Preparation of carbon fiber heating elements and their effects on the properties of resistance welding joints in thermoplastic composite materials

-

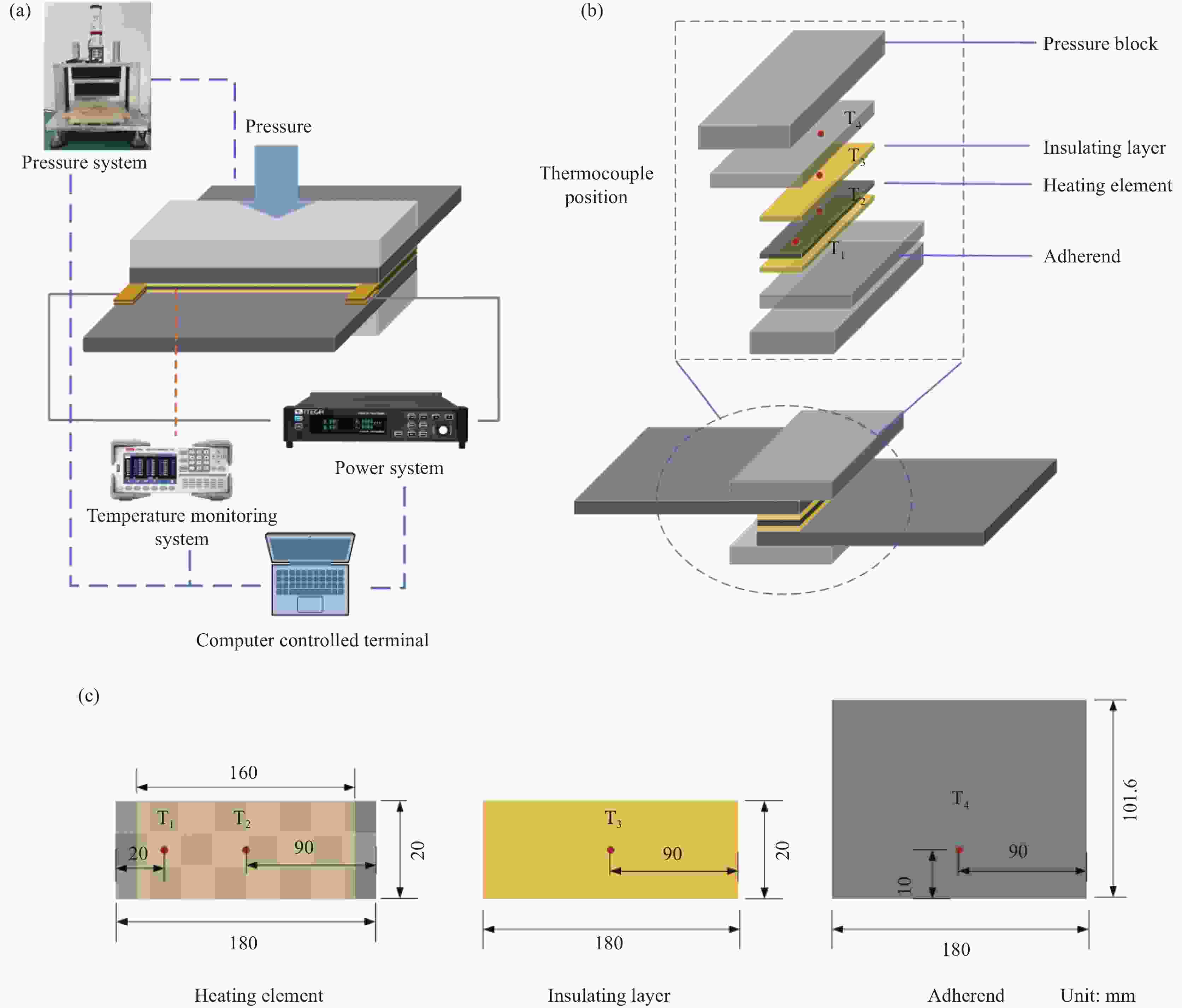

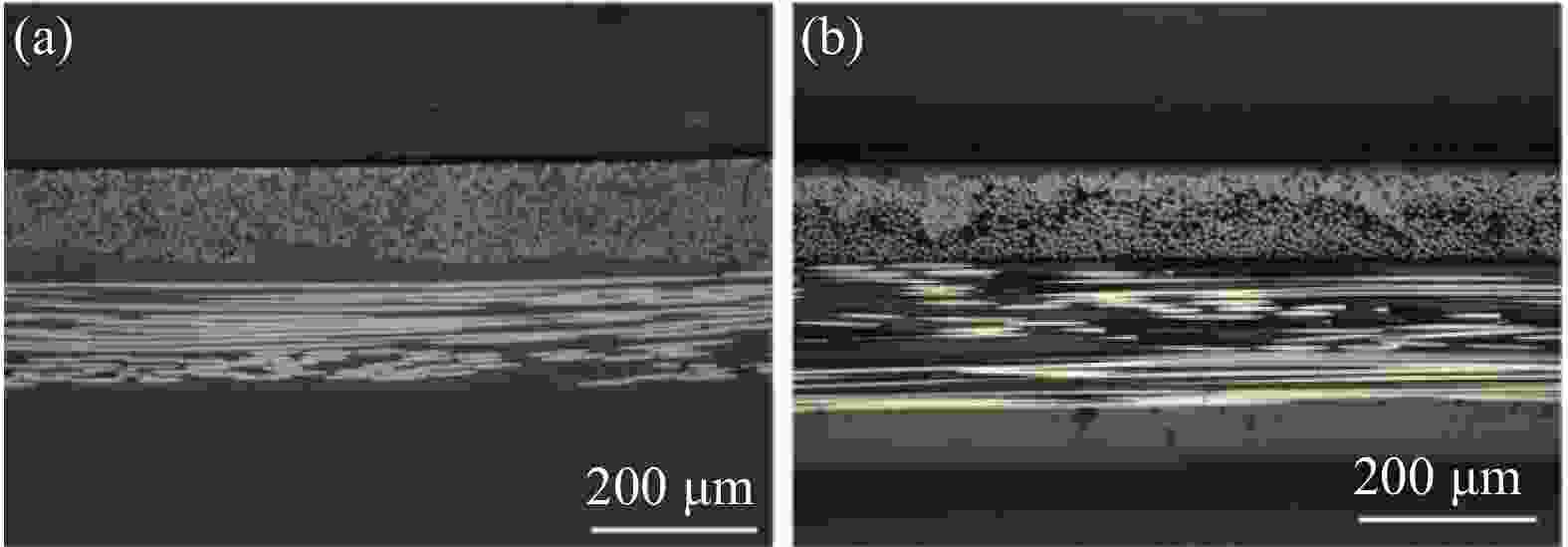

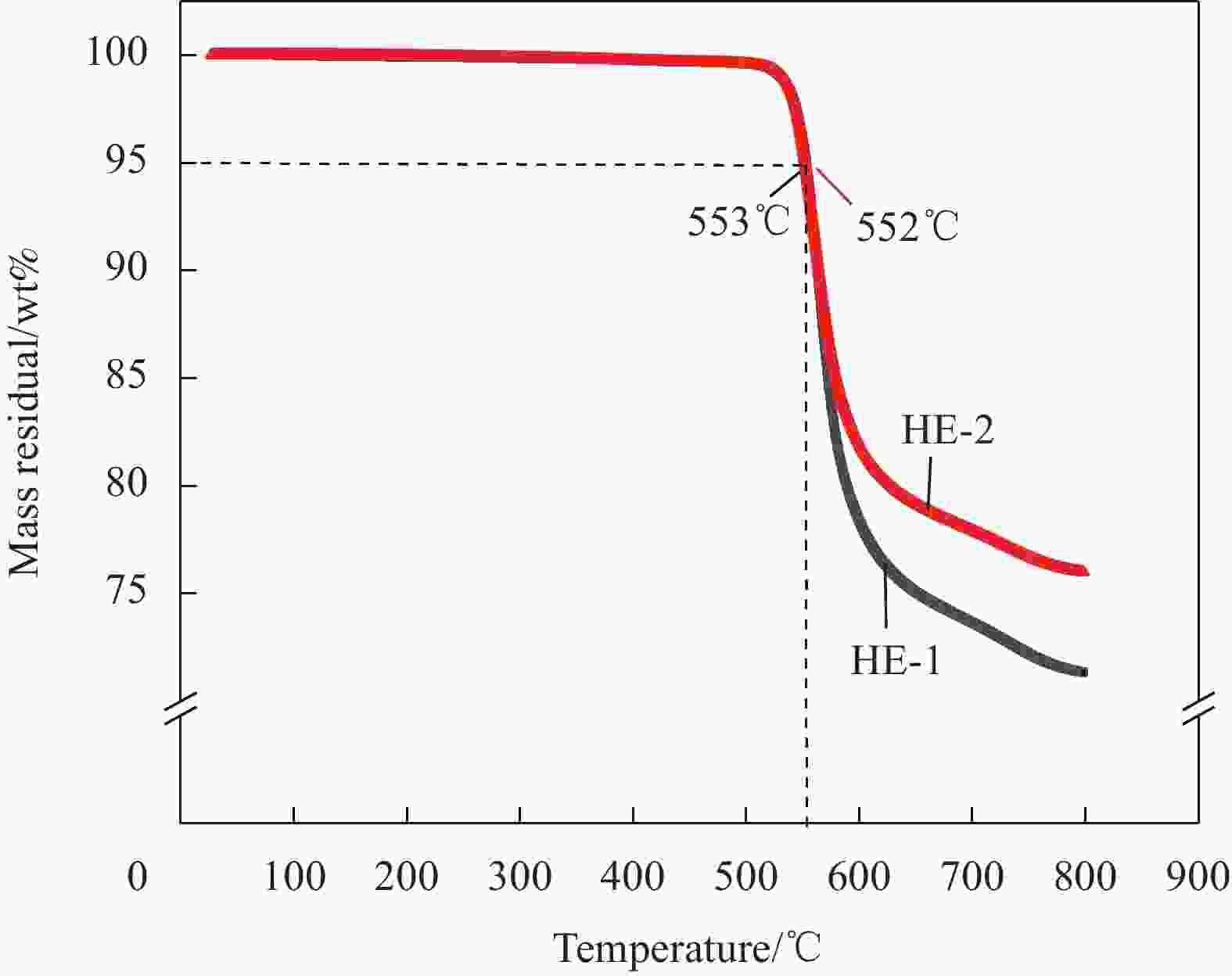

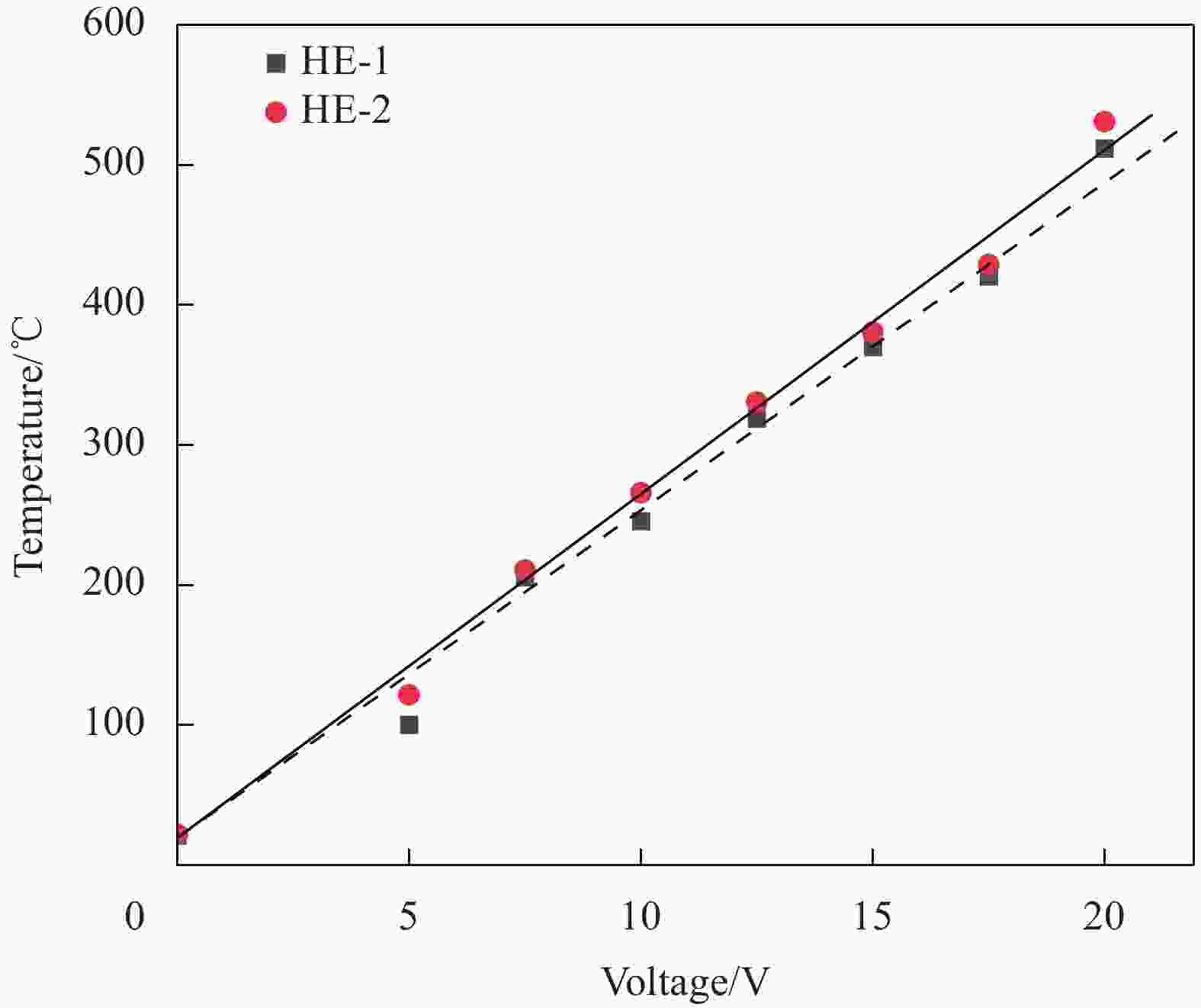

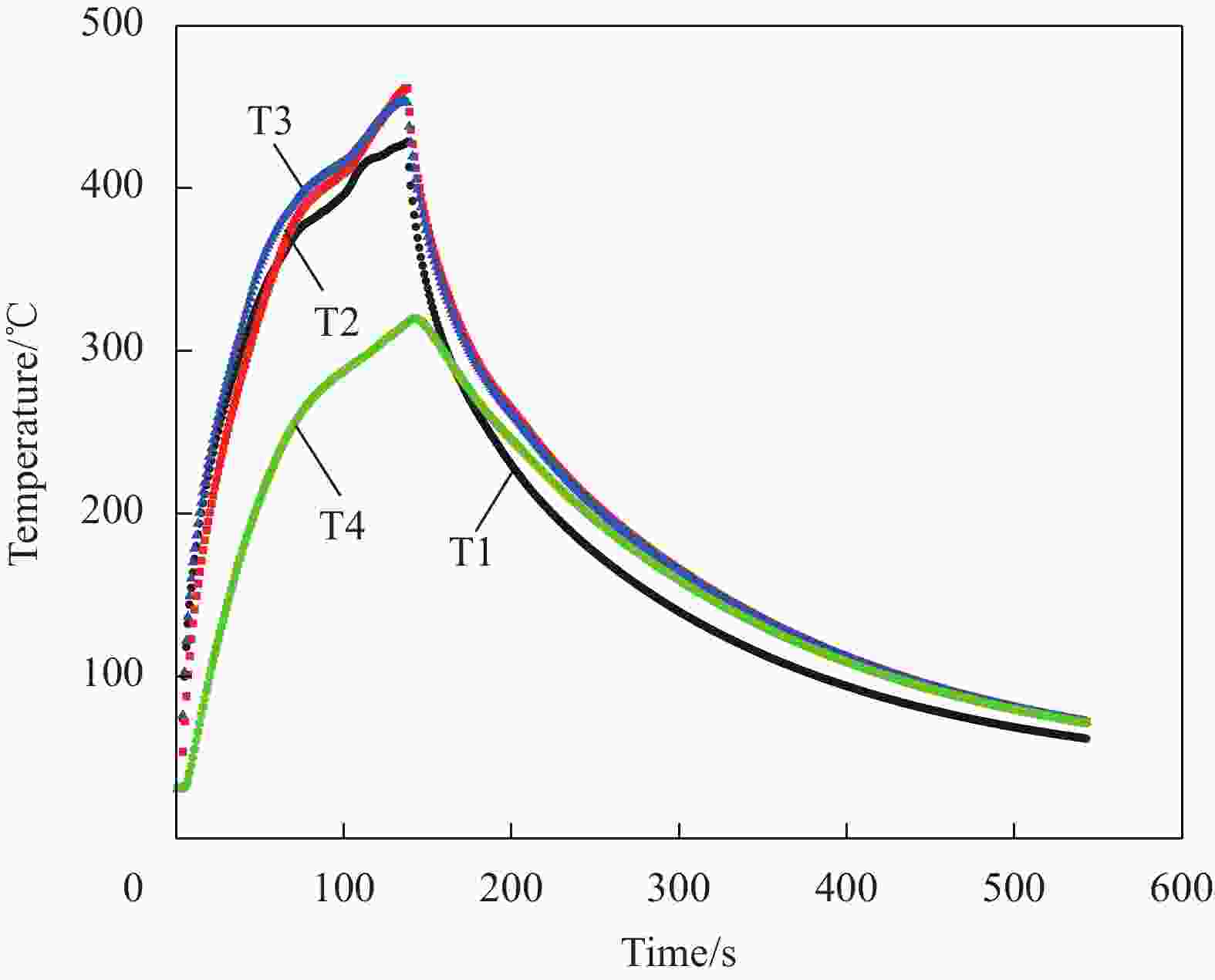

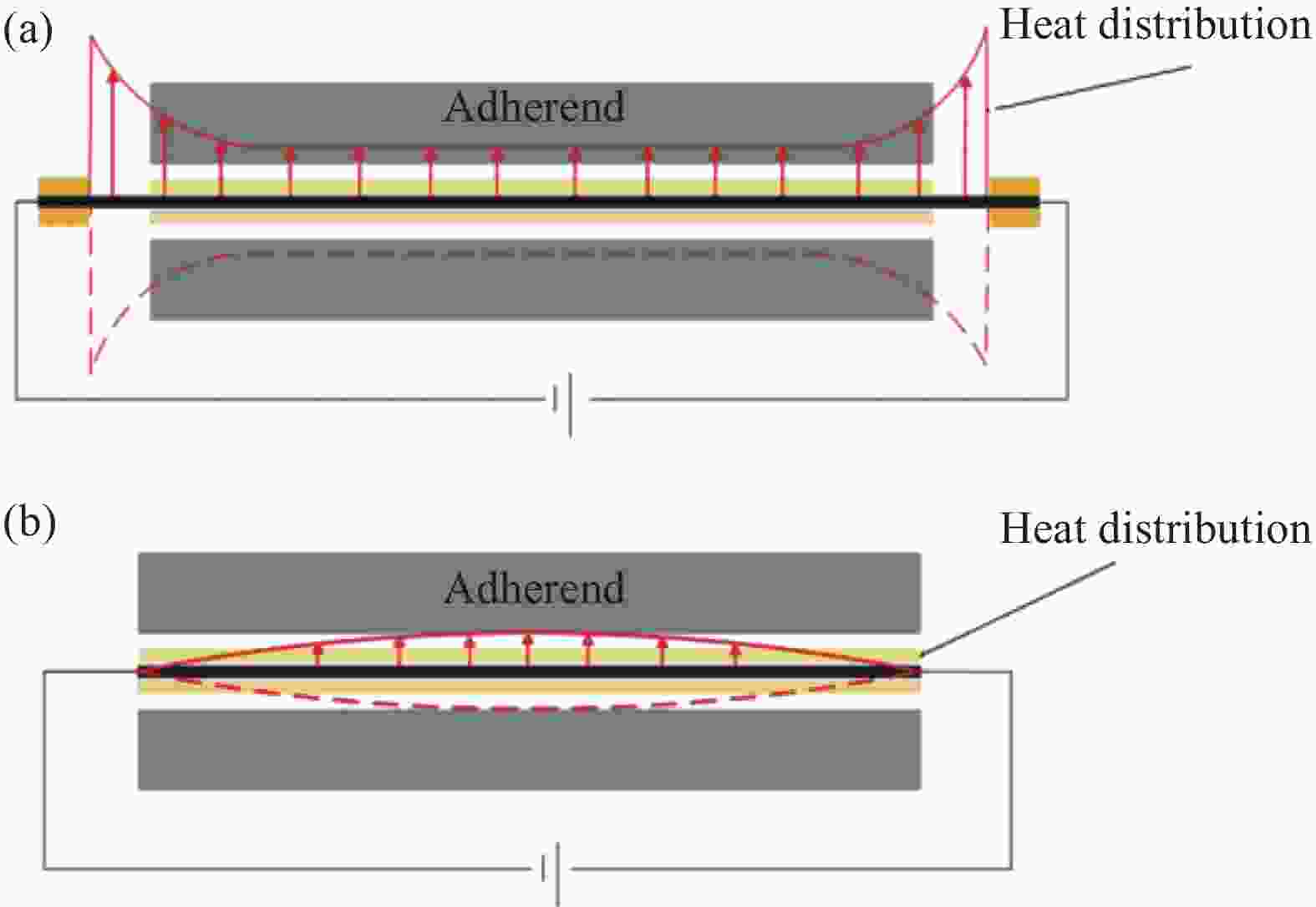

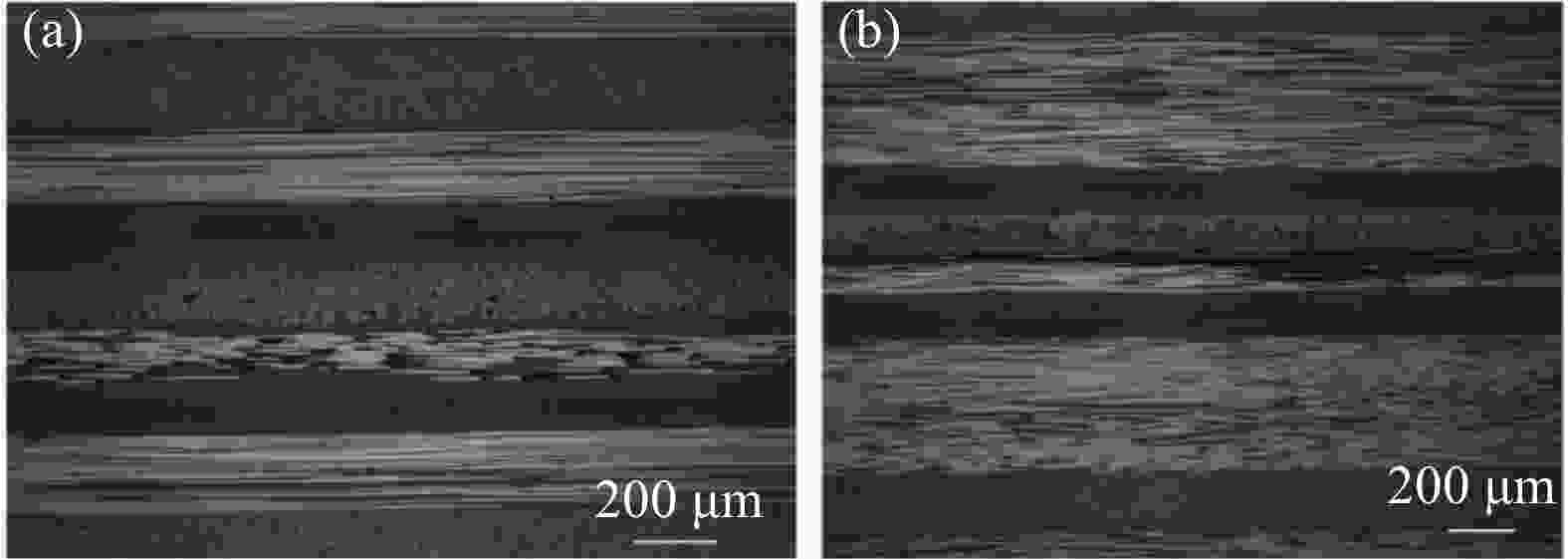

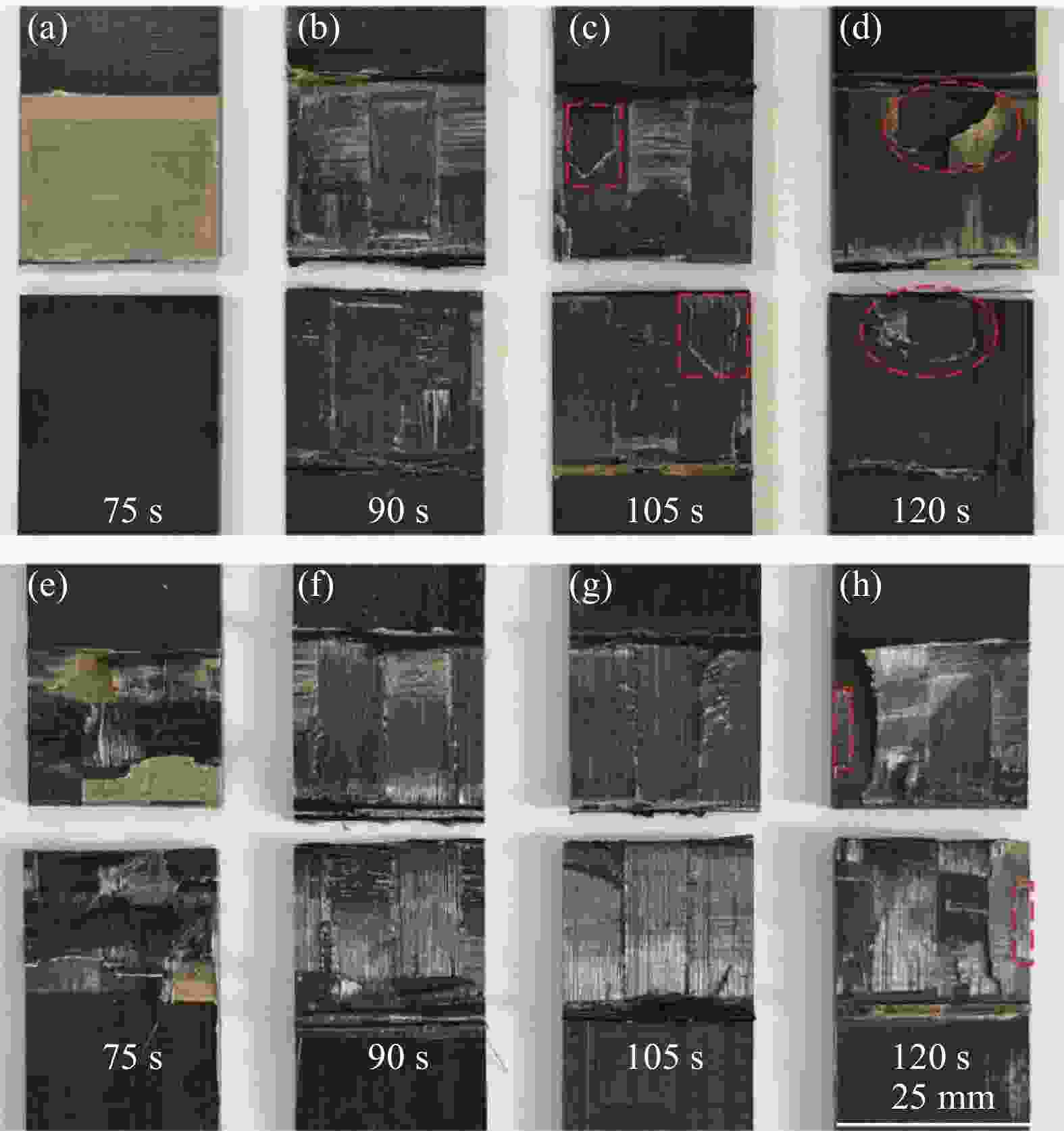

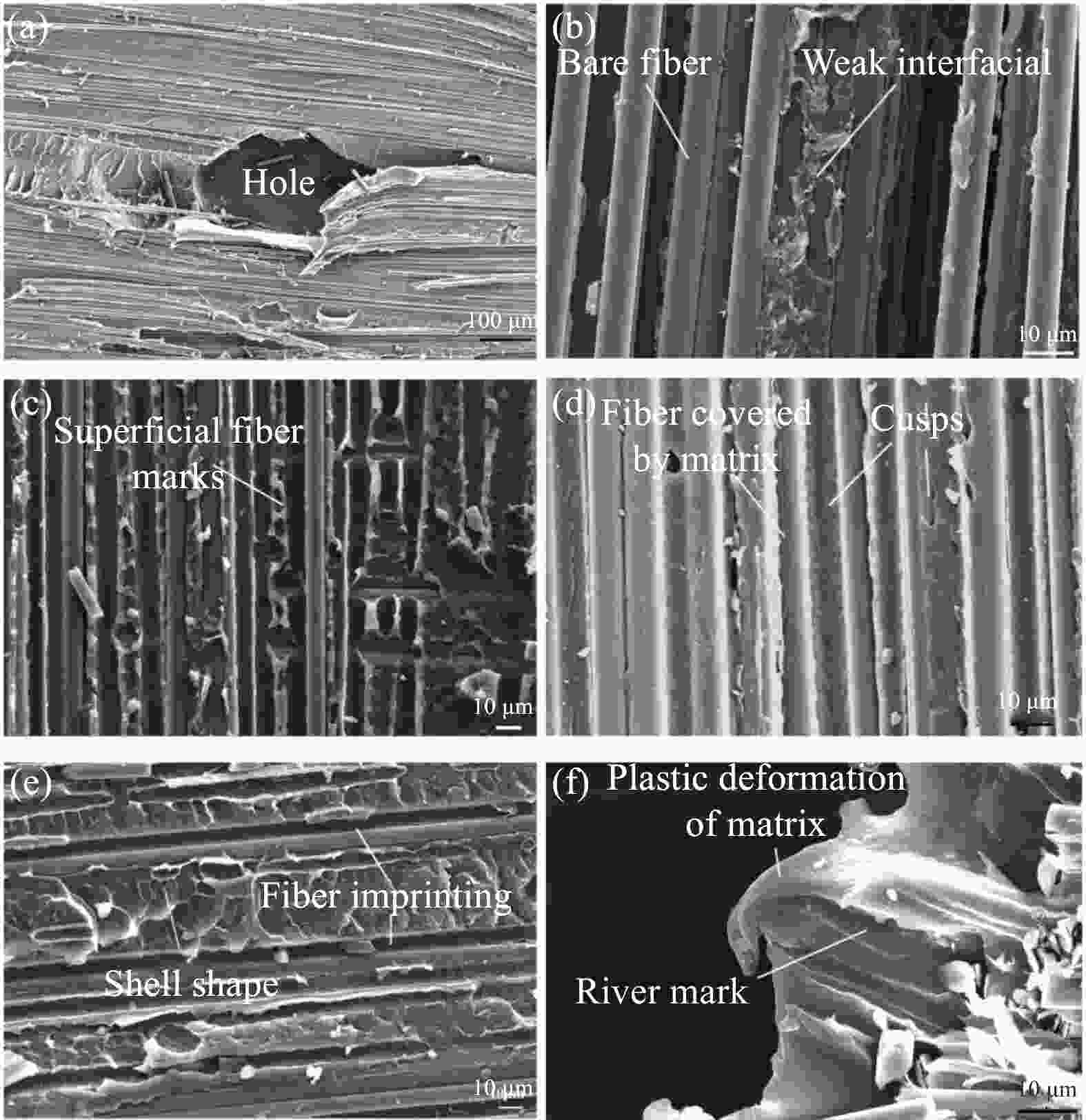

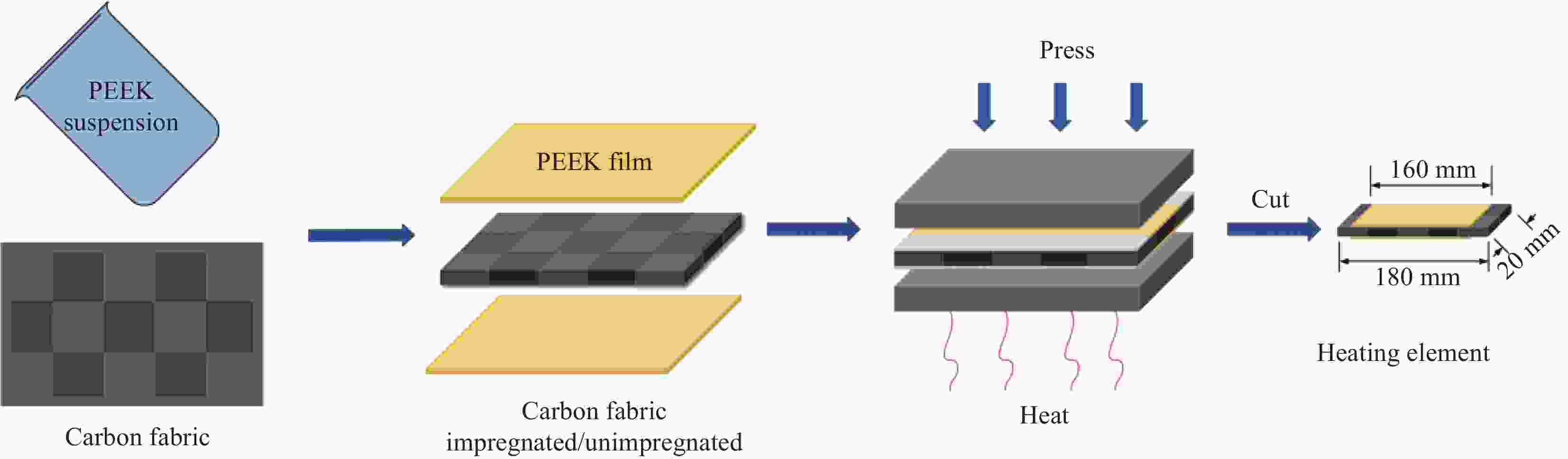

摘要: 本文采用聚醚醚酮(PEEK)粉末悬浮浸渍工艺和PEEK树脂膜熔融浸渍工艺制备了两种不同的薄层碳纤维展宽布加热元件,并对碳纤维增强聚醚醚酮复合材料层合板的电阻焊接技术进行了实验研究。结果表明,采用“埋入式”电极布置方式,有效避免了电阻焊接过程中因加热元件裸露而产生的“边缘效应”现象。加热时间对焊接接头强度有明显的影响,接头强度随加热时间先增加后减小,在120 s时达到最大值28.1 MPa,断口失效模式从最初的粘接失效变为植入体与纤维的混合失式模式。对比粉末悬浮浸渍与熔融浸渍两种工艺制备的加热元件相应的焊接接头强度,在相同焊接工艺条件下前者相比后者提升15%。Abstract: This paper presents the preparation of two types of thin-layer carbon fiber stretched-width cloth heating elements using the suspension impregnation process with polyether-ether-ketone (PEEK) powder and the melt impregnation process with PEEK resin film. The resistance welding technology for carbon fiber reinforced polyether-ether-ketone composite laminates was experimentally investigated. The results demonstrated that employing an “embedded type” electrode arrangement effectively mitigates the “edge effect” caused by exposed heating elements during resistance welding. Moreover, it was found that the heating time significantly influences the strength of welded joints, which initially increases and then decreases, reaching a maximum value of 28.1 MPa at 120 s. Additionally, the fracture failure mode has changed from initial adhesive failure to a mixed failure mode of implant and fiber. Furthermore, compared to melt impregnation, powder suspension impregnation process enhance joint strength by 15% under identical welding conditions.

-

Key words:

- resistance welding /

- thermoplastic composite material /

- PEEK /

- failure mode /

- mechanical property

-

表 1 加热元件单位长度的电阻值

Table 1. Resistance per unit length of heating element

Heating Element Resistance per unit length/(Ω·m−1) HE-1 12.1 HE-2 12.5 -

[1] 周典瑞, 高亮, 霍红宇, 等. 热塑性树脂基复合材料用碳纤维上浆剂研究进展[J]. 复合材料学报, 2020, 37(08): 1785-1795.ZHOU DIANRUI, GAO LIANG, HUO HONGYU, et al. Research progress of carbon fiber sizing agents for thermoplastic composites[J]. Acta Materiae Compositae Sinica, 2020, 37(08): 1785-1795(in Chinese). [2] 高亮, 贾伟, 石峰晖, 等. 反气相色谱法测定聚醚醚酮的表面性质及在提升热塑性复合材料层间性能中的应用[J]. 复合材料学报, 2023, 40(05): 2587-2597.GAO LIANG, JIA WEI, SHI FENGHUI, et al. Surface characterization of polyether-ether-ketone by inverse gas chromatography and the application in the improvement of thermoplastic composites interlaminar performance[J]. Acta Materiae Compositae Sinica, 2023, 40(05): 2587-2597 (in Chinese). [3] 马全胜, 李俊含, 田思戗. 热塑性复合材料的成型工艺及其在航空器中的应用[J]. 化工新型材料, 2022, 50(06): 263-266+271.MA QUNSHENG, LI JUNHAN, TIAN SIQIANG. Forming technology of thermoplastic composite its application in aircraft[J]. New Chemical Materials, 2022, 50(06): 263-266+271(in Chinese). [4] GALLAGHER E A, LAMORINIERE S, MCGARRY P. Multi-axial damage and failure of medical grade carbon fibre reinforced PEEK laminates: Experimental testing and computational modelling[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2018, 82: 154-167. doi: 10.1016/j.jmbbm.2018.03.015 [5] 张婷. 高性能热塑性复合材料在大型客机结构件上的应用[J]. 航空制造技术, 2013, (15): 32-5.ZHANG TING. Applications of High Performance Thermoplastic Composites for Commercial Airplane Structural Component[J]. Aeronautical Manufacturing Technology, 2013, (15): 32-5(in Chinese). [6] 肇研, 刘寒松. 连续纤维增强高性能热塑性树脂基复合材料的制备与应用[J]. 材料工程, 2020, 48(08): 49-61.ZHAO YAN, LIU HANSONG. Preparation and application of continuous fiber reinforced high- performance thermoplastic composites[J]. Journal of Materials Engineering, 2020, 48(08): 49-61(in Chinese). [7] BENGU YILDIZ ZEYREK B A, ESRA DILEKCAN , FAHRETTIN OZTURK. Review of Thermoplastic Composites in Aerospace Industry[J]. International Journal on Engineering Technologies and Informatics, 2022, 3(1): 1-6. [8] STAVROV D, BERSEE H E N. Resistance welding of thermoplastic composites - an overview[J]. Composites Part a-Applied Science and Manufacturing, 2005, 36(1): 39-54. doi: 10.1016/S1359-835X(04)00182-4 [9] AHMED T, STAVROV D, BERSEE H, et al. Induction welding of thermoplastic composites—an overview[J]. Composites Part A:Applied Science and Manufacturing, 2006, 37(10): 1638-1651. doi: 10.1016/j.compositesa.2005.10.009 [10] LI H J, CHEN C, YI R X, et al. Ultrasonic welding of fiber-reinforced thermoplastic composites: a review[J]. International Journal of Advanced Manufacturing Technology, 2022, 120(1-2): 29-57. doi: 10.1007/s00170-022-08753-9 [11] HAQUE M S, MOEED K, ZAKA M Z. Laser welding of thermoplastics–A review[J]. Materials Today:Proceedings, 2022, 64: 1479-1485. doi: 10.1016/j.matpr.2022.04.900 [12] 王飞云, 罗杰帮, 张平则, 等. 碳纤维感应元件厚度对碳纤维增强热塑性复合材料感应焊接接头力学性能及断裂形式的影响[J]. 复合材料学报, 2023, 40(04): 2405-2414.WANG FEIYUN, LUO JIEBANG, ZHANG PINGZE, et al. Effect of thickness of carbon fiber susceptor on mechanical property and fracture mode of carbon fiber reinforced thermoplastic composite induction welded joint[J]. Acta Materiae Compositae Sinica, 2023, 40(04): 2405-2414(in Chinese). [13] 杨苑铎, 李洋, 李一昂, 等. 碳纤维增强热塑性复合材料超声波焊接研究进展[J]. 机械工程学报, 2021, 57(22): 130-156. doi: 10.3901/JME.2021.22.130YANG YUANDUO, LI YANG, LI YIANG, et al. Advances in Ultrasonic Welding of Carbon Fiber Reinforced Thermoplastic Composites[J]. Journal of Mechanical Engineering, 2021, 57(22): 130-156(in Chinese). doi: 10.3901/JME.2021.22.130 [14] 焦俊科, 徐纪豪, 井成虎, 等. 碳纤维增强热塑性复合材料/钛合金激光焊接模拟仿真研究[J]. 航空制造技术, 2022, 65(21): 45-53.JIAO JUNKE, XU JIHAO, JING CHENGHU, et al. Numerical simulation of laser welding of carbon fiber reinforced thermoplastic composites and titanium alloy[J]. Aeronautical Manufacturing Technology, 2022, 65(21): 45-53(in Chinese). [15] OFFRINGA A. New thermoplastic composite design concepts and their automated manufacture: AERONAUTICS[J]. JEC composites, 2010, (58): 45-9. [16] Ginger Gardiner. Thermoplastic composite demonstrators-EU roadmap for future airframes [EB/OL], https://www.compositesworld.com/news/stunning-project-completes-lower-half-of-mffd, 2023-07-02. [17] WEI D L, GU Y Z, ZHU H R, et al. Influence of Electrical Heating Metal Mesh and Power Density on Resistance Welding of Carbon Fiber/PEEK Composite[J]. Polymers, 2022, 14(13). [18] GONZALEZ I, SANZ A, FERNANDEZ A. Characterization of metal heating elements for resistance welding of thermoplastic matrix composites (PEEK); proceedings of the 5th Manufacturing Engineering Society International Conference (MESIC), Univ Zaragoza, Zaragoza, SPAIN, F Jun 26-28, 2013 [C]. 2014. [19] ROHART V, LEBEL L L, DUBE M. Improved adhesion between stainless steel heating element and PPS polymer in resistance welding of thermoplastic composites[J]. Composites Part B-Engineering, 2020, 188: 107876. doi: 10.1016/j.compositesb.2020.107876 [20] LI X K, SUN M C, SONG J P, et al. Enhanced adhesion between PEEK and stainless-steel mesh in resistance welding of CF/PEEK composites by various surface treatments[J]. High Performance Polymers, 2021, 33(8): 892-904. doi: 10.1177/09540083211001115 [21] ROHART V, LEBEL L L, DUBE M. Effects of environmental conditions on the lap shear strength of resistance-welded carbon fibre/thermoplastic composite joints[J]. Composites Part B-Engineering, 2020, 198: 108239. doi: 10.1016/j.compositesb.2020.108239 [22] AGEORGES C, YE L, HOU M. Experimental investigation of the resistance welding for thermoplastic-matrix composites. Part I: heating element and heat transfer[J]. Composites Science and Technology, 2000, 60(7): 1027-1039. doi: 10.1016/S0266-3538(00)00005-1 [23] AGEORGES C, YE L, MAI Y-W, et al. Characteristics of resistance welding of lap shear coupons. : Part II. Consolidation[J]. Composites Part A:Applied Science and Manufacturing, 1998, 29(8): 911-919. doi: 10.1016/S1359-835X(98)00023-2 [24] 路鹏程, 陈栋, 王志平. 碳纤维/聚苯硫醚热塑性复合材料电阻焊接工艺[J]. 复合材料学报, 2020, 37(05): 1041-1048.LU PENGCHENG, CHEN DONG, WANG ZHIPING. Resistance welding technology of carbon fiber/polyphenylene sulfide thermoplastic composites[J]. Acta Materiae Compositae Sinica, 2020, 37(05): 1041-1048(in Chinese). [25] ASTM International. Standard test method for lap shear adhesion for fiber reinforced plastic (FRP) bonding: ASTM D5868—01[S]. West Conshohocken: ASTM International, 2014. [26] XIONG X H, WANG D S, WEI J, et al. Resistance welding technology of fiber reinforced polymer composites: a review[J]. Journal of Adhesion Science and Technology, 2021, 35(15): 1593-1619. doi: 10.1080/01694243.2020.1856514 -

下载:

下载: