A review on temperature effect of 3D multi-directional braided composites: Heat conduction, thermal expansion properties and mechanical response

-

摘要: 三维编织复合材料因其结构整体性好、综合性能优异,已成为航天、航空、国防领域部分主承力构件和高功能制件的首选材料。然而,三维编织复合材料结构件在服役过程中不可避免地处于高温、低温或温度急剧变化等恶劣环境,由于三维编织复合材料增强体和基体热物理性能的巨大差异将严重威胁结构尺寸的稳定性及结构使用寿命。本文主要从实验、理论和数值仿真研究三方面,综述了近年来国内外对三维多向编织复合材料热物理性能和温度效应影响下力学性能的研究成果及研究进展。首先分析了现有研究中编织工艺、编织参数、环境温度、界面、缺陷等因素对三维多向编织复合材料热传导性能和热膨胀性能的影响规律。其次以细观结构、全尺寸、多尺度模型为主分析了不同结构几何模型的区别与联系。最后探讨了高、低温环境温度和不同载荷形式对三维多向编织复合材料组分材料损伤、失效形态及热力耦合行为的影响机制,并同时总结了现有研究工作中的重点与发展方向。Abstract: Owing to the good structural integrity and excellent comprehensive properties, 3D braided composites have become the preferred materials for some main load-bearing components and high-function parts in aerospace, aviation and national defense fields. However, 3D braided composite structures will inevitably be exposed to harsh environments such as high temperature, low temperature or rapid temperature changes during service. Due to the great difference of thermophysical properties between reinforcement and matrix of 3D braided composite, the dimensional stability and service life of the structure will be seriously threatened. This article gives an overview of the thermophysical properties and temperature effect on the mechanical properties of 3D multi-directional braided composites both at home and abroad in recent years. The research results and progress mainly include three aspects: experiment, theory and numerical simulation. Firstly, the effects of braiding process, braiding parameters, ambient temperature, interface and defects on the thermal conductivity and thermal expansion properties of 3D braided composites were analyzed. Secondly, the differences and relations of different structural geometric models were analyzed based on the micro structure, full-scale and multi-scale models. Finally, the influence mechanism of high/low ambient temperature and different load forms on the failure mode and thermal-mechanical coupling behavior of 3D multi-directional braided composites was discussed, and the focus and development direction of existing research work were summarized.

-

Key words:

- braiding /

- composite /

- heat conduction /

- thermal expansion /

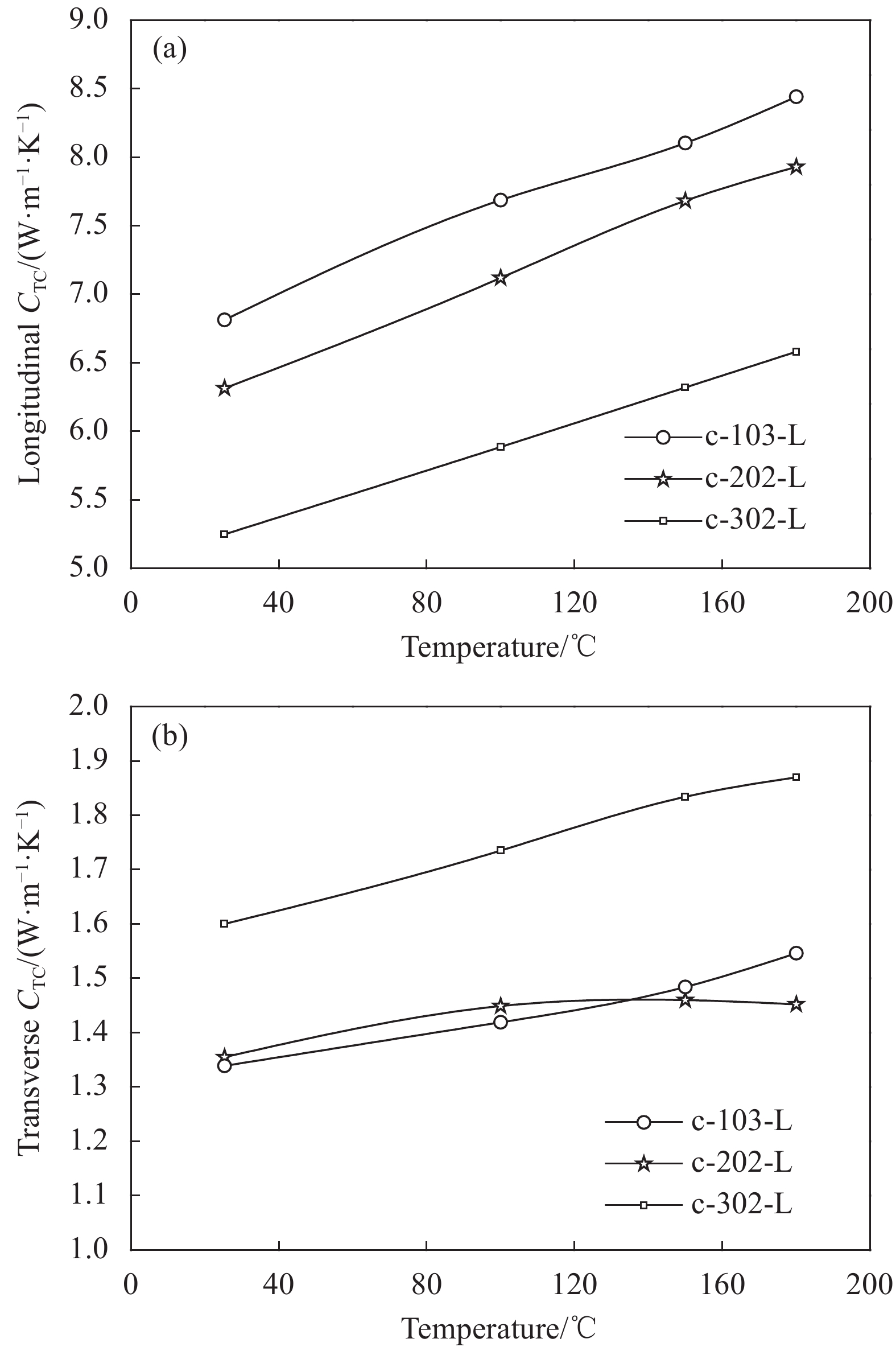

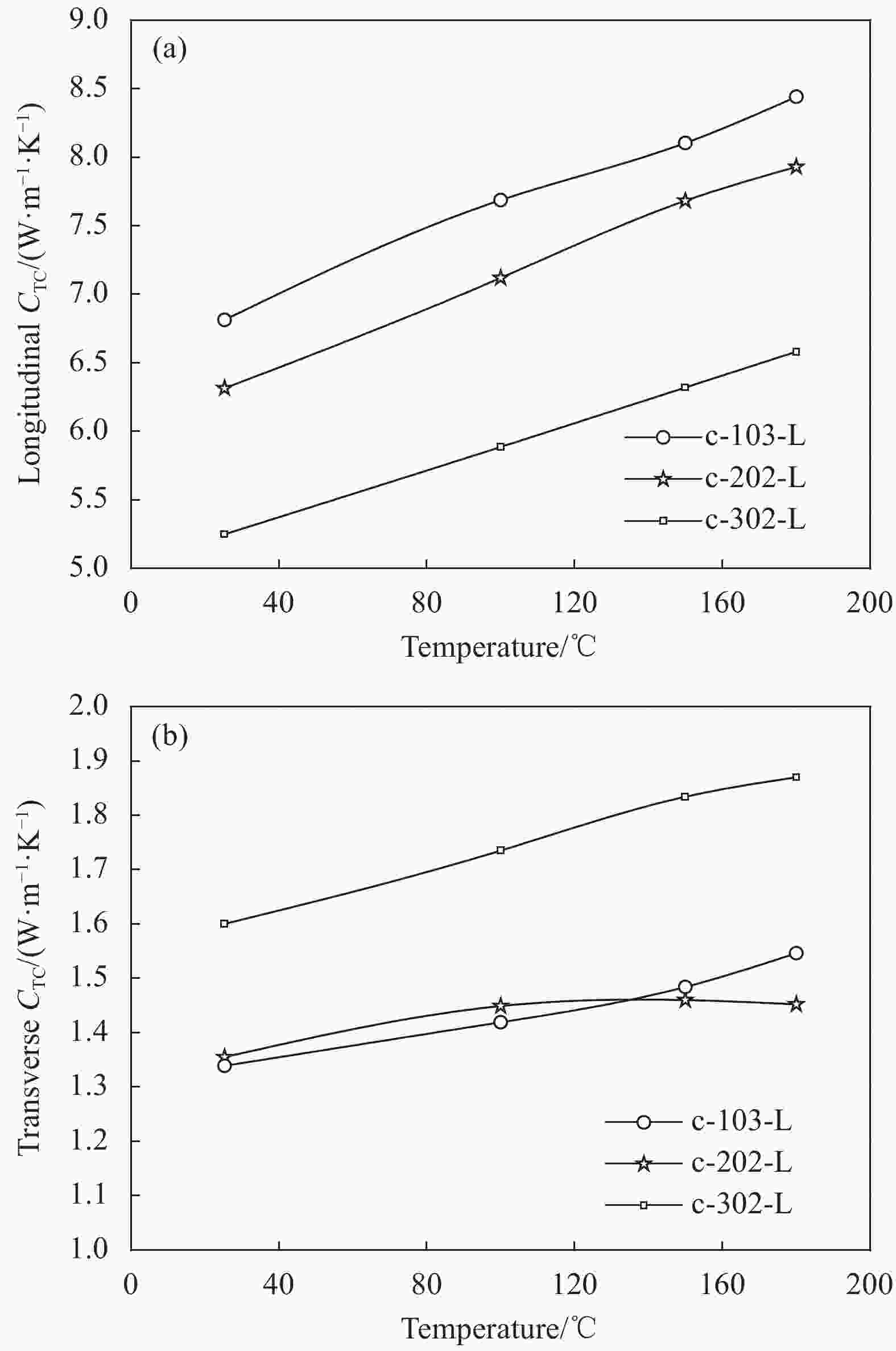

- temperature /

- mechanical properties

-

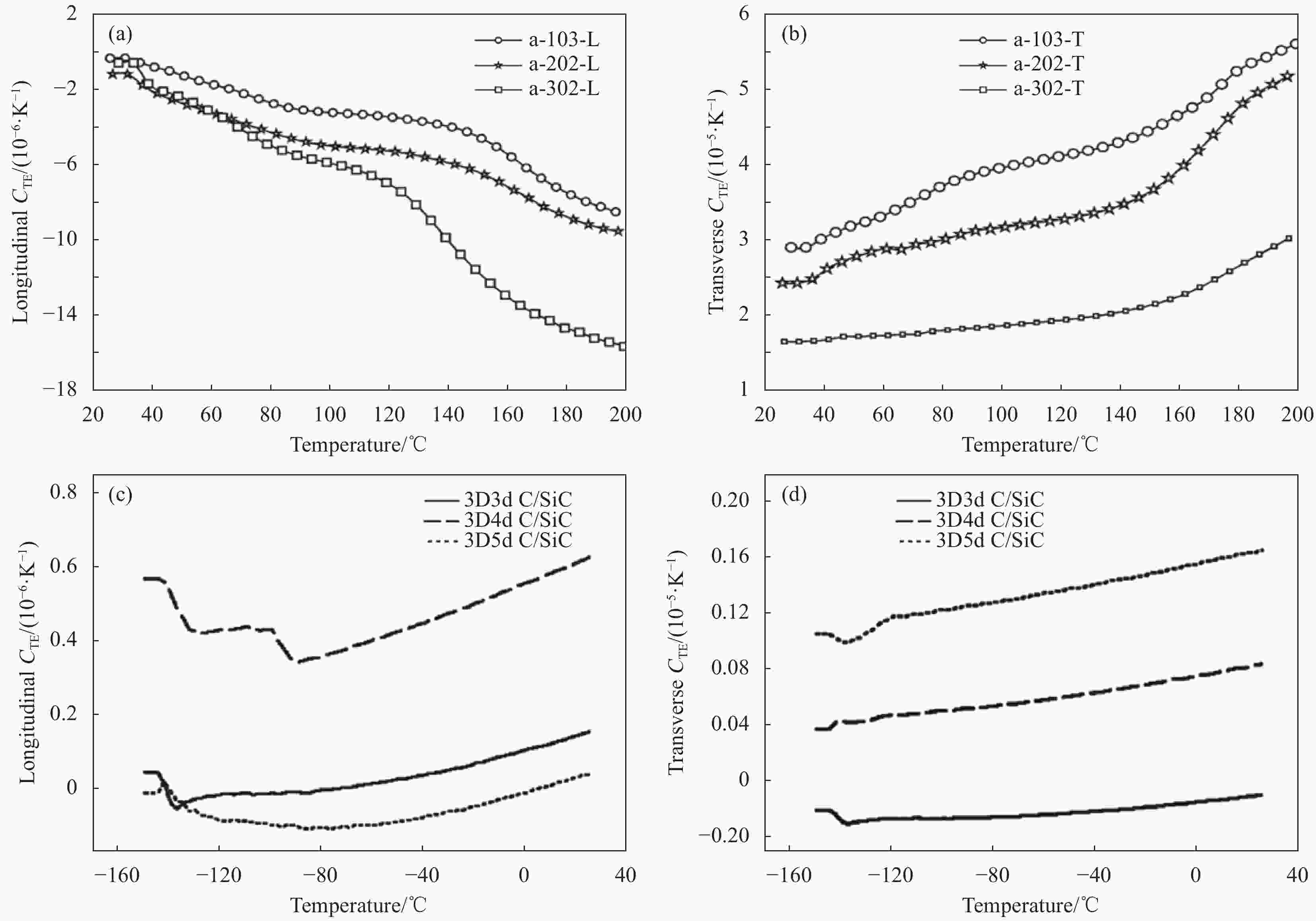

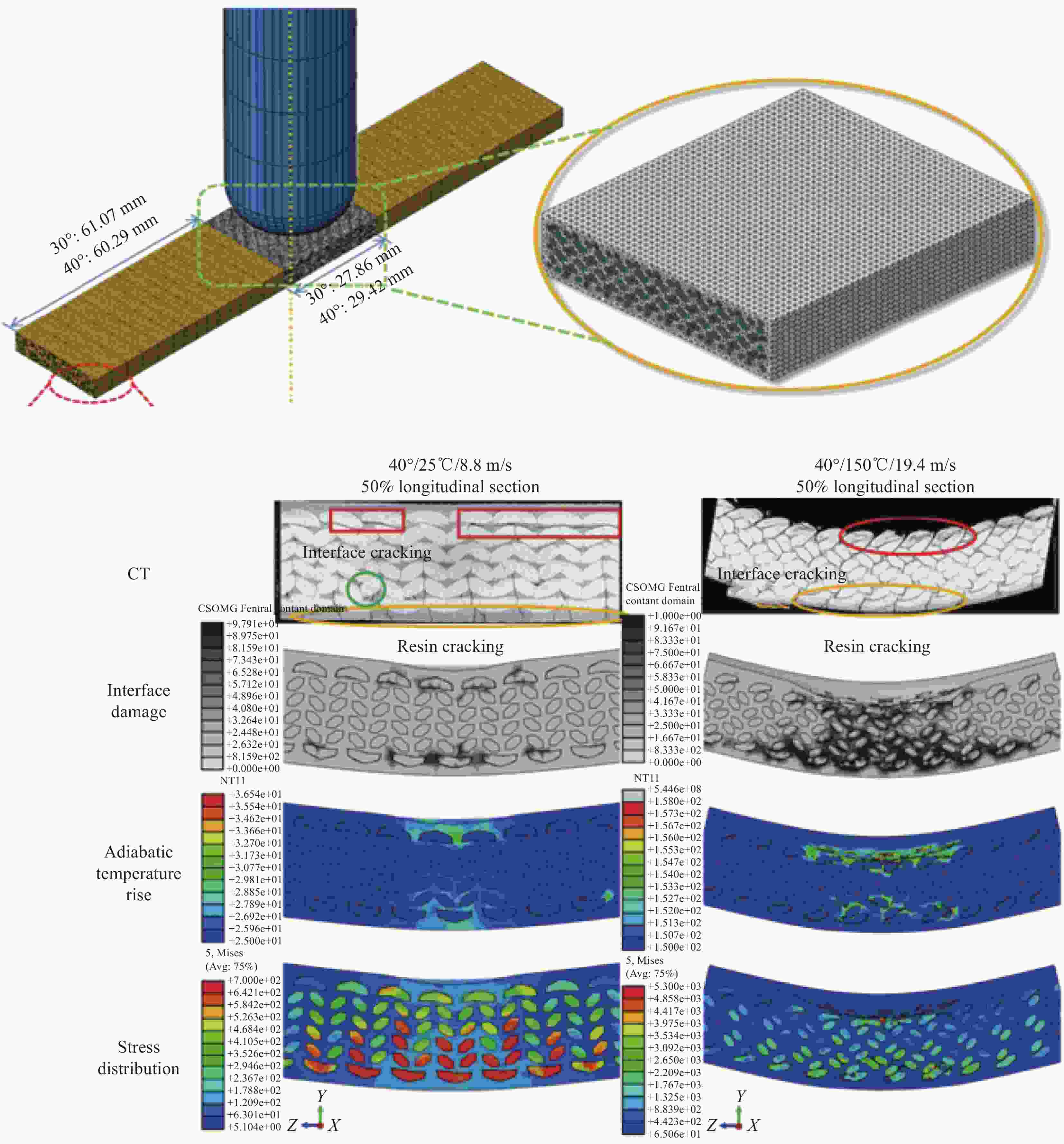

图 3 三维编织复合材料内部单胞有限元模型((a)椭圆截面模型 (三维四向)[25];(b)圆截面模型 (三维四向)[25];(c)六边形截面模型 (三维四向)[28];(d)六边形和正方形截面模型 (三维五向)[28])

Figure 3. Finite element model of internal cell of 3D braided composite ((a) Elliptical section model (3D four directions)[25]; (b) Circular section model (3D four directions)[25]; (c) Hexagon section model (3D four directions)[28]; (d) Hexagon and square section model (3D five directions)[28])

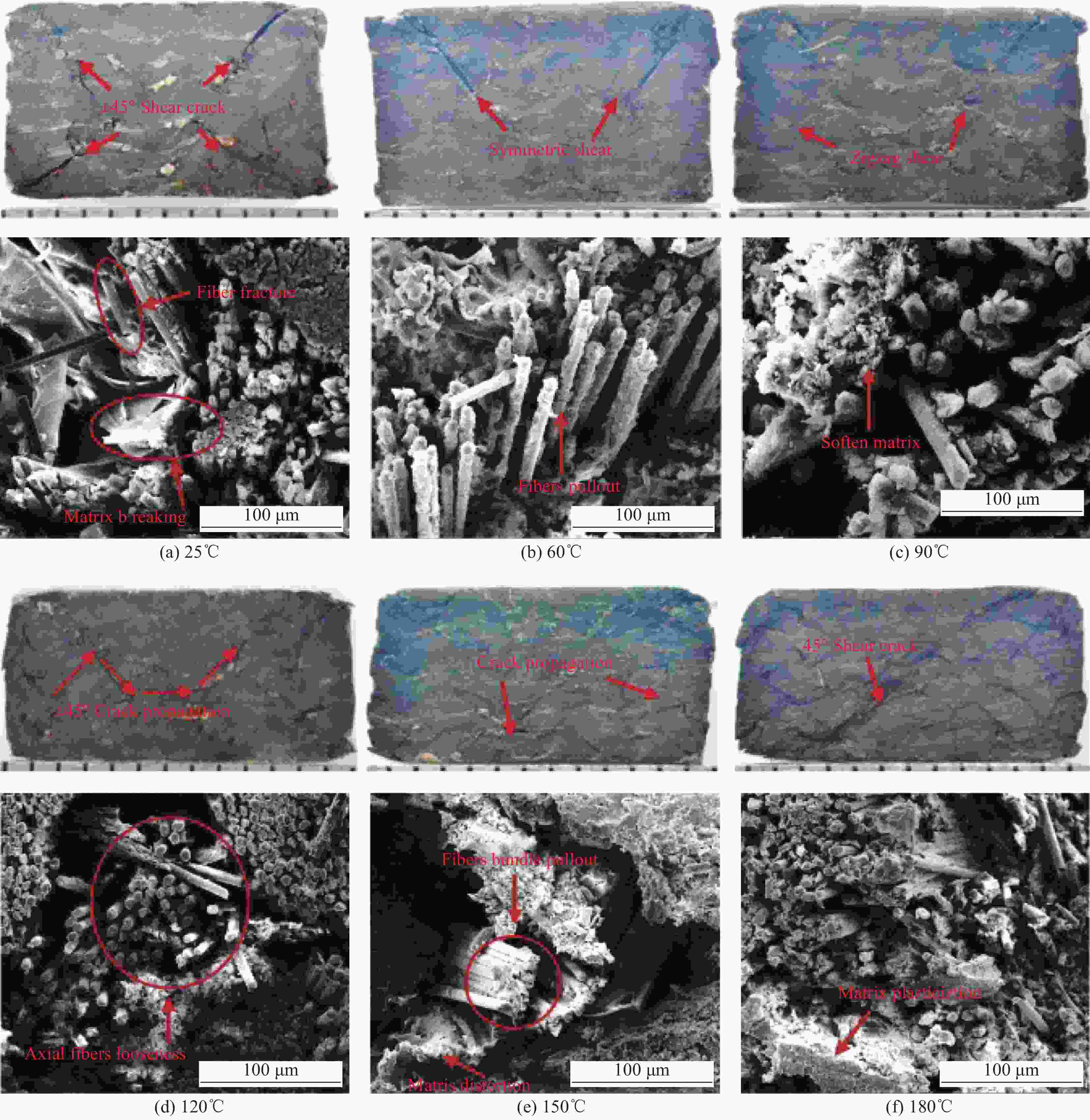

图 8 三维四向编织复合材料在不同温度下的纵向冲击压缩行为:(a) 带有加热装置的分离式霍普金森压力杆试验系统示意图;(b) 在0.25 MPa气压下的典型损伤形态;(c)在0.37 MPa气压下的典型损伤形态;(d) 在0.60 MPa气压下的典型损伤形态[76]

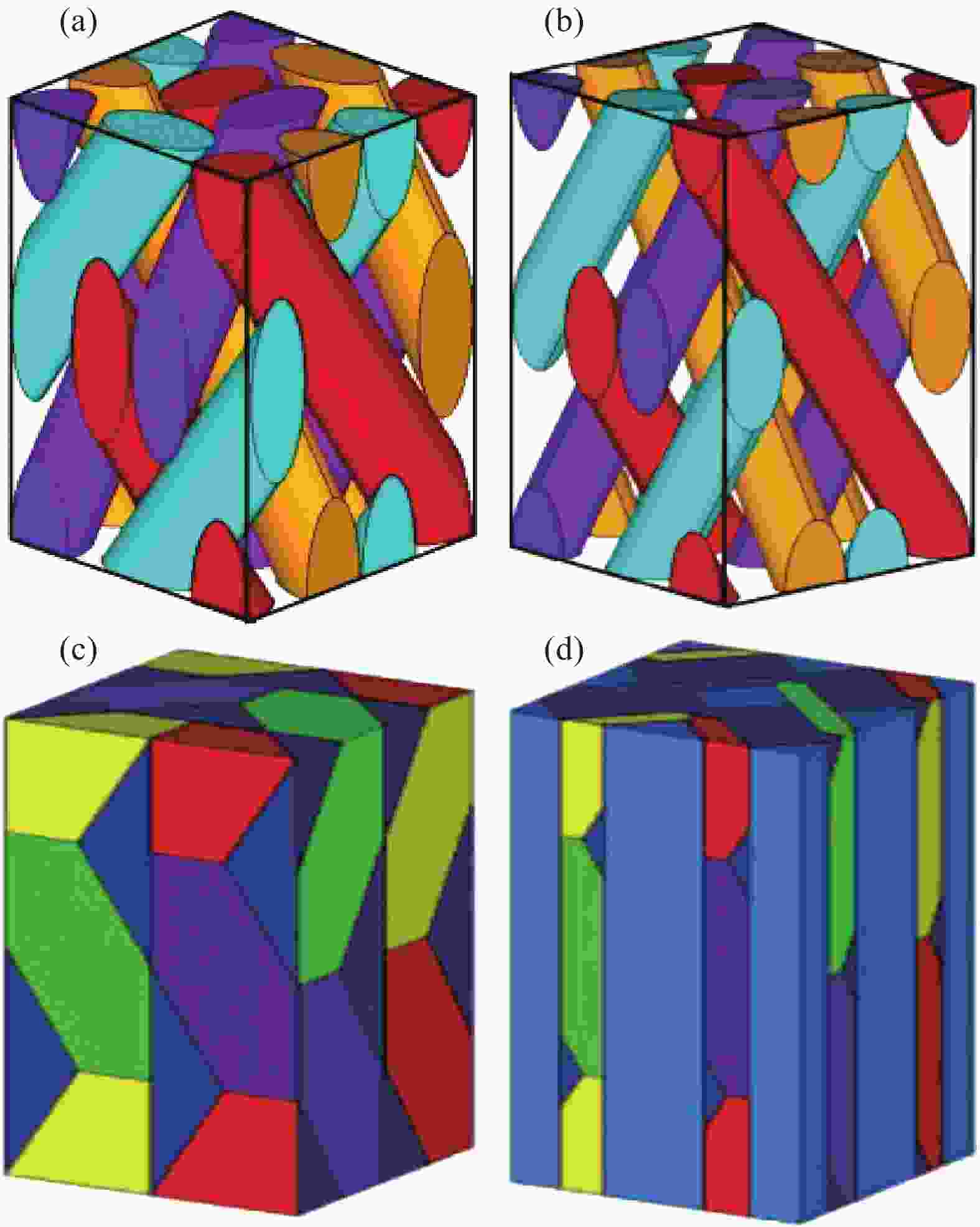

Figure 8. Longitudinal impact compressive behaviour of 3D four-directional braided composite under various temperatures: (a) Schematic sketch of the split Hopkinson pressure bar test system with a heating device; (b) Typical damage morphologies at the gas pressure of 0.25 MPa; (c) Typical damage morphologies at the gas pressure of 0.37 MPa; (d) Typical damage morphologies at the gas pressure of 0.60 MPa[76]

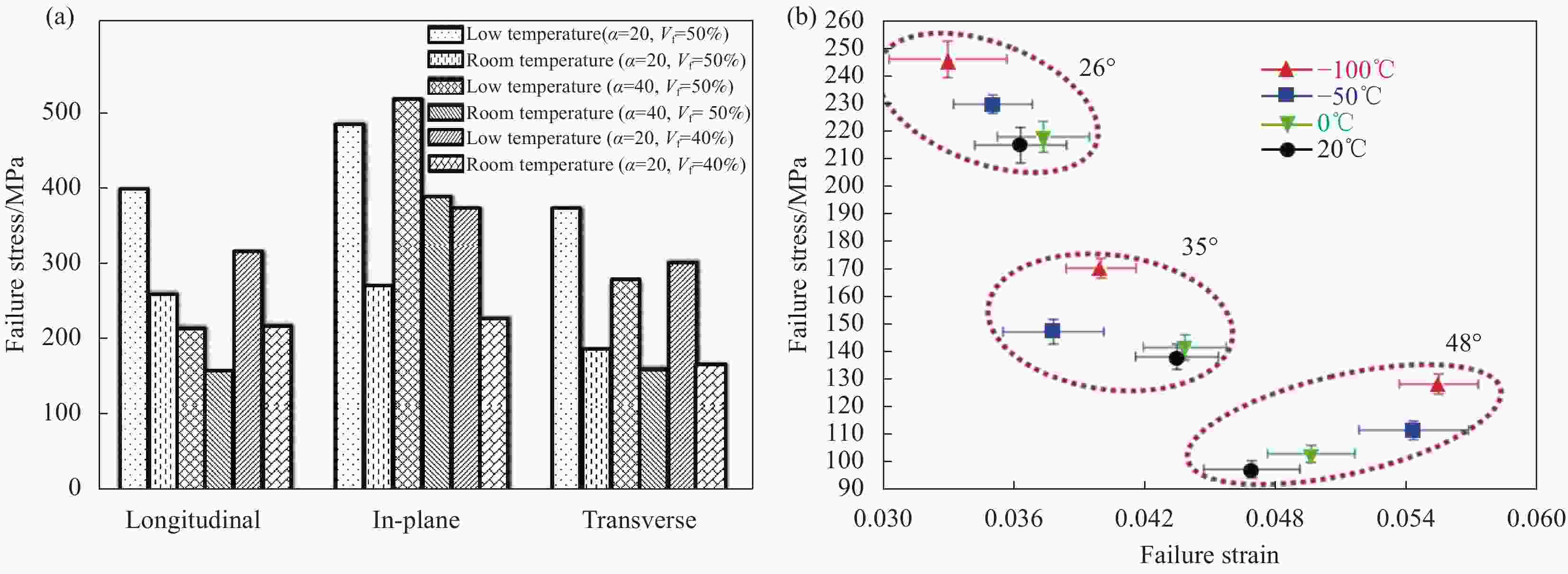

图 10 三维编织复合材料抗压强度比较((a) 玻璃/环氧三维四向编织复合材料室温和液氮温度下的抗压强度对比[90];(b) 碳/环氧三维编织复合材料纵向压缩破坏应力-破坏应变散点图[91])

Figure 10. Comparison of compressive strength of 3D braided composites ((a) Comparison of compressive strength of 3D four directional glass/epoxy composites at room temperature and liquid nitrogen temperature[90]; (b) Failure stress versus failure strain scatter diagram of 3D carbon/epoxy braided composites under longitudinal compression[91])

α—Braiding angle; Vf—Fiber volume fraction

-

[1] RAY B C, RATHORE D. A review on mechanical behavior of FRP composites at different loading speeds[J]. Critical Reviews in Solid State and Materials Sciences,2015,40(2):119-135. doi: 10.1080/10408436.2014.940443 [2] 董凯. 纺织结构复合材料热传导和热膨胀性质实验表征和多尺度有限元分析[D]. 上海: 东华大学, 2018.DONG Kai. Experimental characterization and multi-scale finite element analysis of thermal conduction and thermal expansion properties of textile structural composites[D]. Shanghai: Donghua University, 2018(in Chinese). [3] 王海雷, 高艳秋, 范雨娇. 三维编织复合材料研究及应用现状[J]. 新材料产业, 2017(3):51-54.WANG Hailei, GAO Yanqiu, FAN Yujiao. Research and application status of 3D braided composites[J]. New Material Industry,2017(3):51-54(in Chinese). [4] 李嘉禄. 用于结构件的三维编织复合材料[J]. 航天返回与遥感, 2007, 28(2):53-58.LI Jialu. Three dimensional braiding composites for structural components[J]. Spacecraft Recovery & Remote Sensing,2007,28(2):53-58(in Chinese). [5] STANKOVIC S B, POPOVIC D, POPARIC G B. Thermal properties of textile fabrics made of natural and regenerated cellulose fibers[J]. Polymer Testing,2008,27:41-48. doi: 10.1016/j.polymertesting.2007.08.003 [6] 程伟, 赵寿根, 刘振国, 等. 三维四向编织复合材料等效热特性数值分析和试验研究[J]. 航空学报, 2002, 23(2):102-105. doi: 10.3321/j.issn:1000-6893.2002.02.002CHENG Wei, ZHAO Shougen, LIU Zhenguo, et al. Numerical analysis and experimental study of equivalent thermal properties of three-dimensional four-way braided compo-sites[J]. Journal of Aeronautics,2002,23(2):102-105(in Chinese). doi: 10.3321/j.issn:1000-6893.2002.02.002 [7] SCHUSTER J, HEIDER D, SHARP K, et al. Measuring and modeling the thermal conductivities of three-dimensionally woven fabric composites[J]. Mechanics of Composite Materials,2009,45(2):165-174. doi: 10.1007/s11029-009-9072-y [8] 张琳, 李嘉禄. 三维编织复合材料热传导性能研究[J]. 山东纺织科技, 2015, 5:50-53. doi: 10.3969/j.issn.1009-3028.2015.06.015ZHANG Lin, LI Jialu. Research on thermal conductivity of 3D braided composite[J]. Shandong Textile Technology,2015,5:50-53(in Chinese). doi: 10.3969/j.issn.1009-3028.2015.06.015 [9] 姜黎黎, 徐美玲, 李振国, 等. 三维编织复合材料热物理性能实验[J]. 复合材料学报, 2017, 34(12):2734-2740.JIANG Lili, XU Meiling, LI Zhenguo, et al. Thermophysical properties experiment of three-dimensional braided composites[J]. Acta Materiae Compositae Sinica,2017,34(12):2734-2740(in Chinese). [10] 焦亚男, 李媛琪. 三维五向石英/环氧复合材料的热传导性[J]. 天津工业大学学报, 2017, 36(4):23-26.JIAO Yanan, LI Yuanqi. Thermal conductivity of three-dimensional five-way quartz/epoxy composite[J]. Journal of Tianjin Polytechnic University,2017,36(4):23-26(in Chinese). [11] NAWAB Y, JACQUEMIN F, CASARI P, et al. Study of variation of thermal expansion coefficients in carbon/epoxy laminated composite plates[J]. Composites Part B: Engineering,2013,50:144-149. doi: 10.1016/j.compositesb.2013.02.002 [12] CHILDS P, WONG A C L, GOWRIPALAN N, et al. Measurement of the coefficient of thermal expansion of ultra-high strength cementitious composites using fibre optic sensors[J]. Cement and Concrete Research,2007,37(5):789-795. doi: 10.1016/j.cemconres.2007.02.015 [13] DONG C, LI K, JIANG Y, et al. Evaluation of thermal expansion coefficient of carbon fiber reinforced composites using electronic speckle interferometry[J]. Optics Express,2018,26(1):531-543. doi: 10.1364/OE.26.000531 [14] 姚学峰, 杨桂, 姚振汉, 等. 编织结构复合材料热膨胀特性的实验研究[J]. 复合材料学报, 2000, 17(4):20-25. doi: 10.3321/j.issn:1000-3851.2000.04.005YAO Xuefeng, YANG Gui, YAO Zhenhan, et al. Experimental research on thermal expansion characteristics of braided composite[J]. Acta Materiae Compositae Sinica,2000,17(4):20-25(in Chinese). doi: 10.3321/j.issn:1000-3851.2000.04.005 [15] ZHANG D K, CAO Y B, LIU R J, et al. Effect of 3D-braided structure on thermal expansion of PIP-Cf/SiC composites[J]. Powder Metallurgy & Metal Ceramics,2014,52(11-12):722-726. [16] 成玲. 碳/环氧编织复合材料热膨胀特性分析[J]. 固体火箭技术, 2010(1):108-111.CHENG Ling. Analysis of thermal expansion characteristics of carbon/epoxy braided composite[J]. Solid Rocket Technology,2010(1):108-111(in Chinese). [17] GU Q, QUAN Z, YU J, et al. Structural modeling and mechanical characterizing of three-dimensional four-step braided composites: A review[J]. Composite Structures,2018,207:119-128. [18] 庞宝君, 曾涛, 杜善义, 等. 含微裂纹三维多向编织复合材料热膨胀系数的细观力学分析[J]. 哈尔滨工业大学学报, 2001, 33(2):155-157.PANG Baojun, ZENG Tao, DU Shanyi, et al. Micromechanical analysis of thermal expansion coefficient of three-dimensional multidirectional braided composites with microcracks[J]. Journal of Harbin Institute of Technology,2001,33(2):155-157(in Chinese). [19] 梁军, 杜善义, 韩杰才, 等. 含缺陷三维编织复合材料热膨胀系数计算[J]. 宇航学报, 1998(1):90-93. doi: 10.3321/j.issn:1000-1328.1998.01.015LIANG Jun, DU Shanyi, HAN Jiecai, et al. Calculation of thermal expansion coefficient of three-dimensional braided composites with defects[J]. Journal of Astronautics,1998(1):90-93(in Chinese). doi: 10.3321/j.issn:1000-1328.1998.01.015 [20] 梁军, 杜善义. 含圆币型微裂纹三维编织复合材料的热膨胀系数预报[J]. 复合材料学报, 1998, 15(3):103-107.LIANG Jun, DU Shanyi. Prediction of thermal expansion coefficient of three-dimensional braided composites containing coin-shaped microcracks[J]. Acta Materiae Compositae Sinica,1998,15(3):103-107(in Chinese). [21] POTTIGAR S A, SANTHOSH B, NAIR R G, et al. Three-dimensional braided composites with zero, negative and isotropic thermal expansion behavior[J]. Journal of Compo-site Materials,2020,54(13):1-21. [22] GUO F L, YAN Y, HONG Y, et al. Prediction and optimization design for thermal expansion coefficients of three-dimensional n-directional-braided composites[J]. Polymer Composites,2019,40(6):1-15. [23] FANG W Z, CHEN L, GOU J J, et al. Predictions of effective thermal conductivities for three-dimensional four-directional braided composites using the lattice Boltzmann method[J]. International Journal of Heat & Mass Transfer,2016,92:120-130. [24] JIANG L L, XU G D, CHENG S, et al. Predicting the thermal conductivity and temperature distribution in 3D braided composites[J]. Composite Structures,2014,108:578-583. doi: 10.1016/j.compstruct.2013.09.030 [25] GOU J J, ZHANG H, DAI Y J, et al. Numerical prediction of effective thermal conductivities of 3D four-directional braided composites[J]. Composite Structures,2015,125:499-508. doi: 10.1016/j.compstruct.2015.02.009 [26] 李典森, 卢子兴, 刘振国, 等. 三维五向编织复合材料导热性能的有限元分析[J]. 航空动力学报, 2008(8):1455-1460.LI Diansen, LU Zixing, LIU Zhenguo, et al. Finite element analysis of thermal conductivity of three-dimensional five-directional braided composites[J]. Aerodynamics,2008(8):1455-1460(in Chinese). [27] LIU Z, ZHANG H, Lu Z, et al. Investigation on the thermal conductivity of 3-dimensional and 4-directional braided composites[J]. Chinese Journal of Aeronautics,2007,20(4):327-331. doi: 10.1016/S1000-9361(07)60051-X [28] 夏彪, 卢子兴. 三维编织复合材料热物理性能的有限元分析[J]. 航空学报, 2011, 32(6):1040-1049.XIA Biao, LU Zixing. Finite element analysis of thermophysical properties of three-dimensional braided composites[J]. Journal of Aeronautics,2011,32(6):1040-1049(in Chinese). [29] 卢子兴, 王成禹, 夏彪. 三维全五向编织复合材料弹性性能及热物理性能的有限元分析[J]. 复合材料学报, 2013, 30(3):160-167.LU Zixing, WANG Chengyu, XIA Biao. Finite element analysis of elastic properties and thermophysical properties of three-dimensional five-way braided composites[J]. Acta Materiae Compositae Sinica,2013,30(3):160-167(in Chinese). [30] MOHAJERJASBI S. Predictions for coefficients of thermal expansion of three-dimensional braided composites[J]. AIAA Journal,1997,35(1):141-144. doi: 10.2514/2.75 [31] DONG K, ZHANG J, JIN L, et al. Multi-scale finite element analyses on the thermal conductive behaviors of 3D braided composites[J]. Composite Structures,2016,143:9-22. doi: 10.1016/j.compstruct.2016.02.029 [32] GOU J J, FANG W Z, DAI Y J, et al. Multi-size unit cells to predict effective thermal conductivities of 3D four-directional braided composites[J]. Composite Structures,2017,163:152-167. doi: 10.1016/j.compstruct.2016.12.034 [33] ZHAI J J, CHENG S, ZENG T, et al. Thermo-mechanical behavior analysis of 3D braided composites by multiscale finite element method[J]. Composite Structures,2017,176:664-672. doi: 10.1016/j.compstruct.2017.05.064 [34] ZHAI J J, CHENG S, ZENG T, et al. Extended multiscale FE approach for steady-state heat conduction analysis of 3D braided composites[J]. Composites Science & Technology,2017,151:317-324. [35] 袁欣, 孙慧玉. 粘弹性树脂基三维编织复合材料的热膨胀性能研究[J]. 固体力学学报, 2012, 4:379-385. doi: 10.3969/j.issn.0254-7805.2012.04.005YUAN Xin, SUN Huiyu. Study on thermal expansion performance of viscoelastic resin matrix three-dimensional braided composite[J]. Journal of Solid Mechanics,2012,4:379-385(in Chinese). doi: 10.3969/j.issn.0254-7805.2012.04.005 [36] ZHAI J J, KONG X X, WANG L C. Thermo-viscoelastic response of 3D braided composites based on a novel FsMsFE method[J]. Materials,2021,14(2):1-18. [37] LU Z, WANG C, XIA B, et al. Effect of interfacial properties on the thermophysical properties of 3D braided compo-sites: 3D multiscale finite element study[J]. Polymer Composites,2013,35:1690-1700. [38] WANG H, CAO M, SIDDIQUE A, et al. Numerical analysis of thermal expansion behaviors and interfacial thermal stress of 3D braided composite materials[J]. Computational Materials Science,2017,138:77-91. doi: 10.1016/j.commatsci.2017.06.023 [39] HU C X, LI H J, ZHANG S Y, et al. Numerical simulation on thermal expansion coefficient of 3D braided C/C compo-sites[J]. Rare Metals,2014,33(1):101-108. [40] 王波, 矫桂琼, 潘文革, 等. 三维编织C/SiC复合材料的拉压实验研究[J]. 复合材料学报, 2004, 21(3):110-114. doi: 10.3321/j.issn:1000-3851.2004.03.021WANG Bo, JIAO Guiqiong, PAN Wenge, et al. Research on tension and compression of 3D braided C/SiC composite[J]. Acta Materiae Compositae Sinica,2004,21(3):110-114(in Chinese). doi: 10.3321/j.issn:1000-3851.2004.03.021 [41] 卢子兴, 冯志海, 寇长河, 等. 编织复合材料拉伸力学性能的研究[J]. 复合材料学报, 1999, 16(3):129-134.LU Zixing, FENG Zhihai, KOU Changhe. Study on the tensile mechanical properties of braided composites[J]. Acta Materiae Compositae Sinica,1999,16(3):129-134(in Chinese). [42] 卢子兴, 胡奇. 三维编织复合材料压缩力学性能的实验研究[J]. 复合材料学报, 2003, 20(6):67-72.LU Zixing, HU Qi. Experimental research on compressive mechanical properties of three-dimensional braided composites[J]. Acta Materiae Compositae Sinica,2003,20(6):67-72(in Chinese). [43] 李仲平, 卢子兴, 冯志海, 等. 三维五向碳/酚醛编织复合材料的拉伸性能及破坏机理[J]. 航空学报, 2007, 28(4):869-873.LI Zhongping, LU Zixing, FENG Zhihai, et al. Tensile properties and failure mechanism of three-dimensional five-directional carbon/phenolic woven composites[J]. Journal of Aeronautics,2007,28(4):869-873(in Chinese). [44] LI D S, LU Z X, FANG D N. Longitudinal compressive behavior and failure mechanism of three-dimensional five-directional carbon/phenolic braided composites at high strain rates[J]. Materials Science & Engineering A,2009,526(1-2):134-139. [45] ZHENG Y Y, SUN Y, Ll J L, et al. Tensile response of carbon-aramid hybrid 3D braided composites[J]. Materials & Design,2016,116:246-252. [46] CAO H J, QIAN K, XU W X, et al. Compressive properties of three-dimensional full five-directional braided compo-sites[J]. Journal of Textile Research,2013,34(8):68-71. [47] 焦亚男, 李嘉禄, 魏丽梅, 等. 损伤形式对三维编织复合材料拉压性能的影响[J]. 复合材料学报, 2006, 23(6):52-56. doi: 10.3321/j.issn:1000-3851.2006.06.008JIAO Yanan, LI Jialu, WEI Limei, et al. Influence of damage type on tensile and compression properties of three-dimensional braided composites[J]. Acta Materiae Compositae Sinica,2006,23(6):52-56(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.06.008 [48] 李嘉禄, 贺桂芳, 陈光伟. 温度对三维五向编织/环氧树脂复合材料拉伸性能的影响[J]. 复合材料学报, 2010, 27(6):58-63.LI Jialu, HE Guifang, CHEN Guangwei. Effect of temperature on tensile properties of three-dimensional five-directional braided/epoxy composite[J]. Acta Materiae Compositae Sinica,2010,27(6):58-63(in Chinese). [49] ZUO H M, LI D S, JIANG L. High temperature mechanical response and failure analysis of 3D five-directional braided composites with different braiding angles[J]. Materials,2019,12(21):3506. doi: 10.3390/ma12213506 [50] 李典森, 刘子仙, 卢子兴, 等. 三维五向炭纤维/酚醛编织复合材料的压缩性能及破坏机制[J]. 复合材料学报, 2008(1):133-139. doi: 10.3321/j.issn:1000-3851.2008.01.023LI Diansen, LIU Zixian, LU Zixing, et al. Compression properties and failure mechanism of three-dimensional five-directional carbon fiber/phenolic woven composite[J]. Acta Materiae Compositae Sinica,2008(1):133-139(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.023 [51] DING G, WANG H J, WAN Z K, et al. Effects of temperature on compression properties of three-dimensional and five-directional braided composites and laminated compo-sites[J]. Optoelectronics and Advanced Materials-Rapid Communications,2015,9(5):762-771. [52] LI D, FANG D, ZHANG G, et al. Effect of temperature on bending properties and failure mechanism of three-dimensional braided composite[J]. Materials & Design,2012,41(16):167-170. [53] 韩红梅, 李贺军, 李克智, 等. 高温对碳/碳复合材料性能影响的研究[J]. 西北工业大学学报, 2003, 21(3):352-355.HAN Hongmei, LI Hejun, LI Kezhi, et al. Study on the effect of high temperature on the properties of carbon/carbon composites[J]. Journal of Northwestern Polytechnical University,2003,21(3):352-355(in Chinese). [54] 韩红梅, 张秀莲, 李贺军, 等. 炭/炭复合材料高温力学行为研究[J]. 新型炭材料, 2003, 18(1):20-24.HAN Hongmei, ZHANG Xiulian, LI Hejun, et al. Study on high temperature mechanical behavior of carbon/carbon composite[J]. New Carbon Materials,2003,18(1):20-24(in Chinese). [55] 姜黎黎, 吴日娜, 徐美玲, 等. 三维四向编织碳纤维/环氧树脂复合材料在热环境中的拉压力学性能实验[J]. 复合材料学报, 2020, 37(2):309-317.JIANG Lili, WU Rina, XU Meiling, et al. Tensile and compressive properties of three-dimensional four-way braided carbon fiber/epoxy resin composites in thermal environment[J]. Acta Materiae Compositae Sinica,2020,37(2):309-317(in Chinese). [56] GUO Y F, YANG J, HE Y H, et al. Tensile and bending strengths of tr-30s carbon fiber three dimensional braided composites at different temperature[J]. Advanced Materials Research,2010,97-101:1616-1619. doi: 10.4028/www.scientific.net/AMR.97-101.1616 [57] LIU Q, YANG J, HE Y H, et al. Effects of high temperature on tensile and bending strengths of T300 carbon fiber three dimensional braided composites[J]. Advanced Materials Research,2013:602-604. [58] ZHANG M, ZUO C P, SUN B Z, et al. Thermal ageing degradation mechanisms on compressive behavior of 3-D braided composites in experimental and numerical study[J]. Composite Structures,2016,140:180-191. doi: 10.1016/j.compstruct.2016.01.029 [59] ZHANG M, SUN B, GU B. Accelerated thermal ageing of epoxy resin and 3-D carbon fiber/epoxy braided compo-sites[J]. Composites Part A: Applied Science and Manufacturing,2016,85:163-171. doi: 10.1016/j.compositesa.2016.03.028 [60] FAN W, LI J L, ZHENG Y Y, et al. The effect of reinforced structure on thermo-oxidative stability of polymer-matrix composites[J]. Journal of Industrial Textiles,2015,46(1):237-255. [61] LI P, JIA N, PEI X Y, et al. Effects of temperature on bending properties of three-dimensional and five-directional braided composite[J]. Molecules,2019,24(21):3977. doi: 10.3390/molecules24213977 [62] JIANG L L, XU G D, CHENG S, et al. Finite element analysis of thermo-mechanical properties of 3d braided compo-sites[J]. Applied Composite Materials,2014,21(2):325-340. doi: 10.1007/s10443-013-9339-2 [63] WANG H L, SUN B Z, GU B H. Numerical modeling on compressive behaviors of 3-D braided composites under high temperatures at microstructure level[J]. Composite Structures,2017,160:925-938. doi: 10.1016/j.compstruct.2016.10.130 [64] PAN Z X, GU B H, SUN B Z, et al. Numerical analyses of thermo-mechanical behaviors of 3-D rectangular braided composite under different temperatures[J]. Journal of the Textile Institute,2015,106(2):173-186. doi: 10.1080/00405000.2014.906941 [65] HE C W, GE J G, ZHANG B B, et al. A hierarchical multiscale model for the elastic-plastic damage behavior of 3D braided composites at high temperature[J]. Compo-sites Science and Technology,2020,196:108230. doi: 10.1016/j.compscitech.2020.108230 [66] CAI Y M, SUN H Y. Thermo-viscoelastic analysis of three-dimensionally braided composites[J]. Composite Structures,2013,98:47-52. doi: 10.1016/j.compstruct.2012.11.012 [67] LI W, FANG G D, LI W J, et al. Role of mesoscopic features on thermochemical ablative behavior of 3D C/C braided composites[J]. International Journal of Heat and Mass Transfer,2019,144:118602. doi: 10.1016/j.ijheatmasstransfer.2019.118602 [68] LI Z M. Thermal postbuckling behavior of 3D braided rectangular plates[J]. Journal of Thermal Stresses,2011,34(7):626-649. doi: 10.1080/01495739.2011.581050 [69] CHU G P, LI Z M. Postbuckling behavior of 3D braided rectangular plates subjected to uniaxial compression and transverse loads in thermal environments[J]. Science China Technological Sciences,2014,57:1439-1453. doi: 10.1007/s11431-014-5568-3 [70] ZHAO Y X, LIU T, LI Z M. Nonlinear bending analysis of a 3D braided composite cylindrical panel subjected to transverse loads in thermal environments[J]. Chinese Journal of Aeronautics,2018,31(8):85-96. [71] LI Z M. Thermal postbuckling behavior of 3D braided beams with initial geometric imperfection under different type temperature distributions[J]. Composite Structures,2014,108:924-936. doi: 10.1016/j.compstruct.2013.10.028 [72] LI Z M, YANG D Q. Thermal postbuckling analysis of 3D braided composite cylindrical shells[J]. Journal of Mechanics,2010,26(2):113-122. doi: 10.1017/S1727719100002975 [73] LI Z M, SHEN H S. Postbuckling analysis of 3D braided composite cylindrical shells under torsion in thermal environments[J]. Composite Structures,2009,87(3):242-256. doi: 10.1016/j.compstruct.2008.01.013 [74] ZHANG M, SUN B Z, GU B H. Meso-structure ageing mechanism of 3-D braided composite's compressive behaviors under accelerated thermo-oxidative ageing environment[J]. Mechanics of Materials,2017,115:47-63. doi: 10.1016/j.mechmat.2017.09.002 [75] ZHANG M, SUN B Z, GU B H. Experimental and numerical analyses of matrix shrinkage and compressive behavior of 3-D braided composite under thermo-oxidative ageing conditions[J]. Composite Structures,2018,204:320-332. doi: 10.1016/j.compstruct.2018.07.099 [76] PAN Z X, GU B H, SUN B Z. Longitudinal compressive behaviour of 3D braided composite under various temperatures and strain rates[J]. Applied Physics A,2015,118(4):1315-1337. doi: 10.1007/s00339-014-8839-8 [77] PAN Z X, GU B H, SUN B Z. Thermo-mechanical behaviors of 3-D braided composite material subject to high strain rate compressions under different temperatures[J]. Mechanics of Advanced Materials & Structures,2016,23(4):385-401. [78] ZHANG W, PAN Z X, GIDEON R K, et al. Effects of temperature and strain rate on impact compression behaviors of three-dimensional carbon fiber/epoxy braided compo-sites[J]. Journal of Composite Materials,2014,49(7):771-782. [79] XU K, CHEN W, LIU L, et al. Longitudinal compressive property of three-dimensional four-step braided compo-sites after cyclic hygrothermal aging under high strain rates[J]. Applied Sciences,2020,10(6):1-18. [80] HU M Q, LIU S K, ZHANG J J, et al. Multiple transverse impact damage behaviors of 3-D-braided composite beams under room and high temperatures[J]. International Journal of Damage Mechanics,2019,29(5):715-747. [81] ZHANG W, GU B H, SUN B Z. Transverse impact behaviors of 3D braided composites T-beam at elevated temperatures[J]. Journal of Composite Materials,2016,50(28):3961-3971. doi: 10.1177/0021998316630394 [82] ZHANG X H, GAO H S, WEN Z X, et al. Effect of film cooling holes on the mechanical properties of 3D braided SiCf/SiC composites at 1350℃ in air[J]. Ceramics International,2020,46(6):7982-7990. doi: 10.1016/j.ceramint.2019.12.020 [83] ZHANG X H, GAO H S, WEN Z X, et al. Tension-tension fatigue behaviour of 3D braided SiCf/SiC composite with film cooling holes at 1350℃ in air[J]. Ceramics International,2020,46(6):7703-7710. doi: 10.1016/j.ceramint.2019.11.273 [84] ZHANG W, GU B H, SUN B Z. Thermal-mechanical coupling modeling of 3D braided composite under impact compression loading and high temperature field[J]. Compo-sites Science & Technology,2017,140:73-88. [85] SHI B H, ZHANG M, LIU S K, et al. Multi-scale ageing mechanisms of 3D four directional and five directional braided composites’ impact fracture behaviors under thermo-oxidative environment[J]. International Journal of Mechanical Sciences,2019,155:50-65. doi: 10.1016/j.ijmecsci.2019.02.040 [86] LIU S K, ZHANG J J, SHI B H, et al. Damage and failure mechanism of 3D carbon fiber/epoxy braided composites after thermo-oxidative ageing under transverse impact compression[J]. Composites,2019,161:677-690. doi: 10.1016/j.compositesb.2018.11.140 [87] LIU S K, ZHANG J J, CHEN Z T, et al. Modeling the coupling effects of braiding structure and thermo-oxidative aging on the high-speed impact responses of 3D braided composites[J]. Thin-Walled Structures,2020,150:106705. doi: 10.1016/j.tws.2020.106705 [88] 胡美琪, 孙宝忠, 顾伯洪. 三维编织复合材料冲击损伤分布的温度和结构效应[J]. 中国科学: 技术科学, 2021, 51(1):108-118.HU Meiqi, SUN Baozhong, GU Bohong. Temperature and structure effects on impact damage distribution of three-dimensional braided composites[J]. Science in China: Technological Science,2021,51(1):108-118(in Chinese). [89] CAI Y M, SUN H Y. Dynamic response of thermo-viscoelasticity of three-dimensionally braided composites[J]. Journal of Composite Materials,2013,48(13):1575-1583. [90] LI D S, ZHAO C Q, GE T Q, et al. Experimental investigation on the compression properties and failure mechanism of 3D braided composites at room and liquid nitrogen temperature[J]. Composites Part B: Engineering,2014,56:647-659. doi: 10.1016/j.compositesb.2013.08.068 [91] WANG H L, SUN B Z, GU B H. Coupling effect of temperature and braided angle on compressive behaviors of 3D braided carbon-epoxy composite at low temperature[J]. Journal of Composite Materials,2016,51(18):2531-2547. [92] HAN W F, LI D S, JIANG L. Mechanical properties and failure mechanisms of 3D six-directional braided composites at elevated and liquid nitrogen temperatures[J]. Materials Letters X,2019,6:100035. [93] 刘军, 刘奎, 宁博, 等. 三维编织复合材料T型梁的低温场弯曲性能[J]. 纺织学报, 2019, 40(12):57-62.LIU Jun, LIU Kui, NING Bo, et al. Low temperature field bending performance of three-dimensional braided composite T-beam[J]. Journal of Textile Research,2019,40(12):57-62(in Chinese). [94] WU X Y, ZHANG Q, GU B H, et al. Influence of temperature and strain rate on the longitudinal compressive crashworthiness of 3D braided composite tubes and finite element analysis[J]. International Journal of Damage Mechanics,2017,26(7):1003-1027. doi: 10.1177/1056789516648369 [95] 蒋欢, 潘忠祥, 张威, 等. 低温场下三维编织复合材料的冲击压缩性能[J]. 东华大学学报(自然科学版), 2015, 41(6):756-759.JIANG Huan, PAN Zhongxiang, ZHANG Wei, et al. Impact compression properties of three-dimensional braided composites in low temperature field[J]. Journal of Donghua University (Natural Science Edition),2015,41(6):756-759(in Chinese). [96] PAN Z X, SUN B Z, GU B H. Experimental investigation of high-strain rate properties of 3-D braided composite material in cryogenic field[J]. Composites Part B: Engineering,2015,77:379-390. doi: 10.1016/j.compositesb.2015.03.002 [97] PAN Z X, SUN B Z, GU B H. Thermo-mechanical numerical modeling on impact compressive damage of 3-D braided composite materials under room and low temperatures[J]. Aerospace Science and Technology,2016,54:23-40. doi: 10.1016/j.ast.2016.03.027 -

下载:

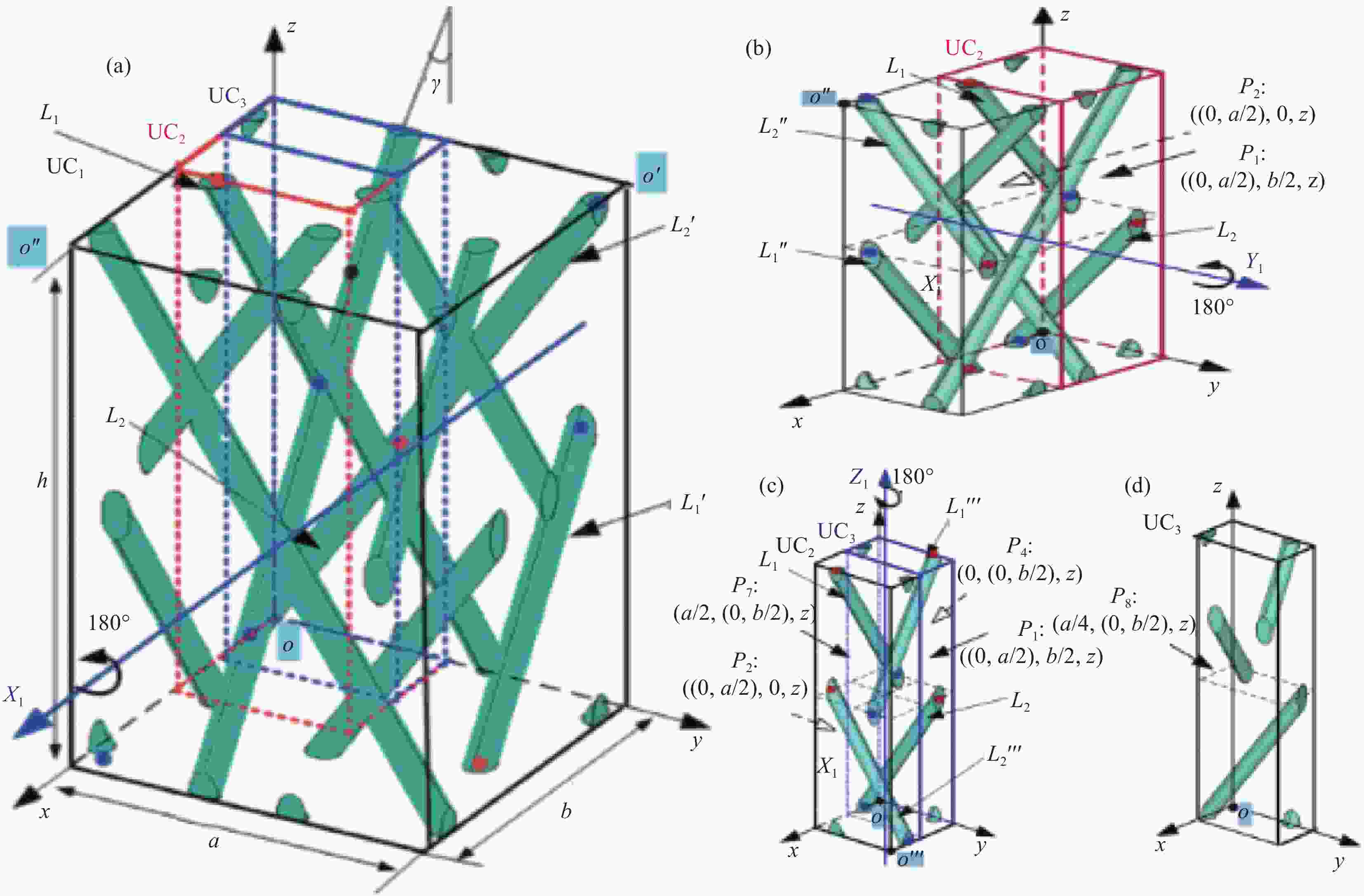

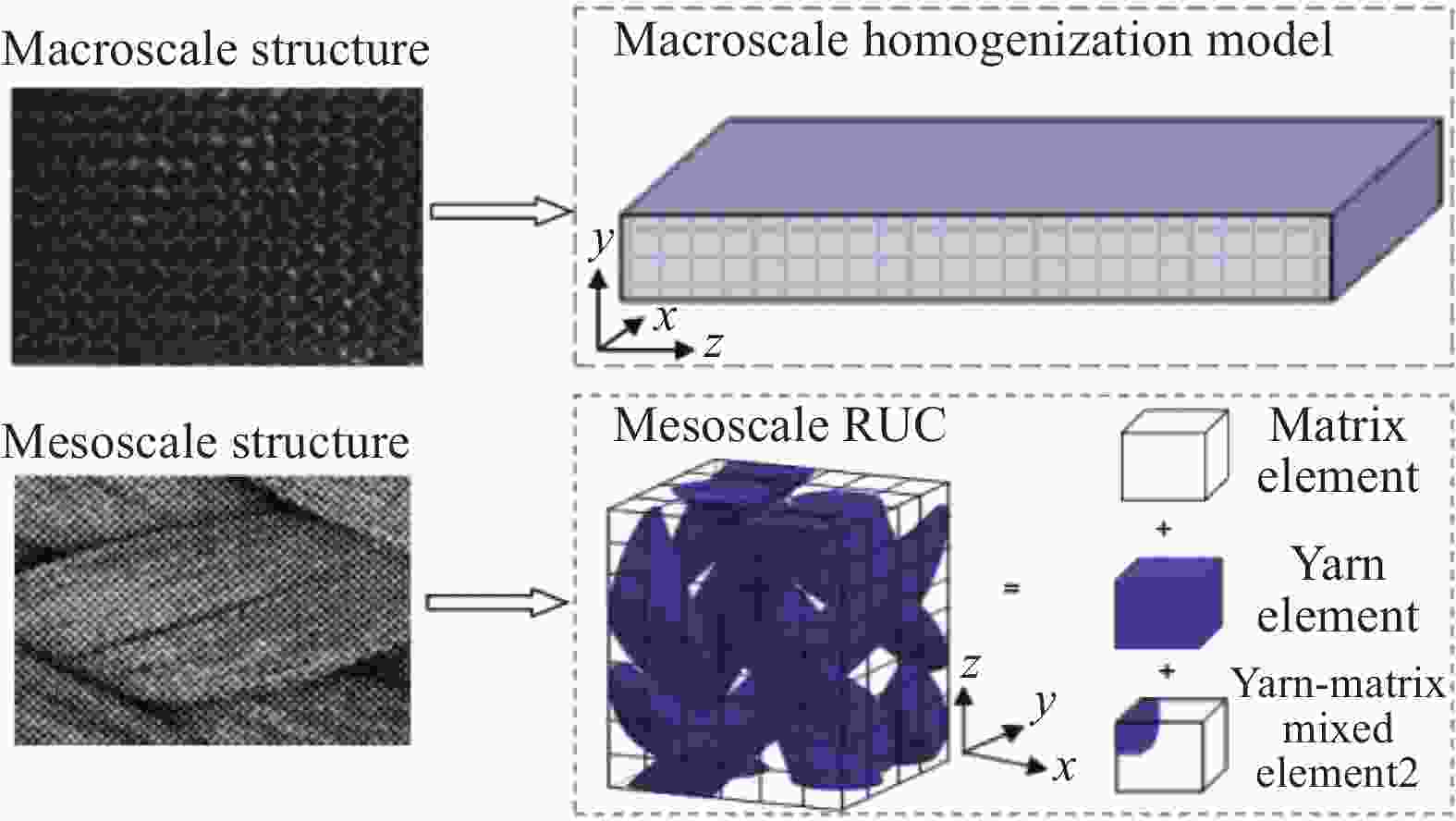

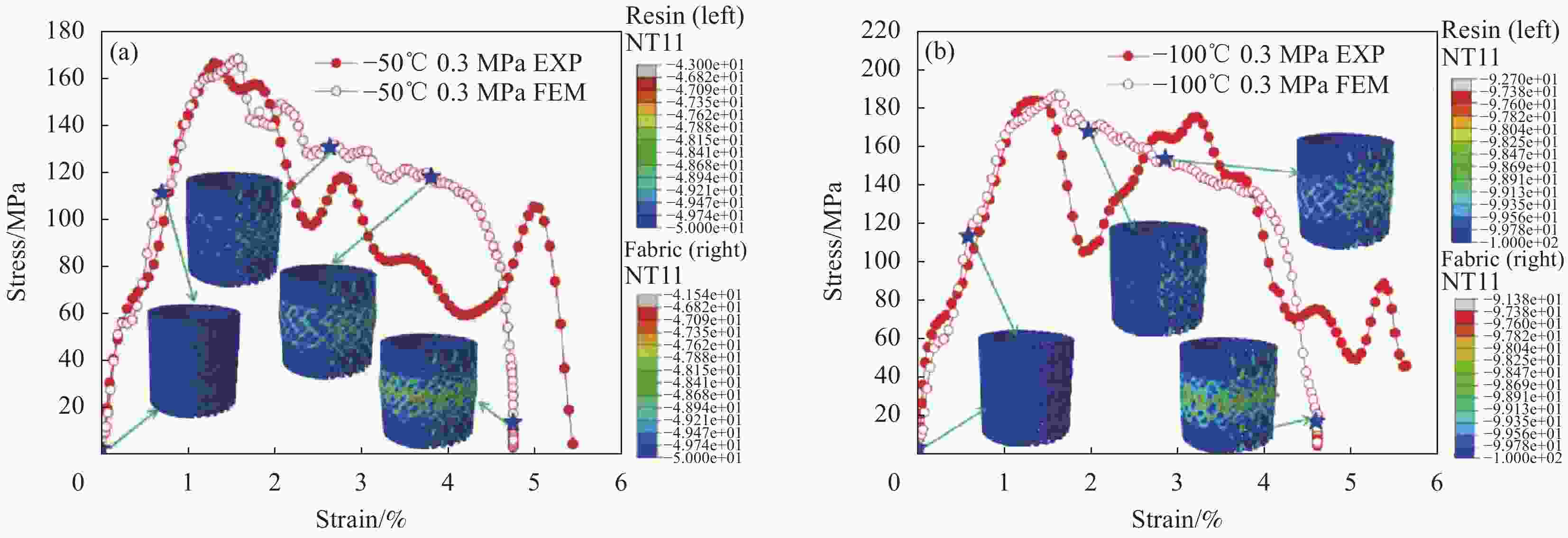

下载: