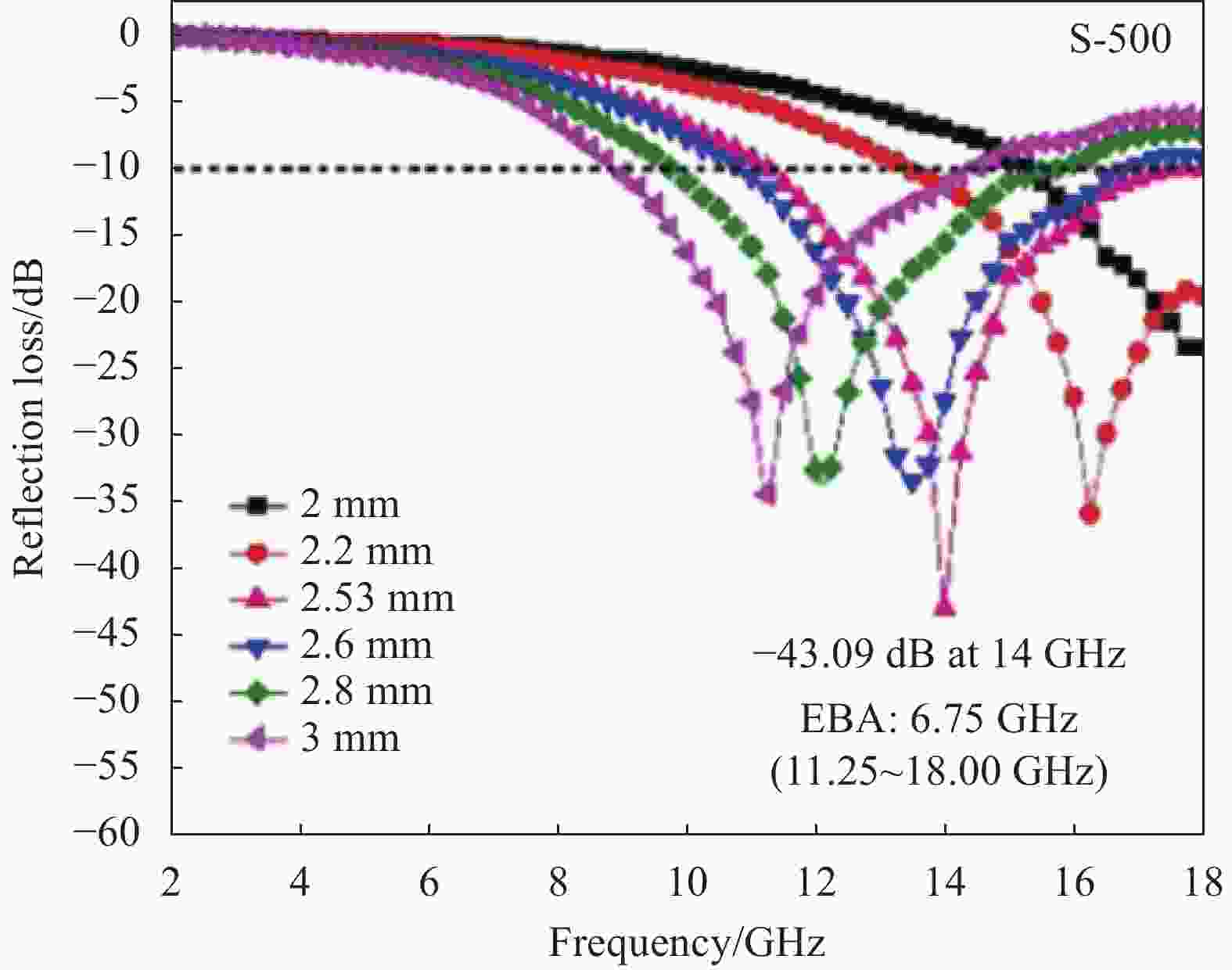

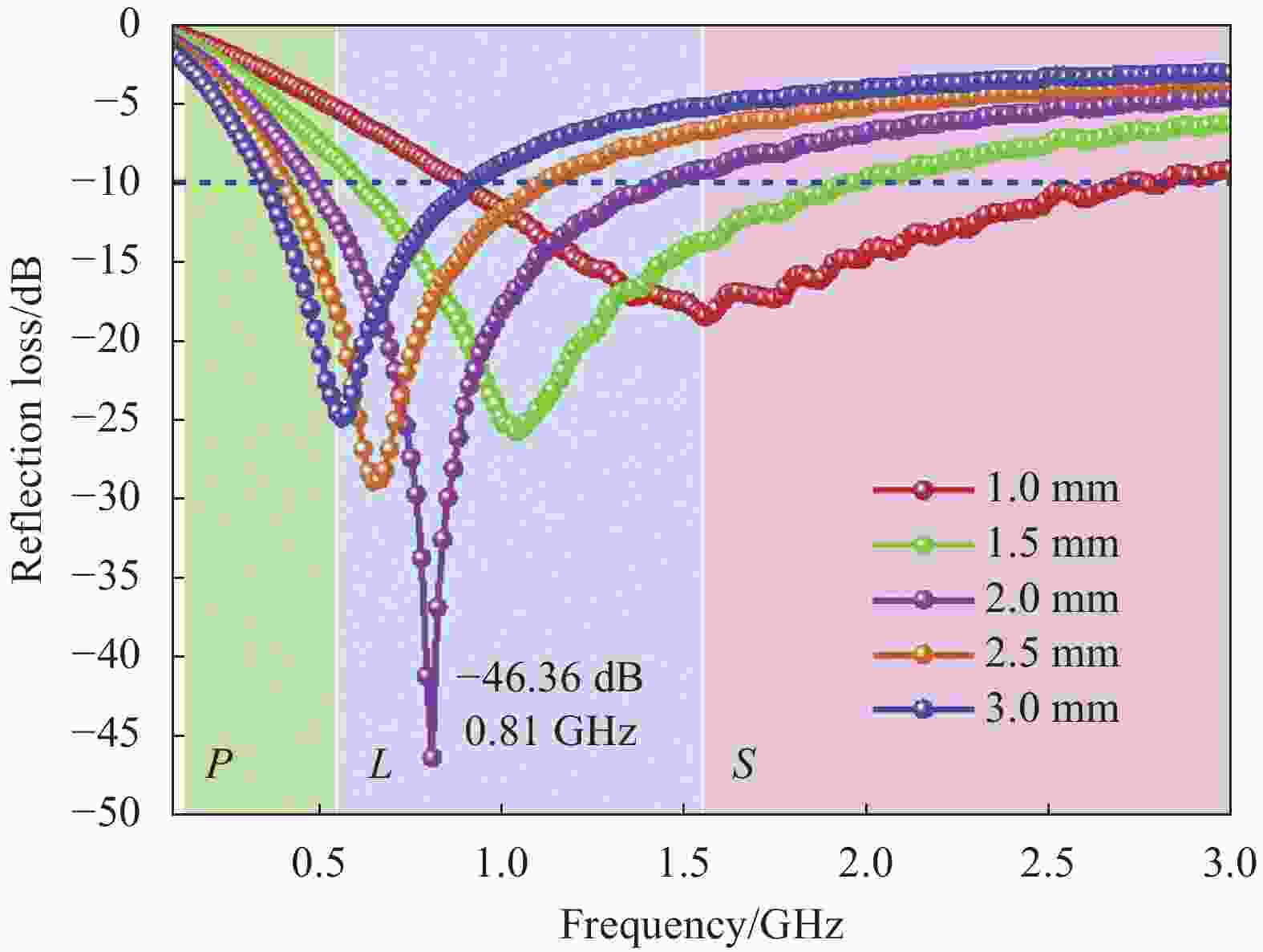

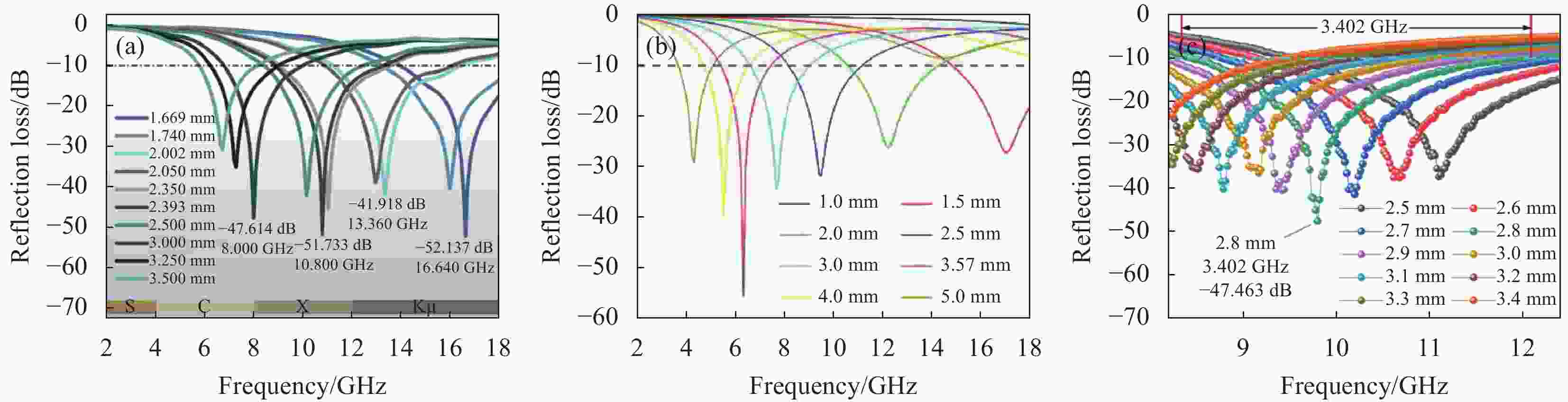

Table 6. Microwave absorption performance of plant biomass-derived carbon-based composite absorbing materials

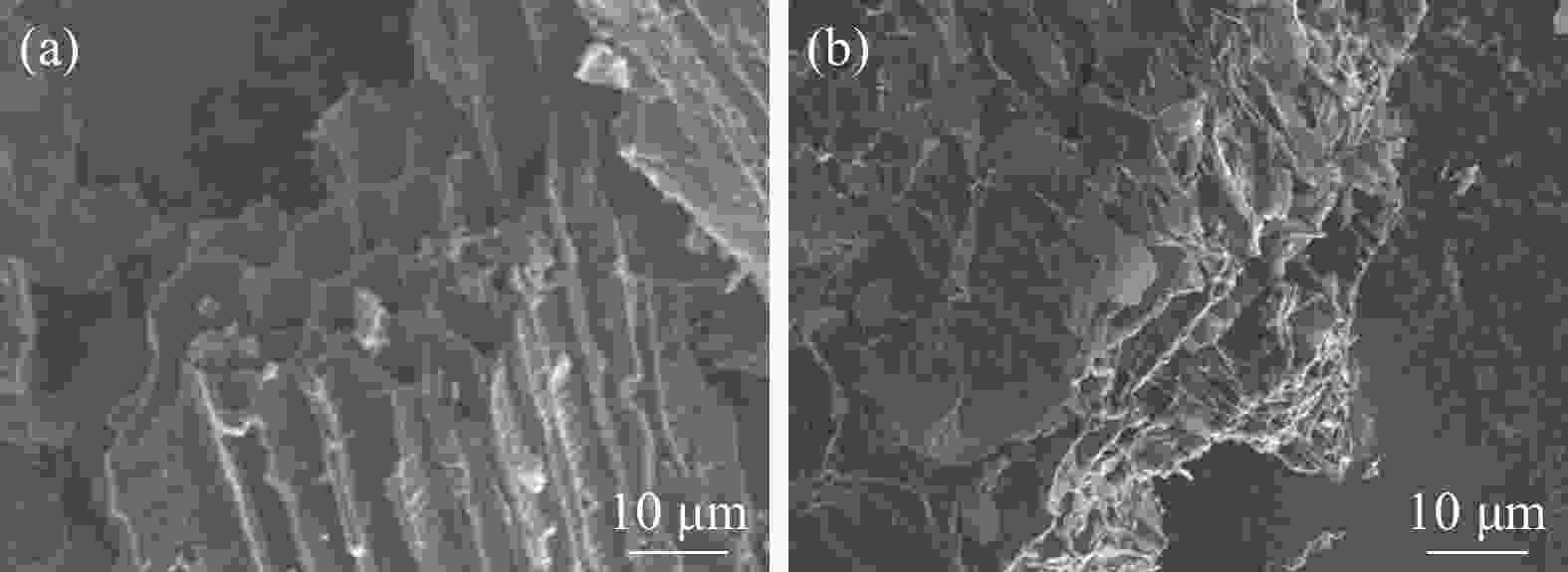

Precursor material Amount of fill /wt% Abosober Thickness/

mmFrequence/

GHzRLmin/

dBEAB/

GHzDistribution area of

EAB/GHzRef Peatmoss 40% Ni/BDC 2.4 8.7 −52 2.6 7.3-9.9 [32] 40% Ni/BDC 2.4 9.4 −52 2.6 [33] Fe3O4/BDC 1.6 14.2 −51.6 4.1 Ginkgo-leaf 30% CaS/BDC 2.0 9.6 −15.47 2.08 [36] Fir 10% CoFe/BDC 2.4 12.2 −54.4 2.6 9.7-12.3 [41] 2.2 1.9 −53.6 4.2 8.2-12.4 [42] Pine 20% Fe3O4/BDC 3.2 12.16 −49.5 6.24 9.04-15.28 [40] 20% Ni/BDC 5.7 6.00 −50.38 3.76 6.4-10.16 [43] Pinecone 16.7% BDC 2.1 15.36 −76.0 [45] 2.3 5.92 11.92-17.84 Purslane 10% Co@BDC/CoO 2.5 14.0 −43.09 6.75 11.25-18 [49] Wheat-straw 10% BDC 2.5 12.1 −37 8.8 7.2-16 [48] 40% (Fe,Ni)/ BDC 1 0.81 −46.36 1.92 0.89-2.81 [50] Rice-hull 40% Fe3O4/ BDC 2.39 10.8 −51.73 [53] 30% NiCo2/BDC 3.57 6.32 −55.62 [54] 10% BDC 2.8 9.796 −47.46 3.40 8.47-11.87 [55] Coconut shell 10% BDC 2.5 −30.5 5.20 [56] 表 7 部分原生生物类生物质的结构与成分

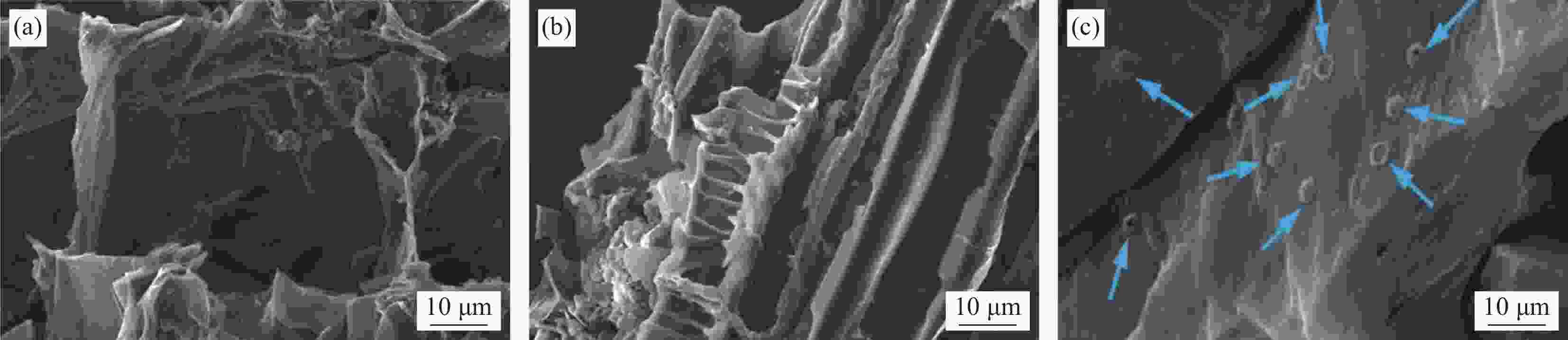

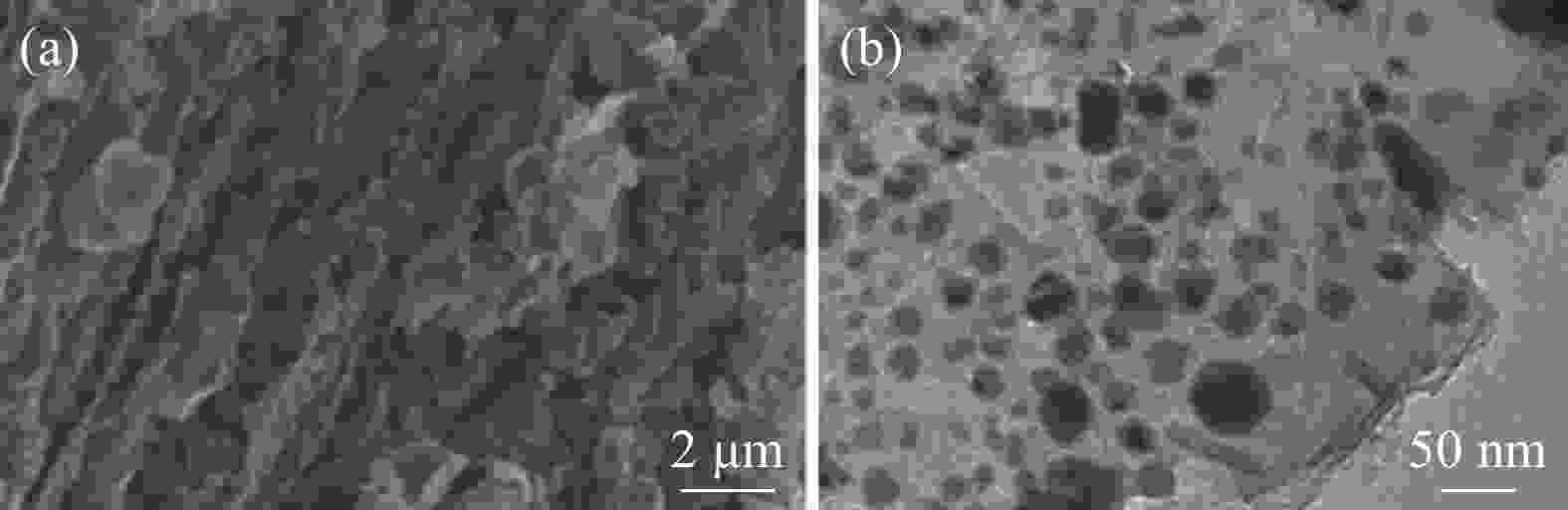

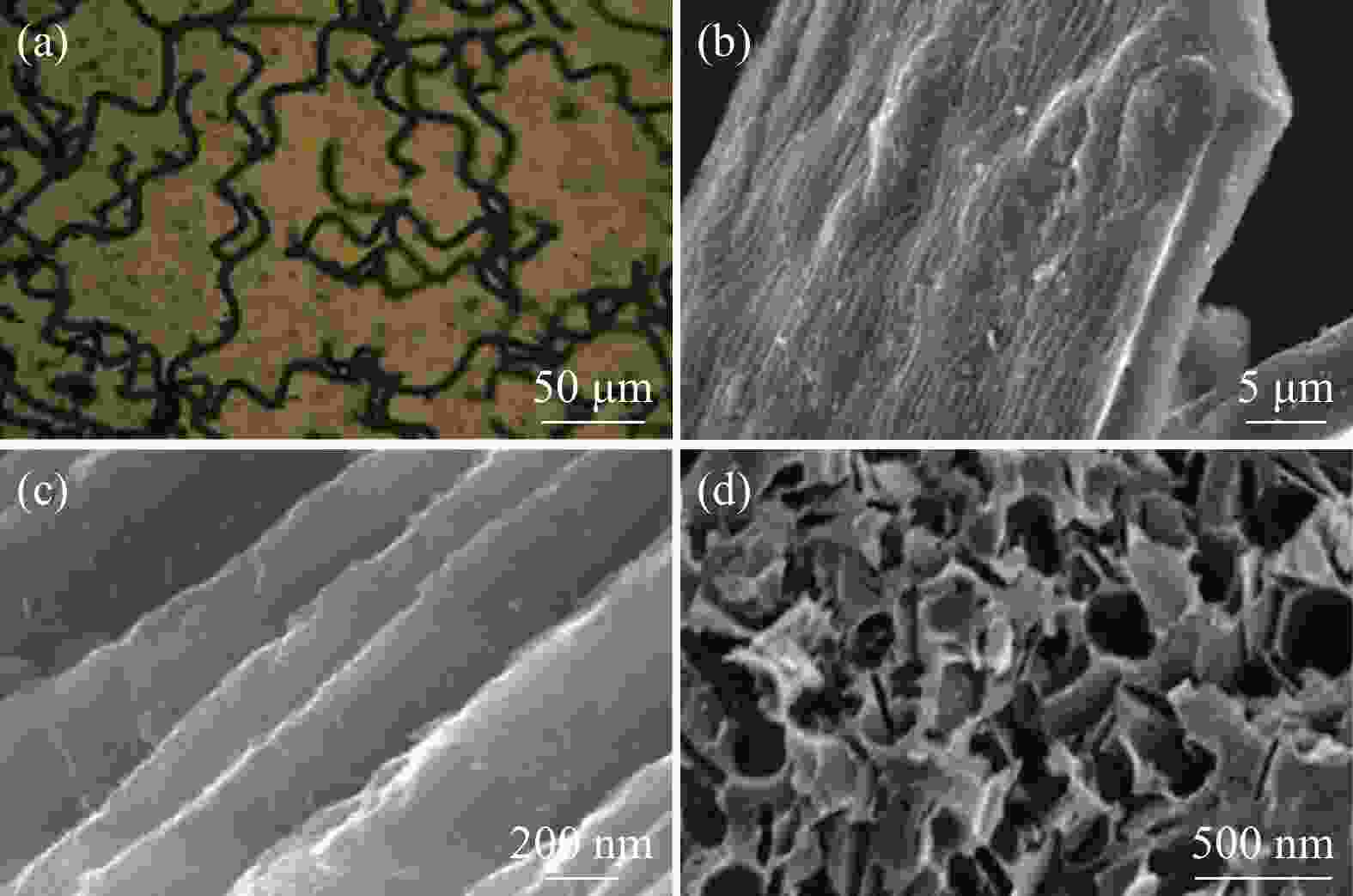

Table 7. Structure and composition of partial protist biomass

Biomass species Spirulina Nori Kelp Heteroelement element/wt% P: 1.2

S: 1.1P: 5.097-7038

Fe: 0.025-0.119N: 1.7-3.0

P: 0.25-0.42Structural molecule Cellulose, hemicellulose, pectin Pore size scope /μm Plasmodesma: 30-60 nm;Air hole 0.2-1.0 μm surface area/(m2/g) 214.4 — 68.3 表 8 原生生物类生物质衍生碳复合材料的结构与成分

Table 8. Structure and composition of protist biomass derived carbon composites

BDC species Spirulina Nori Kelp Heteroelement species P、S P P、N Carbonization temperature /℃ 650 650 650 650 800 ID/IG 1.09 0.99 1.13 0.98 1.01 Pore size scope /nm 30-200 2 — 200-1000 3.50 BET surface area/(m2/g) 2400 1145 — 1145 1085.9 Pore volume/(cm3/g) — 0.58 — 0.58 — Ref. [59] [61] [62] [63] [64] 表 9 原生生物质衍生碳基复合吸波材料的微波吸收性能

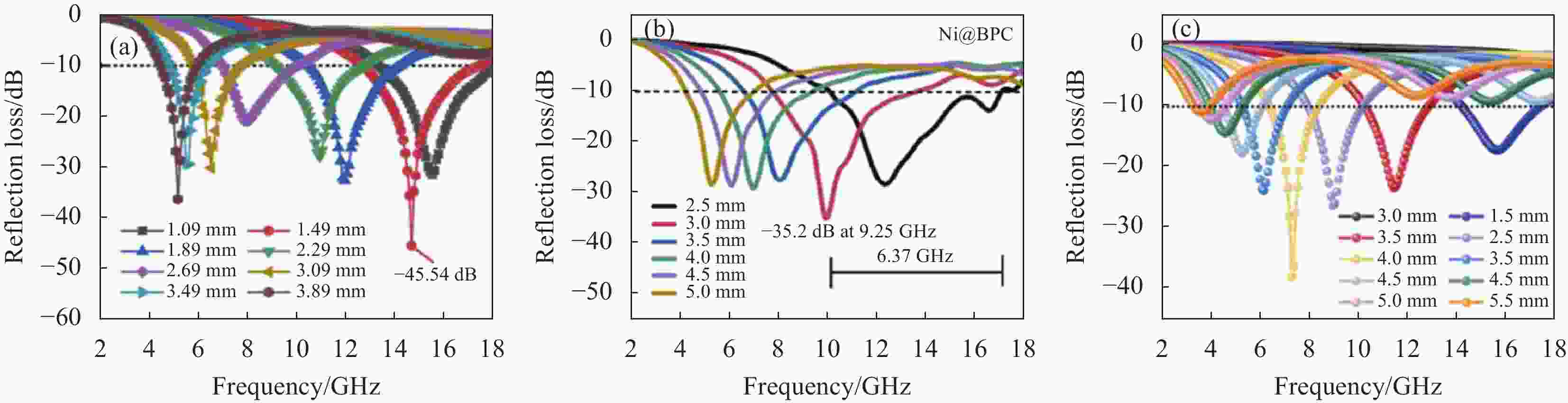

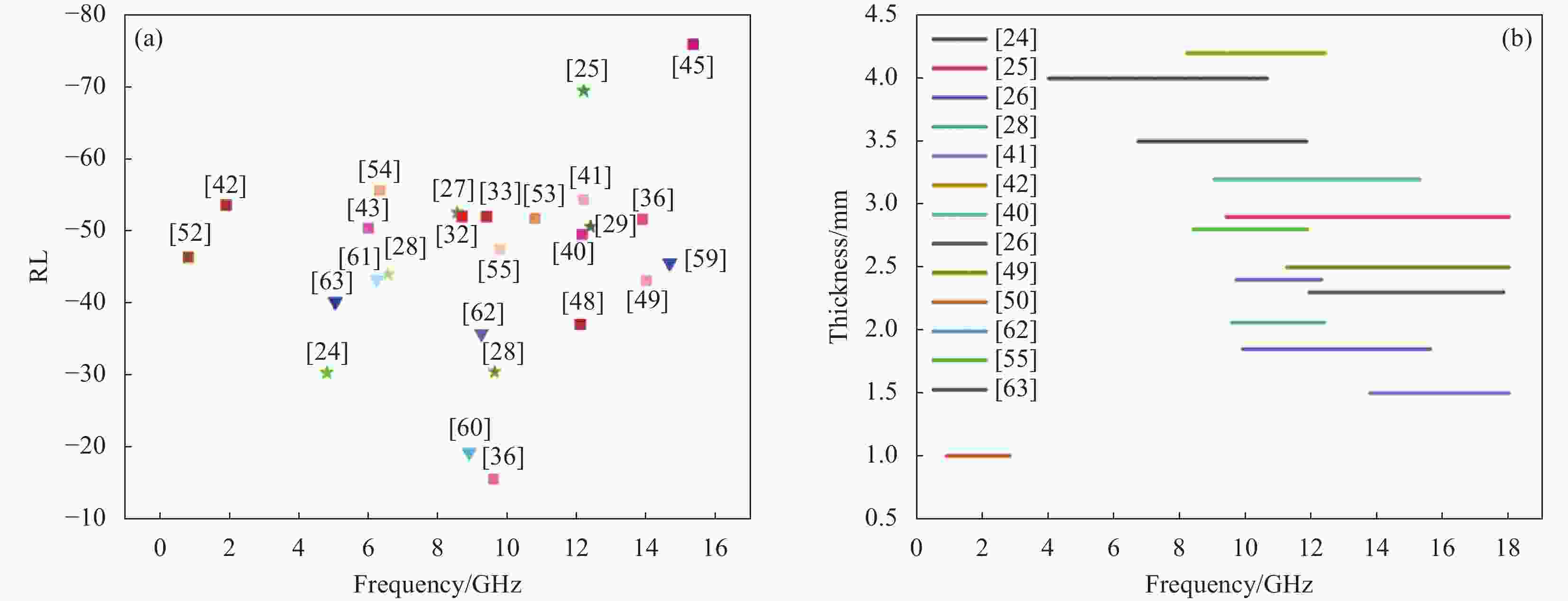

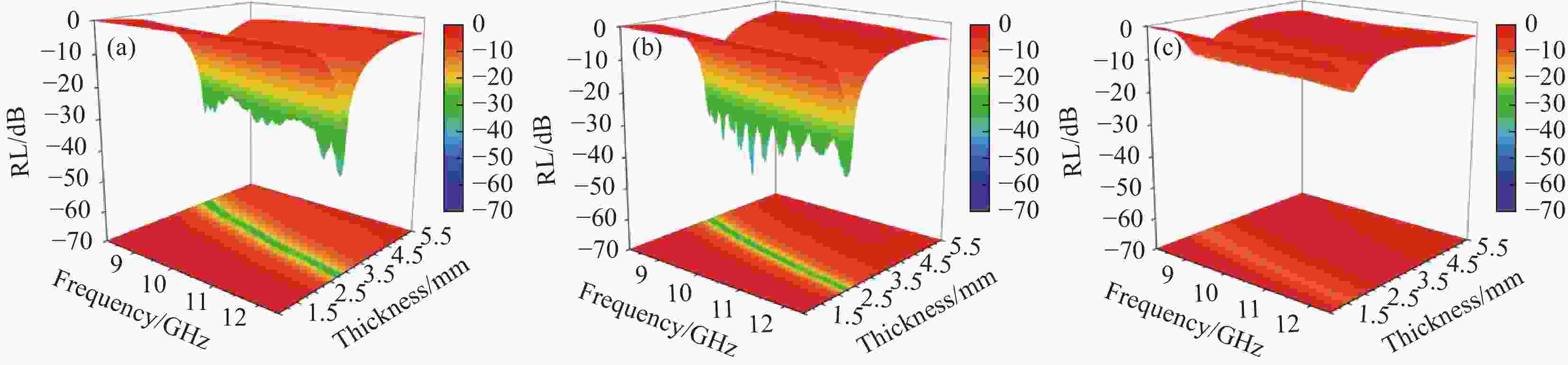

Table 9. Microwave absorption properties of carbon based composite absorbing materials derived from primary biomass

Precursor

materialAmount of

fill/wt%Abosober Thickness/mm Frequence/GHz RLmin/dB EAB/GHz Distribution Area

of EAB/GHzRef. Spirulina 18.6 Fe3O4@BDC 1.49 14.68 −45.54 5.14 12.45-17.59 [59] 60 Ni/BDC 3 8.9 −19.2 4 [60] Nori 30 NiCo2O4/BDC 5.5 6.24 −43.20 3.3 [61] 28.6 Ni@BDC 3.0 9.25 −35.73 [62] 2.5 6.37 10.35-16.72 30 MnO2/BDC 5.5 5.04 −40.16 [63] 3.5 5.12 6.72-11.84 Kelp 30 NiO-NixSy/BDC 3 7.28 −38.2 2.05 6.33–8.38 [64] 表 10 真菌类、植物类、原生生物类生物质组成成分及吸波机制特点总结

Table 10. Summarizes the composition and absorbing mechanism characteristics of fungi, plants and protists.

Biomass species Structural components Characteristics of absorbing mechanism Fungus Chitin, cellulose Natural heteroatoms P and Fe produce more defects; Phosphorus atoms form a polarization center, which increases the dipole polarization loss. Natural iron ions give magnetic loss Plants Lignin, cellulose, hemicellulose Lignin, cellulose decomposition, and diaryl ether bond cleavage produce a large amount of CO, and the framework cell wall begins to become rough and fluffy, forming more pore structures Protista Cellulose, hemicellulose, pectin After the cellulose reticulum is carbonized, a network of extensive aromatic porous carbon with a macroporous structure is formed. After the pyrolysis of a large number of nitrogen-containing proteins, nitrogen enters the crystal lattice, forming lattice defects and dipoles, forming polarization centers and increasing polarization losses 表 11 真菌类、植物类、原生生物类生物质微观结构及吸波机制特点总结

Table 11. Summary of microscopic structure and wave absorbing mechanism of fungi, plants and protists

Types of BDC Carbon structure Pore size/nm Absorbing mechanism Microstructure and mechanistic characteristics Fungus Multicellular Bulk porous carbon combined with a honeycomb carbon fiber mesh 0.5-5 1. A large number of polarization sites and structural defects;

2. Pore structure to improve impedance matching;

3. Charge polarization due to the gas/solid interface;

4. The lattice defect becomes the polarization center and improves the dipole polarization;

5. Three-dimensional conductive network to improve conductive loss;

6. Magnetic particles provide magnetic loss;

7. The heterogeneous interface provides interfacial polarization lossThe internal pores provide a large number of magnetic particle adsorption sites; Natural heteroatoms form polarization centers to enhance dipole polarization Unicellular Carbon microspheres, cellular efflux, and chitin pyrolysis form micropores 5-15 Plants Leaf Honeycomb hexagonal pores 1.2-2 /4 The internal inorganic salts act as templates, and the surface patterns of the blades form a rough undulating surface Stem/trunk Hollow frame three-dimensional carbon fiber layer, internal vascular and tracheid carbon channels 2/2-50 The wavelength of the incident electromagnetic wave is smaller than the size of the cell and tracheid to be absorbed, and some carbonized stems have a threaded structure Fruit/seed shell Honeycomb porous layered pores with natural mass transfer channels and multi-level pore structures inside 1.4-4/4-50 Amorphous soft carbon with low crystallinity and small grain size Protista Phaeophyta Flaked/filamentous porous carbon with numerous porous folds on the surface 1-3 Hard carbon, which is difficult to graphitize, retains its original shape more stably and completely after heat treatment Spirulina Spiral structure porous carbon 2-5 The spiral structure creates multiple areas of eddy current loss -

[1] DENG S, AI H M, WANG B M. Research on the electromagnetic wave absorption properties of GNPs/EMD cement composite[J]. Construction and Building Materials, 2022, 321: 126398. doi: 10.1016/j.conbuildmat.2022.126398 [2] ZHANG W, XIANG H, DAI F Z, et al. Achieving ultra-broadband electromagnetic wave absorption in high-entropy transition metal carbides (HE TMCs)[J]. Journal of Advanced Ceramics, 2022, 11(4): 545-555. doi: 10.1007/s40145-021-0554-2 [3] YAN X, JI T, YE W, et al. Surface Modification of activated carbon fibers with Fe3O4 for enhancing their electromagnetic wave absorption property[J]. Journal of Nanomaterials, 2020, 2020: 1-14. [4] WU N, LIU X, OR S W. Core/shell-structured nickel/nitrogen-doped onion-like carbon nanocapsules with improved electromagnetic wave absorption properties[J]. AIP Advances, 2016, 6(5): 056206. doi: 10.1063/1.4943357 [5] ZHOU X, JIA Z, FENG A, et al. Synthesis of porous carbon embedded with NiCo/CoNiO2 hybrids composites for excellent electromagnetic wave absorption performance[J]. J Colloid Interface Sci, 2020, 575: 130-139. doi: 10.1016/j.jcis.2020.04.099 [6] 武志红, 姚程, 蒙真真, 等. 生物质衍生碳基复合吸波材料的研究进展[J]. 硅酸盐学报, 2022, 50(7): 2056-2066WU Z H, YAO C, MENG Z Z, et al. Research progress on biomass derived carbonaceous composite microwave absorbing materials[J]. Journal of the Chinese ceramic society, 2022, 50(7): 2056-2066(in Chinese). [7] PANCHAKARLA L S, GOVINDARAJ A, RAO C N. Nitrogen- and boron-doped double-walled carbon nanotubes[J]. ACS Nano, 2007, 1(5): 494-500. doi: 10.1021/nn700230n [8] QIAO J, ZHANG X, XU D, et al. Design and synthesis of TiO2/Co/carbon nanofibers with tunable and efficient electromagnetic absorption[J]. Chemical Engineering Journal, 2020, 380: 122591. doi: 10.1016/j.cej.2019.122591 [9] WEI Y, YUE J, TANG X Z, et al. Enhanced magnetic and microwave absorption properties of FeCo-SiO2 nanogranular film functionalized carbon fibers fabricated with the radio frequency magnetron method[J]. Applied Surface Science, 2018, 428: 296-303. doi: 10.1016/j.apsusc.2017.09.079 [10] 尚楷. SiC/竹炭(BC)多孔复合材料的制备及吸波性能研究[D]. 西安建筑科技大学, 2024.SHANG K. Study on preparation of SiC/ bamboo carbon (BC) porous composites and their absorbing properties [D]. Xi 'an University of Architecture and Technology, 2024(in Chinese). [11] KHARBER N N, ALI F Z, ABDULLAH H, et al. Return Loss Simulation of Coconut Ashes in Microwave Absorber Brick[J]. ASiDCON 2018 Proceeding Book, 2018: 46. [12] LAN D, ZHOU H, WU H. A polymer sponge with dual absorption of mechanical and electromagnetic energy[J]. J Colloid Interface Sci, 2023, 633: 92-101. doi: 10.1016/j.jcis.2022.11.102 [13] OU J, DENG H, ZHANG H, et al. Nitrogen and phosphorus co-doped porous carbon prepared by direct carbonization method as potential anode material for Li-ion batteries[J]. Diamond and Related Materials, 2022, 124: 108931. doi: 10.1016/j.diamond.2022.108931 [14] BERGNA D, VARILA T, ROMAR H, et al. Activated carbon from hydrolysis lignin: Effect of activation method on carbon properties[J]. Biomass and bioenergy, 2022, 159: 106387. doi: 10.1016/j.biombioe.2022.106387 [15] YIN P, ZHANG L, SUN P, et al. Apium-derived biochar loaded with MnFe2O4@C for excellent low frequency electromagnetic wave absorption[J]. Ceramics International, 2020, 46(9): 13641-13650. doi: 10.1016/j.ceramint.2020.02.150 [16] 陆晓欣. 碳纤维增强树脂基复合材料表面阻抗调制与结构吸波性能研究 [D]. 哈尔滨工业大学, 2014.Lu X X, Research on the surface impedance modulation and structural absorbing properties of carbon fiber reinforced plastic [D]. Harbin Engineering University, 2014(in Chinese). [17] CHENG Y, ZHAO H, LV H, et al. Lightweight and flexible cotton aerogel composites for electromagnetic absorption and shielding applications[J]. Advanced electronic materials, 2019, 6(1): 1900796. [18] HAN D, OR S W, DONG X, et al. FeSn2/defective onion-like carbon core-shell structured nanocapsules for high-frequency microwave absorption[J]. Journal of alloys and compounds, 2017, 695: 2605-2611. doi: 10.1016/j.jallcom.2016.11.167 [19] 万佳宁, 章炉军, 周陈力, 等. 利用石蜡切片方法观察香菇子实体发育初期组织结构[J]. 食用菌学报, 2021, 28(4): 82-90.WAN J N, ZHANG L J, ZHOU C L, et al. Microscopic observation of early fruiting body development of lentinual edodes by a modified Paraffin Section Method[J]. Acta Edulis Fungi, 2021, 28(4): 82-90(in Chinese). [20] 孙春水, 郭德才, 陈剑. 碳化木耳多孔碳的制备及在硫正极中的应用[J]. 储能科学与技术, 2021, 10(6): 2060-2068.HOU G Y. Preparation and research of carbonized agaric material for sulfur cathodes[J]. Energy Storage Science and Technology, 2021, 10(6): 2060-2068(in Chinese). [21] 侯光耀. 核壳结构CoNi纳米合金/碳复合催化剂制备及析氧性能研究 [D]. 哈尔滨: 哈尔滨工业大学, 2022.HOU G Y. Preparation and oxygen evolution performance of core-shell structure coni nano alloys/carbon composite catalyst [D]. Harbin: Harbin Institute of Technology, 2022(in Chinese). [22] 胡青桃, 张文达, 李涛, 等. 香菇生物质基氮掺杂微孔碳材料的制备及其在超级电容器中的应用[J]. 无机化学学报, 2020, 36(8): 1573-1581.HU Q T, ZHANG W D, LI T, et al. Preparation and application in supercapacitors of shiitake biomass based nitrogen doped microporous carbon[J]. Chinese journal of inorganic chemistry, 2020, 36(8): 1573-1581(in Chinese). [23] WEN J, HE P, LEI C, et al. Fabrication of metal-organic framework@Yeast composite materials for efficient removal of Pb2+ in water[J]. Journal of Solid State Chemistry, 2019, 274: 26-31. doi: 10.1016/j.jssc.2019.03.011 [24] 强荣, 冯帅博, 李婉莹, 等. 生物质衍生磁性碳基复合材料的制备及其吸波性能[J]. 纺织学报, 2022, 43(1): 21-27.QIANG R, FENG S F, CHEN W Y, et al. Biomass-derived magnetic carbon composites towards microwave absorption[J]. Journal of Textile Research, 2022, 43(1): 21-27(in Chinese). [25] ZHENG H, NAN K, LU Z, et al. Core-shell FeCo@carbon nanocages encapsulated in biomass-derived carbon aerogel: Architecture design and interface engineering of lightweight, anti-corrosion and superior microwave absorption[J]. J Colloid Interface Sci, 2023, 646: 555-566. doi: 10.1016/j.jcis.2023.05.076 [26] LIU T, LIU N, GAI L, et al. Hierarchical carbonaceous composites with dispersed Co species prepared using the inherent nanostructural platform of biomass for enhanced microwave absorption[J]. Microporous and Mesoporous Materials, 2020, 302: 110210. doi: 10.1016/j.micromeso.2020.110210 [27] DONG Y, ZHU X, PAN F, et al. Implanting NiCo2O4 equalizer with designable nanostructures in agaric aerogel-derived composites for efficient multiband electromagnetic wave absorption[J]. Carbon, 2022, 190: 68-79. doi: 10.1016/j.carbon.2022.01.008 [28] SU J, YANG R, ZHANG P, et al. Fe/Fe3O4/biomass carbon derived from agaric to achieve high-performance microwave absorption[J]. Diamond and Related Materials, 2022, 129: 109386. doi: 10.1016/j.diamond.2022.109386 [29] LU Z, REN F, GUO Z, et al. Facile construction of core-shell Carbon@CoNiO2 derived from yeast for broadband and high-efficiency microwave absorption[J]. J Colloid Interface Sci, 2022, 625: 415-424. doi: 10.1016/j.jcis.2022.06.012 [30] WU Z, JIN C, YANG Z, et al. Integrating hierarchical interfacial polarization in yeast-derived Mo2C/C nanoflower/microsphere nanoarchitecture for boosting microwave absorption performance[J]. Carbon, 2022, 189: 530-538. doi: 10.1016/j.carbon.2021.12.073 [31] 陈天驰. 泥炭藓的超亲水机理研究 [D]. 北京: 中国矿业大学, 2018.CHEN T C. Study on Superhydrophilic Mechanism of Sphagnum [D]. Beijing: China University of Mining and Technology, 2018(in Chinese). [32] WANG B, ZHANG Y, YANG Y, et al. Facile preparation of carbon nanosheet frameworks/magnetic nanohybrids with heterogeneous interface as an excellent microwave absorber[J]. Journal of Alloys and Compounds, 2020, 838: 155586. doi: 10.1016/j.jallcom.2020.155586 [33] 张艳. 生物质碳材料及生物质碳/磁性粒子复合材料的微波吸收性能研究[D]. 秦皇岛: 燕山大学, 2020.ZHANG Y. Microwave absorption performance of biomass carbon materials and biomass carbon/magnetic nanoparticlecomposites [D]. Qinhuangdao: Yanshan University, 2020(in Chinese). [34] MAO F, LONG L, ZENG G, et al. Achieving excellent electromagnetic wave absorption property by constructing VO2 coated biomass carbon heterostructures[J]. Diamond and Related Materials, 2022, 130: 109422. doi: 10.1016/j.diamond.2022.109422 [35] 江泽鹏. 银杏叶基多孔炭材料的制备及其应用的研究[D]. 北京: 北京化工大学, 2020.JIANG Z P. Preparation and applications of ginkgo leaf deiuved porous carbon materials [D]. Beijing: Beijing University of Chemical Technology, 2020. (in Chinese). [36] LU J, YAN X, LIU D, et al. In situ loading of calcium sulfide on N, S Co-doped porous carbon derived from ginkgo biloba leaves to ameliorate the mechanism of electromagnetic wave absorption[J]. Vacuum, 2023, 211: 111933. doi: 10.1016/j.vacuum.2023.111933 [37] 王沈南. 热处理温度对杉木木材性质的影响机制研究 [D]. 北京: 中国林业科学研究院, 2017.WANG S N. Effect mechanism of heat treatment temperature on wood properties of Chinese fir [D]. Beijing: Chinese Academy of Forestry, 2017(in Chinese). [38] CHENG M, REN W, Li H, et al. Multiscale collaborative coupling of wood-derived porous carbon modified by three-dimensional conductive magnetic networks for electromagnetic interference shielding[J]. Composites Part B:Engineering, 2021, 224: 109169. doi: 10.1016/j.compositesb.2021.109169 [39] 樊正强, 彭立民, 刘美宏, 等. 微波处理对辐射松吸声性能的影响[J]. 林业科学, 2021, 57(7): 142-149.FAN Z Q, PENG L M, LIU M H, et al. Effect of microwave treatment on the sound absorption performance of radiata Pine[J]. Scientia silvae sinicae, 2021, 57(7): 142-149(in Chinese). [40] 杨喜, 曹敏, 简煜, 等. 多孔木炭/Fe3O4复合吸波材料的制备与性能[J]. 复合材料学报, 2022, 39(10): 4590-4601.WANG X, CAO M, JIAN Y, et al. Preparation and microwave absorption properties of porous charcoal/ Fe3O4 composites[J]. Acta materae compositae siniac(in Chinese). [41] JI C, LIU Y, XU J, et al. Enhanced microwave absorption properties of biomass-derived carbon decorated with transition metal alloy at improved graphitization degree[J]. Journal of Alloys and Compounds, 2022, 890: 161834. doi: 10.1016/j.jallcom.2021.161834 [42] JI C, LIU Y, LI Y Y. Facile preparation and excellent microwave absorption properties of cobalt-iron/porous carbon composite materials[J]. Journal of Magnetism and Magnetic Materials, 2021, 527: 167776. doi: 10.1016/j.jmmm.2021.167776 [43] 汪帆. 多孔碳基材料的制备及吸波性能研究 [D]. 兰州: 兰州理工大学, 2021.WANG F. Research on the preparation and microwave absorbing properties of porous carbon-based materials [D]. Lanzhou: Lanzhou University of Technology, 2021(in Chinese). [44] 武志红, 李妤婕, 张聪, et. al. 竹炭/SiC复合材料结构及其吸波性能[J]. 硅酸盐学报, 2018, 46(1): 150-155.WU Z H, LI Y J, ZHANG C, et al. Structure and Microwave Absorption Properties of Bamboo Charcoal/SiC Composites[J]. Journal of the Chinese Ceramic Society, 2018, 46(1): 6(in Chinese). [45] ZHAO H, CHENG Y, LIU W , et al. Biomass derived porous carbon based nanostructures for microwave absorption[J]. Nano-Micro Letters, 2019, 11(2): 81-97. [46] ZHOU X, JIA Z, FENG A, et al. Dependency of tunable electromagnetic wave absorption performance on morphology-controlled 3D porous carbon fabricated by biomass[J]. Composites Communications, 2020, 21: 100404. doi: 10.1016/j.coco.2020.100404 [47] 刘海燕, 廉士珍, 王秀飞, 等. 玉米秸秆不同部位纤维组成和结构的研究[J]. 粮食与饲料工业, 2017, (11): 55-58.LIU H Y, LIAN S Z, WANG X F, et al. Fibre composition and structure of different fractions of corn stalk[J]. Food and feed industry, 2017, (11): 55-58(in Chinese). [48] ASLAM M A, DING W, UR R S, et al. Low cost 3D bio-carbon foams obtained from wheat straw with broadened bandwidth electromagnetic wave absorption performance[J]. Applied Surface Science, 2021, 543: 148785. doi: 10.1016/j.apsusc.2020.148785 [49] SONG W, ZHAO Q, WANG Z. Magnetic biomass porous carbon@Co/CoO nanocomposite for highly efficient microwave absorption[J]. Materials Research Bulletin, 2023, 167: 112371. doi: 10.1016/j.materresbull.2023.112371 [50] YIN P, ZHANG L, JIANG Y, et al. Recycling of waste straw in sorghum for preparation of biochar/(Fe, Ni) hybrid aimed at significant electromagnetic absorbing of low-frequency band[J]. Journal of Materials Research and Technology, 2020, 9(6): 14212-14222. doi: 10.1016/j.jmrt.2020.10.034 [51] 苏建君. 稻壳基纳米碳化硅的制备及吸波性能研究 [D]. 武汉: 武汉科技大学, 2017.SU J J. Synthesis and electromagnetic wave absorption properties of silicon carbide nanomaterials from rice husks [D]. Wuhan: Wuhan University of Science and Technology, 2017. (in Chinese). [52] 周帆, 毕辉, 黄富强. 用稻壳制备亚甲基蓝高吸附容量的超高比表面积活性炭[J]. 无机材料学报, 2021, 36(8): 893-903. doi: 10.15541/jim20200632ZHOU F, BI H, HUANG F Q. Ultra large specific surface area activated carbon synthesized from rice husk with high adsorption capacity for methylene blue[J]. Journal of Inorganic Materials, 2021, 36(8): 893-903(in Chinese). doi: 10.15541/jim20200632 [53] SHU X, FANG B, WU W, et al. Acicular or octahedral Fe3O4/rice husk-based activated carbon composites through graphitization synthesis as superior electromagnetic wave absorbers[J]. Composites Part A:Applied Science and Manufacturing, 2021, 151: 106635. doi: 10.1016/j.compositesa.2021.106635 [54] YAN L, XIANG J, LI Y, et al. Facile synthesis of NiCo2 nanoparticles grown on rice husk waste-derived porous carbon for high-efficiency microwave absorption[J]. Journal of Materials Research and Technology, 2023, 24: 9780-9792. doi: 10.1016/j.jmrt.2023.05.177 [55] WU Z, MENG Z, YAO C, et al. Rice husk derived hierarchical porous carbon with lightweight and efficient microwave absorption[J]. Materials Chemistry and Physics, 2022, 275: 125246. doi: 10.1016/j.matchemphys.2021.125246 [56] KHARBER N N, DAMIT D S A, ABDULLAH H, et al. Characteristic of biomass percentage in cement brick composites microwave absorber [C]//2017 International Conference on Electrical, Electronics and System Engineering, 2017: 21-26. [57] MISHRA S P, NATH G, MISHRA P. Ultrasonically synthesized dielectric microwave absorbing material from coconut coir dust[J]. Waste and Biomass Valorization, 2020, 11: 1481-1490. doi: 10.1007/s12649-018-0478-4 [58] ZHANG Y, CHENG H, LIU J, et al. Laver derived carbon as an anode for sibs with excellent electrochemical performance[J]. International Journal of Electrochemical Science, 2020, 15(6): 5144-5153. doi: 10.20964/2020.06.86 [59] CHEN T, CAI J, GONG D, et al. Facile fabrication of 3D biochar absorbers dual-loaded with Fe3O4 nanoparticles for enhanced microwave absorption[J]. Journal of Alloys and Compounds, 2023, 935(1): 168085. [60] 顾鹏. 微生物负载Ni吸波材料的制备及性能研究 [D]. 镇江: 江苏大学, 2012.GU P. Study on the preparation and properties of microbial supported Ni absorbing materials [D]. Zhenjiang: Jiangsu University, 2012(in Chinese). [61] 陈晓雯, 罗驹华, 江陈烨, 等. NiCo2O4/BPC复合材料的制备及吸波性能研究[J]. 现代化工, 2022, 42(1): 140-144.CHEN X W, LUO Yihua, JIANG Chenye, et al. Preparation of NiCo2O4 /BPC composite and study on its properties in absorbing microwave[J]. Modern Chemical Industry, 2022, 42(1): 140-144(in Chinese). [62] WANG Z, XU G. 3D porous Ni@BPC composites for enhanced electromagnetic wave absorption[J]. Journal of Alloys and Compounds, 2022, 24(2): 647-674 [63] 陈晓雯. 紫菜衍生多孔碳材料吸波性能增强方法及吸波机理研究 [D]. 镇江: 江苏大学, 2021.CHEN X W. Research on improving microwave absorption property of porphyra derived porous carbon and its absorbing mechanism [D]. Zhenjiang: Jiangsu University, 2021(in Chinese). [64] WANG X T, XIAO Z Y, NIU W S, et al. Nickel oxide/sulfide nanoparticle-embedded porous carbon prepared from kelp for excellent asymmetrical supercapacitors and microwave absorbers[J]. Journal of Alloys and Compounds, 2022, 918: 165721. doi: 10.1016/j.jallcom.2022.165721 -

点击查看大图

点击查看大图

计量

- 文章访问数: 53

- HTML全文浏览量: 34

- 被引次数: 0

下载:

下载: