Advances in silica aerogel composites and their research in aerospace

-

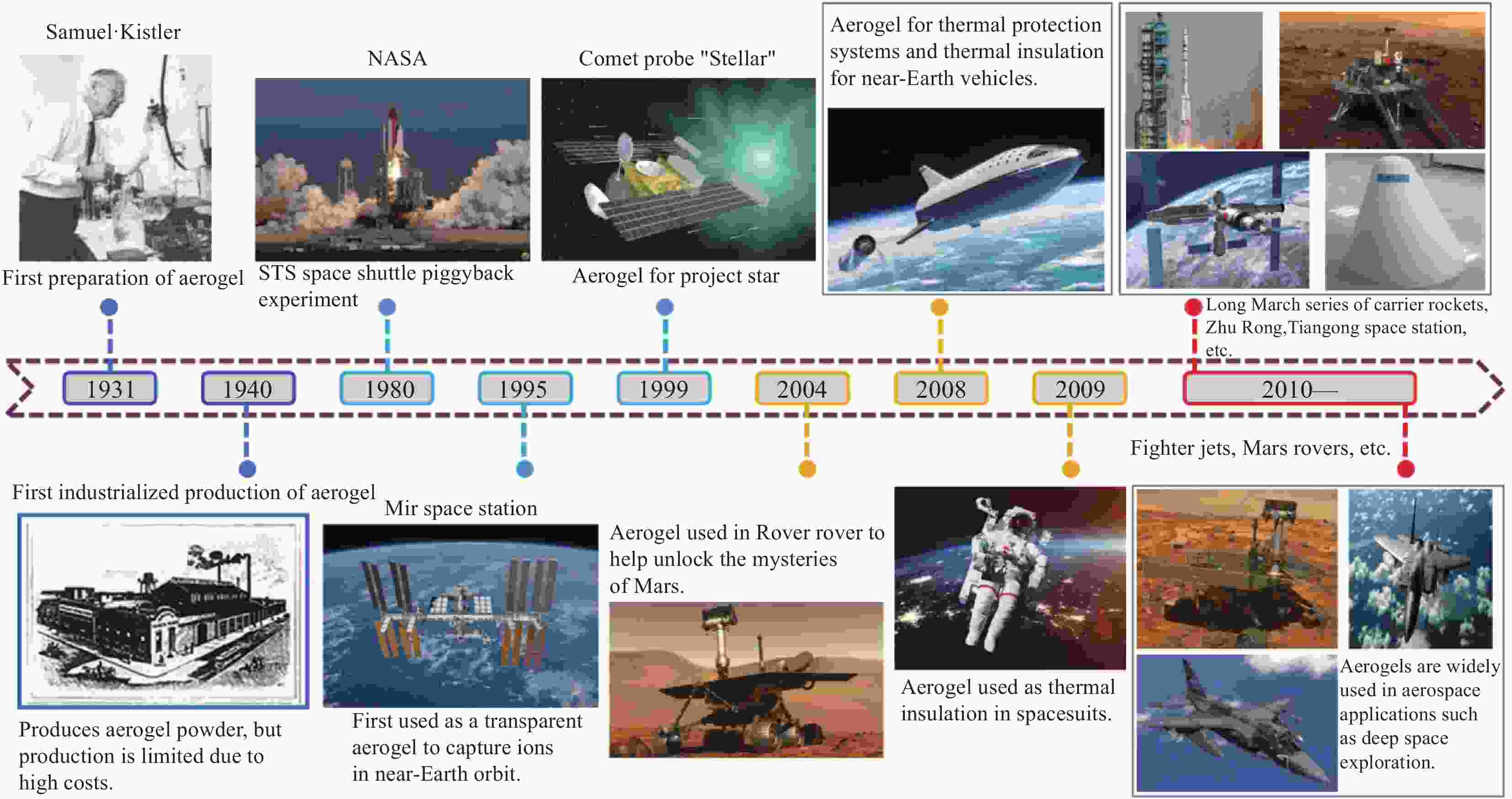

摘要: 航空航天作为目前最前沿、最基础和最具影响力的科学技术研究领域,其科学研究发展水平是衡量国家科学技术创新性的重要标志。航空航天保温隔热材料作为航空航天技术发展最重要的技术支撑,如何制备出具有良好保温隔热性能和机械强度的材料对航空航天技术的发展具有重要意义。SiO2气凝胶凭借超低热导率、高孔隙率、高比表面积和超低密度等优异性能,在深空探测器、太阳能翻板、航天飞机发动机、固体火箭助推器和返回舱底座等特种工程设备材料具有较好的应用前景。近年来,随着SiO2气凝胶研究方法与制备技术的不断发展,通过将其与具有高强度、耐高温性等功能材料进行复合,可协同提升其保温隔热和机械强度等性能,对航空航天特种工程材料发展至关重要。鉴于此,本文简述了SiO2气凝胶的发展历程,详细分析总结了SiO2气凝胶与常见氧化物、纤维增强和有机聚合物等增强材料复合形成的气凝胶复合材料在航空航天领域的研究进展,主要从SiO2气凝胶复合材料的制备方法、结构特征、保温隔热、力学性能等方面进行评述,并展望了SiO2气凝胶复合材料在该领域研究应用所存在的问题、面临的挑战和未来发展方向。Abstract: As the most cutting-edge, basic and influential science and technology research field, the level of scientific research development is an important symbol to measure the innovation of national science and technology. However, aerospace thermal insulation materials are the most important technical support for the development of aerospace technology, and how to prepare materials with good thermal insulation properties and mechanical strength is of great significance for the development of aerospace technology. Silicon dioxide aerogel with ultra-low thermal conductivity, high porosity, high specific surface area and ultra-low density and other excellent properties, in the deep space probe, solar panels, space shuttle engines, solid rocket boosters and return capsule base and other special engineering equipment materials have a better application prospects.. In recent years, with the continuous development of silica aerogel research methods and preparation technology, by compounding it with functional materials with high strength and high temperature resistance, it can synergistically enhance its properties such as thermal insulation and mechanical strength, which is crucial for the development of aerospace special engineering materials. In view of this, this paper briefly describes the development history of silica aerogel, analyzes and summarizes in detail the research progress of aerogel composites formed by compositing silica aerogel with common oxides, fiber-reinforced and organic polymers and other reinforcing materials in the field of aerospace, and mainly comments on the preparation method, structural characteristics, heat insulation, mechanical properties, etc., and looks ahead to the problems, challenges, and future directions of the research and application of silica aerogel composites in this field.

-

Key words:

- silica aerogels /

- oxide aerogels /

- fiber-reinforced /

- phases organic polymers /

- mechanical reinforcement /

- aerospace

-

图 4 (a)~(d):ZrO2-SiO2-X 的照片;(e)~(h):多重浸渍过程示意图:图(f)-(h)中的蓝点代表多重浸渍过程中形成的ZrO2和SiO2纳米颗粒[33]

Figure 4. (a)~(d): The photographs of ZrO2-SiO2-X; (e)~(h): The illustration of the multiple impregnation process (the blue dots in figure (f)-(h) represent ZrO2 and SiO2 nanoparticles formed during multiple impregnation process)[33]

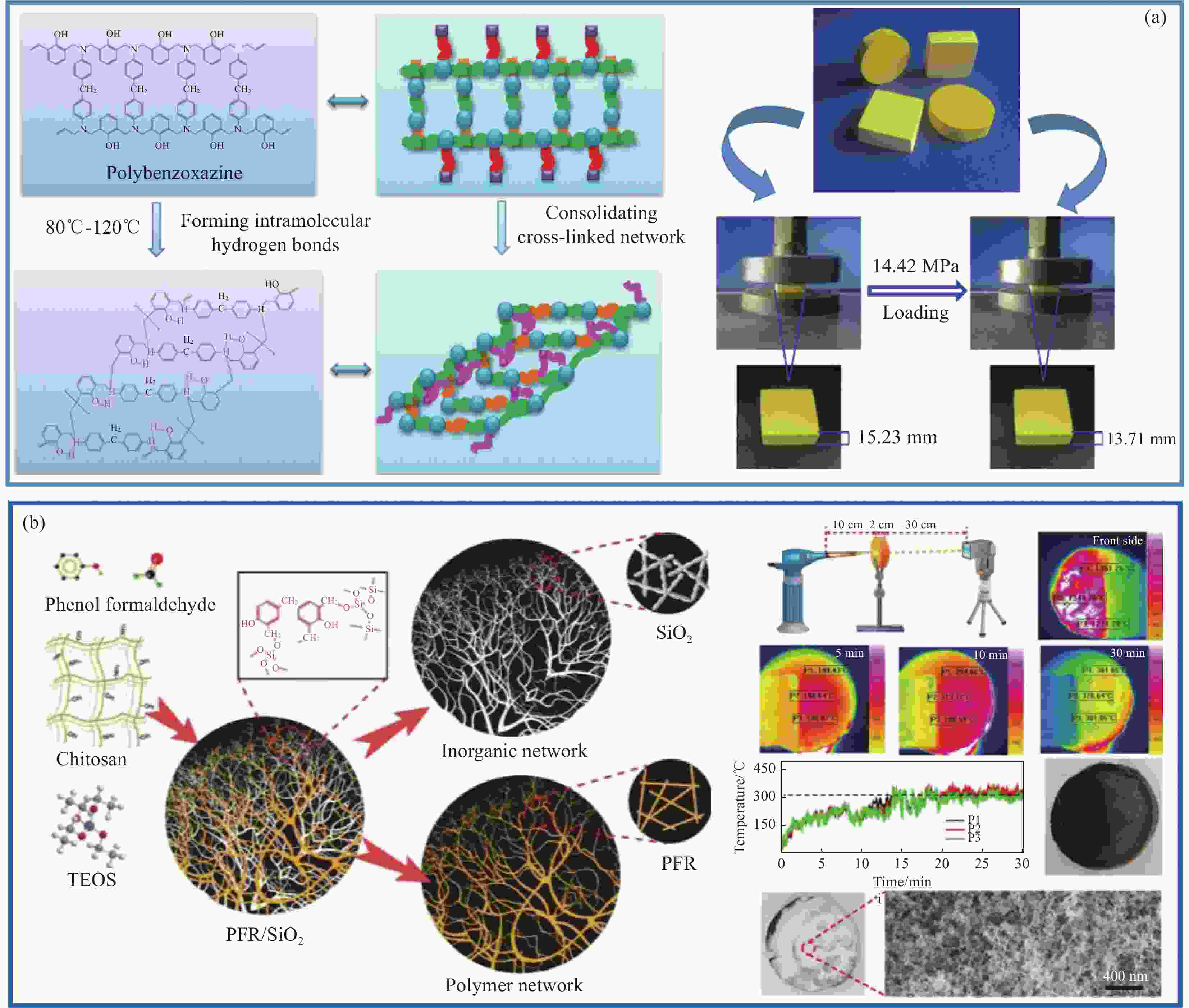

图 9 有机聚合物复合SiO2气凝胶的合成机理:(a)聚苯并恶嗪(PBO)气凝胶中分子内氢键形成和负载下的抗压强度[71];(b)互穿二元网络酚醛树脂(PFR)/SiO2复合气凝胶的合成和结构组成[75]

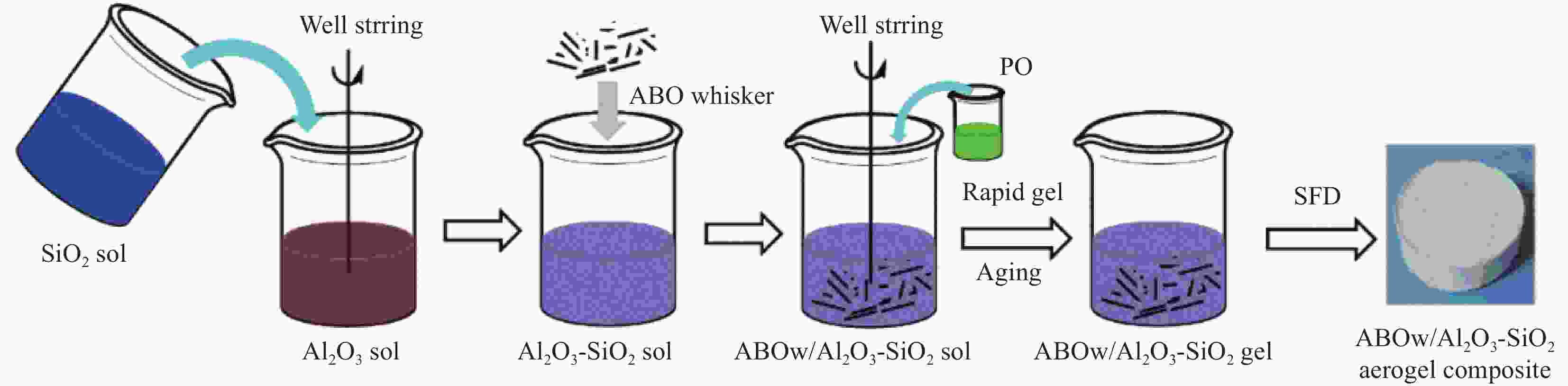

Figure 9. Synthesis mechanism of organic polymer composite silica aerogels: (a) intramolecular hydrogen bond formation and compressive strength under loading in PBO aerogels[71]; (b) synthesis and structural composition of interpenetrating binary network PFR/SiO2 composite aerogels[75]

表 1 常见SiO2气凝胶复合材料主要性能特征及应用对比情况

Table 1. Comparison of the main performance characteristics and applications of common silica aerogel composites

Forms Reinforcing phase material Main Performance Characteristics Key scientific questions References Thermal conductivity/(W·(m·K)-1) Mechanical strength

/MPaSpecific surface area

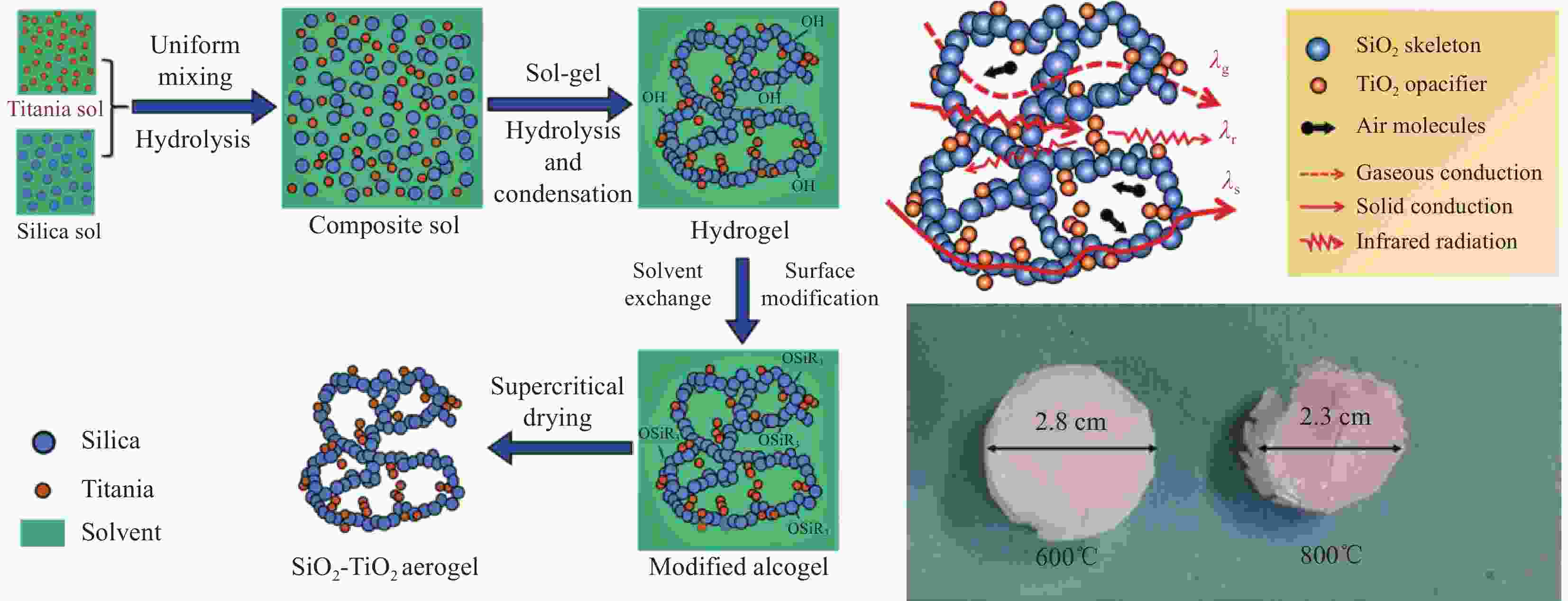

(m2/g)/%High porosity

/%

Pore volume

/(m3·g-1)Low density

/(g·m-3)Oxide-reinforced composite SiO2 aerogels Al2O3 0.029-

0.0401.400 122.70-123.90 m2/g 63.10% 0.250 It mainly solves the technical bottleneck of reuse of aircraft thermal insulation materials and improves the high-temperature structural stability of SiO2 aerogel composites, which can be used as thermal insulation materials for aircraft shells, solar cells and other devices. [15-17] TiO2 — — 105-645

m2/g2.63-2.85

m3/g— [20-21] ZrO2 0.024-

0.0320.510-3.110 59.20% 90.8% 0.160-

0.460[32-33] Fiber-reinforced SiO2 composite aerogel Glass fiber 0.019-

0.0260.580-12.000 870.90

m2/g— 0.239 The mechanical strength of SiO2 aerogel composites has been enhanced by fiber reinforcement, which can be used as a good super-insulating and thermal protection material for spacecraft. [39-44] Ceramic fiber 0.022-

0.1820.050-1.050 — — — [46-47,50] Carbon fiber 0.024-

0.5301.000-2.846 746.87 m2/g 89.10% 0.005 [54-56] Organic polymer composite SiO2 aerogel Polyurethane

(PU)0.028-

0.1300.221-0.486 — — — It mainly solves the properties of durability, heat insulation and mechanical strength of materials in the air and space environment, and is expected to solve the technical difficulties of heat insulation materials under special aerospace conditions. [61,65] Polyimide

(PI)0.020-

0.05714.42 51.00-75.00% 90.00% 0.050-

0.412[67,71] Phenol formaldehyde

(PF)— 39.22-57.22 — — 0.200 [75-76] -

[1] KISTLER S S. Coherent Expanded Aerogels and Jellies[J]. Nature, 1931, 127: 741-741. [2] KISTLER S S. Coherent Expanded-Aerogels[J]. Journal of Physical Chemistry, 1932, 36(1): 52-64. doi: 10.1021/j150331a003 [3] 吴晓栋, 宋梓豪, 王伟, 等. 气凝胶材料的研究进展[J]. 南京工业大学学报( 自然科学版), 2020, 42(4): 405-451.WU Xiaodong, SONG Zihao, WANG Wei, et al. Advances of aerogels materials[J]. Journal of Nanjing Tech University (Natural Science Edition), 2020, 42(4): 405-451(in Chinese). [4] 潘月磊, 程旭东, 闫明远, 等. 二氧化硅气凝胶及其在保温隔热领域应用进展[J]. 化工进展, 2023, 42(1): 297-309.PAN Yuelei, CHENG Xudong, YAN Mingyuan, et al. Silica aerogel and its application in the field of thermal insulation[J]. Chemical Industry and Engineering Progress, 2023, 42(1): 297-309(in Chinese). [5] 裴雨辰, 张晚林, 李文静, 等. 空天领域气凝胶研究与应用进展[J]. 空天技术, 2022, (1): 64-73.PEI Yuchen, ZHANG Wanlin, LI Wenjing, et al. Research status and application prospect of aerogels in the aerospace field[J]. Aerospace Technology, 2022, (1): 64-73(in Chinese). [6] 张鹏飞, 梁龙, 陶积柏, 等. 深空环境下热防护材料的研究及应用进展[J]. 深空探测学报, 2016, 3(1): 77-82.ZHANG Pengfei, LIANG Long, TAO Jibai, et al. Research and development of thermal protection materials applied in deep space exploration[J]. Journal of Deep Space Exploration, 2016, 3(1): 77-82(in Chinese). [7] 邢悦, 井致远, 陈永雄, 等. 航空航天用气凝胶材料的研究进展[J]. 材料导报, 2022, 36(22): 137-151.XING Yue, JING Zhiyuan, CHEN Yongxiong et al. Research process on aerogel materials used for Aviation and Aerospace[J]. Materials Reports, 2022, 36(22): 137-151(in Chinese). [8] GOLD V, LOENING K L, MCNAUGHT A D, et al. International union of pure and applied chemistry compendium of chemical terminology IUPAC recommendations[M]. Oxford: Blackwell Scientific Publications Limited, 1987: 230. [9] LINHARES T, PESSOA DE A M, DURÃES L. Silica aerogel composites with embedded fibres: A review on their preparation, properties and applications[J]. Journal of Materials Chemistry A, 2019, 7(40): 22768-22802. doi: 10.1039/C9TA04811A [10] BODAY Dylan, MURIITHI Beatrice, STOVER Robert, et al. Polyaniline nanofiber-silica composite aerogels[J]. Journal of NonCrystalli- ne Solids, 2012, 358(12/13): 1575-1580. [11] AEGERTER M, LEVENTIS N, KOEBEL M. Aerogels handbook[M]. USA: Springer Science and Business Media, 2011. [12] HÜSING Nicola, SCHUBERT Ulrich. Aerogels-airy materials: Chemistry, structure, and properties[J]. Angewandte Chemie International Edition, 1998, 37(1/2): 22-45. [13] KOCON L, DESPETIS F, PHALIPPOU B. Ultralow density silica aerogels by alcohol supercritical drying[J]. Journal of Non-Crystalline Solids, 1998, 225: 96-100. doi: 10.1016/S0022-3093(98)00322-6 [14] JIA H , LIU S , MAO Z , et al. Preparation and properties of the Al2O3-SiO2 aerogel/alumina framework composite[J]. Ceramics International, 2020, 47(01): 1466-1471. [15] HOU X, ZHANG R, FANG D. Novel whisker-reinforced Al2O3-SiO2 aerogel composites with ultra-low thermal conductivity[J]. Ceramics International, 2017, 43(12): 9547-9551. doi: 10.1016/j.ceramint.2017.04.043 [16] YANG Z, ZHU D, LI H. A chitosan-assisted co-assembly synthetic route to low-shrinkage Al2O3-SiO2 aerogel via ambient pressure drying[J]. Microporous and Mesoporous Materials, 2020, 293: 109781. doi: 10.1016/j.micromeso.2019.109781 [17] 张恩爽, 黄红岩, 刘韬, 等. 结构强健的Al2O3-SiO2气凝胶的制备及可重复使用性能[J]. 高等学校化学学报, 2019, 40(12): 2566-2573.ZHANG Enshuang, HUANG Hongyan, LIU Tao, et al. Synthesis and reusable properties of robust Al2O3-SiO2 Aerogel[J]. Chemical Journal of Chinese universities, 2019, 40(12): 2566-2573(in Chinese). [18] 吴佳臻, 徐长伟, 张忠伦, 等. Al2O3-SiO2复合纳米气凝胶材料耐高温性能研究[J/OL]. 复合材料科学与工程: 1-9[2023-04-25]. http://kns.cnki.net/kcms/detail/10.1683.tu.20230306.1802.002.html.WU Jiazhen, XU Changwei, ZHANG Zhonglun, et al. High temperature resistance of Al2O3-SiO2 composite Nano Aerogel Materials[J/OL]. Composites science and engineering: 1-9[2023-04-25]. http://kns.cnki.net/kcms/detail/10.1683.tu.20230306.1802.002.html(in Chinese). [19] 纪跃成, 李晓雷, 于慧君, 等. Al2O3-SiO2复合气凝胶的制备及改性剂对其结构与隔热性能的影响[J]. 复合材料学报, 2020, 37(3): 635-641.JI Yuecheng, LI Xiaolei, YU Hujun, et al. Preparation of Al2 O3-SiO2 composite aerogel and effect of modifier on its structure and thermal insulation properties[J]. Acta Materiae Compositae Sinica, 2020, 37(3): 635-641 (in Chinese). [20] 刘敬肖, 冷小威, 史非, 等. 常压干燥制备TiO2-SiO2复合气凝胶的结构与性能[J]. 硅酸盐学报, 2010, 38(12): 2296-2302.LIU Jinxiao, LENG Xiaowei, SHI Fei, et al. Microstructure and properties of TiO2-SiO2 composite aerogels prepared via the ambient pressure drying[J]. Journal of the Chinese ceramic society, 2010, 38(12): 2296-2302(in Chinese). [21] 冷小威, 刘敬肖, 史非, 等. TiO2-SiO2复合气凝胶: 常压干燥制备及性能表征[J]. 无机化学学报, 2009, 25(10): 1791-1796.LENG Xiaowei, LIU Jingxiao, SHI Fei, et al. TiO2-SiO2 composite aerogel: Preparation by ambient pressure drying process and characterization[J]. Chinese Journal of inorganic chemistry, 2009, 25(10): 1791-1796(in Chinese). [22] LIU, JX. , SHI, F. , BAI, LN. et al. Synthesis of TiO2-SiO2 aerogel via ambient pressure drying: effects of sol pre-modification on the microstructure and pore characteristics[J]. Journal of Sol-Gel Science and Technology 2014, 69: 93-101. [23] LIU Jia, LIU Jingxiao, SHI Fei. et al. F/W co-doped TiO2-SiO2 composite aerogels with improved visible light-driven photocatalytic activity[J]. Journal of Solid State Chemistry, 2019, 275: 8-15. doi: 10.1016/j.jssc.2019.03.042 [24] REN Y, Li W, CAO Z, et al. Robust TiO2 Nanorods-SiO2 Core-Shell Coating with High-Performance Self-Cleaning Properties under Visible Light[J]. Applied Surface Science, 2020, 509: 145377. doi: 10.1016/j.apsusc.2020.145377 [25] LIU S, WU X, LI Y, et al. Hydrophobic in-situ SiO2-TiO2 composite aerogel for heavy oil thermal recovery: synthesis and high temperature performance[J]. Applied Thermal Engineering, 2021, 190: 116745. doi: 10.1016/j.applthermaleng.2021.116745 [26] 傅颖怡, 丁新更, 孟成, 等. SiO2/TiO2复合气凝胶的孔道结构研究[J]. 材料科学与工艺, 2015, 23(2): 1-7.FU Yingyi, DING Xingeng, MENG Cheng, et al. Synthesis and pore structure of porous SiO2 /TiO2 composite aerogel[J]. Materials science and technology, 2015, 23(2): 1-7(in Chinese). [27] 刘朝辉, 侯根良, 苏勋家, 等. 热处理温度对TiO2/SiO2复合气凝胶光催化性能的影响[J]. 无机材料学报, 2012, 27(10): 1179-1183.LIU Zhaohui, HOU Genliang, SU Xunjia, et al. Effects of heat treatment temperature on photocatalytic activity of TiO2/SiO2 composite aerogels[J]. Journal of inorganic materials, 2012, 27(10): 1179-1183(in Chinese). [28] 夏正斌, 涂伟萍, 杨卓如, 等. 建筑隔热涂料的研究进展[J]. 精细化工, 2001, (10): 599-602.XIA Zhengbin, TU Weiping, YANG Zhuoru, et al. Advances in devlopment of thermal insulation coatings[J]. Fine Chemicals, 2001, (10): 599-602(in Chinese). [29] 侯先波, 叶长收, 张如炳. 轻质ZrO2-SiO2气凝胶复合材料的制备及性能研究[C]//北京力学会. 北京力学会第二十四届学术年会会议论文集.HOU Xianbo, YE Changcheng, ZHANG Rubing. Preparation and properties of lightweight ZrO2-SiO2 aerogel composites[C]//Beijing Mechanics Society. Proceedings of the 24th Annual Conference of the Beijing Mechanics Society(in Chinese). [30] 邹文兵, 沈军, 祖国庆, 等. 耐高温ZrO2/SiO2复合气凝胶的制备及表征[J]. 南京工业大学学报(自然科学版), 2016, 38(2): 42-46.ZOU Wenbing, SHEN Jun, ZU Guoqing, et al. Preparation and characterization of heat-resistant zirconia/silica composite aerogel[J]. Journal of Nanjing Tech University ( Natural Science Edition), 2016, 38(2): 42-46(in Chinese). [31] 朱俊阳, 陈恒, 刘瑞祥. ZrO2-SiO2复合气凝胶的制备及其热稳定性研究[J]. 现代技术陶瓷, 2016, 37(1): 47-53.ZHU Jun-Yang, CHEN Heng, LIU Rui-Xiang, et al. Preparation and Thermal Stability of ZrO2-SiO2 Composite Aerogels[J]. Advanced Ceramics, 2016, 37(1): 47-53(in Chinese). [32] YU H , TONG Z , QIAO Y , et al. High thermal stability of SiO2-ZrO2 aerogels using solvent-thermal aging[J]. Journal of Solid State Chemistry, 2020, 291: 121624. [33] HOU Xiaobo, ZHANG Rubing, WANG Baolin. Novel self-reinforcing ZrO2-SiO2 aerogels with high mechanical strength and ultralow thermal conductivity[J]. Ceramics International, 2018, 44(13): 15440-15445. doi: 10.1016/j.ceramint.2018.05.199 [34] 罗丹, 龙丽娟, 秦舒浩, 等. 玻璃纤维和碳纤维增强二氧化硅气凝胶复合材料的制备及性能研究[J]. 化工新型材料, 2022, 50(4): 161-165.LUO Dan, LONG Lijuan, QIN Shuhao, et al. Preparation and property of GF and CF reinforced SiO2 aerogel composites[J]. New Chemical Materials, 2022, 50(4): 161-165(in Chinese). [35] 石小靖, 张瑞芳, 何松, 等. 玻璃纤维增韧SiO2气凝胶复合材料的制备及隔热性能[J]. 硅酸盐学报, 2016, 44(1): 129-135.SHI Xiaojing, ZHANG Ruifang, HE Song, et al. Synthesis and heat insulation performance of glass fiber feinforced SiO2 aerogel composites[J]. Journal of the Chinese Ceramic Society, 2016, 44(1): 129-135(in Chinese). [36] 张怡, 葛欣国, 卢国建, 等. 硅酸铝纤维和玻璃纤维复合二氧化硅气凝胶材料的制备与性能[J]. 无机盐工业, 2020, 52(10): 68-71.ZHANG Yi, GE Xinguo, LU Guojian, et al. Synthesis and heat insulation performance of glass fiber reinforced SiO2 aerogel composites[J]. Inorganic Chemicals Industry, 2020, 52(10): 68-71(in Chinese). [37] 马佳, 沈晓冬, 崔升, 等. 纤维增强二氧化硅气凝胶复合材料的制备和低温性能[J]. 材料导报, 2015, 29(20): 43-46+63.MA Jia, SHEN Xiaodong, CUI Sheng, et al. Preparation and Low-temperature Properties of Fiber Reinforced SiO2 Aerogel Composites[J]. Materials Reports, 2015, 29(20): 43-46+63(in Chinese). [38] 周婷. 共前驱体法玻璃纤维增强SiO2气凝胶复合材料制备及燃烧性能研究[D]. 中国科学技术大学, 2019. , 2019(in Chinese).ZHOU Ting. Preparation and combustion performance study of glass fiber reinforced silica aerogel composites based on co-precursor method [D]. Hefei: University of Science and Technology of China [39] EHSAN U Haq, SYED Farrukh Alam Zaidi, MUHHAMMAD Zubair, et al. Hydrophobic silica aerogel glass-fibre composite with higher strength and thermal insulation based on methyltrimethoxysilane (MTMS) precursor[J]. Energy and Buildings, 2017, 151(10): 494-500. [40] ZHOU T, CHENG X, PAN Y, et al. Mechanical performance and thermal stability of glass fiber reinforced silica aerogel composites based on co-precursor method by freeze drying[J]. Applied Surface Science, 2018, 437(4): 321-328. [41] HUANG Yajun, HE Song, CHEN, Guangnan. et al. Fast preparation of glass fiber/silica aerogel blanket in ethanol and water solvent system[J]. Journal of Non-Crystalline Solids: 2019, 505(02): 286-291. [42] LI C, CHENG X, LI Z, et al. Mechanical, thermal and flammability properties of glass fiber film/silica aerogel composites[J]. Journal of Non-Crystalline Solids, 2017, 457(2): 52-59. [43] TIAN J , SHAFI S , TAN H , et al. Mechanical and thermal-insulating performance of silica aerogel enhanced jointly with glass fiber and fumed silica by a facile compressing technique[J]. Chemical Physics Letters, 2020, 739(01): 136950. [44] SHAFI Sameera, TIAN Jiaqi, NAVIK Rahul, et al. Fume silica improves the insulating and mechanical performance of silica aerogel/glass fiber composite[J]. The Journal of Supercritical Fluids, 2019, 148(6): 9-15. [45] 吕双祺, 孙燕涛, 腾雪峰, 等. 陶瓷纤维增强SiO2气凝胶复合材料面内拉伸非均匀全场应变测量与分析[J]. 复合材料学报, 2021, 38(7): 2336-2347.LV Shuangqi, SUN Yantao, TENG Xuefeng, et al. Measurement and analysis of in-plane tensile non-uniform full-field strain of ceramic fiber reinforced SiO2 aerogel composites[J]. Acta Materiae Compositae Sinica, 2021, 38(7): 2336-2347(in Chinese). [46] YANG X , SUN Y , SHI D. Experimental investigation and modeling of the creep behavior of ceramic fiber-reinforced SiO2 aerogel[J]. Journal of Non-Crystalline Solids, 2012, 358(3): 519-524. [47] JIAN H, LI X, DONG S, et al. Ultra-low thermal conductivity and high strength of aerogels/fibrous ceramic composites[J]. Journal of the European Ceramic Society, 2016, 36(6): 1487-1493. doi: 10.1016/j.jeurceramsoc.2015.11.021 [48] SLYU, S. , YANG, X. , SHI, D. et al. Effect of high temperature on compression property and deformation recovery of ceramic fiber reinforced silica aerogel composites[J]. Science China Technological Sciences, 2017, 60: 1681–1691 . [49] RAJPOOT Shalini, ROHIT Malik, YOUNG Wook Kim. Effects of polysiloxane on thermal conductivity and compressive strength of porous silica ceramics[J]. Ceramics International, 2019, 45(17): 21270-21277. doi: 10.1016/j.ceramint.2019.07.109 [50] AN Zhimin, HOU Xianbo, ZHOU Peng, et al. A novel flexible, layered, recoverable SiO2 fiber skeleton and aerogel composites material prepared by papermaking process[J]. Ceramics International, 2021, 47(9): 12963-12969. doi: 10.1016/j.ceramint.2021.01.159 [51] LIU He, LIU Jiabo, TIAN You. et al. Investigation of high temperature thermal insulation performance of fiber-reinforced silica aerogel composites[J]. International Journal of Thermal Sciences, 2023, 183: 107827 doi: 10.1016/j.ijthermalsci.2022.107827 [52] MEI Hui, LI Hao, JIN Zhipeng. et al. 3D-printed SiC lattices integrated with lightweight quartz fiber/silica aerogel sandwich structure for thermal protection system[J]. Chemical Engineering Journal, 2023, 454(3): 140408. [53] LU W, STEIGERWALT E S, MOORE J T, et al. Carbothermal transformation of a graphitic carbon nanofiber/silica aerogel composite to a SiC/silica nanocomposite.[J]. J Nanosci Nanotechnol, 2004, 4(7): 803-808. doi: 10.1166/jnn.2004.119 [54] LIU, Y. , CHEN, Z. , ZHANG, J. et al. Ultralight and thermal insulation carbon foam/SiO2 aerogel composites[J]. J Porous Mater, 2019, 26, 1305-1312. [55] HUNG W C, HORNG R S, SHIA R E. Investigation of thermal insulation performance of glass/carbon fiber-reinforced silica aerogel composites[J]. Journal of Sol-Gel Science and Technology, 2021, 97: 414-421. doi: 10.1007/s10971-020-05444-3 [56] WU X, SHAO G, SHEN X, et al. Evolution of the novel C/SiO2/SiC ternary aerogel with high specific surface area and improved oxidation resistance[J]. Chemical Engineering Journal, 2017, 330(10): 1022-1034. [57] AN Zhimin , YE Changshou, ZHANG Rubing , et al. Multifunctional C/SiO2/SiC-based aerogels and composites for thermal insulators and electromagnetic interference shielding[J]. Journal of Sol-Gel Science and Technology, 2019, 89(3). [58] AN R. Synthesis of monolithic SiC aerogels with high mechanical strength and low thermal conductivity[J]. Ceramics International, 2019, 45(9): 11368-11374. doi: 10.1016/j.ceramint.2019.02.216 [59] ZHANG J J, QU Z G, FU R P, et al. Experimental study on the transient thermal characteristics of an integrated deflector under the periodic impingement of a supersonic flame jet[J]. International Journal of Heat and Mass Transfer, 2015, 85(7): 811-823. [60] CHANG, KJ. , WANG, YZ. , PENG, KC, et al. Preparation of silica aerogel/polyurethane composites for the application of thermal insulation[J]. J Polym Res, 2014, 21: 338. [61] CHO J, JANG H G, KIM S Y, et al. Flexible and coatable insulating silica aerogel/polyurethane composites via soft segment control[J]. Composites Science and Technology, 2019, 171(2): 244-251. [62] LETIZIA Verdolotti, LAVORGNA M, LAMANNA R, et al. Polyurethane-silica hybrid foam by sol–gel approach: Chemical and functional properties[J]. Polymer, 2015, 56: 20-28. doi: 10.1016/j.polymer.2014.10.017 [63] Dourbash A, Buratti C, Belloni E, et al. Preparation and characterization of polyurethane/silica aerogel nanocomposite materials[J]. Journal of Applied Polymer Science, 2017, 134(8): 44521. doi: 10.1002/app.44521 [64] NAZERAN N, MOGHADDAS J. Synthesis and characterization of silica aerogel reinforced rigid polyurethane foam for thermal insulation application[J]. Journal of Non-Crystalline Solids, 2017, 461: 1-11. doi: 10.1016/j.jnoncrysol.2017.01.037 [65] LI Mengen, WANG Shuixiu, HAN Linxuan, et al. Hierarchically porous SiO2/polyurethane foam composites towards excellent thermal insulating, flame-retardant and smoke-suppressant performances[J]. Journal of Hazardous Materials, 2019, 375(8): 61-69. [66] LEE Dong Ik, HA Yeon Hee, JEON Hanyong. et al. Preparation and Properties of Polyurethane Composite Foams with Silica-Based Filler[J]. Applied Sciences-basel, 2022, 12(15): 7418. doi: 10.3390/app12157418 [67] KIM S. Y. , NOH Y. J. , LIM J. et al. Silica aerogel/polyimide composites with preserved aerogel pores using multi-step curing[J]. Macromol. Res, 2014, 22: 108-111. [68] XUE Rujing, LIU Guoliang, LIU Fujuan. A simple and efficient method for the preparation of SiO2/PI/AF aerogel composite fabrics and their thermal insulation performance[J]. Ceramics International, 2023, 49(1): 210-215 doi: 10.1016/j.ceramint.2022.08.330 [69] ZHOU Xiao, CHE Jing, LI Huaxin , et al. Superhydrophobic and elastic silica/polyimide aerogel based on double confinement growth strategy of the co-sol system[J]. Materials Chemistry Frontiers, 2022, 6(4): 482-490. [70] LI Jiaqiang, ZHANG, Ling, PANG Yucen. et al. Polyimide composite aerogels towards highly efficient microwave absorption and thermal insulation[J]. Composites Part A:Applied Science and Manufacturing, 2022, 161: 107112. doi: 10.1016/j.compositesa.2022.107112 [71] XIAO Y, LI L, ZHANG S, et al. Thermally insulating polybenzoxazine aerogels based on 4, 4′-diamino-diphenylmethane benzoxazine[J]. Journal of Materials Science, 2019, 54(15): .12951-12961. [72] KANTOR Zuzanna, WU Tingting, ZENG Zhihui, et al. Heterogeneous silica-polyimide aerogel-in-aerogel nanocomposites[J]. Chemical Engineering Journal, 2022, 443: 136401. doi: 10.1016/j.cej.2022.136401 [73] LIU R, WANG J, LIAO J, et al. Robust Silica–Polyimide Aerogel Blanket for Water-Proof and Flame-Retardant Self-Floating Artificial Island[J]. Frontiers in Materials, 2021, 8: 659655. doi: 10.3389/fmats.2021.659655 [74] ZHANG Jun, YIN Rong, CHENG Haiming, et al. Characterization, mechinical, thermal and ablative properties of ceramic modified phenolic resinaerogels synthsized by ambient pressure[C]//21st International Conference on Composite Materials (ICCM-21). 2017. [75] YU Zhilong, NING Yang, VARVARA Apostolopoulou-Kalkavoura, et al. Fire-Retardant and Thermally Insulating Phenolic-Silica Aerogels[J]. Angewandte Chemie, 2018, 57(17): 4538-4542. doi: 10.1002/anie.201711717 [76] WANG H, QUAN X, YIN L, et al. Lightweight quartz fiber fabric reinforced phenolic aerogel with surface densified and graded structure for high temperature thermal protection[J]. Composites, Part A. Applied science and manufacturing, 2022, (159): 107022. [77] WU K, ZHOU Q, CAO J, et al. Ultrahigh-strength carbon aerogels for high temperature thermal insulation.[J]. Journal of colloid and interface science, 2022, 609: 667-675. doi: 10.1016/j.jcis.2021.11.067 -

下载:

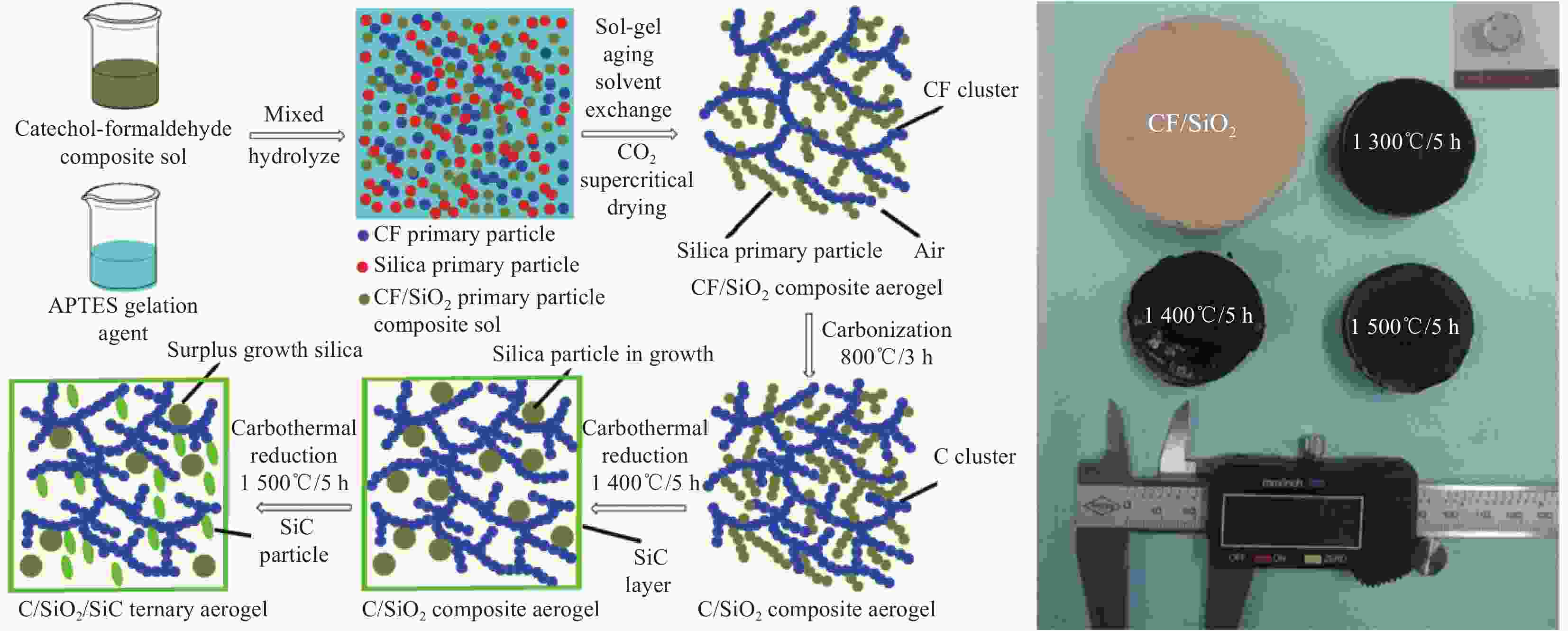

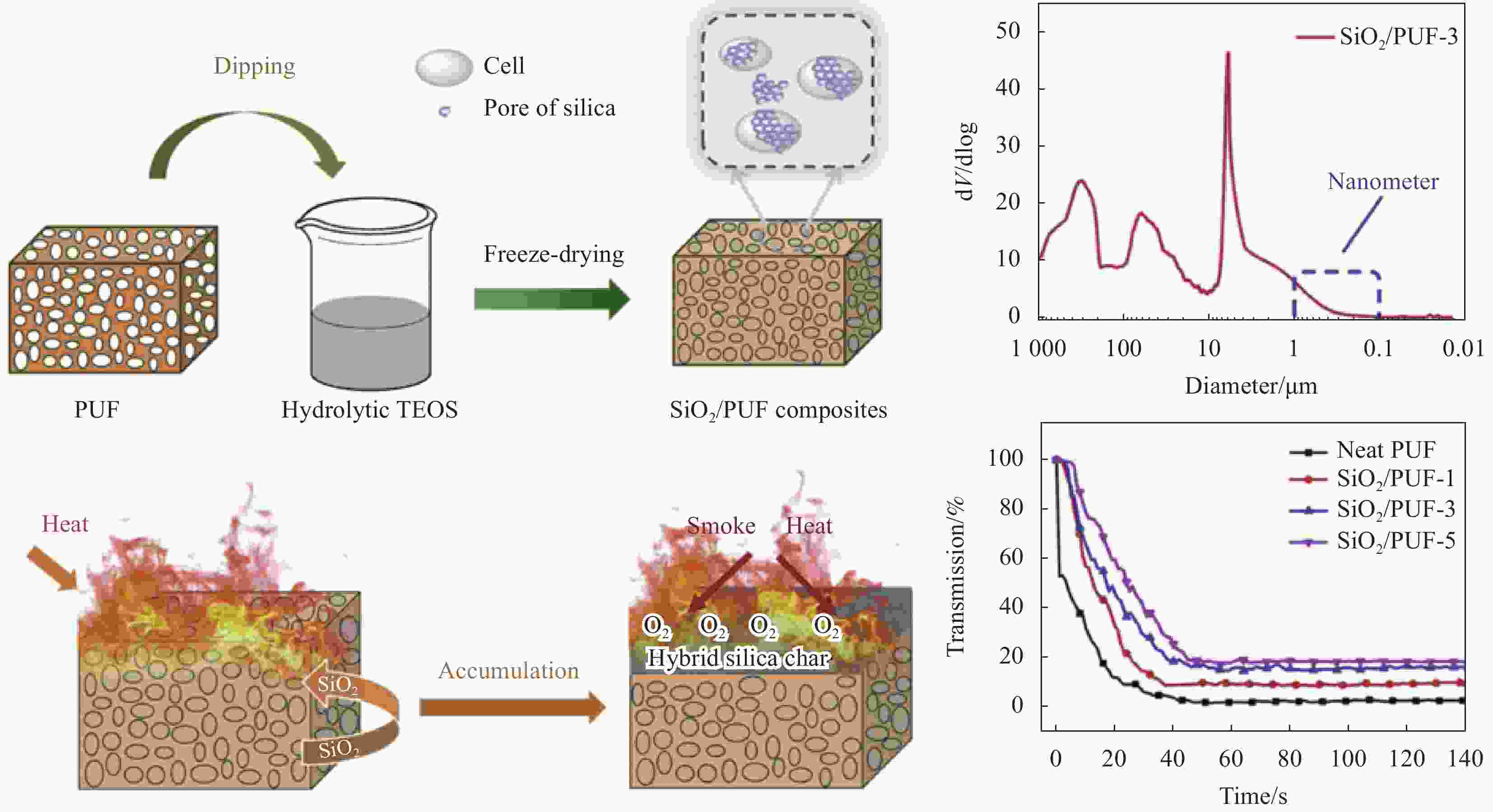

下载: