Flexural creep test and prediction of GFRP-balsa sandwich beams

-

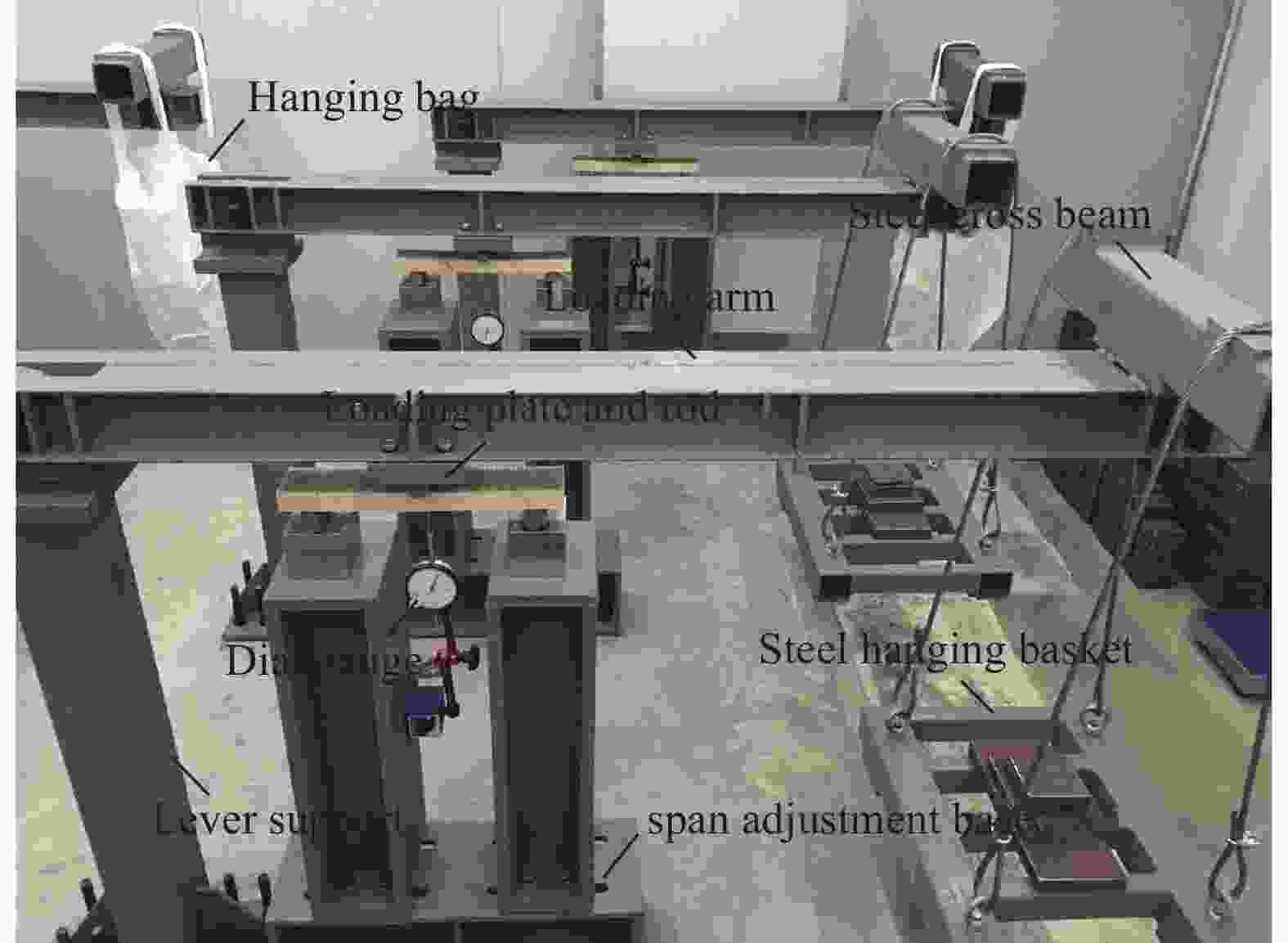

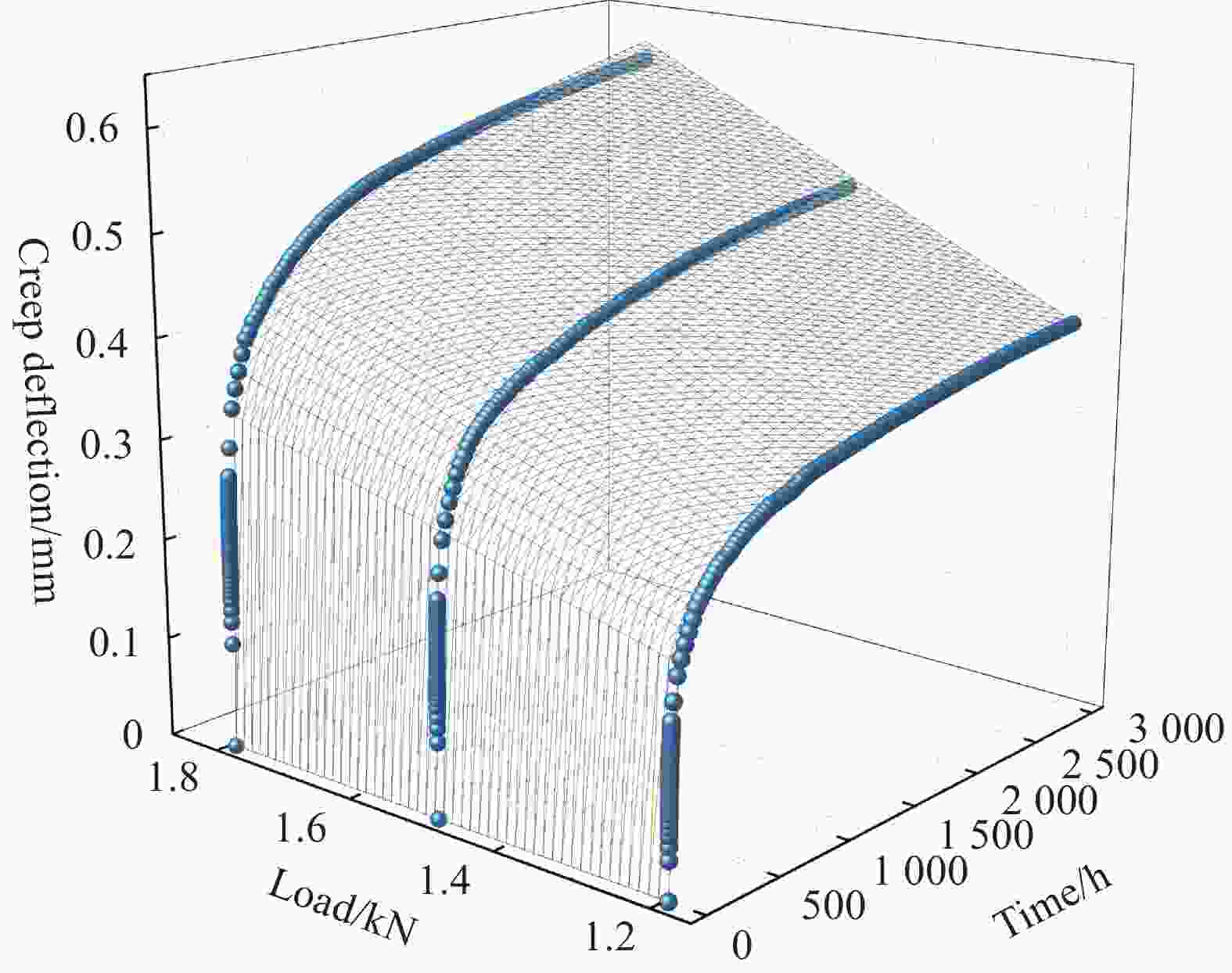

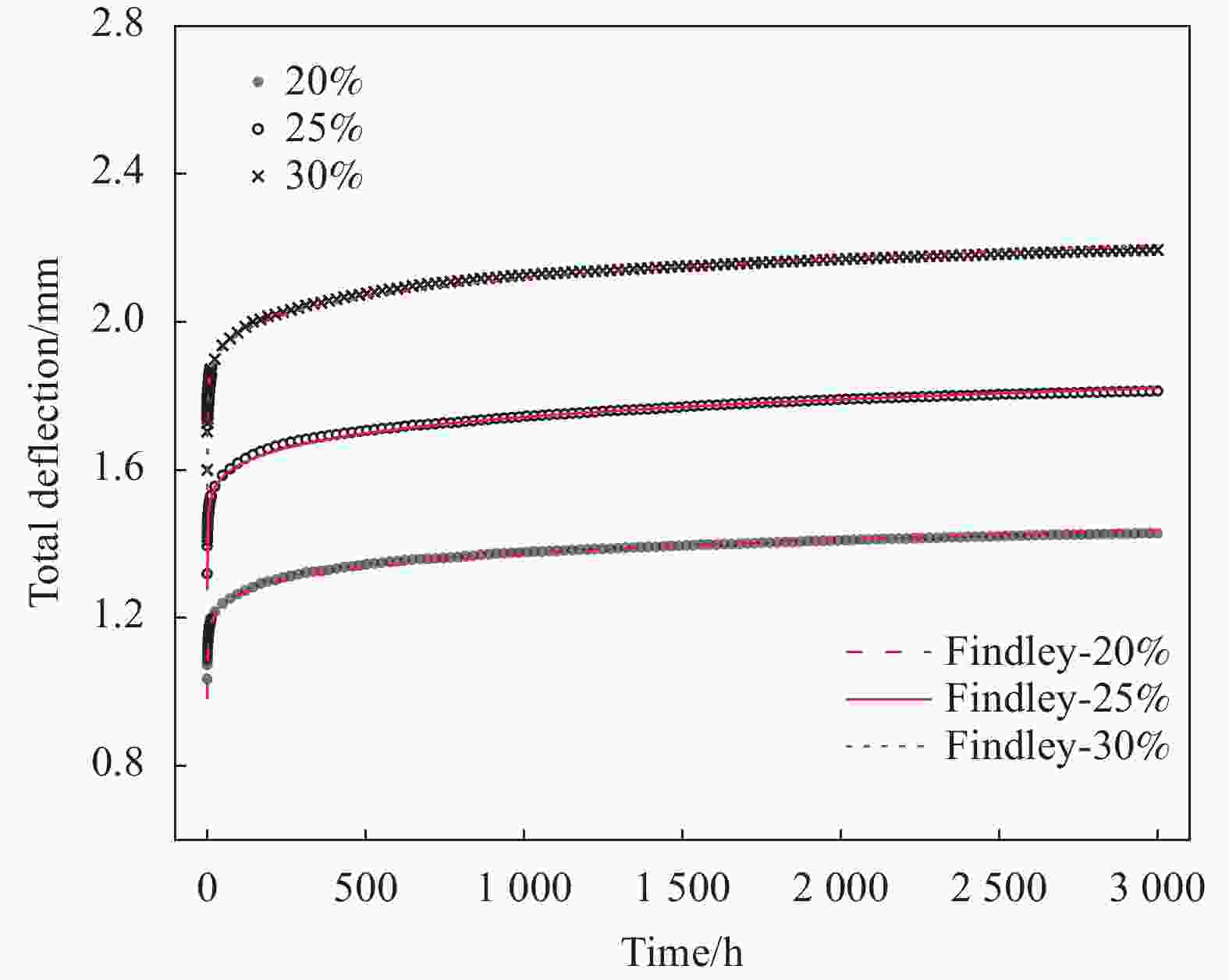

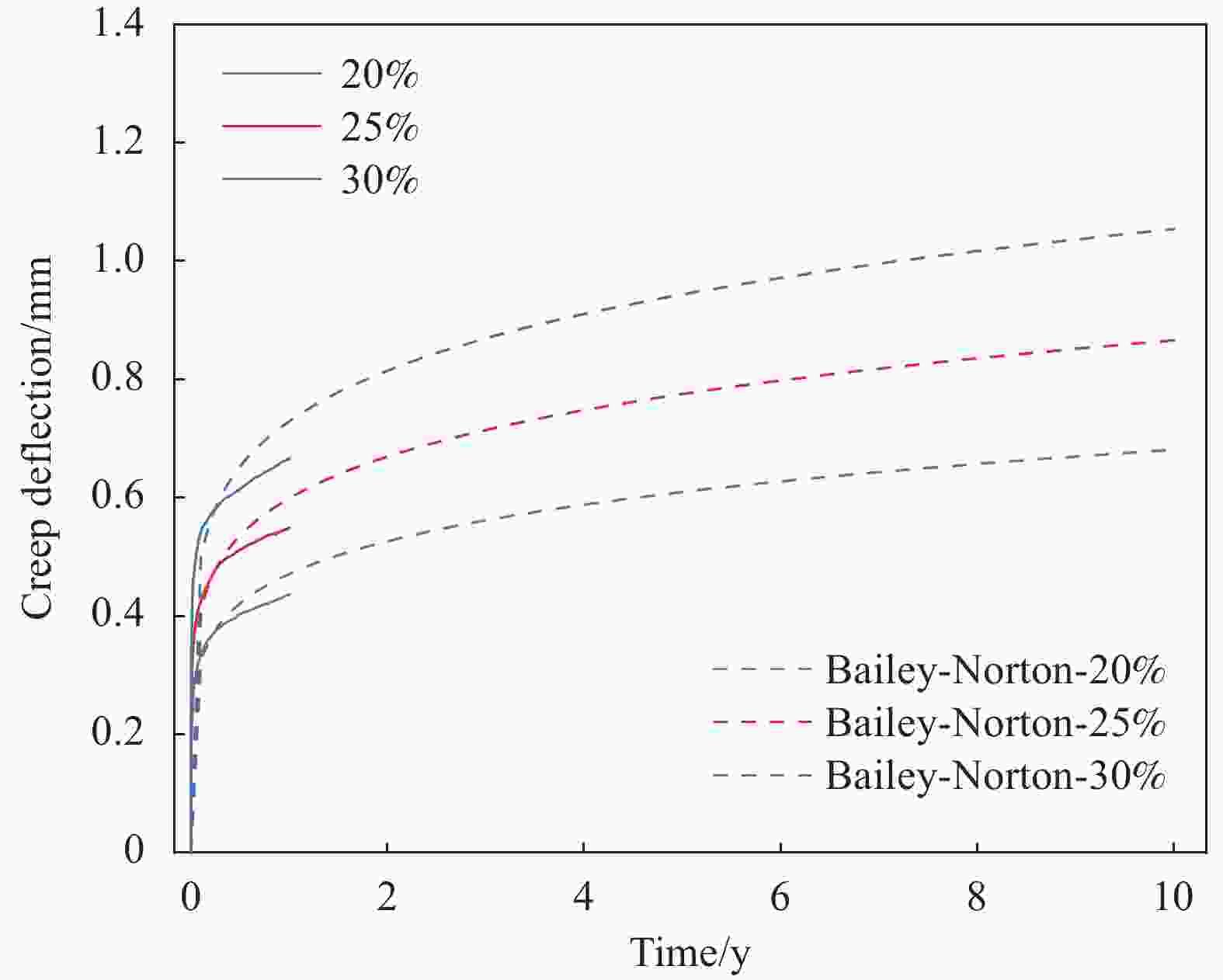

摘要: 以玻璃纤维增强复合材料(GFRP)为面层,轻木(balsa)为芯材的GFRP-balsa夹芯结构在基础设施领域的应用范围不断扩大,但GFRP-balsa夹芯结构具有粘弹性,易于发生蠕变变形。为此,在温度为(25±1)°C,相对湿度为55%±5%的环境下,利用自主设计的弯曲蠕变加载装置对GFRP-balsa夹芯梁在20%、25%和30%荷载等级下的三点弯曲蠕变性能进行了3000~8760 h的测试,并利用多种模型对GFRP-balsa夹芯梁的蠕变响应进行了模拟和预测。结果表明:在试验荷载等级下,GFRP-balsa夹芯梁表现出线性粘弹性;弯曲蠕变对GFRP-balsa夹芯梁的跨中挠度具有重要影响,所有试件在3000 h的蠕变系数均不小于0.35;Findley模型适用于单一荷载等级下GFRP-balsa夹芯梁时变总挠度的拟合,在3000 h的拟合值与试验值之间的最大相对误差仅为0.7%;Bailey-Norton模型和通用幂次律模型分别适用于荷载等级不超过30%的GFRP-balsa夹芯梁蠕变挠度和时变总挠度的预测,在一年时,Bailey-Norton模型和通用幂次律模型预测值与试验值之间的最大相对误差分别为8.3%和5.9%。

-

关键词:

- 玻璃纤维增强复合材料 /

- 轻木 /

- 夹芯梁 /

- 弯曲蠕变 /

- 预测模型

Abstract: The application scope of the glass fiber reinforced plastic (GFRP)-balsa sandwich structure composed of GFRP facings and a balsa wood core is constantly expanding in the field of infrastructure. However, GFRP-balsa sandwich structures are susceptible to creep deformation due to their viscoelasticity. Under the controlled temperature of (25±1)°C and relative humidity of 55%±5%, the three-point flexural creep performance of the GFRP-balsa sandwich beams at 20%, 25% and 30% load levels were tested for a period of 3000~8760 h using the self-designed flexural creep loading devices. Various models were used to simulate and predict the creep response of the GFRP-balsa sandwich beams. The results show that the GFRP-balsa sandwich beams exhibit linear viscoelasticity at the test load levels. Flexural creep has an important impact on the mid-span deflection of the GFRP-balsa sandwich beams, and the creep coefficients at 3000 h of all the specimens are not less than 0.35. The Findley model is applicable for fitting the time-dependent total deflection of the GFRP-balsa sandwich beams at a single load level, and the maximum relative error between the fitting value and the test value at 3000 h is only 0.7%. The Bailey-Norton model and the general power law model are applicable for predicting the creep deflection and the time-dependent total deflection of the GFRP-balsa sandwich beams when the load level does not exceed 30%, respectively. At one year, the maximum relative error between the predicted value of the Bailey-Norton model and the test value is 8.3%, and the maximum relative error between the predicted value of the general power law model and the test value is 5.9%.-

Key words:

- glass fiber reinforced plastic /

- balsa /

- sandwich beam /

- flexural creep /

- prediction model

-

表 1 蠕变测试试件尺寸及加载情况汇总

Table 1. Summary of the dimensions and the loading conditions of the creep test specimens

Specimen Length

/mmWidth

/mmDepth

/mmF/N 20%-1 380.3 69.82 28.80 1196 20%-2 379.8 69.88 28.76 20%-3 380.5 70.02 28.74 25%-1 380.0 69.90 28.82 1495 25%-2 380.2 69.96 28.78 25%-3 379.4 69.96 28.70 30%-1 380.0 69.78 28.74 1794 30%-2 380.2 69.98 28.72 30%-3 380.1 70.00 28.78 Notes: "20%", "25%" and "30%" refer to the load level; "−1", "−2" and "−3" refer to the serial number in a repeated test; F—Required force to be applied at the loading point. 表 2 GFRP-balsa夹芯梁三点弯曲蠕变测试结果汇总

Table 2. Summary of the three-point flexural creep test results of the GFRP-balsa sandwich beams

Specimen d/mm da/mm D/mm Da/mm Dc/mm Dca/mm $\phi $ 20%-1 1.11 1.03 ± 0.075 1.52 1.43 ± 0.085 0.41 0.40 ± 0.012 0.37 20%-2 0.96 1.35 0.39 0.41 20%-3 1.03 1.42 0.39 0.38 25%-1 1.30 1.32 ± 0.082 1.80 1.81 ± 0.091 0.50 0.49 ± 0.012 0.38 25%-2 1.25 1.73 0.48 0.38 25%-3 1.41 1.91 0.50 0.35 30%-1 1.55 1.60 ± 0.050 2.15 2.19 ± 0.040 0.60 0.59 ± 0.021 0.39 30%-2 1.65 2.23 0.57 0.35 30%-3 1.60 2.20 0.61 0.38 Notes: d—Initial static deflection; da—Mean initial static deflection; D—Total deflection at 3000 h; Da—Mean total deflection at 3000 h; Dc—Creep deflection at 3000 h; Dca—Mean creep deflection at 3000 h; $\phi $—Creep coefficient at 3000 h. 表 3 不同荷载等级下GFRP-balsa夹芯梁测试跨中挠度与容许挠度的对比

Table 3. Comparison of the test mid-span deflections and the allowable deflections of the GFRP-balsa sandwich beams at the different load levels

Load level Deflection type Comparison [l/150] [l/200] [l/250] 20% da < < < Da < < > 25% da < < > Da < > > 30% da < > > Da > > > Notes: da—The mean initial static deflection; Da—The mean total deflection at 3000 h; l—The span length. 表 4 Findley模型中各参数拟合结果汇总

Table 4. Summary of the fitting results of various parameters in the Findley model

Load level d a N R2 20% 0.9798 0.1481 0.1410 0.9953 25% 1.2752 0.1767 0.1410 0.9978 30% 1.5454 0.2299 0.1320 0.9971 Notes: d—Initial static deflection; a—Amplitude of creep; N—Time exponent; R2—Determination coefficients. 表 5 GFRP-balsa夹芯梁一年时的蠕变测试值与模型预测值对比

Table 5. Comparison of the creep test values and the model prediction values at one year for the GFRP-balsa sandwich beams

Load level Dce

/mmDcB

/mmδ1

/%De

/mmDG

/mmδ2

/%20% 0.44 0.47 6.4 1.47 1.48 0.7 25% 0.55 0.60 8.3 1.85 1.91 3.1 30% 0.67 0.73 8.2 2.22 2.36 5.9 Notes: Dce—The creep deflection test value at one year; DcB—The Bailey-Norton model extrapolated value at one year; δ1—The relative error between Dce and DcB; De—The total deflection test value at one year; DG—The general power law model prediction value at one year; δ2—The relative error between De and DG. -

[1] CHENG Y, REN K, FU J, et al. Simulation study on the anti-penetration performance and energy absorption characteristics of honeycomb aluminum sandwich structure[J]. Composite Structures, 2023, 310: 116776. doi: 10.1016/j.compstruct.2023.116776 [2] HUANG S, LIU Y, WEN K, et al. Optimization design of a novel microwave absorbing honeycomb sandwich structure filled with magnetic shear-stiffening gel[J]. Composites Science and Technology, 2023, 232: 109883. doi: 10.1016/j.compscitech.2022.109883 [3] CHEN C, FANG H, ZHU L, et al. Low-velocity impact properties of foam-filled composite lattice sandwich beams: Experimental study and numerical simulation[J]. Composite Structures, 2023, 306: 116573. doi: 10.1016/j.compstruct.2022.116573 [4] JOSEPH C, MUTHUKUMAR C, NG L F, et al. The effect of nanoclay on the performance of basalt-epoxy facesheet and foam core sandwich panels[J]. Journal of Sandwich Structures & Materials, 2023, 25(7): 730-746. [5] ZHANG L, LIU W, WANG L, et al. Mechanical behavior and damage monitoring of pultruded wood-cored GFRP sandwich components[J]. Composite Structures, 2019, 215: 502-520. doi: 10.1016/j.compstruct.2019.02.084 [6] ÖNAL T, TEMIZ Ş. Experimental and numerical investigation of flexural behavior of balsa core sandwich composite structures[J]. Materials Testing, 2023, 65(7): 1056-1068. doi: 10.1515/mt-2022-0375 [7] FANG H, BAI Y, LIU W, et al. Connections and structural applications of fibre reinforced polymer composites for civil infrastructure in aggressive environments[J]. Composites Part B:Engineering, 2019, 164: 129-143. doi: 10.1016/j.compositesb.2018.11.047 [8] 刘伟庆, 方海, 方园. 纤维增强复合材料及其结构研究进展[J]. 建筑结构学报, 2019, 40(4): 1-16. doi: 10.14006/j.jzjgxb.2019.04.001LIU Weiqing, FANG Hai, FANG Yuan. Research progress of fiber-reinforced composites and structures[J]. Journal of Building Structures, 2019, 40(4): 1-16(in Chinese). doi: 10.14006/j.jzjgxb.2019.04.001 [9] CHEN J, ZHUANG Y, FANG H, et al. Energy absorption of foam-filled lattice composite cylinders under lateral compressive loading[J]. Steel and Composite Structures, 2019, 31(2): 133-148. [10] GARRIDO M, MADEIRA J F A, PROENÇA M, et al. Multi-objective optimization of pultruded composite sandwich panels for building floor rehabilitation[J]. Construction and Building Materials, 2019, 198: 465-478. doi: 10.1016/j.conbuildmat.2018.11.259 [11] 梁军, 杜善义. 粘弹性复合材料力学性能的细观研究[J]. 复合材料学报, 2001, 18(1): 97-100. doi: 10.3321/j.issn:1000-3851.2001.01.023LIANG Jun, DU Shanyi. Study of mechanical properties of viscoelastic matrix composite by micromechanics[J]. Acta Materiae Compositae Sinica, 2001, 18(1): 97-100(in Chinese). doi: 10.3321/j.issn:1000-3851.2001.01.023 [12] 张尧, 朱四荣, 陆士平, 等. 考虑界面效应的GFRP复合材料蠕变模型[J]. 复合材料学报, 2021, 38(11): 3682-3692. doi: 10.13801/j.cnki.fhclxb.20210119.001ZHANG Yao, ZHU Sirong, LU Shiping, et al. Creep model of GFRP composites considering interface effect[J]. Acta Materiae Compositae Sinica, 2021, 38(11): 3682-3692(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210119.001 [13] HUANG J S, GIBSON L J. Creep of sandwich beams with polymer foam cores[J]. Journal of Materials in Civil Engineering, 1990, 2(3): 171-182. doi: 10.1061/(ASCE)0899-1561(1990)2:3(171) [14] SHENOI R A, ALLEN H G, CLARK S D. Cyclic creep and creep-fatigue interaction in sandwich beams[J]. Strain Analysis for Engineering Design, 1997, 32(1): 1-18. doi: 10.1243/0309324971513175 [15] CHEN Z, YAN N, DENG J, et al. Flexural creep behavior of sandwich panels containing Kraft paper honeycomb core and wood composite skins[J]. Materials Science and Engineering:A, 2011, 528(16-17): 5621-5626. doi: 10.1016/j.msea.2011.03.092 [16] DU Y, YAN N, KORTSCHOT M T. An experimental study of creep behavior of lightweight natural fiber-reinforced polymer composite/honeycomb core sandwich panels[J]. Composite Structures, 2013, 106: 160-166. doi: 10.1016/j.compstruct.2013.06.007 [17] GARRIDO M, CORREIA J R, BRANCO F A, et al. Creep behaviour of sandwich panels with rigid polyurethane foam core and glass-fibre reinforced polymer faces: Experimental tests and analytical modelling[J]. Journal of Composite Materials, 2014, 48(18): 2237-2249. doi: 10.1177/0021998313496593 [18] GARRIDO M, CORREIA J R, KELLER T, et al. Creep of sandwich panels with longitudinal reinforcement ribs for civil engineering applications: Experiments and composite creep modeling[J]. Journal of Composites for Construction, 2017, 21(1): 1-11. [19] GARRIDO M, CORREIA J R, KELLER T. Effect of service temperature on the flexural creep of vacuum infused GFRP laminates used in sandwich floor panels[J]. Composites Part B:Engineering, 2016, 90: 160-171. doi: 10.1016/j.compositesb.2015.12.027 [20] GARRIDO M, CORREIA J R, KELLER T. Effect of service temperature on the shear creep response of rigid polyurethane foam used in composite sandwich floor panels[J]. Construction and Building Materials, 2016, 118: 235-244. doi: 10.1016/j.conbuildmat.2016.05.074 [21] BOTTONI M, MAZZOTTI C, SAVOIA M. Creep tests on GFRP pultruded specimens subjected to traction or shear[J]. Composite Structures, 2014, 108: 514-523. doi: 10.1016/j.compstruct.2013.09.057 [22] GONILHA J A, CORREIA J R, BRANCO F A. Creep response of GFRP-concrete hybrid structures: Application to a footbridge prototype[J]. Composites Part B:Engineering, 2013, 53: 193-206. doi: 10.1016/j.compositesb.2013.04.054 [23] GARRIDO M, CORREIA J R. Elastic and viscoelastic behaviour of sandwich panels with glass-fibre reinforced polymer faces and polyethylene terephthalate foam core[J]. Journal of Sandwich Structures and Materials, 2018, 20(4): 399-424. doi: 10.1177/1099636216657388 [24] KELLER T, ROTHE J, CASTRO J D, et al. GFRP-balsa sandwich bridge deck: concept, design, and experimental validation[J]. Journal of Composites for Construction, 2014, 18(2): 785-793. [25] American Society for Testing and Materials. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039/3039M-17 [S]. West Conshohocken, PA, USA: ASTM International, 2017. [26] American Society for Testing and Materials. Standard test method for compressive properties of polymer matrix composite materials with unsupported gage section by shear loading: ASTM D3410/D3410M-16 [S]. West Conshohocken, PA, USA: ASTM International, 2016. [27] American Society for Testing and Materials. Standard test method for core shear properties of sandwich constructions by beam flexure: ASTM C393/C393M-20 [S]. West Conshohocken, PA, USA: ASTM International, 2016. [28] American Society for Testing and Materials. Standard test method for flexure creep of sandwich constructions: ASTM C480/C480M-16 [S]. West Conshohocken, PA, USA: ASTM International, 2016. [29] American Society for Testing and Materials. Standard test methods for direct moisture content measurement of wood and wood-based materials: ASTM D4442-20 [S]. West Conshohocken, PA, USA: ASTM International, 2020. [30] SCOTT D W, ZUREICK A H. Compression creep of a pultruded E-glass/vinylester composite[J]. Composites Science and Technology, 1998, 58(8): 1361-1369. doi: 10.1016/S0266-3538(98)00009-8 -

下载:

下载: