Damage resistance and residual compressive strength of carbon fiber reinforced plastic optimized by aramid pulp

-

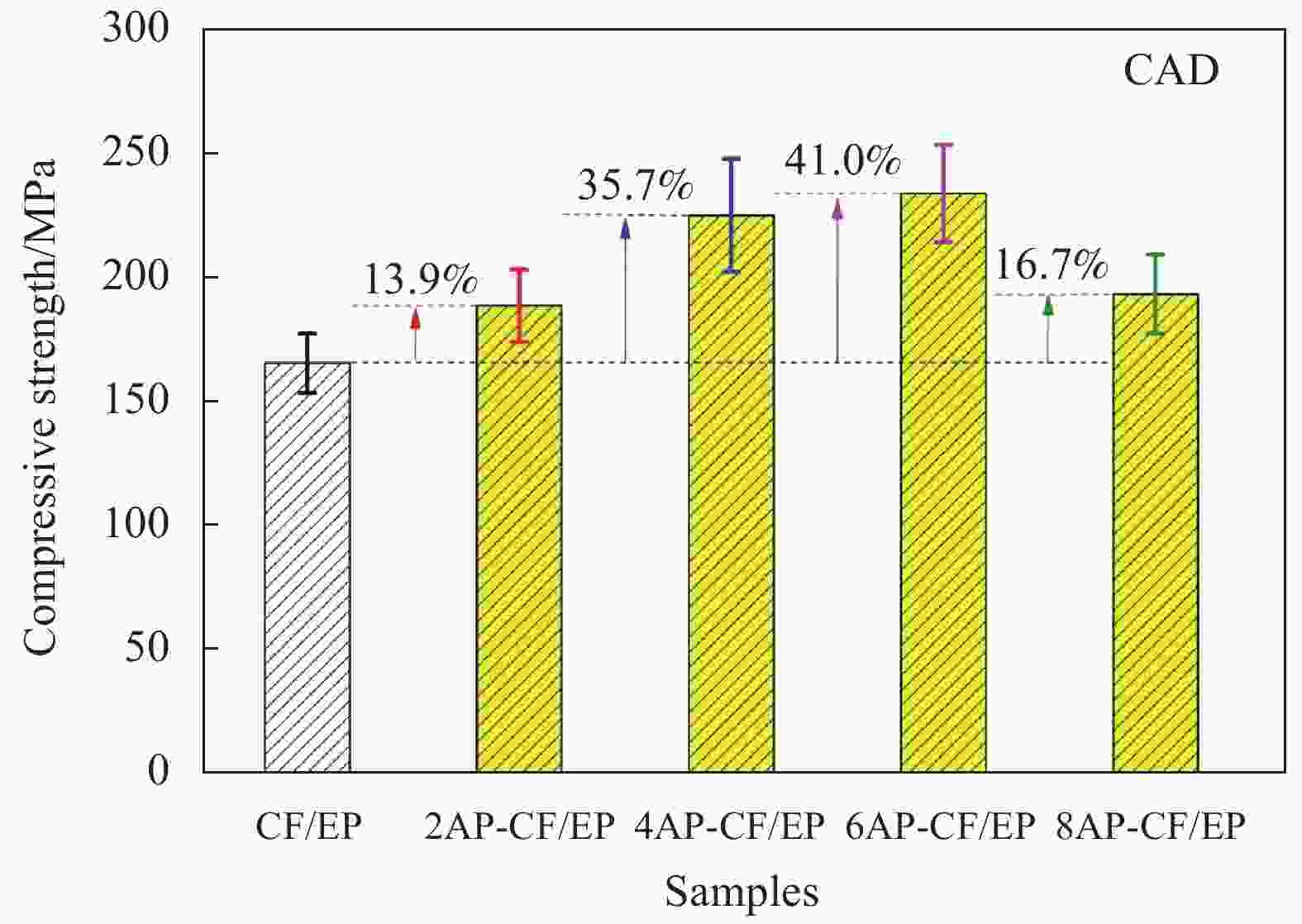

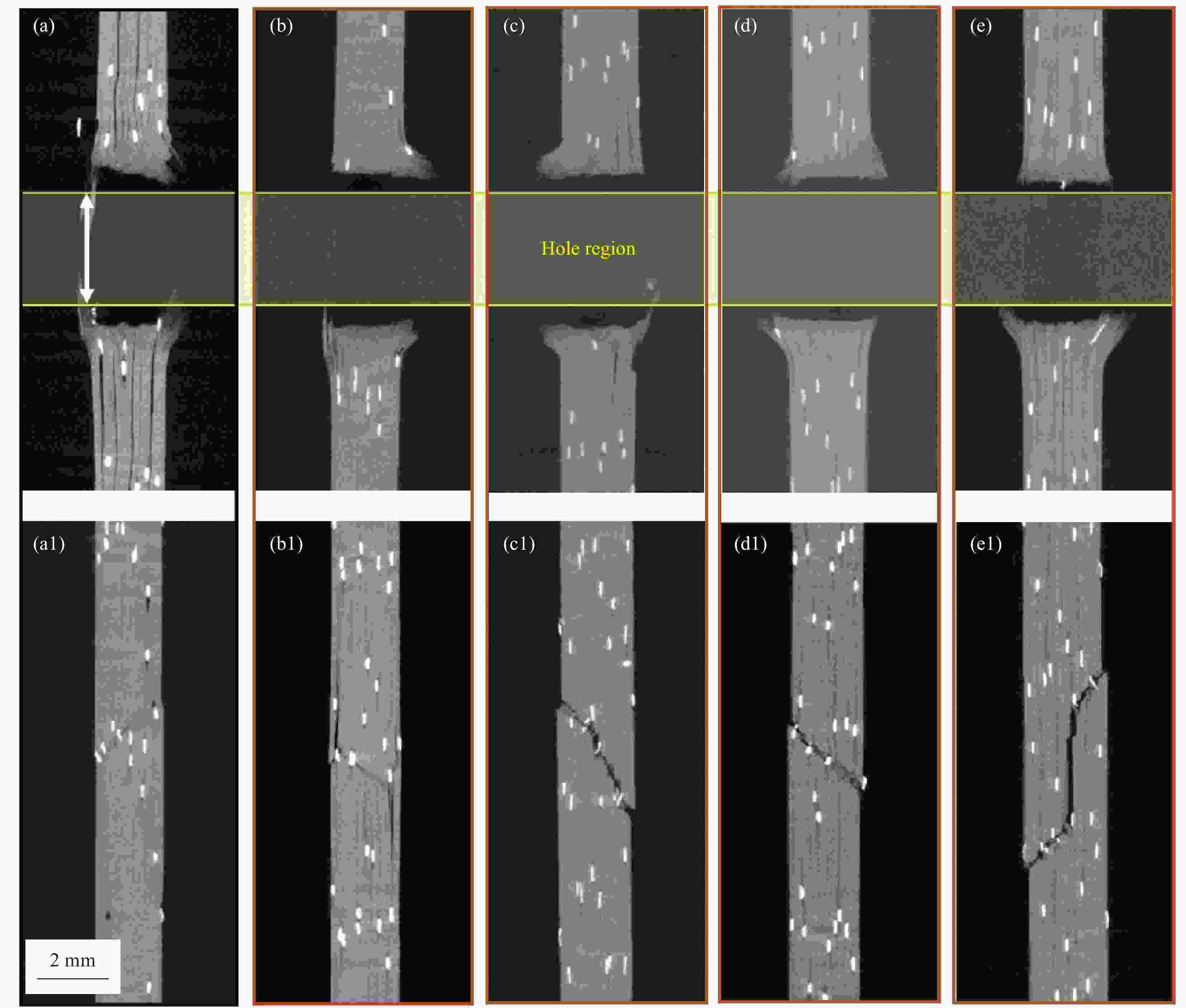

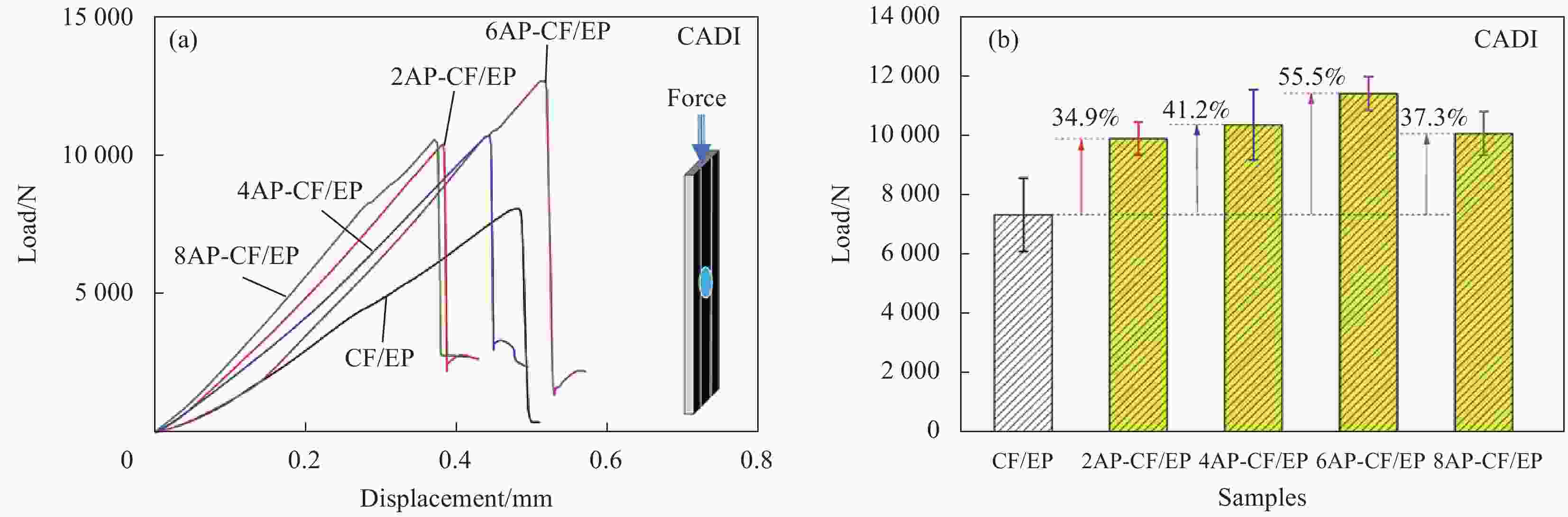

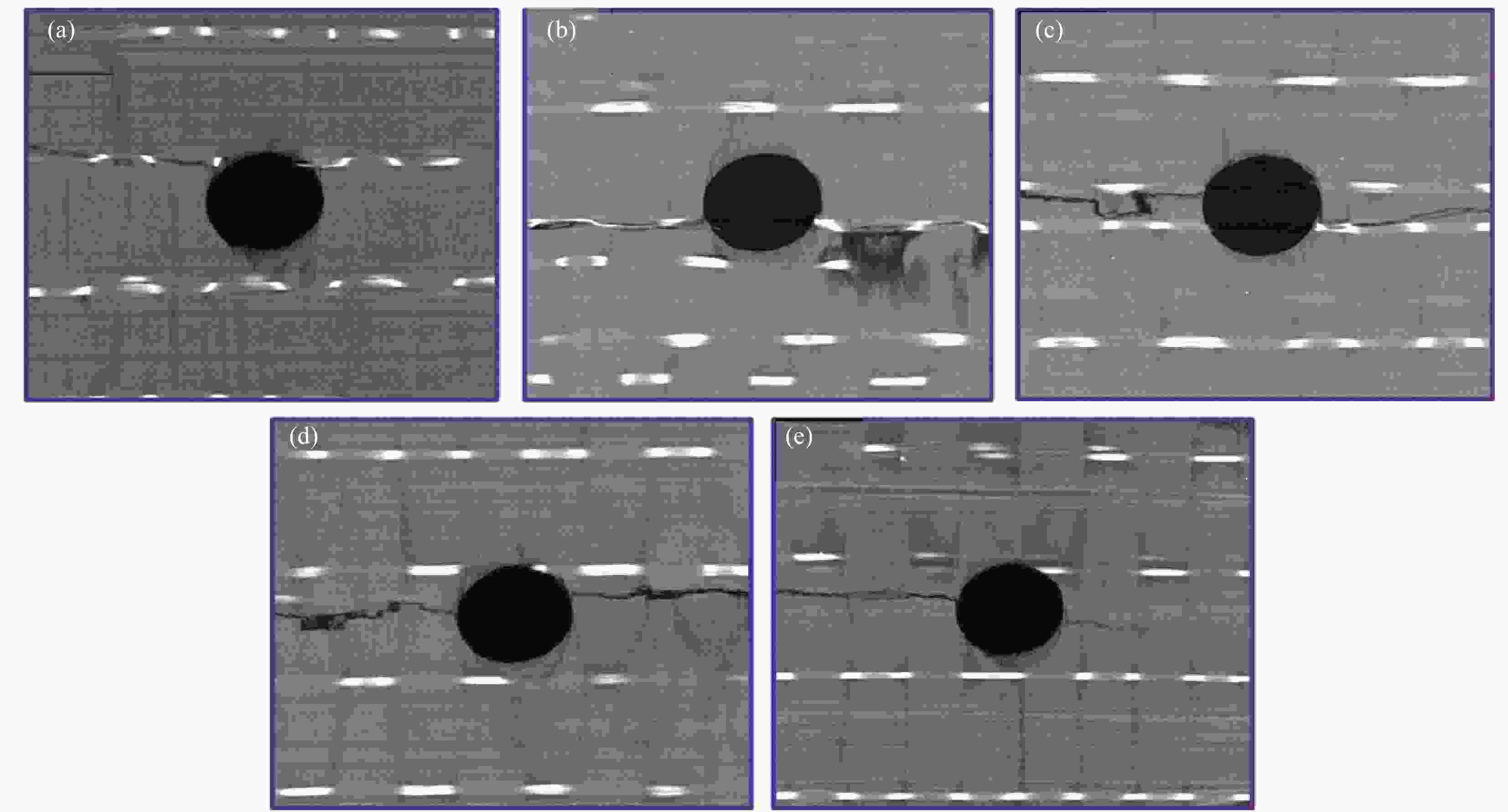

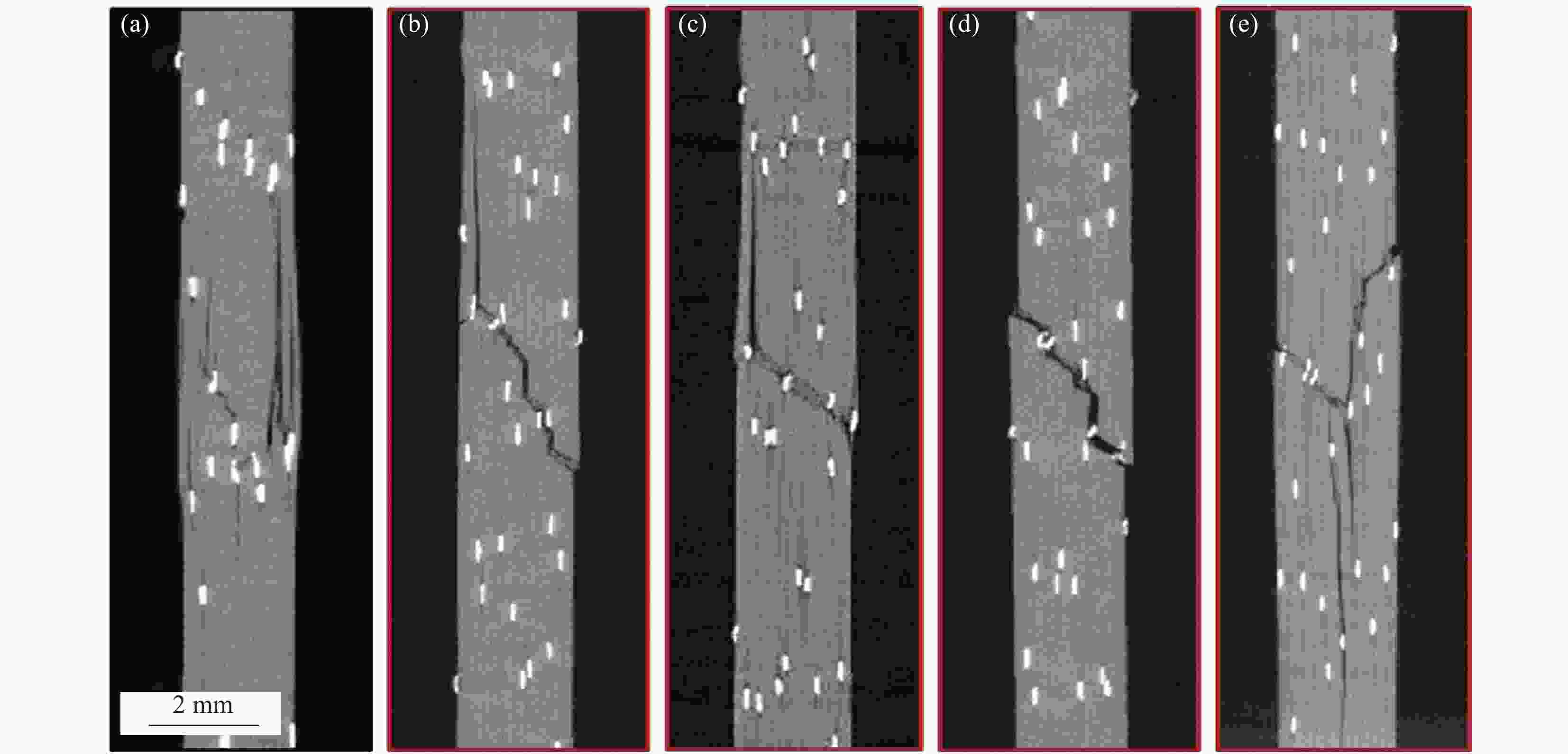

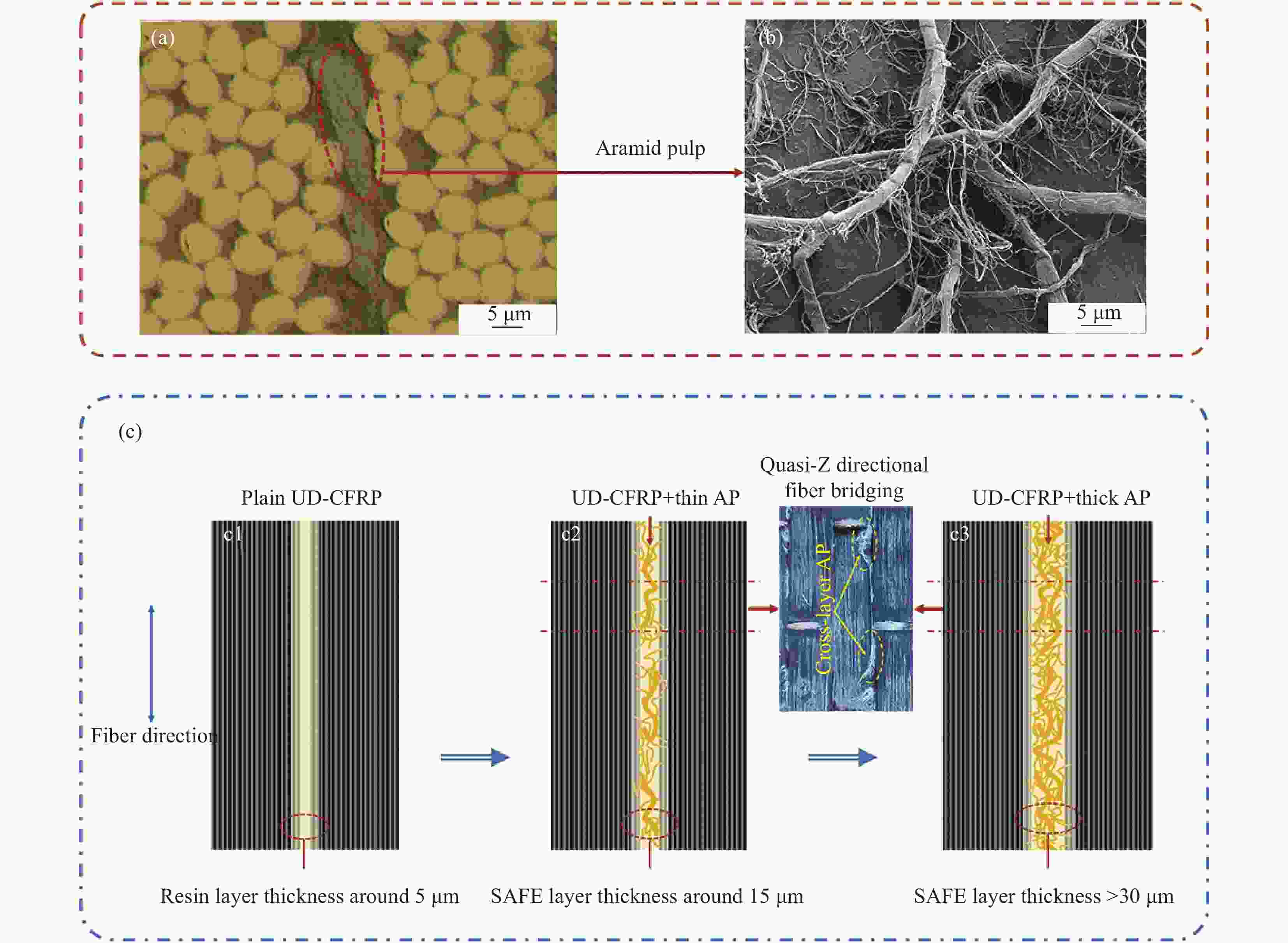

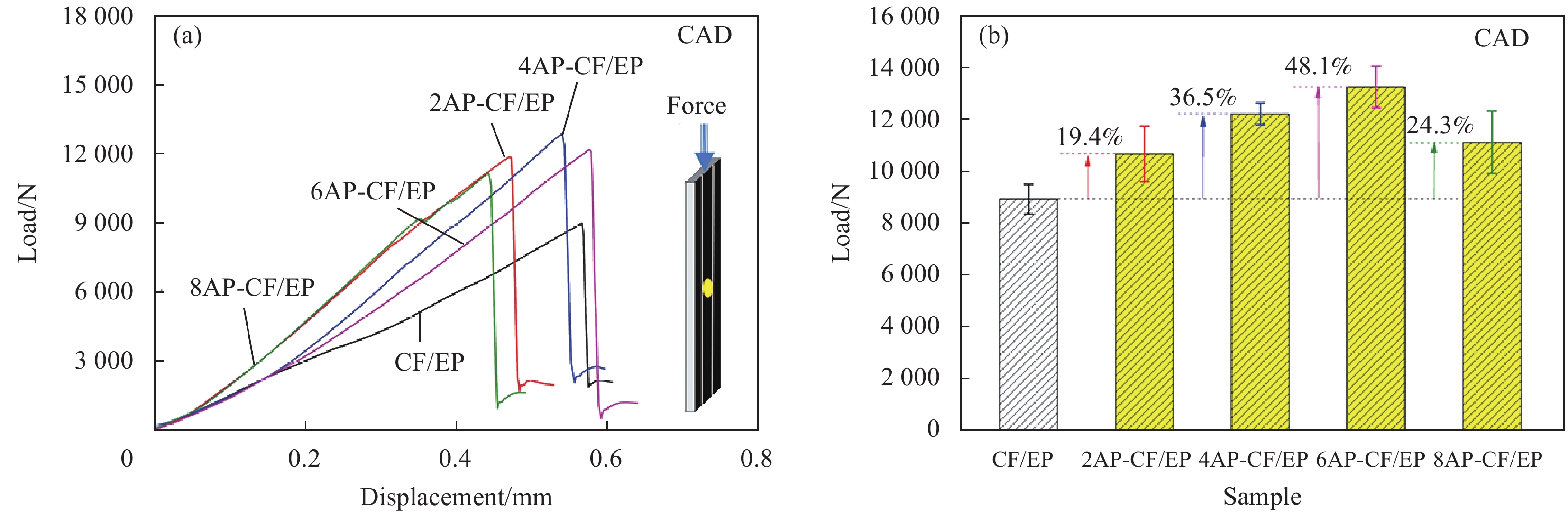

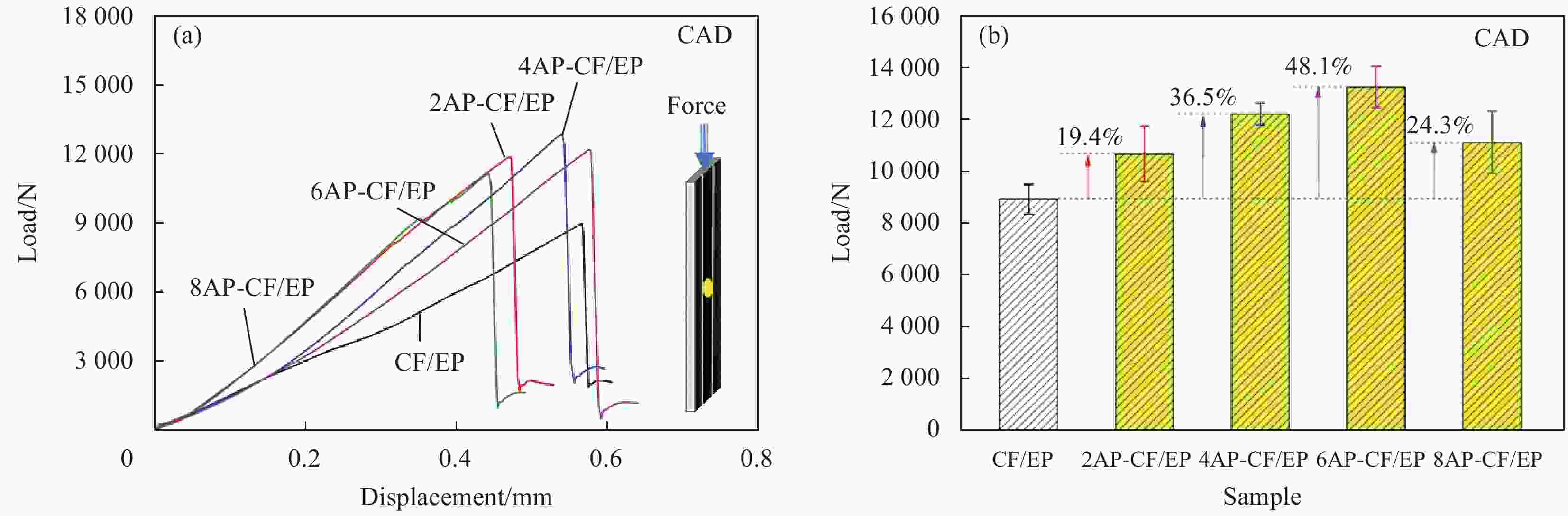

摘要: 针对树脂基复合材料树脂粘接层脆性大且存在结构缺陷,易发生剥离和分层等突出问题,提出以轻质高强的芳纶pulp(AP)作为增强剂,通过模压成型制得强化的碳纤维增强树脂基复合材料(CFRP),研究不同添加面密度对复合材料抗钻孔、钻孔-冲击二次损抗性能和损伤后的抗压强度的影响。结果表明,6 g/m2 AP使复合材料直接、钻孔以及钻孔-冲击后抗压强度分别增强37.3%、41.0%和41.8%。分析认为:AP改善了树脂脆性,消除层间富树脂区域,提升层间断裂韧性,抑制了裂纹生长;同时AP以纤维桥连形式贯穿于树脂层和碳纤维层,不仅改善了树脂与碳纤维粘接界面的缺陷,也构建准Z方向的纤维排布,避免裂纹向单层界面扩展而导致结构分层,从而实现结构强化。

-

关键词:

- 碳纤维增强树脂基复合材料 /

- 芳纶pulp /

- 非编织芳纶树脂超薄层 /

- 层间增韧 /

- 纤维桥联 /

- 抑制分层

Abstract: Aiming at the large brittleness of resin adhesive layer, structural defect of carbon fiber layer, prone to peeling and delamination, etc. the carbon fiber reinforced plastics (CFRP) with aramid pulp (AP) toughening were prepared by compression molding via using AP with high strength and toughness as interface enhancer. The effects of AP with different interface densities on the compressive strength, impact resistance and compressive strength after damages of CFRP were studied. The compressive strengths of directly testing, testing after impact, drill and drill-impact are improved by 37.3%, 41.0% and 41.8% correspondingly for longitudinal CFRP with AP interface density of 6 g/m2. AP improves brittleness of resin, eliminates interlayer resin-rich region, toughens the interlayer toughness and suppressed cracks generation. The formed AP fiber-bridging structure throughout resin layer and carbon fiber layer not only remove the bonding interface defect, but also build quasi-Z fiber distribution to achieve tightly connected structure, which prevent cracks expanding along interlayer and delamination failure, thereby to achieve structure reinforced.-

Key words:

- CFRP /

- AP /

- non-woven ultra-thin aramid-epoxy layer /

- interlayer toughening /

- fiber-bridging /

- delamination failure

-

表 1 不同面密度的AP增强的单向碳纤维增强树脂基复合材料(CFRP)所设置的实验相关参数

Table 1. Relevant experiment data of carbon fiber reinforced plastics (CFRP) with different interface densities of AP

Sample AP/

wt%AP-epoxy/

gEpoxy in

AP-epoxy/gHardener/

gAP-epoxy

layer /pliesCF fabric/

pliesAP interface

density/(g·m−2)CF/EP 0 0 12.500 2.500 9 10 0 2AP-CF/EP 1 12.5 12.375 2.475 9 10 2 4AP-CF/EP 2 12.5 12.250 2.450 9 10 4 6AP-CF/EP 3 12.5 12.125 2.425 9 10 6 8AP-CF/EP 4 12.5 12.000 2.400 9 10 8 表 2 不同面密度的AP增强的CFRP复合材料经过钻孔损伤后的压缩强度性能

Table 2. Compressive strength of CFRP with different interface densities of AP after drilled

Sample Compression test

without drillingCompression test

after drillingReduction to undrilled

compression testCompressive

strength/

MPaStandard

deviation/

MPaPmax/

NStandard

deviation/

NCompressive

strength/

MPaStandard

deviation/

MPaCompressive

strength/

MPaDecrease /

%CF/EP 198.63 22.53 8 769.11 563.04 159.09 11.43 39.54 19.9 2AP-CF/EP 215.21 24.71 10 472.70 1 040.72 181.24 13.92 33.97 15.8 4AP-CF/EP 258.93 28.65 11 970.00 411.94 215.87 21.83 43.06 16.6 6AP-CF/EP 272.85 26.43 12 984.25 778.25 224.37 18.65 48.48 17.8 8AP-CF/EP 233.33 28.31 10 900.30 1 177.07 188.70 15.18 44.63 19.1 Note: Pmax—Maximum load. 表 3 不同面密度的AP增强的CFRP复合材料经过钻孔-冲击损伤后的压缩强度性能

Table 3. Compressive strength of CFRP with different interface densities of AP after drilled and impact

Sample Pmax/N Standard deviation/N Compressive strength/MPa Standard deviation/MPa Reduction to drilled strength/MPa Decrease/% CF/EP 7 238.36 1 216.09 132.04 29.21 27.05 17.0 2AP-CF/EP 9 767.84 541.15 168.86 16.27 12.38 6.8 4AP-CF/EP 10 222.60 1 164.90 179.43 31.28 36.44 16.9 6AP-CF/EP 11 258.01 562.54 187.17 16.19 37.20 16.6 8AP-CF/EP 9 937.03 716.39 160.52 21.44 28.18 14.9 -

[1] 鲍学淳, 程礼, 陈煊, 等. 碳纤维树脂基复合材料三点弯曲超高周疲劳实验研究[J]. 机械强度, 2019, 41(4):858-863.BAO X C, CHENG L, CHEN X, et al. Experimental study on three-point bending ultra-high cycle fatigue of carbon fiber resin matrix composites[J]. Mechanical Strength,2019,41(4):858-863(in Chinese). [2] 陈鑫, 马士东, 刘升辉. 基于ABAQUS碳纤维树脂基复合材料抗冲击性能研究[J]. 科技风, 2019(2):194-195.CHEN X, MA S D, LIU S H. Research on impact resistance of carbon fiber resin matrix composites based on ABAQUS[J]. KEJIFENG,2019(2):194-195(in Chinese). [3] 王振, 宋凯, 朱国华, 等. 单向碳纤维复合材料锥管轴向吸能特性研究[J]. 振动与冲击, 2018, 37(7):172-178.WANG Z, SONG K, ZHU G H, et al. Axial energy absorption characteristics of unidirectional carbon-fiber composite cone tubes[J]. Journal of Vibration and Shock,2018,37(7):172-178(in Chinese). [4] 徐林, 孙文磊. 风力发电机复合材料叶片结构特性分析[J]. 可再生能源, 2013, 31(3):56-59.XU L, SUN W L. Structural characteristics analysis of wind turbine composite material blade[J]. Renewable Energy Resource,2013,31(3):56-59(in Chinese). [5] 包建文, 蒋诗才, 张代军. 航空碳纤维树脂基复合材料的发展现状和趋势[J]. 科技导报, 2018, 36(9):52-63.BAO J W, JIANG S C, ZHANG D J. Current status and trends of aeronautical resin matrix composites reinforced by carbon fiber[J]. Science & Technology Review,2018,36(9):52-63(in Chinese). [6] 黄硕, 王亮, 陈超. 我国碳纤维复合材料在汽车上的应用趋势和建议[J]. 中国材料科技与设备, 2015, 3:59-62.HUANG S, WANG L, CHEN C. Application and prospect of carbon fiber composite material in the automotive[J]. Materials Science Technology & Equipment,2015,3:59-62(in Chinese). [7] 牛峰, 王建平, 马春草, 等. 碳纤维复合材料在舰艇显控台上的应用[J]. 舰船科学技术, 2018, 41(6):85-88.NIU F, WANG J P, MA C C, et al. The application of carbon fiber composite material in naval vessel console[J]. Ship Science and Technology,2018,41(6):85-88(in Chinese). [8] 王晨阳. 碳纤维树脂基复合材料在交通装备领域的应用[J]. 中国战略新兴产业, 2019(4):189-191.WANG C Y. Application of carbon fiber resinbased composite materials in the field of transportation equipment[J]. China Strategic Emerging Industry,2019(4):189-191(in Chinese). [9] 罗永康, 李炜, 胡红, 等. 碳纤维复合材料在风力发电机叶片中的应用[J]. 电网与清洁能源, 2008, 24(11):53-57. doi: 10.3969/j.issn.1674-3814.2008.11.012LUO Y K, LI W, HU H, et al. Application of carbon fiber composite materials in wind turbine blades[J]. Power System and Clean Energy,2008,24(11):53-57(in Chinese). doi: 10.3969/j.issn.1674-3814.2008.11.012 [10] 杜善义, 关志东. 我国大型客机先进复合材料技术应对策略思考[J]. 复合材料学报, 2008, 25(1):1-10. doi: 10.3321/j.issn:1000-3851.2008.01.001DU S Y, GUAN Z D. Strategic considerations for development of advanced composite technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinica,2008,25(1):1-10(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.001 [11] ZHAI Y J, WANG Z C, HUANG W, et al. Improved mechanical properties of epoxy reinforced by low content nanodiamond powder[J]. Materials Science & Engineering A,2011,528(24):7295-7300. [12] YUAN B Y, HU Y S, CHENG F, et al. Flexure and flexure-after-impact properties of carbon fibre composites interleaved with ultra-thin non-woven aramid fibre veils[J]. Composites Part A-Applied Science and Manufacturing,2020,131:105831. [13] GARCIA-RODRIGUEZ S M, COSTA J, SINGERY V, et al. The effect interleaving has on thin-ply non-crimp fabric laminate impact response: X-ray tomography investigation[J]. Composites Part A: Appllied Science Manufacture,2018,107:409-420. doi: 10.1016/j.compositesa.2018.01.023 [14] NASH N H, YOUNG T M, MCGRAIL P T, et al. Inclusion of a thermoplastic phase to improve impact and post-impact performances of carbon fibre reinforced thermosetting composites—A review[J]. Material and Design,2015,85:582-597. doi: 10.1016/j.matdes.2015.07.001 [15] YUAN B Y, TAN B, HU Y S, et al. Improving impact resistance and residual compressive strength of carbon fibre composites using un-bonded non-woven short aramid fibre veil[J]. Composites Part A: Applied Science and Manufacturing,2019,121:439-448. doi: 10.1016/j.compositesa.2019.04.006 [16] 林智育, 许希武. 复合材料层板低速冲击后剩余压缩强度[J]. 复合材料学报, 2008, 25(1):140-146. doi: 10.3321/j.issn:1000-3851.2008.01.024LIN Z Y, XU X W. Residual compressive strength of composite laminates after low-velocity impact[J]. Acta Materiae Compositae Sinica,2008,25(1):140-146(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.024 [17] 管清宇, 严文军, 吴光辉, 等. 碳纤维/环氧树脂复合材料层压板冲击凹坑的回弹特性[J]. 复合材料学报, 2020, 37(2):284-292.GUAN Q Y, YAN W J, WU G H, et al. Impact dent relaxation characteristic of carbon fiber/epoxy resin composite laminate[J]. Acta Materiae Compositae Sinica,2020,37(2):284-292(in Chinese). [18] 贾晓龙, 还献华, 齐鹏飞, 等. 碳纤维树脂基复合材料的高性能化[J]. 科学通报, 2018, 63(34):3555-3569. doi: 10.1360/N972018-00842JIA X L, HUAN X H, QI P F, et al. Performance improvement in carbon fiber reinforced polymer-based composites[J]. Chinese Science Bulletin,2018,63(34):3555-3569(in Chinese). doi: 10.1360/N972018-00842 [19] YAO X, GAO X, JIANG J, et al. Comparison of carbon nanotubes and graphene oxide coated carbon fiber for improving the interfacial properties of carbon fiber/epoxy composites[J]. Composites Part B : Engineering,2018,132:170-7. doi: 10.1016/j.compositesb.2017.09.012 [20] OU Y, GONZALEZ C, VILATELA J J. Interlaminar toughening in structural carbon fiber/epoxy composites interleaved with carbon nanotube veils[J]. Composites Part A: Applied Science and Manufacturing,2019,124:105477. doi: 10.1016/j.compositesa.2019.105477 [21] ZHANG J, LIN T, WANG X. Electrospun nanofibre toughened carbon/epoxy composites: Effects of polyetherketone cardo (PEK-C) nanofibre diameter and interlayer thickness[J]. Composites Science Technology,2010,70:1660-6. doi: 10.1016/j.compscitech.2010.06.019 [22] YANG H H. Aromatic high strength fibres[M]. New York: Wiley-Inter science, 1989 [23] SOHN M S, HU X Z. Mode Ⅱ delamination toughness of carbon-fibre/epoxy composites with chopped Kevlar fibre reinforcement[J]. Composites Science and technology,1994,52(3):439-448. doi: 10.1016/0266-3538(94)90179-1 [24] YASAEE M, BOND I P, TRASK R S, et al. Mode Ⅱ interfacial toughening through discontinuous interleaves for damage suppression and control[J]. Composites Part A: Applied Science and Manufacturing,2012,43:121-128. doi: 10.1016/j.compositesa.2011.09.026 [25] YUAN B Y, WEE E P J, CHOENG J L K, et al. Quasi-Z-directional toughening from un-bonded non-woven veil at interface in laminar composites[J]. Composites Communications,2017,6:20-24. doi: 10.1016/j.coco.2017.07.007 [26] CHENG F, HU Y S, YUAN B Y, et al. Transverse and longitudinal flexural properties of unidirectional carbon fiber composites interleaved with hierarchical Aramid pulp micro/nano-fibers[J]. Composites Part B: Engineering,2020,188:107897. doi: 10.1016/j.compositesb.2020.107897 [27] HU Y S, CHENG F, YUAN B Y, et al. Effect of aramid pulp on low temperature flexural properties of carbon fibre reinforced plastics[J]. Composites Science and Technology,2020,192:108095. doi: 10.1016/j.compscitech.2020.108095 [28] CALLISTER W D and RETHWISCH D G. Materials science and engineering[M]. New York: John wiley & sons, 2011. -

下载:

下载: