Study on Stretched Aramid Honeycomb cell Structure Based on the Viscoelastic Constitutive Model of Adhesive

-

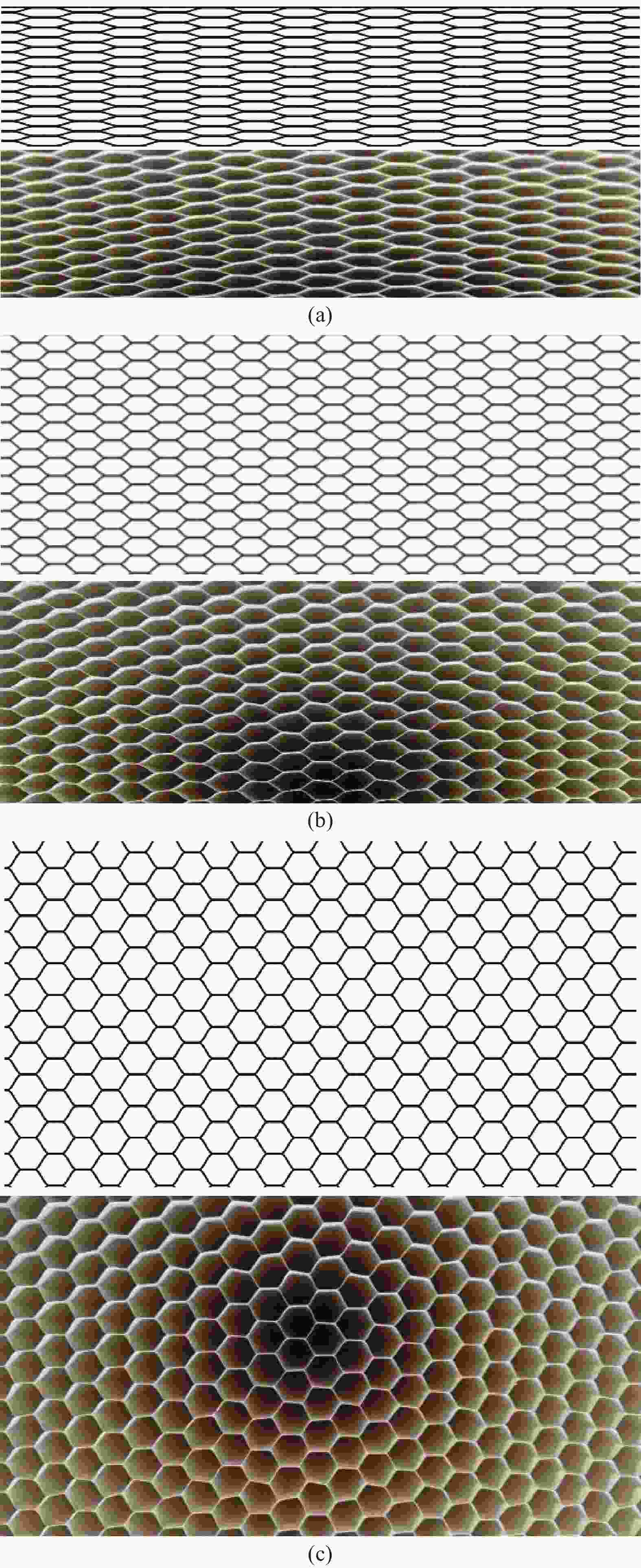

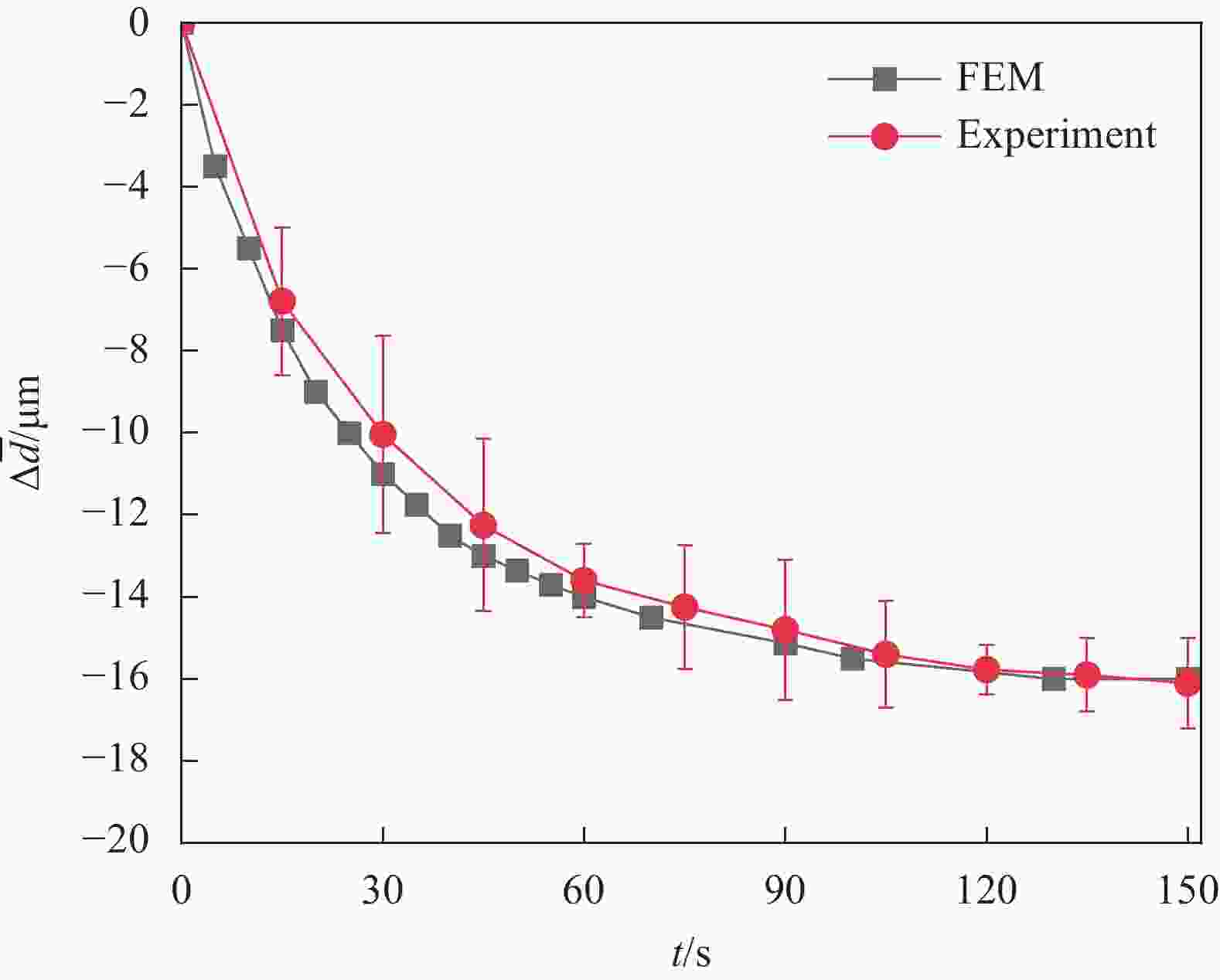

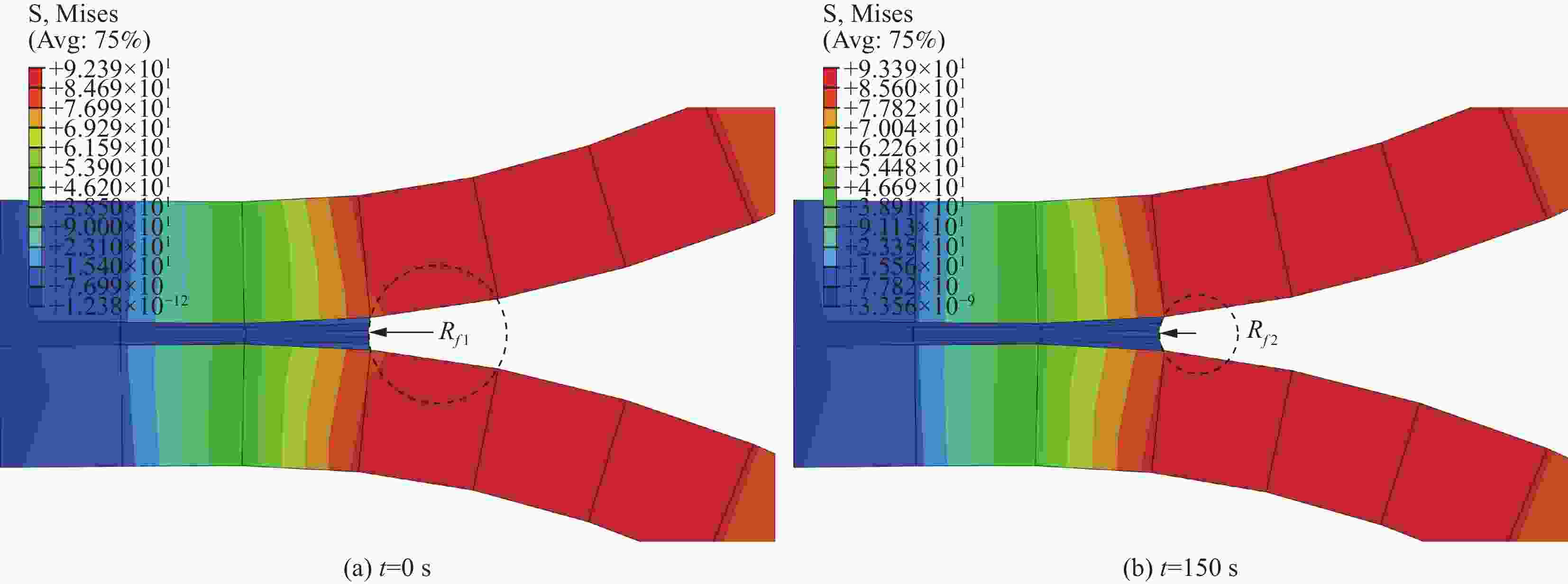

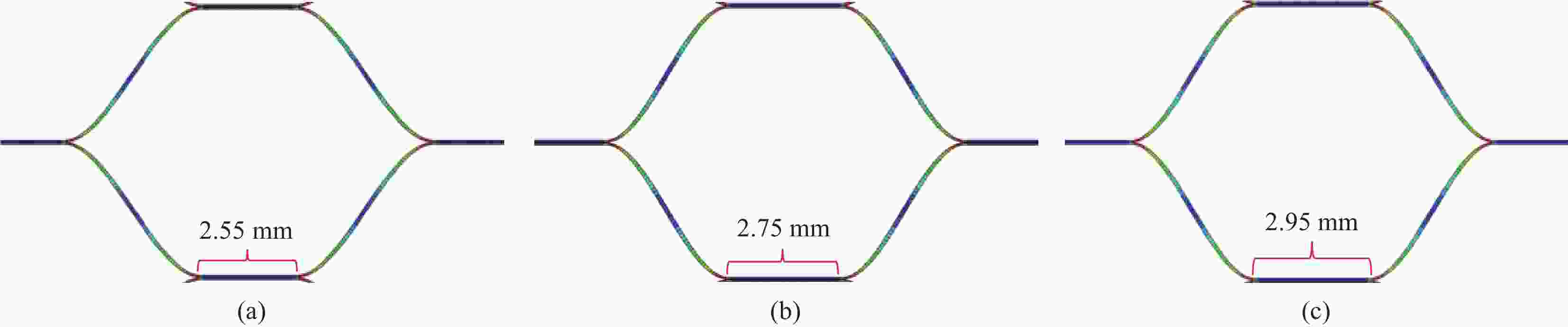

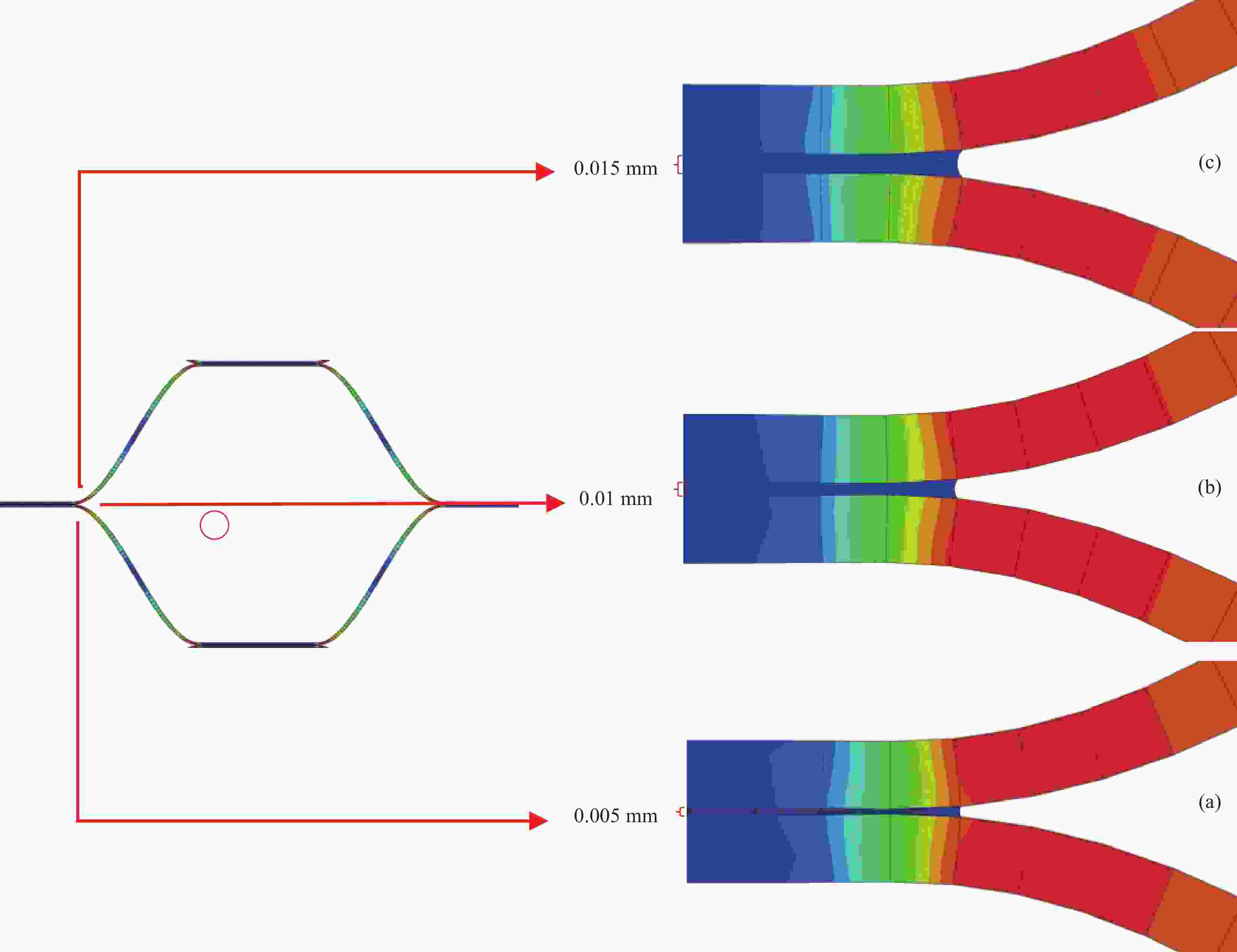

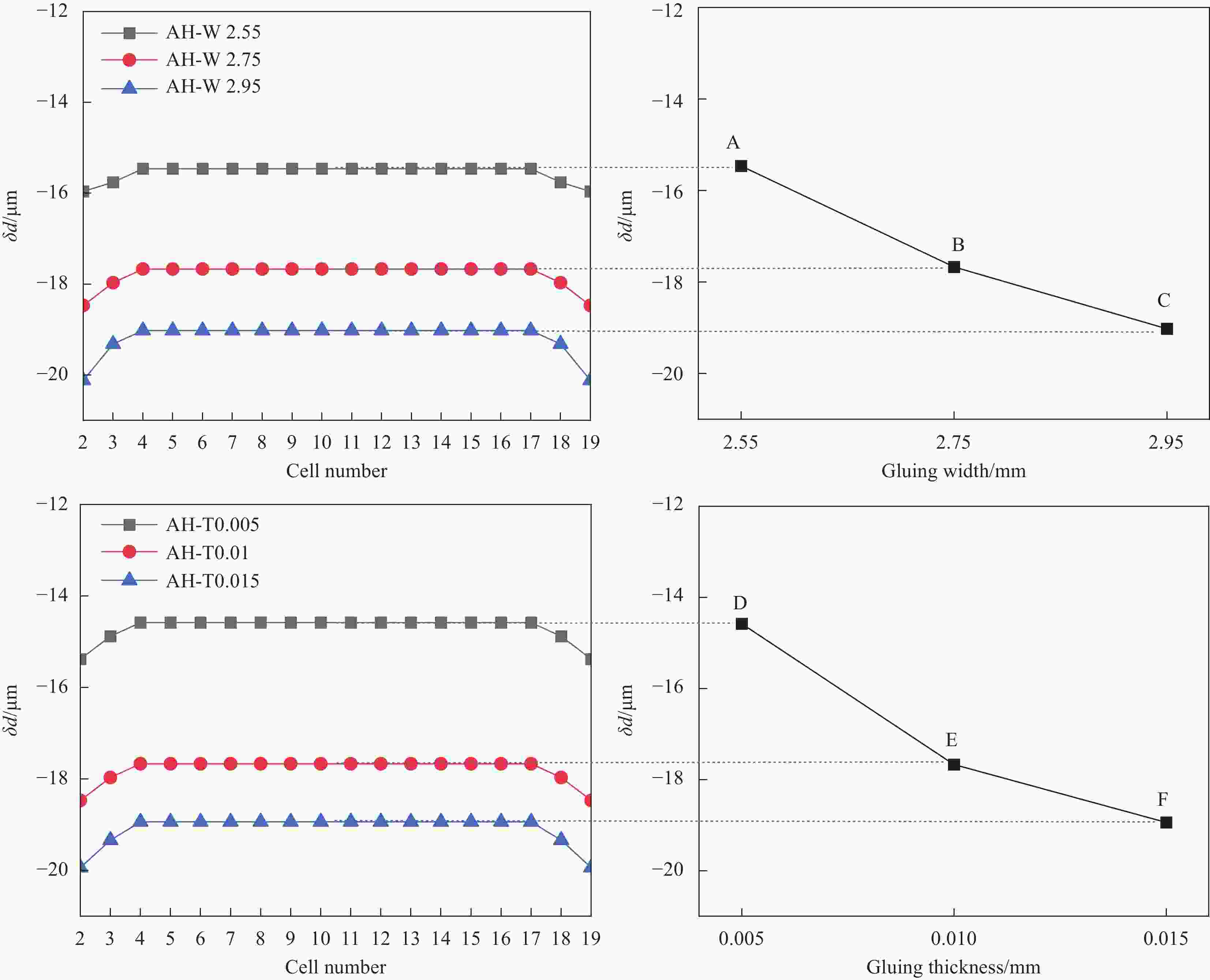

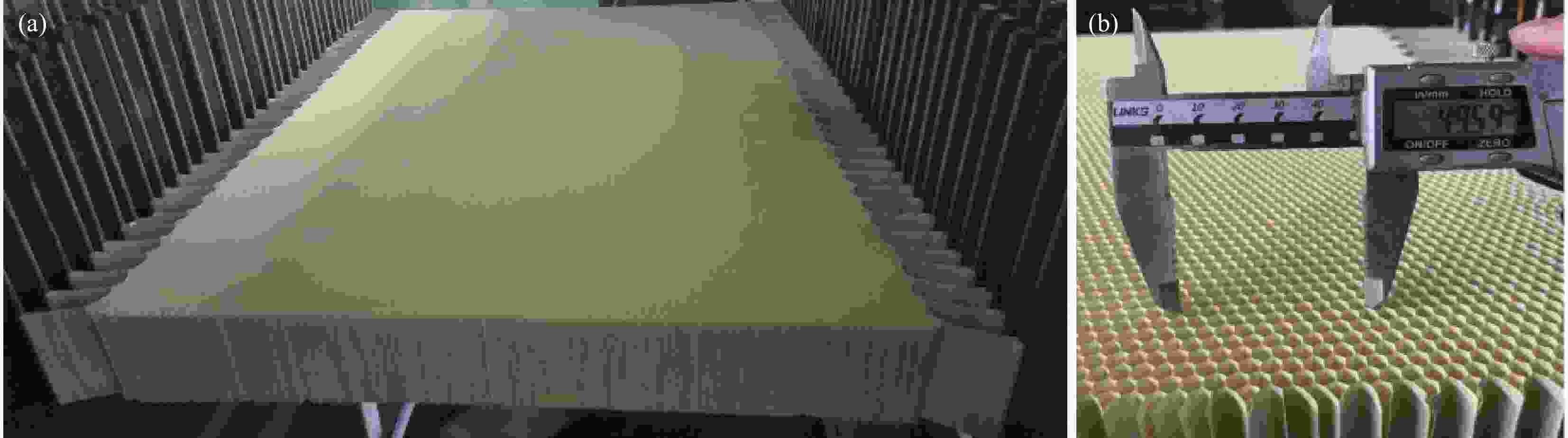

摘要: 拉伸工艺是影响芳纶纸蜂窝孔格形态最关键的工序之一。本研究基于纳米压痕法确定了芯条胶粘弹性力学本构关系,建立了芳纶纸蜂窝双边拉伸工艺有限元模型。通过蜂窝拉伸-保载实验验证了该模型的有效性。研究发现,芯条胶的应力松弛行为导致了蜂窝两端孔格内切圆直径增大,使得蜂窝中部孔格内切圆直径减小。同时,在保载过程中纸-胶粘接处孔格粘结圆角半径减小导致蜂窝孔格内角减小。最后,基于该有限元模型探索了涂胶工艺参数对拉伸后蜂窝孔格尺寸的影响规律。研究表明涂胶宽度和涂胶厚度的增加会导致蜂窝孔格内切圆直径的减小,而蜂窝孔格内角仅受涂胶宽度的影响,随涂胶宽度的增加而增大。Abstract: Stretching process is one of the critical procedures that affect the honeycomb cell structure of Aramid honeycomb. In this study, the viscoelastic constitutive relationship of node bond adhesive was determined by a fitting method based on nanoindentation, and a finite element model of honeycomb biaxial stretching process was established. The validity of the model was verified by the honeycomb stretching-holding experiment. The study found that the stress relaxation behavior of the adhesive caused an increase in the radius of the inscribed circles at both ends of the honeycomb and a decrease in the middle. Meanwhile, during the holding process, the node bond adhesive fillet radius decreased, leading to a decrease in the internal angle of the honeycomb cell. Finally, the influence of gluing process parameters on the size of honeycomb cell after stretching was explored based on the finite element model. The study showed that the increase in gluing width and thickness would lead to a decrease in the diameter of the inscribed circle of the honeycomb cell, and the honeycomb cell's internal angle was only affected by the gluing width, which increased with the gluing width.

-

Key words:

- Aramid honeycomb /

- Adhesive /

- Viscoelasticity /

- Honeycomb cell structure /

- Finite element model

-

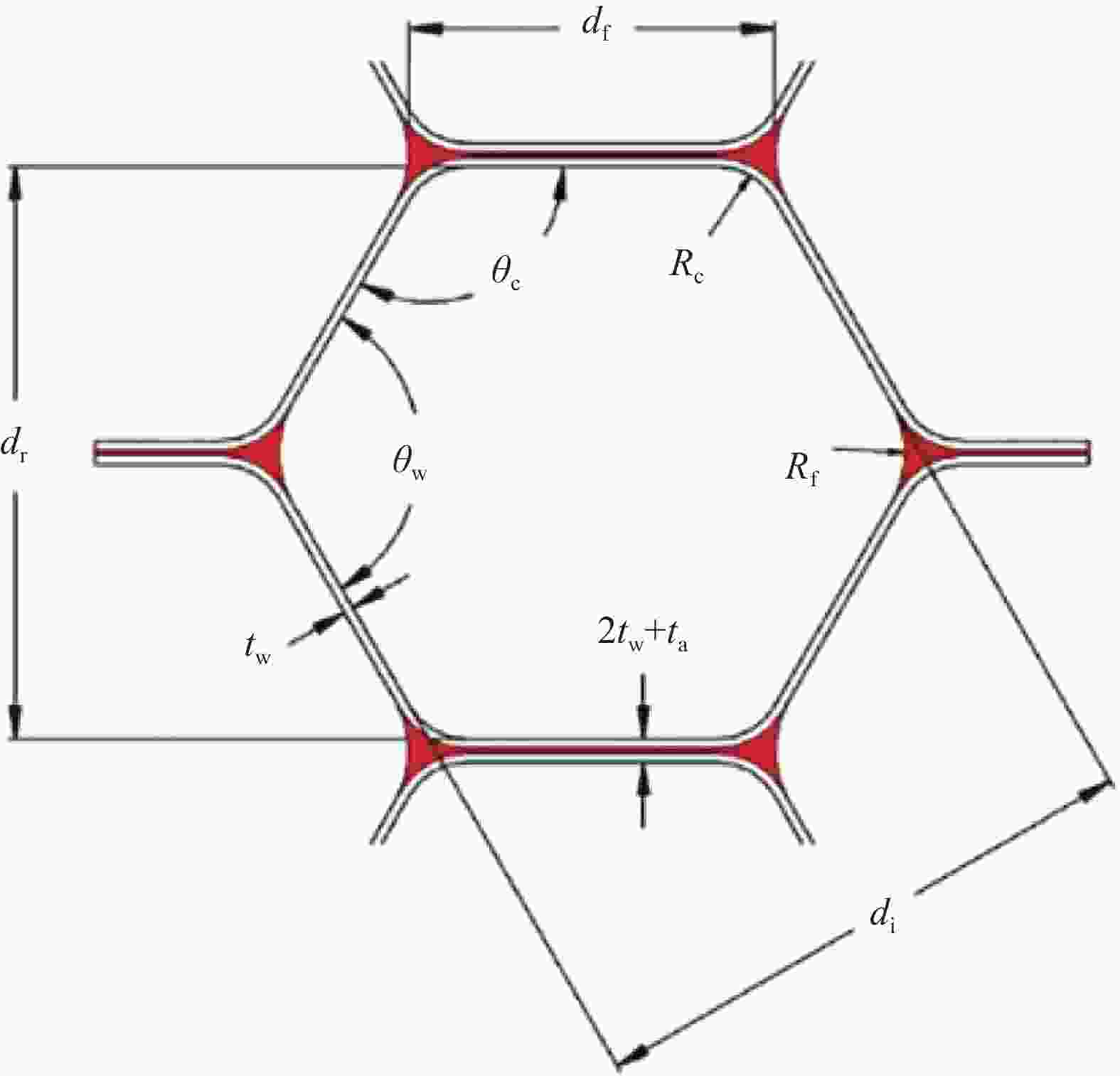

图 7 蜂窝孔格尺寸参数[32]

Figure 7. Parameters of Honeycomb Cell Size[32]

$ {d}_{r} $-diameter of the incircle of honeycomb cell; $ {t}_{w} $-cell wall thickness; $ {t}_{a} $-adhesive thickness; $ {d}_{i} $-distance between opposite walls; $ {d}_{f} $-length of adhesive bondline; $ {R}_{c} $-radius at intersections; $ {R}_{f} $-fillet radius; $ {\theta }_{w} $-internal angle; $ {\theta }_{c} $-angle between inclined and horizontal wall

图 9 保载前后蜂窝孔格参数在蜂窝拉伸方向上的分布:(a)$ \delta d $;(b)$ {\theta }_{w} $

Figure 9. Distribution of Honeycomb cell Size Parameters in the Direction of Honeycomb Stretching before and after Holding: (a)$ \delta d $;(b)$ {\theta }_{w} $

$ \delta d $- deviation from the standard value of the diameter of the incircle of a honeycomb cell; $ {\theta }_{w} $-internal angle

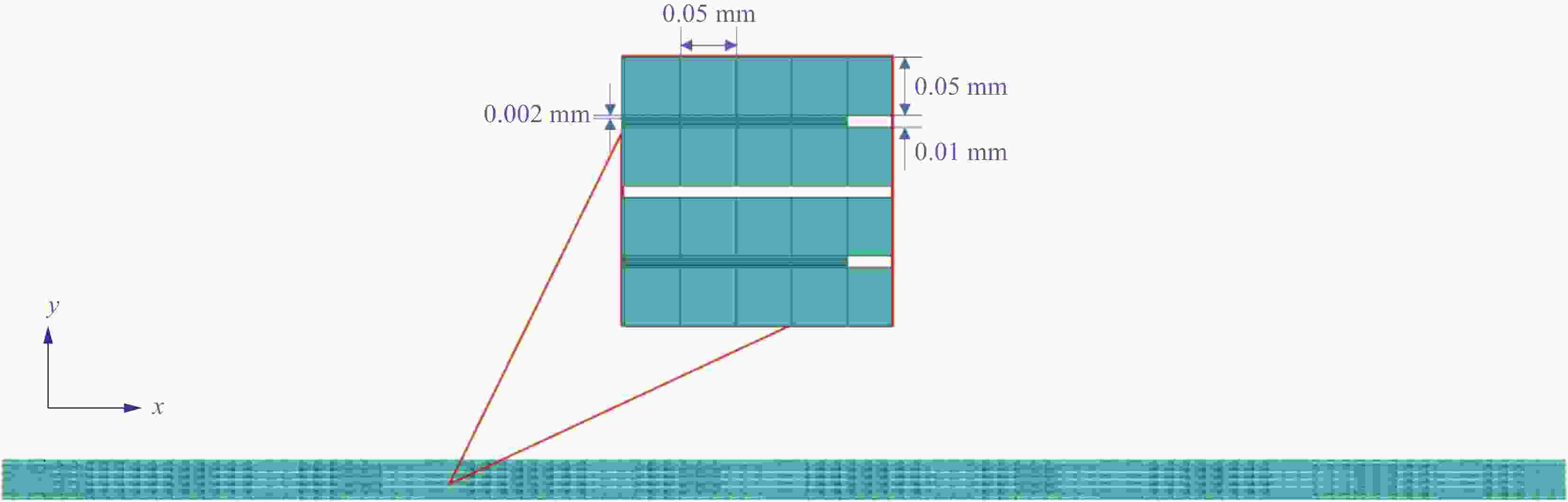

表 1 有限元模型的材料参数

Table 1. Material Parameters of Finite Element Model

Material Density/

(g*cm−3)Modulus/

GPaPoisson’s

ratioAramid paper 0.842 2.46 0.32 Node bond adhesive 1.12×10−3 0.089 0.39 表 2 蠕变柔量相关参数

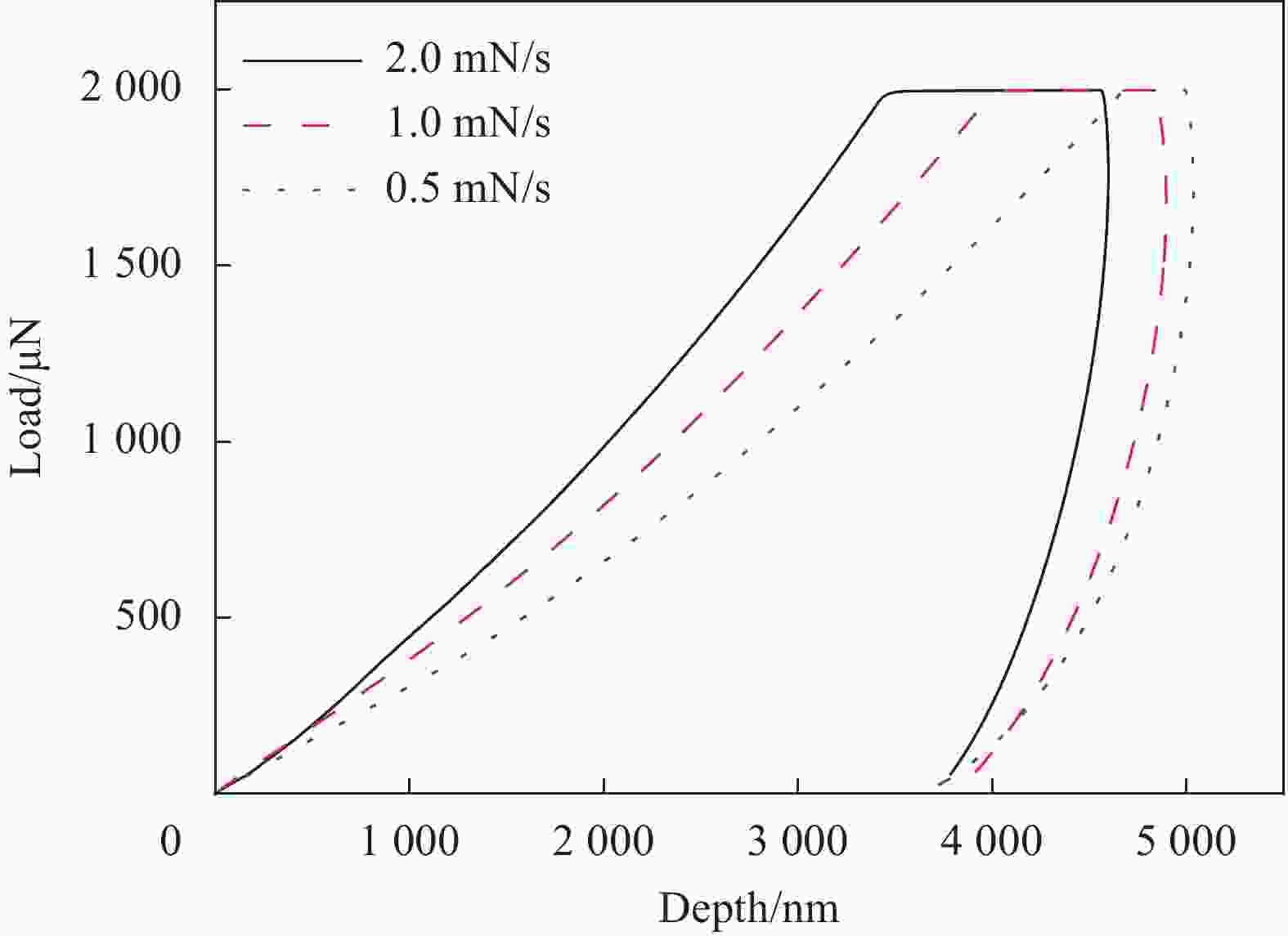

Table 2. Parameters Related to Creep Compliance

Parameter $ {J}_{0}/\mathrm{M}\mathrm{P}{\mathrm{a}}^{-1} $ $ {J}_{1}/\mathrm{M}\mathrm{P}{\mathrm{a}}^{-1} $ $ {J}_{2}/\mathrm{M}\mathrm{P}{\mathrm{a}}^{-1} $ $ {J}_{3}/\mathrm{M}\mathrm{P}{\mathrm{a}}^{-1} $ $ {\tau }_{1}/\mathrm{s} $ $ {\tau }_{2}/\mathrm{s} $ $ {\tau }_{3}/\mathrm{s} $ Value 0.01416 0.06 0.04275 0.00655 8×10-4 60 25000 Notes: $ {J}_{0} $ is the initial creep compliance; $ {J}_{i} $ (i=1,2,3) is the creep compliance of the i-th Maxwell element; $ {\tau }_{i}(\mathrm{i}=\mathrm{1,2},3) $ is the relaxation time of the i-th Maxwell element. 表 3 $ h\left(t\right) $与$ P\left(t\right) $的关系参数

Table 3. Relationship Parameters between h(t) and P(t)

Loading rate$ {v}_{0} $/(mN·s−1) $ {J}_{0}+{\displaystyle\sum }_{i=1}^{3}{J}_{i} $ $ {J}_{1}{v}_{0}{\tau }_{1} $ $ {J}_{2}{v}_{0}{\tau }_{2} $ $ {J}_{3}{v}_{0}{\tau }_{3} $ $ {v}_{0}{\tau }_{1} $ $ {v}_{0}{\tau }_{2} $ $ {v}_{0}{\tau }_{3} $ 2 $ 0.12346 $ 9.6×10−5 5.13 327.5 1.6×10−3 120 50000 1 $ 0.12346 $ 4.8×10−5 2.565 163.75 8×10−4 60 25000 0.5 $ 0.12346 $ 2.4×10−5 1.2825 81.875 4×10−4 30 12500 表 4 松弛模量拟合参数

Table 4. Fitting Parameters of Relaxation Modulus

$ {E}_{\mathrm{\infty }} $(MPa) $ {E}_{1} $(MPa) $ {E}_{2} $(MPa) $ {E}_{3} $(MPa) $ {\tau }_{1} $(s) $ {\tau }_{2} $(s) $ {\tau }_{3} $(s) $ {R}^{2} $ 2.75 69.68 3.75 13.21 12 357 1750 0.99 Notes: $ {E}_{\mathrm{\infty }} $ is the equilibrium relaxation modulus, $ {E}_{\mathrm{i}} $ (i=1,2,3) is the relaxation modulus of the spring in the i-th Maxwell element; $ {R}^{2} $ is the correlation coefficient. 表 5 芯条胶的三阶Prony级数参数

Table 5. Third-order Prony series parameters of node bond adhesive

i $ {G}_{i} $ $ {K}_{i} $ $ {{\tau }_{i}}^{G} $ 1 0.7795 0 12 2 0.0419 0 357 3 0.1477 0 1750 Notes: $ {G}_{i} $ is the shear modulus; $ {K}_{i} $ is the bulk modulus; $ {{\tau }_{i}}^{G} $ is the relaxation time of each component in the Prony series. 表 6 有限元模型AH-W与AH-T系列涂胶工艺参数

Table 6. Gluing Process Parameters of AH-W and AH-T finite element model series

Gluing width/mm Gluing thickness/mm AH-W2.55 2.55 0.01 AH-W2.75 2.75 0.01 AH-W2.95 2.95 0.01 AH-T0.005 2.75 0.005 AH-T0.01 2.75 0.01 AH-T0.015 2.75 0.015 -

[1] BITZER T N. Honeycomb technology: materials, design, manufacturing, applications and testing[M]. Springer Science & Business Media, 1997. [2] CRUPI V, EPASTO G, GUGLIELMINO E. Collapse mophologydes in aluminium honeycomb sandwich panels under bending and impact loading[J]. International Journal of Impact Engineering, 2012, 43: 6-15. doi: 10.1016/j.ijimpeng.2011.12.002 [3] WANG Z, LI Z, XIONG W. Experimental investigation on bending behavior of honeycomb sandwich panel with ceramic tile face-sheet[J]. Composites Part B:Engineering, 2019, 164: 280-286. doi: 10.1016/j.compositesb.2018.10.077 [4] CASTANIÉ B, BOUVET C, GINOT M. Review of composite sandwich structure in aeronautic applications[J]. Composites Part C:Open Access, 2020, 1: 100004. doi: 10.1016/j.jcomc.2020.100004 [5] RAMNATH B V, ALAGARRAJA K, ELANCHEZHIAN C. Review on sandwich composite and their applications[J]. Materials Today:Proceedings, 2019, 16: 859-864. doi: 10.1016/j.matpr.2019.05.169 [6] SIMONE A E, GIBSON L J. Efficient structural components using porous metals[J]. Materials Science and Engineering:A, 1997, 229(1-2): 55-62. doi: 10.1016/S0921-5093(96)10842-X [7] TORQUATO S, GIBIANSKY L V, SILVA M J, et al. Effective mechanical and transport properties of cellular solids[J]. International Journal of Mechanical Sciences, 1998, 40(1): 71-82. doi: 10.1016/S0020-7403(97)00031-3 [8] HE M, HU W. A study on composite honeycomb sandwich panel structure[J]. Materials & Design, 2008, 29(3): 709-713. [9] GAO X, ZHANG M, HUANG Y, et al. Experimental and numerical investigation of thermoplastic honeycomb sandwich structures under bending loading[J]. Thin-Walled Structures, 2020, 155: 106961. doi: 10.1016/j.tws.2020.106961 [10] 刘杰, 郝巍. 芳纶纸蜂窝外观缺陷分析[J]. 宇航材料工艺, 2018, 48(3): 90-93. doi: 10.12044/j.issn.1007-2330.2018.03.019LIU J, HAO W. Analysis of appearance defects of aramid paper honeycomb[J]. Aerospace Materials & Technology, 2018, 48(3): 90-93. (In Chinese doi: 10.12044/j.issn.1007-2330.2018.03.019 [11] 郑付来. 芳纶纸蜂窝芯条胶与国产芳纶纸的匹配性研究[J]. 高科技纤维与应用, 2018, 43(5): 35-41. doi: 10.3969/j.issn.1007-9815.2018.05.005ZHENG F L. Study on the compatibility of aramid honeycomb strip adhesive and domestically produced aramid paper[J]. High Technology Fibers & Applications, 2018, 43(5): 35-41(in Chinese). doi: 10.3969/j.issn.1007-9815.2018.05.005 [12] WANG Z, LI Z, ZHOU W, et al. On the influence of structural defects for honeycomb structure[J]. Composites Part B:Engineering, 2018, 142: 183-192. doi: 10.1016/j.compositesb.2018.01.015 [13] YING F, ZHOU L, WANG L. Analysis of the structural performance and stretching process of the honeycomb paper core[J]. Journal of Advanced Manufacturing Systems, 2008, 7(01): 187-192. doi: 10.1142/S0219686708001346 [14] 黄钧铭, 孙茂健, 朱敏英等. 蜂窝结构材料用国产芳纶纸性能分析[J]. 高科技纤维与应用, 2008, 33(6): 33-38. doi: 10.3969/j.issn.1007-9815.2008.06.007HUANG J, SUN M, ZHU M, et al. Performance analysis of domestically produced aramid paper for honeycomb structure materials[J]. Journal of Advanced Textile Science & Technology, 2008, 33(6): 33-38(in Chinese). doi: 10.3969/j.issn.1007-9815.2008.06.007 [15] 王厚林, 王宜, 姚运振等. 芳纶纸蜂窝力学性能与纸张性能相关性的研究[J]. 功能材料, 2013, 44(3): 349-352. doi: 10.3969/j.issn.1001-9731.2013.03.011WANG H, WANG Y, YAO Y, et al. Study on the correlation between mechanical properties of aramid paper honeycomb and paper properties[J]. Functional Materials, 2013, 44(3): 349-352(in Chinese). doi: 10.3969/j.issn.1001-9731.2013.03.011 [16] Handbook of adhesion technology[M]. Heidelberg: Springer, 2011. [17] BULA A, KOZŁOWSKI M, HULIMKA J, et al. Analysis of methyl methacrylate adhesive (MMA) relaxation with non-linear stress–strain dependence[J]. International Journal of Adhesion and Adhesives, 2019, 94: 40-46. doi: 10.1016/j.ijadhadh.2019.05.011 [18] REZA A, SHISHESAZ M, NADERAN-TAHAN K. The effect of viscoelasticity on creep behavior of double-lap adhesively bonded joints[J]. Latin American Journal of Solids and Structures, 2014, 11: 35-50. doi: 10.1590/S1679-78252014000100003 [19] SHISHESAZ M, REZA A. The effect of viscoelasticity of adhesives on shear stress distribution in a double-lap joint using analytical method[J]. Journal of adhesion science and technology, 2013, 27(20): 2233-2250. doi: 10.1080/01694243.2013.769085 [20] WANG Y, SHANG L, ZHANG P, et al. Measurement of viscoelastic properties for polymers by nanoindentation[J]. Polymer Testing, 2020, 83: 106353. doi: 10.1016/j.polymertesting.2020.106353 [21] CHRISTENSEN S F, MCKINLEY G H. Rheological modelling of the peeling of pressure-sensitive adhesives and other elastomers[J]. International journal of adhesion and adhesives, 1998, 18(5): 333-343. doi: 10.1016/S0143-7496(98)00015-3 [22] HAMOODI-TABAR M, REZA A. Long-term shear stress distribution in adhesively bonded tubular joints under tensile load using the time-temperature superposition principle[J]. The Journal of Adhesion, 2021, 97(4): 328-345. doi: 10.1080/00218464.2019.1666367 [23] GUNAWAN M, DAVILA L T, WONG E H, et al. Static and cyclic relaxation studies in nonconductive adhesives[J]. Thin solid films, 2004, 462: 419-426. [24] 尹久仁, 张平, 郭翠芳. 线黏弹性网格结构离散模型研究[J]. 湘潭大学自然科学学报, 2003, 25(4): 126-130. doi: 10.13715/j.cnki.nsjxu.2003.04.021YIN J R, ZHANG P, GUO C F. Discrete model of line-viscoelastic grid structure[J]. Journal of Xiangtan University(Natural Science), 2003, 25(4): 126-130(in Chinese). doi: 10.13715/j.cnki.nsjxu.2003.04.021 [25] MAEDA K, OKAZAWA S, NISHIGUCHI K. Visco-rubber elastic model for pressure sensitive adhesive[C]//Lecture Notes in Engineering and Computer Science: Proceedings of the International MultiConference of Engineering and Computer Scientists. 2010: 393-398. [26] 邓科涛, 吴晓. 粘弹性材料的几个材料函数的测定[J]. 强度与环境, 2002, 29(3): 58-63. doi: 10.3969/j.issn.1006-3919.2002.03.011DENG K T, WU X. Determination of several material functions of viscoelastic materials[J]. Strength and Environment, 2002, 29(3): 58-63(in Chinese). doi: 10.3969/j.issn.1006-3919.2002.03.011 [27] SNEDDON I N. The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile[J]. International journal of engineering science, 1965, 3(1): 47-57. doi: 10.1016/0020-7225(65)90019-4 [28] CHENG Y T, CHENG C M. General relationship between contact stiffness, contact depth, and mechanical properties for indentation in linear viscoelastic solids using axisymmetric indenters of arbitrary profiles[J]. Applied Physics Letters, 2005, 87(11): 111914. doi: 10.1063/1.2048820 [29] Polymer viscoelasticity: stress and strain in practice[M]. CRC Press, 1999. [30] HERNÁNDEZ-JIMÉNEZ A, HERNÁNDEZ-SANTIAGO J, MACIAS-GARCIA A, et al. Relaxation modulus in PMMA and PTFE fitting by fractional Maxwell model[J]. Polymer Testing, 2002, 21(3): 325-331. doi: 10.1016/S0142-9418(01)00092-7 [31] XU Y, BHARGAVA P, ZEHNDER A. Time and temperature dependent mechanical behavior of HFPE-II-52 polyimide at high temperature[J]. Mechanics of Materials, 2016, 100: 86-95. doi: 10.1016/j.mechmat.2016.06.009 [32] BALAWI S, ABOT J L. The Effect of Honeycomb Relative Density on its Effective Elastic Properties: A Theoretical and Experimental Study[C]//ASME International Mechanical Engineering Congress and Exposition. 2006, 47667: 93-104. -

点击查看大图

点击查看大图

计量

- 文章访问数: 224

- HTML全文浏览量: 106

- 被引次数: 0

下载:

下载: