Mica nanosheets splitting of aramid fiber and enhanced mechanical and insulation performances of the composites nanofilms

-

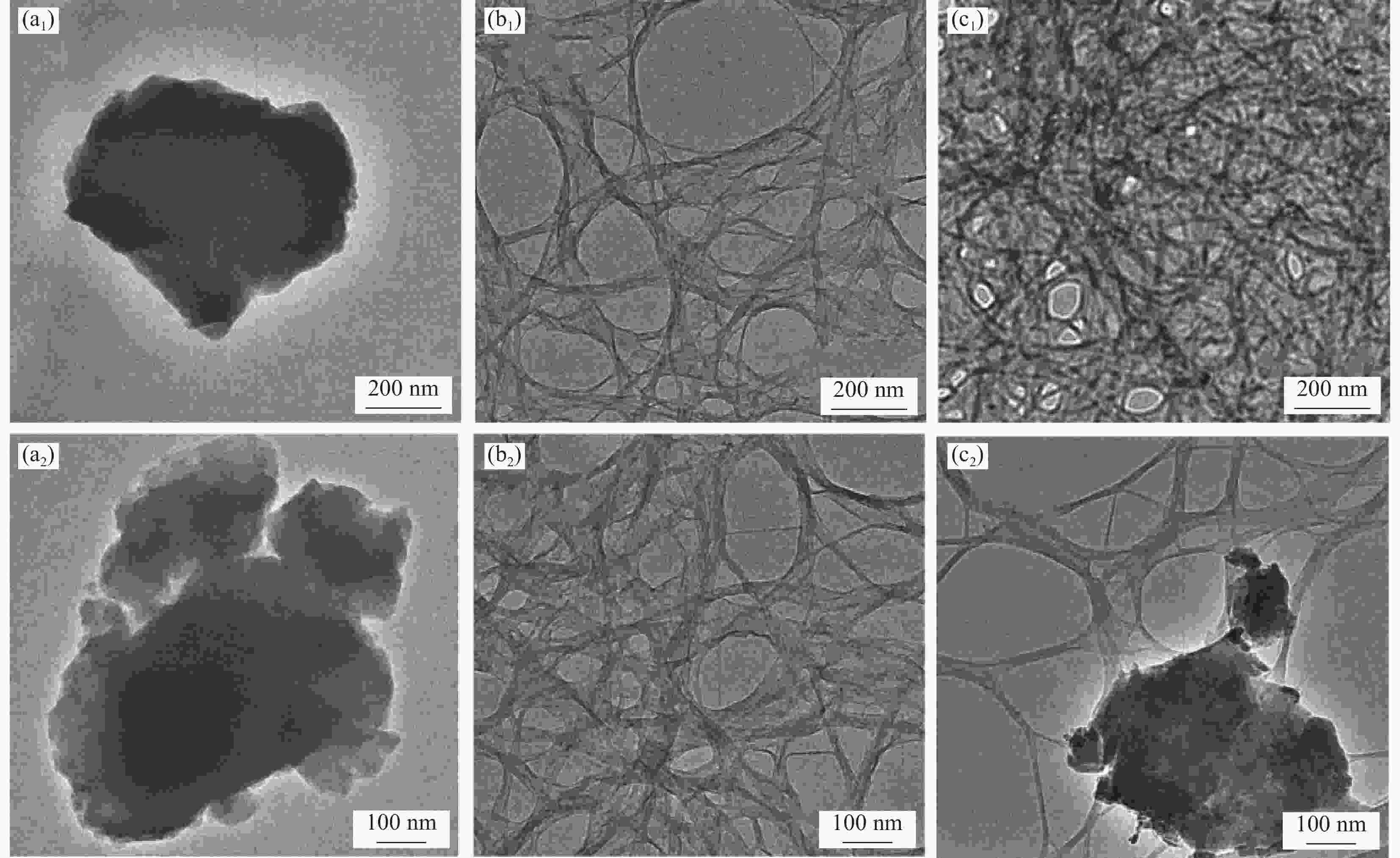

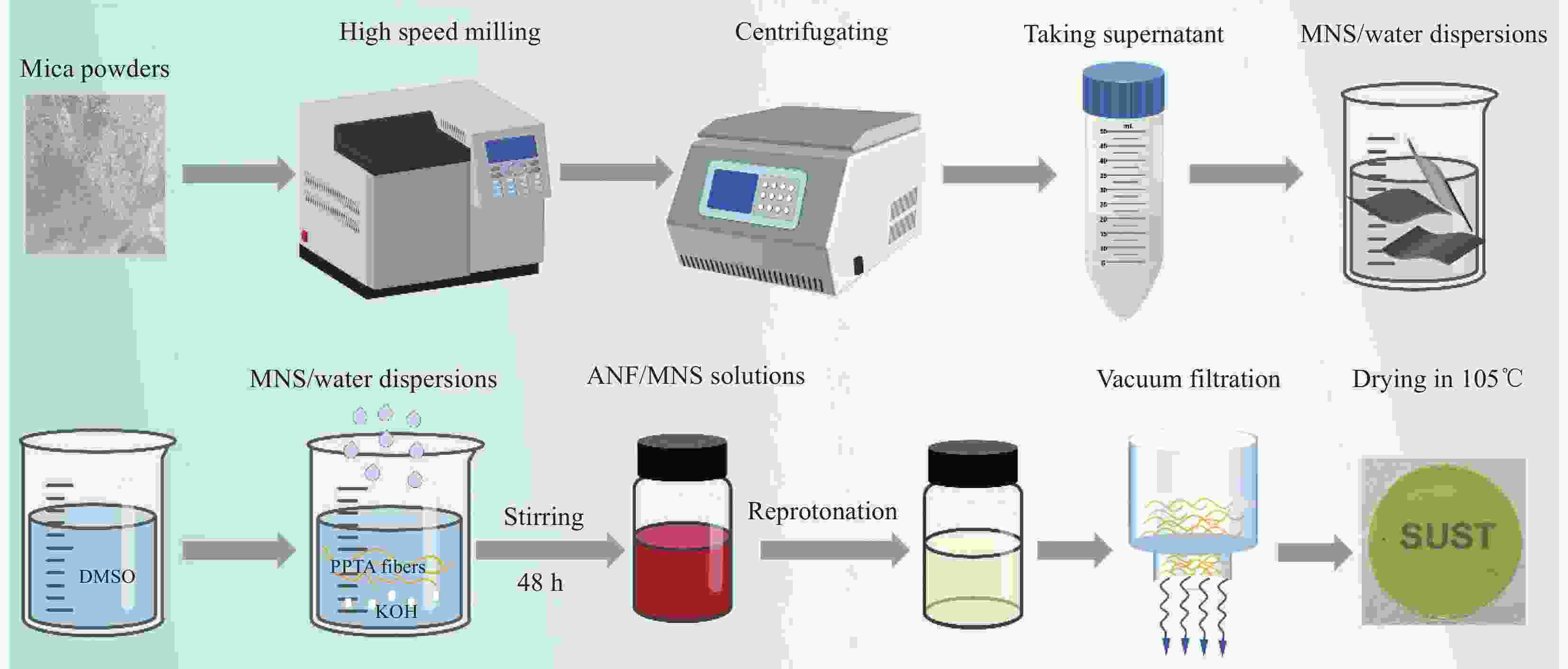

摘要: 芳纶纳米纤维 (ANF)兼具芳纶纤维轻质、高强高模、耐高温等的特点以及高性能纤维纳米尺度效应的双重优势,其薄膜强韧化受到研究者的广泛关注。本研究采用高速机械球磨法制备云母纳米片 (MNSs) 作为增强体,将其引入芳纶纤维的裂解过程中,在二甲基亚砜/氢氧化钾 (DMSO/KOH) 体系中制备芳纶纳米纤维,通过真空辅助过滤法制备ANF/MNS复合薄膜,重点探究了MNS含量对ANF薄膜力学性能的影响。结果表明:当MNS含量为0.041 wt.% 时所制备的薄膜力学性能和绝缘性能均最佳,拉伸强度可达249.3 MPa、韧性36.7 MJ·m−3、介电击穿强度46.2 kV·mm−1,与原始ANF薄膜相比,分别提升了45.1%、197.1%和60.0%。纳米尺度的MNS可以与ANF形成强的界面相互作用,MNS的固有强度对纳米薄膜力学性能的提升也有重要贡献。Abstract: The mica nanosheets (MNSs) were prepared by high-speed mechanical ball milling as the reinforcement, and introduced into the splitting process of aramid fibers. The aramid nanofibers (ANFs) were prepared in a dimethyl sulfoxide/potassium hydroxide (DMSO/KOH) system. ANF/MNS composite films were prepared by vacuum-assisted filtration, and the effect of MNS content on the mechanical properties of ANF films was investigated. It gains the best mechanical properties and insulation properties when the MNS content is 0.041 wt.%. The tensile strength is 249.3MPa, the toughness is 36.7 MJ·m−3, and the dielectric breakdown strength is 46.2 kV·mm−1. They increased by 45.1%, 197.1%, and 60.0% compared with the pure ANF films, respectively. Nanoscale MNS can form strong interfacial interaction with ANF, and the inherent strength of MNS also contributes to the improvement of the mechanical properties of nanofilms.

-

Key words:

- Aramid nanofibers /

- Mica nanosheets /

- composite film /

- Mechanical properties /

- Insulating property.

-

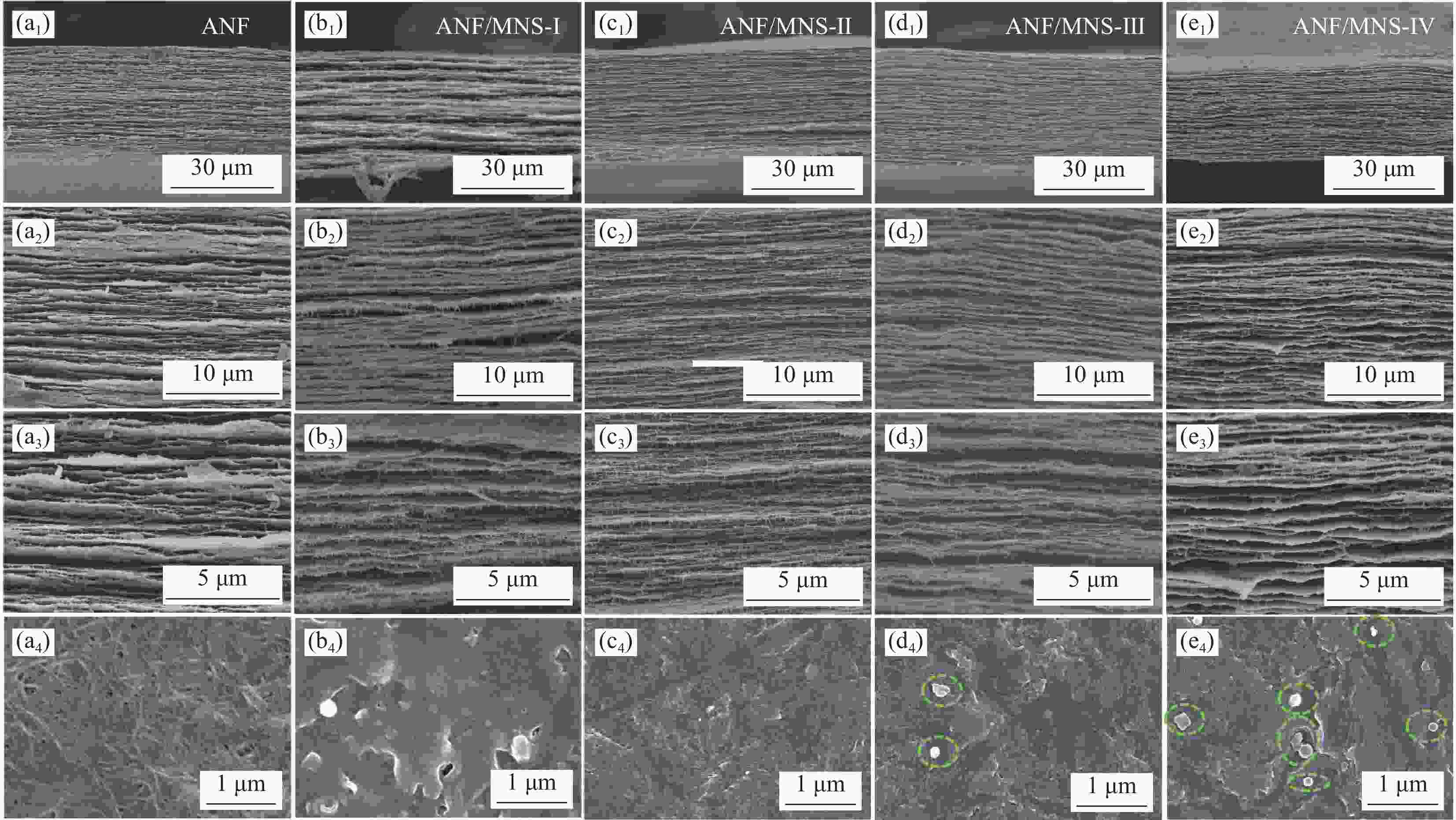

图 5 纯ANF薄膜以及不同MNS添加量的MNS/ANF复合薄膜断裂截面和薄膜表面的SEM图, (a1-a4) ANF, (b1-b4) ANF/MNS-I, (c1-c4) ANF/MNS-II, (d1-d4) ANF/MNS-III和(e1-e4) ANF/MNS-IV

Figure 5. Cross-sectional and surface SEM images of pure ANF and ANF/MNS composite films with different MNS additions. (a1-a4) ANF, (b1-b4) ANF/MNS-I, (c1-c4) ANF/MNS-II, (d1-d4) ANF/MNS-III, and (e1-e4) ANF/MNS-IV

图 6 纯ANF薄膜以及不同MNS添加量的MNS/ANF复合薄膜的绝缘性能。(a)介电常数, (b)介电损耗, (c) 由威布尔分布推导出的介电击穿失效概率, (d)介电击穿强度, 和 (e) 绝缘电阻

Figure 6. Insulation properties of pure ANF films and MNS/ANF composite films with different MNS additions. (a) The dielectric constant, (b) dielectric loss, (c) the failure probability of dielectric breakdown deduced from the Weibull distribution, (d) the dielectric breakdown strength, and (e) insulation resistance

表 1 100 mL芳纶纳米纤维 (ANF)溶液中云母纳米片 (MNSs)分散液和去离子水具体添加量

Table 1. Dosage of mica nanosheets (MNSs) dispersion and deionized water in 100 mL aramid nanofibers (ANFs) solution

Sample MNS dispersions/μL DI water/μL MNS/wt.%) ANFs 0 1000 0 ANFs/MNS-I 200 800 0.020 ANFs/MNS-II 400 600 0.041 ANFs/MNS-III 600 400 0.061 ANFs/MNS-IV 800 200 0.082 -

[1] 董志荣, 陈玥溪, 刘余田, 等. 对位芳纶纳米纤维用量对对位芳纶纸结构及性能的影响[J]. 中国造纸学报, 2022, 41(11): 11-17.DONG Z R, CHEN Y X, LIU Y T, et al. Effect of the Amount of Para-aramid Nanofiber on the Structure and Properties of Para-aramid Paper[J]. Transactions of China Pulp and Paper, 2022, 41(11): 11-17(in Chinese). [2] 彭锦荣, 谭英伟, 严玉蓉, 等. 芳香族聚酰胺纤维功能化改性[J]. 合成材料老化与应用, 2007, 36(2): 40-43. doi: 10.3969/j.issn.1671-5381.2007.02.010PENG J R, TAN Y W, YAN Y R, et al. The functionalization of aromatic polyamide fibers[J]. Synthetic Materials Aging and Application, 2007, 36(2): 40-43(in Chinese). doi: 10.3969/j.issn.1671-5381.2007.02.010 [3] YANG B, WANG L, ZHANG M Y, et al. Fabrication, Applications, and Prospects of Aramid Nanofiber[J]. Adv. Funct. Mater., 2020, 30(22): 2000186. doi: 10.1002/adfm.202000186 [4] YANG M, CAO K Q, SUI L, et al. Dispersions of Aramid Nanofibers: A New Nanoscale Building Block[J]. ACS Nano, 2011, 5(9): 6945-6954. doi: 10.1021/nn2014003 [5] ZHANG B, WANG W C, TIAN M, et al. Preparation of aramid nanofiber and its application in polymer reinforcement: A review[J]. Eur. Polym. J., 2020, 139: 109996. doi: 10.1016/j.eurpolymj.2020.109996 [6] 耿 博, 俄松峰, 马 秦, 等. 芳纶纳米纤维/丝素蛋白复合薄膜的制备及其性能研究[J]. 陕西科技大学学报, 2022, 40(6): 9-17.GENG B, E S F, MA Q, et al. Study on preparation and properties of aramid nanofiber/silk fibroin composite films[J]. Journal of Shaanxi University of Science & Technology, 2022, 40(6): 9-17(in Chinese). [7] 郭子瞻, 贾峰峰, 董佳玥, 等. 炭黑/芳纶沉析/碳纤维纸的制备及电热性能分析[J]. 中国造纸学报, 2022, 41(9): 1-10.GUO Z Z, JIA F F, DONG J Y, et al. Fabrication and Analysis of Electric Heating Property of Carbon Black/Aramid Fibrid/Carbon Fiber-based Paper[J]. Transactions of China Pulp and Paper, 2022, 41(9): 1-10(in Chinese). [8] LU Z Q, SI L M, DANG W B, et al. Transparent and mechanically robust poly (para-phenylene terephthamide) PPTA nanopaper toward electrical insulation based on nanoscale fibrillated aramid-fibers[J]. Compos. Part A, 2018, 115: 321-330. doi: 10.1016/j.compositesa.2018.10.009 [9] HYUN Chan Kim and HENRY Angelo Sodano, Ultra-High Toughness Fibers Using Controlled Disorder of Assembled Aramid Nanofibers[J]. Adv[J]. Funct. Mater., 2023, 33(4): 202208661. [10] LU Z Q, GENG B, MA Q, et al. Polymer induced strengthening and toughening of aramid nanofiber film: The importance of densification and hydrogen bonding[J]. App. Surf. Sci., 2023, 607: 155045. doi: 10.1016/j.apsusc.2022.155045 [11] E. S F, MA Q, HUANG J Z, et al. Polyvinyl alcohol-mediated splitting of Kevlar fibers and superior mechanical performances of the subsequently assembled nanopapers[J]. Nanoscale, 2021, 13(43): 18201-18209. doi: 10.1039/D1NR05362K [12] LU Z Q, MA Q, E. S F, et al. Robust aramid nanopaper based on the uniform wrap of sodium alginate on the surface of nanofibers[J]. J. Mater. Sci., 2022, 57(2): 1111-1122. doi: 10.1007/s10853-021-06620-8 [13] ZHU J Q, CAO W X, YUE M L, et al. Strong and Stiff Aramid Nanofiber/Carbon Nanotube Nanocomposites[J]. ACS Nano, 2015, 9(3): 2489-2501. doi: 10.1021/nn504927e [14] HU P Y, LYU J, FU C, et al. Multifunctional Aramid Nanofiber/Carbon Nanotube Hybrid Aerogel Films[J]. ACS Nano, 2020, 14(1): 688-697. doi: 10.1021/acsnano.9b07459 [15] LIN M Y, LI Y H, XU K, et al. Thermally conductive nanostructured, aramid dielectric composite films with boron nitride nanosheets[J]. Compos. Sci. Technol., 2019, 175: 85-91. doi: 10.1016/j.compscitech.2019.02.006 [16] FAN J C, SHI Z X, TIAN M, et al. Graphene-aramid nanofiber nanocomposite paper with high mechanical and electrical performance[J]. Rsc Adv., 2013, 3(39): 17664-17667. doi: 10.1039/c3ra42515k [17] WU Y D, WANG F, LI X L, et al. Fabrication of a graphene oxide/nanoscale aramid fiber composite membrane with improved hydrophilicity and mechanical strength via a fast-drying method using absolute ethanol as proton donor[J]. J. Mater. Sci., 2018, 53(24): 16383-16392. doi: 10.1007/s10853-018-2798-y [18] ZHANG Z, YANG S, ZHANG P P, et al. Mechanically strong MXene/Kevlar nanofiber composite membranes as high-performance nanofluidic osmotic power generators[J]. Nat. Commun., 2019, 10: 2920. doi: 10.1038/s41467-019-10885-8 [19] 解 原, 汪 灵. 白云母类矿物在绝缘材料中的应用现状与开发利用建议[J]. 中国非金属矿工业导刊, 2004, (6): 5.XIE Y, WANG L. Application status of Muscovite minerals in insulating materials and suggestions for development and utilization[J]. China Non-metallic Minerals Industry, 2004, (6): 5(in Chinese). [20] 张美云, 袁世波, 宋顺喜, 等. 云母粒径对芳纶云母纸基绝缘材料性能的影响[J]. 陕西科技大学学报, 2018, 36(6): 7. doi: 10.3969/j.issn.1000-5811.2018.06.002ZHANG M Y, YUAN S B, SONG S X, et al. Influence of particle size on the properties of aramid mica paper-based insulation materials[J]. Journal of Shaanxi University of Science & Technology, 2018, 36(6): 7(in Chinese). doi: 10.3969/j.issn.1000-5811.2018.06.002 [21] 张小伟. 高性能复合云母纸的制造技术及增强机制的研究[D]. 武汉: 武汉理工大学, 2011.ZHANG X W. Technology of producing high performance mica paper composite and research of its enhancement mechanism[D]. Wuhan: Wuhan University of Technology, 2011. (in Chinese) [22] 王腊梅. 芳纶纤维/云母混合制备芳纶云母纸及其纸张性能研究[D]. 陕西: 陕西科技大学, 2017.WANG L M. Study on the manufacture of aramid-mica paper and its properties by mixing aramid fiber and mica[D]. Shaanxi: Shaanxi University of Science & Technology, 2017. (in Chinese) [23] SCOTT P. Fillery, Hilmar Koerner, Lawrence Drummy, et al. Nanolaminates: Increasing Dielectric Breakdown Strength of Composites[J]. ACS Appl. Mater. Interfaces., 2012, 4(3): 1388-1396. doi: 10.1021/am201650g [24] CHEN S S, SONG S X, LI Z J, et al. Constructing a BNNS/aramid nanofiber composite paper via thiol-ene click chemistry for improved thermal conductivity[J]. Mater. Today Commun., 2022, 31: 103806. doi: 10.1016/j.mtcomm.2022.103806 [25] LU Z Q, LI N, GENG B, et al. Solvent effects on the mechanical properties of aramid nanofibers film[J]. Chem. Phys. Lett., 2022, 804: 139871. doi: 10.1016/j.cplett.2022.139871 [26] E. S F, MA Q, HUANG J Z, et al. Enhancing mechanical strength and toughness of aramid nanofibers by synergetic interactions of covalent and hydrogen bonding[J]. Compos. Part A, 2020, 137: 106031. [27] E. S F, MA Q, NING D D, et al. Bio-inspired covalent crosslink of aramid nanofibers film for improved mechanical performances[J]. Compos. Sci. Technol., 2021, 201: 108514. doi: 10.1016/j.compscitech.2020.108514 -

点击查看大图

点击查看大图

计量

- 文章访问数: 47

- HTML全文浏览量: 24

- 被引次数: 0

下载:

下载: