Preparation and electrical properties of recyclable high performance dual-curing epoxy resin

-

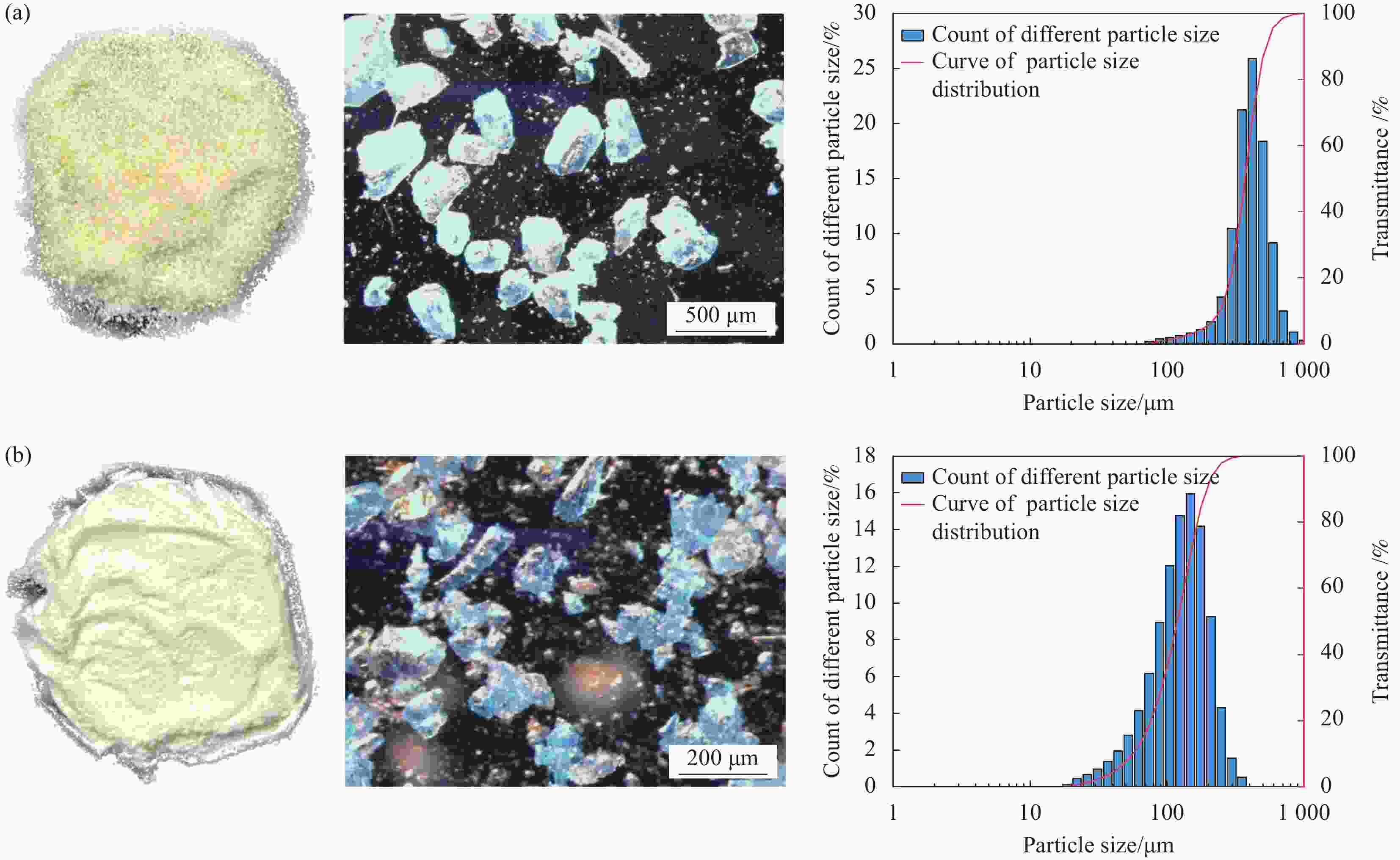

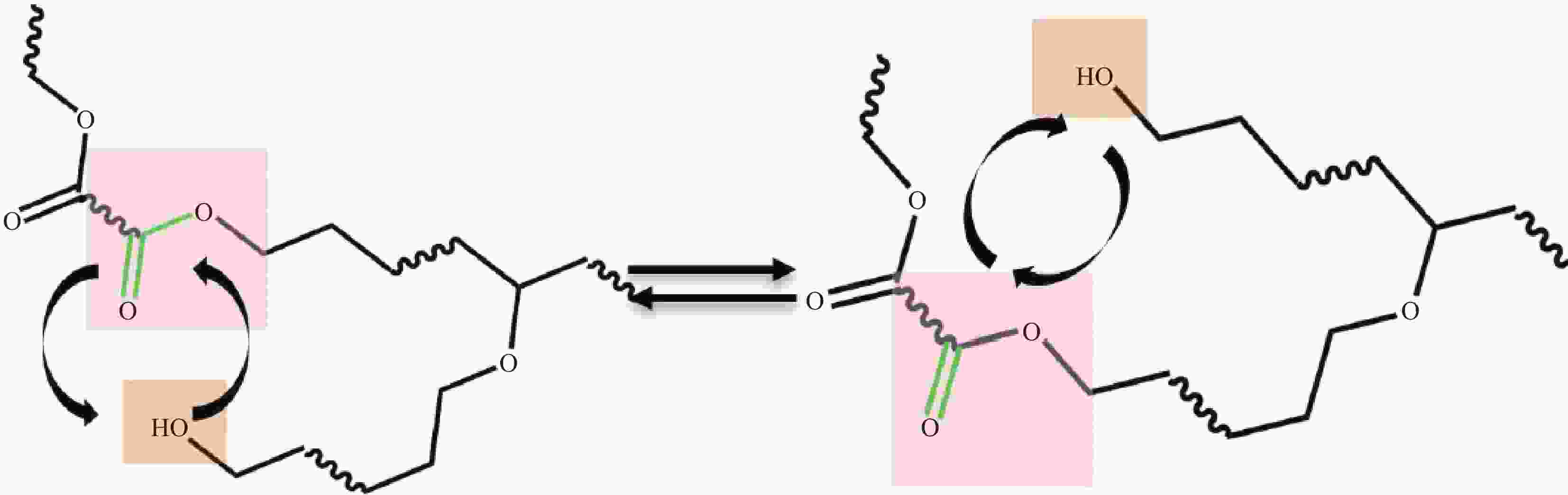

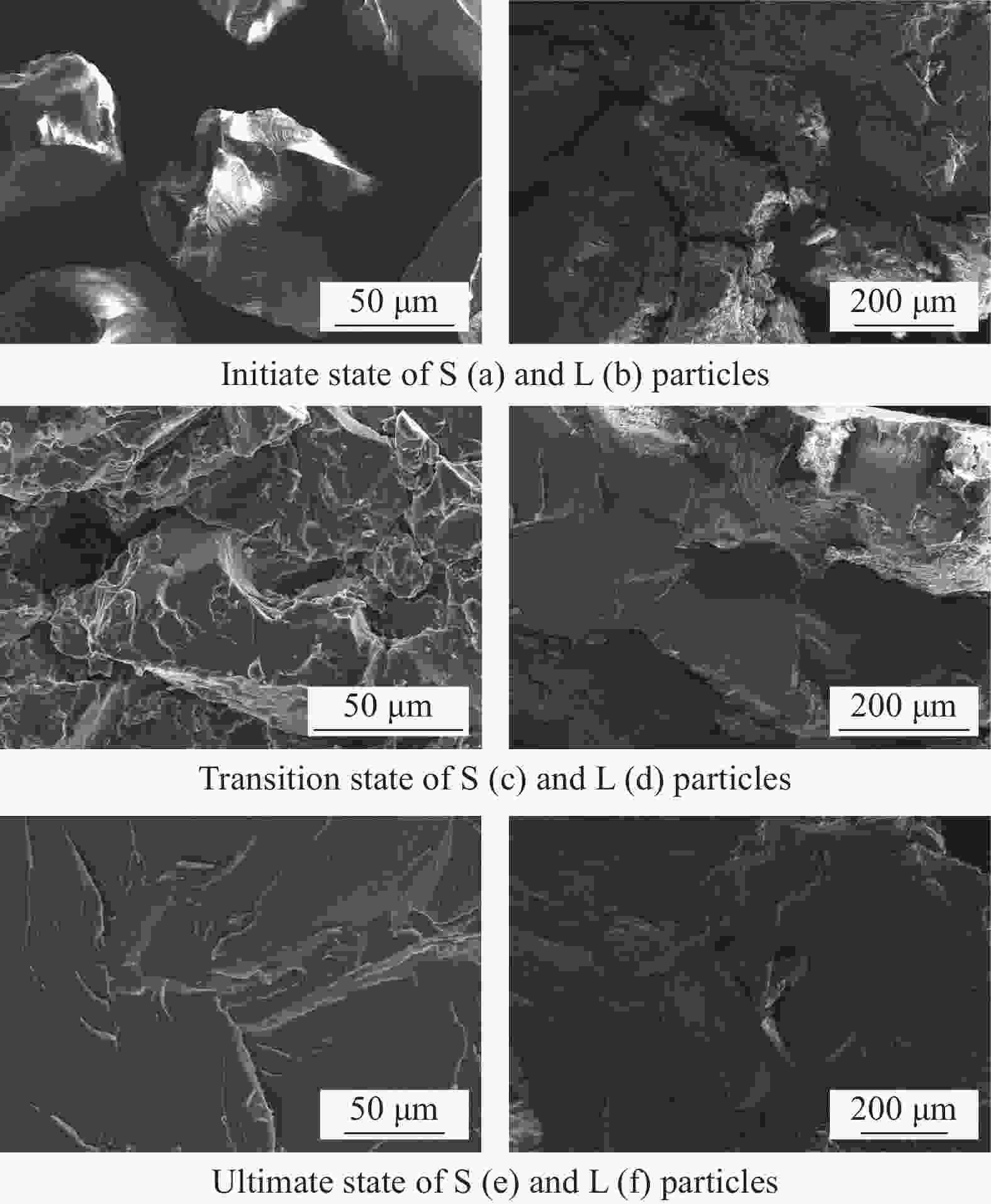

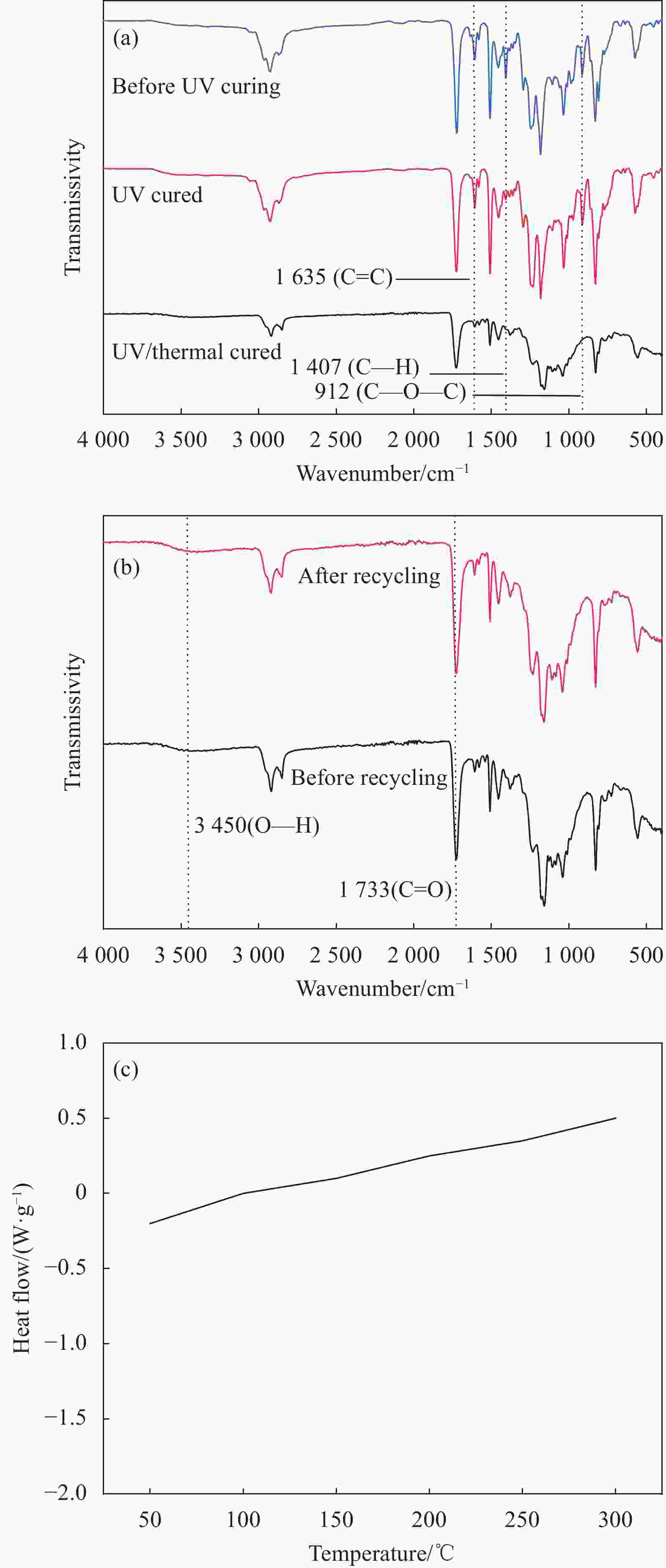

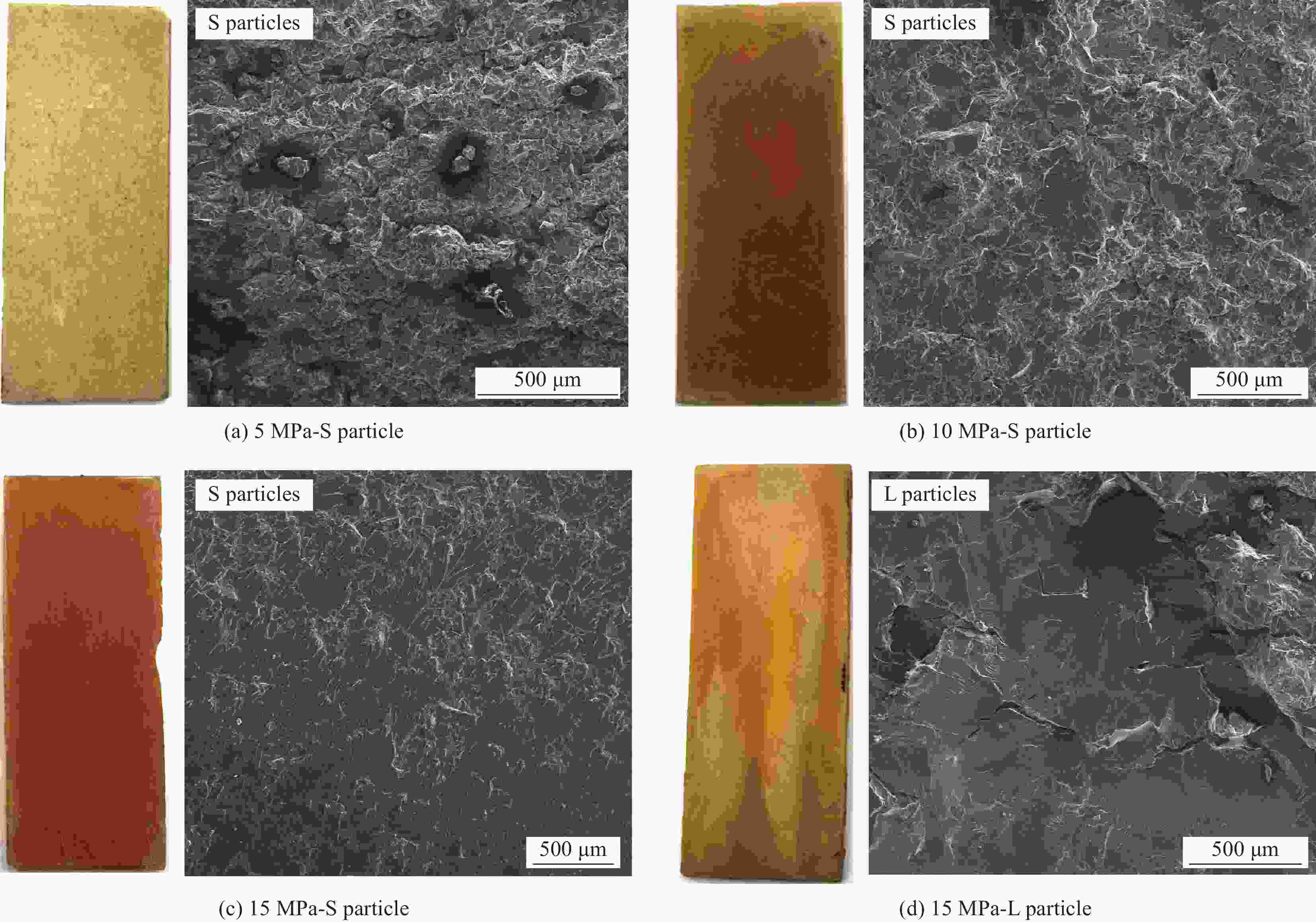

摘要: 环氧树脂为交通电气化进程提供了优异的绝缘、支撑和保护功能,但传统环氧树脂难以回收,这不符合绿色交通的可持续发展目标。现有可回收环氧树脂综合性能较差,限制了其在交通电气化进程中的应用,亟需开发高性能可回收的环氧树脂。本文提出了光敏油基树脂和环氧树脂的光-热双固化方法,利用酯交换机制,在无催化剂的高温高压环境下实现了双固化环氧树脂的回收,同时回收树脂仍保持出色的理化和电气性能。结果表明:回收前双固化环氧树脂的综合性能良好;回收树脂的粒径越小、热压压强越大,回收后树脂的理化和电气性能越好,在220℃、10 MPa的环境下热压3 h后回收树脂的综合性能最佳,弯曲和拉伸强度恢复率分别为92.0%和93.7%,工频下介电常数和介质损耗与回收前相差不大,击穿强度恢复率达到98.4%。该树脂在推进交通电气化的过程中具有一定潜力和应用前景。Abstract: Epoxy resins play a crucial role in providing insulation, support, and protection for the electrification process in transportation. However, the conventional methods of recycling epoxy resins are quite complex and do not align with the sustainability goals of green transportation. There is an urgent need to develop environmentally friendly and recyclable epoxy resins. To address the issues related to the physical, chemical, and electrical properties of recyclable epoxy resins, this paper introduces a novel photothermal dual-curing method that combines photosensitive oil-based resin with epoxy resin. This innovative approach leverages the transesterification mechanism to recover the dual-curing epoxy resin under high-temperature and high-pressure conditions without the need for a catalyst. Remarkably, the recovered resin retains excellent physical, chemical, and electrical properties. The study demonstrates that the initial properties of the dual-curing epoxy resin are promising. The quality of the recovered resin improves with smaller resin particle sizes and higher hot pressing pressures. After undergoing a hot pressing process at 220℃ and 10 MPa for 3 hours, the recovered resin exhibits its best comprehensive properties, with recovery rates of 92.0% for bending strength and 93.7% for tensile strength. Furthermore, the dielectric constant and dielectric loss at power frequency remain largely unchanged compared to their values before recovery, with a remarkable breakdown strength recovery rate of 98.4%. This research highlights the significant potential and application prospects of dual-curing epoxy resin in advancing the electrification of transportation.

-

表 1 拉伸强度文献比较

Table 1. The comparison of the tensile strength among the literature

-

[1] 刘美琦. 电气化交通辅助逆变电源用LCC逆变器及其控制研究[D]. 湖南大学, 2022.LIU M. Research on LCC inverter and its control for electrified transportation auxiliary inverter[D]. Hu Nan University, 2022(in Chinese). [2] 王洪苹, 胡燕祝, 庄育锋, 等. 电气化交通路网的脆弱性分析[J]. 清华大学学报(自然科学版), 2023, 63(10): 1584-1597.WANG H, HU Y, ZHUANG Y, et al. Analyzing the vulnerability of electrified transportation road networks[J]. Journal of Tsinghua University (Science & Technology), 2023, 63(10): 1584-1597(in Chinese). [3] 徐贺, 包贤哲, 王连杰, 等. 电气化交通中的微型燃机及其电能变换技术综述[J]. 电气工程学报, 2022, 17(2): 2-18.XU H, BAO X, WANG L, et al. Overview of micro-gas turbines in electrified transportation and their electric energy conversion technology[J]. Jounal of Electrical Engineering, 2022, 17(2): 2-18(in Chinese). [4] LI Q, DU B, KONG X. Effect of extremely cold weather and shrinkage stress on interfacial discharge between epoxy and silicone rubber in hv cable terminations[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2023, 30(5): 2386-2393. doi: 10.1109/TDEI.2023.3266308 [5] HUANG J, YE Z, ZHANG G, et al. Study on a 110 kV combined prefabricated joint fault caused by premature failure of grounding grid[J]. Engineering Failure Analysis, 2022, 141: 106701. doi: 10.1016/j.engfailanal.2022.106701 [6] WU Z, LIN B, FAN J, et al. Effect of dielectric relaxation of epoxy resin on dielectric loss of medium-frequency transformer[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2022, 29(5): 1651-1658. doi: 10.1109/TDEI.2022.3193652 [7] FANG Z, YANG X, ZENG H, et al. Research on the performance of green and environmentally friendly epoxy resin impregnated paper 110 kV current transformer[J]. AIP Advances, 2023, 13(8): 085120. doi: 10.1063/5.0166166 [8] QIAN Z, LIU Y, LIU C, et al. Design and skid resistance evaluation of skeleton-dense epoxy asphalt mixture for steel bridge deck pavement[J]. Construction and Building Materials, 2016, 114: 851-863. doi: 10.1016/j.conbuildmat.2016.03.210 [9] ALAMRI M, LU Q. Investigation on the inclusion of reclaimed diluted epoxy asphalt pavement materials into hot mix asphalt[J]. Construction and Building Materials, 2022, 361: 129710. doi: 10.1016/j.conbuildmat.2022.129710 [10] KONDRATENKO YU A, GOLUBEVA N K, KOCHINA T A, et al. Field tests of protective epoxy coatings in a humid tropical climate[J]. Glass Physics and Chemistry, 2023, 49(1): 69-74. doi: 10.1134/S1087659622600818 [11] KONDRATENKO YU A, GOLUBEVA N K, IVANOVA A G, et al. Improvement of the physicomechanical and corrosion-protective properties of coatings based on a cycloaliphatic epoxy matrix[J]. Russian Journal of Applied Chemistry, 2021, 94(11): 1489-1498. doi: 10.1134/S1070427221110045 [12] TÜREL T, TOMOVIĆ Ž. Chemically recyclable and upcyclable epoxy resins derived from vanillin[J]. ACS Sustainable Chemistry & Engineering, 2023, 11(22): 8308-8316. [13] RASHID M A, ZHU S, ZHANG L, et al. High-performance and fully recyclable epoxy resins cured by imine-containing hardeners derived from vanillin and syringaldehyde[J]. European Polymer Journal, 2023, 187: 111878. doi: 10.1016/j.eurpolymj.2023.111878 [14] JIANG Y, WANG S, DONG W, et al. High-strength, degradable and recyclable epoxy resin based on imine bonds for its carbon-fiber-reinforced composites[J]. Materials, 2023, 16(4): 1604. doi: 10.3390/ma16041604 [15] LI H, LI S, LI Q, et al. Universal, mechanically robust and self-healing superhydrophobic coatings enabled by covalent adaptable networks of disulfide bonds[J]. Progress in Organic Coatings, 2023, 175: 107362. doi: 10.1016/j.porgcoat.2022.107362 [16] YANG Z, WANG Q, WANG T. Dual-triggered and thermally reconfigurable shape memory graphene-vitrimer composites[J]. ACS Applied Materials & Interfaces, 2016, 8(33): 21691-21699. [17] ZHAO S, ABU-OMAR M M. Catechol-mediated glycidylation toward epoxy vitrimers/polymers with tunable properties[J]. Macromolecules, 2019, 52(10): 3646-3654. doi: 10.1021/acs.macromol.9b00334 [18] LIU Y, TANG Z, CHEN Y, et al. Engineering of β-hydroxyl esters into elastomer–nanoparticle interface toward malleable, robust, and reprocessable vitrimer composites[J]. ACS Applied Materials & Interfaces, 2018, 10(03): 2992-3001. [19] NIU X, WANG F, LI X, et al. Using Zn2+ ionomer to catalyze transesterification reaction in epoxy vitrimer[J]. Industrial & Engineering Chemistry Research, 2019, 58(14): 5698-5706. [20] JIANG Y, RAN Z, WU Y, et al. Reversible fluorescent adhesives based on covalent adaptable networks with dynamic AIE crosslinking: in situ visualization of adhesion capability[J]. Chemical Communications, 2023: 10.1039. D3CC03677D. [21] SUN J, LIANG M, YIN L, et al. Interfacial compatibility of core–shell cellulose nanocrystals for improving dynamic covalent adaptable networks’ fracture resistance in nanohybrid vitrimer composites[J]. ACS Applied Materials & Interfaces, 2023, 15(33): 39786-39796. [22] SNYDER R L, FORTMAN D J, DE HOE G X, et al. Reprocessable acid-degradable polycarbonate vitrimers[J]. Macromolecules, 2018, 51(02): 389-397. doi: 10.1021/acs.macromol.7b02299 [23] HAN J, LIU T, HAO C, et al. A catalyst-free epoxy vitrimer system based on multifunctional hyperbranched polymer[J]. Macromolecules, 2018, 51(17): 6789-6799. doi: 10.1021/acs.macromol.8b01424 [24] JIANG L, TIAN Y, CHENG J, et al. A biomass-based Schiff base vitrimer with both excellent performance and multiple degradability[J]. Polymer Chemistry, 2021, 12(45): 6527-6537. doi: 10.1039/D1PY01003D [25] 孙文杰, 张磊, 李天宇, 等. 基于动态受阻脲键氢化环氧树脂的介电性能与可修复性能[J]. 高电压技术, 2022, 48(7): 2668-2676.SUN Wenjie, ZHANG Lei, LI Tianyu, et al. Dielectric and repairable properties of hydrogenated epoxy resin based on dynamic hindered urea bonds[J]. High Voltage Engineering, 2022, 48(7): 2668-2676(in Chinese). [26] MEMON H, LIU H, RASHID M A, et al. Vanillin-based epoxy vitrimer with high performance and closed-loop recyclability[J]. Macromolecules, 2020, 53(2): 621-630. doi: 10.1021/acs.macromol.9b02006 [27] TIAN P-X, LI Y-D, WENG Y, et al. Reprocessable, chemically recyclable, and flame-retardant biobased epoxy vitrimers[J]. European Polymer Journal, 2023, 193: 112078. doi: 10.1016/j.eurpolymj.2023.112078 [28] CHEN M, ZHOU L, WU Y, et al. Rapid stress relaxation and moderate temperature of malleability enabled by the synergy of disulfide metathesis and carboxylate transesterification in epoxy vitrimers[J]. ACS Macro Letters, 2019, 8(03): 255-260. doi: 10.1021/acsmacrolett.9b00015 [29] LI W, XIAO L, WANG Y, et al. Thermal-induced self-healing bio-based vitrimers: Shape memory, recyclability, degradation, and intrinsic flame retardancy[J]. Polymer Degradation and Stability, 2022, 202: 110039. doi: 10.1016/j.polymdegradstab.2022.110039 [30] 张樱凡, 黄正勇, 王浩欢, 等. 可回收和高性能3D打印树脂的制备方法[J]. 高电压技术, 2023, 49(3): 962-970.ZHANG Yingfan, HUANG Zhengyong, WANG Haohuan, et al. Preparation of recyclable and high-performance 3D printing resins[J]. High Voltage Engineering, 2023, 49(3): 962-970(in Chinese). [31] SUN W, LUO J, ZHANG L, et al. Insulating silicones based on dynamic hindered urea bonds with high dielectric healability and recyclability[J]. ACS Applied Polymer Materials, 2021, 3(11): 5622-5631. doi: 10.1021/acsapm.1c00948 [32] SOMAN B, SCHWEIZER K, EVANS C, et al. Fragile glass formation and non-arrhenius upturns in ethylene vitrimers revealed by dielectric spectroscopy[J]. Macromolecules, 2023, 56(1): 166-177. doi: 10.1021/acs.macromol.2c01657 [33] 中国国家标准化管理委员会. 塑料 弯曲性能的测定: GB/T 9341—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Plastics-Determination of flexural properties: GB/T 9341—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [34] 中国国家标准化管理委员会. 塑料 拉伸性能的测定第2部分: 模塑和挤塑塑料的试验条件: GB/T 1040.2-2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. Plastics-Determination of tensile properties-Part 2: Test conditions for moulding and extrusion plastics: GB/T 1040.2—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [35] 中国国家标准化管理委员会. 绝缘材料 电气强度试验方法第1部分: 工频下试验: GB/T 1408.1-2016[S]. 北京: 中国标准出版社, 2016.Standardization Administration of the People’s Republic of China. Insulating materials-Test methods for electric strength-Part 1: Test at power frequencies: GB/T 1408.1-2016[S]. Beijing: China Standards Press, 2006(in Chinese). [36] CHEN Z. Recyclable thermosetting polymers for digital light processing 3D printing[J]. Materials and Design, 2021, 197: 109189. doi: 10.1016/j.matdes.2020.109189 [37] ZHANG B, KOWSARI K, SERJOUEI A, et al. Reprocessable thermosets for sustainable three-dimensional printing[J]. Nature Communications, 2018, 9(1): 1831. doi: 10.1038/s41467-018-04292-8 [38] MONTARNAL D, CAPELOT M, TOURNILHAC F, et al. Silica-like malleable materials from permanent organic networks[J]. Science, 2011, 334(6058): 965-968. doi: 10.1126/science.1212648 -

点击查看大图

点击查看大图

计量

- 文章访问数: 100

- HTML全文浏览量: 52

- 被引次数: 0

下载:

下载: