Effect of warp yarn paths on bending properties of 3D woven composites

-

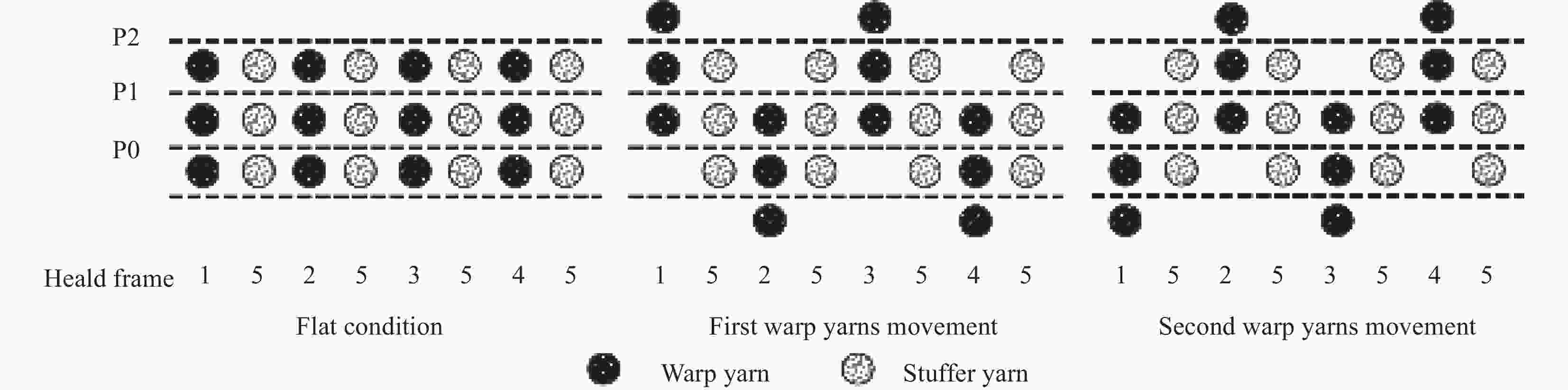

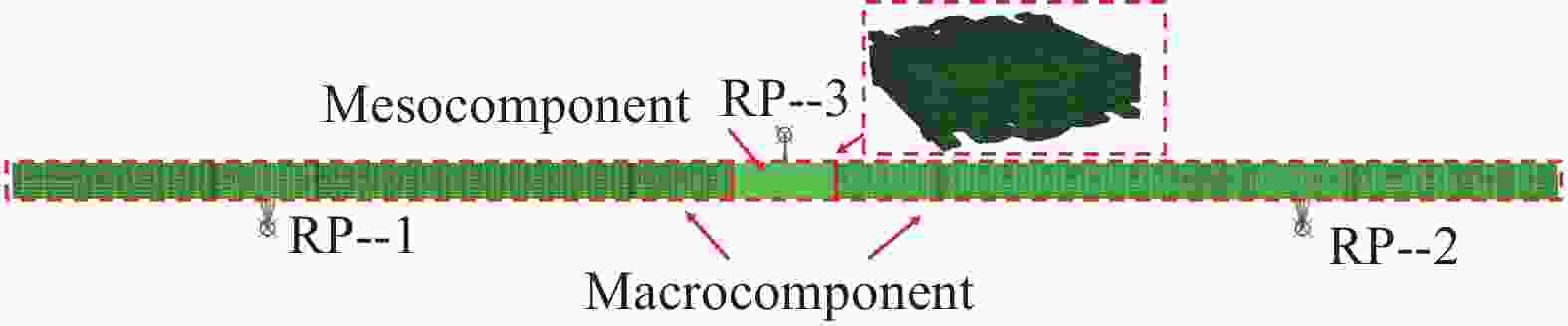

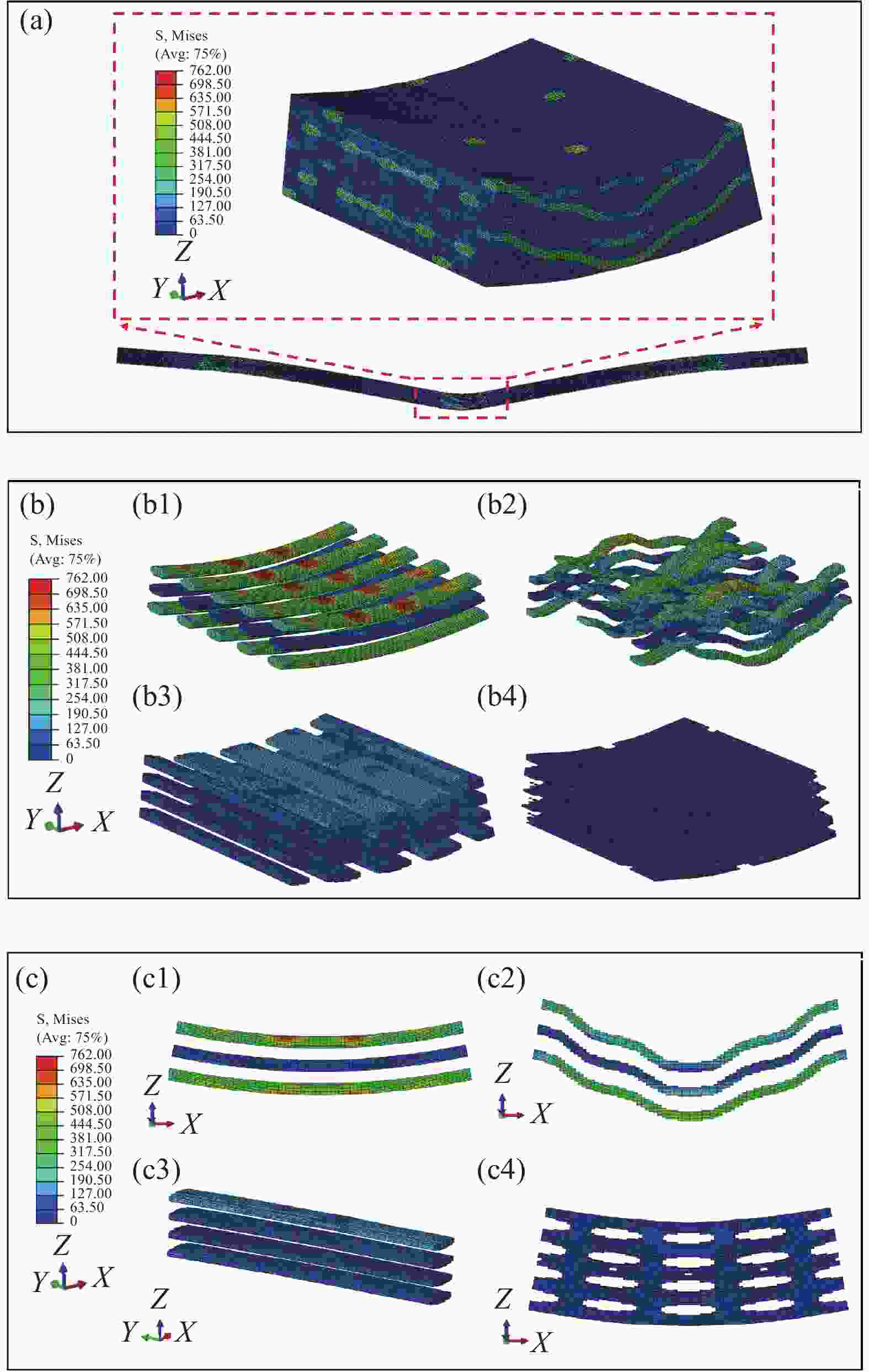

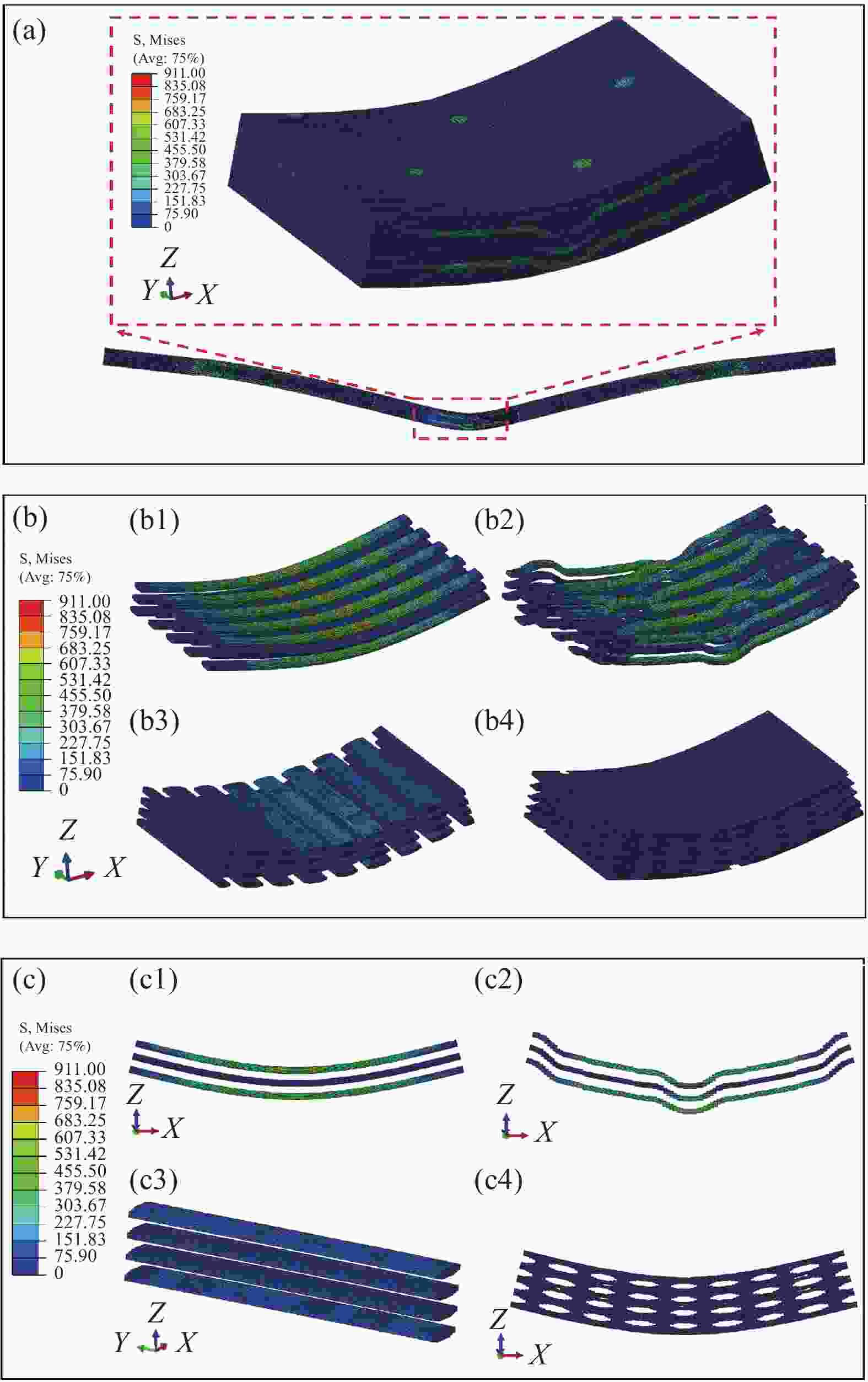

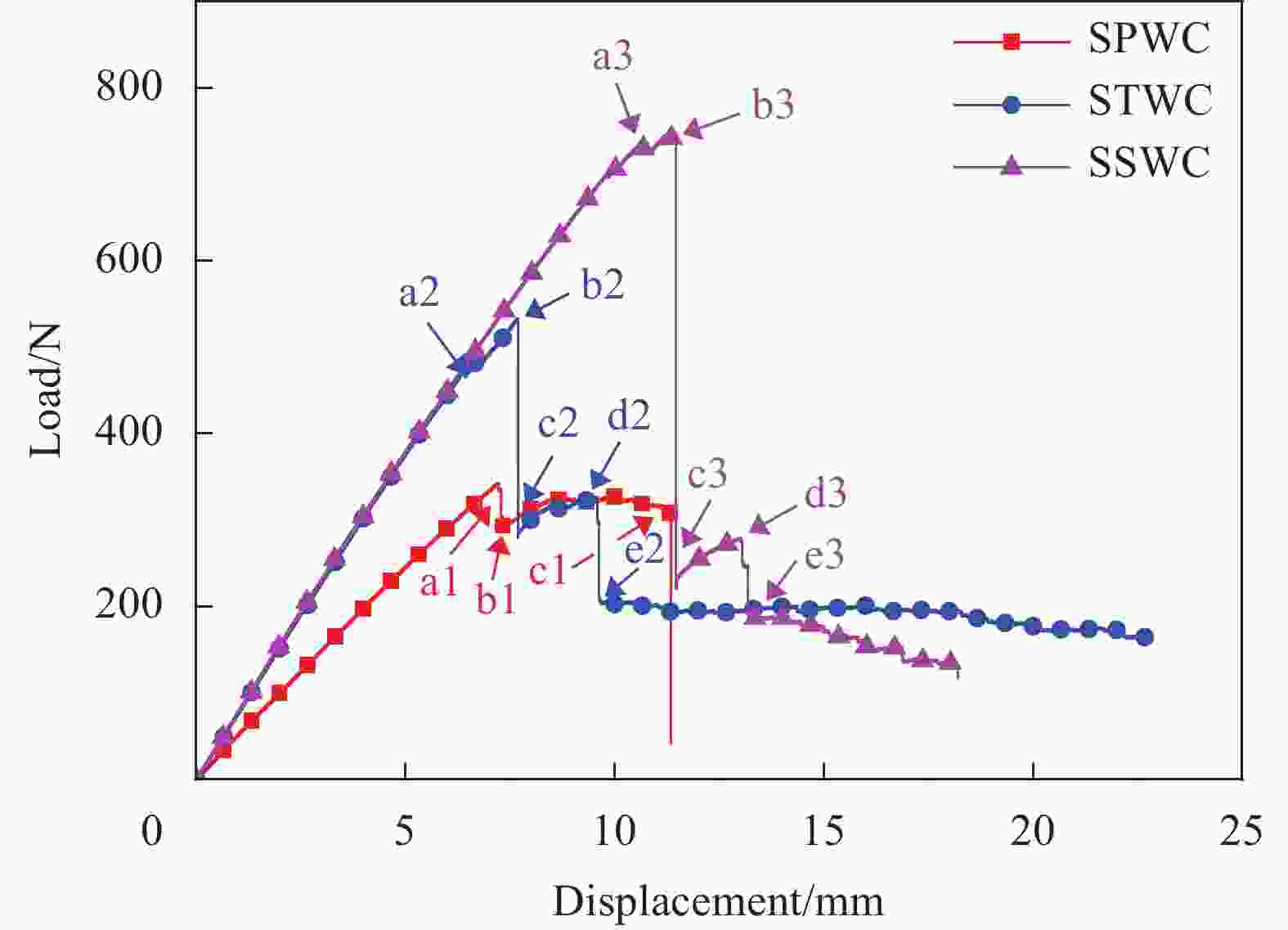

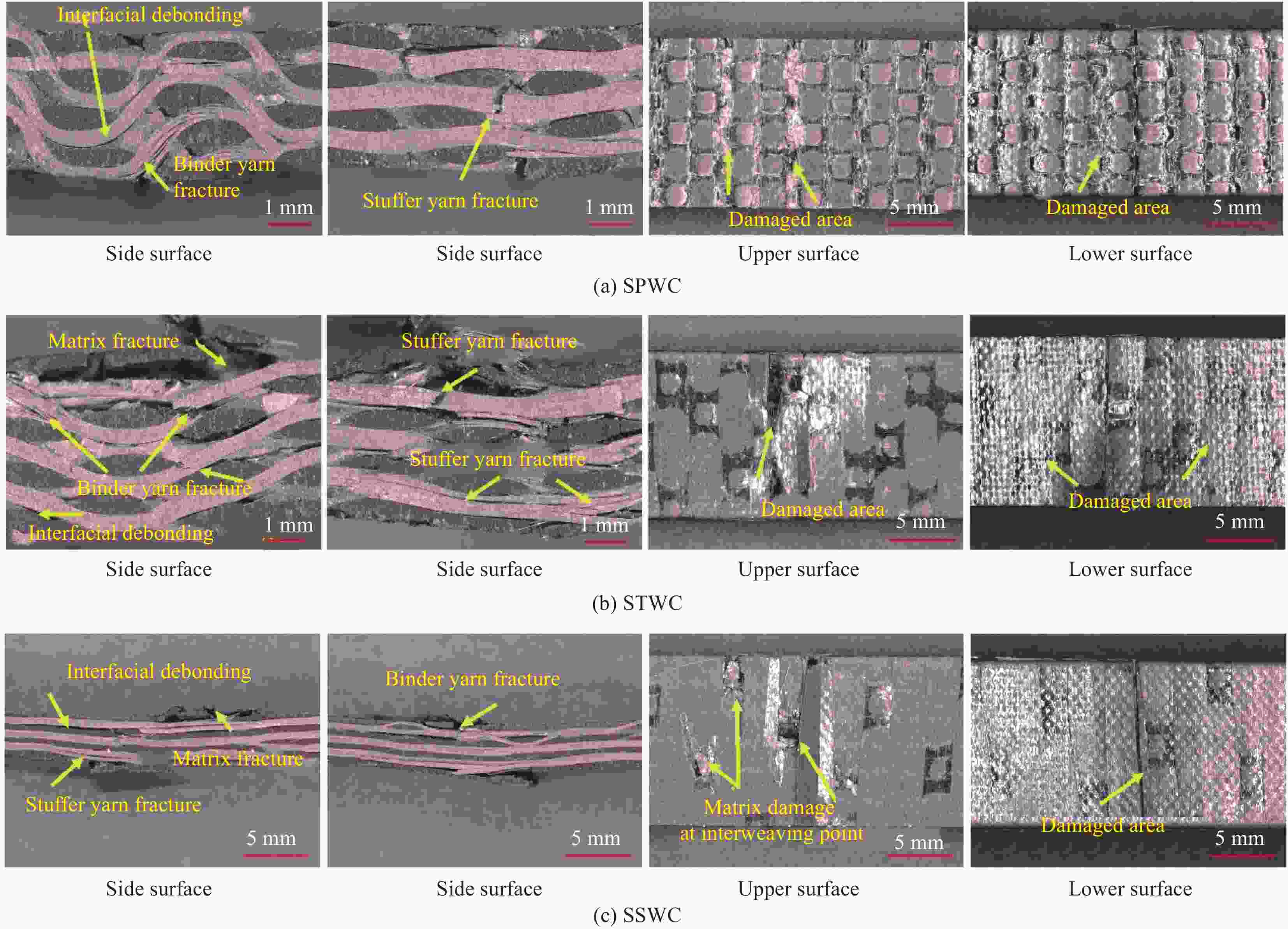

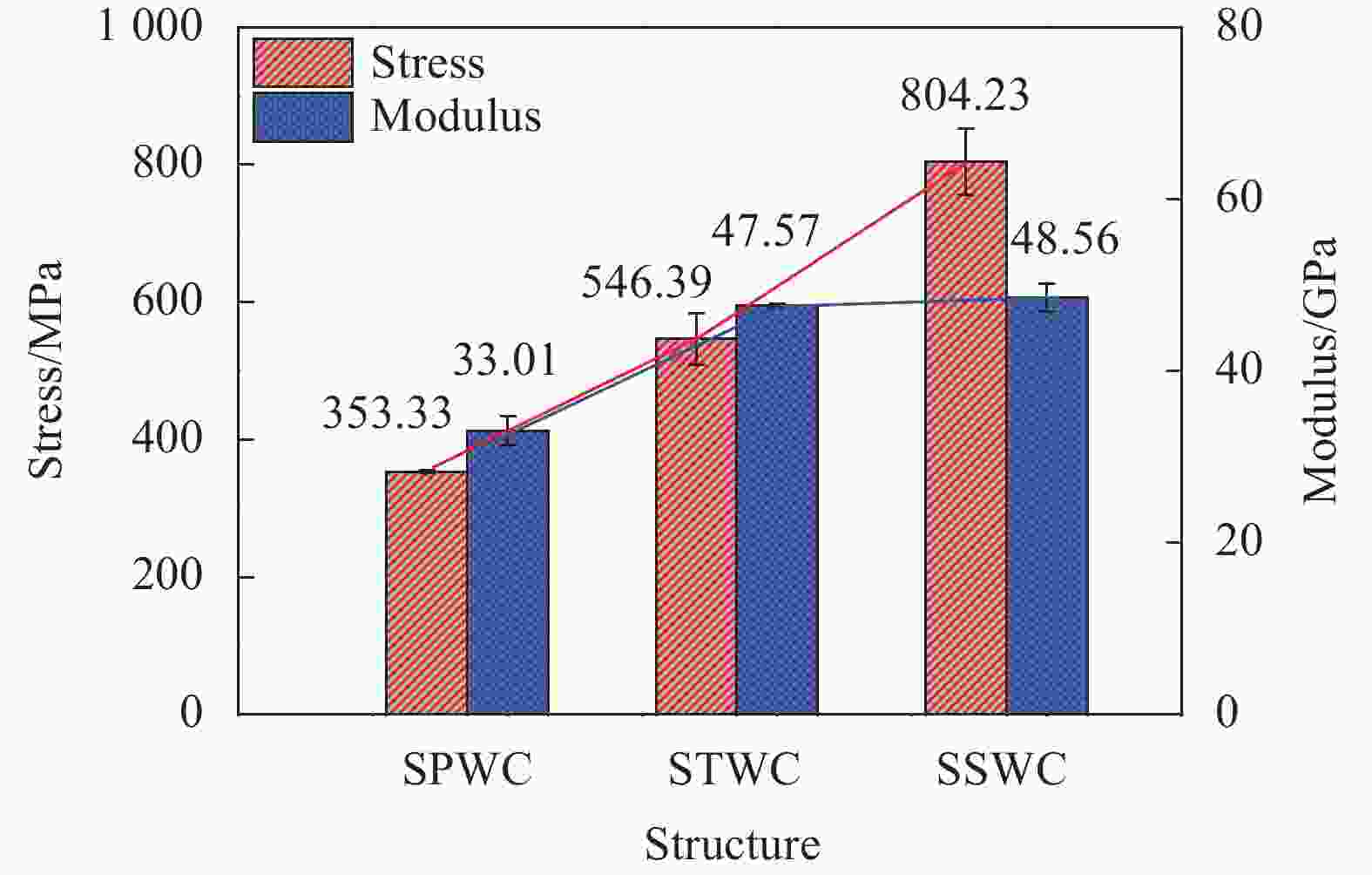

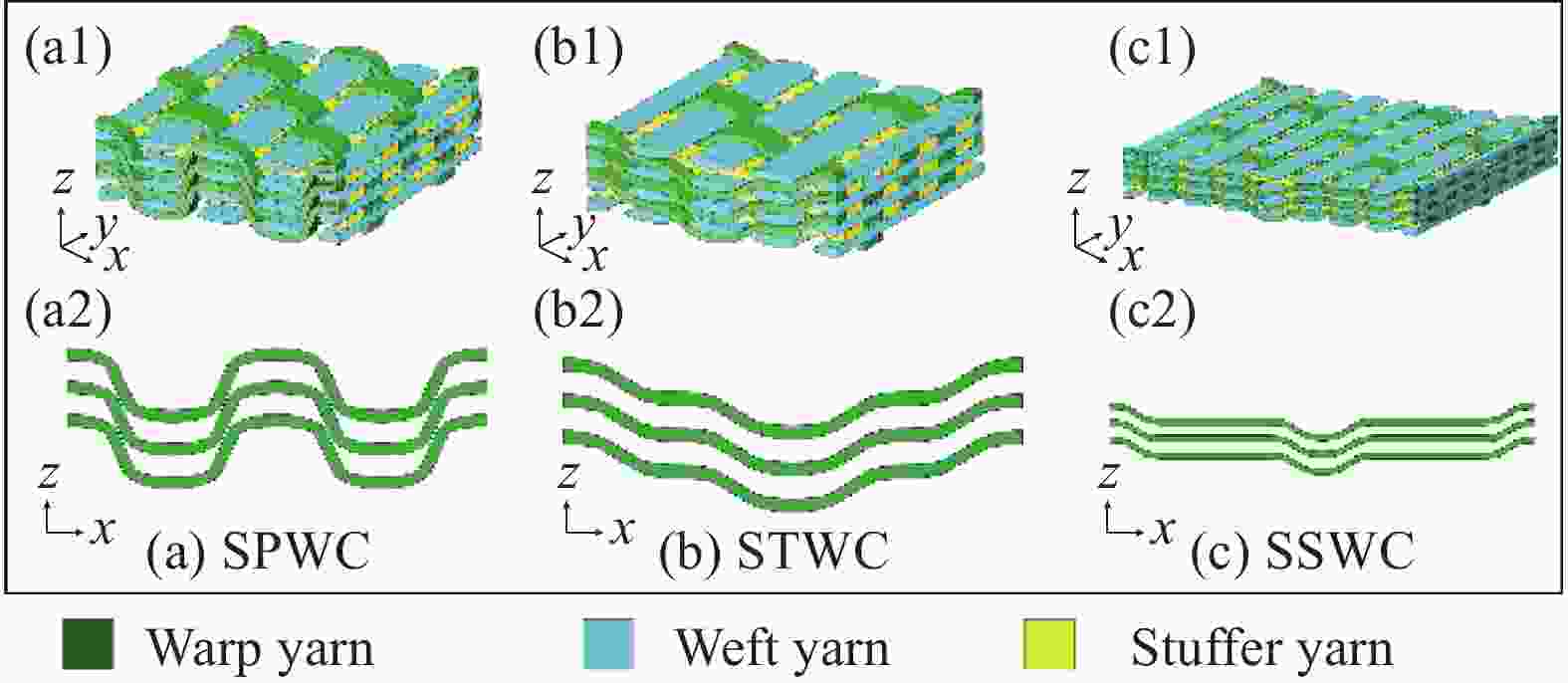

摘要: 设计了三种不同经纱路径的三维机织复合材料(3DWC),利用试验研究,有限元分析,SEM形貌分析相结合的方法,研究了3DWC弯曲性能,损伤机理,断裂形貌特征。研究表明,经纱路径对3DWC弯曲性能有显著影响,相对于衬经平纹机织复合材料(SPWC),随着经纱浮纱长度增加,衬经斜纹和衬经缎纹机织复合材料(STWC和SSWC)弯曲强度分别增加了54.64%和127.61%,弯曲模量分别增加了44.11%和47.11%。SPWC破坏模式为经纱和衬经纱断裂,STWC和SSWC失效模式以纱线断裂和界面脱粘为主。在弯曲载荷加载过程中衬经纱起主要的承载作用,而经纱路径的差异导致三种3DWC应力传递,裂纹扩展,弯曲性能和失效模式发生变化。Abstract: Three types of 3D woven composites (3DWC) with different warp paths were designed. Using a combination of experimental research, finite element analysis and SEM morphology analysis, the bending properties, damage mechanism and fracture morphology of 3DWC were studied. The results show that the warp paths have a significant effect on the bending properties of 3DWC. Compared to the stuffer plain woven composites (SPWC), with the increase of the warp yarns float length, the stuffer twill and stuffer stain woven composites (STWC and SSWC) bending strength increase by 54.64% and 127.61%, and the modulus increase by 44.11% and 47.11%, respectively. The failure modes of the SPWC are the fracture of the stuffer and the warp yarns, while the fracture modes of the STWC and SSWC are mainly yarns fracture and interface debonding. The stuffer yarns play the main role under the process of bending load, while the difference of warp yarn paths leads to the change of stress transfer, crack propagation, bending property and failure mode of three 3DWC.

-

Key words:

- warp yarn paths /

- bending property /

- multi-scale model /

- 3D woven composites /

- failure mode

-

表 1 3DWC预制体织造参数

Table 1. Preform weaving parameter of 3DWC

Structure Interweaving pattern of

preform surfaceWarp specification(500 Tex) Stuffer specification

(1000 Tex)Weft specification

(1000 Tex)Unit cell size/mm SPWC 1/1 12K 24 K 24 K 5×5×3.5 STWC 1/3 12K 24 K 24 K 10×10×3.5 SSWC 8/3 12K 24 K 24 K 20×20×3.5 Notes: SPWC—Stuffer plain woven composites; STWC—Stuffer twill woven composites; SSWC—Stuffer stain woven composites. 表 2 3DWC三种结构建模参数

Table 2. Three structural modeling parameters of 3DWC

Structure Warp cross-section Stuffer cross-section Weft cross-section Height/mm Width/mm Height/mm Width/mm Height/mm Width/mm SPWC 0.32 1.25 0.50 1.25 0.50 1.80 STWC 0.30 1.25 0.56 1.25 0.43 2.40 SSWC 0.30 1.25 0.56 1.25 0.43 3.40 表 3 T800-12K碳纤维工程常数(GPa)

Table 3. Engineering constants of T800-12K carbon fiber bundle (GPa)

E11 E22 E33 G12 G13 G23 v12 v13 v23 221.43 9.12 9.12 6.17 6.17 3.42 0.31 0.31 0.35 表 4 T800-12K碳纤维和5284环氧树脂材料参数

Table 4. Material parameters of T800-12K carbon fiber and 5284 epoxy resin

Material Modulus of elasticity/GPa Poisson's ratio Density/(g·cm−3) Failure stress/MPa Carbon fiber - - 1.79 5700 Epoxy matrix 3.50 0.34 1.12 60 表 5 3DWC工程常数性能参数(GPa)

Table 5. Engineering constant performance parameters of 3DWC (GPa)

Structures E11 E22 E33 G12 G13 G23 v12 v13 v23 SPWC 40.91 64.18 8.26 3.28 2.75 2.46 0.03 0.49 0.35 STWC 47.26 64.14 7.13 3.29 2.71 2.34 0.02 0.49 0.41 SSWC 51.71 62.62 7.11 3.30 2.38 2.29 0.03 0.49 0.43 -

[1] LI Z G, Li D S, Zhu H, et al. Mechanical properties prediction of 3D angle-interlock woven composites by finite element modeling method[J]. Materials Today Communications, 2019, 22. [2] CADORIN N, ZITOUNE R, SEITIER P, et al. Analysis of damage mechanism and tool wear while drilling of 3D woven composite materials using internal and external cutting fluid[J]. Journal of Composite Materials, 2015, 49(22): 2687-2703. doi: 10.1177/0021998314553045 [3] HUANG T, WANG Y L, WANG G. Review of the Mechanical Properties of a 3D Woven Composite and Its Applications[J]. Polymer-Plastics Technology and Engineering, 2018, 57(5-8): 740-756. [4] JIAO W, CHEN L, XIE J B, et al. Effect of weaving structures on the geometry variations and mechanical properties of 3D LTL woven composites[J]. Composite Structures, 2020, 252. [5] WANG T K , LIANG H R, JIANG Z H, et al. Influence of weaving parameters on thermal protection performance of gradient 3D woven composite[J]. POLYMER COMPOSITES, 2020, 44(9), 5381-5395. [6] UMAIR M, HUSSAIN M, SHAKER K, et al. Impact Performance of Three-dimensional Woven Composites with Novel Binding Yarn Patterns[J]. Journal of Natural Fibers, 2022, 19(16): 14461-14476. doi: 10.1080/15440478.2022.2064399 [7] LIU Y, NATSUKI T, HUANG C, et al. Effect of woven structure and aramid binder yarn on the flexural performance of carbon/aramid fiber hybrid three-dimensional woven composites[J]. Polymer Composites, 2022, 43(12): 8831-8849. doi: 10.1002/pc.27065 [8] YAO L, RONG Q, SHAN Z, et al. Static and bending fatigue properties of ultra-thick 3D orthogonal woven composites[J]. Journal of Composite Materials, 2013, 47(5): 569-577. doi: 10.1177/0021998312443141 [9] 薛有松, 薛凌明, 孙宝忠, 等. 碳纤维三维角联锁机织复合材料弯曲作用下力阻响应[J]. 复合材料学, 2023, 40(3): 1468-1476.XUE Yousong, XUE Lingming, SUN Baozhong et al. Piezoresistive effect of carbon fiber 3D angle-interlock woven composites under bending[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1468-1476(in Chinese). [10] LIU Y, HUANG C, XIA H, et al. Research on development of 3D woven textile-reinforced composites and their flexural behavior[J]. Materials & Design, 2021, 212: 110267. [11] 冯古雨, 曹海建, 钱坤. 三维浅交弯联机织复合材料弯曲性能的有限元分析[J]. 宇航材料工艺, 2015, 45(6): 22-26. doi: 10.3969/j.issn.1007-2330.2015.06.005FENG Guyu, CAO Haijian, QIAN Kun. Finite Element Analysis of 3D Curved Shallow-Crossing Linking Woven Composites on Bending Property[J]. Aerospace Materials & Technology, 2015, 45(6): 22-26 (in Chinese). doi: 10.3969/j.issn.1007-2330.2015.06.005 [12] 王颖杰, 王海楼, 张伟. 不同衬经纱占比的三维角联锁机织增强复合材料弯曲性能[J]. 复合材料学报, 2023, 40(6): 3291-3301.WANG Yingjie, WANG Hailou, ZHANG Wei. Bending properties of three-dimensional angle interlocking woven reinforced compositeswith different proportions of warp insertion[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3291-3301(in Chinese). [13] DAI S, CUMNINGHAM PR, MARSHALL S, et al. Influence of fibre architecture on the tensile, compressive and flexural behaviour of 3D woven composites[J]. Composites Part A:Applied Science and Manufacturing, 2015, 69A: 195-207. [14] YANG C Y, ZAN X P, ZHENYING H U. Research of 3D Woven C/C Composites Bending Properties[C]. International Conference on Material Engineering, Architectural Engineering and Informatization. 2012. [15] JIN L, HU H, SUN B, et al. Three-point bending fatigue behavior of 3D angle-interlock woven composite[J]. Journal of Composites, 2012, 46(8): 883-894. [16] JIN L, NIU Z, JIN B C, et al. Comparisons of static bending and fatigue damage between 3D angle-interlock and 3D orthogonal woven composites[J]. Journal of Reinforced Plastics & Composites, 2012, 31(14): 935-945. [17] ZHANG L, QIU R, CHENG J, et al. Experimental investigation and multiscale simulation on the bending fatigue of 2D SiCf/SiC composites[J]. International Journal of Fatigue, 2021, 144: 106051. doi: 10.1016/j.ijfatigue.2020.106051 [18] ZHONG H, YANG S. Multi-scale modelling of the damage behavior for 3D woven composites with variant structure[J]. Journal of Industrial Textiles, 2021, 51(4): 6211-6235. [19] QIAO KAI, XU XIWU, BUI TINH QUOC, et al. Mechanical properties and macro–meso coupled damage behavior of three-dimensional four-directional braided composites under bending loading[J]. Mechanics of Advanced Materials and Structures,DOI: 10.1080/15376494.2023.2185708. [20] JIA X, XIA Z, GU B. Numerical analyses of 3D orthogonal woven composite under three-point bending from multi-scale microstructure pproach[J]. Computational Materials Science, 2013, 79: 468-477. doi: 10.1016/j.commatsci.2013.06.050 [21] ZHANG D Y, WAAS A M, YEN C F, et al. Progressive damage and failure response of hybrid 3D textile composites subjected to flexural loading, part II: Mechanics based multiscale computational modeling of progressive damage and failure[J]. International Journal of Solids & Structures, 2015, 75-76: 321-335. [22] American Society for Testing Materials. Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials: ASTM D7264/D7264M– 2007[S], United States: American Society for Testing Materials International, 2007. [23] 王翔华. 层联机织复合材料无人机起落架结构设计[D]. 天津工业大学, 2022.WANG Xianghua. Structural Design of Layered Woven Composite Material Drone Landing Gear [D]. Tiangong University, 2022 (in Chinese). [24] XIA Z H, ZHANG Y F, ELLYIN F. A unified periodical boundary conditions for representative volume elements of composites and applications[J]. International Journal of Solids and Structures, 2003, 40(8): 1907-1921. doi: 10.1016/S0020-7683(03)00024-6 [25] OUYANG Y W, SUN B Z, GU B H. Finite element analyses on bending fatigue of 3-D five-directional braided composite T-beam with mixed unit-cell model[J]. Journal of Composite Materials, 2018, 52(9): 1139-1154. doi: 10.1177/0021998317722203 [26] HASHIN Z. Failure Criteria for Unidirectional Fiber Composites[J]. Journal of Applied Mechanics, 1980, 47(2): 329-334. doi: 10.1115/1.3153664 [27] WARREN K C, LOPEZ-ANIDO R A , GOERING J. Experimental investigation of three-dimensional woven composites[J]. Composites Part A Applied Science & Manufacturing, 2015, 73: 242-259. -

点击查看大图

点击查看大图

计量

- 文章访问数: 52

- HTML全文浏览量: 27

- 被引次数: 0

下载:

下载: