Recent Progress on Silicon Source Materials and the Related Preparation Process of Silicon-Based Anodes in Lithium-Ion Batteries

-

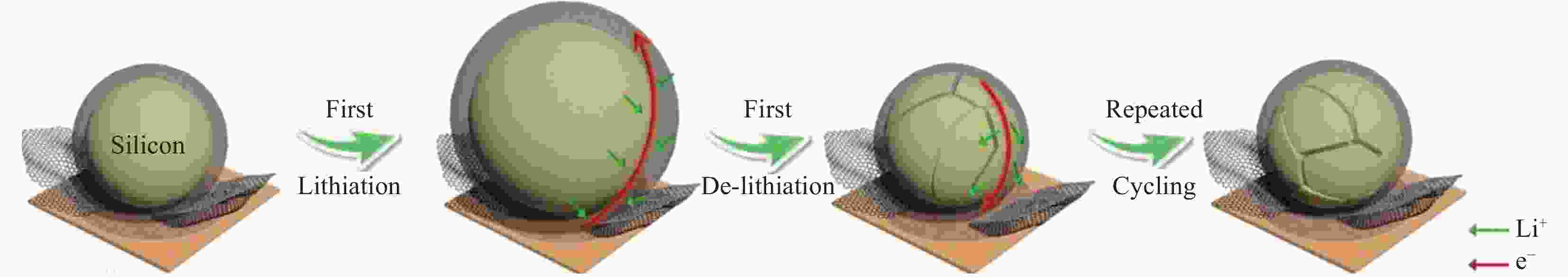

摘要: 近年来,新能源汽车的飞速发展对电池的性能提出了更高要求,而传统石墨类负极材料的比容量较低,难以满足发展的需求。硅具有极高的理论比容量,作为负极材料能有效提高电池性能,具有巨大的发展潜力,而制备硅基负极的硅源材料、硅颗粒的形貌尺寸及其加工制备工艺对硅基负极性能有着重要影响。本文综述了硅基负极材料的最新研究进展,重点关注硅源材料的选择、硅纳米化工艺、硅基负极材料的制备等,提出了不同硅源和对应制备工艺在硅基负极材料制备过程中存在的问题和挑战,为锂离子硅基负极的发展提供重要的参考。Abstract: With the rapid development of new energy vehicles, the traditional graphite carbon-based anodes can no longer meet the increasing demand for high performance lithium-ion battery, especially in terms of capacity. Silicon, boasting an exceptionally high theoretical capacity, serves as a promising anode material capable of significantly enhancing battery performance, showcasing tremendous development potential, where the silicon source materials, the morphology and size of the silicon particles, and the fabrication process play dominant roles on the performance of silicon-based anodes. The present review provides a comprehensive overview of the recent research progresses on the silicon-based anode materials, with a specific emphasis on the selection of silicon source materials, silicon nanostructuring technologies, and the preparation processes. Moreover, it accentuates the challenges and existing problems associated with the different silicon sources as well as the related preparation processes for the silicon-based anode materials, which will eventually provide deep insights for the advancement of silicon-based anodes in lithium-ion battery.

-

Key words:

- silicon /

- anode material /

- nano miniaturization /

- lithium-ion battery /

- electrochemical performance

-

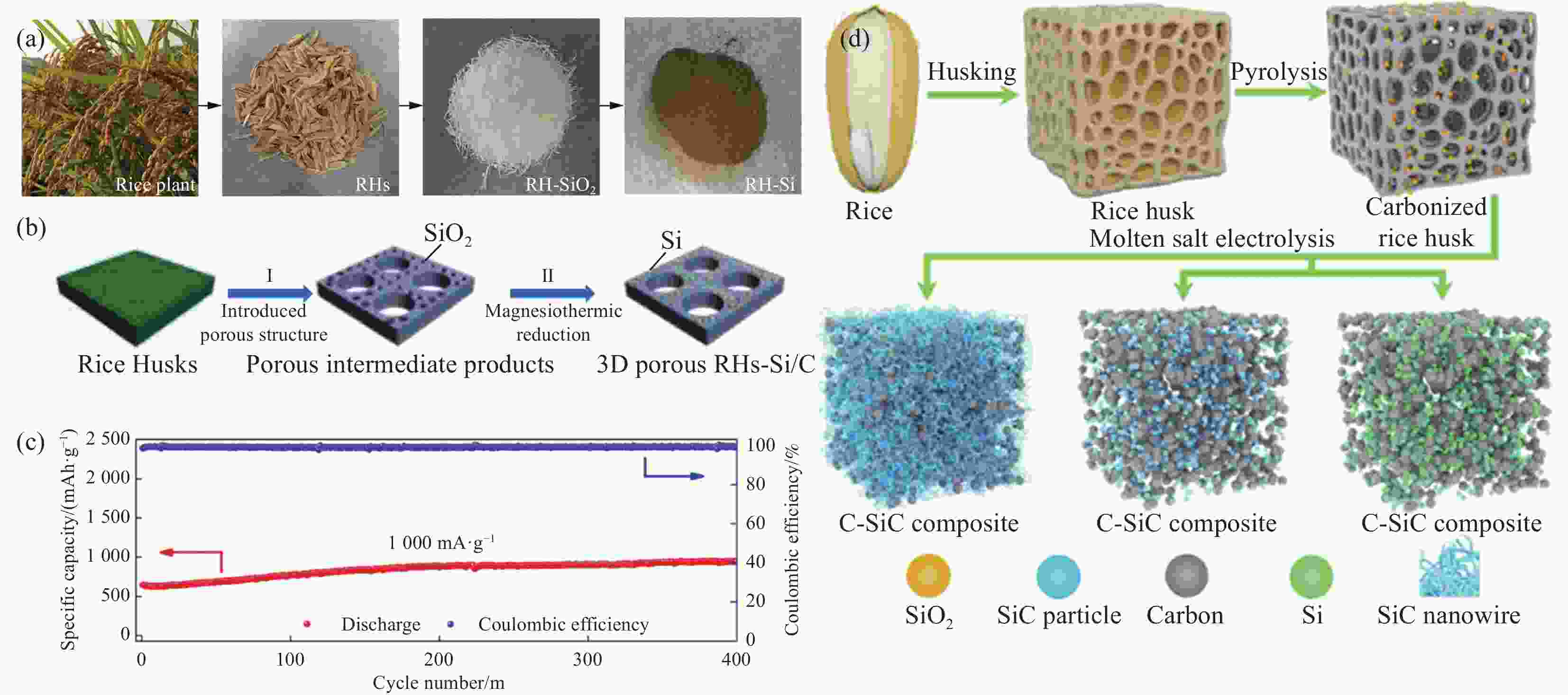

图 3 (a)稻壳制备纳米硅[23]和(b)三维多孔硅/碳纳米复合材料的示意图[24];(c)循环性能图[28] (d) 熔盐电解法制备多孔硅基复合材料示意图[28]

Figure 3. (a) Preparation of Nano Silicon from Rice Hull[23]. (b) Schematic illustration of the formation process of 3 D porous Si/C nanocomposite[24]. (c) Cyclic performance of the prepared materials[28]. (d) Schematic illustration of the preparation of Si composites by the molten salt electrolysis approach[28].

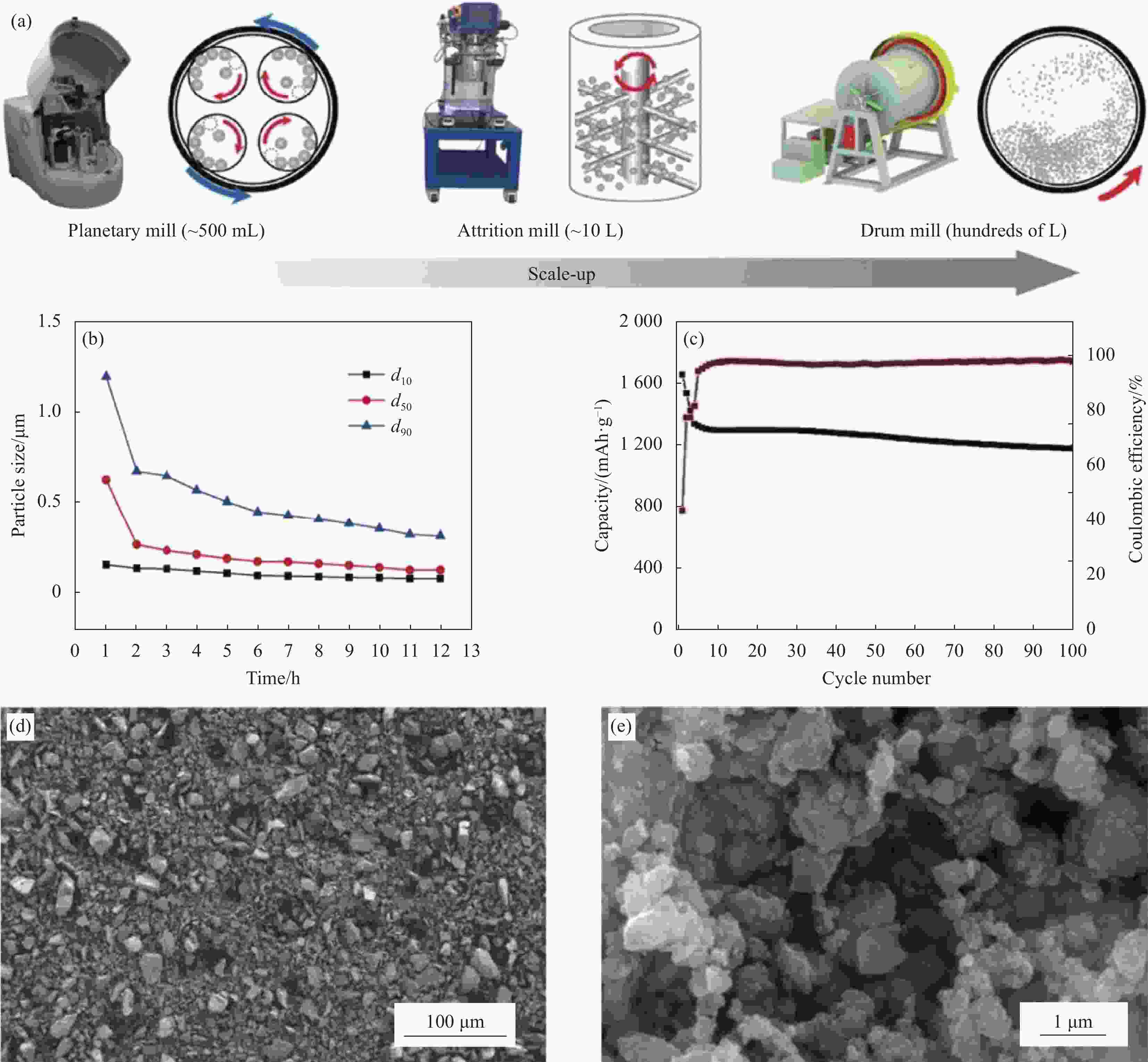

图 5 (a)球磨过程示意图[48];(b)硅颗粒尺寸随球磨时间变化[51];(c)硅碳负极材料的循环性能图;(d)原硅粉SEM图;(e)球磨8 h后硅粉SEM图[52]

Figure 5. (a) The schematic diagram of ball milling process[48]; (b) The change of particle size of silicon with milling time[51]; (c) Cyclic performance; (d) SEM of original Si powders; (e) SEM of Si powders after 8 h ball milling[52].

-

[1] WANG F, LI P, LI W, et al. Electrochemical synthesis of multidimensional nanostructured silicon as a negative electrode material for lithium-ion battery[J]. ACS nano, 2022, 16(5): 7689-7700. doi: 10.1021/acsnano.1c11393 [2] 石永刚, 张志勇, 陈彬, 等. 硅化镁还原 CO2 一步原位合成 Si/C 复合负极[J]. 复合材料学报, 2021, 38(10): 3522-3528.SHI Yonggang, ZHANG Zhiyong, CHEN Bing, et al. In-situ synthesis of Si/C composites anode by one-step reduction of CO2 with magnesium silicide[J]. Acta Materiae Compositae Sinica, 2021, 38(10): 3522-3528(in Chinese). [3] HOU Y L, YANG Y, MENG W J, et al. Core-shell structured Si@Cu nanoparticles encapsulated in carbon cages as high-performance lithium-ion battery anodes[J]. Journal of Alloys and Compounds, 2021, 874: 159988. doi: 10.1016/j.jallcom.2021.159988 [4] PATEL Y, VANPARIYA A, MUKHOPADHYAY I. Si-decorated CNT network as negative electrode for lithium-ion battery[J]. Journal of Solid State Electrochemistry, 2023, 27(2): 501-510. doi: 10.1007/s10008-022-05340-6 [5] DOU F, SHI L, CHEN G, et al. Silicon/carbon composite anode materials for lithium-ion batteries[J]. Electrochemical Energy Reviews, 2019, 2(1): 149-198. doi: 10.1007/s41918-018-00028-w [6] POLAT B D, KELES O, Multi-layered Cu/Si nanorods and its use for lithium ion batteries[J]. Journal of Alloys and Compounds, 2015, 622: 418-425. [7] QIUSHI W, TAO M, YUHANG L, et al. Corrigendum to ‘Consecutive chemical bonds reconstructing surface structure of silicon anode for high-performance lithium-ion battery’[J]. Energy Storage Materials, 2021, 39: 354-364 doi: 10.1016/j.ensm.2021.04.043 [8] HEISKANEN S K , KIM J , LUCHT B L . Generation and Evolution of the Solid Electrolyte Interphase of Lithium-Ion Batteries[J]. Joule, 2019, 3(10): 2322-2333. [9] LI Y, WANG R, ZHANG J, et al. Sandwich structure of carbon-coated silicon/carbon nanofiber anodes for lithium-ion batteries[J]. Ceramics International, 2019, 45(13): 16195-16201. doi: 10.1016/j.ceramint.2019.05.141 [10] HOU L, ZHENG H, CUI R, et al. Silicon carbon nanohybrids with expandable space: A high-performance lithium battery anodes[J]. Microporous and Mesoporous Materials, 2019, 275: 42-49. doi: 10.1016/j.micromeso.2018.08.014 [11] CASIMIR A, ZHANG H, OGOKE O, et al. Silicon-based anodes for lithium-ion batteries: Effectiveness of materials synthesis and electrode preparation[J]. Nano Energy, 2016, 27: 359-376. doi: 10.1016/j.nanoen.2016.07.023 [12] 刘琦, 郝思雨, 冯东, 等. 锂离子电池负极材料研究进展[J]. 复合材料学报, 2022, 39(4): 1446-1456.LIU Qi , HAO Siyu, FENG Dong, et al. Research progress of anode materials for lithium ion battery[J]. Acta Materiae Compositae Sinica, 2022, 39(4): 1446-1456(in Chinese). [13] YI Z, QIAN Y, CAO C, et al. Porous Si/C microspheres decorated with stable outer carbon interphase and inner interpenetrated Si@C channels for enhanced lithium storage[J]. Carbon, 2019, 149: 664-671. doi: 10.1016/j.carbon.2019.04.080 [14] CASIMIR A , ZHANG H , OGOKE O , et al. Silicon-based Anode for Lithium-ion Batteries: Effectiveness of Materials Synthesis and Electrode Preparation[J]. Nano Energy, 2016, 27: 359-376. [15] YANG Y, YANG H X, WU Y Q, et al. Graphene caging core-shell Si@ Cu nanoparticles anchored on graphene sheets for lithium-ion battery anode with enhanced reversible capacity and cyclic performance[J]. Electrochimica Acta, 2020, 341: 136037. doi: 10.1016/j.electacta.2020.136037 [16] PARK E, KIM J, CHUNG D J, et al. Si/SiOx-Conductive Polymer Core-Shell Nanospheres with an Improved Conducting Path Preservation for Lithium-Ion Battery[J]. ChemSusChem, 2016, 9(19): 2754-2758. doi: 10.1002/cssc.201600798 [17] YI Z, LIN N , XU T , et al. TiO2 coated Si/C interconnected microsphere with stable framework and interface for high-rate lithium storage[J]. Chemical Engineering Journal, 2018, 347: 214-222. [18] CHU H, WU Q, HUANG J, et al. Rice husk derived silicon/carbon and silica/carbon nanocomposites as anodic materials for lithium-ion batteries[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2018, 558: 495-503. [19] KROISOVÁ D, DVOŘÁČKOVÁ Š, YAHYA R, et al. Rice Husks-Potential Source of Cellulose Microfibers/Nanofibers and Biogenic Silicon Dioxide Nanoparticles[C]//Key Engineering Materials. Trans Tech Publications Ltd, 2022, 927: 149-153. [20] SUDARMAN S, TAUFIK M. Synthesis and application of nano-silicon prepared from rice husk with the hydrothermal method and its use for anode lithium-ion batteries[J]. Materials Science for Energy Technologies, 2024, 7: 1-8. doi: 10.1016/j.mset.2023.07.003 [21] YANG X, SONG Z, VAN ZWIETEN L, et al. Spatial distribution of plant-available silicon and its controlling factors in paddy fields of China[J]. Geoderma, 2021, 401: 115215. doi: 10.1016/j.geoderma.2021.115215 [22] CUI J, CUI Y, LI S, et al. Microsized porous SiOx@ C composites synthesized through aluminothermic reduction from rice husks and used as anode for lithium-ion batteries[J]. ACS applied materials & interfaces, 2016, 8(44): 30239-30247. [23] ZHANG Y C, YOU Y, XIN S, et al. Rice husk-derived hierarchical silicon/nitrogen-doped carbon/carbon nanotube spheres as low-cost and high-capacity anodes for lithium-ion batteries[J]. Nano energy, 2016, 25: 120-127. doi: 10.1016/j.nanoen.2016.04.043 [24] FAN X, YIN B, WU T, et al. Rice Husk-Based 3D Porous Silicon/Carbon Nanocomposites as Anode for Lithium-Ion Batteries[J]. Energy Technology, 2019, 7(6): 1800787. doi: 10.1002/ente.201800787 [25] FENG Y , LIU L , LIU X , et al. Enabling the ability of Li storage at high rate as anodes by utilizing natural rice husks-based hierarchically porous SiO2/N-doped carbon composites[J]. Electrochimica Acta, 2020, 359: 136933. [26] DAULAY A, GEA S. Synthesis and application of silicon nanoparticles prepared from rice husk for lithium-ion batteries[J]. Case Studies in Chemical and Environmental Engineering, 2022, 6: 100256. doi: 10.1016/j.cscee.2022.100256 [27] LI D, YAN X, ZHANG X, et al. Improving long-cycle stability of rice husk–derived Si/C by coating it with rationally designed carbon[J]. Biomass Conversion and Biorefinery, 2022, 12: 1-15. [28] ZHAO Z, XIE H, QU J, et al. A natural transporter of silicon and carbon: conversion of rice husks to silicon carbide or carbon-silicon hybrid for lithium-ion battery anodes via a molten salt electrolysis approach[J]. Batteries & Supercaps, 2019, 2(12): 1007-1015. [29] LIU J, KOPOLD P, VAN AKEN P A, et al. Energy storage materials from nature through nanotechnology: a sustainable route from reed plants to a silicon anode for lithium-ion batteries[J]. Angewandte Chemie, 2015, 127(33): 9768-9772. doi: 10.1002/ange.201503150 [30] GARCÍA-GAYTÁN V, BOJÓRQUEZ-QUINTAL E, HERNÁNDEZ-MENDOZA F, et al. Polymerized silicon (SiO2·nH2O) in equisetum arvense: potential nanoparticle in crops[J]. Journal of the Chilean Chemical Society, 2019, 64(1): 4298-4302. doi: 10.4067/s0717-97072019000104298 [31] 李昆儒, 胡省辉, 张正富, 等. 源于溪木贼的高性能锂离子电池三维多孔生物质硅/碳复合负极材料[J]. 无机材料学报, 2021, 36(9): 929-935. doi: 10.15541/jim20200525LI Kunru, HU Xinghui, ZHANG Zhengfu, et al. Three-dimensional porous biogenic Si/C composite for high performance lithium-ion battery anode derived from equisetum fluviatile[J]. Journal of Inorganic Materials, 2021, 36(9): 929-935(in Chinese). doi: 10.15541/jim20200525 [32] SHEN L , GUO X , FANG X , et al. Magnesiothermically reduced diatomaceous earth as a porous silicon anode material for lithium ion batteries[J]. Journal of Power Sources, 2012, 213: 229-232. [33] GUO L, ZHANG S, XIE J, et al. Controlled synthesis of nanosized Si by magnesiothermic reduction from diatomite as anode material for Li-ion batteries[J]. International Journal of Minerals, Metallurgy and Materials, 2020, 27(4): 515-525. doi: 10.1007/s12613-019-1900-z [34] DI F, WANG N, LI L, et al. Coral-like porous composite material of silicon and carbon synthesized by using diatomite as self-template and precursor with a good performance as anode of lithium-ions battery[J]. Journal of Alloys and Compounds, 2021, 854: 157253. doi: 10.1016/j.jallcom.2020.157253 [35] MIAO R, YANG J, WU Y, et al. Nanoporous silicon from low-cost natural clinoptilolite for lithium storage[J]. RSC advances, 2015, 5(70): 56772-56779. [36] FAVORS Z, WANG W, BAY H H, et al. Scalable synthesis of nano-silicon from beach sand for long cycle life Li-ion batteries[J]. Scientific reports, 2014, 4(1): 1-7. [37] MAGASINSKI A , DIXON P , HERTZBERG B, et al. High-performance lithium-ion anodes using a hierarchical bottom-up approach[J]. Nature Materials, 2010, 9(5): 461-461. [38] MESARITIS G, SYMEOU E, DELIMITIS A, et al. Recycling Si-kerf from photovoltaics: A very promising route to thermoelectrics[J]. Journal of Alloys and Compounds, 2019, 775: 1036-1043. doi: 10.1016/j.jallcom.2018.10.050 [39] POWELL D M, WINKLER M T, CHOI H J, et al. Crystalline silicon photovoltaics: a cost analysis framework for determining technology pathways to reach baseload electricity costs[J]. Energy & Environmental Science, 2012, 5(3): 5874-5883. [40] WAGNER N P, TRON A, TOLCHARD J R, et al. Silicon anodes for lithium-ion batteries produced from recovered kerf powders[J]. Journal of Power Sources, 2019, 414: 486-494. doi: 10.1016/j.jpowsour.2019.01.035 [41] YANG H L, LIU I T, LIU C E, et al. Recycling and reuse of kerf-loss silicon from diamond wire sawing for photovoltaic industry[J]. Waste Management, 2019, 84: 204-210. doi: 10.1016/j.wasman.2018.11.045 [42] LI J, LIN Y, WANG F, et al. Progress in recovery and recycling of kerf loss silicon waste in photovoltaic industry[J]. Separation and Purification Technology, 2021, 254: 117581. doi: 10.1016/j.seppur.2020.117581 [43] SHI J, JIANG X, BAN B, et al. Carbon nanotubes-enhanced lithium storage capacity of recovered silicon/carbon anodes produced from solar-grade silicon kerf scrap[J]. Electrochimica Acta, 2021, 381: 138269. doi: 10.1016/j.electacta.2021.138269 [44] LIU W, LIU J, ZHU M, et al. Recycling of lignin and Si waste for advanced Si/C battery anodes[J]. ACS Applied Materials & Interfaces, 2020, 12(51): 57055-57063. [45] RYU I, CHOI J W, CUI Y, et al. Size-dependent fracture of Si nanowire battery anodes[J]. Journal of the Mechanics and Physics of Solids, 2011, 59(9): 1717-1730. doi: 10.1016/j.jmps.2011.06.003 [46] LIU X H, ZHONG L, HUANG S, et al. Size-dependent fracture of silicon nanoparticles during lithiation[J]. ACS nano, 2012, 6(2): 1522-1531. doi: 10.1021/nn204476h [47] CHO W C, KIM H J, LEE H I, et al. 5L-scale magnesio-milling reduction of nanostructured SiO2 for high capacity silicon anodes in lithium-ion batteries[J]. Nano letters, 2016, 16(11): 7261-7269. doi: 10.1021/acs.nanolett.6b03762 [48] NILSSEN B E, KLEIV R A. Silicon powder properties produced in a planetary ball mill as a function of grinding time, grinding bead size and rotational speed[J]. Silicon, 2020, 12(10): 2413-2423. doi: 10.1007/s12633-019-00340-0 [49] ZHU X, CAI X, ZHANG S, et al. The Impact of Ball Milling Process Parameters on the Preparation of Nano Silicon Powder[J]. Integrated Ferroelectrics, 2021, 217(1): 255-264. doi: 10.1080/10584587.2021.1911318 [50] LI J, YANG J Y, WANG J T, et al. A scalable synthesis of silicon nanoparticles as high-performance anode material for lithium-ion batteries[J]. Rare Metals, 2019, 38(3): 199-205. doi: 10.1007/s12598-017-0936-3 [51] MADDIPATLA R, LOKA C, CHOI W J, et al. Nanocomposite of Si/C anode material prepared by hybrid process of high-energy mechanical milling and carbonization for Li-ion secondary batteries[J]. Applied Sciences, 2018, 8(11): 2140. doi: 10.3390/app8112140 [52] HOSEINPUR A, ANDERSSON S, TANG K, et al. Selective vacuum evaporation by the control of the chemistry of gas phase in vacuum refining of Si[J]. Langmuir, 2021, 37(24): 7473-7485. doi: 10.1021/acs.langmuir.1c00876 [53] OHTA R, FUKADA K, TASHIRO T, et al. Effect of PS-PVD production throughput on Si nanoparticles for negative electrode of lithium ion batteries[J]. Journal of Physics D:Applied Physics, 2018, 51(10): 105501. doi: 10.1088/1361-6463/aaab37 [54] WOLLNY P, MENSER J, ENGELMANN L, et al. The role of phase transition by nucleation, condensation, and evaporation for the synthesis of silicon nanoparticles in a microwave plasma reactor—Simulation and experiment[J]. Chemical Engineering Journal, 2022, 453: 139695 [55] PUGLISI R A, BONGIORNO C, CACCAMO S, et al. Chemical vapor deposition growth of silicon nanowires with diameter smaller than 5 nm[J]. ACS omega, 2019, 4(19): 17967-17971. doi: 10.1021/acsomega.9b01488 [56] LIU B, HUANG P, XIE Z, et al. Large-Scale Production of a Silicon Nanowire/Graphite Composites Anode via the CVD Method for High-Performance Lithium-Ion Batteries[J]. Energy & Fuels, 2021, 35(3): 2758-2765. [57] HU M, WU H, ZHANG G J. High-performance silicon/graphite anode prepared by CVD using SiCl4 as precursor for Li-ion batteries[J]. Chemical Physics Letters, 2023, 833: 140917. doi: 10.1016/j.cplett.2023.140917 [58] XING Z, LU J, JI X. A brief review of metallothermic reduction reactions for materials preparation[J]. Small Methods, 2018, 2(12): 1800062. doi: 10.1002/smtd.201800062 [59] YAN Z, GUO J. High-performance silicon-carbon anode material via aerosol spray drying and magnesiothermic reduction[J]. Nano Energy, 2019, 63: 103845. doi: 10.1016/j.nanoen.2019.06.041 [60] WANG M, MA Y, JIANG J, et al. Hierarchical microspheres of aggregated silicon nanoparticles with nanometre gaps as the anode for lithium-ion batteries with excellent cycling stability[J]. ChemElectroChem, 2019, 6(4): 1139-1148. doi: 10.1002/celc.201801405 [61] REN Y, ZHOU X, ZHOU H, et al. Zn-assisted magnesiothermic reduction for the preparation of ultra-fine silicon nanocrystals for lithium ion batteries[J]. Chemical Engineering Journal, 2017, 328: 691-696. doi: 10.1016/j.cej.2017.07.040 [62] XIANG B, AN W L, FU J J, et al. Graphene-encapsulated blackberry-like porous silicon nanospheres prepared by modest magnesiothermic reduction for high-performance lithium-ion battery anode[J]. Rare Metals, 2021, 40: 383-392. doi: 10.1007/s12598-020-01528-9 -

下载:

下载: