Effect of hyperbranched polyethyleneimine ammonium polyphosphate on the properties of oriented strand boards

-

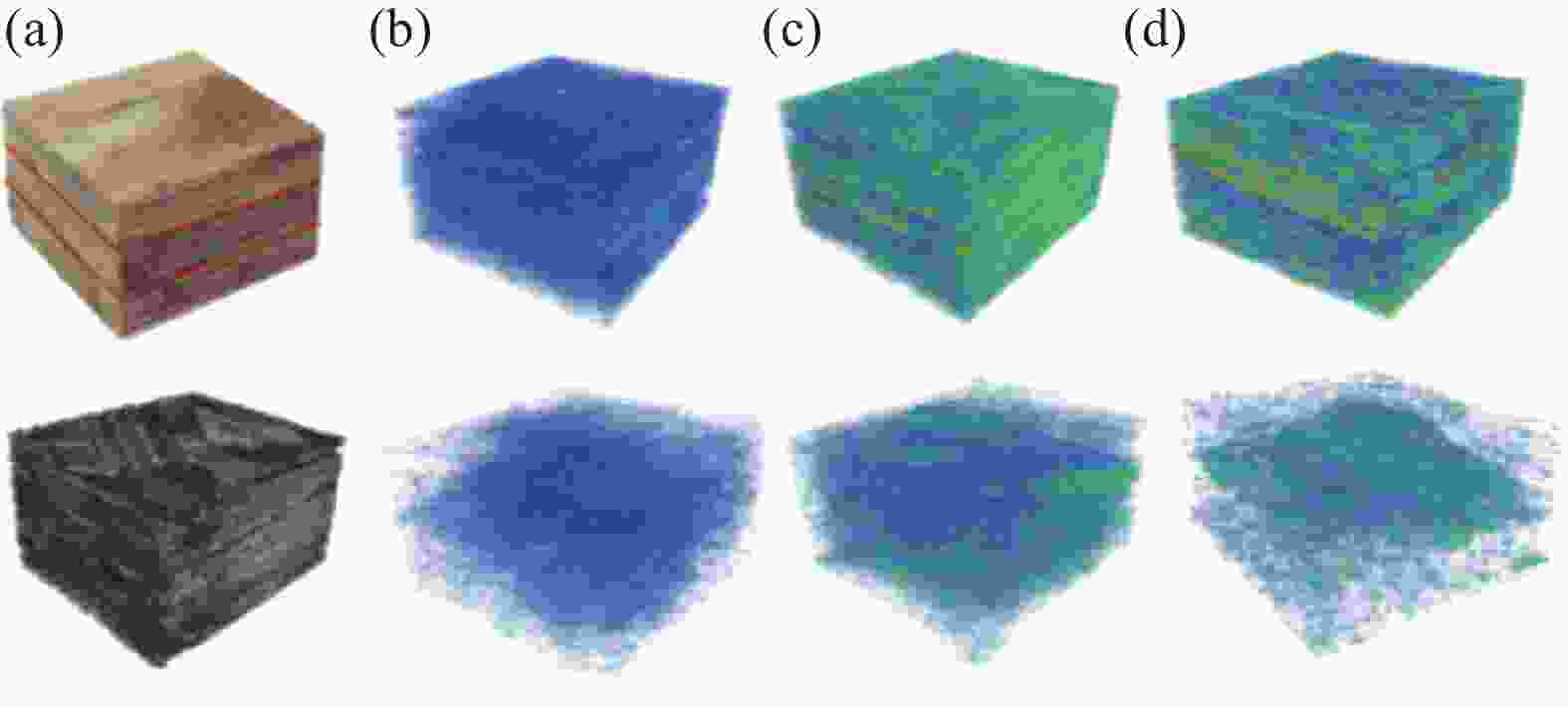

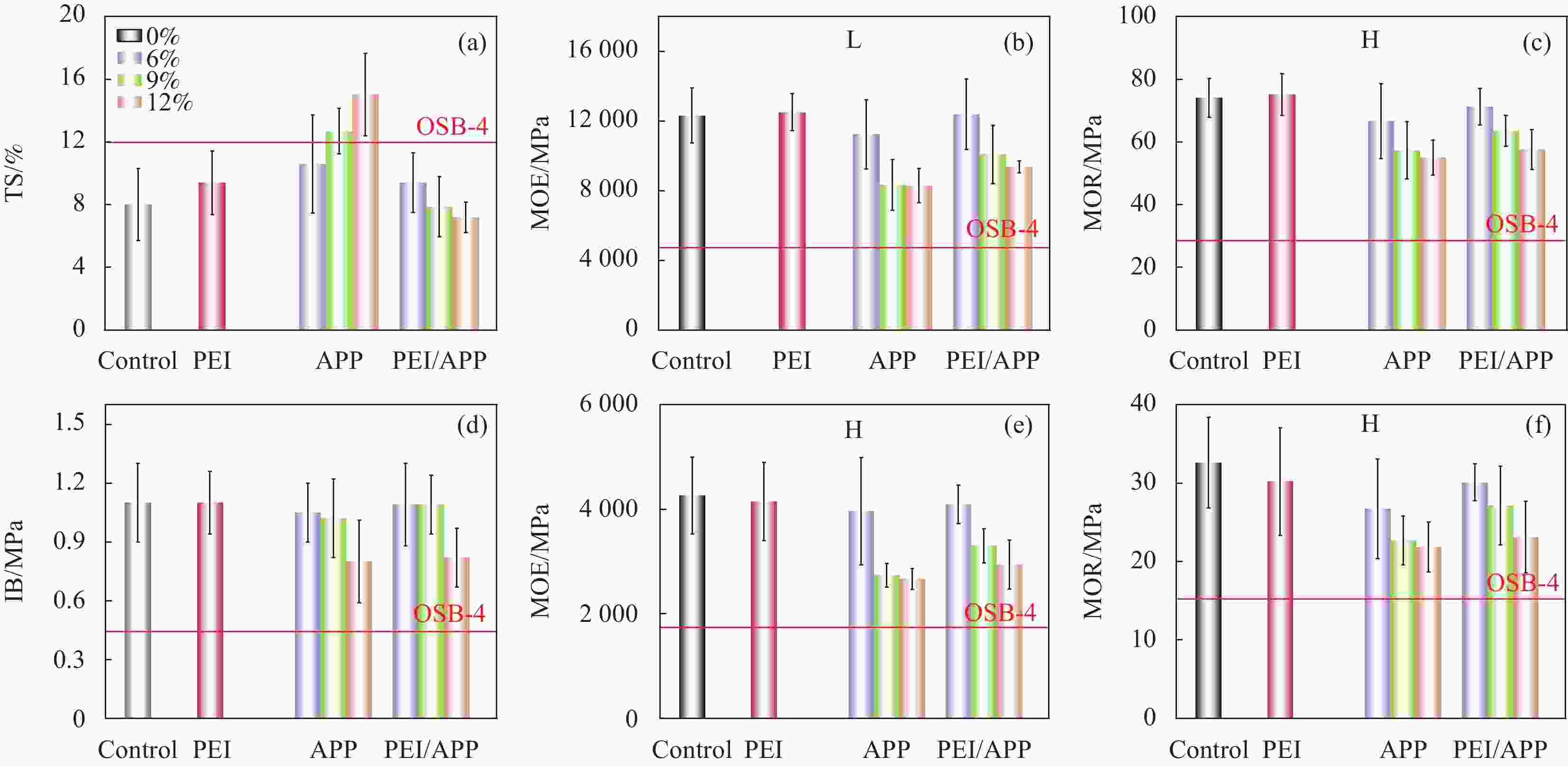

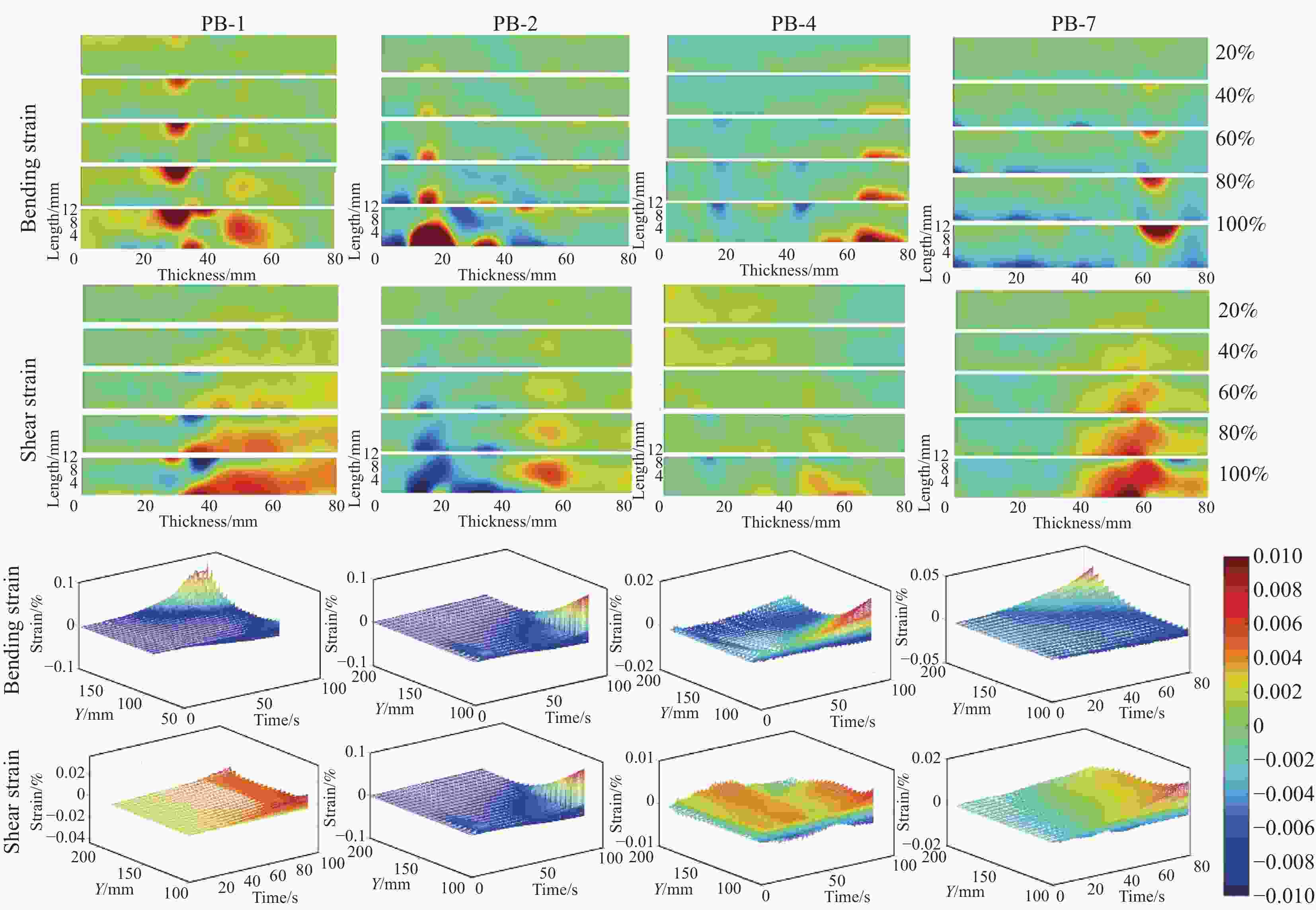

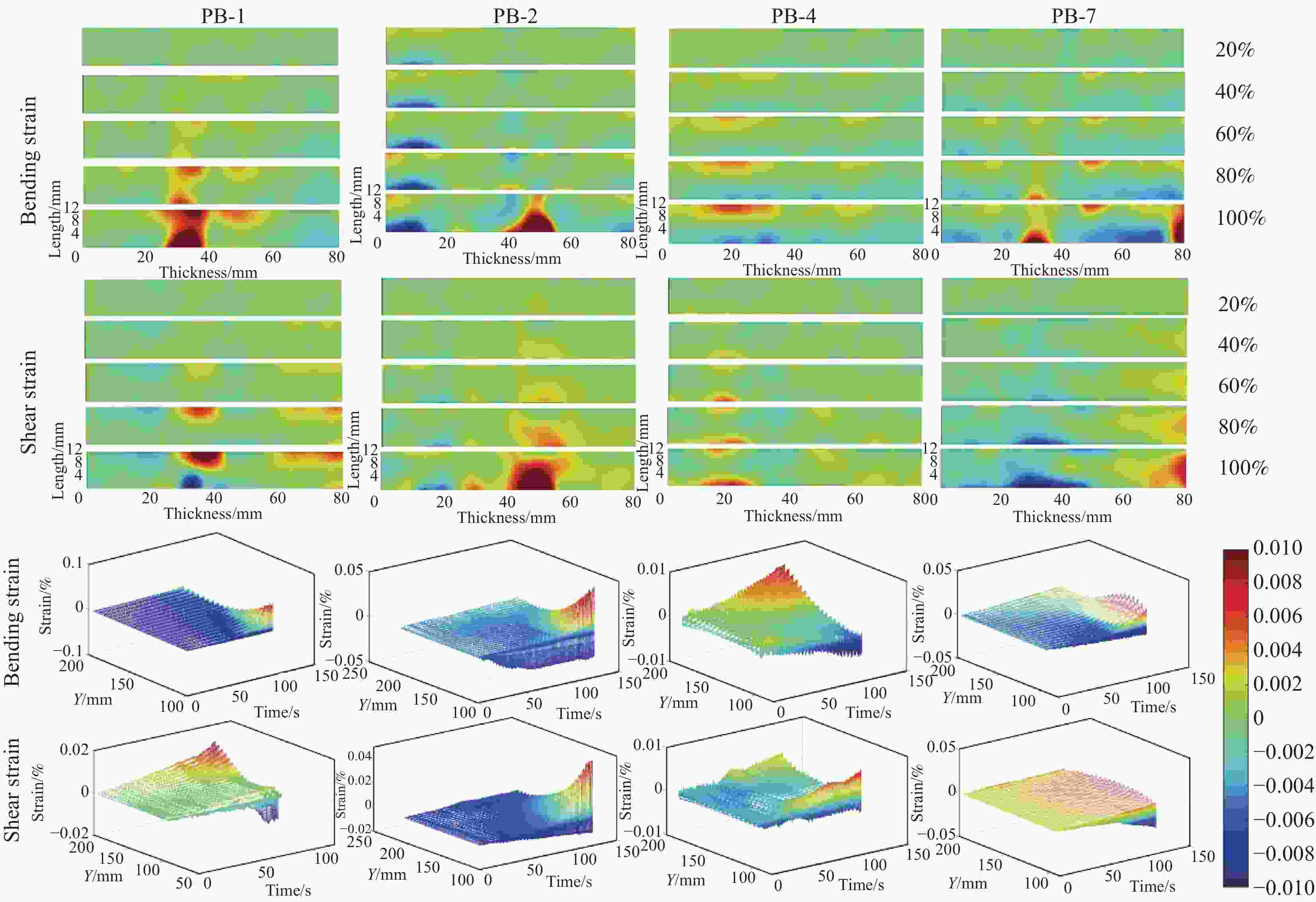

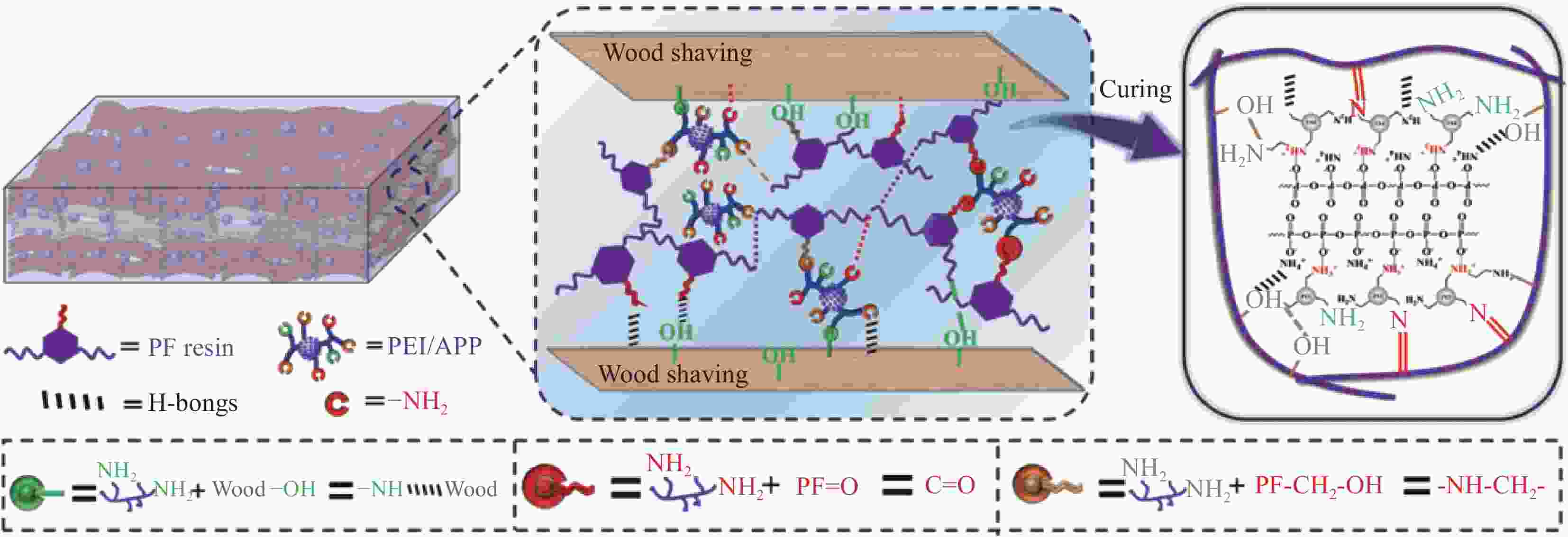

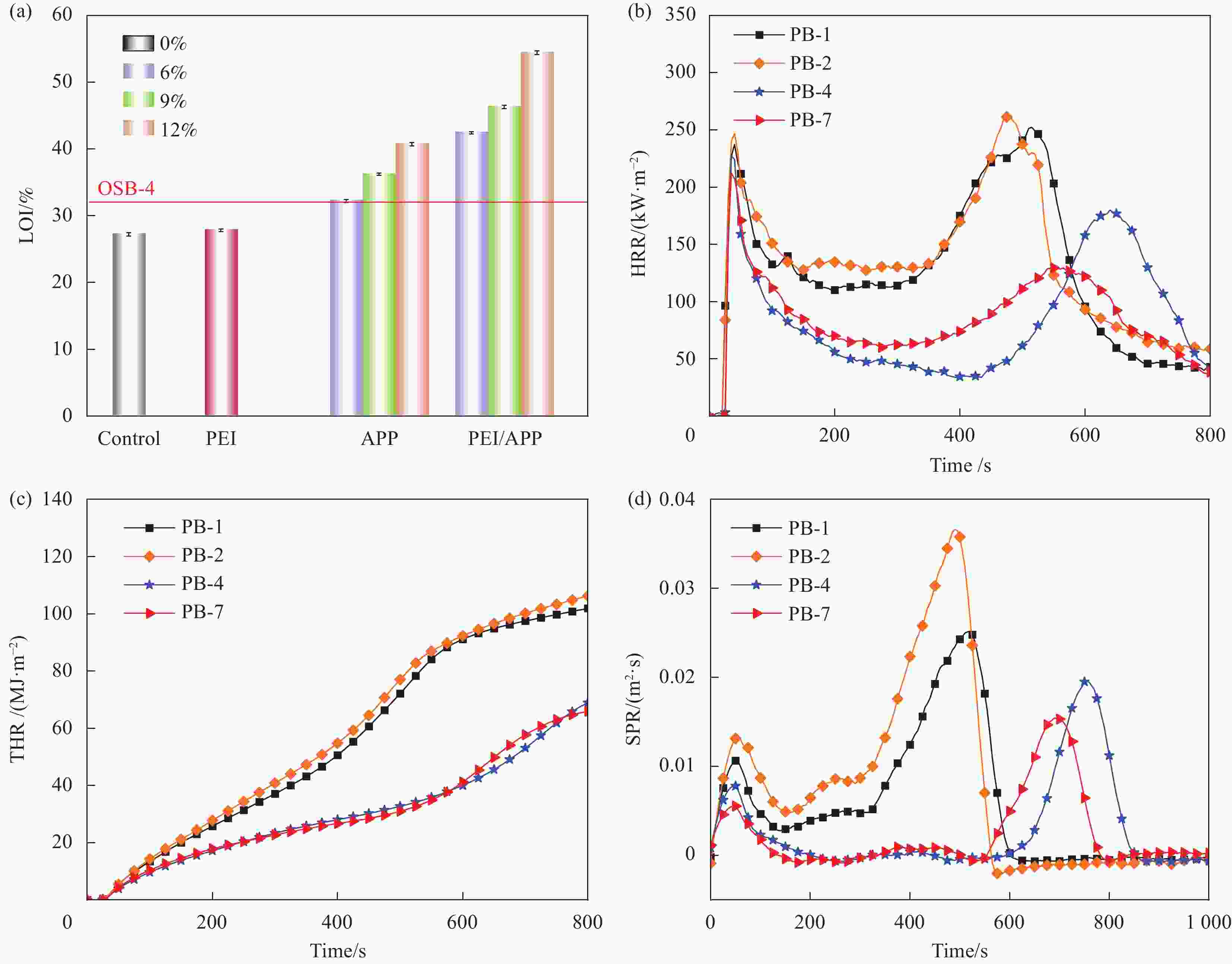

摘要: 本文以超支化聚乙烯亚胺(Polyethyleneimine, PEI)改性的聚磷酸铵(Ammonium polyphosphate, APP)为阻燃剂(PEI/APP)、以酚醛树脂(Phenol formaldehyde resin, PF)为胶黏剂制备定向刨花板(Oriented strand boards, OSB)。采用DSC探讨了PEI/APP对酚醛树脂固化过程的影响,PEI/APP能够与PF形成分子间的氢键和亚胺键(C=N)促进酚醛树脂的固化过程,使其等温固化时的放热峰温度降低至71.6℃,终止固化温度降低至74.1℃。采用力学性能分析仪、数字图像相关(Digital image correlation, DIC)和X射线计算机断层扫描扫描仪(X-ray computed tomography, X-CT)探究OSB的力学性能及其增强机制。相比于APP添加量为9%的定向刨花板,PEI/APP添加量为9%的OSB主向(L)和次向(H)的弹性模量分别提高了21.1%和20.7%;主向和次向的弯曲强度分布提高了10.8%和19.6%,内结合强度提高了6.9%,吸水厚度膨胀率降低了37.9%。DIC显示,OSB在承受弯曲载荷时,应变积累主要发生在顶层和底层,然后沿着或穿过中心层传播。主向的顶层和底层结构变化为股线分层或折断,次向上仅出现折断。X-CT测试结果显示,PEI/APP和PF树脂均匀分散在OSB的表层和芯层。因此,超支化改性提高了APP与大片刨花、PF树脂之间的界面结合,使得应变沿着中心层的传递更明显,中心层吸收载荷能量,从而提高了OSB的弯曲强度。采用LOI和锥形量热仪测试了OSB的阻燃性能,当PEI/APP添加量为9%时,OSB的极限氧指数为46.3%,热释放速率峰值为188.5 kW/m2,相比于APP添加量为9%的OSB,其极限氧指数提高了27.9%,热释放速率峰值降低了14.2%。超支化改性APP能够促使OSB脱水炭化产生连续致密的膨胀炭层,同时产生NH3,实现气相和凝聚相的协同阻燃。阻燃高强的定向刨花板在绿色建筑、家居、交通应用领域具有十分广阔的应用前景。

-

关键词:

- 定向刨花板 /

- 复合聚电解质 /

- 酚醛树脂固化动力学 /

- 动态应变传递 /

- X射线计算机断层扫描

Abstract: In this paper, we are using hyperbranched polyethyleneimine (PEI) modified ammonium polyphosphate (APP) as flame retardant (PEI/APP) and phenol formaldehyde resin (PF) as an adhesive to prepare oriented strand boards. Using DSC to explore the influence of PEI/APP on the curing process of phenol-formaldehyde resin, PEI/APP was able to form intermolecular hydrogen and imine bonds (C=N) with PF to promote the curing process of the phenol-formaldehyde resin, so that the peak temperature of curing was lowered to 71.6℃, and the end of curing temperature was lowered to 74.1℃. Using mechanical property analyzer, digital image correlation and X-ray computed tomography to understand the mechanical properties of oriented strand boards (OSB) and its enhancement mechanism. Compared to the oriented strand board with 9% APP addition, the modulus of elasticity of OSB with 9% PEI/APP addition increased by 21.1% and 20.7% in the major (L) and minor (H) directions, respectively; the major and minor modulus of rupture was increased by 10.8% and 19.6%, the internal bond strength was increased by 6.9%, and the thickness swelling of the absorbed water was reduced by 37.9%. DIC shows that when OSB is loaded in bending, strain accumulation mainly occur in the top and bottom layers and then propagate along or across the central layer. Structural changes in the top and bottom layers of major specimens was either strand delamination or snap off, while only snap off is found in minor specimens. X-CT test results show that PEI/APP and PF resins are widely spread in the surface layer and core layer of OSB. Therefore, the hyperbranching modification improves the interfacial bonding between APP and the large wood shavings and PF resins, which results in making strain transfer along the center layer more pronounced. The center layer absorbs the energy of the load, which im-proves the bending strength of the OSB. The flame retardancy of OSB was tested using LOI and cone calorimetry. Its limiting oxygen index increased by 27.9% and its peak heat release rate decreased by 14.2%. Hyperbranched modified APP could induce OSB dehydration charring to produce a dense and continuous expanded char layer, and at the same time produce NH3 to realize synergistic flame retardation in both gas and condensed phases. Flame-retardant and high-strength oriented strand board has a very wide application prospect in the field of green building, furniture and transportation applications. -

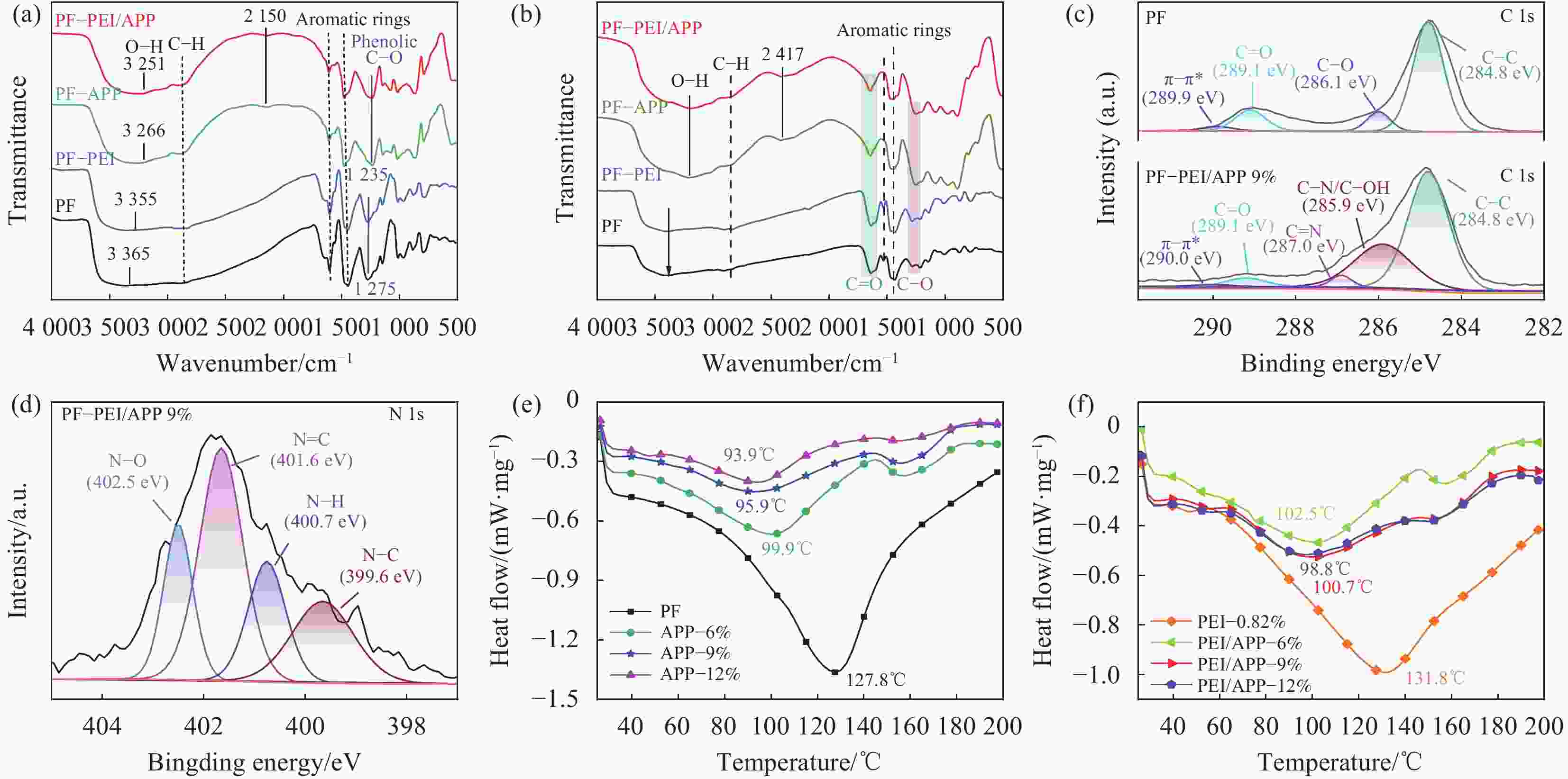

图 2 PEI/APP与酚醛树脂(PF)交联体系的表征结果: (a) PEI/APP交联PF的固化前的FTIR;(b)固化后的FTIR; PF和PF-PEI/APP 9%的XPS图谱:(c) C1s; (d) N1s; (e)不同APP添加量下交联体系的DSC曲线; (f) 不同PEI/APP添加量下交联体系的DSC曲线

Figure 2. Characterization results of PEI/APP and phenol formaldehyde resin (PF) cross-linking system: (a) FTIR of PEI/APP cross-linked PF before curing; (b) FTIR after curing; XPS spectra of PF and PF-PEI/APP 9%resin: (c) C1s; (d) N1s; (e) DSC curves of cross-linked systems under different APP dosage;(f) DSC curves of cross-linked systems with different PEI/APP additions.

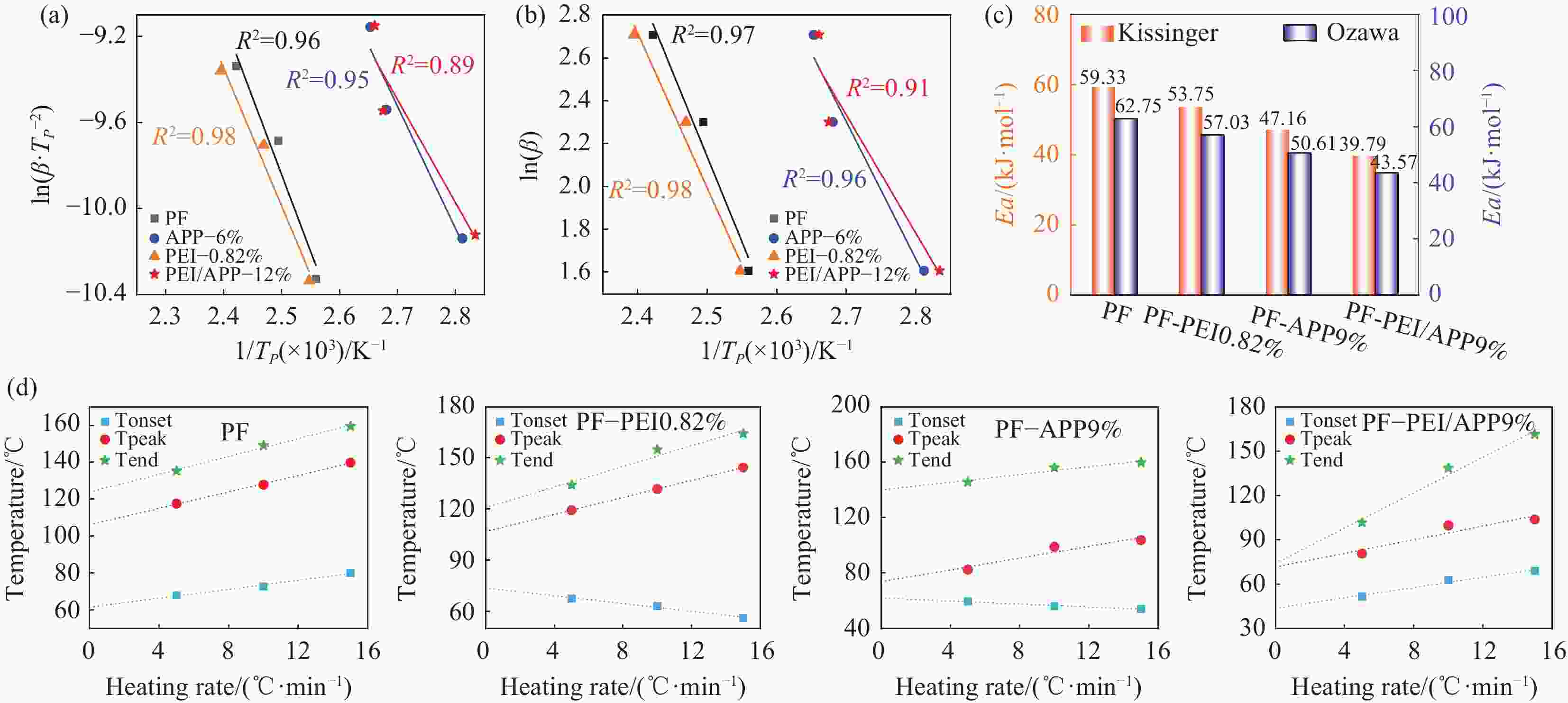

图 4 (a) Kissinger方程线性拟合图;(b) Ozawa方程线性拟合图;(c)两组方程得到的活化能; (d) PEI、APP以及PEI/APP交联PF后的Tonset、Tpeak和Tend的线性拟合

Figure 4. (a) Kissinger equation linear fitting diagram; (b) Ozawa equation linear fitting diagram; (c) Activation energy obtained from two sets of equations; (d) Linear fitting of Tonset, Tpeak, and Tend after PEI, APP, and PEI/APP crosslinked PF.

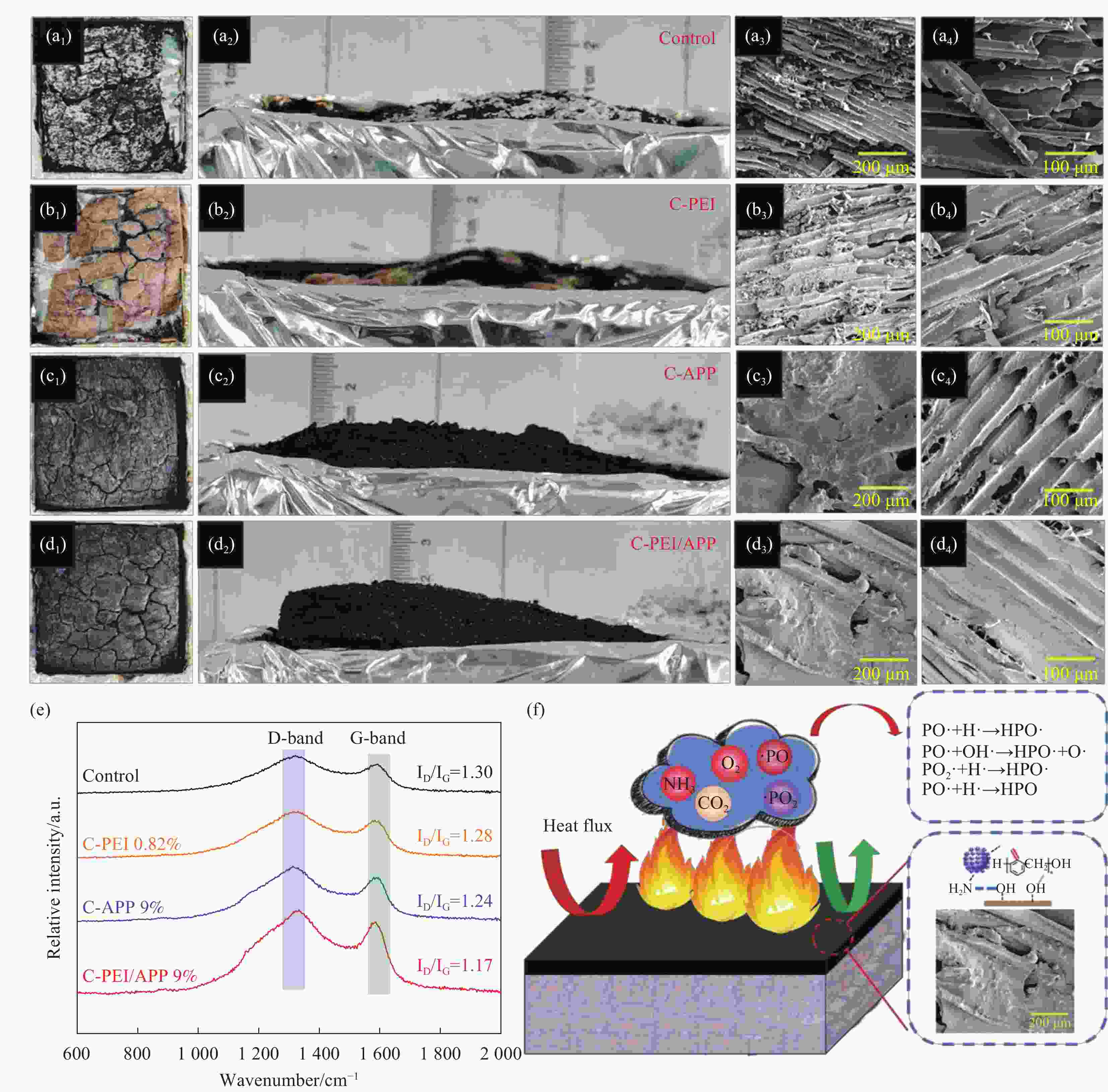

图 11 不添加、添加PEI以及添加APP、PEI/APP的定向刨花板燃烧后的残炭照片(a1,b1,c1,d1,a2,b2,c2,d2)及其残炭的表层和内层的SEM图像(a3,b3,c3、d3、a4、b4、c4、d4);锥形量热测试后残炭的拉曼光谱(e); 阻燃机制示意图(f)

Figure 11. Digital photos of the residual carbon of the oriented particle without or with the addition of PEI, APP, and PEI/APP after combustion (a1, b1, c1, d1, a2, b2, c2, d2) and their exterior and interior layers of the residual carbon SEM images (a3, b3, c3, d3, a4, b4, c4, d4) after cone calorimetry testing; Raman spectra of carbon residue from cone calorimeter test (e), and the flame-retardant mechanism diagram (f).

表 1 定向刨花板(OSB)中阻燃剂的类型和添加量

Table 1. Types and addition of flame retardants in oriented strand boards (OSB)

Sample Type of flame

retardantAdditive

amount/wt%Density/

(g·cm−3)PB-1 \ \ 0.72±0.05 PB-2 Polyethyleneimine (PEI) 0.82 0.73±0.04 PB-3 Ammonium

polyphosphate (APP)6 0.75±0.04 PB-4 APP 9 0.73±0.05 PB-5 APP 12 0.72±0.03 PB-6 PEI/APP 6 0.70±0.06 PB-7 PEI/APP 9 0.73±0.05 PB-8 PEI/APP 12 0.74±0.04 Notes: the addition amount of flame retardant is the ratio of the mass of flame retardant to the mass of absolute dry wood shavings. Repeat once for each condition. 表 2 各组分在不同升温速率下的DSC参数

Table 2. DSC parameters of each component at different heating rates

Sample β/(℃·min−1) Tonset /℃ Tpeak /℃ Tend /℃ ΔH/(J·g−1) PF 5 68 117.6 135.4 232.3 10 72.8 127.8 149.1 238.4 15 80.1 139.8 159.5 120.5 PF-PEI0.82% 5 67.6 119.4 134.1 204.9 10 63.2 131.8 154.9 156.3 15 56.2 144.4 164.4 84.7 PF-APP9% 5 59.5 82.5 145.8 55.7 10 56.1 99.9 156.2 87.9 15 54.2 103.8 159.8 34.2 PF-PEI/APP9% 5 51.7 80.7 101.7 35.3 10 62.8 100.7 138.6 90.4 15 69.1 103.8 161.5 43.5 Notes: β is the heating rate; Tonset is the initial curing temperature; Tpeak (Tp) is the peak curing temperature; Tend is the curing termination temperature; ΔH is the enthalpy change during the curing process. 表 3 各组分在升温速率为0℃/min时的固化工艺参数

Table 3. Curing process parameters of each component at a heating rate of 0℃/min

Sample Tonset /℃ Tpeak /℃ Tend /℃ PF 61.5 106.2 123.9 PF-PEI0.82% 73.7 106.9 120.8 PF-APP9% 61.9 73.8 139.9 PF-PEI/APP9% 43.8 71.6 74.1 表 4 定向刨花板的锥形量热仪的测试结果

Table 4. Test results of cone calorimeter of oriented particle board

Sample TTI/s Average HRR

(60 s)/(kW·m−2)Average HRR

(120 s) /(kW·m−2)Peak HRR/

(kW·m−2)THR/

(MJ·m−2)Average EHC

(120 s)/(MJ·kg−1)TSP/m2 PB-1 18.5(2.5) 176.7(0.8) 159.0(2.4) 252.2(17.5) 102.7(0.8) 11.5(0.2) 5.6(0.2) PB-2 16.0(2.0) 180.8(3.1) 163.7(1.8) 261.9(21.3) 106.6(0.3) 11.3(0.1) 7.8(0.1) PB-4 18.5(0.5) 149.5(1.6) 122.4(4.6) 180.0(7.6) 70.5(1.6) 10.8(0.5) 2.4(0.1) PB-7 22(0) 127.1(1.2) 107.3(1.6) 131.2(3.9) 67.3(1.4) 9.9(0.1) 3.1(0.3) Notes: TTI is the ignition time; Average HRR in 60 s is the average heat release rate in 60 seconds; Average HRR in 120 s is the average heat release rate in 120 seconds; Average EHC in 120 s is the average heat of combustion in 120 seconds; TSP is the smoke production of the whole combustion process. -

[1] 国家市场监督管理总局. 定向刨花板: GB/T 41715—2022[S]. 北京: 中国标准出版社, 2022.State Administration of Market Supervision and Administration. Oriented Strand Board: GB/T 41715-2022[S]. Beijing: China Standards Press, 2022(in Chinese). [2] CAMPOS L E, STEIGENBERGER A C, MARTINS R H B, et al. Oriented Strand Board panels of residual reforestation wood with Al2O3 nanoparticles[J]. Industrial Crops and Products, 2023, 200: 116777. doi: 10.1016/j.indcrop.2023.116777 [3] CHRISTOFORO A L, FERRO F S, ARROYO F N, et al. Chromated copper borate influence on physical and mechanical properties of oriented strand boards using Schizolobium amazonicum wood specie[J]. Construction and Building Materials, 2022, 356: 129237. doi: 10.1016/j.conbuildmat.2022.129237 [4] LI W Z, LI D H, DUAN Y J, et al. Combining X-ray CT and DIC to understand the bending strength of OSB[J]. Construction and Building Materials, 2022, 354: 129125. doi: 10.1016/j.conbuildmat.2022.129125 [5] PERCIN O, ALTUNOK M. Some physical and mechanical properties of laminated veneer lumber reinforced with carbon fiber using heat-treated beech veneer[J]. European Journal of Wood and Wood Products, 2017, 75: 193-201. doi: 10.1007/s00107-016-1125-z [6] 姚建龙, 郑洪连. 浅析定向刨花板的应用与质量要求[J]. 中国人造板, 2023, 30(2): 38-40.YAO Jianlong, ZHENG Honglian. Application and quality requirements of oriented strand board[J]. China Artificial Board, 2023, 30(2): 38-40(in Chinese). [7] YANG P, SHEN A, CAO Y Z, et al. Effects of air-plasma treatment in enhancing the mechanical properties of oriented strand boards[J]. International Journal of Adhesion and Adhesives, 2023, 125: 103435. doi: 10.1016/j.ijadhadh.2023.103435 [8] 中国国家标准化管理委员会. 公共场所阻燃制品及组件燃烧性能要求及标识: GB 20286—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of China. Fire retardant products and com-ponents in public places, combustion performance requirements and identification: GB 20286—2006 [S]. Beijing: China Standards Press, 2006(in Chinese). [9] BAI G, GUO C G, LI L P. Synergistic effect of intumescent flame retardant and expandable graphite on mechanical and flame-retardant properties of wood flour polypropylene composites[J]. Construction and Building Materials, 2014, 50: 148-153. doi: 10.1016/j.conbuildmat.2013.09.028 [10] CINI N, BALL V. Polyphosphates as inorganic polyelectrolytes interacting with oppositely charged ions, polymers and deposited on surfaces: fundamentals and applications[J]. Advances in Colloid and Interface Science, 2014, 209: 84-97. doi: 10.1016/j.cis.2014.01.011 [11] DING C X, PAN M Z, CHEN H, et al. An anionic polyelectrolyte hybrid for wood-polyethylene composites with high strength and fire safety via self-assembly[J]. Construction and Building Materials, 2020, 248: 118661. doi: 10.1016/j.conbuildmat.2020.118661 [12] 黄伟江, 何文涛, 龙丽娟, 等. 新型含磷高温尼龙的阻燃和力学性能[J]. 材料工程, 2018, 46(7): 68-75. doi: 10.11868/j.issn.1001-4381.2016.001374HUANG Weijiang, HE Wentao, LONG Lijuan, et al. Flame retardancy and mechanical properties of a Novel P-containing high Temperature Nylon Composites[J]. Journal of Materials Engineering, 2018, 46(7): 68-75(in Chinese). doi: 10.11868/j.issn.1001-4381.2016.001374 [13] YUAN Z G, SHU Z H, QI L, et al. Curing behavior, mechanical, and flame-retardant properties of epoxy-based composites filled by expandable graphite and ammonium polyphosphate[J]. Journal of Applied Polymer Science, 2022, 141(1): 53267. [14] LIU D B, QASEM B, HOU J F, et al. Recycling construction wastes to fabricate particle boards with admirable flame retardancy, smoke suppression and mechanical performance[J]. Construction and Building Materials, 2023, 404: 133265. doi: 10.1016/j.conbuildmat.2023.133265 [15] ZHANG Y B , YAN H X, FENG G P, et al. Non-aromatic Si, P, N-containing hyperbranched flame retardant on reducing fire hazards of epoxy resin with desirable mechanical properties and lower curing temperature[J]. Composites Part B: Engineering, 2021, 222: 109043. [16] 王帅旗, 张宇婷, 张帅, 等. 聚乙烯亚胺/聚磷酸铵复合聚电解质对脲醛树脂固化行为的影响及其阻燃木质刨花板[J]. 复合材料学报, 2023, 40(12): 6583-6595.WANG Shuaiqi, ZHANG Yuting ZHANG Shuai, et al. PEI/APP polyelectrolyte complex effects on the curing behavior of urea-formaldehyde resin and its flame retardant wood particle board[J]. Acta Materiae Compositae Sinica, 2024, 40(12): 6583-6595(in Chinese). [17] BIZIKS V, VAN A J, MILITZ H, et al. Density and density profile changes in birch and spruce caused by thermo-hydro treatment measured by X-ray computed tomography[J]. Wood Science and Technology, 2019, 54(2): 491-504. [18] ZHANG Y T, ZHU G Y, MA T T, et al. Densification and polyelectrolyte assisted fabricating laminated wood composites for outstanding flame retardancy and mechanical properties[J]. Construction and Building Materials, 2023, 393: 132041. doi: 10.1016/j.conbuildmat.2023.132041 [19] CHEN Y X, WEI W, ZHU Y, et al. Noncovalent functionalization of carbon nanotubes via co-deposition of tannic acid and polyethyleneimine for reinforcement and conductivity improvement in epoxy composite[J]. Composites Science and Technology, 2019, 170: 25-33. doi: 10.1016/j.compscitech.2018.11.026 [20] LI W Z, VAN DEN BULCKE J, MANNES D, et al. Impact of internal structure on water-resistance of plywood studied using neutron radiography and X-ray tomography[J]. Construction and Building Materials, 2014, 73(30): 171-179. [21] 武多多, 郑会龙, 康振亚, 等. 金属-机织复合材料混合结构的三点弯曲力学性能及失效机制[J]. 材料工程, 2022, 50(12): 79-88.WU Duoduo, ZHENG Huilong, KANG Zhenya, et al. Mechanical properties and failure mechanism of metal-woven composite hybrid structures under three-point bending[J]. Journal of Materials Engineering, 2012, 50(12): 79-88(in Chinese). [22] 毛威, 田飞宇, 朱春锋, 等. 聚磷酸铵分层阻燃处理对杨木大片刨花板性能的影响[J]. 林业工程学报, 2023, 8(3): 71-78.MAO Wei, TIAN Feiyu, ZHU Chunfeng, et al. Effect of layered flame retardant treatment with ammonium polyphosphate on the properties of poplar large-size particleboard[J]. Journal of Forest Engineering, 2023, 8(3): 71-78(in Chinese). [23] 全国人造板标准化技术委员会. 人造板及饰面人造板理化性能试验方法: GB/T17657—2013[S]. 北京: 中国标准出版社, 2014.National Technical Committee on Wood-based Panels Standardization of China. Test methods of evaluating the properties of wood-based panels and surfaces decorated wood-based panels: GB/T17657—2013[S]. Beijing: Standards Press of China, 2014(in Chinese). [24] 中国国家标准化管理委员会. 塑料用氧指数法测定燃烧行为第2部分: 室温试验: GB/T2406.2—2009[S]. Beijing: Standards Press of China, 2010(in Chinese). [25] LI JJ, ZHU W J, ZHANG S F, et al. Depolymerization and characterization of Acacia mangium tannin for the preparation of mussel-inspired fast-curing tannin-based phenolic resins[J]. Chemical Engineering Journal, 2019, 375: 420-431. [26] LIU J M, XIE E J, TANG Y R, et al. Eco-friendly phenol formaldehyde resin wood adhesive from bagasse lignin liquefaction[J]. Sustainable Chemistry and Pharmacy, 2023, 33: 101129. doi: 10.1016/j.scp.2023.101129 [27] YAN Y T, DONG S J, JIANG H C, et al. Efficient and Durable Flame-Retardant Coatings on Wood Fabricated by Chitosan, Graphene Oxide, and Ammonium Polyphosphate Ternary Complexes via a Layer-by-Layer Self- Assembly Approach[J]. ACS Omega, 2022, 7(33): 29369-29379. doi: 10.1021/acsomega.2c03624 [28] ESLAH F, JONOOBI M, FAEZIPOUR M, et al. Chemical modification of soybean flour-based adhesives using acetylated cellulose nanocrystals[J]. Polymer Composites, 2018, 39(10): 3618-3625. doi: 10.1002/pc.24389 [29] LIU Y, LI K. Preparation and characterization of demethylated lignin-polyethylenimine adhesives[J]. The Journal of Adhesion, 2006, 82(6): 593-605. doi: 10.1080/00218460600766632 [30] YAN YT, WANG Y D, Wu J, et al. Preparation and characterization of high-strength and water resistant lignocelluloses based composites bonded by branched polyethylenimine (PEI)[J]. International Journal of Biological Macromolecules, 2019, 141: 369-377. doi: 10.1016/j.ijbiomac.2019.09.004 [31] CHUA C K, PUMERA M. Monothiolation and Reduction of Graphene Oxide via One-Pot Synthesis: Hybrid Catalyst for Oxygen Reduction[J]. ACS Nano, 2015, 9(4): 4193-4199. doi: 10.1021/acsnano.5b00438 [32] ZHAO S J, WANG Z, KANG H J, et al. Construction of bioinspired organic-inorganic hybrid composite by cellulose-induced interfacial gelation assisted with Pickering emulsion template[J]. Chemical Engineering Journal, 2019, 359: 275-284. doi: 10.1016/j.cej.2018.11.126 [33] LI J J, ZHU Y, BIAN R H, et al. Construction of a boron nitride nanosheet hybrid for tough, strong, and flame-retardant phenolic resins[J]. Chemical Engineering Journal, 2023, 471: 144463. doi: 10.1016/j.cej.2023.144463 [34] SHI Y J, ZHANG T, REN H Q, et al. Polyethylene imine modified hydrochar adsorption for chromium (VI) and nickel (II) removal from aqueous solution[J]. Bioresource Technology, 2018, 247: 370-379. doi: 10.1016/j.biortech.2017.09.107 [35] Wang Y J, Liu M M, Fan F, et al. Enhanced full-spectrum photocatalytic activity of 3D carbon-coated C3N4 nanowires via giant interfacial electric field[J]. Applied Catalysis B:Environmental, 2022, 318: 121829. doi: 10.1016/j.apcatb.2022.121829 [36] WANG J H, WANG R S, JI X X, et al. Enhancing and toughening bamboo interfacial bonding strength by reactive hyperbranched polyethyleneimine modified phenol formaldehyde resin adhesive[J]. Journal of Materials Research and Technology, 2023, 26: 8213-8228. doi: 10.1016/j.jmrt.2023.09.176 [37] 王辉, 周晓剑, 王凤, 等. 低摩尔比脲醛树脂掺杂支化聚合物体系研究[J]. 中南林业科技大学学报, 2022, 42(4): 145-151.WANG Hui, ZHOU Xiaojian, WANG Feng, et al. Research on low molar ratio urea-formaldehyde resin doped branched polymer system[J]. Journal of Central South University of Forestry Science and Technology, 2022, 42(4): 145-151(in Chinese). [38] UBIS M A R, PARK B D, LEE S M. Microencapsulation of polymeric isocyanate for the modification of urea-formaldehyde resins[J]. International Journal of Adhesion and Adhesives, 2020, 100: 102599. doi: 10.1016/j.ijadhadh.2020.102599 [39] TENG N, DAI J Y, WANG S P, et al. Hyperbranched flame retardant for epoxy resin modification: Simultaneously improved flame retardancy, toughness and strength as well as glass transition temperature[J]. Chemical Engineering Journal, 2022, 428: 131226. doi: 10.1016/j.cej.2021.131226 [40] TUDORACHI N, MUSTATA F. Curing and thermal degradation of diglycidyl ether of bisphenol A epoxy resin crosslinked with natural hydroxy acids as environmentally friendly hardeners[J]. Arabian Journal of Chemistry, 2020, 13(1): 671-682. doi: 10.1016/j.arabjc.2017.07.008 [41] VAN DEN BULCKE J, BOONE MA, DHAENE J, et al. Advanced X-ray CT scanning can boost tree ring research for earth system sciences[J]. Annals of Botany, 2019, 124(5): 837-847. doi: 10.1093/aob/mcz126 [42] TIAN F Y, MAO W, XU X W. Effect of a layered combination of APP and TBC on the mechanics and flame retardancy of poplar strand boards[J]. Construction and Building Materials, 2023, 401: 132881. doi: 10.1016/j.conbuildmat.2023.132881 [43] LI W Z, MEI C T, VAN DEN BULCKE J, et al. The effect of water sorption/desorption on fatigue deflection of OSB[J]. Construction and Building Materials, 2019, 223: 1196-1203. doi: 10.1016/j.conbuildmat.2019.07.283 [44] LI W Z, LI D H, DUAN Y J, et al. Combining X-ray CT and DIC to understand the bending strength of OSB[J]. Construction and Building Materials, 2022, 354: 129125. doi: 10.1016/j.conbuildmat.2022.129125 [45] YU Y, XIN R X, ZENG W H, et al. Fracture resistance curves of wood in the longitudinal direction using digital image correlation technique[J]. Theoretical and Applied Fracture Mechanics, 2021, 114: 102997. doi: 10.1016/j.tafmec.2021.102997 [46] KHALILI P, LIU X L, Tshai K Y, et al. Development of fire retardancy of natural fiber composite encouraged by a synergy between zinc borate and ammonium polyphosphate[J]. Composites Part B:Engineering, 2019, 159: 165-172. doi: 10.1016/j.compositesb.2018.09.036 [47] KUMAR R, CHAUHAN S. Effect of ammonium polyphosphate as synergist with nano silica dioxide on flammability of boron compound pretreated bamboo flour-HDPE composite[J]. Fire Safety Journal, 2022, 133: 103647. doi: 10.1016/j.firesaf.2022.103647 [48] TENG N, DAI J Y, WANG S P, et al. Hyperbranched flame retardant for epoxy resin modification: Simultaneously improved flame retardancy, toughness and strength as well as glass transition temperature[J]. Chemical Engineering Journal, 2022, 428: 131226. doi: 10.1016/j.cej.2021.131226 [49] HI X H, LIU Q Y, LI X L, et al. Construction phosphorus/nitrogen-containing flame-retardant and hydrophobic coating toward cotton fabric via layer-by-layer assembly[J]. Polymer Degradation and Stability, 2022, 197: 109839. doi: 10.1016/j.polymdegradstab.2022.109839 [50] YU M, ZHANG T T, LI J, et al. Facile Synthesis of Eugenol-Based Phosphorus/Silicon-Containing Flame Retardant and Its Performance on Fire Retardancy of Epoxy Resin[J]. ACS Applied Polymer Materials, 4(3): 1794-1804. -

点击查看大图

点击查看大图

计量

- 文章访问数: 42

- HTML全文浏览量: 16

- 被引次数: 0

下载:

下载: