Nonlinear transient heat transfer analysis of functionally graded material sandwich slabs by incremental differential quadrature element method

-

摘要: 作为首次尝试,采用增量微分求积单元法(IDQEM)开展了功能梯度材料(FGM)夹层板的一维非线性瞬态传热分析。夹层板组分材料的热工参数随空间位置变化,且具有温度依赖性。基于IDQEM,沿层界面将夹层板划分为三个空间子域,同时将整个受热过程划分为若干时间子域。采用微分求积技术对任一时间子域内的控制方程、初始条件、界面条件以及边界条件进行离散处理。由于所获得的离散方程建立在不同区域的节点上,因此对方程进行修改并将其表示为矩阵形式,以便它们可以建立在同一区域中。采用Kronecker积将联立的矩阵方程转化为一系列代数方程组,并采用Newton-Raphson迭代法近似求解,即可获得单个时间子域内的温度解。由于每个时间子域的初始条件可由上一个时间子域最终时刻的温度分布决定,因此从第一个时间子域逐渐递推到最后一个子域,即可获得整个受热过程的温度分布。数值算例验证了本方法的快速收敛性,与已有文献的解析和数值结果的对比验证了本方法的正确性。最后,讨论了热工参数温度依赖性、体积分数指数以及热边界条件对FGM夹层板温度分布的影响。

-

关键词:

- 功能梯度材料夹层板 /

- 温度依赖性 /

- 瞬态传热 /

- 增量微分求积单元法 /

- Newton-Raphson迭代法

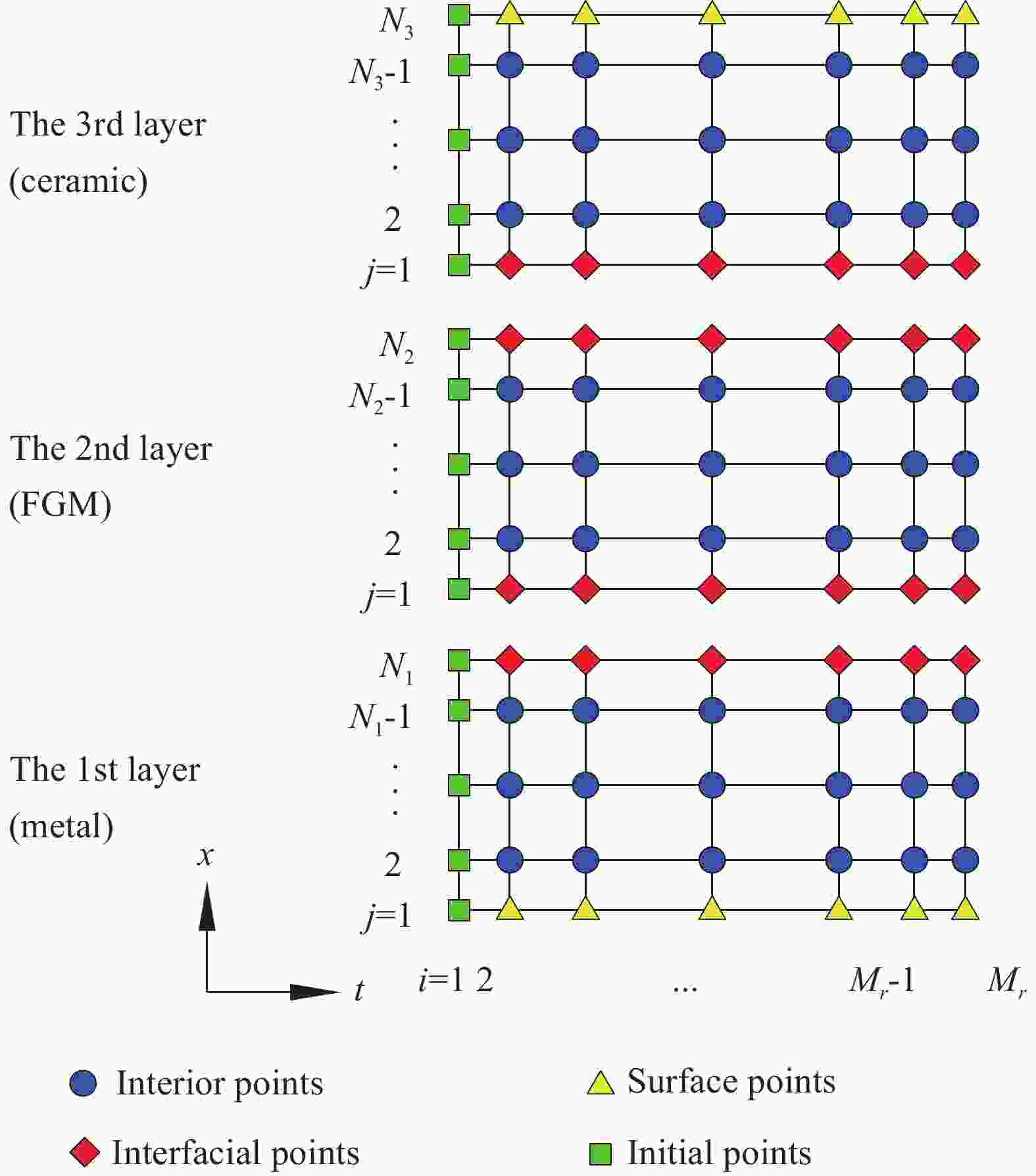

Abstract: As a first attempt, the incremental differential quadrature element method (IDQEM) was adopted to perform the one-dimensional nonlinear transient heat transfer analysis of functionally graded material (FGM) sandwich slabs. The thermophysical properties of the slab were considered to be position- and temperature-dependent. To implement the IDQEM, the sandwich slab was divided into three spatial sub-domains along the layer interfaces, and the entire heating process was also divided into several temporal sub-domains. For each temporal sub-domain, the governing equations as well as the initial condition, interfacial condition, and boundary condition were discretized by the differential quadrature technique. Because the obtained discrete equations were built in different regions of grid points, a modification of the equations was proposed which were then expressed in the matrix forms so that they can be built in the same regions. Using the Kronecker product, the simultaneous matrix equations were transformed into a set of nonlinear algebraic equations, which were then solved by the Newton-Raphson iteration method to obtain the temperature profile for each temporal sub-domain. Because the initial condition of each temporal sub-domain was defined by the temperature results at the end of the previous sub-domain, the temperature profile of the slab during the entire heating process can be obtained by repeating the calculation procedure from the first temporal sub-domain to the last one. Numerical examples were carried out to verify the fast convergence of the present method. The correctness of the present method was verified through comparison with the analytical and numerical results reported in previous works. The effects of temperature-dependent thermophysical properties, volume fraction index, and thermal boundary on the temperature profile of the slab were discussed. -

Material Property P0 P−1 P1 P2 P3 SUS304 λ/(W∙(m∙K)−1) 15.379 0 −1.264 × 10−3 2.092×10−6 −7.223×10−10 c/(J∙(kg∙K)−1) 496.56 0 −1.151×10−3 1.636×10−6 −5.863×10−10 ρ/(kg∙m−3) 8166.0 0 0 0 0 Si3N4 λ/(W∙(m∙K)−1) 13.723 0 −1.032× 10−3 5.466 × 10−7 −7.876×10−11 c/(J∙(kg∙K)−1) 555.11 0 1.016×10-3 2.920×10−7 −1.670×10−10 ρ/(kg∙m−3) 2370.0 0 0 0 0 Ti−6Al−4V λ/(W∙(m∙K)−1) 1.0000 0 1.704×10−2 0 0 c/(J∙(kg∙K)−1) 625.30 0 −4.224×10−4 7.179×10−7 0 ρ/(kg∙m−3) 4420.0 0 0 0 0 ZrO2 λ/(W∙(m∙K)−1) 1.7000 0 1.276×10−4 6.648×10−8 0 c/(J∙(kg∙K)−1) 487.34 0 3.049×10−4 −6.037×10−8 0 ρ/(kg∙m−3) 5700.0 0 0 0 0 Notes: λ, c, and ρ−Thermal conductivity, specific heat, and density, respectively; Pk (k = −1, 0, 1, 2, 3) − Temperature coefficients; SUS304, Si3N4, Ti−6Al−4V, and ZrO2 denote stainless steel, silicon nitride, titanium alloy, and zirconia, respectively. 表 2 η = 0.2时SUS304/Si3N4夹层板x = 0.75H处的温度结果(单位:K)

Table 2. Temperature results at x = 0.75H for the SUS304/Si3N4 sandwich slab with η = 0.2 (Unit: K)

Time Temporal grid point number Spatial grid point number N = 12 N = 20 N = 28 N = 36 t = 0.01 s M = 4 342.16 (0.0312 s) 342.96 (0.0625 s) 342.98 (0.0938 s) 342.99 (0.1154 s) M = 12 342.16 (0.1406 s) 343.01 (0.1719 s) 343.00 (0.2193 s) 343.01 (0.4688 s) M = 20 342.16 (0.1875 s) 343.01 (0.3281 s) 343.01 (0.5806 s) 343.01 (1.0312 s) M = 28 342.16 (0.2031 s) 343.01 (0.5156 s) 343.01 (1.1562 s) 343.01 (2.1094 s) t = 0.03 s M = 4 362.95 (0.0469 s) 362.80 (0.0712 s) 362.81 (0.1024 s) 362.80 (0.1193 s) M = 12 362.87 (0.1562 s) 362.69 (0.1736 s) 362.68 (0.2056 s) 362.68 (0.5021 s) M = 20 362.87 (0.1719 s) 362.70 (0.3598 s) 362.69 (0.6006 s) 362.69 (1.0156 s) M = 28 362.87 (0.2031 s) 362.70 (0.5469 s) 362.69 (1.0625 s) 362.69 (2.2188 s) Notes: M and N – Total numbers of grid points in the temporal and spatial domains, respectively. The content in parentheses represents the CPU-time. 表 3 两种情况下数值结果和CPU计算时间的对比

Table 3. Comparison of numerical results and CPU-time in the two cases

Position Time/s Case 1/K Case 2/K Error CPU-time of case 1/s CPU-time of case 2/s x = 0.25H 0.01 302.43 301.40 0.34% 0.6094 0.6310 0.03 314.28 312.23 0.66% 0.5938 0.5781 x = 0.75H 0.01 349.05 343.01 1.76% 0.6094 0.6310 0.03 365.93 362.69 0.89% 0.5938 0.5781 Notes: In Case 1, only the thermal conductivity is considered to be TD; in Case 2, all the thermophysical properties are considered to be TD. 表 4 时变热流的多项式拟合

Table 4. Polynomial fits for the time-dependent heat flux

Time/s a0 a1 a2/10−3 a3/10−6 0-431.1 0 0.003196 1.021 −1.383 431.1-660.2 −228.7 1.595 −2.670 1.471 660.2-1561 253.4 −0.5961 −0.6477 −0.2043 1561-2200 −1257 2.307 −1.212 0.1929 Notes: ak (k = 0, 1, 2, 3) – Fitting coefficients. -

[1] 刘浩洋, 吕超雨, 石姗姗, 等. 芳纶纤维增韧碳纤维增强环氧树脂复合材料-铝蜂窝夹芯结构界面性能和增韧机制[J]. 复合材料学报, 2022, 39(2): 559-567.LIU Haoyang, LV Chaoyu, SHI Shanshan, et al. Interfacial toughening and toughening mechanism of aramid staple fiber to carbon fiber reinforced epoxy resin composite-aluminum honeycomb sandwich structure[J]. Acta Materiae Compositae Sinica, 2022, 39(2): 559-567 (in Chinese). [2] 李华冠, 丁颖, 章月, 等. 玻璃纤维立体织物增强环氧树脂泡沫夹层复合材料的制备及力学性能[J]. 复合材料学报, 2023, 40(1): 601-612.LI Huaguan, DING Ying, ZHANG Yue, et al. Preparation and mechanical properties of glass fiber reinforced 3D fabric reinforced epoxy foam sandwich composites[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 601-612 (in Chinese). [3] Xie H, Li W, Fang H, et al. Flexural behavior evaluation of a foam core curved sandwich beam[J]. Composite Structures, 2024, 328: 117729. doi: 10.1016/j.compstruct.2023.117729 [4] Wang X, Wang Z, Zeng T, et al. Exact analytical solution for steady-state heat transfer in functionally graded sandwich slabs with convective-radiative boundary conditions[J]. Composite Structures, 2018, 192: 379-386. doi: 10.1016/j.compstruct.2018.03.006 [5] Daikh A A, Megueni A. Thermal buckling analysis of functionally graded sandwich plates[J]. Journal of Thermal Stresses, 2018, 41(2): 139-159. doi: 10.1080/01495739.2017.1393644 [6] Daikh A A, Drai A, Bensaid I, et al. On vibration of functionally graded sandwich nanoplates in the thermal environment[J]. Journal of Sandwich Structures & Materials, 2021, 23(6): 2217-2244. [7] Shen H-S, Li S-R. Postbuckling of sandwich plates with FGM face sheets and temperature-dependent properties[J]. Composites Part B:Engineering, 2008, 39(2): 332-344. doi: 10.1016/j.compositesb.2007.01.004 [8] Pandey S, Pradyumna S. A finite element formulation for thermally induced vibrations of functionally graded material sandwich plates and shell panels[J]. Composite Structures, 2017, 160: 877-886. doi: 10.1016/j.compstruct.2016.10.040 [9] Pandey S, Pradyumna S. Transient stress analysis of sandwich plate and shell panels with functionally graded material core under thermal shock[J]. Journal of Thermal Stresses, 2018, 41(5): 543-567. doi: 10.1080/01495739.2017.1422999 [10] Malekzadeh P, Rahideh H. IDQ two-dimensional nonlinear transient heat transfer analysis of variable section annular fins[J]. Energy Conversion and Management, 2007, 48(1): 269-276. doi: 10.1016/j.enconman.2006.04.005 [11] Chen Y, Zhang L, He C, et al. Thermal insulation performance and heat transfer mechanism of C/SiC corrugated lattice core sandwich panel[J]. Aerospace Science and Technology, 2021, 111: 106539. doi: 10.1016/j.ast.2021.106539 [12] Striz A, Chen W, Bert C. Static analysis of structures by the quadrature element method[C]//35th Structures, Structural Dynamics, and Materials Conference. Reston, Virigina: American Institute of Aeronautics and Astronautics, 1994, 3(94): 1567–1574. [13] 沈景凤, 张翠, 刘方. 基于热弹性耦合理论的功能梯度材料薄壁旋转碟片力学性能[J]. 复合材料学报, 2019, 36(4): 1017-1028.SHEN Jingfeng, ZHANG Cui, LIU Fang. Thermally coupled analysis of thermoelastic field in a thin-walled rotating FGM circular disk[J]. Acta Materiae Compositae Sinica, 2019, 36(4): 1017-1028 (in Chinese). [14] 金晶, 邢誉峰, 廖选平, 等. 瞬态传热问题的微分求积和精细积分求解方法[J]. 北京航空航天大学学报, 2015, 41(8): 1526-1531.JIN Jing, XING Yufeng, LIAO Xuanping, et al. Application of differential quadrature and precise integration methods in analysis of transient heat transfer[J]. Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(8): 1526-1531 (in Chinese). [15] 林鹏程, 滕兆春. 热冲击下轴向运动FGM梁的自由振动分析[J]. 振动与冲击, 2020, 39(12): 249-256.LIN Pengcheng, TENG Zhaochun. Free vibration analysis of axially moving FGM beams under thermal shock[J]. Journal of Vibration and Shock, 2020, 39(12): 249-256 (in Chinese). [16] Wang X, Gu H. Static analysis of frame structures by the differential quadrature element method[J]. International Journal for Numerical Methods in Engineering, 1997, 40(4): 759-772. doi: 10.1002/(SICI)1097-0207(19970228)40:4<759::AID-NME87>3.0.CO;2-9 [17] Chen W, Striz A G, Bert C W. A new approach to the differential quadrature method for fourth-order equations[J]. International Journal for Numerical Methods in Engineering, 1997, 40(11): 1941-1956. doi: 10.1002/(SICI)1097-0207(19970615)40:11<1941::AID-NME145>3.0.CO;2-V [18] Malekzadeh P, Heydarpour Y, Haghighi M R G, et al. Transient response of rotating laminated functionally graded cylindrical shells in thermal environment[J]. International Journal of Pressure Vessels and Piping, 2012, 98: 43-56. doi: 10.1016/j.ijpvp.2012.07.003 [19] Dai T, Li B, Tao C, et al. Thermo-mechanical analysis of a multilayer hollow cylindrical thermal protection structure with functionally graded ultrahigh-temperature ceramic to be heat resistant layer[J]. Aerospace Science and Technology, 2022, 124: 107532. doi: 10.1016/j.ast.2022.107532 [20] Shen H-S, Xiang Y, Reddy J N. Assessment of the effect of negative Poisson’s ratio on the thermal postbuckling of temperature dependent FG-GRMMC laminated cylindrical shells[J]. Computer Methods in Applied Mechanics and Engineering, 2021, 376: 113664. doi: 10.1016/j.cma.2020.113664 [21] Wang Y, Feng C, Yang J, et al. Nonlinear vibration of FG-GPLRC dielectric plate with active tuning using differential quadrature method[J]. Computer Methods in Applied Mechanics and Engineering, 2021, 379: 113761. doi: 10.1016/j.cma.2021.113761 [22] Wang X, Yuan Z. Accurate stress analysis of sandwich panels by the differential quadrature method[J]. Applied Mathematical Modelling, 2017, 43: 548-565. doi: 10.1016/j.apm.2016.11.034 [23] Hao Y X, Cao Z, Zhang W, et al. Stability analysis for geometric nonlinear functionally graded sandwich shallow shell using a new developed displacement field[J]. Composite Structures, 2019, 210: 202-216. doi: 10.1016/j.compstruct.2018.11.027 [24] Zenkour A M, Sobhy M. Dynamic bending response of thermoelastic functionally graded plates resting on elastic foundations[J]. Aerospace Science and Technology, 2013, 29(1): 7-17. doi: 10.1016/j.ast.2013.01.003 [25] Reddy J N, Chin C D. Thermomechanical analysis of functionally graded cylinders and plates[J]. Journal of Thermal Stresses, 1998, 21(6): 593-626. doi: 10.1080/01495739808956165 [26] Wang B L, Tian Z H. Application of finite element-finite difference method to the determination of transient temperature field in functionally graded materials[J]. Finite Elements in Analysis and Design, 2005, 41(4): 335-349. doi: 10.1016/j.finel.2004.07.001 [27] Zhang Z, Zhou D, Zhang J, et al. Transient analysis of layered beams subjected to steady heat supply and mechanical load[J]. Steel and Composite Structures, 2021, 40(1): 87-100. [28] Uyanna O, Najafi H, Rajendra B. An inverse method for real-time estimation of aerothermal heating for thermal protection systems of space vehicles[J]. International Journal of Heat and Mass Transfer, 2021, 177: 121482. doi: 10.1016/j.ijheatmasstransfer.2021.121482 -

点击查看大图

点击查看大图

计量

- 文章访问数: 46

- HTML全文浏览量: 33

- 被引次数: 0

下载:

下载: