In-plane tensile property of deformable honeycomb structure with compliant hinge

-

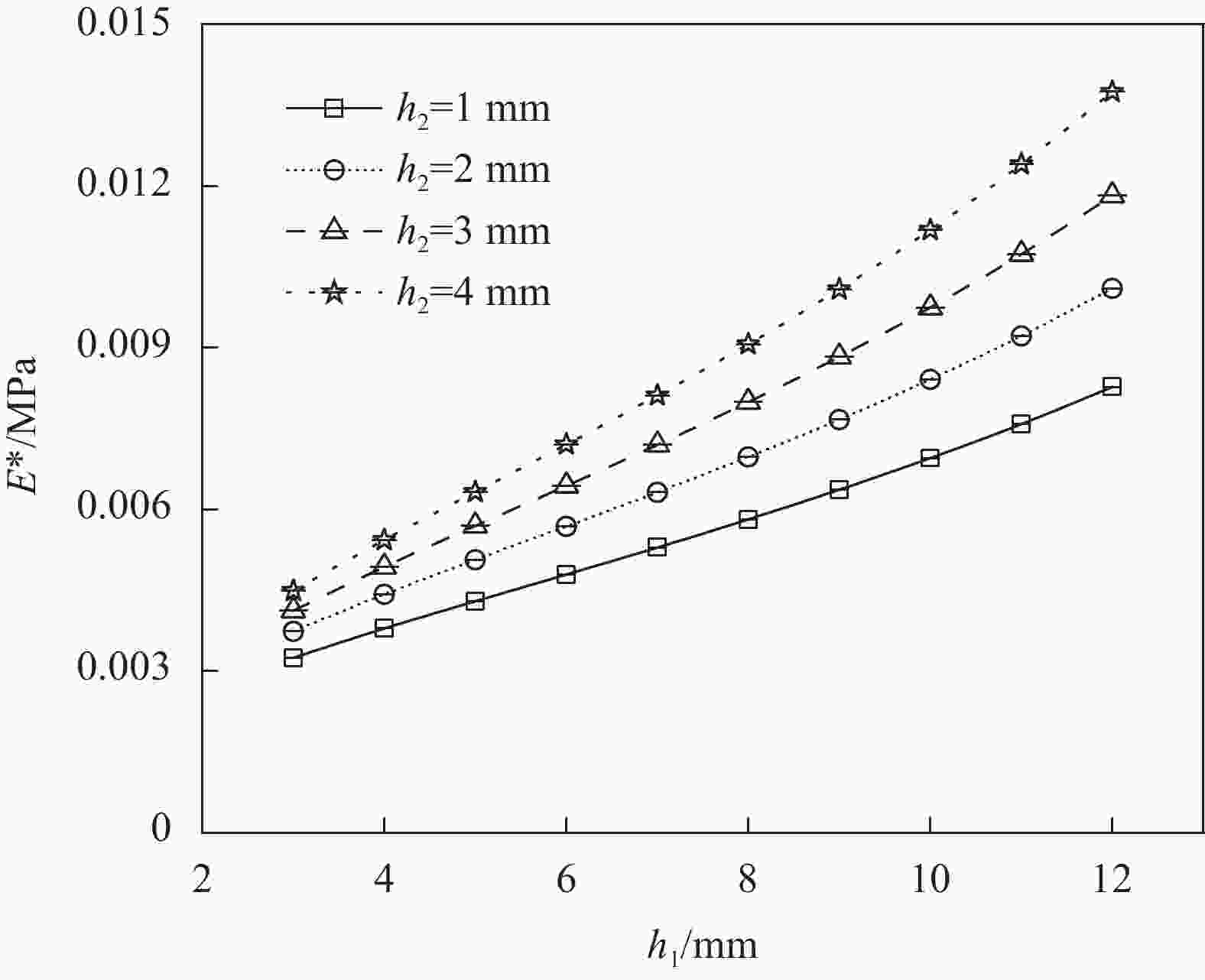

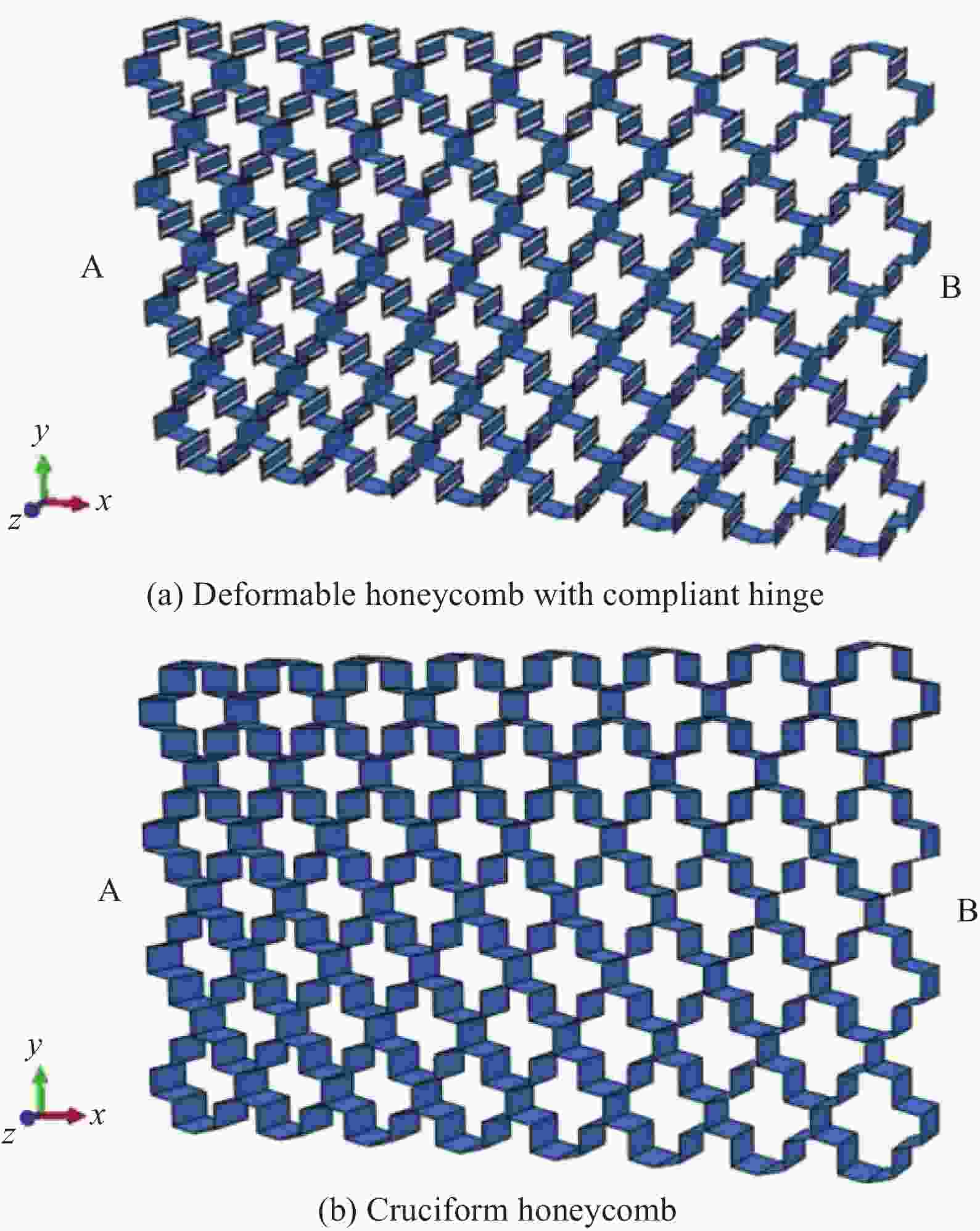

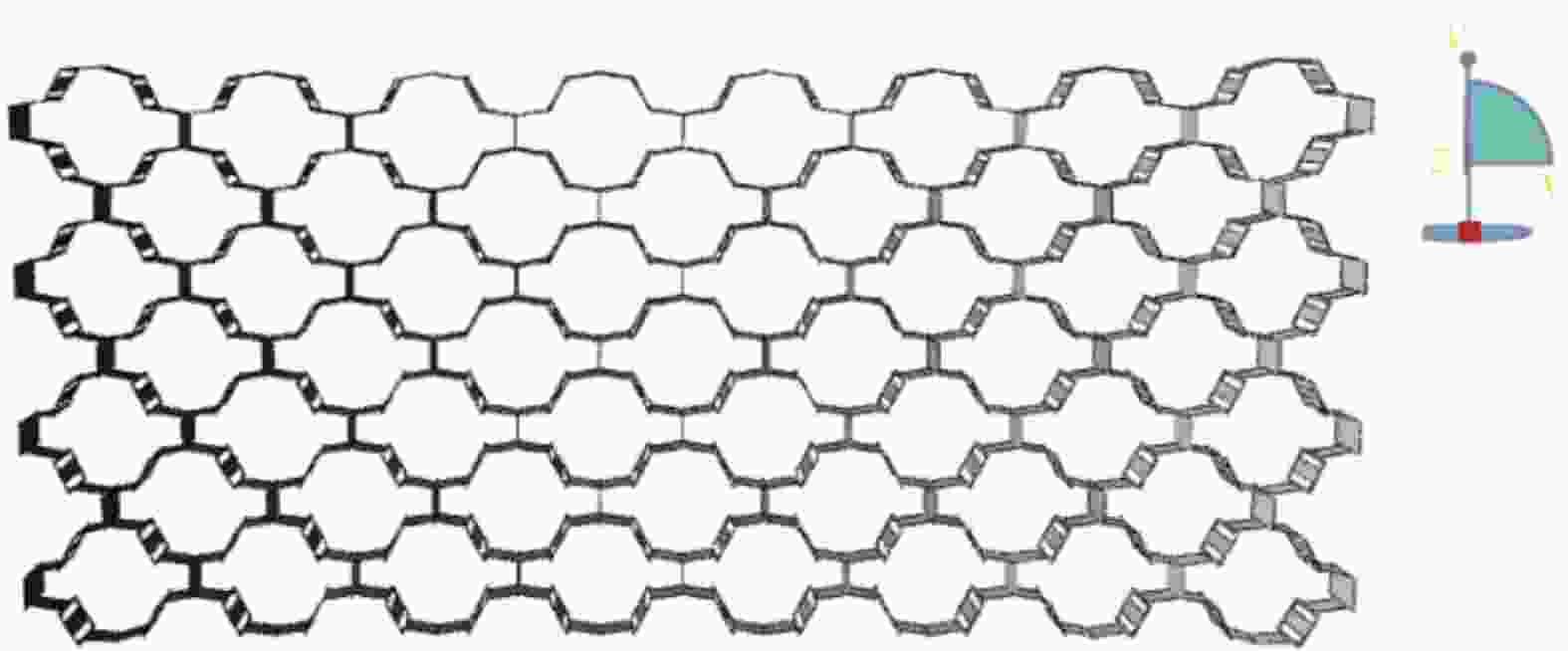

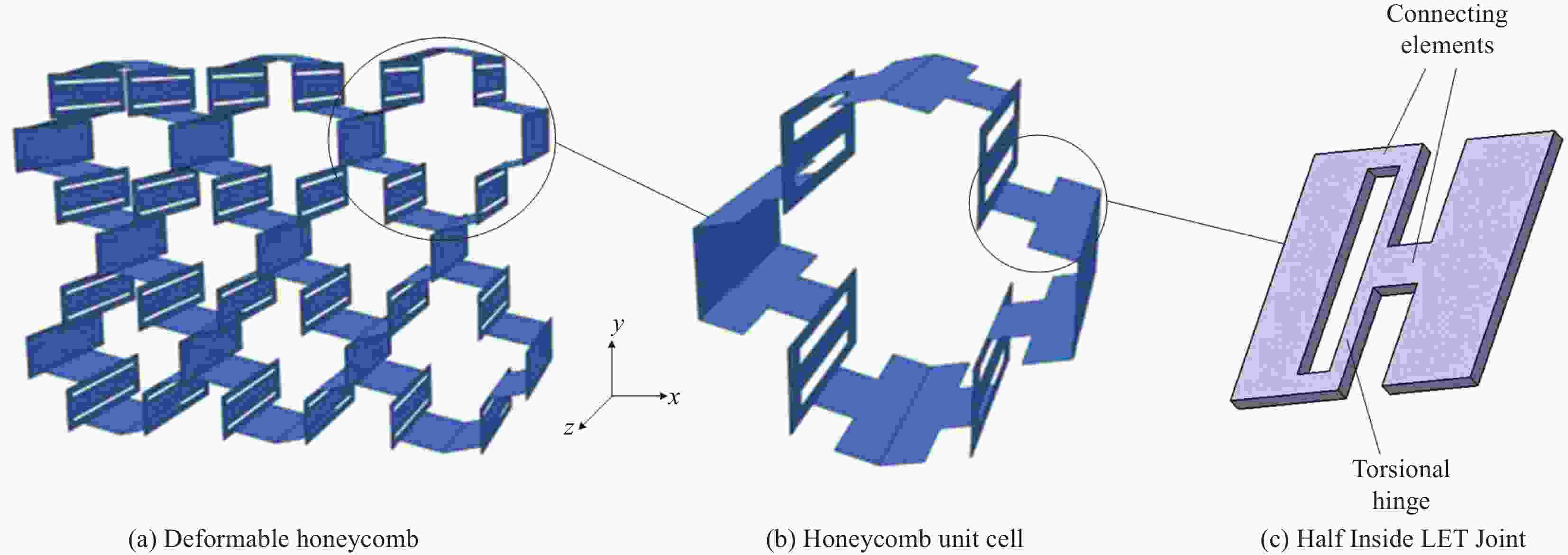

摘要: 提出了一种柔性铰可变形蜂窝结构,该结构由十字形蜂窝和内LET半铰(Half Inside Lamina Emergent Torsional Joint)组成,通过降低结构面内刚度提升变形能力,具有重量轻、面内模量低的特点。通过理论分析研究了柔性铰可变形蜂窝结构的面内等效弹性模量,并进行了仿真和实验验证,分析了几何参数对结构等效弹性模量的影响,最后通过仿真和实验比较了柔性铰可变形蜂窝与十字形蜂窝的面内刚度。结果表明:柔性铰可变形蜂窝的等效弹性模量与十字形蜂窝相比降低了80%以上,具有更优秀的面内变形能力,将可变形蜂窝结构与柔性铰链巧妙结合是一种提升蜂窝结构面内变形能力的有效方式。Abstract: A deformable honeycomb structure with compliant hinge which is composed of the cross-shaped honeycomb and the half inside Lamina Emergent Torsional joint was proposed. By reducing the in-plane stiffness, the deformation ability of the structure is improved, and it has the characteristics of light weight and low in-plane modulus. The in-plane equivalent elastic modulus of the deformable honeycomb structure was studied by theoretical analysis, and simulation and experimental verification were carried out. The influence of geometric parameters on the equivalent elastic modulus of the structure was also analyzed. The in-plane deformation ability of the deformable honeycomb with compliant hinge and the cross-shaped honeycomb were compared through simulation and experiment. The results show that the deformable honeycomb structure with compliant hinge has better in-plane deformable ability. Compared with cross-shaped honeycomb, the equivalent elastic modulus of deformable honeycomb with compliant hinge is reduced by more than 80%. Thus, the combination of compliant hinge and deformable honeycomb structure is an effective way to improve the in-plane deformation ability of honeycomb structure.

-

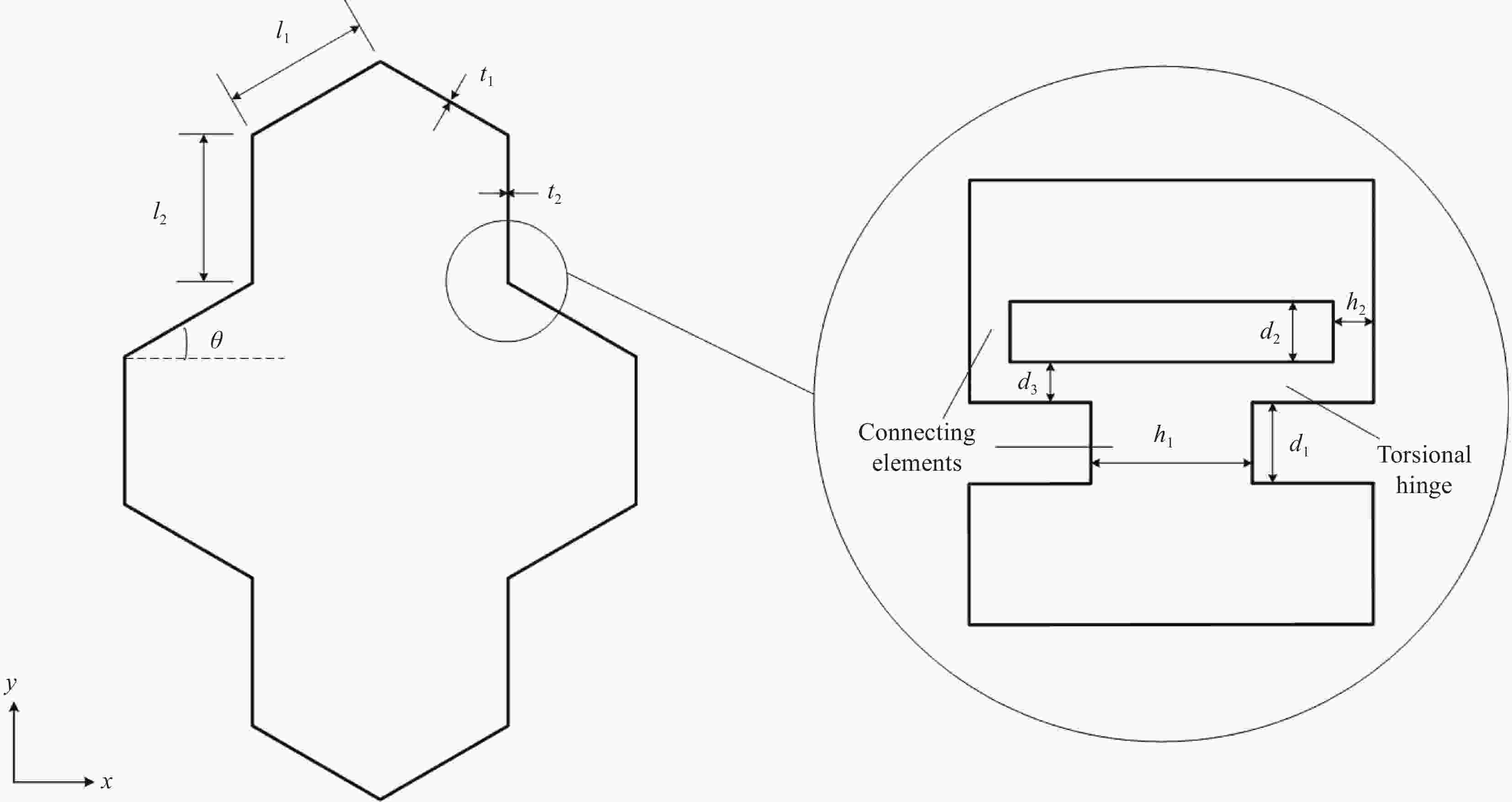

图 2 柔性铰可变形蜂窝单元的几何参数

Figure 2. Geometric parameters of deformable honeycomb with compliant hinge unit cell

l1—Length of the inclined beam; t1—Thickness of the inclined beam; l2—Length of the vertical beam; t2 —Thickness of the vertical beam; θ—Honeycomb angle; d1—Width of connecting element in the inclined beam; h1 —Length of connecting element in the inclined beam; d2—Width of the connecting element in the vertical beam; h2—Length of the connecting element in the vertical beam; d3—Width of torsional hinge

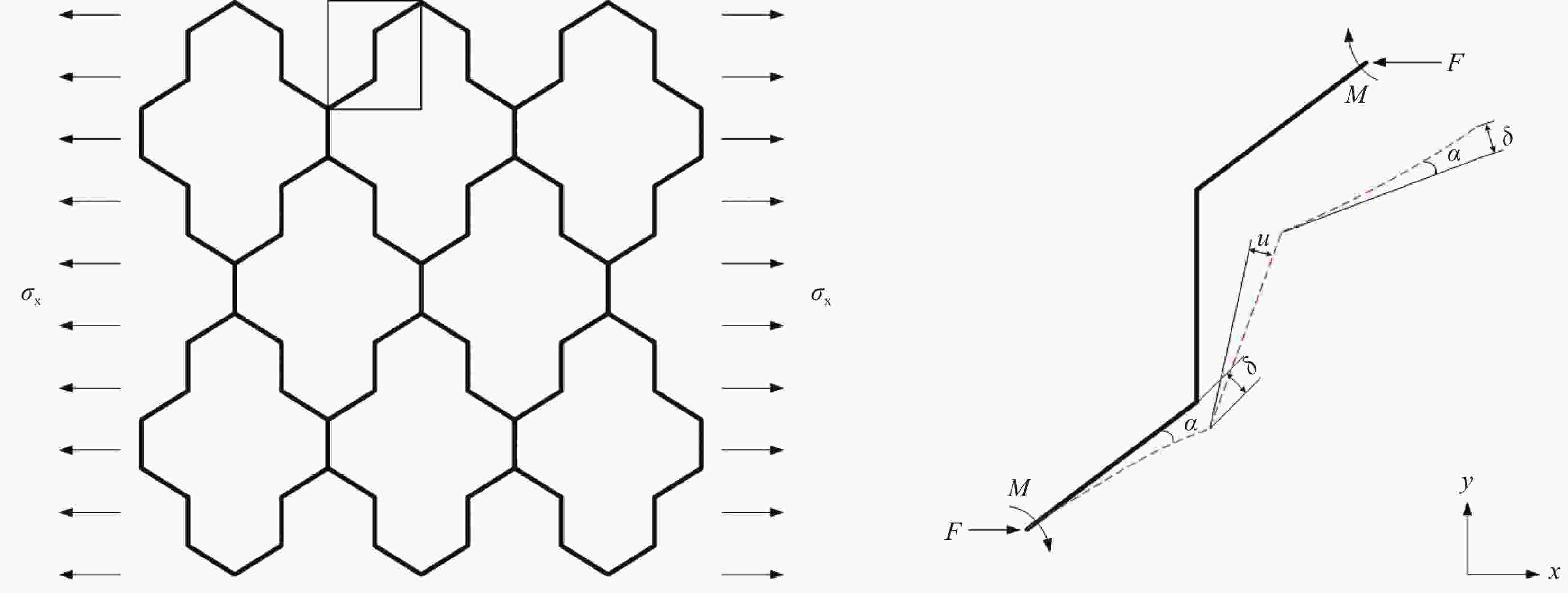

图 3 在x方向加载时柔性铰可变形蜂窝受力分析

Figure 3. Force analysis of deformable honeycomb with compliant hinge loaded in x direction

σx—Equivalent stress along the x-direction; F—Tensile load along the x-direction; M—Bending moment of the cross section; δ—Deflection of the inclined beam; α—Rotation angle of the inclined beam; u—Deflection of the vertical beam

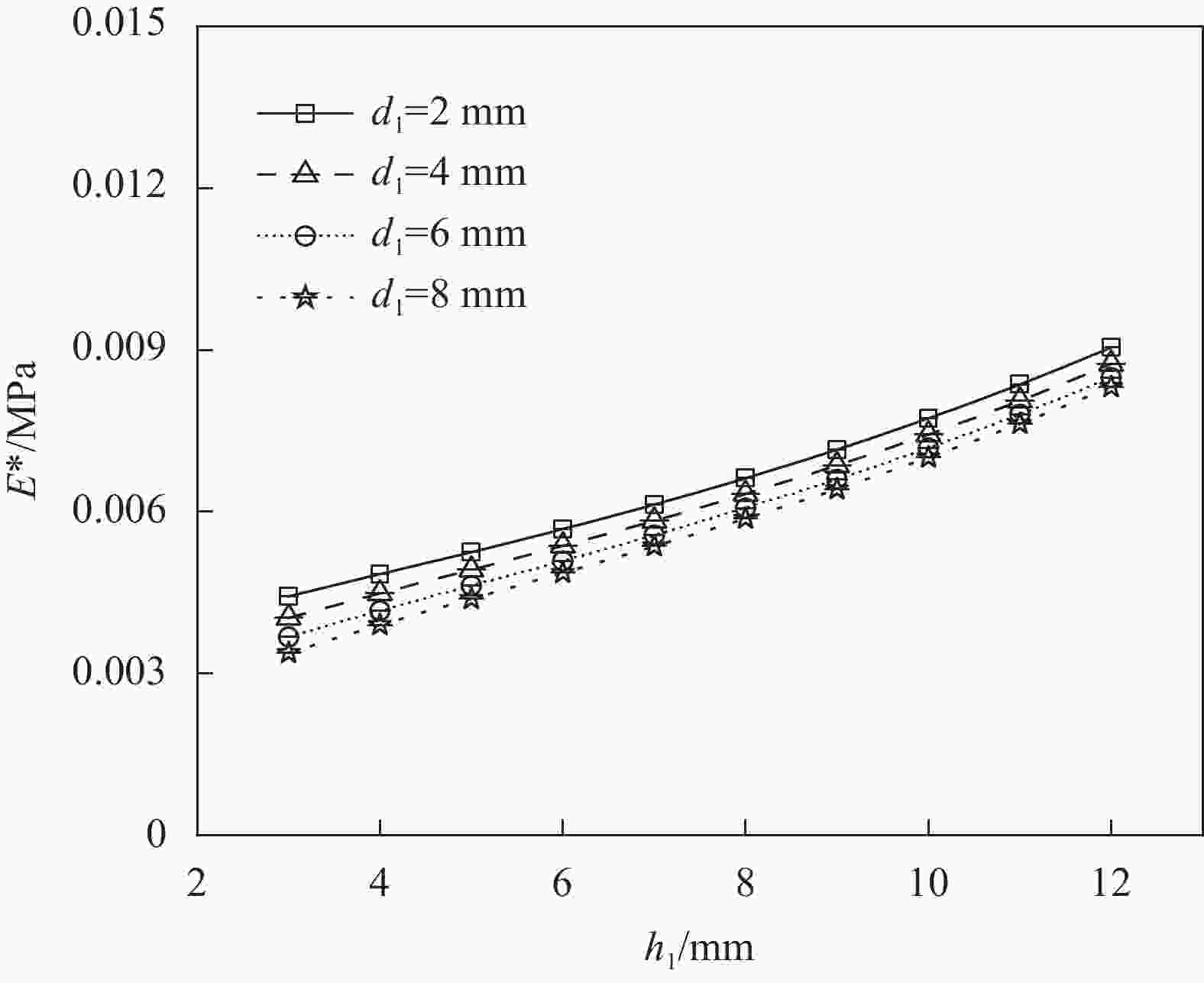

表 1 柔性铰可变形蜂窝结构等效弹性模量E*理论与仿真值的比较

Table 1. Comparison between the theoretical and FEM results of equivalent elastic modulus E*of the deformable honeycomb structure with compliant hinge

Number Parameter of the unit/mm E*/MPa(Theoretical value) E*/MPa(FEM value) Error/% 1 d1=2, d2=2, d3=1h1=7, h2=1 6.20×10−3 6.13×10−3 1.13 2 d1=4, d2=2, d3=1h1=7, h2=1 5.90×10−3 5.83×10−3 1.19 3 d1=6, d2=2, d3=1h1=7, h2=1 5.60×10−3 5.56×10−3 0.71 4 d1=10, d2=2, d3=1h1=4, h2=1 3.90×10−3 3.79×10−3 2.82 5 d1=10, d2=2, d3=1.5h1=4, h2=1 4.80×10−3 4.72×10−3 1.67 6 d1=10, d2=2, d3=2h1=4, h2=1 5.40×10−3 5.49×10−3 1.67 7 d1=10, d2=2, d3=1h1=3, h2=2 3.80×10−3 3.74×10−3 1.58 8 d1=10, d2=2, d3=1h1=3, h2=3 4.10×10−3 4.12×10−3 0.49 9 d1=10, d2=2, d3=1h1=3, h2=4 4.40×10−3 4.49×10−3 2.05 10 d1=10, d2=0.75, d3=1h1=6, h2=1 5.20×10−3 5.05×10−3 2.88 11 d1=10, d2=1.5, d3=1h1=6, h2=1 4.90×10−3 4.87×10−3 0.61 12 d1=10, d2=2.25, d3=1h1=6, h2=1 4.60×10−3 4.75×10−3 3.26 表 2 柔性铰可变形蜂窝和十字形蜂窝的结构参数

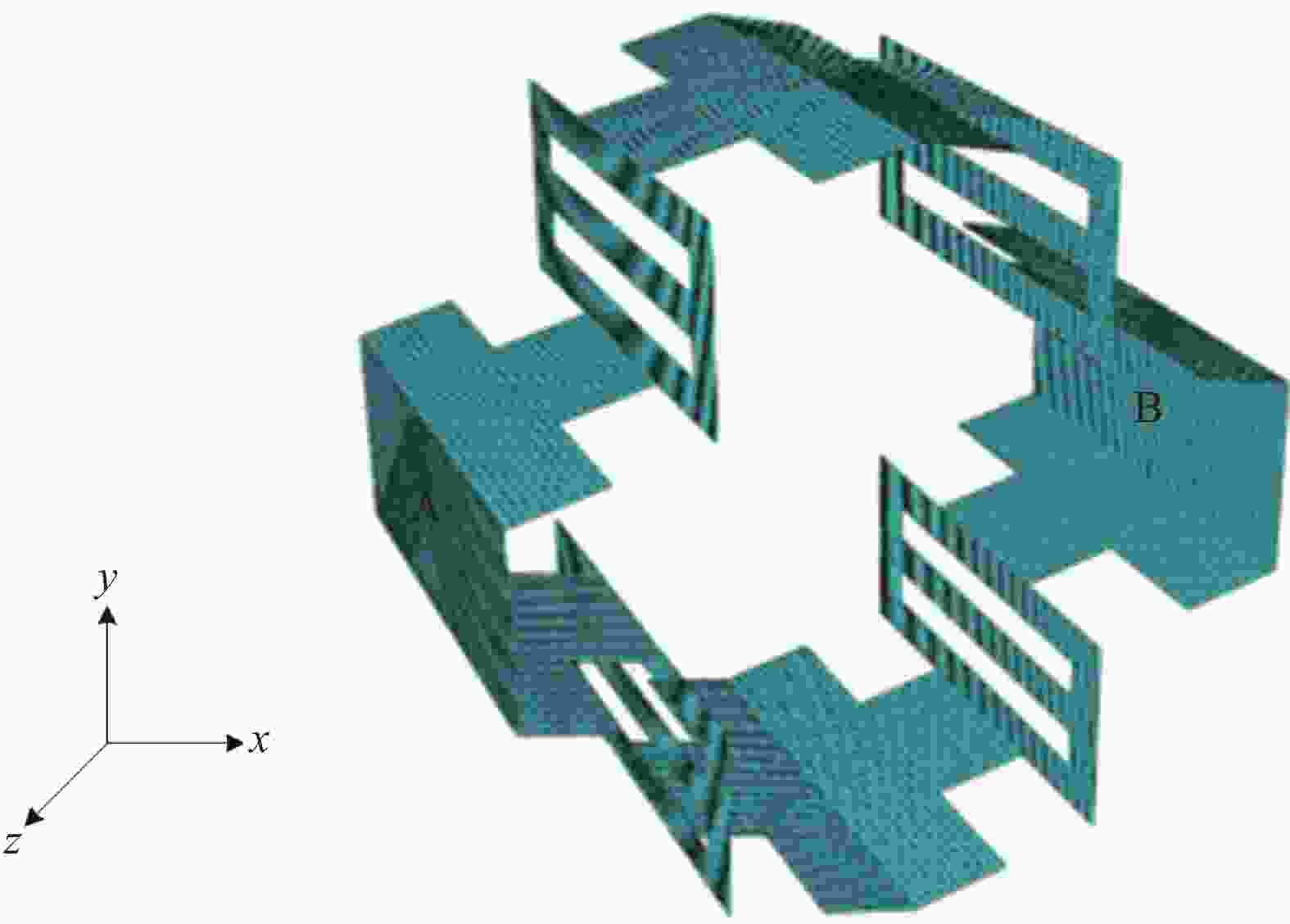

Table 2. Parameters of the deformable honeycomb with compliant hinge and the cruciform honeycomb

Number Configuration Parameter of the honeycomb unit/mm Parameter of the compliant hinge/mm Parameter of the model/mm 1 4×8 l1= l2=10, t1= t2=0.25, b=25, θ=13° d1=10, d2=2, d3=1h1=12, h2=1 312×186×25 2 5×10 l1= l2=5, t1= t2=0.1, b=10, θ=13° d1=5, d2=1, d3=0.5h1=5, h2=0.5 195×118×10 3 6×8 l1= l2=20, t1= t2=1, b=40, θ=13° d1=20, d2=4, d3=3h1=20, h2=2 624×568×40 表 3 柔性铰可变形蜂窝结构和十字形蜂窝结构的面内拉伸等效弹性模量E*

Table 3. Equivalent elastic modulus E*of the deformable honeycomb structure with compliant hinge and the cruciform honeycomb

Number Configuration E*/MPa (The deformable honeycomb

with compliant hinge)E*/MPa(The cruciform honeycomb) Difference value/% 1 4×8 0.0064 0.0595 89.2 2 5×10 0.0054 0.0305 82.3 3 6×8 0.0725 0.4515 83.9 -

[1] LI D, ZHAO S, DA Ronch A, et al. A review of modelling and analysis of morphing wings[J]. Progress in Aerospace Sciences, 2018, 100(JUN): 46-62. [2] LI Y Z, GE W J, ZHOU J, et al. Design and experiment of concentrated flexibility-based variable camber morphing wing[J]. Chinese Journal of Aeronautics, 2022, 35(5): 455-469. doi: 10.1016/j.cja.2021.04.030 [3] WEISSHAAR T A. Morphing aircraft systems: Historical perspectives and future challenges[J]. Journal of Aircraft, 2013, 50(2): 337-353. doi: 10.2514/1.C031456 [4] CHU L L, LI Q, GU F, et al. Design, modeling, and control of morphing aircraft: A review[J]. Chinese Journal of Aeronautics, 2022, 35(5): 220-246. doi: 10.1016/j.cja.2021.09.013 [5] MKHOYAN T, THAKRAR NR, DE Breuker R, et al. Morphing wing design using integrated and distributed trailing edge morphing[J]. Smart Materials and Structures, 2022, 31(12): 125025. doi: 10.1088/1361-665X/aca18b [6] 沈元, 昂海松, 刘卫东. 用于变形机翼夹心式柔性伸缩蒙皮的梯形蜂窝支撑结构[J]. 复合材料学报, 2015, 32(3): 815-822.SHEN Yuan, ANG Haisong, LIU Weidong. Trapezoidal cellular support structure applied to flexible telescope sandwich skin of morphing wing[J]. Acta Materiae Compositae Sinica, 2015, 32(3): 815-822(in Chinese). [7] 徐云研, 程小全, 张纪奎, 等. 复合材料蜂窝夹层结构T型接头拉伸性能研究[J]. 工程力学, 2015, 32(7): 243-256. doi: 10.6052/j.issn.1000-4750.2013.12.1236XU Yunyan, CHENG Xiaoquan, ZHANG Jikui, et al. Study on composite honeycomb sandwich structure formed T-joints under tensile load[J]. Engineering Mechanics, 2015, 32(7): 243-256(in Chinese). doi: 10.6052/j.issn.1000-4750.2013.12.1236 [8] LIU W D, YANG Z D, Du S, et al. Theoretical, numerical and experimental study on the in-plane elastic behavior of a 2D chiral cellular structure[J]. Composite Structures, 2022, 296: 115889. doi: 10.1016/j.compstruct.2022.115889 [9] YU X D, ZHANG Q C, KONTOPOULOU A, et al. In-plane elasticity of beetle elytra inspired sandwich cores[J]. Composite Structures, 2022, 300: 116155. doi: 10.1016/j.compstruct.2022.116155 [10] 沈元, 朱华, 刘卫东, 等. 三种柔性蒙皮支撑结构的力学特性[J]. 振动. 测试与诊断, 2017, 37(1): 18-25.SHEN Yuan, ZHU Hua, LIU Weidong. Mechanical characteristics of three support structures of flexible skin[J]. Journal of Vibration, Measurement & Diagnosis, 2017, 37(1): 18-25(in Chinese). [11] FENG N, Wang S B, Tie Y H, et al. Elastic deformability and zero Poisson’s ratio within a novel structure inspired by the gardenia from nature[J]. Mechanics of Advanced Materials and Structures,DOI: 10.1080/15376494.2022.2135052. [12] CHEN J J, SHEN X, LI J F. Zero Poisson’s ratio flexible skin for potential two-dimensional wing morphing[J]. Aerospace Science and Technology, 2015, 45: 228-241. doi: 10.1016/j.ast.2015.05.011 [13] 郭之熙, 肖俊华. 多弧段曲边内凹蜂窝可调泊松比结构的力学性能研究[J]. 工程力学, 2022, 39.GUO Zhixi, XIAO Junhua. Mechanical properties of multi-arc concave honeycomb structure with adjustable Poisson’s ratio[J]. Engineering Mechanics, 2022, 39 (in Chinese). [14] SCARPA F, SMITH F C. CHAMBERS, B, et al. FE analysis of the in-plane mechanical properties of a novel Voronoi-type lattice with positive and negative Poisson's ratio configurations[J]. International Journal of Solids and Structures, 2010, 107(1069): 175-183. [15] BOUAKBA M, BEZAZI A, SCARPA F. Mechanical and electromagnetic behaviour of auxetic honeycomb structures[J]. Aeronautical Journal, 2012, 49(18): 2450-2459. [16] HU L L, LUO Z R, ZHANG Z Y, LIAN M K, et al. Mechanical property of re-entrant anti-trichiral honeycombs under large deformation[J]. Composites Part B-Engineering, 2019, 163: 107-120. doi: 10.1016/j.compositesb.2018.11.010 [17] 尤泽华, 肖俊华, 王美芬. 弧边内凹蜂窝负泊松比结构的力学性能[J]. 复合材料学报, 2022, 39(7): 3570-3580.YOU Zehua, XIAO Junhua, WANG Meifen. Mechanical properties of arc concave honeycomb structure with negative Poisson’s ratio[J]. Acta Materiae Compositae Sinica, 2012, 39(7): 3570-3580 (in Chinese). [18] GRIMA J N, GATT R, FARRUGIA P S. On the properties of auxetic meta-tetrachiral structures[J]. Physica Status Solidi B-Basic Solid State Physics, 2008, 245(3): 511-520. doi: 10.1002/pssb.200777704 [19] FU M H, ZHENG B B, LI W H. A novel chiral three-dimensional material with negative Poisson's ratio and the equivalent elastic parameters[J]. Composite Structures, 2017, 176: 442-448. doi: 10.1016/j.compstruct.2017.05.027 [20] 王雪松, 刘卫东, 刘典. 新型反四手性蜂窝结构的面内拉伸弹性[J]. 复合材料学报, 2023, 40(8): 4849-4861.WANG Xuesong, LIU Weidong, LIU Dian. In-plane tensile elasticity of a novel anti-tetrachiral cellular structure[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4849-4861(in Chinese). [21] QIAO J X, CHEN C Q. Impact resistance of uniform and functionally graded auxetic double arrowhead honeycombs[J]. International Journal of Impact Engineering, 2015, 83: 47-58. doi: 10.1016/j.ijimpeng.2015.04.005 [22] GAO Q, WANG L M, ZHOU Z, et al. Theoretical, numerical and experimental analysis of three-dimensional double-V honeycomb[J]. Materials & Design, 2018, 139: 380-391. [23] OLYMPIO K R, GANDHI F. Flexible skins for morphing aircraft using cellular honeycomb core[J]. Journal of Intelligent Material Systems and Structure, 2010, 21(17): 1719-1735. doi: 10.1177/1045389X09350331 [24] ZHANG P, ZHOU L, QIU T. Design and application of cross-shaped cellular honeycomb for a variable camber wing[J]. Journal of Aircraft, 2012, 49(5): 1451-1459. doi: 10.2514/1.C031733 [25] 程文杰, 周丽, 张平, 等. 零泊松比十字形混合蜂窝设计分析及其在柔性蒙皮中的应用[J]. 航空学报, 2015, 36(2): 680-690.CHENG Wenjie, ZHOU Li, ZHANG P, et al. Design and analysis of a zero Poisson’s ratio mixed cruciform honeycomb and its application in flexible skin[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(2): 680-690(in Chinese). [26] GONG X B, HUANG J, SCARPA F, LIU Y J, et al. Zero Poisson's ratio cellular structure for two-dimensional morphing applications[J]. Composite Structures, 2015, 134: 384-392. doi: 10.1016/j.compstruct.2015.08.048 [27] JACOBSEN J O, CHEN G M, HOWELL L L, et al. Lamina Emergent Torsional (LET) Joint[J]. Mechanism and Machine Theory, 2009, 44(11): 2098-2109. doi: 10.1016/j.mechmachtheory.2009.05.015 -

点击查看大图

点击查看大图

计量

- 文章访问数: 49

- HTML全文浏览量: 22

- 被引次数: 0

下载:

下载: