Mechanical properties of micro silicon powder -rubber/cement mortar under dynamic and static loading

-

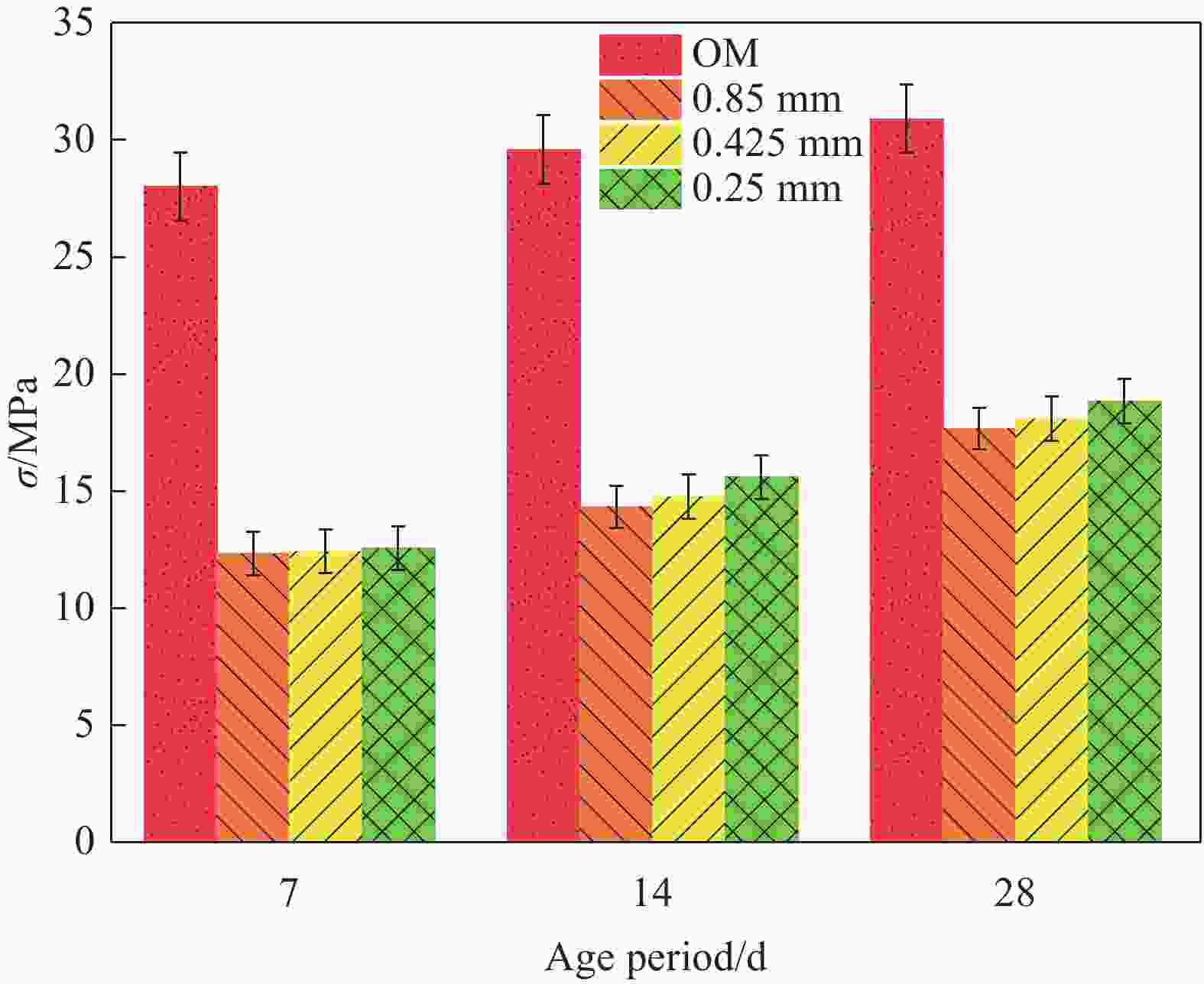

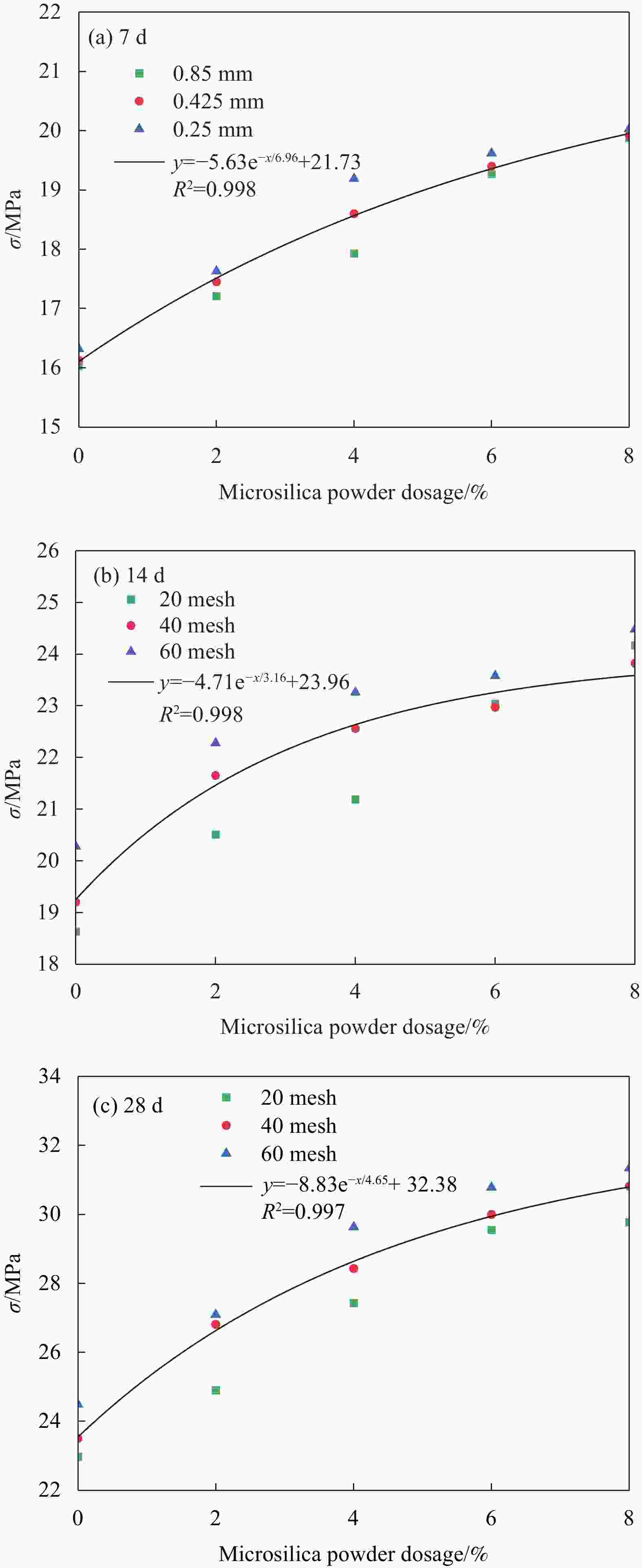

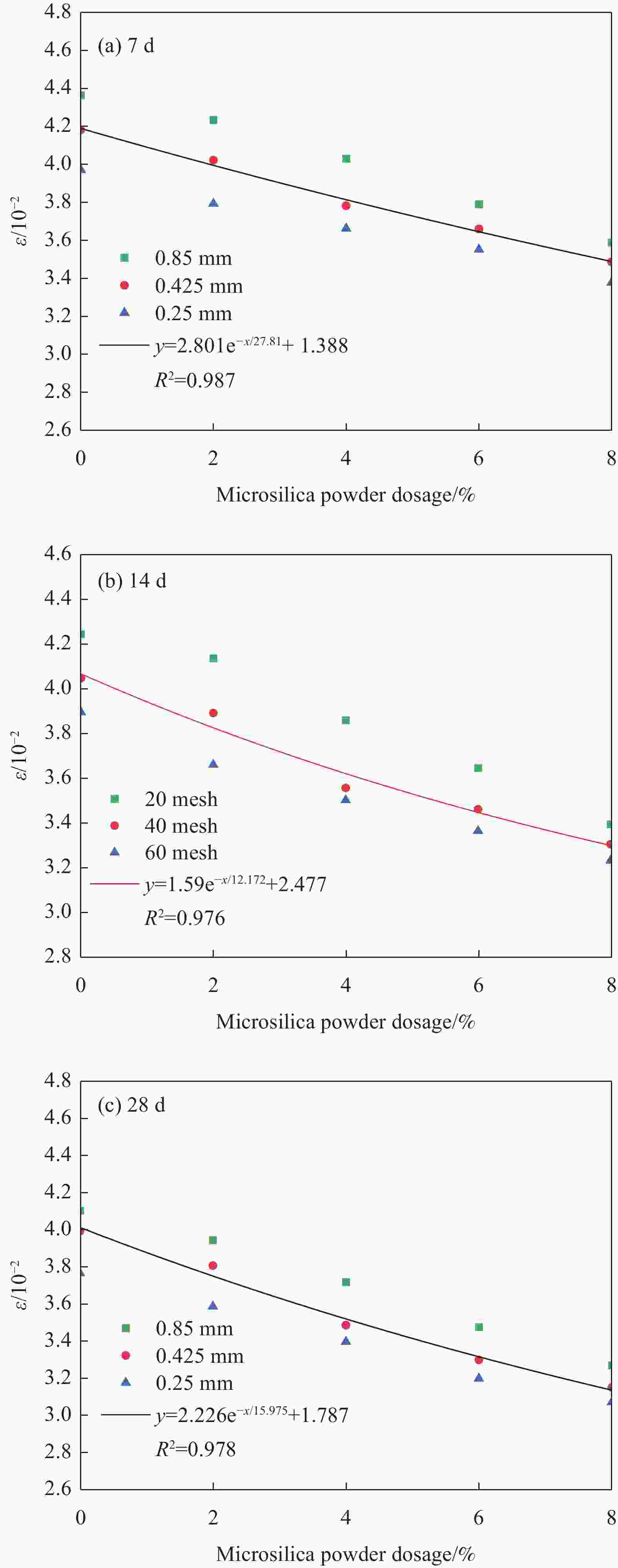

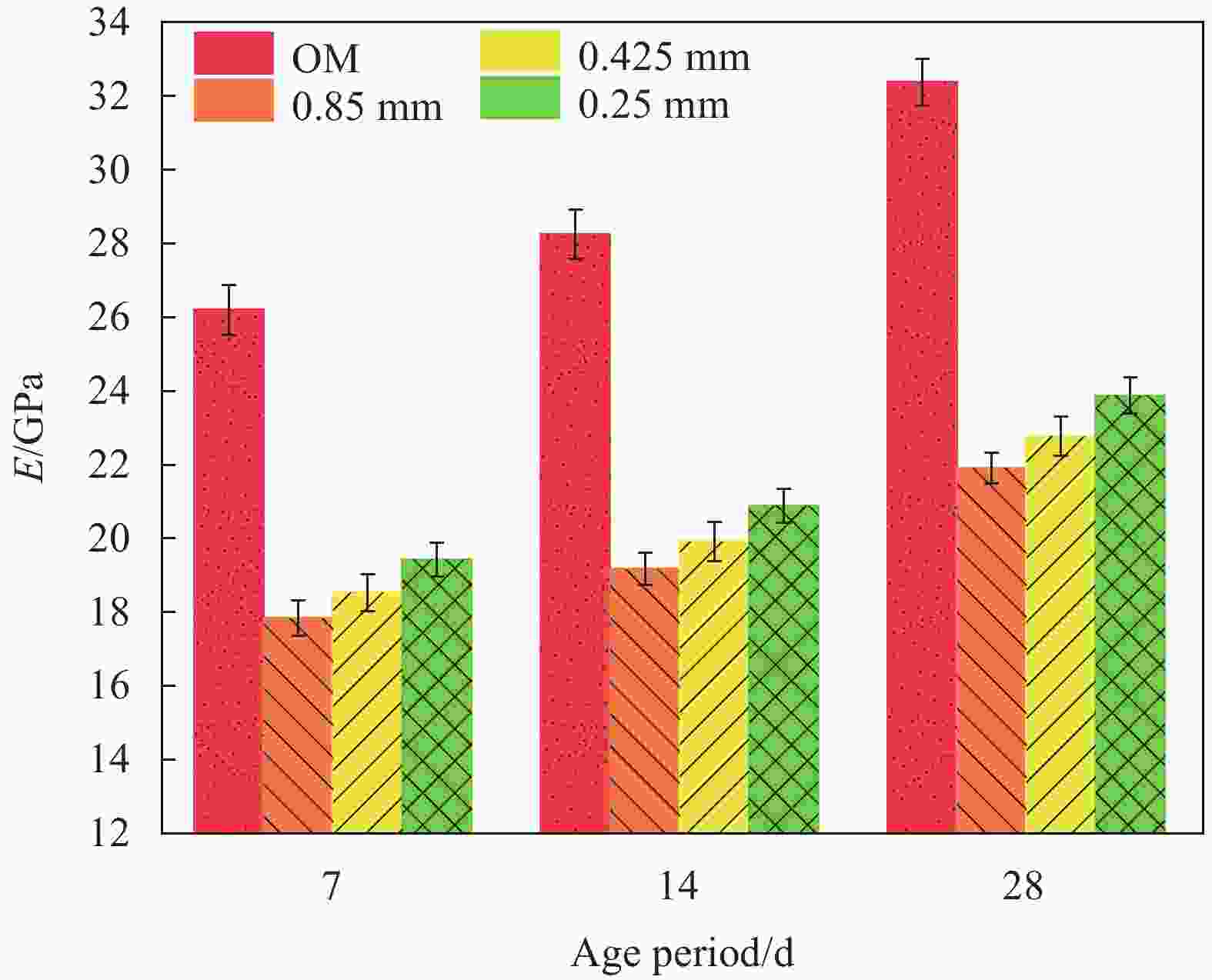

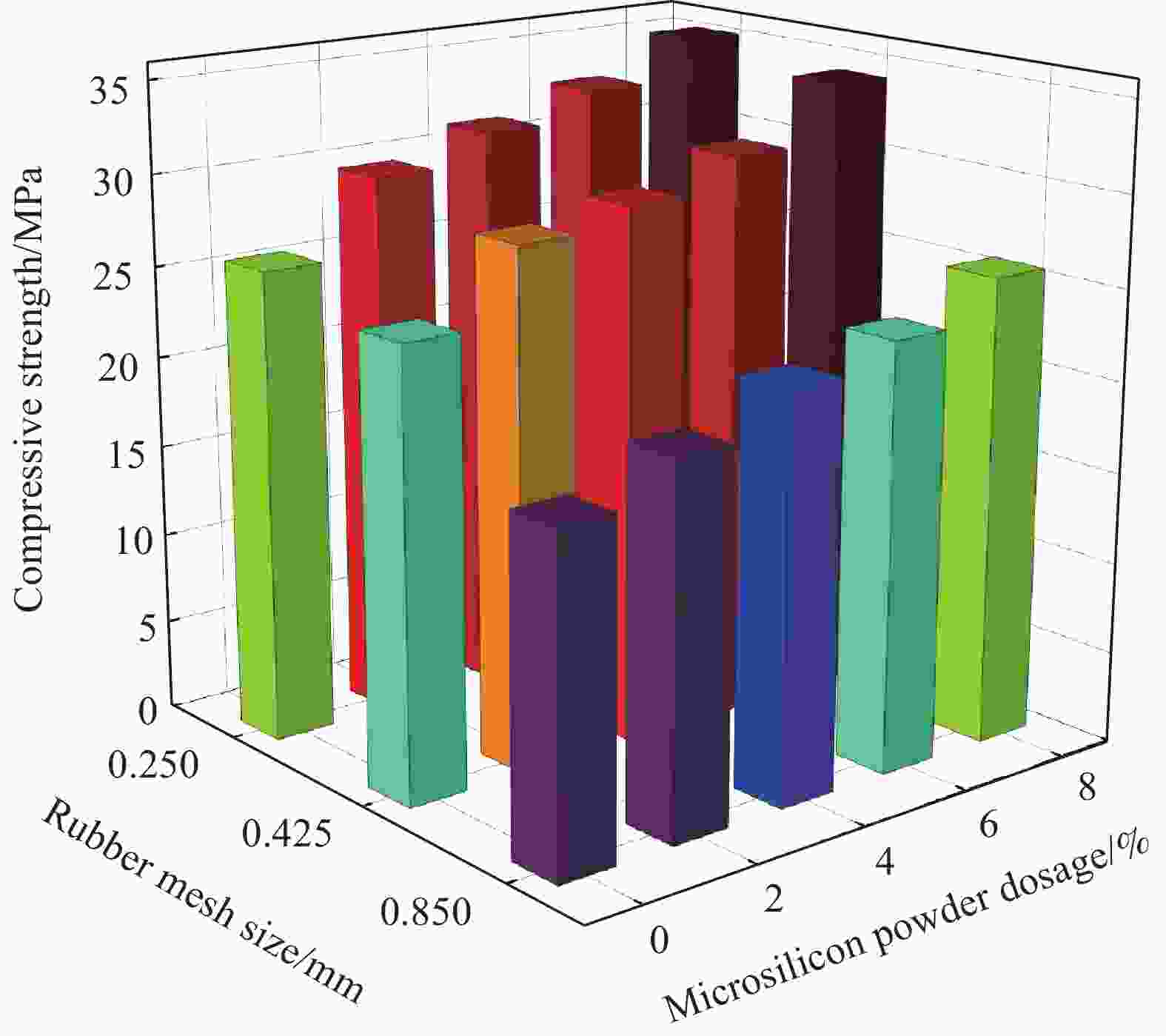

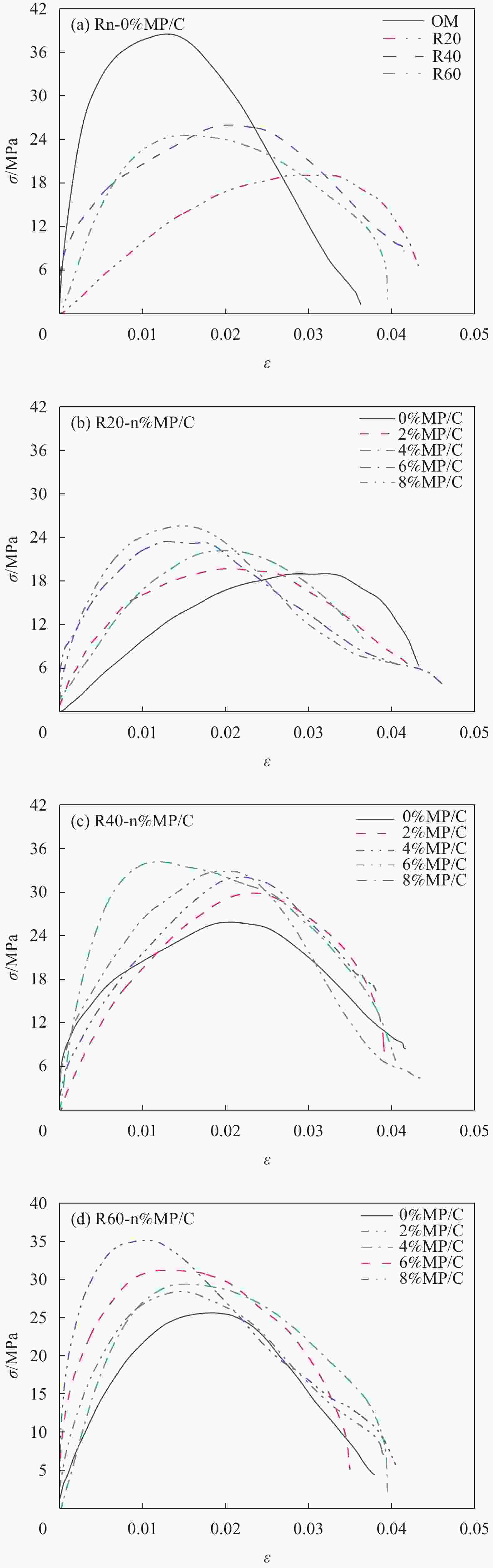

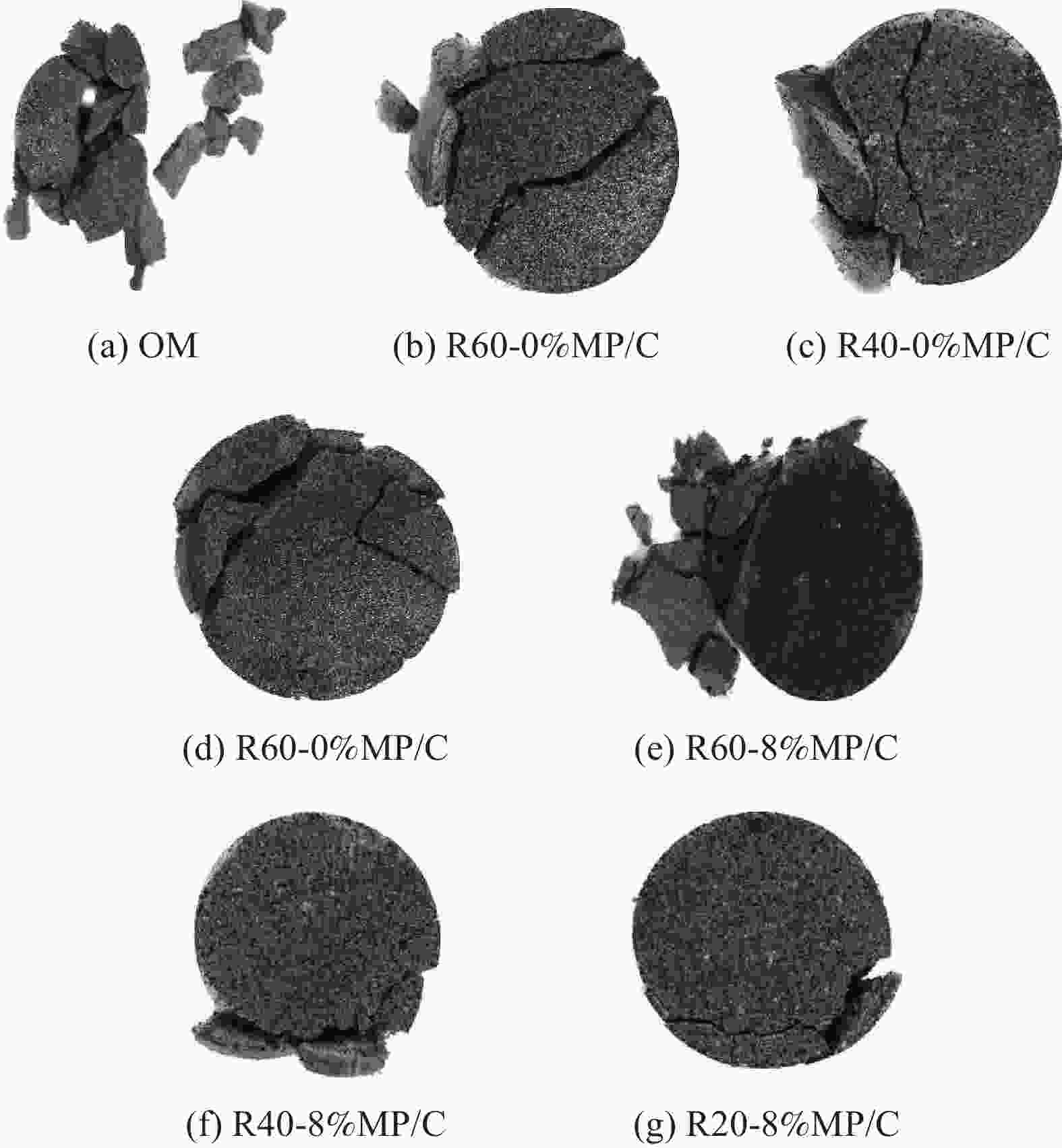

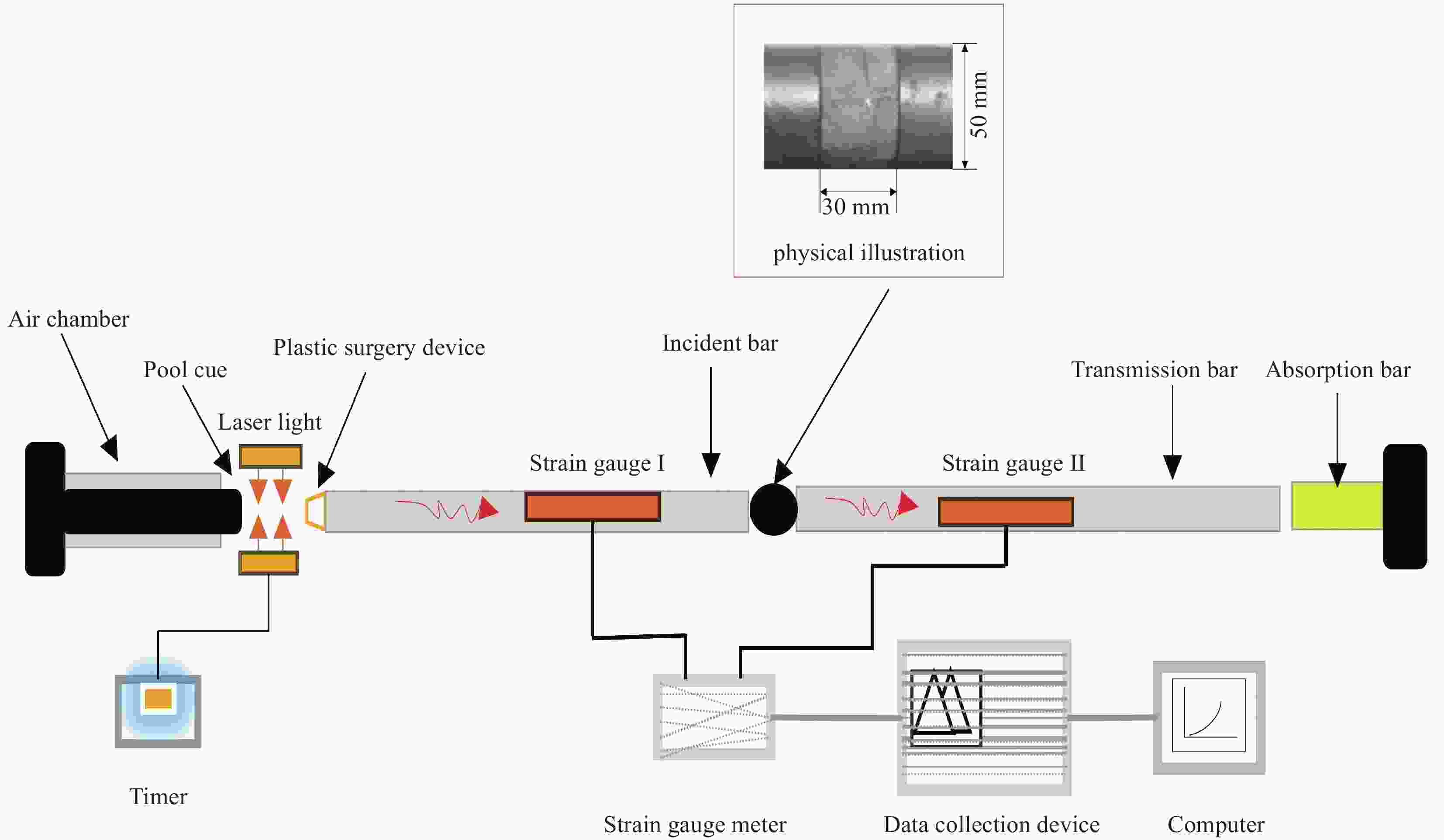

摘要: 为研究微硅粉(Micro silicon powder, MP)-橡胶/水泥砂浆的力学性能,试验设计了16组试件,通过单轴抗压试验与抗冲击试验(SHPB)分析不同微硅粉掺量、橡胶粒径和养护龄期试件的峰值应力、峰值应变、弹性模量,抗冲击强度、破坏形态与应力-应变曲线。单轴抗压试验表明:在相同的养护龄期下,橡胶颗粒的加入使得砂浆试件的抗压强度与弹性模量降低,峰值应变增加,加入微硅粉后试件的强度与弹性模量会有所回升。抗冲击试验表明:橡胶会降低砂浆的抗冲击强度,但能改善砂浆的破坏形态,而微硅粉不仅能增强这种改善作用,还能提升橡胶/水泥砂浆的抗冲击强度,另外加入微硅粉后,试件的应力-应变曲线的峰值荷载会因为其弹性变形与弹塑性变形阶段的缩短而向左偏移,但破坏阶段明显延长。

-

关键词:

- 微硅粉-橡胶/水泥砂浆 /

- 橡胶掺量 /

- 微硅粉掺量 /

- 分离式霍普金森压杆(SHPB) /

- 单轴抗压

Abstract: In order to study the mechanical properties of micro silicon powder (MP)-rubber/cement mortar, 16 sets of specimens were designed and analyzed by uniaxial compression test and impact test (SHPB) for peak stress, peak strain, modulus of elasticity, impact strength, damage morphology and stress-strain curves of the specimens with different micro silicon powder dosage, rubber particle sizes and curing ages. The uniaxial compressive test shows that the addition of rubber particles decreases the compressive strength and modulus of elasticity of mortar specimens and increases the peak strain at the same age of maintenance, and the strength and modulus of elasticity of the specimens recover after the addition of micro silica powder. The impact resistance test shows that: rubber will reduce the impact strength of mortar, but can improve the damage morphology of mortar, and micro silica powder not only enhances this improvement, but also improves the impact strength of rubber/cement mortar, in addition, after the addition of micro silica powder, the peak load of the stress-strain curve of the specimen will be shifted to the left due to the shortening of the elastic deformation and elasto-plastic deformation stages, but the damage stage is obviously prolonged. -

表 1 微硅粉性能参数

Table 1. Performance index of micro silicon powder

Sample status The specific surface area/(m2·g−1) SiO2/% Cl−/% Reduce the amount of burning/% White powder 21 98.4 0.01 1.48 表 2 试验橡胶水泥砂浆配合比

Table 2. Mixture of rubber cement mortar

Specimen Cement mortar material dosage/(kg·m−3) Cement Water Sand Rubber Micro silicon powder OM 450 280 1080 0 0 R20-0%MP/C 450 280 864 62 0 R20-2%MP/C 441 280 864 62 9 R20-4%MP/C 432 280 864 62 18 R20-6%MP/C 423 280 864 62 27 R20-8%MP/C 414 280 864 62 36 R40-0%MP/C 450 280 864 62 0 R40-2%MP/C 441 280 864 62 9 R40-4%MP/C 432 280 864 62 18 R40-6%MP/C 423 280 864 62 27 R40-8%MP/C 414 280 864 62 36 R60-0%MP/C 450 280 864 62 0 R60-2%MP/C 441 280 864 62 9 R60-4%MP/C 432 280 864 62 18 R60-6%MP/C 423 280 864 62 27 R60-8%MP/C 450 280 864 62 36 Notes: OM is the blank group, R20, R40 and R60 are the R rubber mesh, indicating that the mesh of the blended rubber powder is 20 mesh, 40 mesh and 60 mesh, respectively, and n%MP/C is the percentage of blended microsilica powder, indicating that the blended micro silico powder accounts for 0%, 2%, 4%, 6%, and 8% of the mass of the cement, respectively. -

[1] 中国轮胎循环利用协会. 《中国轮胎循环利用行业“十四五” 发 展 规 划 》 征 求 行 业意 见[J]. 中 国 轮 胎 资 源 综 合 利 用, 2020, (11): 12-19.China Tire Recycling Association. Soliciting industry opinions for "the 14th five-year development plan of China’ s Tire Recycling Industry"[J]. China Tire Resources Recycling, 2020, (11): 12-19(in Chinese). [2] 姜雪丹. 富氧条件下废弃轮胎颗粒的着火、燃烧和排放特性研究[D]. 中国科学技术大学, 2020: 3-12.JIANG Xuedan. Study on ignition, combustion and emission characteristics of waste tire particles under oxygen-enriched conditions[D]. University of Science and Technology of China, 2020: 3-12 (in Chinese). [3] Thomas B S, Gupta R C. Long term behaviour of cement concrete containing discarded tire rubber[J]. Journal of Cleaner Production, 2015, 102(9): 78-87. [4] 杨荣周, 徐颖, 陈佩圆, 等. SHPB劈裂试验下橡胶水泥砂浆的动态力学、能量特性及破坏机理试验研究[J]. 材料导报, 2021, 35(10): 10062-10072. doi: 10.11896/cldb.20030105YANG Rongzhou, XU Ying, CHEN, Peiyuan, et al. Experimental Study on Dynamic Mechanics, Energy Characteristics, and FailureMechanism of Rubber Cement Mortar UnderSHPB Splitting Test[J]. Material Reports B:Research Papers, 2021, 35(10): 10062-10072(in Chinese). doi: 10.11896/cldb.20030105 [5] 朱浩君, 薛刚, 刘利强, 等. 橡胶混凝土的疲劳行为与损伤机理[J/OL]. 武汉大学学报(工学版): 1-92023-08-11]. ZHU Haojun, XUE Qiang, LIU Liqiang, etal. Fatigue behavior and damage mechanism of rubber concrete[J]. Engineering Journal ofWuhan University: 1-9[2023-08-11] (in Chinese). [6] 杨若冲, 谈至明, 黄晓明, 等. 硅灰改性橡胶混凝土路用性能研究[J]. 公路交通科技, 2010, 27(10): 6-10. doi: 10.3969/j.issn.1002-0268.2010.10.002YANG Ruoming, TAN Zhiming, HUANG Xiaoming, et al. Study on Performance of Silice Fume Modified Rubberized Concrete[J]. Journal of Highway and Transportation Research and Development, 2010, 27(10): 6-10(inChinese). doi: 10.3969/j.issn.1002-0268.2010.10.002 [7] TIAN L, QIU L C, LI J J, et al. Experimental study of waste tire rubber, wood-plastic particles and shale cream site on the performance of self-compacting concrete[J]. Journalof Renewable Materials, 2020, 8(2): 154-170. doi: 10.32604/jrm.2020.08701 [8] ASLANI F, MA G W, YIM W D L, et al. Development of high-performance self-compacting concrete using waste recycled concrete aggregates and rubber granules[J]. Journal of Cleaner Production, 2018, 182: 553-566. doi: 10.1016/j.jclepro.2018.02.074 [9] HILAL N N. Hardened properties of self-compacting concrete with different crumb rubber size and content[J]. International Journal of Sustainable Built Environment, 2017, 6(1): 191-206. doi: 10.1016/j.ijsbe.2017.03.001 [10] 梁炯丰, 谢挺挺, 吴华英, 等. 橡胶粉改性再生混凝土基本力学性能研究[J]. 混凝土, 2015, (11): 21-26. doi: 10.3969/j.issn.1002-3550.2015.11.006LIANG Jiongfeng, XIE Tingting, WU Yinghua, et al. Experimental research on the basic mechanical properties of rubber recycled coarse aggregate concrete[J]. Concrete, 2015, (11): 21-26(in Chinese). doi: 10.3969/j.issn.1002-3550.2015.11.006 [11] 张卫东, 何卫忠. 废橡胶对再生混凝土抗压性能影响的试验研究[J]. 混凝土, 2013, (7): 62-64. doi: 10.3969/j.issn.1002-3550.2013.07.017ZHANG Wwidong, HE Weizhong. Influence of w aste rubber on the compressive performance of recycled concrete[J]. Concrete, 2013, (7): 62-64(in Chinese). doi: 10.3969/j.issn.1002-3550.2013.07.017 [12] ISMAIL M K, HASSAN A A A. Impact resistance and mechanical properties of self-consolidating rubberized concrete reinforced with steel fibers[J]. Journal of Materials in Civil Engineering, 2017, 29(1): 1-14. [13] ABDELALEEM B H, ISMAIL M K, HASSAN A A A. The combined effect of crumb rubber and synthetic fibers on impact resistance of self-consolidating concrete[J]. Construction and Building Materials, 2018, 162: 816-829. doi: 10.1016/j.conbuildmat.2017.12.077 [14] 龙广成, 李宁, 薛逸骅, 等. 冲击荷载作用下掺橡胶颗粒自密实混凝土的力学性能[J]. 硅酸盐学报, 2016, 44(8): 1081-1090.LONG Guangcheng, LI Ning, XUE Yihua, et al. Mechanical Properties of Self-Compacting Concrete Incorporating Rubber Particles under Impact Load[J]. Bull Chin Ceram Soc, 2016, 44(8): 1081-1090 (in Chinese). [15] LI N, LONG G C, MA C, et al. Properties of self-compacting concrete (SCC) with recycled tire rubber aggregate: a comprehensive study[J]. Journal of Cleaner Production, 2019, 236: 117707. doi: 10.1016/j.jclepro.2019.117707 [16] 赵秋红, 董硕, 朱涵. 钢纤维-橡胶/混凝土抗剪性能试验[J]. 复合材料学报, 2020, 37(12): 3201-3213ZHAO Qiuhong, DONG Shuo, ZHU Han. Experimental study on shear behavior of steel fiber-rubber/concrete[J]. Acta MateriaeCompositae Sinica, 2020, 37(12): 3201-3213(in Chinese). [17] 赵秋红, 董硕, 朱涵. 钢纤维-橡胶/混凝土单轴受压全曲线试验及本构模型[J]. 复合材料学报, 2021, 38(7): 2359-2369.ZHAO Qiuhong, DONG Shuo, ZHU Han. Experiment on stress-strain behavior and constitutive model of steel fiber-rubber/ concrete subjected to uniaxial compression[J]. Acta Materiae Compositae Sinica, 2021, 38(7): 2359-2369(in Chinese). [18] 李伟, 黄振, 王晓初, 等. 胶乳改性橡胶混凝土基本力学性能研究[J]. 建筑科学, 2015, 31(3): 68-72.LI Wei, HUAN Zhen, WANG Chuxiao, et al. Basic Mechanical Performance of Latex Modified Rbber Concrete[J]. Building Science, 2015, 31(3): 68-72(in Chinese). [19] 林强, 刘赞群, 禹雷, 等. 乳化沥青橡胶混凝土的力学性能[J]. 复合材料学报, 2023, 40(3): 1560-1568.LIN Qiang, LIU Zanqun, YU Lei, et al. Mechanical properties of emulsified asphalt rubber concrete[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1560-1568(in Chinese). [20] 冯森林, 屠艳平, 章翔. 纳米SiO2浸泡改性再生橡胶混凝土力学性能研究[J]. 水泥工程, 2022, (06): 75-79.FENG Senlin, TU Yanping, ZHANG Xiang. Study on mechanical properties of recycled rubber concrete modified by nano-SiO2 immersion[J]. Cement Engineering, 2022, (06): 75-79. [21] 王娟, 王文超, 许耀群, 等. 纳米SiO2对橡胶混凝土断裂行为的影响[J]. 建筑材料学报, 2023, 26(07): 731-738. doi: 10.3969/j.issn.1007-9629.2023.07.005WANG Juan, WANG Wenchao, XU Yaoqun, et al. Effect of Nano-SiO2 on Fracture Behavior of Rubber Concrete[J]. Journal of Building Materials, 2023, 26(07): 731-738(in Chinese). doi: 10.3969/j.issn.1007-9629.2023.07.005 [22] Danying G, Tao Z, Yuyang P, et al. Flexural behavior analysis and strength prediction of steel fiber-and-nanosilica reinforced rubber concrete[J]. Advances in Structural Engineering, 2022, 25(4): 864-876. doi: 10.1177/13694332211050988 [23] MOHAMMED B S, WANG A B, WANG S S, et al. Properties of nano silica modified rubber concrete[J]. J Clean Prod, 2016, 119: 66-75. doi: 10.1016/j.jclepro.2016.02.007 [24] ONUAGULUCHI O. Effects of surface pre-coating and silica fume on crumb rubber-cement matrix interface and cement mortar properties[J]. Journal of Cleaner Production, 2015, 104: 339-345. doi: 10.1016/j.jclepro.2015.04.116 [25] 马海彬, 胡凡, 马晴晴等. 橡胶粒径与掺量对砂浆力学性能影响的试验研究[J]. 科学技术与工程, 2019, 19 (04): 232-236.MA Haibing, HU Fan, MA Qingqing, et al. Experimental investigation on effect of particle size and dosage of rubber on mechanical properties of mortar[J]. cience Technology and Engineering, 2019, 19( 4) : 232-236 [26] 任翔, 胡功宏, 吴帆等. 纳米硅粉对大掺量橡胶砂浆力学及收缩性能影响试验研究[J]. 科学技术与工程, 2019, 19(22): 299-304. doi: 10.3969/j.issn.1671-1815.2019.22.044REN Xiang, HU Gonghong, WU Fan, et al. Effect of nano silica powder on mechanical and shrinkage properties of high volume rubber mortar[J]. Science Technology and Engineering, 2019, 19(22): 299-304 (in Chinese). doi: 10.3969/j.issn.1671-1815.2019.22.044 [27] ASTM C109, Standard test method for compressive strength of hydraulic cement mortars[S]. ASTM International, 2016, West Conshohocken, PA. [28] 叶仁传, 田阿利, 沈超明. 霍普金森压杆(SHPB)实验波形振荡问题的影响与解决方法[J]. 科学技术与工程, 2014, 14(01): 1-4+9. doi: 10.3969/j.issn.1671-1815.2014.01.001YE Renzhuan, TIAN Ali, SHEN Chaoming. Hopkinson Pressure Bar (SHPB) Experimental Waveform Oscillations Impact of the problem and solutions[J]. Science Technology and Engineering, 2014, 14(01): 1-4+9(in Chinese). doi: 10.3969/j.issn.1671-1815.2014.01.001 [29] 阮波, 李雪松, 邓威, 等. 水泥砂浆桩无侧限抗压强度试验研究[J]. 铁道科学与工程学报, 2017, 14(9): 1859-1862. doi: 10.3969/j.issn.1672-7029.2017.09.008RUAN Bo, LI Xuesong, DENG Wei, et al. Experimental study of unconfined compressive strength of cement mortar pile[J]. Journal of Railway Science and Engineering, 2017, 14(9): 1859-1862(in Chinese). doi: 10.3969/j.issn.1672-7029.2017.09.008 [30] MEI J P, TAN H B, LI H N, et a1. Effect of sodium sulfate and Nano-SiO2: on hydration and microstructure of cementitious materials containing high volume fly ash under steam curing[J]. Construction and Building Materials, 2018, (163): 812-825 [31] BEHFARMIA K, ROSTAMI M. Effects of micro and nanoparticles of SiO2 on the permeability of alkali activated slag concrete[J]. Construction and Building Materials, 2017, (131): 205-213. [32] 郭帆, 曾磊, 莫金旭, 等. 外掺橡胶粉的苯丙乳液改性混凝土力学性能及微观结构[J]. 建筑材料学报, 2019, 22(5): 714-720,729. doi: 10.3969/j.issn.1007-9629.2019.05.007GUO Fan, ZENG Lei, MO Jingxu, et al. Mechanical Properties and Microstructure of Styrene-Acrylic Emulsion Modified Concrete with Rubber Powder[J]. Journal of Building Materials, 2019, 22(5): 714-720,729 (in Chinese). doi: 10.3969/j.issn.1007-9629.2019.05.007 -

点击查看大图

点击查看大图

计量

- 文章访问数: 55

- HTML全文浏览量: 22

- 被引次数: 0

下载:

下载: