Multi-objective optimization of fiber orientation and grammage of recycled carbon fiber felt

-

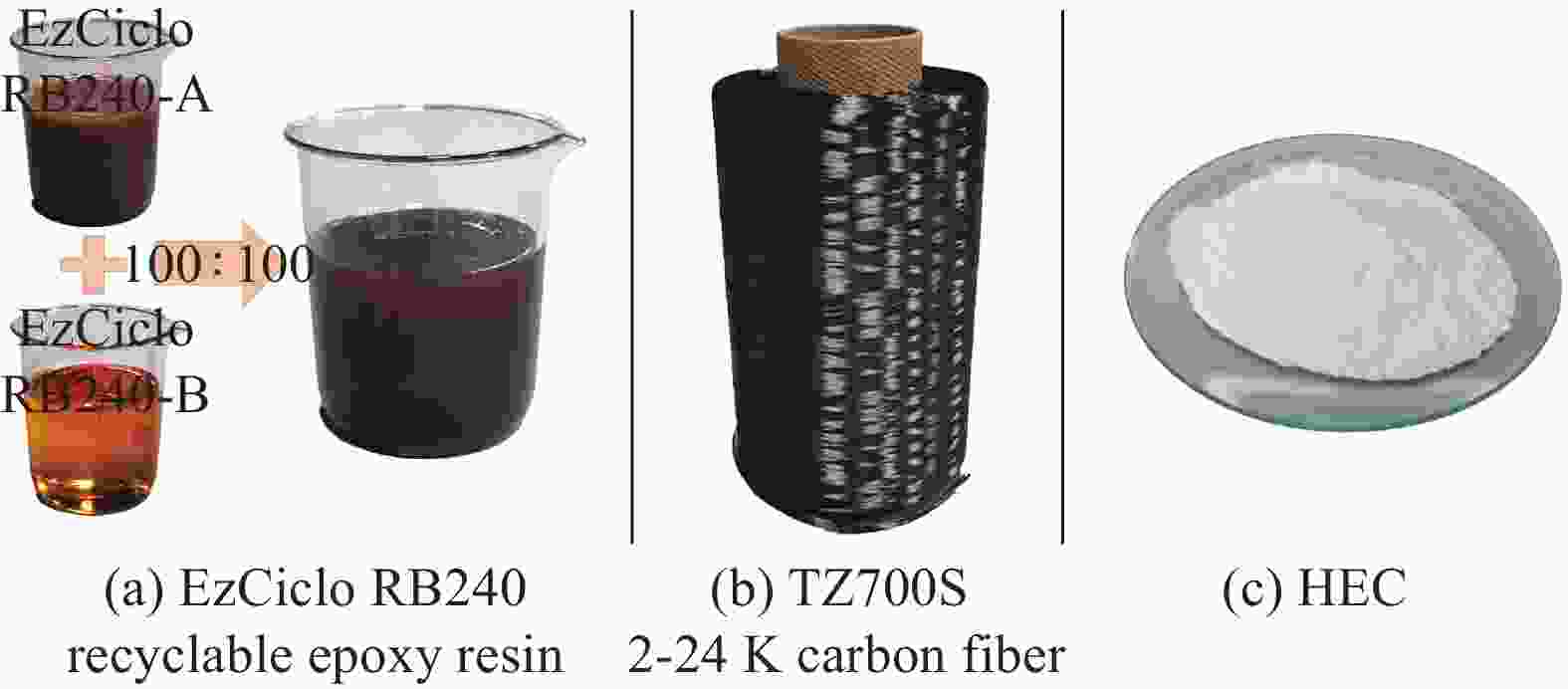

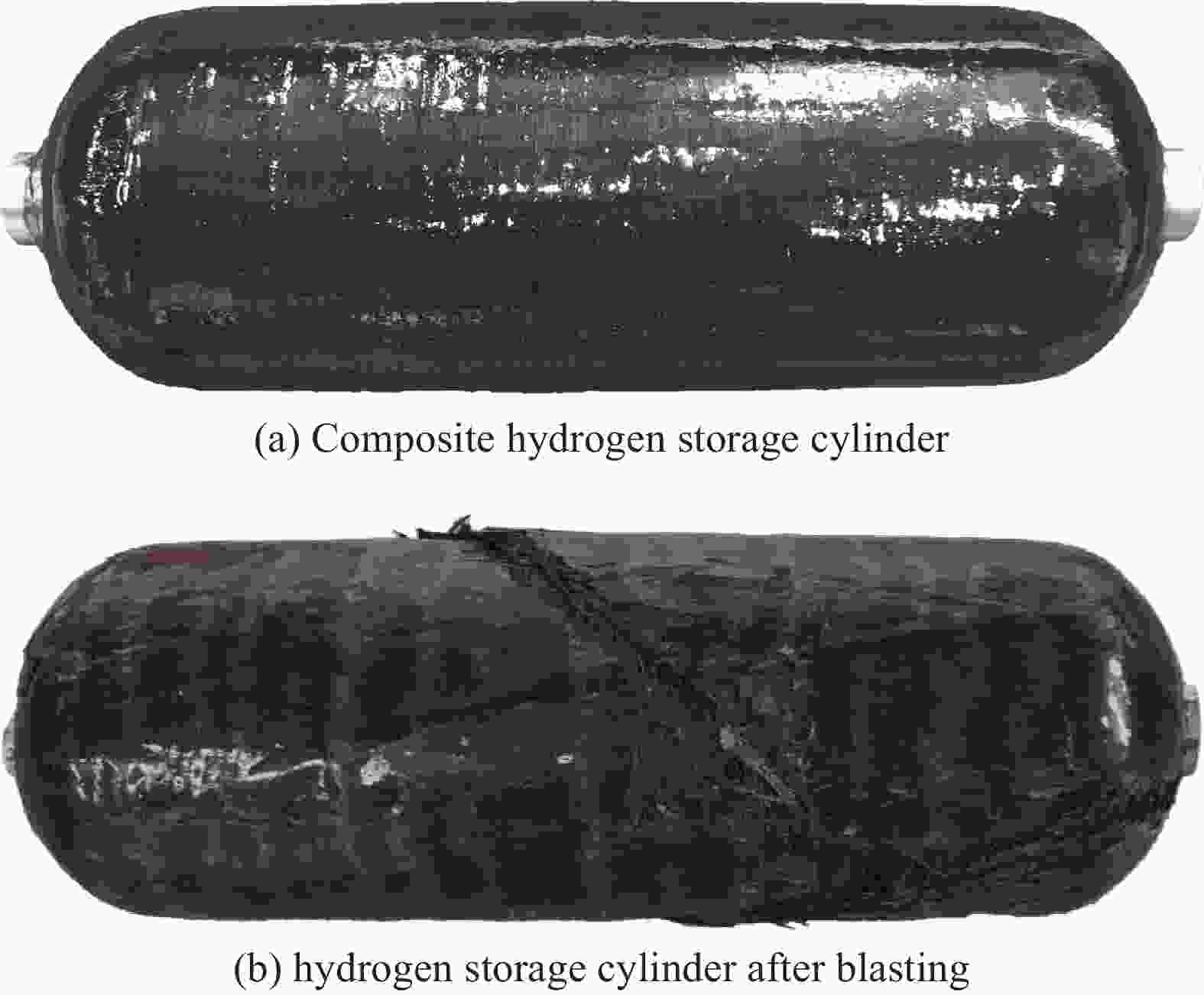

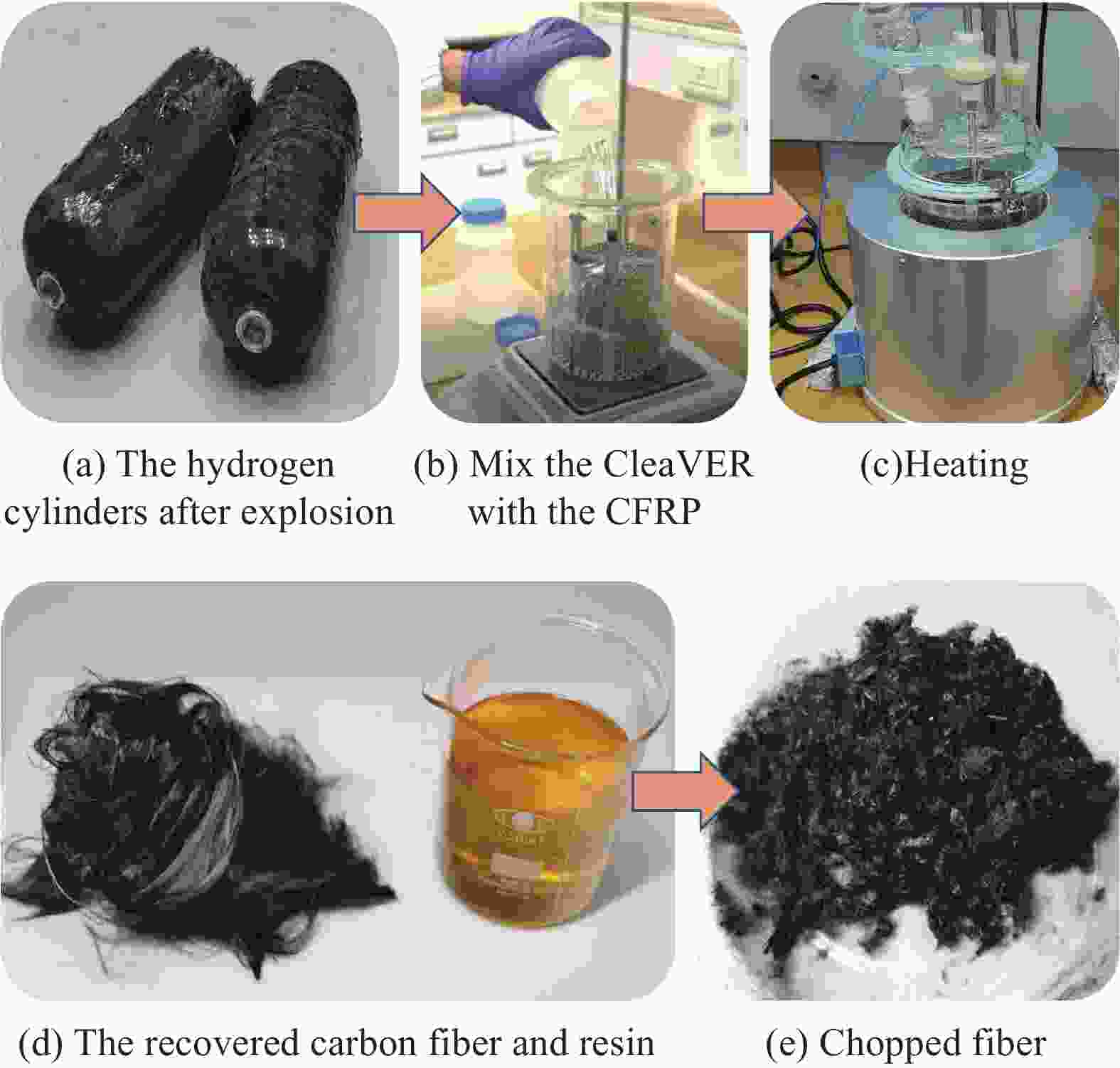

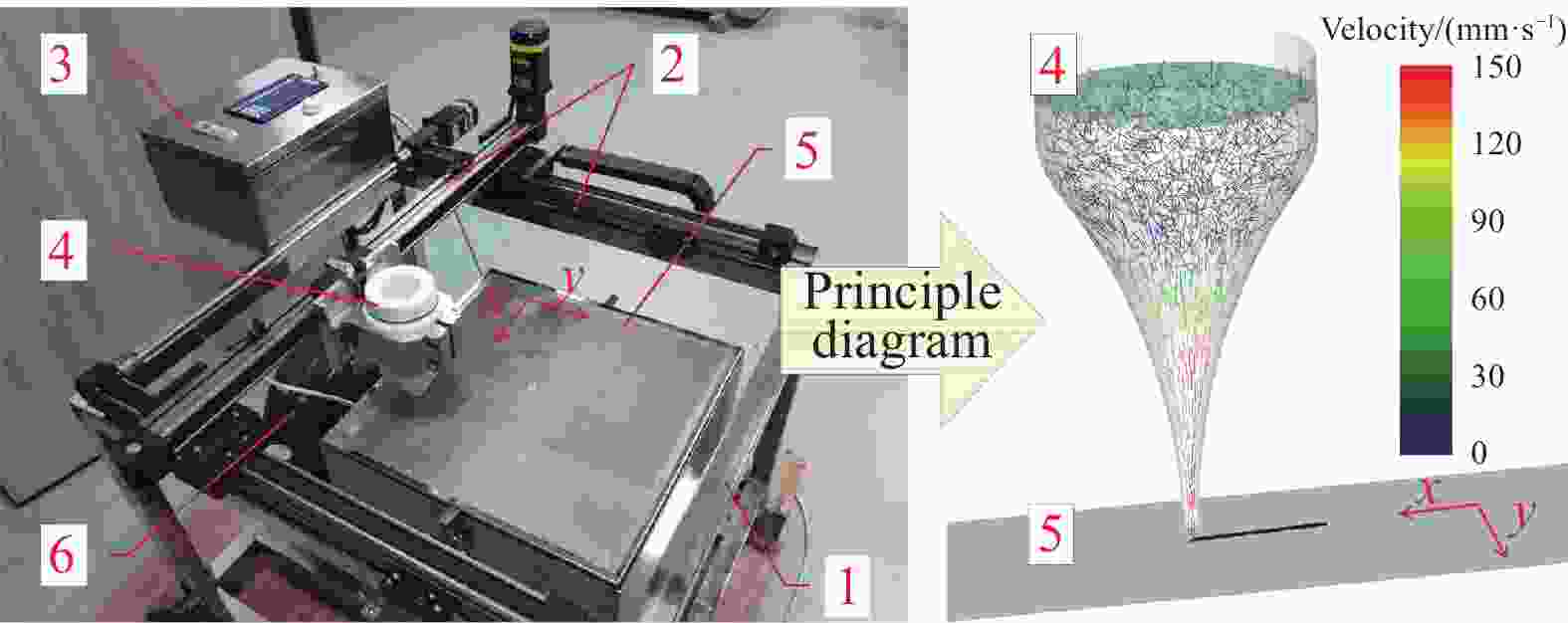

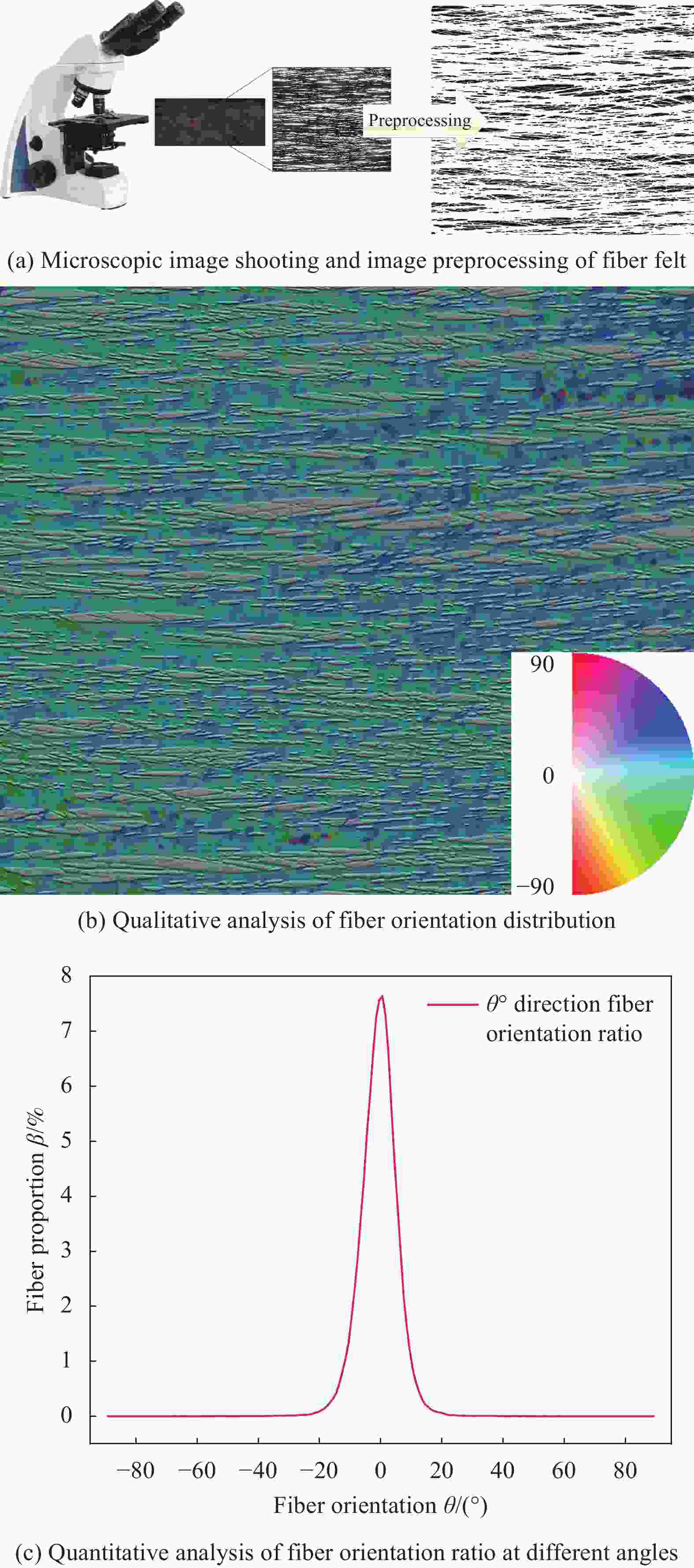

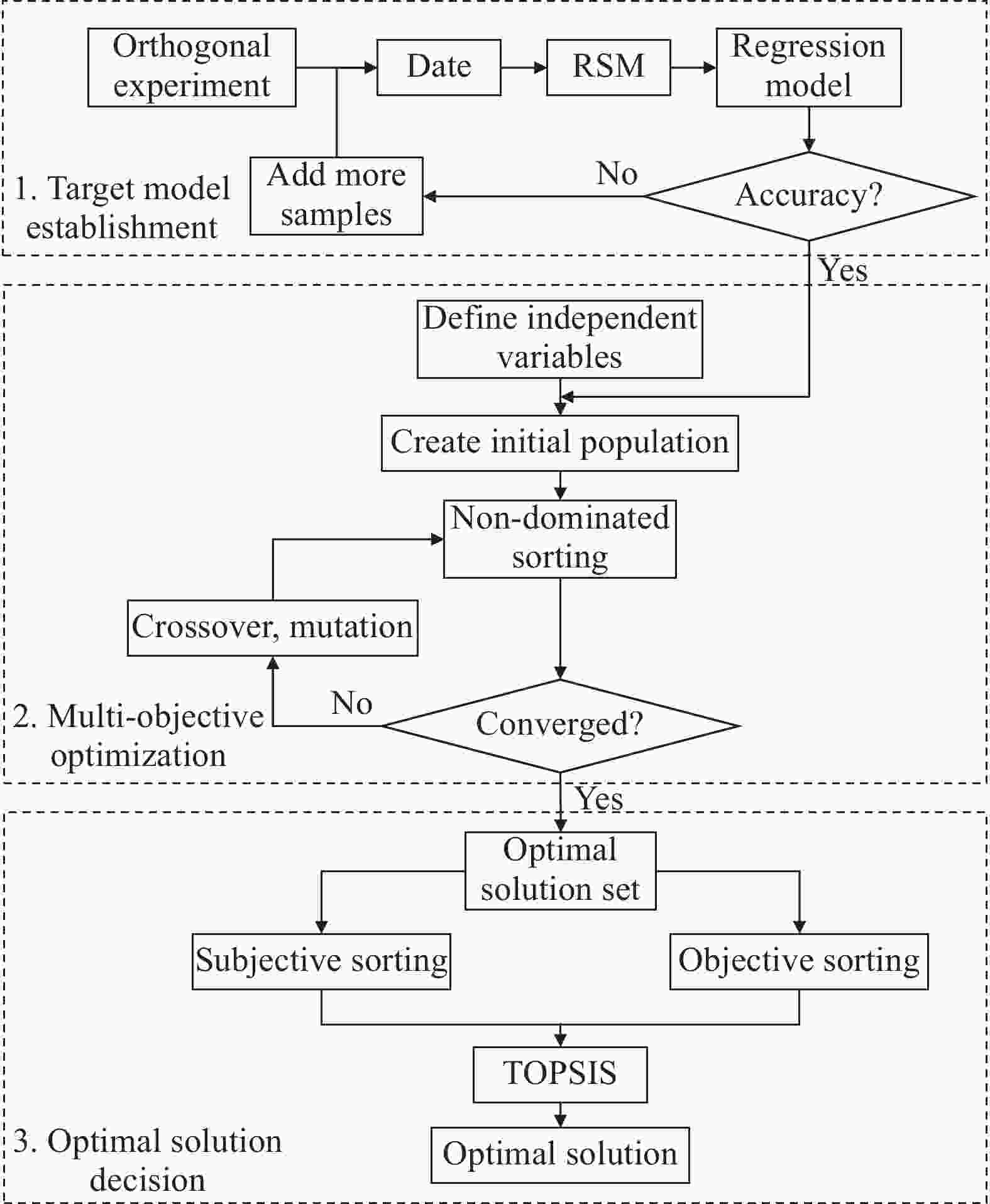

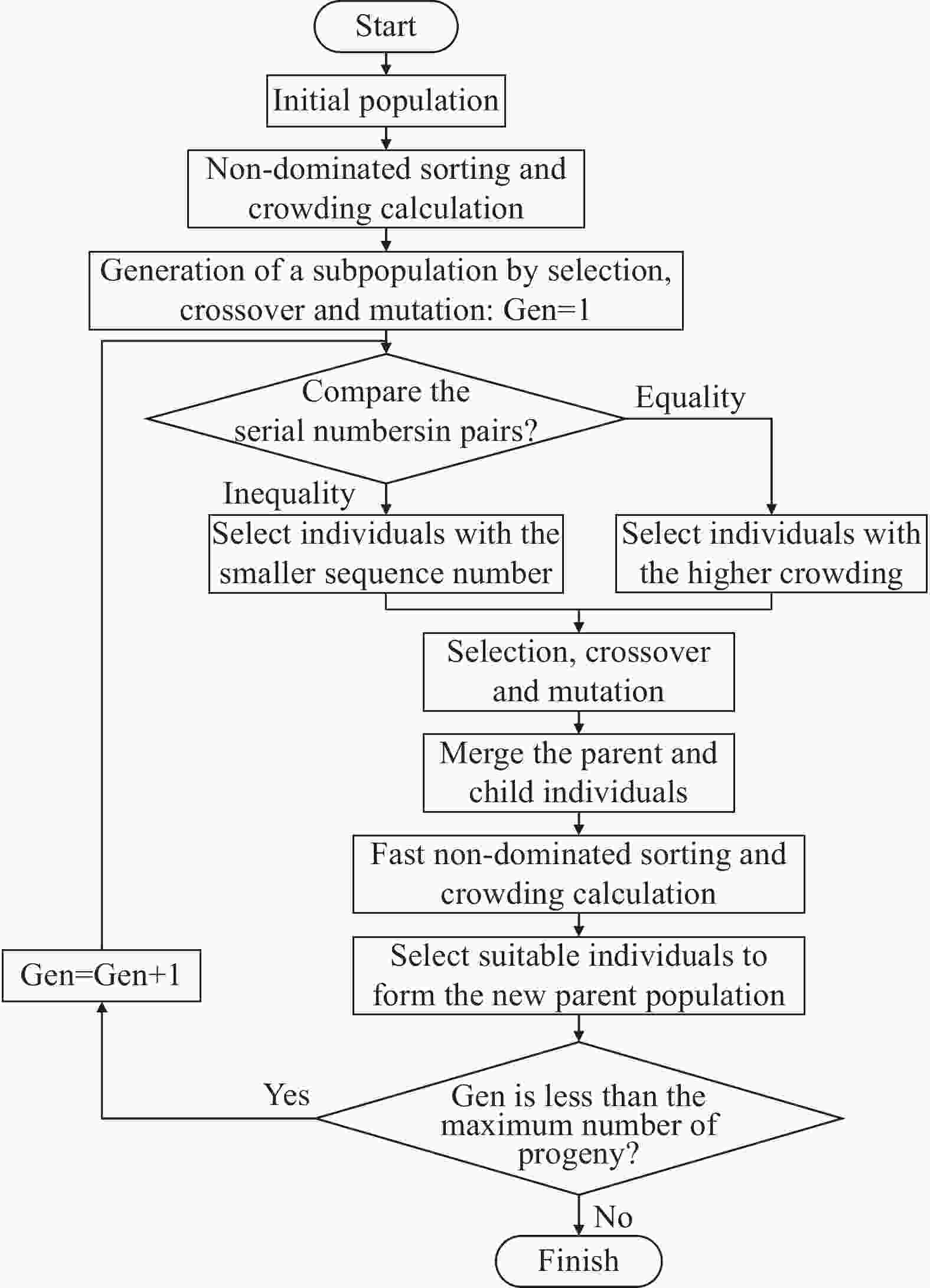

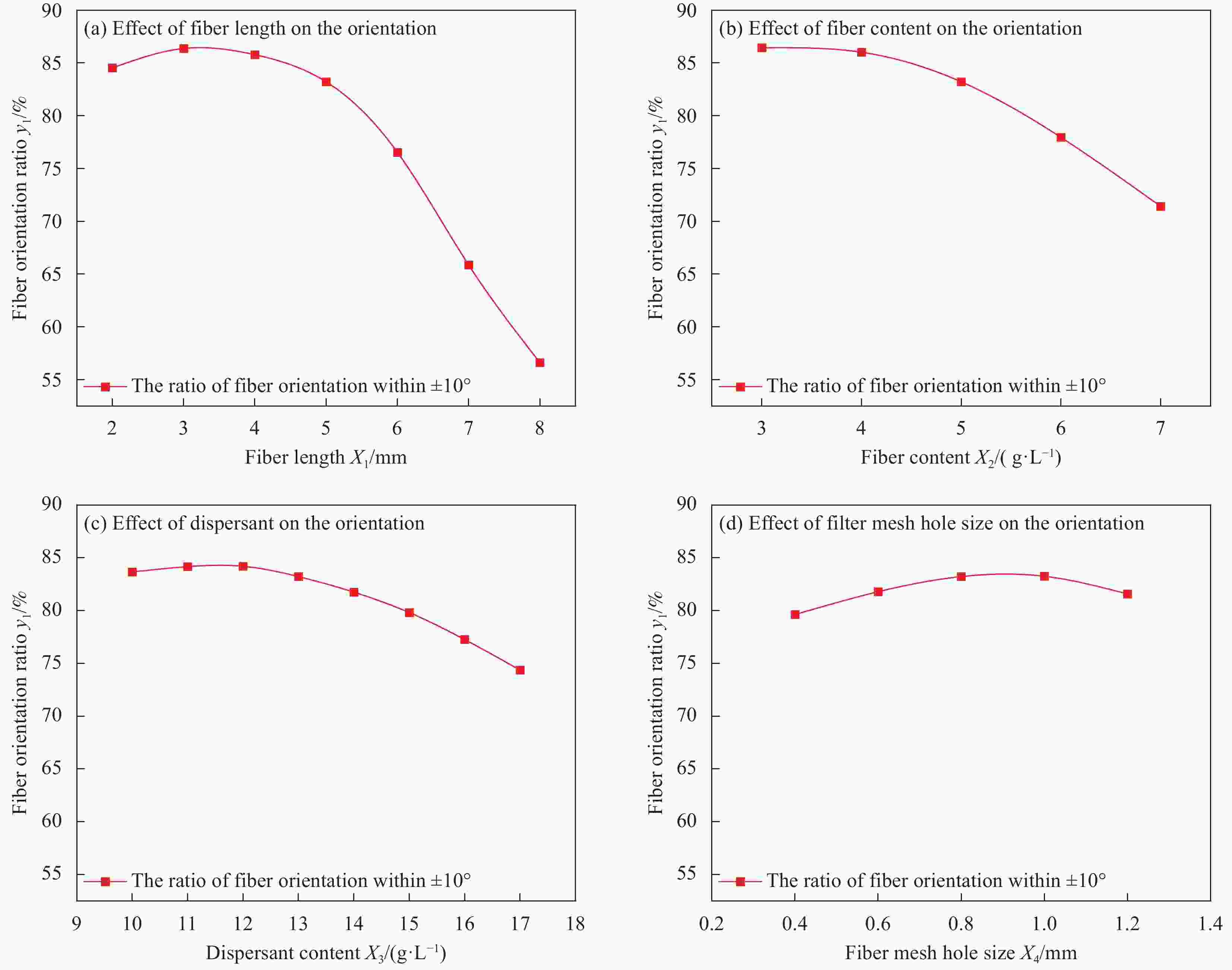

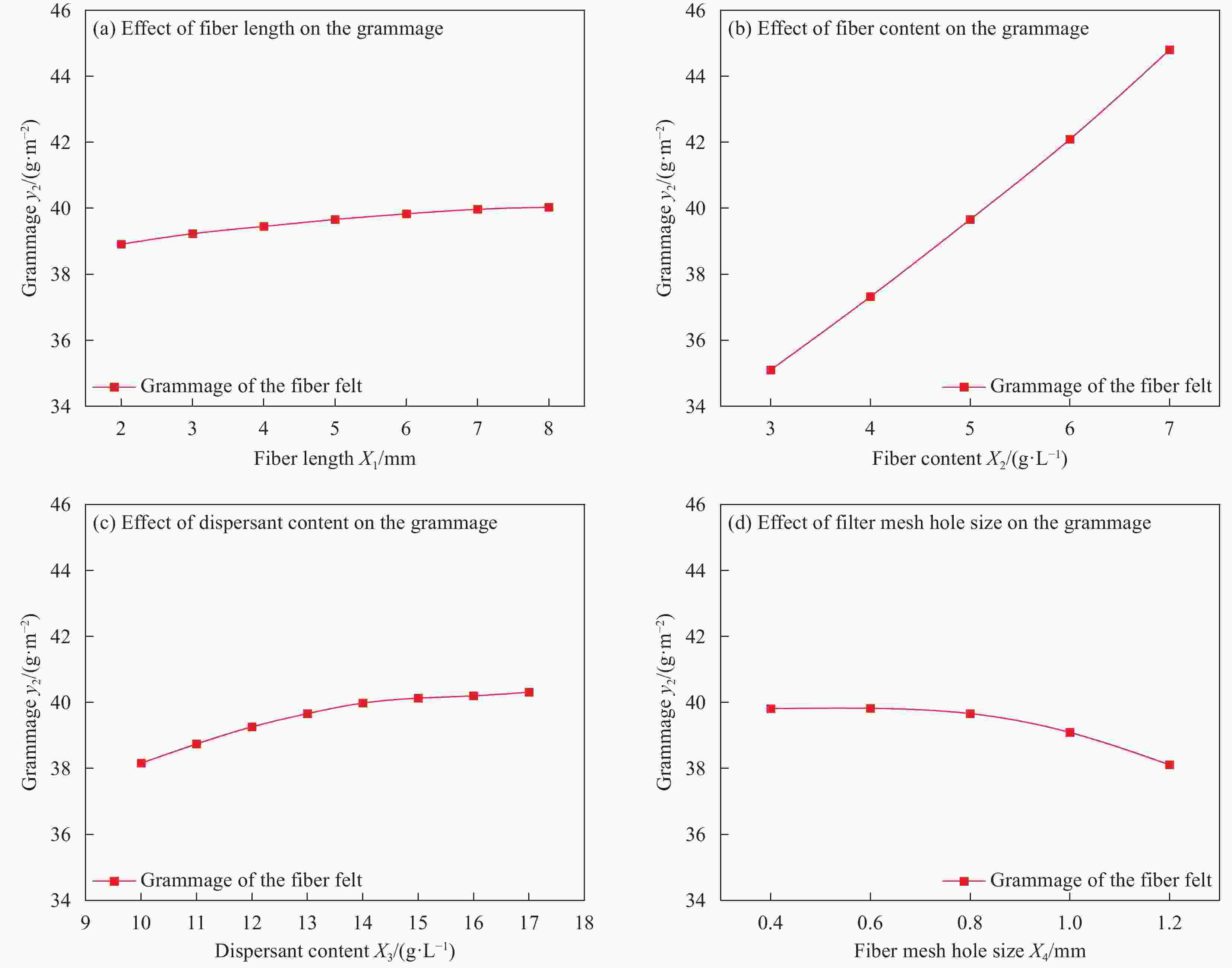

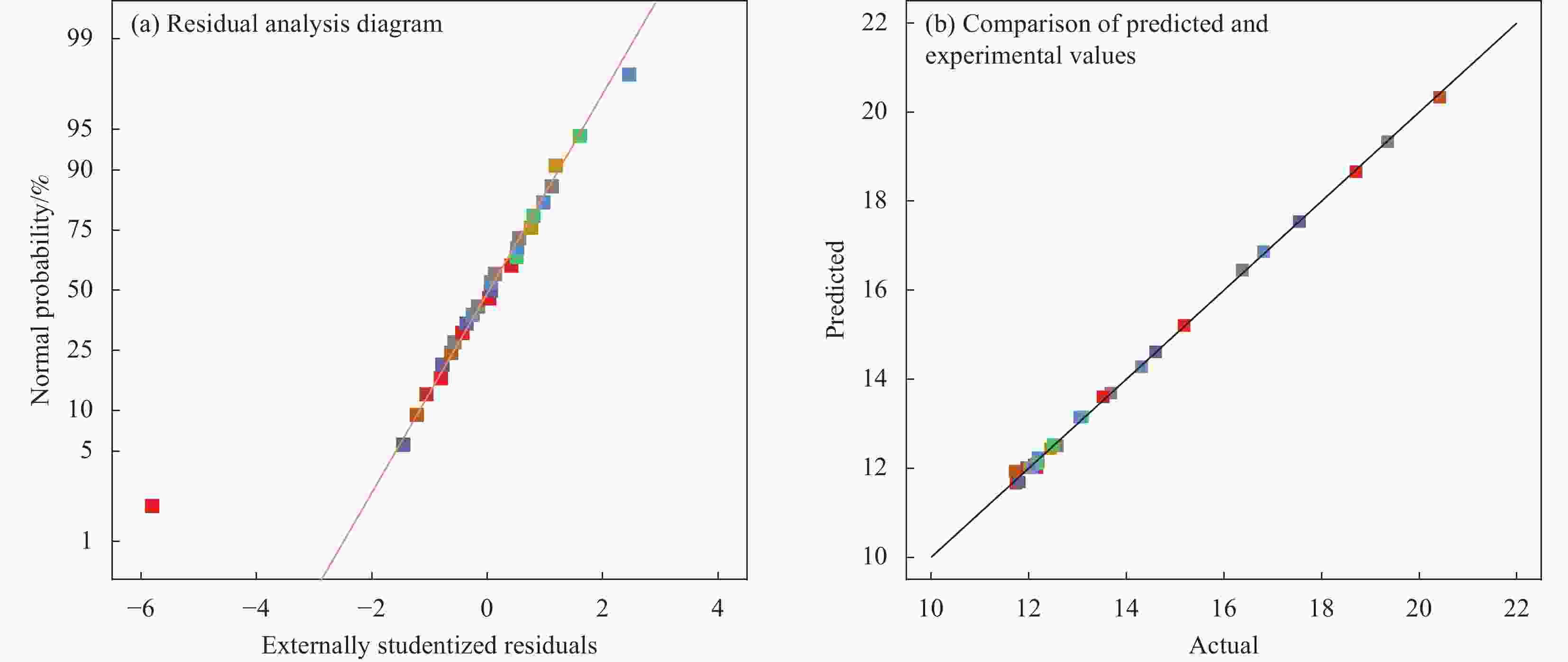

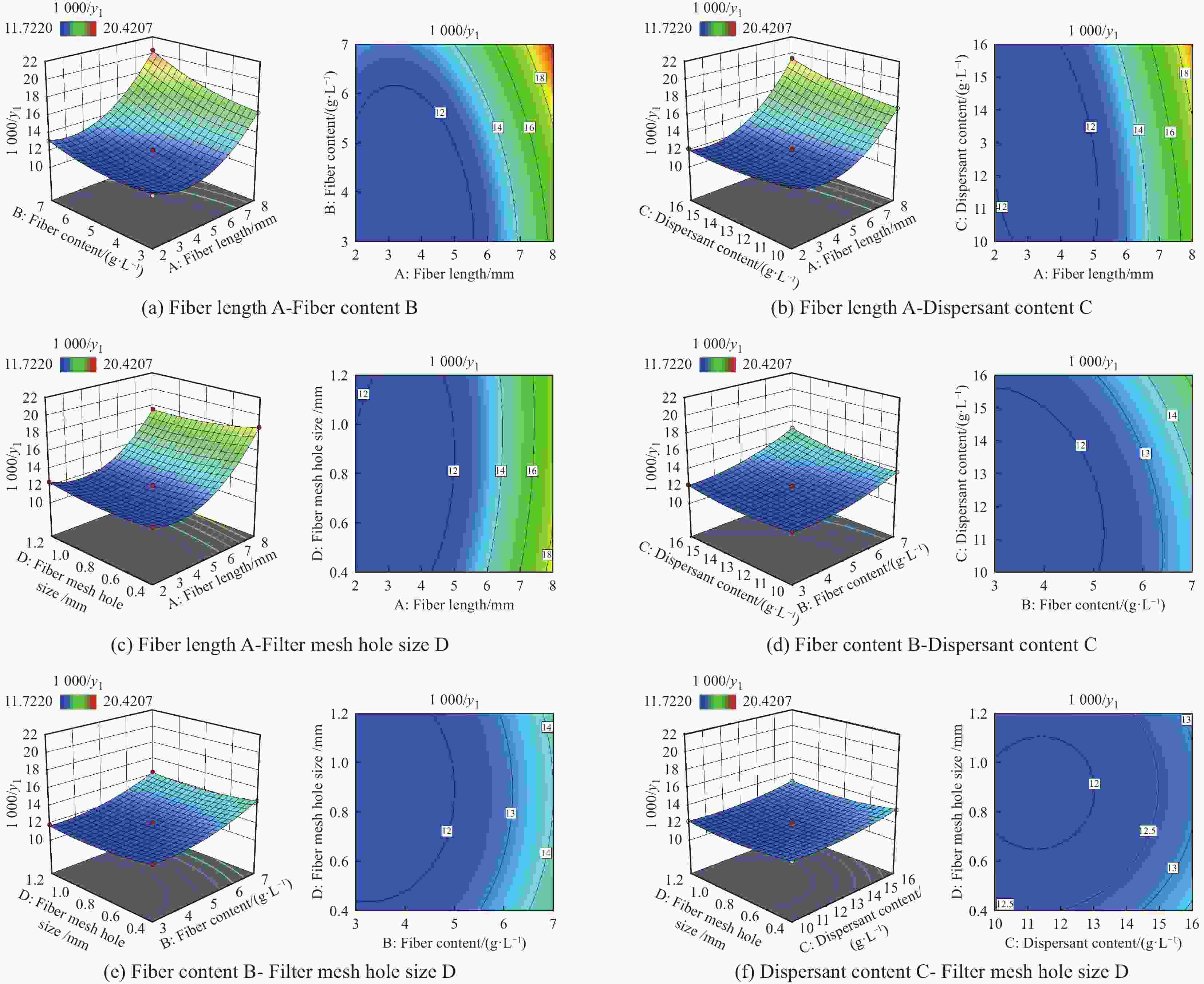

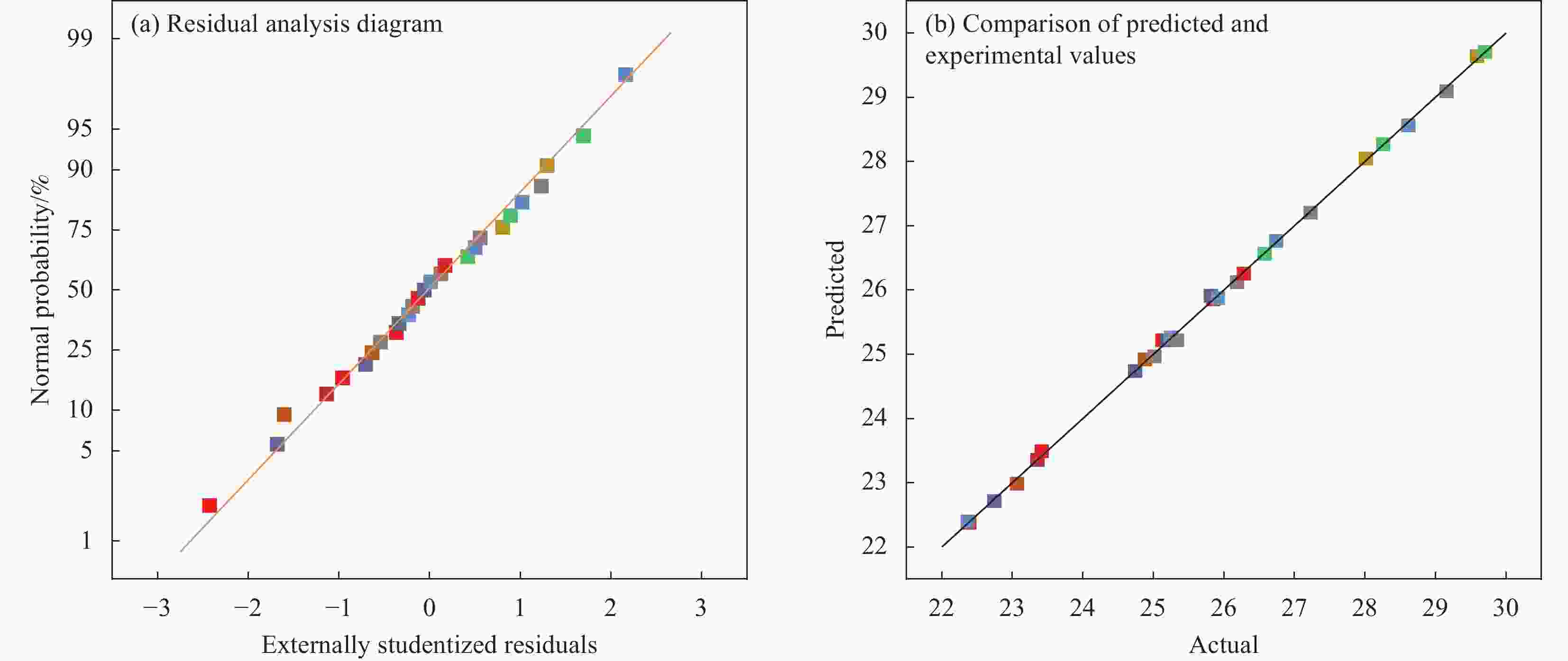

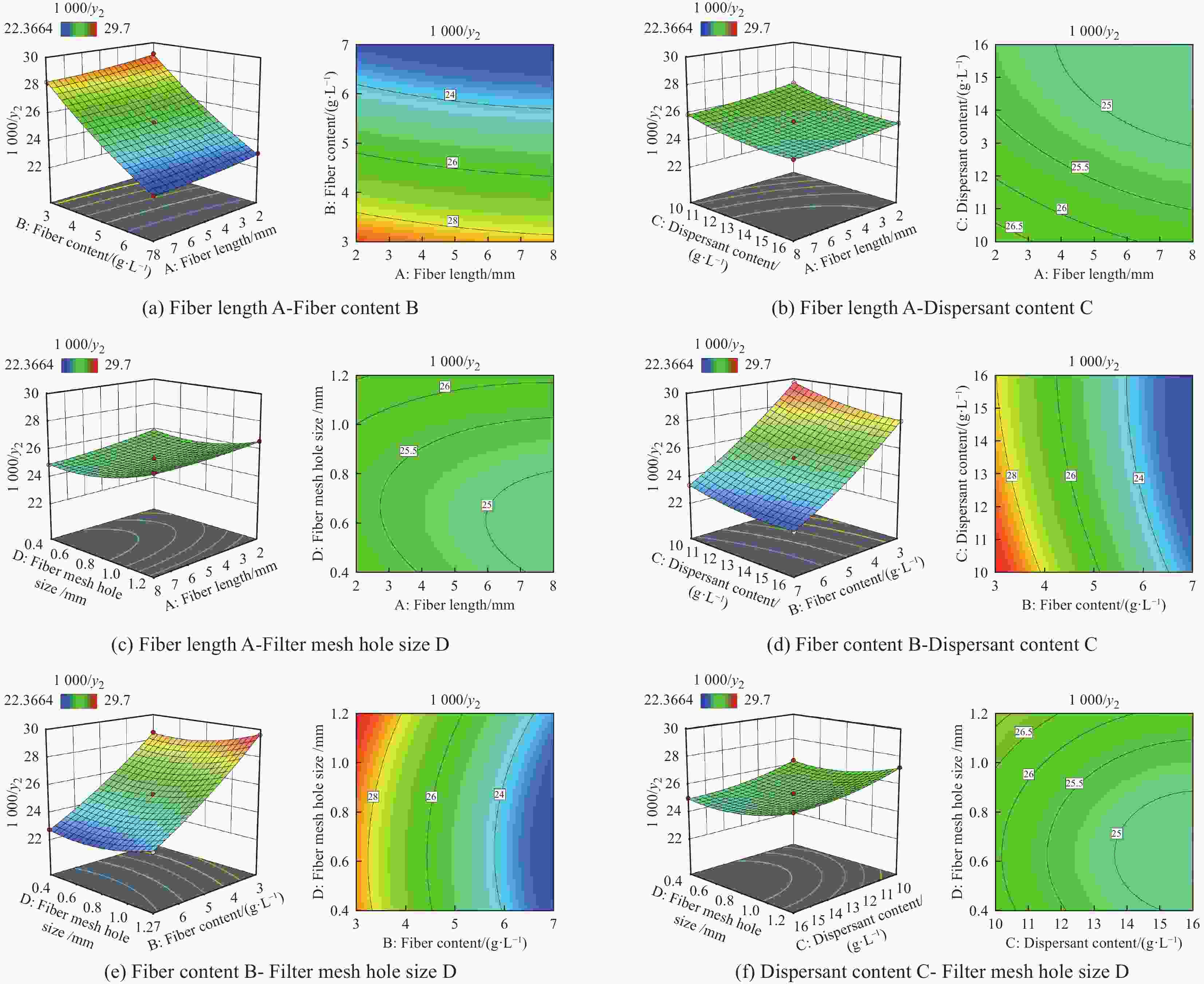

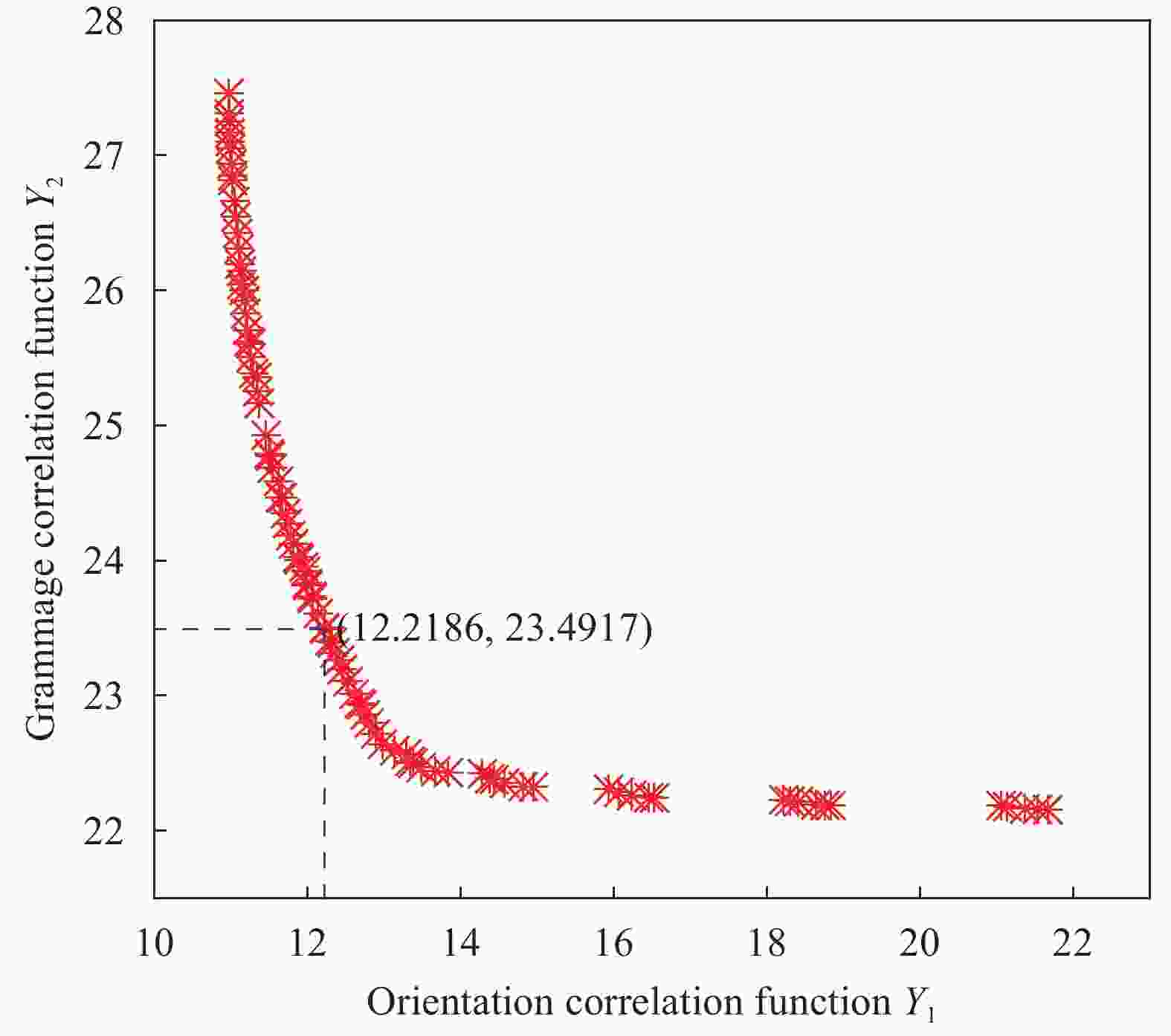

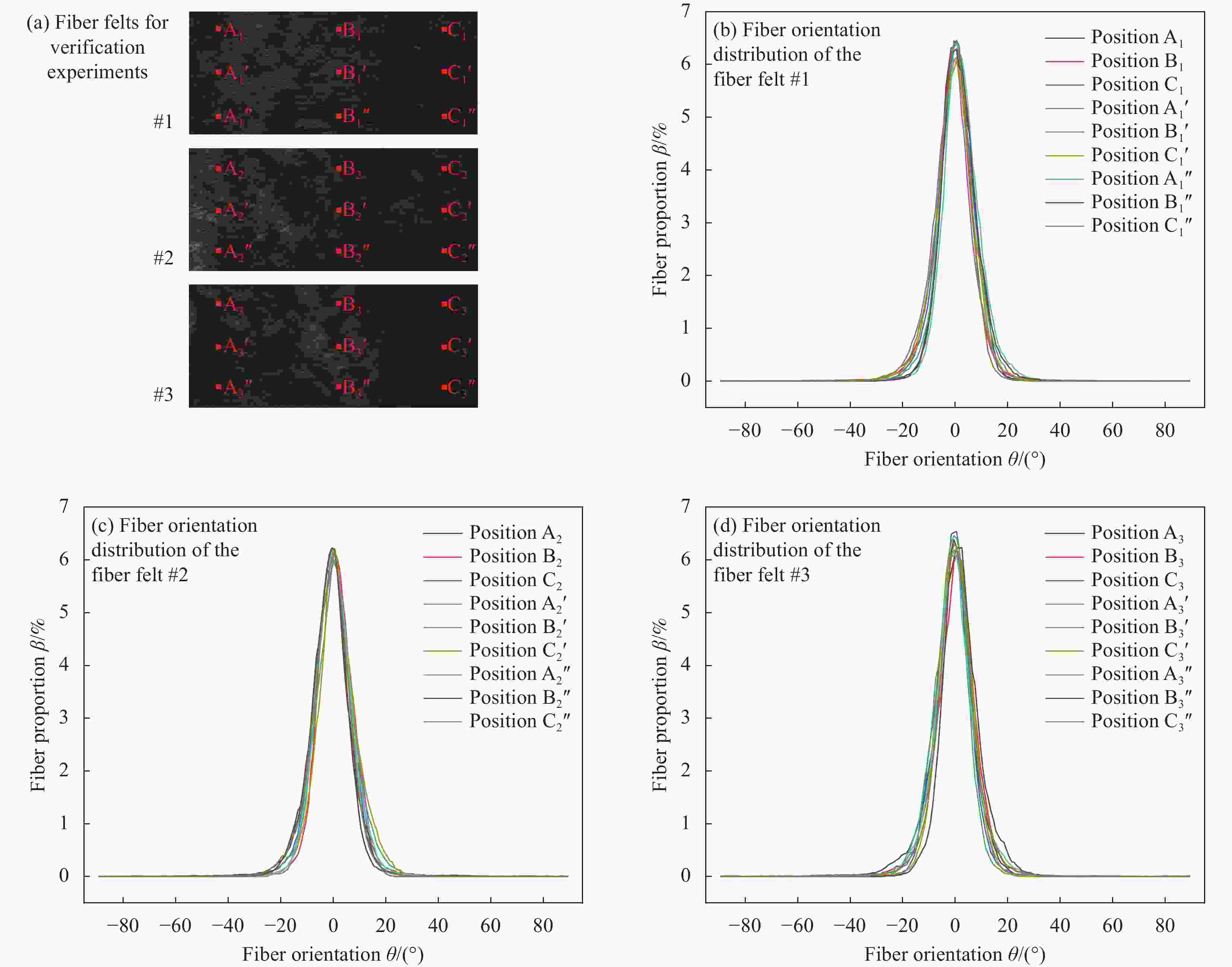

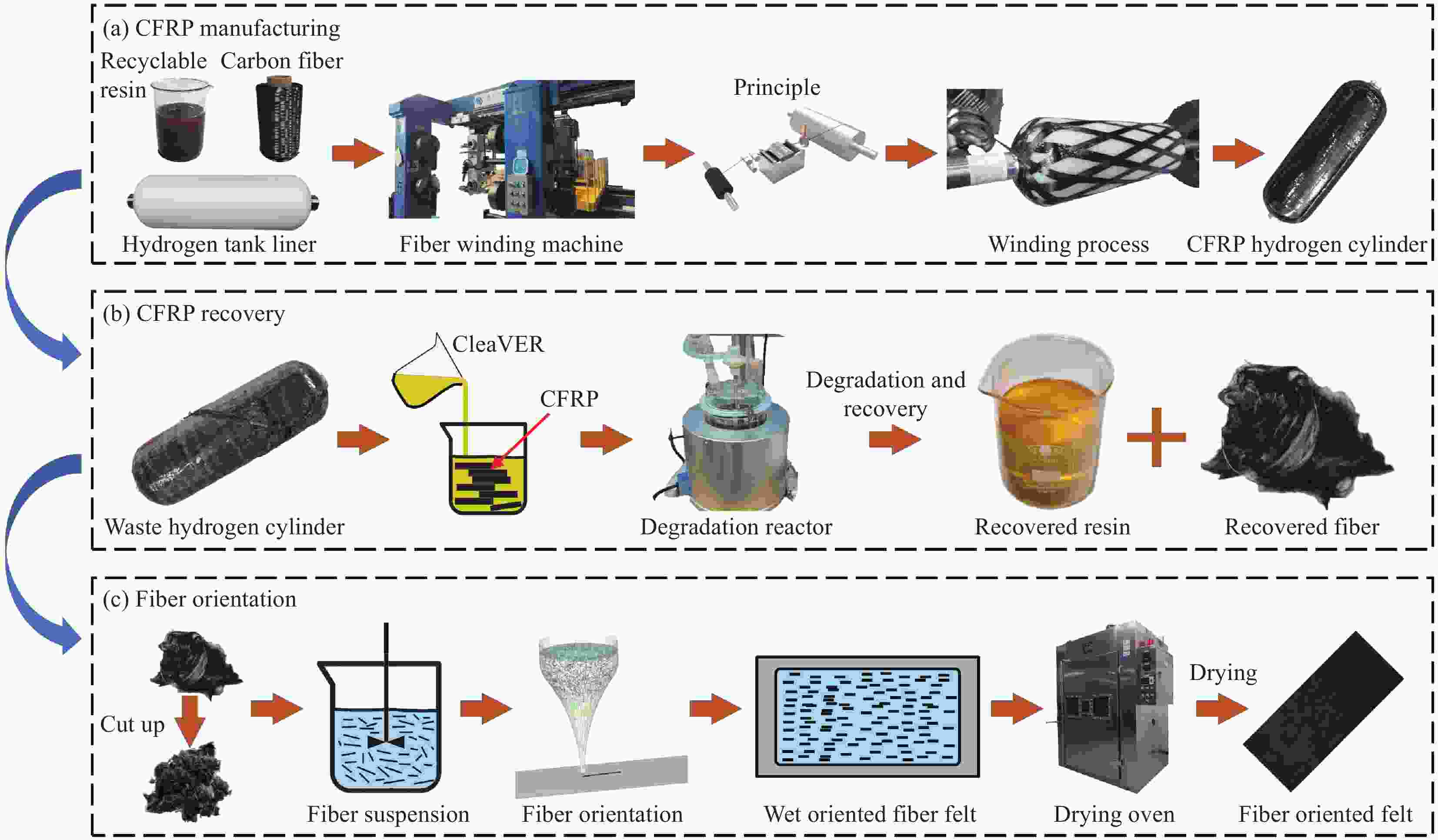

摘要: 废弃复合材料的回收再利用具有重要意义,传统回收方法能耗高且易损伤材料结构,回收纤维取向杂乱,无法进行高价值利用。本文采用团队研发的新型可回收环氧树脂制备Ⅳ型储氢气瓶废弃复合材料为对象,研究碳纤维的高效回收方法。自主搭建纤维湿法取向装置制备纤维毡,探究湿法取向过程各工艺对再生纤维毡制备效果包括取向度及克重的影响;利用响应面法(RSM)建立取向度和克重目标模型并进行可靠性分析,结合非支配排序遗传算法Ⅱ(NSGA-Ⅱ)对湿法取向工艺参数进行多目标优化;采用优劣解距离法(TOPSIS)决策选择最优解,实验验证多目标优化结果。结果表明:各工艺条件对纤维毡取向度影响大小为纤维长度>纤维含量>分散剂含量>滤网孔径;对纤维毡克重影响大小为纤维含量>分散剂含量>滤网孔径>纤维长度。目标函数模型具有较高的准确性;多目标优化纤维毡制备最佳工艺为纤维长度3 mm、纤维含量6.37 g/L、分散剂含量13.37 g/L、滤网孔径0.75 mm;验证实验制备纤维毡取向度81.08%,与遗传算法预测取向度(81.84%)误差0.94%;实验制备纤维毡克重42.86 g/m2,与遗传算法预测克重(42.57 g/m2)误差0.68%。Abstract: It is of great significance to realize the recycling and reuse of waste composite materials. Traditional recycling methods consume high energy and are easy to damage the material structure of the fibers. The recycled fibers are oriented in a disorderly manner and cannot be utilized for high value. In this research, the new recyclable epoxy resin developed by our team was used to manufacture type IV hydrogen storage vessel, and the efficient recycling method of carbon fiber from waste composite hydrogen cylinder was studied. The fiber wet orientation device was designed independently to prepare oriented fiber felt. The effects of various process in the wet orientation process on the quality of regenerated fiber felt samples, including orientation degree and weight, were explored. The response surface method (RSM) was used to establish the objective models related to the orientation and grammage of the fiber felt, and the reliability of the models were analyzed. Based on the models, the non-dominated sorting genetic algorithm Ⅱ (NSGA-Ⅱ) was used to perform multi-objective optimization of the parameters of fiber wet orientation process. The optimal solution was selected using technique for order preference by similarity to ideal solution (TOPSIS), and experiments were designed to verify the results of multi-objective optimization. The results show that the impact of various process conditions on the orientation of fiber felt is ranked as fiber length > fiber content > dispersant content > filter mesh hole size. And the order of the impact of various process conditions on the grammage of fiber felt is fiber content > dispersant content > filter mesh hole size > fiber length. The objective function models are very reliable for analyzing the orientation and grammage of the fiber felt. Through the multi-objective optimization algorithm, the optimal process parameters for the preparation of regenerated fiber felt are fiber length 3 mm, fiber content 6.37 g/L, dispersant content 13.37 g/L, and filter mesh hole size 0.75 mm. The orientation degree of the fiber felt prepared by verification experiment is 81.08%, with an error of 0.94% from the orientation degree(81.84%) predicted by genetic algorithm. The grammage of the fiber felt experimentally prepared is 42.86 g/m2, with an error of 0.68% from the grammage(42.57 g/m2) predicted by genetic algorithm.

-

表 1 EzCiclo RB240环氧树脂混合物基本属性

Table 1. The basic properties of EzCiclo RB240 epoxy resin mixtures

Property quantitative value Blending ratio of A and B (weight ratio) 100∶100(±2) Viscosity-25℃/cps 800~1200 Viscosity-40℃/cps 200~400 Liquid state density-25℃/(g·cm−3) 1.10~1.20 Density after curing-25℃/(g·cm−3) 1.15~1.25 Operable time-30℃/h >8 表 2 单因素实验方案设计及结果

Table 2. Single factor experimental scheme design and experimental results

$ {X}_{1} $/mm $ {X}_{2} $/(g·L−1) $ {X}_{3} $/(g·L−1) $ {X}_{4} $/mm $ {y}_{1} $/% $ {y}_{2} $/(g·m−2) 1 2 5 13 0.8 84.54 38.91 2 3 5 13 0.8 86.38 39.23 3 4 5 13 0.8 85.79 39.45 4 5 5 13 0.8 83.22 39.66 5 6 5 13 0.8 76.53 39.83 6 7 5 13 0.8 65.87 39.97 7 8 5 13 0.8 56.62 40.03 8 5 3 13 0.8 86.45 35.1 9 5 4 13 0.8 86.02 37.32 10 5 6 13 0.8 77.96 42.09 11 5 7 13 0.8 71.42 44.8 12 5 5 10 0.8 83.65 38.16 13 5 5 11 0.8 84.16 38.74 14 5 5 12 0.8 84.2 39.26 15 5 5 14 0.8 81.74 39.98 16 5 5 15 0.8 79.81 40.13 17 5 5 16 0.8 77.26 40.2 18 5 5 17 0.8 74.36 40.31 19 5 5 13 0.4 79.62 39.81 20 5 5 13 0.6 81.79 39.82 21 5 5 13 1.0 83.25 39.09 22 5 5 13 1.2 81.58 38.11 Notes:$ {X}_{1} $ is the length of the regenerated fiber; $ {X}_{2} $ is the content of fibers in the dispersing solution; $ {X}_{3} $ is the content of dispersant in the dispersing solution; $ {X}_{4} $ is the size of the filter mesh hole; $ {y}_{1} $ is the ratio of fiber orientation within ±10°; $ {y}_{2} $ is the grammage of the fiber felt 表 3 再生纤维毡质量主要影响工艺参数取值范围

Table 3. The value range of process parameters which mainly affect the quality of recycled fiber felt

$ {X}_{1} $/mm $ {X}_{2} $/(g·L−1) $ {X}_{3} $/(g·L−1) $ {X}_{4} $/mm Value range 2~8 3~7 10~16 0.4~1.2 Notes:$ {X}_{1} $ is the length of the regenerated fiber; $ {X}_{2} $ is the content of fibers in the dispersing solution; $ {X}_{3} $ is the content of dispersant in the dispersing solution; $ {X}_{4} $ is the size of the filter mesh hole. 表 4 取向工艺四因素三水平正交实验方案

Table 4. The orthogonal experiment scheme with four factors and three levels of orientation technology

$ {X}_{1} $/mm $ {X}_{2} $/(g·L−1) $ {X}_{3} $/(g·L−1) $ {X}_{4} $/mm $ {Y}_{1} $ $ {Y}_{2} $ 1 2 5 13 0.8 11.722 29.155 2 3 5 13 0.8 16.375 28.498 3 4 5 13 0.8 13.101 23.052 4 5 5 13 0.8 20.421 23.047 5 6 5 13 0.8 12.500 26.281 6 7 5 13 0.8 13.523 25.342 7 8 5 13 0.8 12.195 26.802 8 5 3 13 0.8 13.048 25.615 9 5 4 13 0.8 12.115 25.641 10 5 6 13 0.8 18.702 25.510 11 5 7 13 0.8 12.449 26.157 12 5 5 10 0.8 17.544 25.773 13 5 5 11 0.8 11.737 29.700 14 5 5 12 0.8 13.680 23.629 15 5 5 14 0.8 12.191 28.329 16 5 5 15 0.8 15.181 23.105 17 5 5 16 0.8 12.585 26.738 18 5 5 17 0.8 16.807 26.344 19 5 5 13 0.4 12.167 25.714 20 5 5 13 0.6 19.350 25.602 21 5 5 13 1.0 12.165 28.612 22 5 5 13 1.2 14.599 22.847 Notes:$ {X}_{1} $ is the length of the regenerated fiber; $ {X}_{2} $ is the content of fibers in the dispersing solution; $ {X}_{3} $ is the content of dispersant in the dispersing solution; $ {X}_{4} $ is the size of the filter mesh hole; $ {Y}_{1} $ is the regression function related to orientation ratio of fiber orientation within ±10°; $ {Y}_{2} $ is the regression function related to grammage of the fiber felt. 表 5 取向度相关回归模型$ {Y}_{1} $方差分析

Table 5. Analysis of variance of the regression model $ {Y}_{1} $ related to the orientation

Source Sum of Squares df Mean Square F-value p-value Model 172.09 14 12.29 957.31 < 0.0001 $ {X}_{1} $ 102.43 1 102.43 7976.99 < 0.0001 $ {X}_{2} $ 19.51 1 19.51 1519.59 < 0.0001 $ {X}_{3} $ 2.96 1 2.96 230.20 < 0.0001 $ {X}_{4} $ 0.4233 1 0.4233 32.97 < 0.0001 $ {X}_{1}{X}_{2} $ 1.78 1 1.78 138.48 < 0.0001 $ {X}_{1}{X}_{3} $ 2.19 1 2.19 170.72 < 0.0001 $ {X}_{1}{X}_{4} $ 0.5562 1 0.5562 43.31 < 0.0001 $ {X}_{2}{X}_{3} $ 0.2746 1 0.2746 21.38 0.0006 $ {X}_{2}{X}_{4} $ 0.0015 1 0.0015 0.1155 0.7399 $ {X}_{3}{X}_{4} $ 0.0072 1 0.0072 0.5611 0.4683 $ {X}_1^2 $ 39.78 1 39.78 3098.24 < 0.0001 $ {X}_{2}^2 $ 2.80 1 2.80 218.21 < 0.0001 $ {X}_{3}^2 $ 1.01 1 1.01 78.41 < 0.0001 $ {X}_{4}^2 $ 1.00 1 1.00 78.00 < 0.0001 Residual 0.1541 12 0.0128 Lack of Fit 0.1488 10 0.0149 5.61 0.1607 Pure Error 0.0053 2 0.0027 Cor Total 172.25 26 R2 0.9991 R2Adj 0.9981 Notes:df is the degree of freedom; F is ratio between interclass variance and intraclass variance; p is used to evaluate the significance of the model and is related to F. 表 6 克重相关回归模型$ {Y}_{2} $方差分析

Table 6. Analysis of variance of the regression model $ {Y}_{2} $ related to the grammage

Source Sum of Squares df Mean Square F-value p-value Model 119.37 14 8.53 1489.50 < 0.0001 $ {X}_{1} $ 1.54 1 1.54 269.04 < 0.0001 $ {X}_{2} $ 107.97 1 107.97 18861.72 < 0.0001 $ {X}_{3} $ 5.14 1 5.14 898.25 < 0.0001 $ {X}_{4} $ 2.58 1 2.58 450.13 < 0.0001 $ {X}_{1}{X}_{2} $ 0.0123 1 0.0123 2.14 0.1688 $ {X}_{1}{X}_{3} $ 0.0372 1 0.0372 6.49 0.0256 $ {X}_{1}{X}_{4} $ 0.0750 1 0.0750 13.11 0.0035 $ {X}_{2}{X}_{3} $ 0.1231 1 0.1231 21.50 0.0006 $ {X}_{2}{X}_{4} $ 0.0229 1 0.0229 4.00 0.0687 $ {X}_{3}{X}_{4} $ 0.0005 1 0.0005 0.0828 0.7784 $ {X}_{1}^2 $ 0.0786 1 0.0786 13.73 0.0030 $ {X}_{2} ^2$ 0.6247 1 0.6247 109.13 < 0.0001 $ {X}_{3}^2 $ 0.5321 1 0.5321 92.95 < 0.0001 $ {X}_{4}^2 $ 1.56 1 1.56 272.64 < 0.0001 Residual 0.0687 12 0.0057 Lack of Fit 0.0458 10 0.0046 0.3999 0.8684 Pure Error 0.0229 2 0.0115 Cor Total 119.44 26 R2 0.9994 $R_{{\rm{Adj}}}^2 $ 0.9988 Notes:df is the degree of freedom; F is ratio between interclass variance and intraclass variance; p is used to evaluate the significance of the model and is related to F. 表 7 不同评估指标专家打分值

Table 7. Expert scores for different evaluation indicators

Expert number Indicator 1

(orientation)Indicator 2

(grammage)1 5 4 2 5 3 3 4 4 4 4 3 5 5 4 6 5 3 7 5 3 8 4 3 9 5 4 10 4 3 表 8 Pareto最优解集中次序前10的解

Table 8. The top 10 solutions in the Pareto solution set

Ranking Process parameters Evaluation indicators $ {R}_{m} $ Fiber

Length/mmFiber

content/(g·L−1)Dispersant

content/(g·L−1)Filter mesh

hole size/mmFiber orientation

ratio within ±10°/%Grammage/

(g·m−2)1 3 6.37 13.37 0.75 81.84 42.57 0.85192 2 3 6.46 13.37 0.75 81.28 42.77 0.85157 3 3 6.46 13.71 0.75 81.01 42.87 0.85115 4 3 6.2 13.98 0.7 82.29 42.37 0.85072 5 3 6.2 13.37 0.75 82.88 42.18 0.85002 6 3 6.58 13.37 0.7 80.43 43.07 0.84926 7 3 6.47 13.07 0.8 81.37 42.64 0.84921 8 3 6.2 13.98 0.8 82.37 42.29 0.84906 9 3 6.1 13.71 0.75 83.22 42.05 0.84880 10 3 6.1 13.37 0.75 83.46 41.95 0.84747 Notes:$ {R}_{m} $ is the proximity index of each non-dominated solution to the optimal level. 表 9 最优工艺参数实验验证结果

Table 9. Experimental verification results of optimal process parameters

Predicted value Fiber felt #1 Fiber felt #2 Fiber felt #3 Experimental mean Average error /% Fiber orientation ratio within ±10° /% 81.84 82.01 80.52 80.71 81.08 0.94% Grammage /(g·m−2) 42.57 41.85 43.57 43.16 42.86 0.68% -

[1] 李美琪, 李晓飞, 王瑞涛, 等. 碳纤维增强聚合物基复合材料界面特性研究进展[J]. 材料导报, 2023, 37(20): 229-240.LI Meiqi, LI Xiaofei, WANG Ruitao, et al. Research progress on the interface properties of carbon fiber reinforced polymer matrix composites[J]. Materials Review, 37(20): 229-240(in Chinese). [2] LIU L, JIA C, HE J, et al. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites[J]. Composites Science and Technology, 2015, 121: 56-72. doi: 10.1016/j.compscitech.2015.08.002 [3] 张登科, 王光辉, 方登科, 等. 碳纤维增强树脂基复合材料的应用研究进展[J]. 化工新型材料, 2022, 50(01): 1-5.ZHANG Dengke, WANG Guanghui, FANG Dengke, et al. Progress in application and research of carbon fiber reinforced resin matrix composites[J]. New Chemical Materials, 2021, 50(1): 1-5(in Chinese). [4] WERKEN N V D, TEKINALP H, KHANBOLOUKI P, et al. Additively manufactured carbon fiber-reinforced composites: State of the art and perspective[J]. Additive Manufacturing, 2020, 31: 100962. doi: 10.1016/j.addma.2019.100962 [5] MISHNAEVSKY L, BRANNER K, PETERSEN H N, et al. Materials for Wind Turbine Blades: An Overview[J]. Materials, 2017, 10(11): 1285. doi: 10.3390/ma10111285 [6] 胡侨乐, 端玉芳, 刘志, 等. 碳纤维增强聚合物基复合材料回收再利用现状[J]. 复合材料学报, 2022, 39(1): 64-76.HU Qiaole, DUAN Yufang, LIU Zhi, et al. Current status of carbon fiber reinforced polymer composites recycling and re-manufacturing[J]. Acta Materiae Compositae Sinica, 2022, 39(1): 64-76(in Chinese). [7] 张亚东. 碳纤维复合材料的回收与再利用技术研究[J]. 广东化工, 2022, 49(10): 26-7+52. doi: 10.3969/j.issn.1007-1865.2022.10.009ZHANG Yadong. Study on recycling and reuse technology of carbon fiber reinforced plastic[J]. Guangdong Chemical, 2022, 49(10): 26-7+52(in Chinese). doi: 10.3969/j.issn.1007-1865.2022.10.009 [8] KIM K-W, LEE H-M, AN J-H, et al. Recycling and characterization of carbon fibers from carbon fiber reinforced epoxy matrix composites by a novel super-heated-steam method[J]. Journal of Environmental Management, 2017, 203(P3): 872-9. [9] 邓建英. 微波热解碳纤维/环氧树脂复合材料回收碳纤维的研究 [D]; 昆明理工大学, 2020.DENG Jianying. Study on microwave pyrolysis of carbon fiber/epoxy composites to recover carbon fibers[D]. Kunming: Kunming University of Science and Technology, 2019(in Chinese). [10] JIANG J, DENG G, CHEN X, et al. On the successful chemical recycling of carbon fiber/epoxy resin composites under the mild condition[J]. Composites Science and Technology, 2017, 151: 243-251. doi: 10.1016/j.compscitech.2017.08.007 [11] LIU T, ZHANG M, GUO X, et al. Mild chemical recycling of aerospace fiber/epoxy composite wastes and utilization of the decomposed resin[J]. Polymer Degradation and Stability, 2017, 139: 20-27. doi: 10.1016/j.polymdegradstab.2017.03.017 [12] CHENG H, HUANG H, ZHANG J, et al. Degradation of carbon fiber-reinforced polymer using supercritical fluids[J]. Fibers and Polymers, 2017, 18(4): 795-805. doi: 10.1007/s12221-017-1151-4 [13] WANG B, MA S, YAN S, et al. Readily recyclable carbon fiber reinforced composites based on degradable thermosets: a review[J]. Green Chemistry, 2019. [14] 上纬新材料科技股份有限公司. 上纬荣获「JEC WORLD 2023 运动休闲领域创新奖」[EB/OL]; (2023-3-3)[2023-10-12]. http://www.swancor.com.cn/news_detail.aspx?id=247.Swancor Advanced Materials Co. , Ltd. Swancor won the "JEC WORLD 2023 Sports and Leisure Innovation Award" [EB/OL]; (2023-3-3)[2023-10-12]. http://www.swancor.com.cn/news_detail.aspx?id=247(in Chinese). [15] YAMAGUCHI A, HASHIMOTO T, KAKICHI Y, et al. Recyclable carbon fiber-reinforced plastics (CFRP) containing degradable acetal linkages: Synthesis, properties, and chemical recycling[J]. Journal of Polymer Science Part A:Polymer Chemistry, 2015, 53(8): 1052-1059. doi: 10.1002/pola.27575 [16] YANG P, ZHOU Q, LI X-Y, et al. Chemical recycling of fiber-reinforced epoxy resin using a polyethylene glycol/NaOH system[J]. Journal of Reinforced Plastics and Composites, 2014, 33(22): 2106-2114. doi: 10.1177/0731684414555745 [17] TUAN L, CHENG H, LIWEI W, et al. Eugenol-Derived Biobased Epoxy: Shape Memory, Repairing, and Recyclability[J]. Macromolecules, 2017, 50(21): 8588-8597. doi: 10.1021/acs.macromol.7b01889 [18] TAKAHASHI A, OHISHI T, GOSEKI R, et al. Degradable epoxy resins prepared from diepoxide monomer with dynamic covalent disulfide linkage[J]. Polymer, 2016, 82: 319-326. doi: 10.1016/j.polymer.2015.11.057 [19] VYAKARNAM M N, DRZAL L T. Composite material of aligned discontinuous fibers, US6025285(A) [P/OL].https://d.wanfangdata.com.cn/patent/ChJQYXRlbnROZXdTMjAyMzA5MDESDVVTMTk5NzA4MjYyMTUaCDQycTRremdh. [20] MIRONOV V S, PARK M. Electroflocking technique in the fabrication and performance enhancement of fiber-reinforced polymer composites[J]. Composites Science and Technology, 2000, 60(6): 927-933. doi: 10.1016/S0266-3538(99)00142-6 [21] TIMBRELL V. Alignment of carbon and other man‐made fibers by magnetic fields[J]. Journal of Applied Physics, 1972, 43(11): 4839-4840. doi: 10.1063/1.1661036 [22] 杨爱玉. 短纤维复合材料中的纤维取向控制[J]. 固体火箭技术, 1991, (2): 103-110.YANG Aiyu. Fiber orientation control in short fiber composites[J]. JOURNAL OF SOLID ROCKET TECHNOLOGY, 1991, (2): 103-110(in Chinese). [23] BAGG G, EVANS M, PRYDE A J C. The glycerine process for the alignment of fibres and whiskers[J]. Composites, 1969, 1(2): 97-100. doi: 10.1016/0010-4361(69)90007-X [24] YU H, LONGANA M L, JALALVAND M, et al. Pseudo-ductility in intermingled carbon/glass hybrid composites with highly aligned discontinuous fibres[J]. Composites, Part A. Applied science and manufacturing, 2015, 73A: 35-44. [25] 冯茜, 李擎, 全威, 等. 多目标粒子群优化算法研究综述[J]. 工程科学学报, 2021, 43(6): 745-753.Feng Qian, Li Qing, Quan Wei, et al. Overview of Multiobjective Particle Swarm Optimization Algorithm[J]. Chinese Journal of Engineering, 2021, 43(6): 745-753(in Chinese). [26] 王浩杰, 王晓强, 朱其萍, 等. 基于粒子群算法的超声滚挤压工艺参数多目标优化[J]. 塑性工程学报, 2022, 29(12): 47-55.WANG Haojie, WANG Xiaoqiang, ZHU Qiping, et al. Multi-objective Optimization of Ultrasonic Rolling Extrusion Process Parameters Based on Particle Swarm Optimization[J]. Journal of Plastic Engineering, 2022, 29(12): 47-55(in Chinese). [27] 王秋莲, 魏鹏, 段星皓. 基于响应面法和人工蜂群算法的数控车削工艺参数多目标优化[J]. 工业工程与管理, 2022, 27(3): 117-126.WANG Qiulian, WEI Peng, DUAN Xinghao. Multi-Objective Optimization of Computer Numerical Control Turning Process Parameters Based on Response Surface Method and Artificial Bee Colony Algorithm[J]. Industrial Engineering and Management, 2022, 27(3): 117-126(in Chinese). [28] 张鑫何, 白海清, 杨思瑞, 等. 基于遗传算法的钛合金SLM多目标优化[J]. 应用激光, 2023, 43(9): 23-31.ZHANG Xinhe, BAI Haiqing, YANG Sirui, et al. Multi-objective optimization of titanium alloy SLM based on Genetic Algorithm[J]. APPLIED LASER, 2023, 43(9): 23-31(in Chinese). [29] 邓明, 曹子荷, 王静南, 等. 缠绕张力对干法缠绕复合材料结构残余应力及回弹变形的影响[J]. 复合材料学报, 2023, 40(12): 6884-6896.DENG Ming, CAO Zihe, WANG Jingnan, et al. Investigation on the influence of winding tension on residual stress and spring-in deformation of dry wound composite structure[J]. Acta Materiae Compositae Sinica, 2023, 40(12): 6884-6896(in Chinese). [30] E M E, N T A, J S C, et al. A validated software application to measure fiber organization in soft tissue[J]. Biomechanics and modeling in mechanobiology, 2016, 15(6): 1467-1478. doi: 10.1007/s10237-016-0776-3 [31] ZSUZSANNA P, MARTIN S, DANIEL S, et al. Transforms and Operators for Directional Bioimage Analysis: A Survey[J]. Advances in anatomy, embryology, and cell biology, 2016, 219: 69-93. [32] 肖荣鸽, 庞琳楠, 刘亚龙. 天然气液化与BOG提氦联产工艺的设计与优化[J]. 油气储运, 2023, 42(12): 1352-1361.XIAO Rongge, PANG Linnan, LIU Yalong. Design and optimization of co-production process of natural gas liquefaction and BOG helium extraction[J]. Oil & Gas Storage and Transportation, 2023, 42(12): 1352-1361(in Chinese). [33] 邓聪颖, 游倩, 赵洋, 等. 多因素影响下基于Bagging-NSGAⅡ的数控铣削稳定性预测与优化研究[J/OL]. 工程科学与技术. https://link.cnki.net/urlid/51.1773.TB.20231204.1340.004.DENG Congying, YOU Qian, ZHAO Yang, et al. Research on the Stability Prediction and Optimization of CNC Milling based on Bagging-NSGAⅡ under the Influence of Multiple Factors[J/OL]. Advanced Engineering Sciences. https://link.cnki.net/urlid/51.1773.TB.20231204.1340.004 (in Chinese). [34] 田应权, 尹瑞雪, 易望远, 等. 面向表面质量的镍基高温合金铣削参数多目标优化研究[J/OL]. 重庆理工大学学报(自然科学), https://link.cnki.net/urlid/50.1205.T.20231027.1532.002.TIAN Yingquan, YIN Ruixue, YI Wangyuan, et al. Research on multi-objective optimization of milling parameters for nickel based high-temperature alloys facing surface quality[J/OL]. Journal of Chongqing University of Technology (Natural Science), https://link.cnki.net/urlid/50.1205.T.20231027.1532.002 (in Chinese). [35] 闫倩, 郝春沣, 潘世兵, 等. 基于NSGA-Ⅱ算法的污水处理厂多目标优化模型研究[J]. 地理与地理信息科学, 2023, 39(6): 18-22.YAN Qian, HAO Chunfeng, PAN Shibing, et al. Research on multi-objective optimization model of wastewater treatment plant based on NSGA-Ⅱ algorithm[J]. Geography and Geo-Information Science, 2023, 39(6): 18-22(in Chinese). [36] 卜康正, 赵勇, 郑先昌. 基于NSGA2遗传算法的地铁隧道上方基坑工程优化设计[J]. 道科学与工程学报, 2021, 18(2): 459-467.BU Kangzheng, ZHAO Yong, ZHENG Xianchang. Optimization design for foundation pit above metro tunnel based on NSGA2 genetic algorithm[J]. Journal of Railway Science and Engineering, 2021, 18(2): 459-467(in Chinese). [37] 吴平川, 杨壮, 齐虎, 等. 基于组合赋权法与TOPSIS法的砌体结构加固方案优选[J]. 地震研究, 2024, 47(1): 146-155.WU Pingchuan, YANG Zhuang, QI Hu, et al. Optimization of masonry structure reinforcement scheme based on the combination weighting and TOPSIS methods[J]. Journal of Seismological Research, 2024, 47(1): 146-155(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 54

- HTML全文浏览量: 59

- 被引次数: 0

下载:

下载: