Preparation and research of Diatomite@PNIPAm-stabilized Pickering emulsion with temperature responsiveness

-

摘要: 针对由表面活性剂所稳定的乳液具有毒性且不环保的缺点,对硅藻土颗粒(Diatomite,DE)进行改性,并对其所制备的具有温度响应性的Pickering乳液进行了研究。由于硅藻土颗粒具有生物相容性好的优势,在化妆品和制药领域具有应用潜力。先通过硅烷偶联剂(MPS)疏水改性DE得到Diatomite@MPS,再接枝温敏型聚合物聚N-异丙基丙烯酰胺(PNIPAm),成功合成了具有温度响应性的改性硅藻土颗粒(Diatomite@PNIPAm)。由TGA结果表明制备Diatomite@PNIPAm的最佳MPS与NIPAm摩尔比为1∶1。随后,将Diatomite@PNIPAm作为乳化剂分别在不同浓度的条件下制备了水包油(O/W)型Pickering乳液,确定了3.0 wt%为最佳浓度。此外,确定Diatomite@PNIPAm浓度后,分别从1∶9到9∶1的不同油水体积比制备乳液,结果表明油水体积比为7∶3时最佳。通过差示扫描量热仪(DSC)测定所制备的Pickering乳液的低临界溶解温度(LCST)为40℃,且乳液至少可以进行6次破乳-再乳化循环,具备良好的破乳-再乳化循环性能。

-

关键词:

- 温度响应性 /

- Pickering乳液 /

- 硅藻土 /

- 低临界溶解温度 /

- 破乳-再乳化循环性能

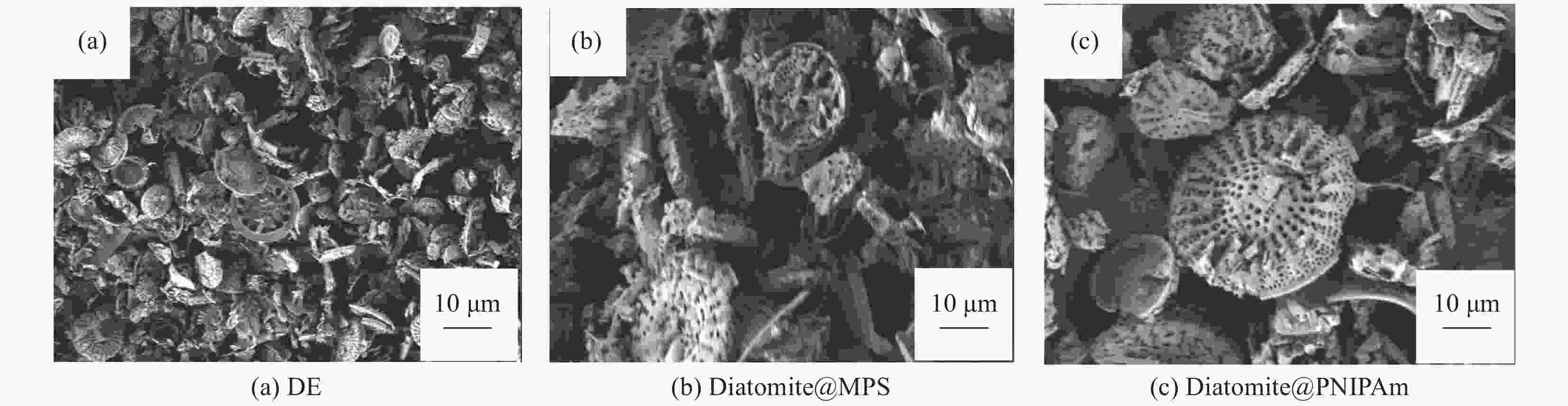

Abstract: Aiming at the shortcomings of the emulsion stabilized by surfactant due to toxicity and non-environmental protection, modified diatomite particles (DE), the temperature-responsive Pickering emulsion was studied. Due to the advantages of superior biocompatibility, DE have application potential in the field of cosmetics and pharmaceuticals. First, the Diatomite@MPS was obtained by silane coupling agent (MPS) hydrophobic modified DE. Then, modified DE (Diatomite@PNIPAm) with temperature responsiveness was synthesized successfully by grafting the temperature-responsive polymer poly N-isopropylacrylamide (PNIPAm). According to the characterization results of FT-IR testing and water contact angle testing, the diatomaceous earth was modified successfully. The TGA results showed that the optimal molar ratio of the Diatomite@PNIPAm prepared from MPS to NIPAm was 1∶1. Subsequently, oil-in-water (O/W) Pickering emulsions were prepared with Diatomite@PNIPAm as an emulsifier at different concentrations, and 3.0 wt% was determined as the optimal concentration. In addition, the emulsion was prepared with different oil-water volume ratios from 1∶9 to 9∶1 after determining the Diatomite@PNIPAm concentration, and the results showed that the oil-water volume ratio was 7∶3 as the best. The characterization results of Differential scanning calorimeter (DSC) testing showed that the lower critical solution temperature (LCST) of the Pickering emulsion was 40℃. The emulsion can undergo at least 6 demulsification-reemulsification cycles, and possesses excellent demulsification-reemulsification cycle performance. -

表 1 不同配方制备的改性硅藻土颗粒

Table 1. Modified diatomite particles prepared with different formulations

Sample Diatomite/g MPS/g NIPAm/g MPS:NIPAm/mol Grafting rate η/% Sample 1 4.0 10 3.19 1:0.7 10.05 Sample 2 4.0 10 4.56 1:1 15.02 Sample 3 4.0 10 9.12 1:2 13.46 Note: MPS—Silane coupling agent. -

[1] TSUJI S, KAWAGUCHI H. Thermosensitive pickering emulsion stabilized by poly(N-isopropylacrylamide)-carrying particles.[J]. Langmuir the Acs Journal of Surfaces & Colloids, 2008, 24(7): 3300-3305. [2] 杨飞, 王君, 蓝强, 等. Pickering乳状液的研究进展[J]. 化学进展, 2009, 21(7): 9.YANG F, WANG J, LAN Q, et al. Research Progress on Pickering Emulsions. Progress in Chemistry, 21(7): 9(in Chinese). [3] ZHANG Y, KARIMKHANI V, MAKOWSKI B T, et al. Nanoemulsions and Nanolatexes Stabilized by Hydrophobically Functionalized Cellulose Nanocrystals[J]. Macromolecules, 2017, 50(16): 6032-6042. doi: 10.1021/acs.macromol.7b00982 [4] WANG C, PEI X, TAN J, et al. Thermoresponsive starch-based particle-stabilized Pickering high internal phase emulsions as nutraceutical containers for controlled release[J]. International Journal of Biological Macromolecules, 2020, 146(5): 171-178. [5] RAMSDEN W. Separation of Solids in the Surface-Layers of Solutions and 'Suspensions' (Observations on Surface-Membranes, Bubbles, Emulsions, and Mechanical Coagulation). -- Preliminary Account[J]. Proceedings of the Royal Society of London, 1972: 156-164. [6] Wu J, Ma G H. Pickering Emulsions: Recent Studies of Pickering Emulsions: Particles Make the Difference (Small 34/2016)[J]. Small, 2016, 12(34): 4582-4582. doi: 10.1002/smll.201670169 [7] ZHAI K, PEI X, WANG C, et al. Water-in-oil Pickering emulsion polymerization of N-isopropyl acrylamide using starch-based nanoparticles as emulsifier[J]. International Journal of Biological Macromolecules, 2019, 131: 1032-1037. doi: 10.1016/j.ijbiomac.2019.03.107 [8] FRELICHOWSKA J, BOLZINGER M A, VALOUR J P, et al. Pickering w/o emulsions: drug release and topical delivery[J]. International Journal of Pharmaceutics, 2008, 368(1-2): 7-15. [9] LOW L E, TAN T H, GOH B H, et al. Magnetic cellulose nanocrystal stabilized Pickering emulsions for enhanced bioactive release and human colon cancer therapy[J]. International Journal of Biological Macromolecules, 2019, 127: 76-84. doi: 10.1016/j.ijbiomac.2019.01.037 [10] JIMENEZ Saelices, CLARA Seantier B, GROHENS Y, et al. Thermal Superinsulating Materials Made from Nanofibrillated Cellulose-Stabilized Pickering Emulsions[J]. Acs Applied Materials & Interfaces, 2018, 10(18): 16193-16202. [11] LIU F, ZHENG J, HUANG C H, et al. Pickering high internal phase emulsions stabilized by protein-covered cellulose nanocrystals[J]. Food Hydrocolloids, 2018, 82: 96-105. doi: 10.1016/j.foodhyd.2018.03.047 [12] CHEVALIER Y, BOLZINGER M A. Emulsions stabilized with solid nanoparticles: Pickering emulsions[J]. Colloids & Surfaces A Physicochemical & Engineering Aspects, 2013, 439: 23-34. [13] SADEGHPOUR A, PIROLT F, GLATTER O. Submicrometer-sized Pickering emulsions stabilized by silica nanoparticles with adsorbed oleic acid.[J]. Langmuir, 2013, 29(20): 6004-6012. doi: 10.1021/la4008685 [14] LI, K. Surfactant-Free Emulsion Polymerization Stabilized by Ultrasmall Superparamagnetic Iron Oxide Particles Using Acrylic Acid or Methacrylic Acid as Auxiliary Comonomers. Macromolecules 49, 2016: 7609-7624. [15] TEIXEIRA R F A, MCKENZIE H S, BOYD A A, et al. Pickering Emulsion Polymerization Using Laponite Clay as Stabilizer To Prepare Armored "Soft" Polymer Latexes[J]. Macromolecules, 2011, 44(18): 7415-7422. doi: 10.1021/ma201691u [16] VOORN D J, MING W, VAN Herk A M. Polymer-clay nanocomposite latex particles by inverse pickering emulsion polymerization stabilized with hydrophobic montmorillonite platelets[J]. Macromolecules, 2006, 39(6): 2137-2143. doi: 10.1021/ma052539t [17] BRIGGS NM, WESTON JS, LI B, et al. Multiwalled Carbon Nanotubes at the Interface of Pickering Emulsions. Langmuir. 2015, 31(48): 13077-84. [18] SARKER M, TOMCZAK N, LIM S. Protein Nanocage as a pH-Switchable Pickering Emulsifier[J]. ACS Applied Materials & Interfaces, 2017, 9(12): 11193-11201. [19] LIU H, WANG C, ZOU S, et al. Simple, reversible emulsion system switched by pH on the basis of chitosan without any hydrophobic modification.[J]. Langmuir, 2012, 28(30): 11017-11024. doi: 10.1021/la3021113 [20] NGAI T, AUWETER H, BEHRENS S H. Environmental Responsiveness of Microgel Particles and Particle-Stabilized Emulsions[J]. Macromolecules, 2006, 39(23): 8171-8177. doi: 10.1021/ma061366k [21] ZHANG Qiangguo, WANG Lingyun, HAI Tao, et al. Pore structure of macroporous polymers using polystyrene/silica composite particles as pickering stabilizers[J]. Langmuir:The ACS Journal of Surfaces and Colloids, 2016, 32(49): 13159-13166. doi: 10.1021/acs.langmuir.6b03285 [22] MARKU D, WAHLGREN M, RAYNER M, et al. Characterization of starch Pickering emulsions for potential applications in topical formulations[J]. Int J Pharm, 2012, 428(1-2): 1-7. doi: 10.1016/j.ijpharm.2012.01.031 [23] IBRAHIM SM, BIN Jumah MN, OTHMAN SI, et al. Synthesis of Chitosan/Diatomite Composite as an Advanced Delivery System for Ibuprofen Drug; Equilibrium Studies and the Release Profile. ACS Omega, 2021 May 13;6(20): 13406-13416. [24] TODD T, ZHEN Z, TANG W, et al. Iron oxide nanoparticle encapsulated diatoms for magnetic delivery of small molecules to tumors[J]. Nanoscale, 2014, 6(4): 2073-2076. doi: 10.1039/c3nr05623f [25] NGO T N N, GREY C, ADLERCREUTZ. P. Chemoenzymatic synthesis of the pH responsive surfactant octyl β-D-glucopyranoside uronic acid[J]. Applied Microbiology and Biotechnology, 2020, 104(3): 1055-1062. doi: 10.1007/s00253-019-10254-x [26] ZHANG J, XU Q, WANG F, et al. pH and redox dual-stimulated wormlike micelles based on cystamine and conventional anionic surfactant, Langmuir, 2019, 35 (47): 15242–15248. [27] QI L, SONG C , WANG T, et al. Polymer-coated nanoparticles for reversible emulsification and recovery of heavy oil, Langmuir, 2018, 34 (22): 6522–6528. [28] TANAKA T, OKAYAMA M, MINAMI. H , et al. Dual stimuli-responsive “Mushroom-like” Janus polymer particles as particulate surfactants, Langmuir, 2010, 26 (14): 11732–11736. [29] FENG H, VERSTAPPEN N A L, KUEHNE A J C, et al. Well-defined temperaturesensitive surfactants for controlled emulsion coalescence, Polym[J]. Chem, 2013, 4(6): 1842-1847. [30] JASINSKI F, GUIMARES T R, DAVID S, et al. Reversible Destabilization of UV-Responsive Polymer Particles (Latex) using a Photoresponsive Surfactant[J]. Macromolecular rapid communications, 2019, 40(22): 1900355. doi: 10.1002/marc.201900355 [31] HOU Q, WANG Y, WANG Z, et al. Temperature sensitivity of CO2-triggered switchable surfactants with acetamidine group, J[J]. Petrol. Sci. Eng, 2020, 186: 106677. doi: 10.1016/j.petrol.2019.106677 [32] XU Y, WANG F, HOU Q, et al. Strategy for synthesizing novel acetamidines as CO2-triggered switchable surfactants via acetimidates, Trans[J]. Tianjin Univ, 2019, 25(03): 237-244. doi: 10.1007/s12209-018-0169-z [33] LV M, WANG L, HUANG R, et al. Preparation of a magnetocaloric dual-response SiO2-based green nano-emulsifier by an SET-LRP method and evaluation of its properties[J]. European Polymer Journal, 2023, 183: 111697. doi: 10.1016/j.eurpolymj.2022.111697 [34] 戎晨亮, 侯立峰, 黄海龙, 等. 温敏性SA/P(NIPAM-co-AM)水凝胶分子运动的固体核磁共振研究[J]. 功能高分子学报, 2019, 32(1): 45-52.RONG C L, HOU L F, HUANG H L, et al. Solid-State NMR Study on the Molecular Motion of Thermal Sensitive SA/P(NIPAM-co-AM) Hydrogel[J]. Journal of Functional Polymers, 2019, 32(1): 45-52 (in Chinese). [35] POURIAVADI. Ali, SAHAND. Rahemipoor, M. Kohestanian. Synthesis and characterization of multi stimuli-responsive block copolymer-silica hybrid nanocomposite with core-shell structure via RAFT polymerization, Composites Science and Technology , 2020, 188: 107951-107951. [36] CHEN F, DONG C, CHEN C, et al. Nitrogen-aeration tuned ultrasonic synthesis of SiO2@PNIPAm nanoparticles and preparation of temperature responsive Pickering emulsion[J]. Ultrasonics Sonochemistry, 2019, 58: 104705. doi: 10.1016/j.ultsonch.2019.104705 [37] PEI X , TAN Y, XU K, et al. Pickering polymerization of styrene stabilized by starch-based nanospheres, Polym. Chem, 2016, 7: 3325–3333. [38] PEI X, ZHAI K, LIANG X, et al. Interfacial activity of starchbased nanoparticles at the oil-water interface, Langmuir, 2017, 33: 3787–3793. [39] CHANG Y H, LIN J H, LII C Y, Effect of ethanol concentration on the physicochemical properties of waxy corn starch treated by hydrochloric acid, Carbohydr. Polym, 2004, 57: 89–96. [40] FERREIRA D C, BASTOS G S, PFEIFET A, et al. Cellulose carboxylate/tosylate mixed esters: Synthesis, properties and shaping into microspheres[J]. Carbohydrate Polymers, 2016, 152: 79-86. doi: 10.1016/j.carbpol.2016.06.075 [41] TIAN B S , YANG C . Temperature-Responsive Nanocomposites Based on Mesoporous SBA-15 Silica and PNIPAAm: Synthesis and Characterization[J]. The Journal of Physical Chemistry C, 2009, 113(12): 4925–4931. -

点击查看大图

点击查看大图

计量

- 文章访问数: 42

- HTML全文浏览量: 26

- 被引次数: 0

下载:

下载: