Interface thermal stability and element diffusion law of SiCf/TC18 composites

-

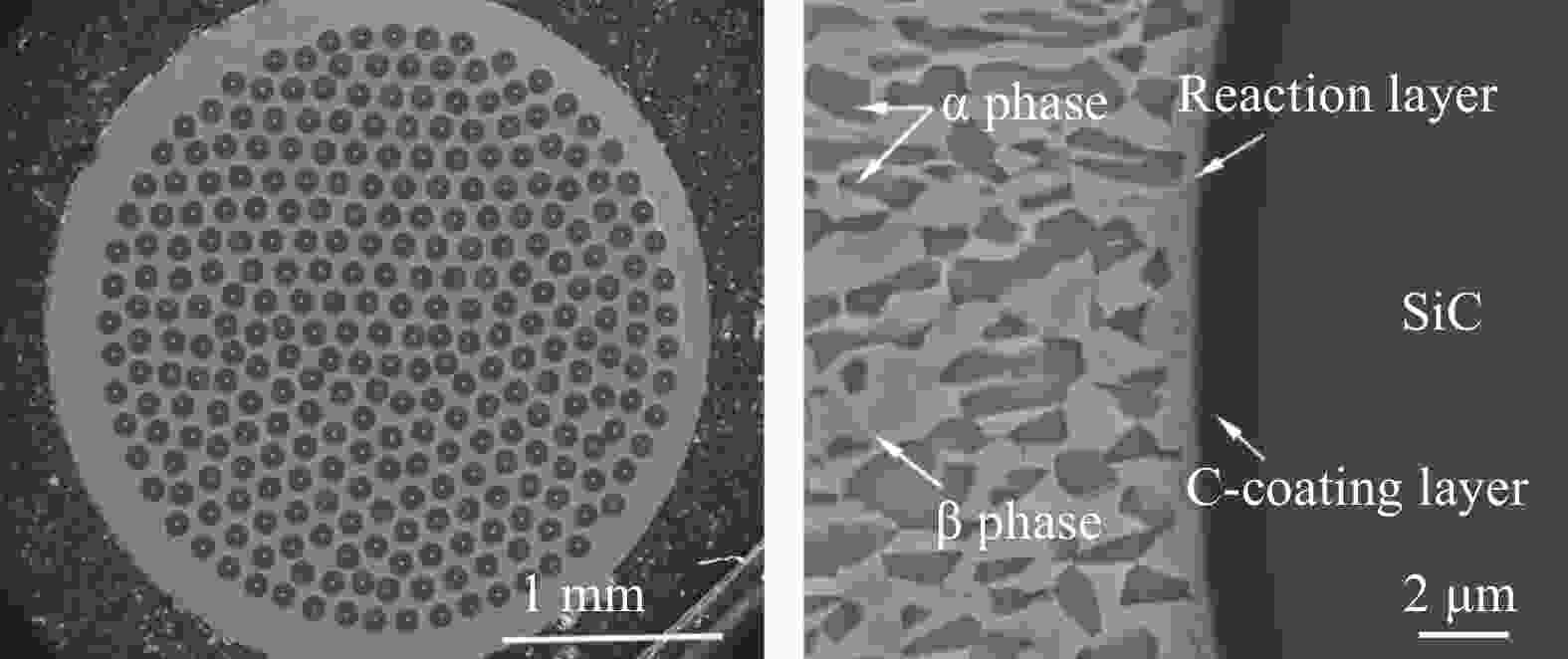

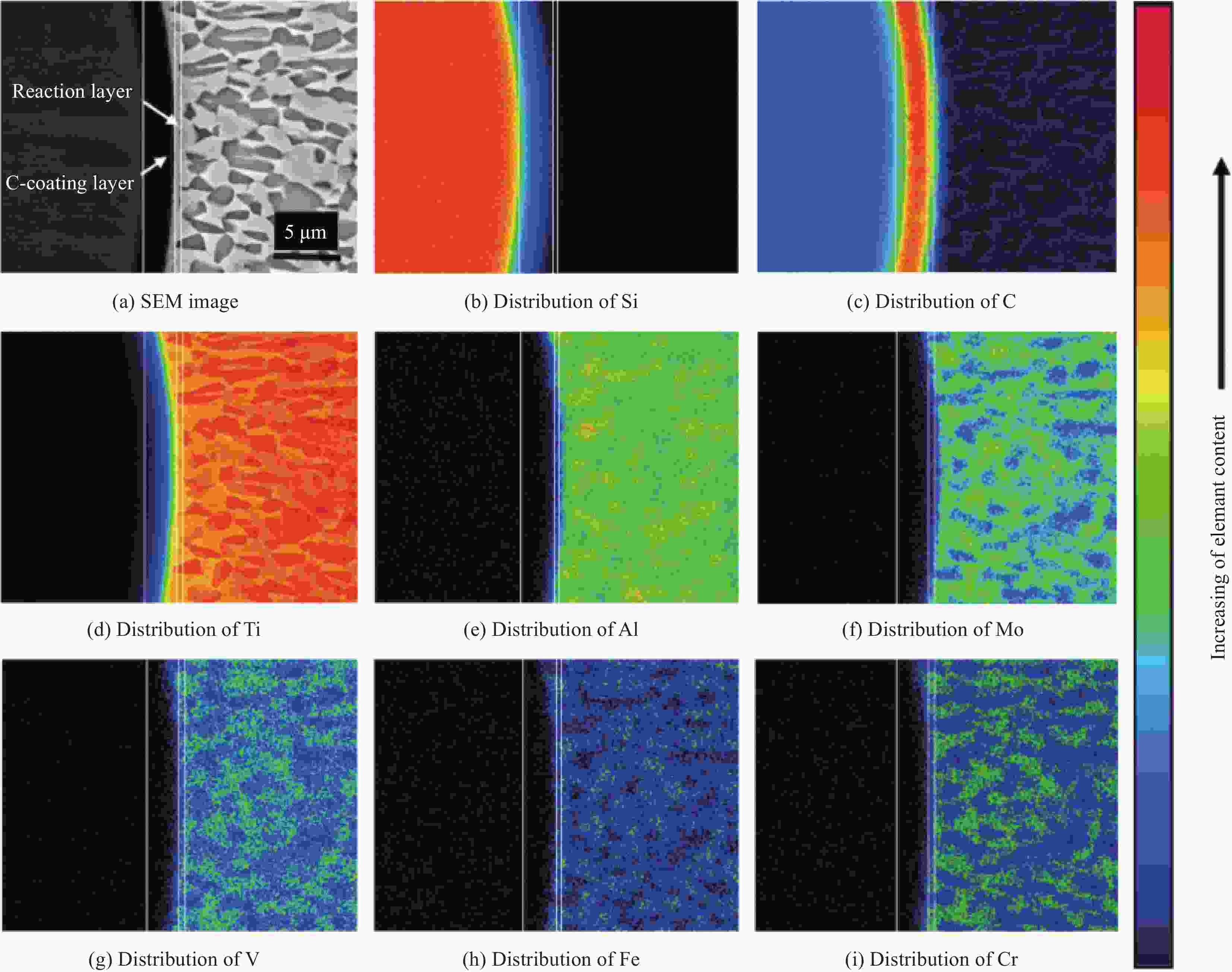

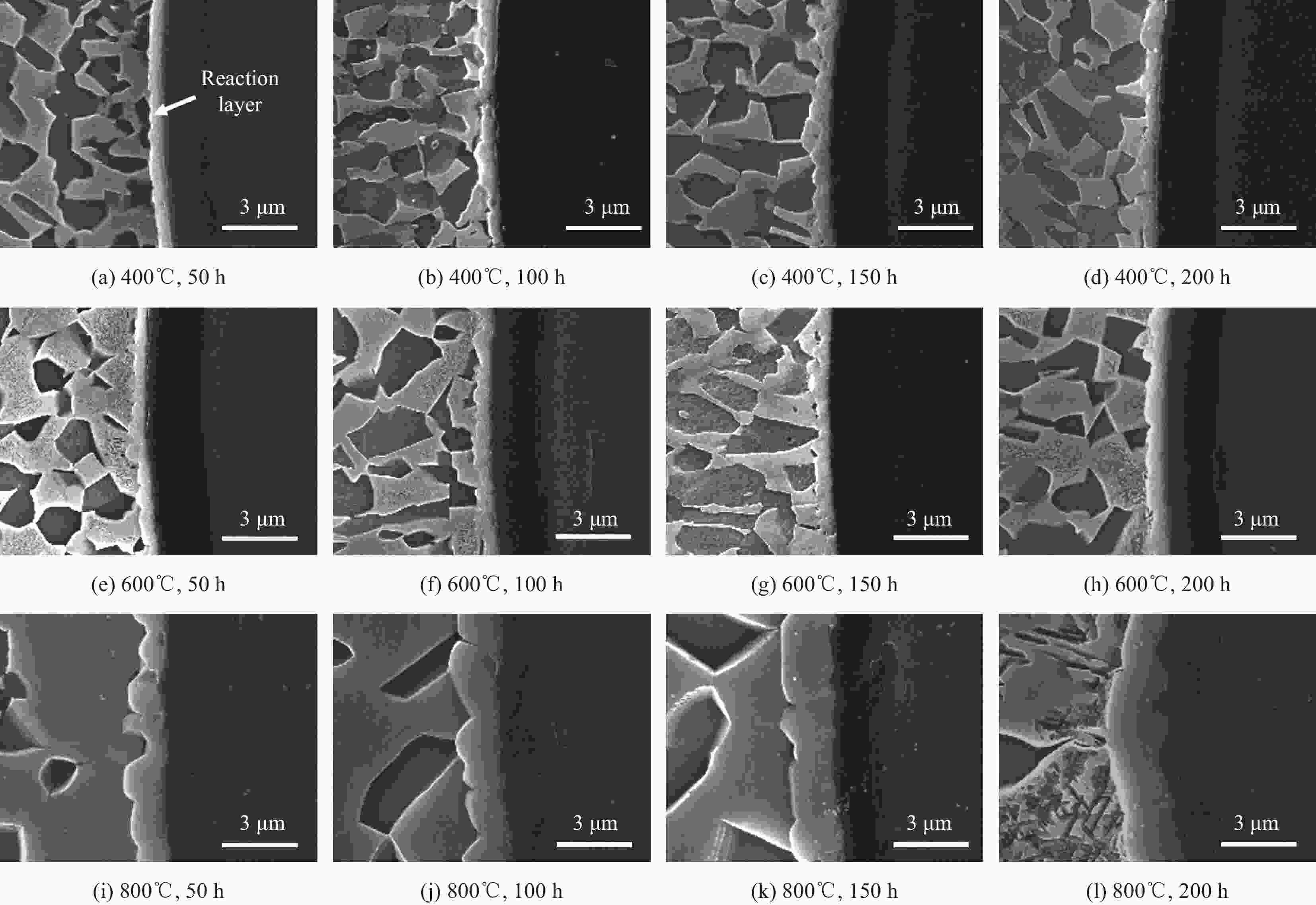

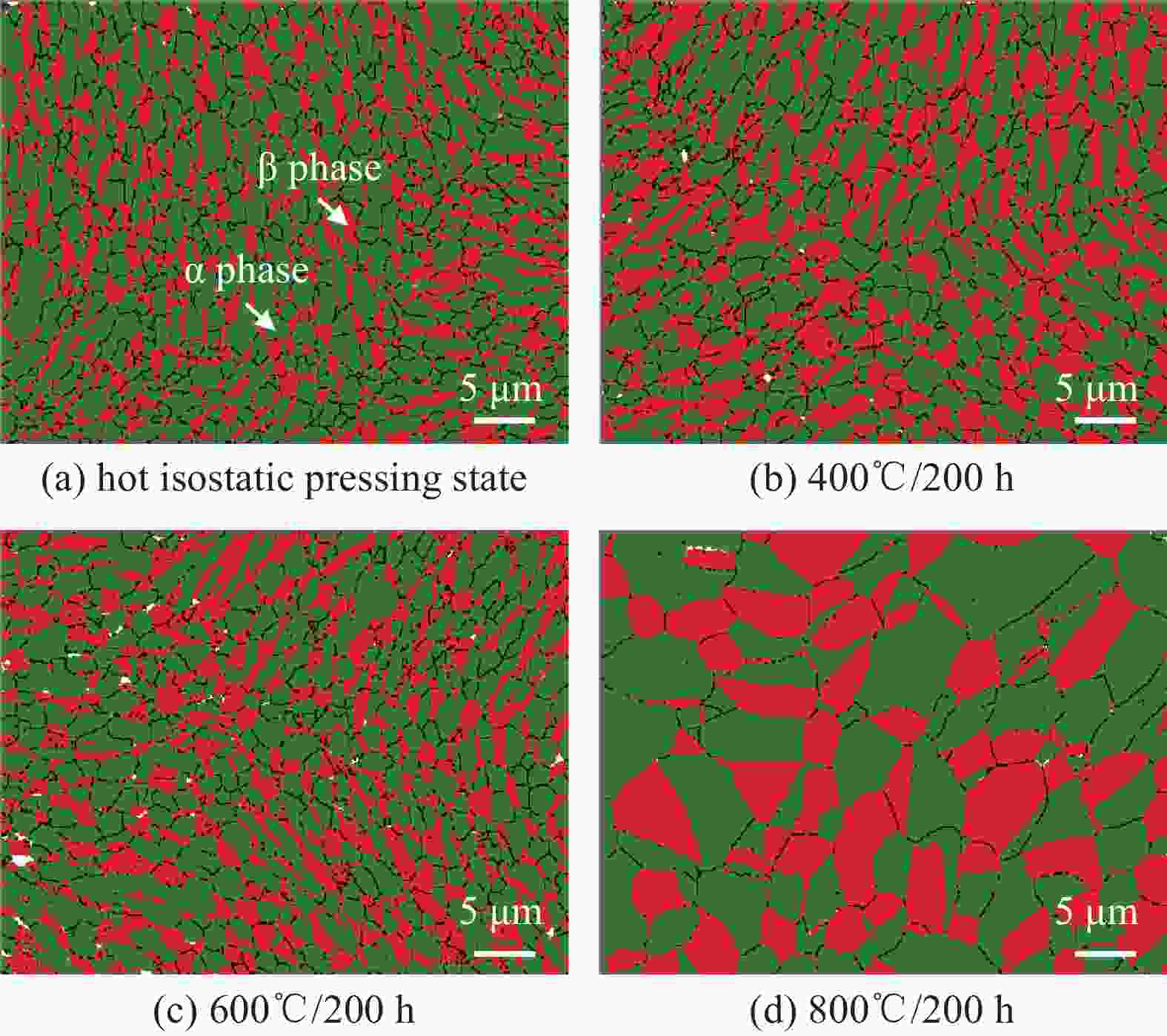

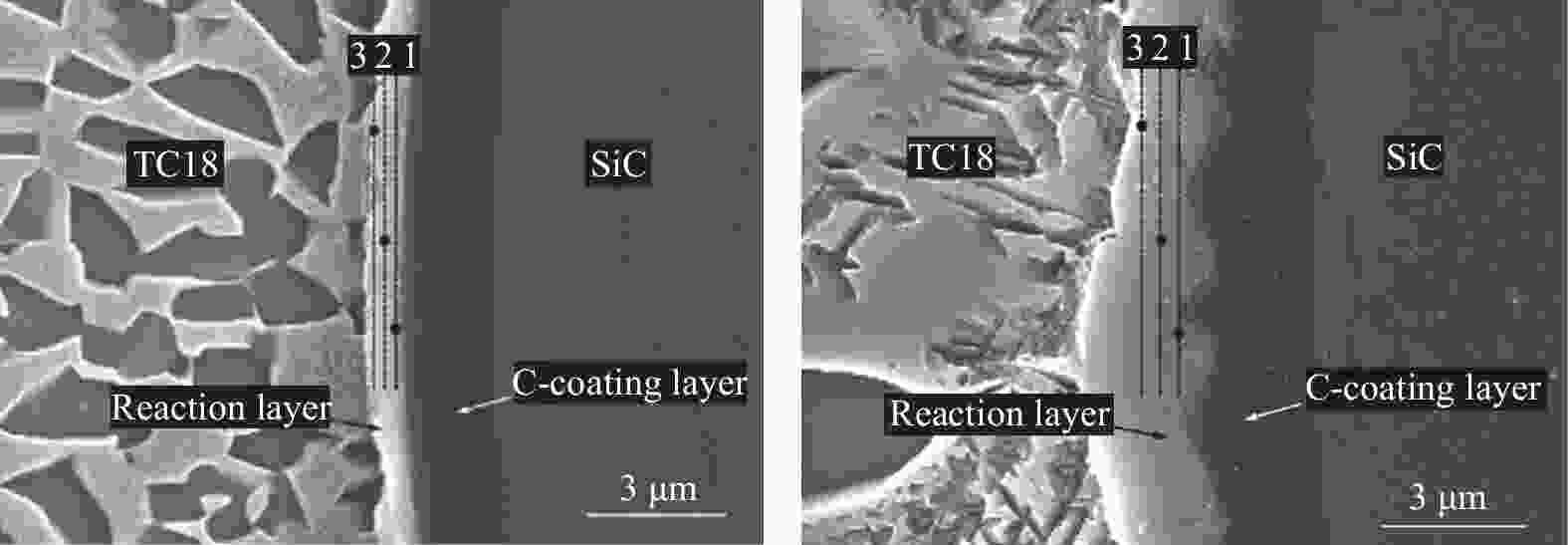

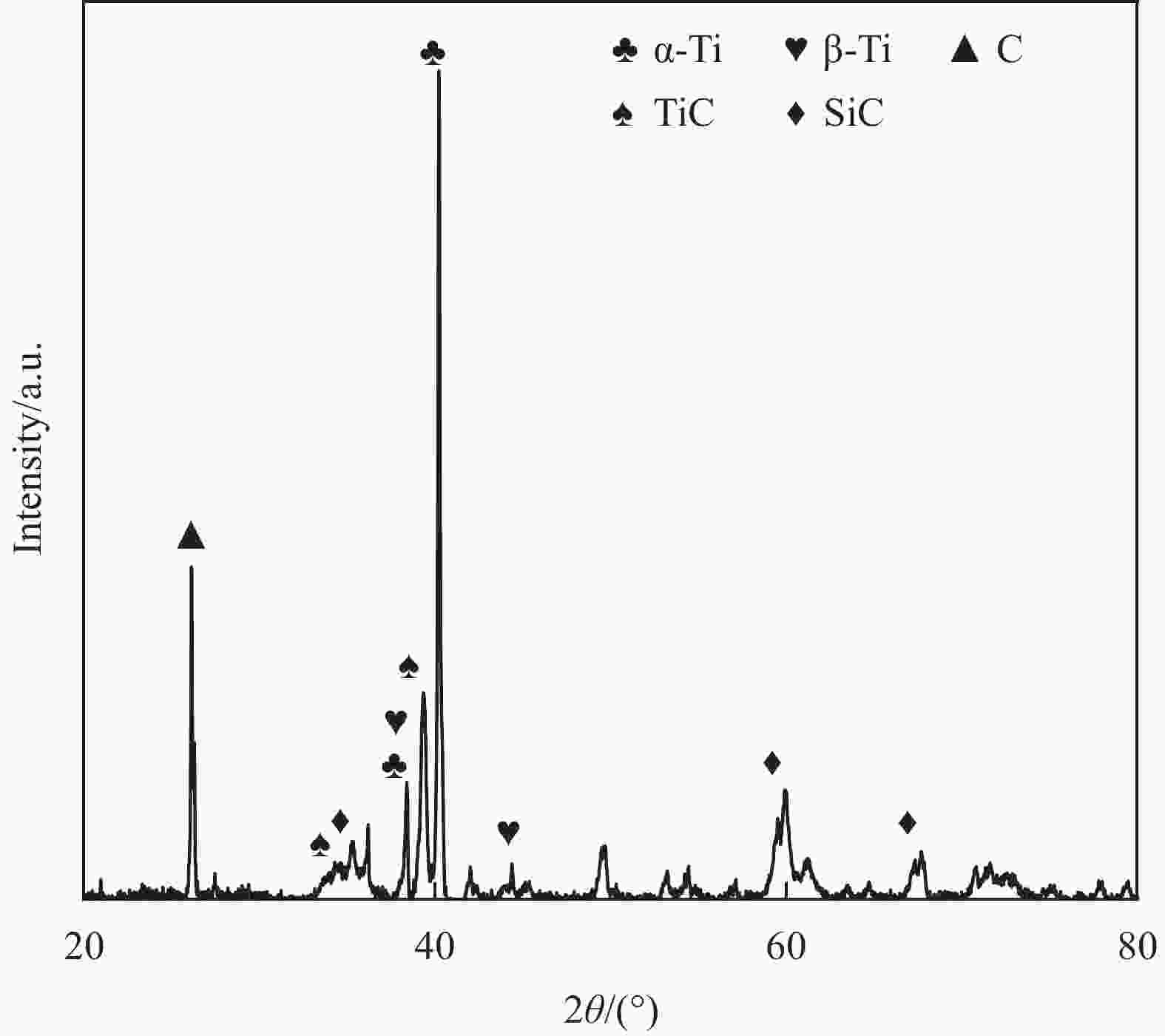

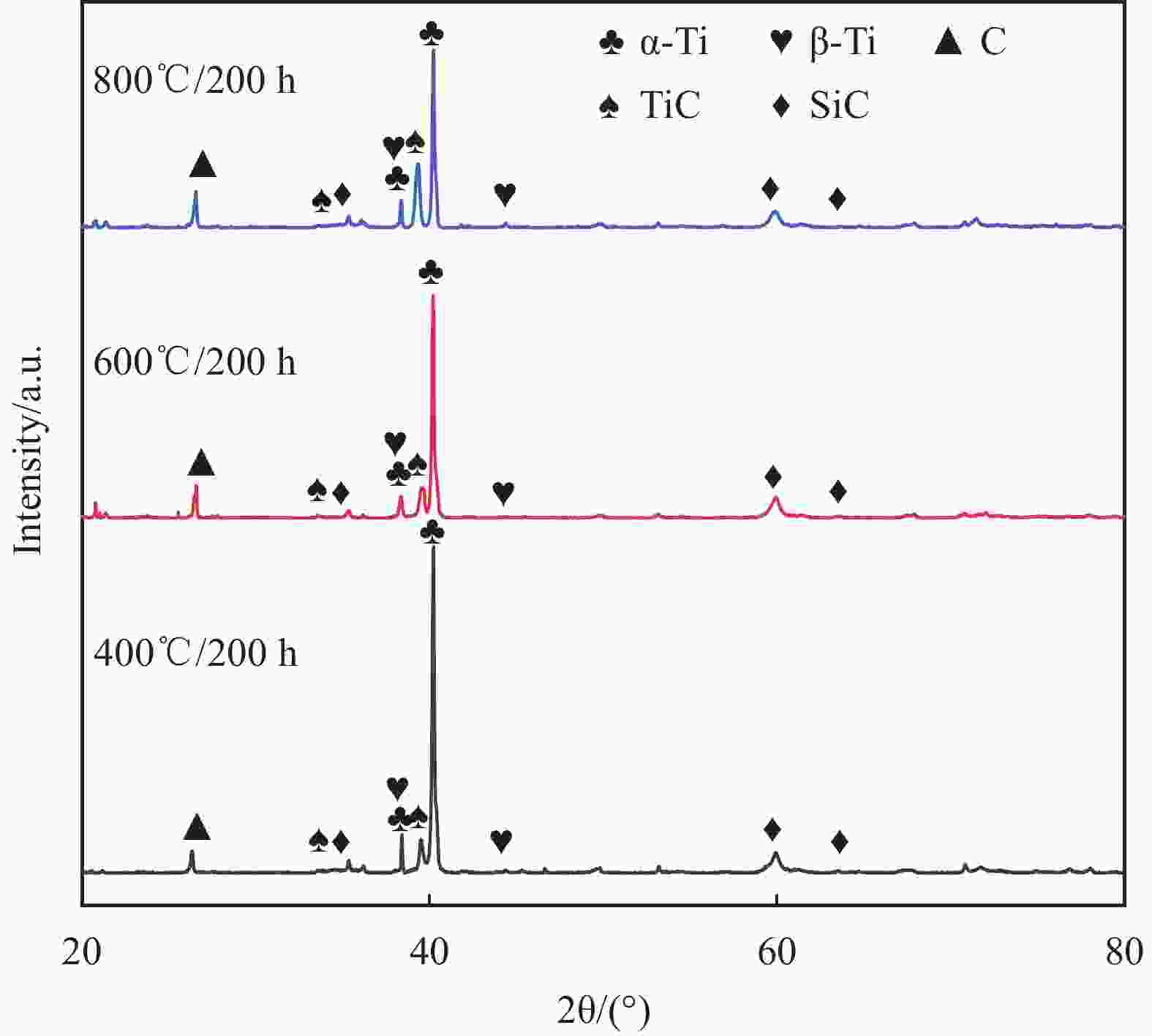

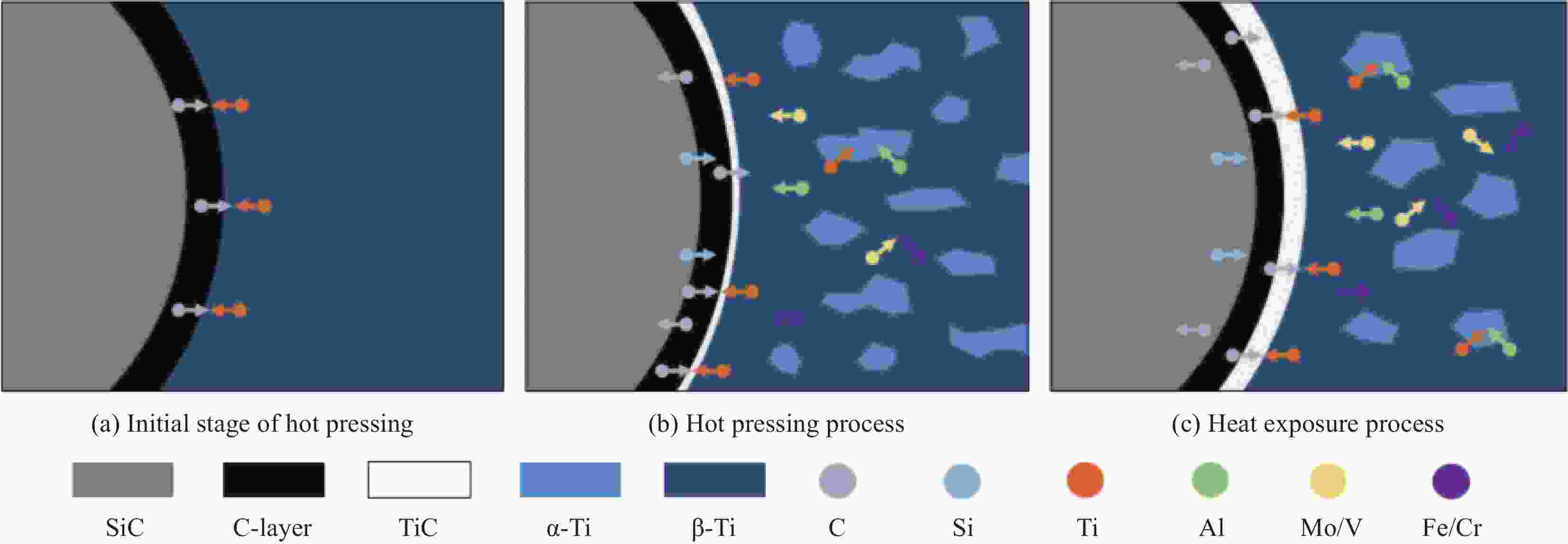

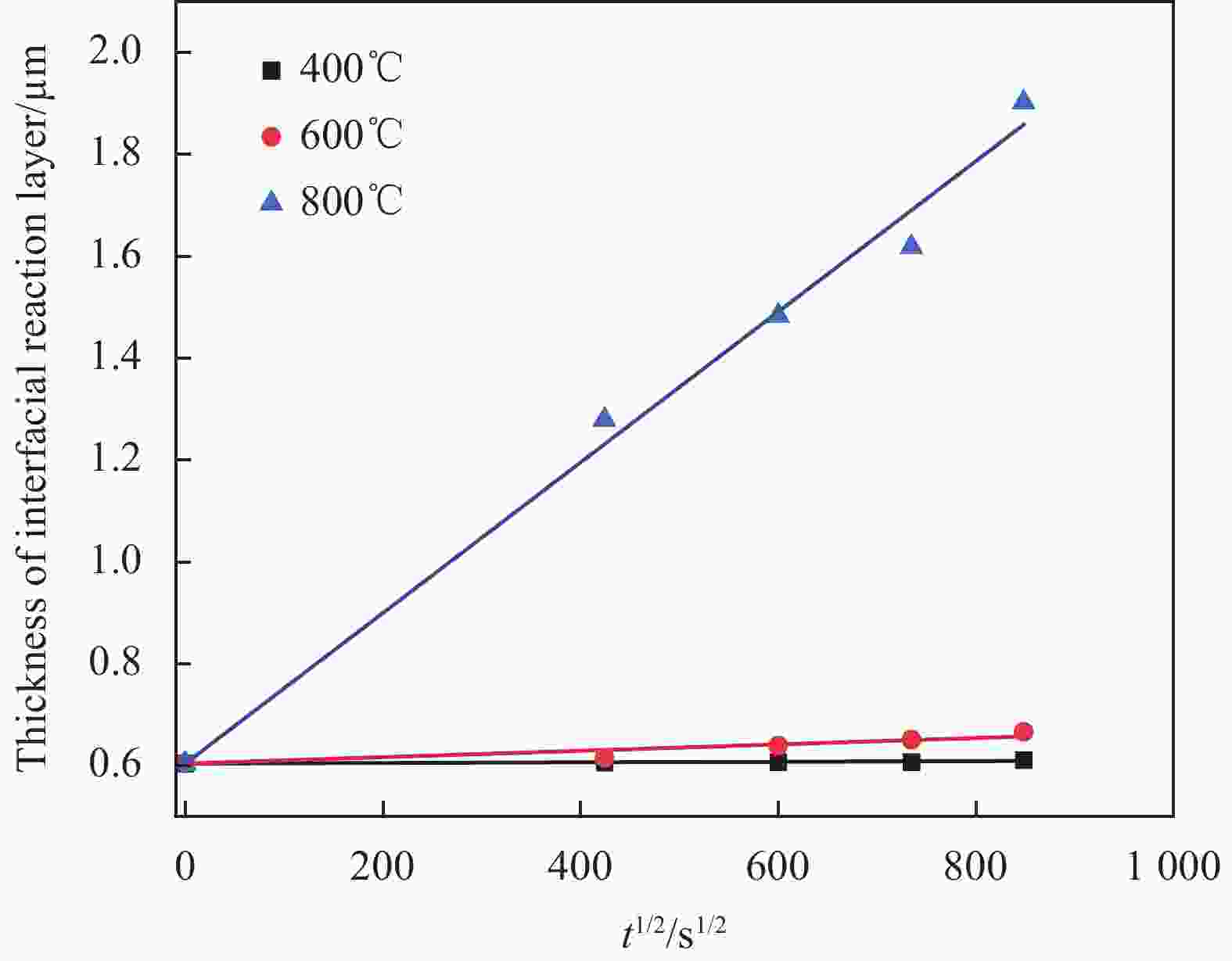

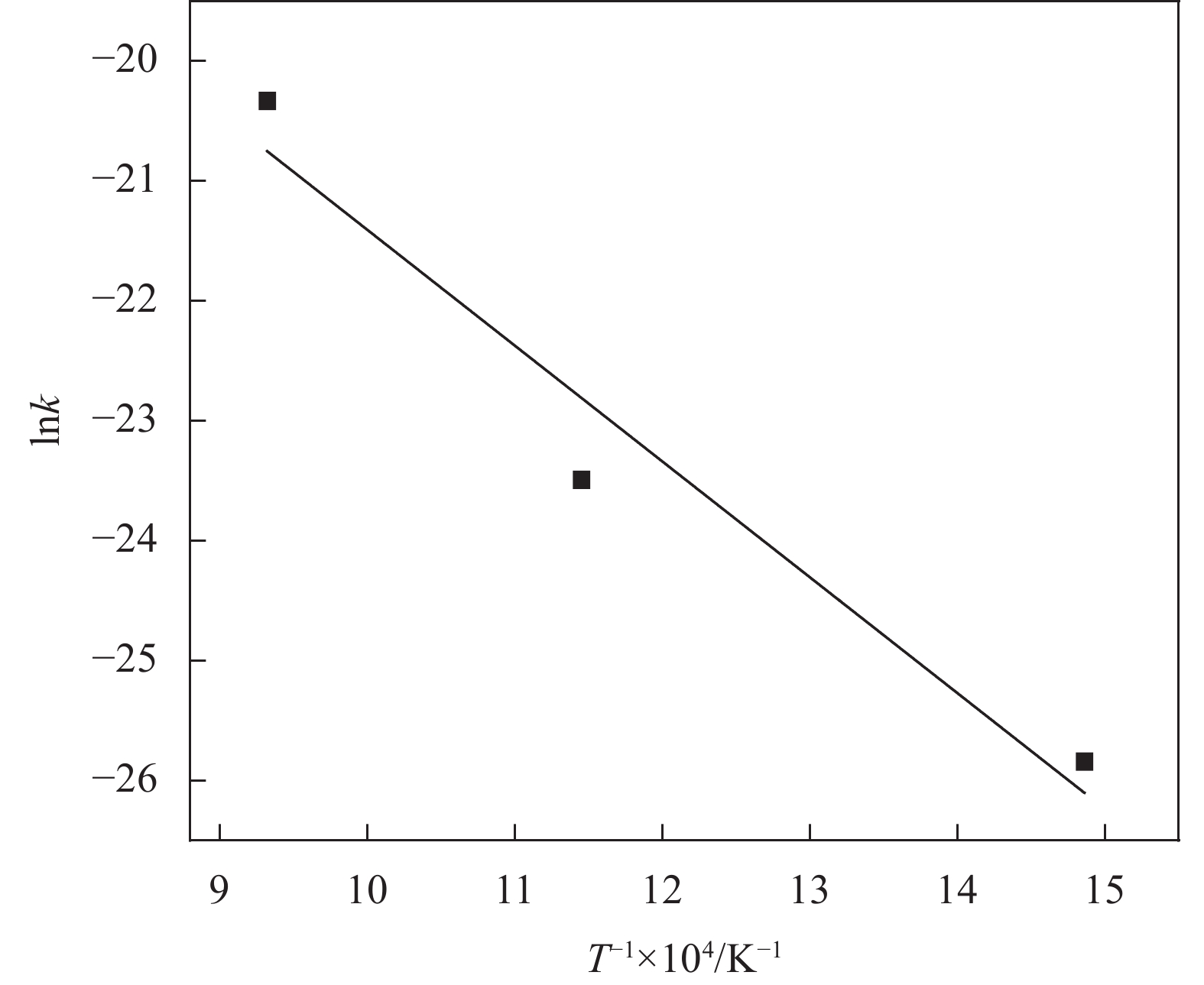

摘要: 界面反应会对钛基复合材料的力学性能产生显著影响,为确定SiCf/TC18复合材料的元素扩散及界面反应层长大规律,采用磁控溅射先驱丝法+热等静压工艺制备了SiCf/TC18复合材料,并在不同温度(400、600、800 ℃)和时间(50、100、150、200 h)下进行热暴露实验,分析了热等静压态和热暴露态SiCf/TC18复合材料的界面反应层厚度变化、元素分布及扩散规律。更为重要的是,本文阐明了元素互扩散的机制,总结了界面反应层厚度随热暴露时间的长大规律,揭示了SiCf/TC18复合材料界面反应层产物主要为TiC。经计算,SiCf/TC18复合材料界面指数因子为4.0 × 10−6 m/s1/2,反应层长大激活能为80.31 kJ/mol,该材料在400 ℃以下时界面热稳定性优异。Abstract: Interfacial reaction will have a significant impact on the mechanical properties of titanium matrix composites. In order to determine the diffusion of elements and the growth law of interfacial reaction layer of SiCf/TC18 composites, SiCf/TC18 composites were prepared using magnetron sputtering precursor wire method and hot isostatic pressing process. Heat exposure experiments were conducted at different temperatures (400, 600, 800 ℃) and times (50, 100, 150, 200 h) to analyze the changes in interfacial reaction layer thickness, element distribution, and diffusion patterns of SiCf/TC18 composites in hot isostatic pressing and hot exposure states. More importantly, this work elucidated the mechanism of element mutual diffusion, summarized the growth law of interface reaction layer thickness with heat exposure time, and revealed that the interface reaction layer products of SiCf/TC18 composites are mainly TiC. After calculation, the interface index factor of SiCf/TC18 composites was 4.0 × 10−6 m/s1/2, the activation energy of reaction layer growth was 80.31 kJ/mol, the material exhibited excellent interfacial thermal stability at below 400 ℃.

-

Key words:

- titanium matrix composite /

- interdiffusion /

- interface reaction /

- reaction products /

- thermal stability

-

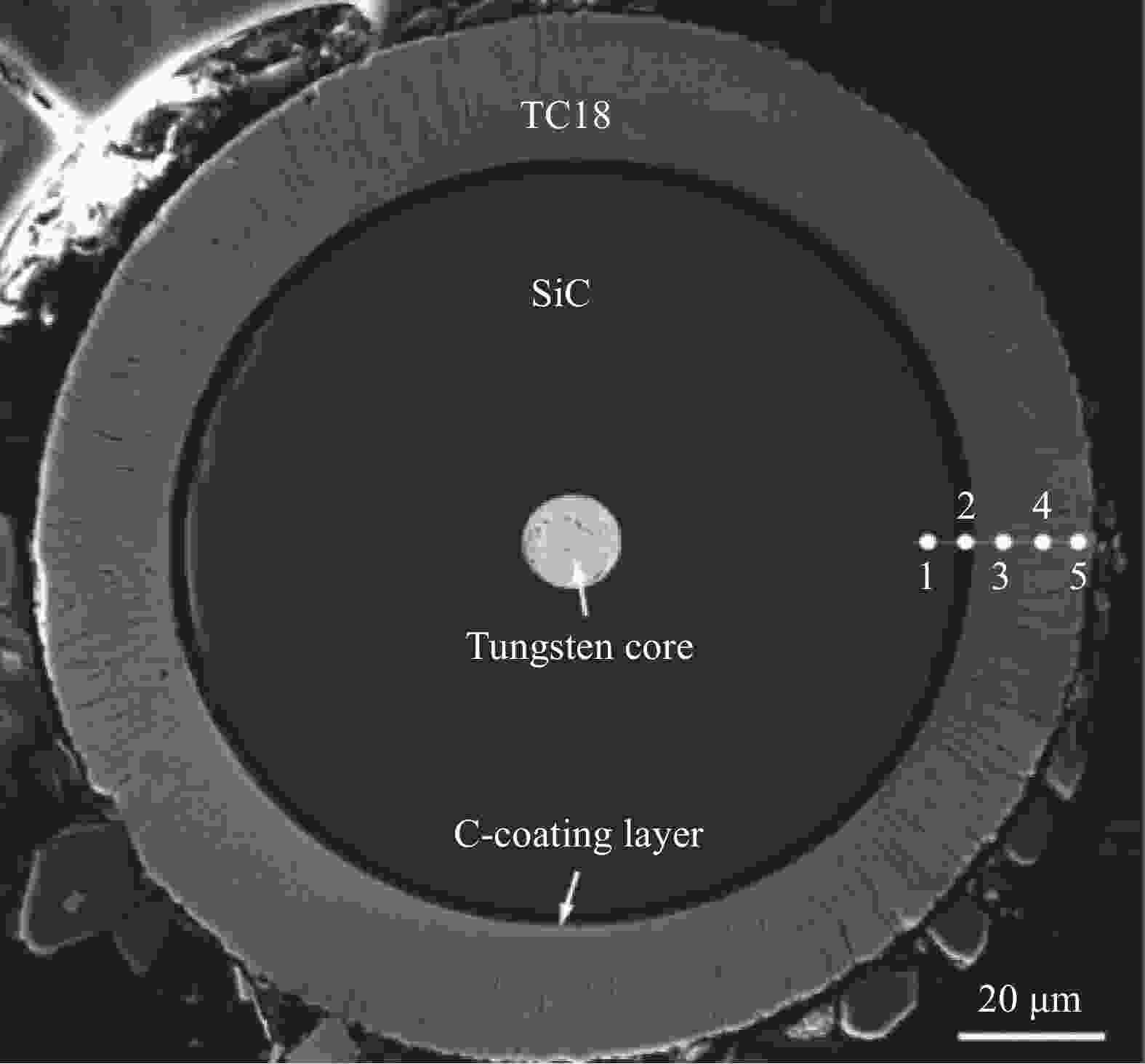

表 1 SiCf/TC18复合材料先驱丝EDS元素定量分析结果

Table 1. Quantitative analysis results of EDS elements in SiCf/TC18 composites precursor wire (Mass fraction/%)

Position C Si Ti Al Mo V Fe Cr Total 1 44.22 55.35 0.20 0.08 0.08 0.03 0.02 0.02 100.00 2 78.02 21.54 0.35 0.05 0.00 0.03 0.00 0.01 100.00 3 7.50 0.17 76.58 4.31 4.37 5.20 1.01 0.86 100.00 4 7.26 0.17 77.34 4.54 4.16 4.87 0.90 0.76 100.00 5 8.02 0.14 76.45 4.53 4.27 4.93 0.92 0.74 100.00 表 2 SiCf/TC18复合材料热暴露后的界面反应层厚度

Table 2. The thickness of the interface reaction layer of SiCf/TC18 composites after heat exposure

Temperature /℃ Thickness of interfacial reaction layer / μm 50 h 100 h 150 h 200 h 400 0.61±0.26 0.61±0.27 0.61±0.32 0.61±0.26 600 0.62±0.17 0.64±0.21 0.65±0.33 0.67±0.25 800 1.28±0.30 1.48±0.37 1.62±0.39 1.90±0.29 表 3 SiCf/TC18复合材料热等静压态与200 h热暴露实验后的晶粒尺寸大小

Table 3. Grain size of SiCf/TC18 composites in hot isostatic pressing state and after 200 h heat exposure experiment

Temperature /℃ Grain size /μm2 α phase β phase Overall size RT 0.30 0.14 0.22 400 0.37 0.28 0.33 600 0.48 0.30 0.39 800 1.02 1.24 1.12 表 4 SiCf/TC18复合材料元素原子半径

Table 4. Element atomic radius of SiCf/TC18 composites

Element symbol C Si Ti Al Mo V Fe Cr Atomic radius/nm 0.077 0.134 0.144 0.143 0.139 0.132 0.124 0.128 表 5 热等静压态反应层EPMA元素定量分析结果

Table 5. Quantitative analysis results of EPMA elements in the reaction layer of hot isostatic pressing state (Mass fraction/%)

Position C Si Ti Al Mo V Fe Cr Total 1 31.67 5.00 59.97 0.84 1.01 0.99 0.21 0.31 100.00 2 23.68 2.94 67.75 1.59 1.67 1.48 0.38 0.51 100.00 3 17.51 1.64 71.18 2.52 2.97 2.53 0.77 0.88 100.00 表 6 热暴露态800℃/200 h反应层EPMA元素定量分析结果

Table 6. Quantitative analysis results of EPMA elements in the reaction layer at 800℃/200 h under thermal exposure

(Mass fraction/%) Position C Si Ti Al Mo V Fe Cr Total 1 20.98 2.48 76.07 0.07 0.04 0.33 0.01 0.02 100.00 2 12.45 0.32 86.57 0.21 0.04 0.39 0.01 0.01 100.00 3 10.13 0.18 87.18 1.54 0.26 0.62 0.03 0.06 100.00 -

[1] 王玉敏, 张国兴, 张旭, 等. 连续SiC纤维增强钛基复合材料研究进展[J]. 金属学报, 2016, 52(10): 1153-1170. doi: 10.11900/0412.1961.2016.00347WANG Yumin, ZHANG Guoxing, ZHANG Xu, et al. Research Progress in Continuous SiC Fiber Reinforced Titanium Matrix Composites[J]. Journal of Metals, 2016, 52(10): 1153-1170(in Chinese). doi: 10.11900/0412.1961.2016.00347 [2] 张汝光, 许守勃. 纤维增强复合材料的基体和界面控制破坏的强度理论[J]. 复合材料学报, 1985, 2(4): 40-Ⅴ.ZHANG Ruguang, XU Shoubo. A Failure Theory Predomenated by Matrix and Interface for Fibrous Composites[J]. Acta Materiae Compositae Sinica, 1985, 2(4): 40-Ⅴ(in Chinese). [3] CLYNE T W, WITHERS P J. An Introduction to Metal Matrix Composites [M]. New York: Cambridge University Press, 1993. [4] 符跃春, 韦泽麒, 杨丽娜, 等. SiCf/Ti2AlNb复合材料的界面反应及热稳定性[J]. 东北大学学报(自然科学版), 2022, 43(8): 1105-1112. doi: 10.12068/j.issn.1005-3026.2022.08.006FU Yuechun, WEI Zeqi, YANG Lina, et al. Interface reaction and thermal stability of SiCf/Ti2AlNb composite materials[J]. Journal of Northeast University (Natural Science Edition), 2022, 43(8): 1105-1112(in Chinese). doi: 10.12068/j.issn.1005-3026.2022.08.006 [5] 罗贤, 李超, 杨延清, 等. SiC/C/Mo/Ti-43Al-9V复合材料的界面热稳定性研究[C]. 中国机械工程学会热处理分会. 第十一次全国热处理大会论文集. 中国机械工程学会热处理分会: 中国机械工程学会, 2015: 7.LUO Xian, LI Chao, YANG Yanqing, et al. Study on Interface Thermal Stability of SiC/C/Mo/Ti-43Al-9V Composite Materials [C]. Heat Treatment Branch of the Chinese Society of Mechanical Engineering. Proceedings of the 11th National Heat Treatment Conference. Heat Treatment Branch of the Chinese Society of Mechanical Engineering: Chinese Society of Mechanical Engineering, 2015: 7(in Chinese). [6] 李虎, 黄旭, 黄浩, 等. 连续SiC纤维增强钛基复合材料界面反应研究[J]. 锻压技术, 2016, 41(4): 103-108.LI Hu, HUANG Xu, HUANG Hao, et al. Study on Interface Reaction of Continuous SiC Fiber Reinforced Titanium Matrix Composite Materials[J]. Forging Technology, 2016, 41(4): 103-108(in Chinese). [7] 曾科军, 金展鹏. SiC纤维增强钛基复合材料界面反应机理[J]. 复合材料学报, 1989, 6(4): 92-Ⅵ.ZENG Kejun, JIN Zhanpeng. Mechanism of The Interfacial Reaction in SiC Filament Reinforced Titanium Matrix Composites[J]. Acta Materiae Compositae Sinica, 1989, 6(4): 92-Ⅵ(in Chinese). [8] 吕祥鸿, 杨延清, 马志军. SiC连续纤维增强Ti基复合材料界面反应扩散研究进展[J]. 稀有金属材料与工程, 2006, (1): 164-168. doi: 10.3321/j.issn:1002-185X.2006.01.042LV Xianghong, YANG Yanqing, MA Zhijun. Research progress on interfacial reaction diffusion of SiC continuous fiber reinforced Ti matrix composites[J]. Rare Metal Materials and Engineering, 2006, (1): 164-168(in Chinese). doi: 10.3321/j.issn:1002-185X.2006.01.042 [9] 王超, 张旭, 王玉敏, 等. SiCf/Ti65 复合材料界面反应与基体相变机理[J]. 金属学报, 2020, 56(9): 1275-1285.WANG Chao, ZHANG Xu, WANG Yumin, et al. Interface Reaction and Matrix Phase Transformation Mechanism of SiCf/Ti65 Composite Materials[J]. Journal of Metals, 2020, 56(9): 1275-1285(in Chinese). [10] GRANT B P S. Chemical interaction between sigma 1140+ SiC fibre and Ti-6Al-4V[J]. Scripta Materialia, 2001, 44(4): 607-612 . doi: 10.1016/S1359-6462(00)00649-7 [11] JONES C, KIELY C J, WANG S S. The characterization of an SCS6/Ti–6Al–4V MMC interphase[J]. Journal of Materials Research, 1989, 4(2): 327-335. doi: 10.1557/JMR.1989.0327 [12] B. A. LERCH, HULL D R, LEONHARDT T A. Microstructure of a SiC/Ti-15-3 composite[J]. Composites, 1990, 21(3): 216-224. doi: 10.1016/0010-4361(90)90236-P [13] FINE M E , CONLEY J G. Discussion of "On the free energy of formation of TiC and Al4C3"[J]. 1990, 21: 2609–2610. [14] GOO G K, GRAVES J A , MECARTNEY M L. Interfacial reaction of coated SiC fibers with gamma-TiAl[J]. Scripta Metallurgica Et Materialia, 1992, 26(7): 1043-1048. [15] XUN Y W, TAN M J, ZHOU J T. Processing and interface stability of SiC fiber reinforced Ti-15V-3Cr matrix composites[J]. Journal of Material Processing Technology, 2000, 102(sl-3): 215-220. [16] UPADHYAYA D, WOOD M, WARD-CLOSE C M, et al. Coating and fiber effects on SiC-reinforced titanium[J]. 1994, 46(11): 62-67. [17] 李渭清, 冯永琦, 王鼎春, 等. 镦粗变形工艺对Tc18组织和性能的影响[J]. 钛工业进展, 2008, 25(4): 24-26. doi: 10.3969/j.issn.1009-9964.2008.04.006LI Weiqing, FENG Yongqi, WANG Dingchun, et al. The effect of upsetting deformation process on the microstructure and properties of Tc18[J]. Progress in Titanium Industry, 2008, 25(4): 24-26(in Chinese). doi: 10.3969/j.issn.1009-9964.2008.04.006 [18] 何磊. Tc18钛合金低倍缺陷分析[J]. 热处理技术与制备, 2022, 43(1): 27-30.HE Lei. Analysis of Macroscopic Defects in Tc18 Titanium Alloy[J]. Heat Treatment Technology in Preparation, 2022, 43(1): 27-30(in Chinese). [19] 韩栋, 张鹏省, 毛小南, 等. 两种典型热处理工艺对TC18钛合金组织性能的影响[J]. 钛工业进展, 2009, 26(6): 23-26. doi: 10.3969/j.issn.1009-9964.2009.06.007HAN Dong, ZHANG Pengsheng, MAO Xiaonan, et al. The effect of two typical heat treatment processes on the microstructure and properties of TC18 titanium alloy[J]. Progress in Titanium Industry, 2009, 26(6): 23-26(in Chinese). doi: 10.3969/j.issn.1009-9964.2009.06.007 [20] X. J, NING, P, et al. The microstructure of SCS-6 SiC fiber[J]. Journal of Materials Research, 1991, 6(10): 2234-2248. doi: 10.1557/JMR.1991.2234 [21] 张旭, 王玉敏, 雷家峰, 等. SiCf/TC17复合材料界面热稳定性及元素扩散机理[J]. 金属学报, 2012, 11(11): 1306-1314.ZHANG Xu, WANG Yumin, LEI Jiafeng, et al. Interface thermal stability and element diffusion mechanism of SiCf/TC17 composite materials[J]. Journal of Metals, 2012, 11(11): 1306-1314(in Chinese). [22] 沈莹莹, 张国兴, 贾清, 等. SiCf/TiAl复合材料界面反应及热稳定性[J]. 金属学报, 2022, 9(9): 1150-1158.SHEN Yingying, ZHANG Guoxing, JIA Qing, et al. Interface Reaction and Thermal Stability of SiCf/TiAl Composite Materials[J]. Journal of Metals, 2022, 9(9): 1150-1158(in Chinese). [23] DYBKOV V I. Reaction diffusion in heterogeneous binary systems[J]. Journal of Materials Science, 1986, 21(9): 3078-3084. doi: 10.1007/BF00553339 [24] P, MARTINEAU, M, et al. SiC filament/titanium matrix composites regarded as model composites[J]. Journal of Materials Science, 1984, 19: 2731-2748. doi: 10.1007/BF00550831 [25] MARTINEAU P, LAHAYE M, PAILLER R, et al. SiC filament/titanium matrix composites regarded as model composites[J]. Journal of Materials Science, 1984, 19(8): 2731-2748. doi: 10.1007/BF00550831 [26] BILBA K, MANAUD J P, PETITCORPS Y L, et al. Investigation of diffusion barrier coatings on SiC monofilaments for use in titanium-based composites[J]. Materials Science & Engineering A, 1991, 135(none): 141-144. [27] NAKA M, FENG J C, SCHUSTER J C. Phase reaction and diffusion path of the SiC/Ti system[J]. Metallurgical & Materials Transactions A, 1997, 28(6): 1385-1390. [28] DE-JUN M. Northwestern Polytechnical University [D]. College & Universuty Admission, 2004. [29] 吕祥鸿. SiC连续纤维增强Ti基复合材料的界面扩散行为研究[D]. 西安: 西北工业大学, 2006.LV Xianghong. Study on Interface Diffusion Behavior of SiC Continuous Fiber Reinforced Ti Matrix Composite Materials [D]. Xi'an: Northwest University of Technology, 2006(in Chinese). [30] 朱艳. SiC纤维增强Ti基复合材料界面反应研究[D]. 西北工业大学, 2003.ZHU Yan, Research on Interface Reaction of SiC Fiber Reinforced Ti Matrix Composite Materials [D]. Northwestern Polytechnical University, 2003(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 50

- HTML全文浏览量: 25

- 被引次数: 0

下载:

下载: