Calculation model for pullout behavior of inclined hooked-end steel fiber in cement-based materials

-

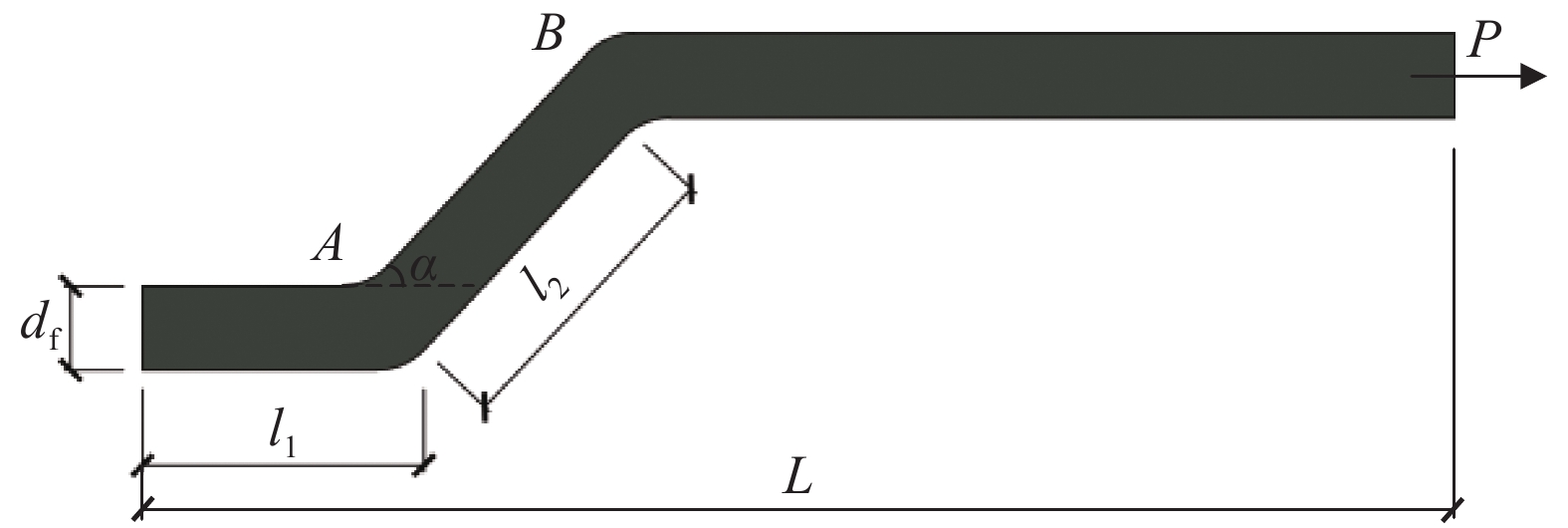

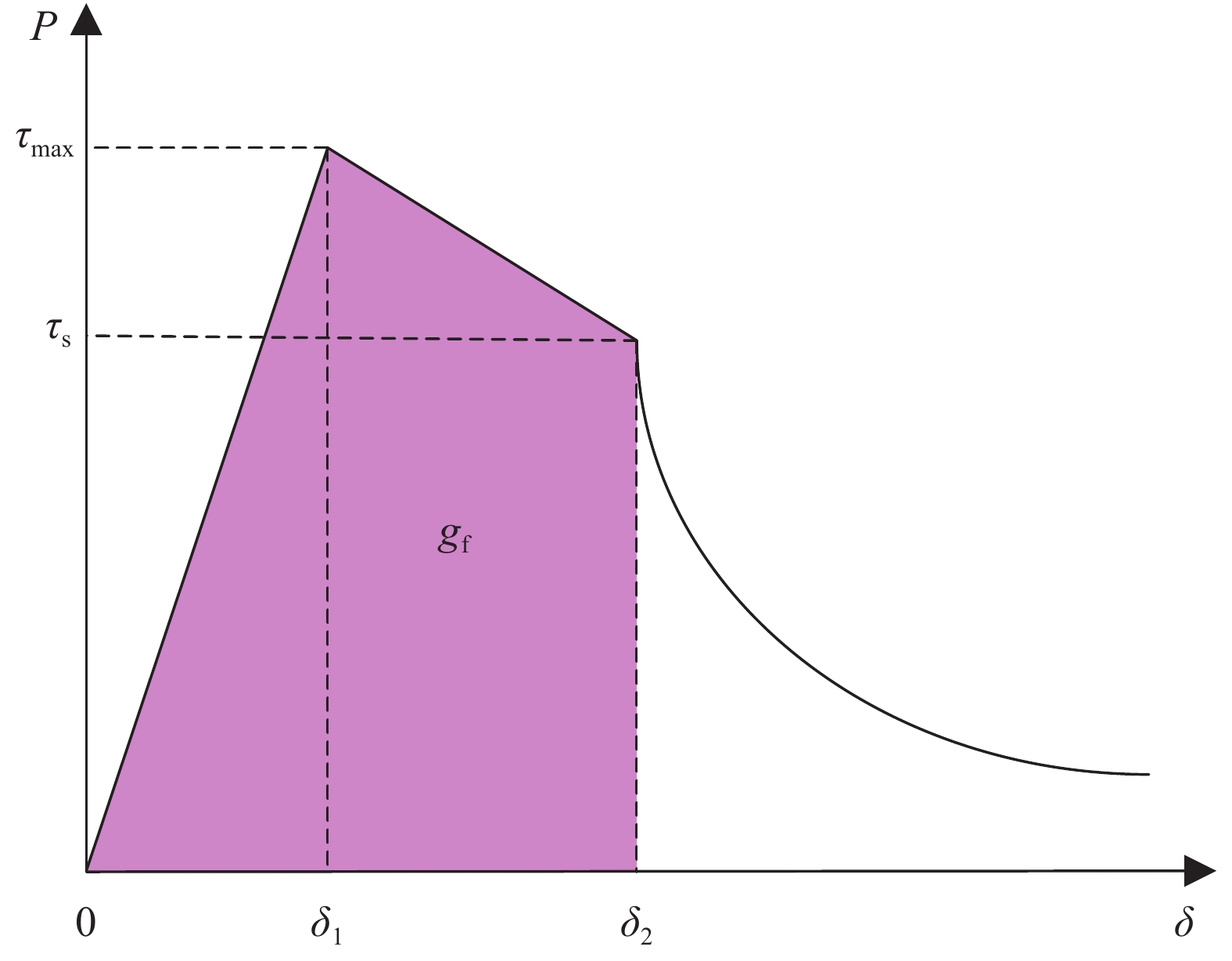

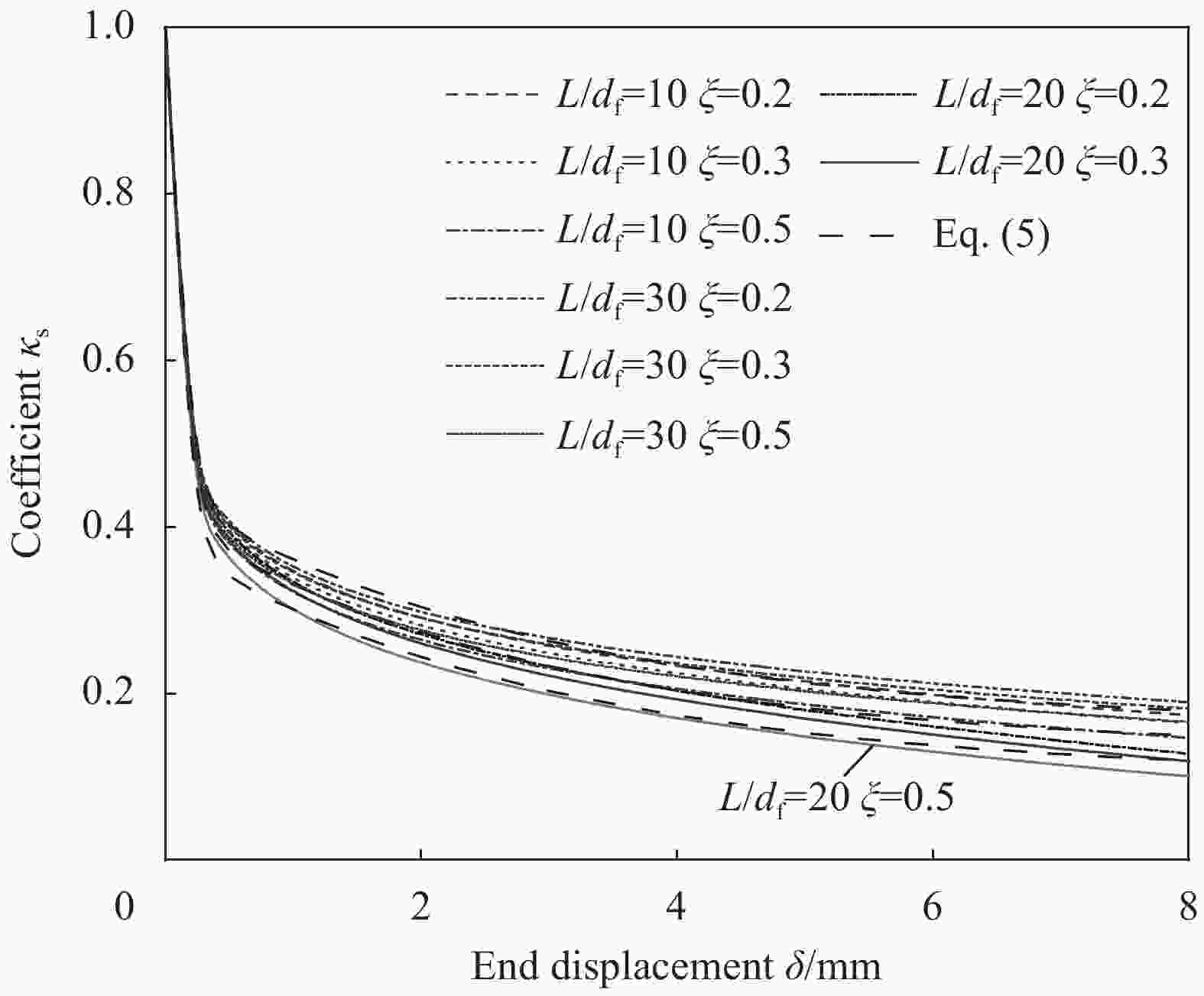

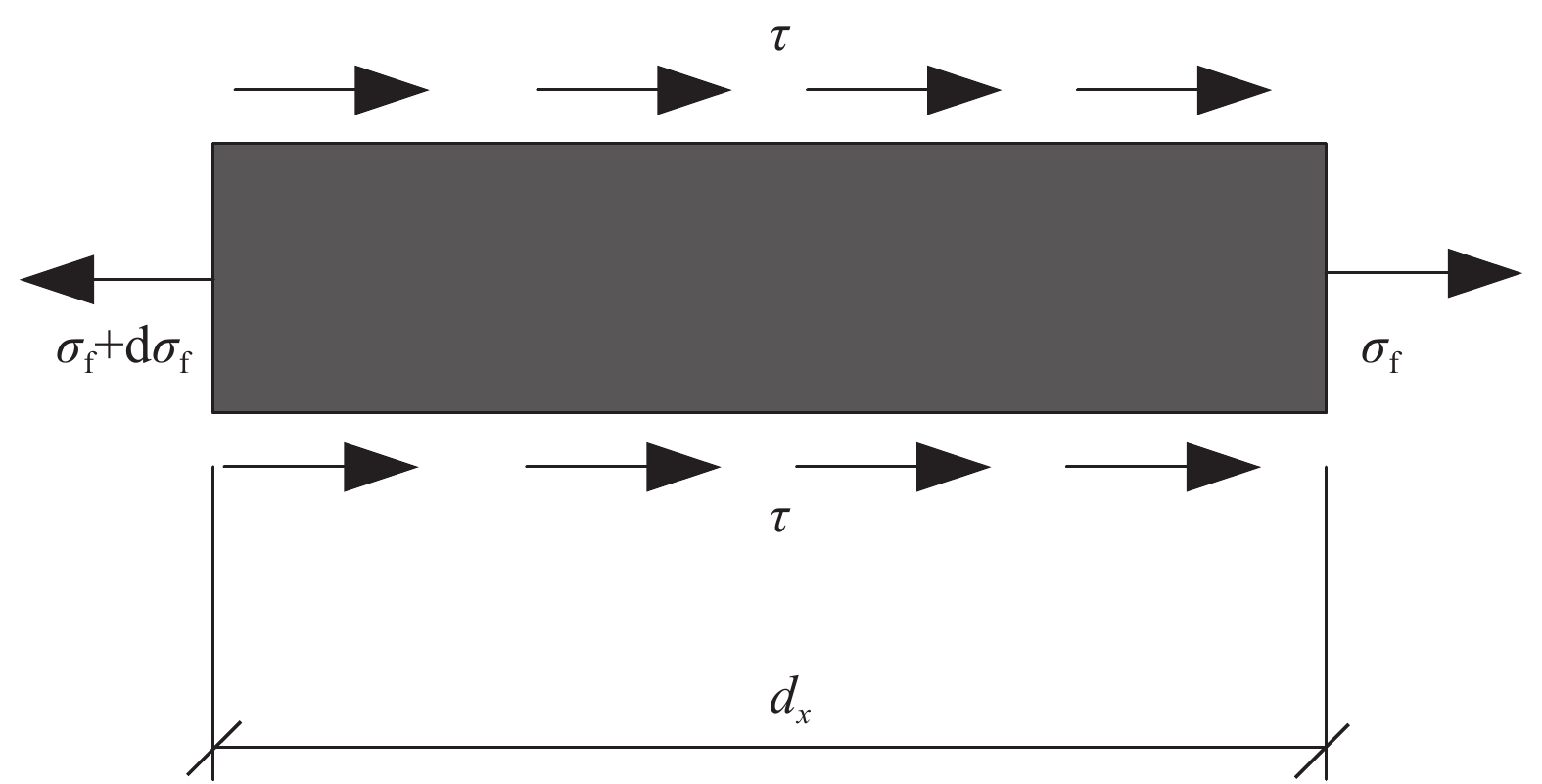

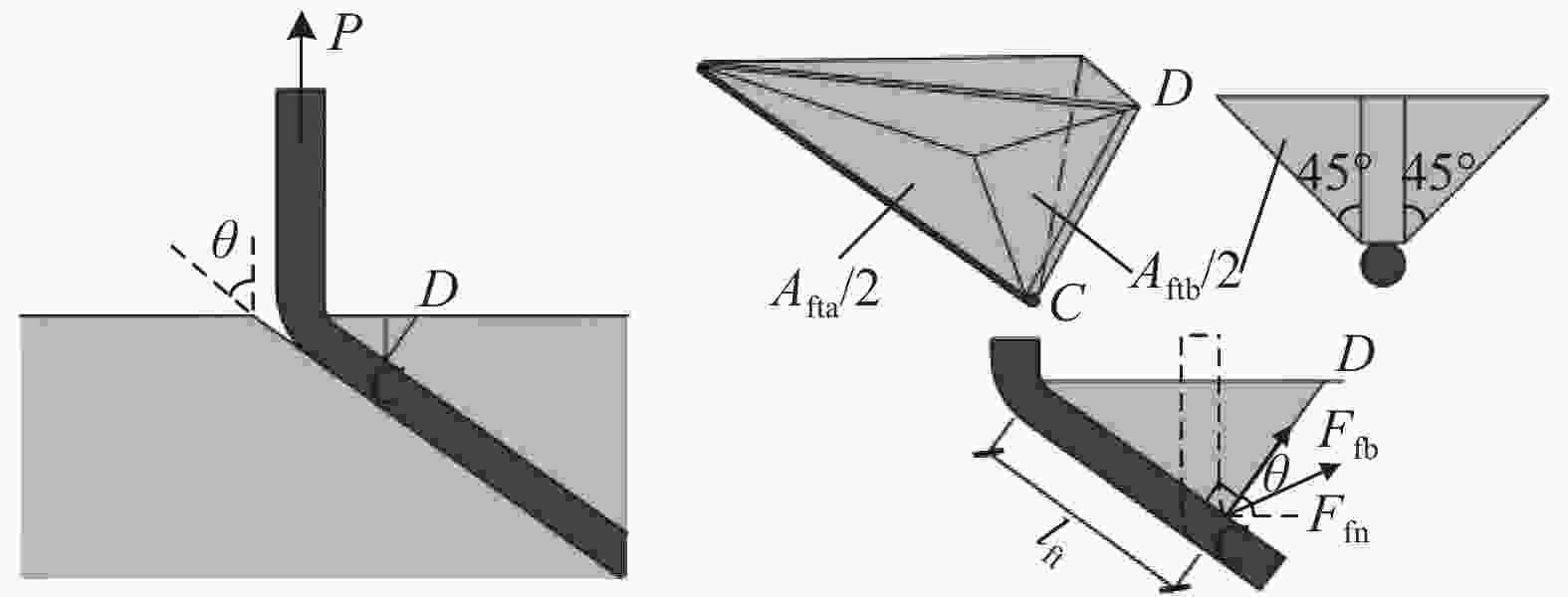

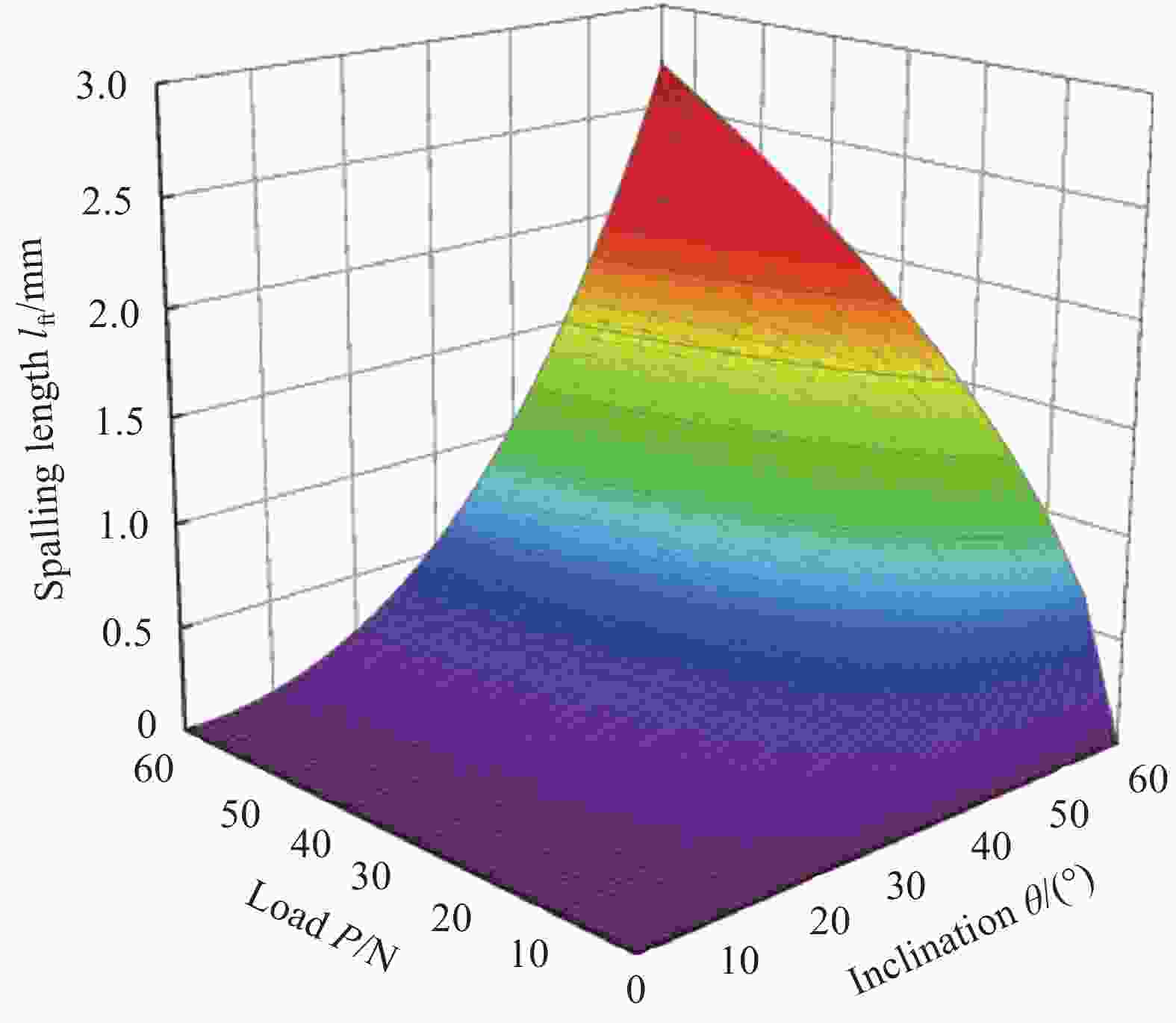

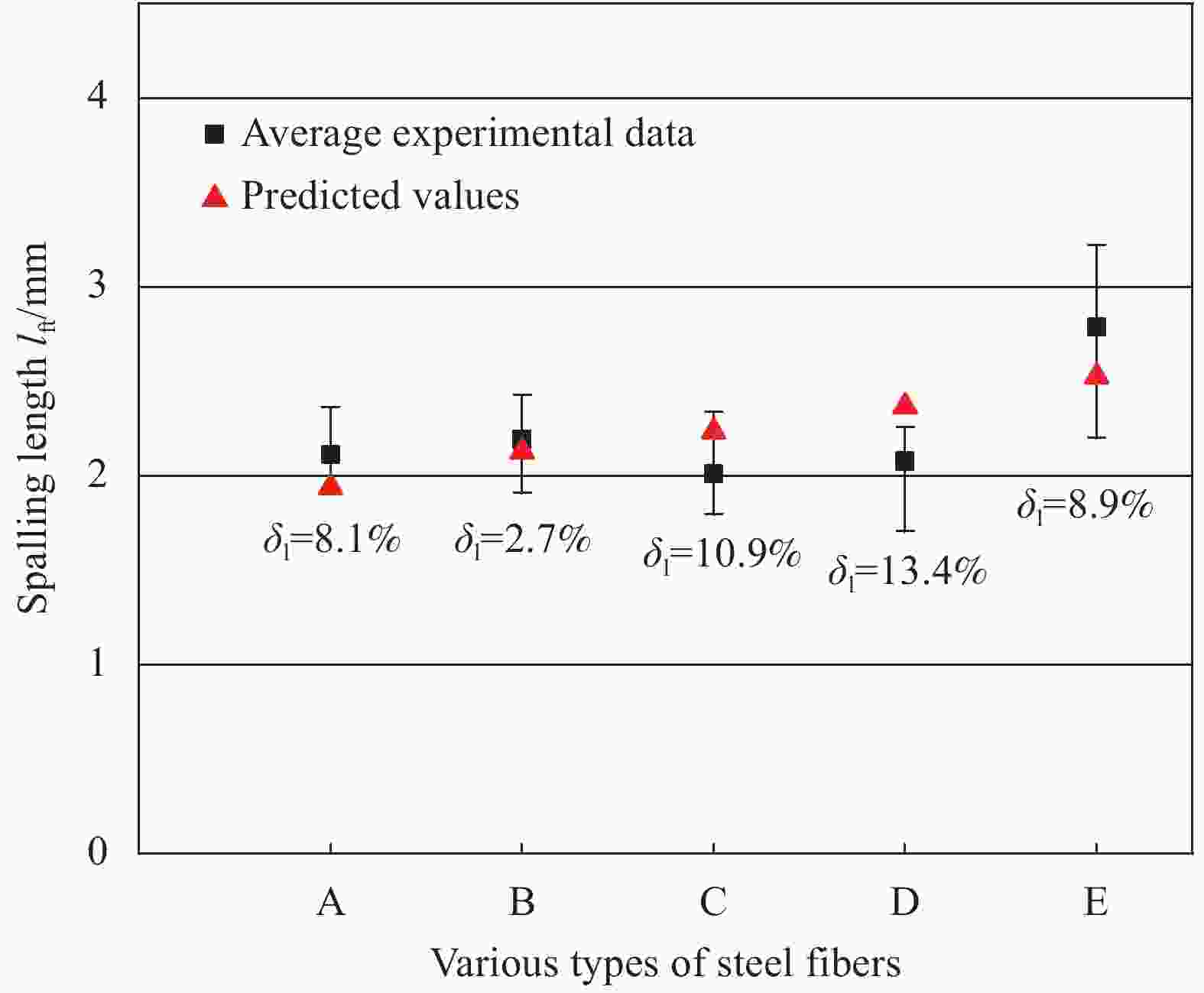

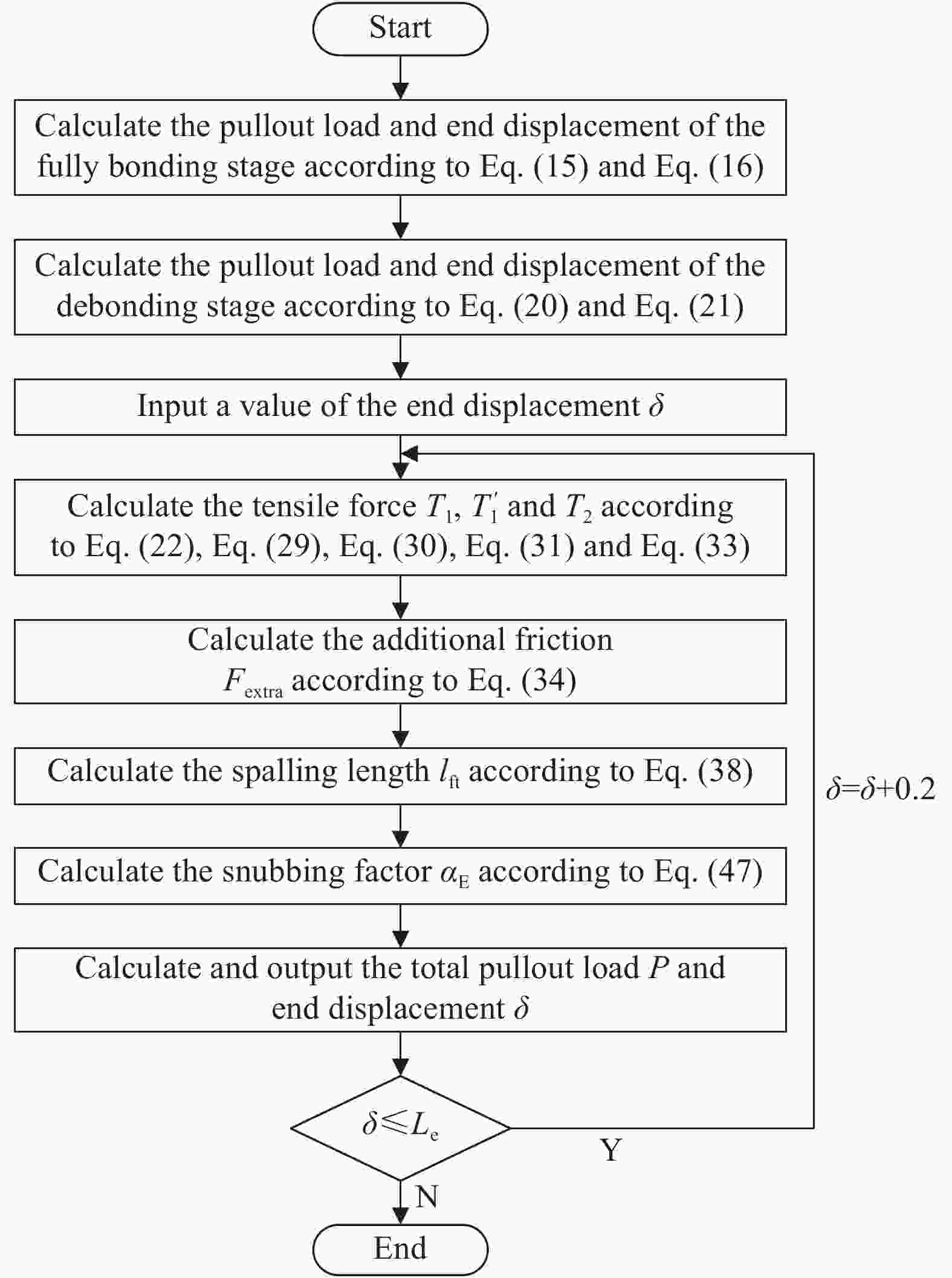

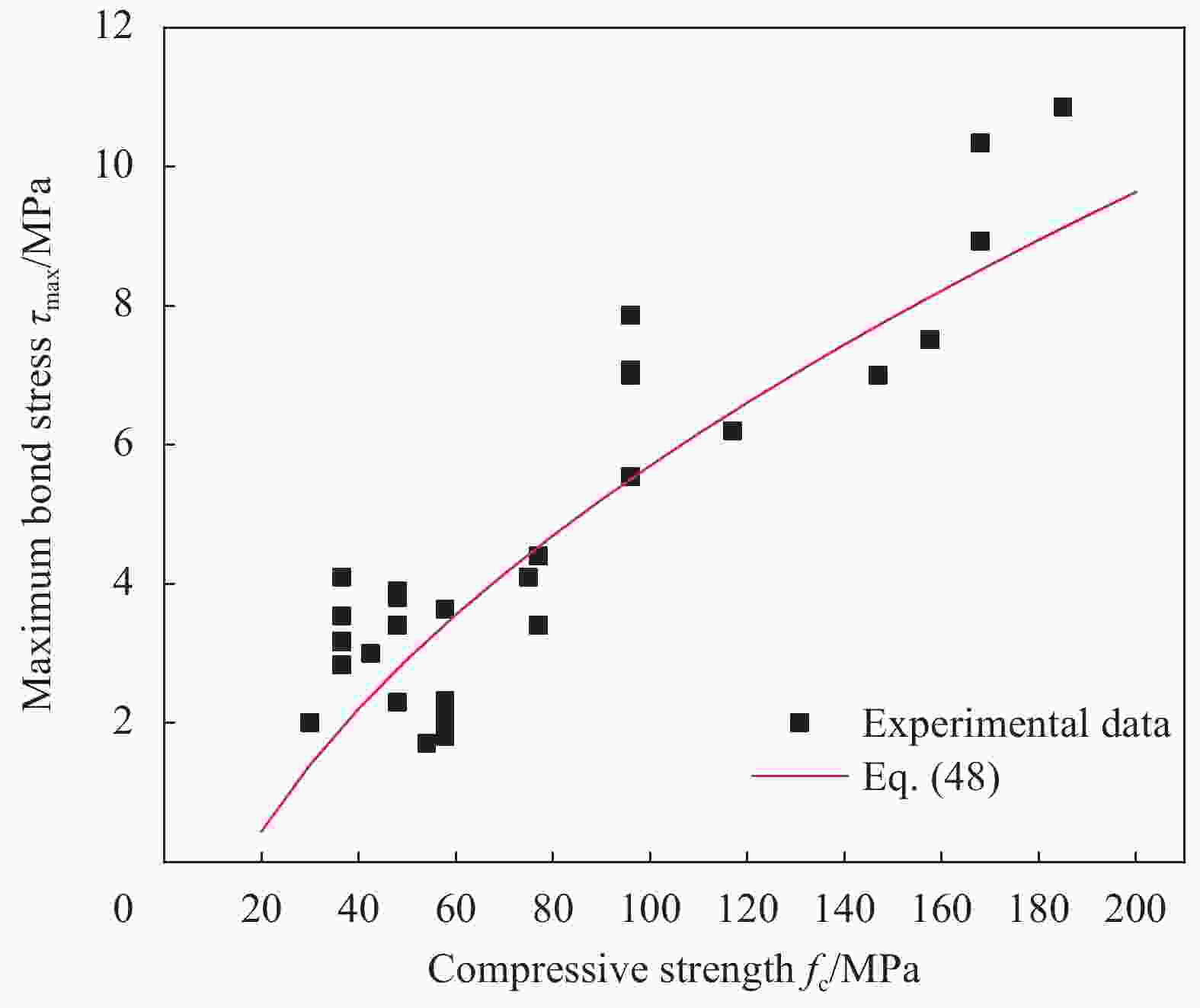

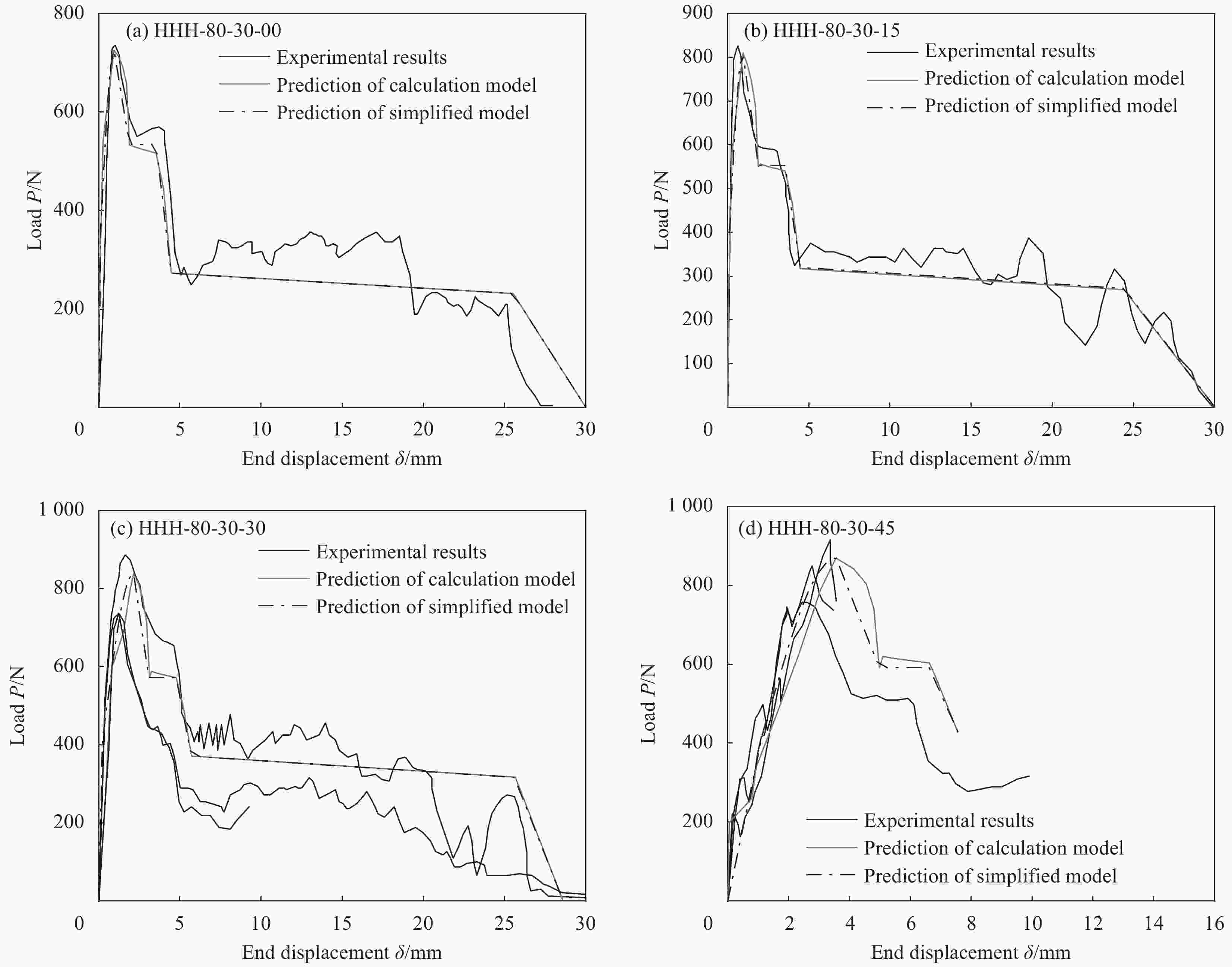

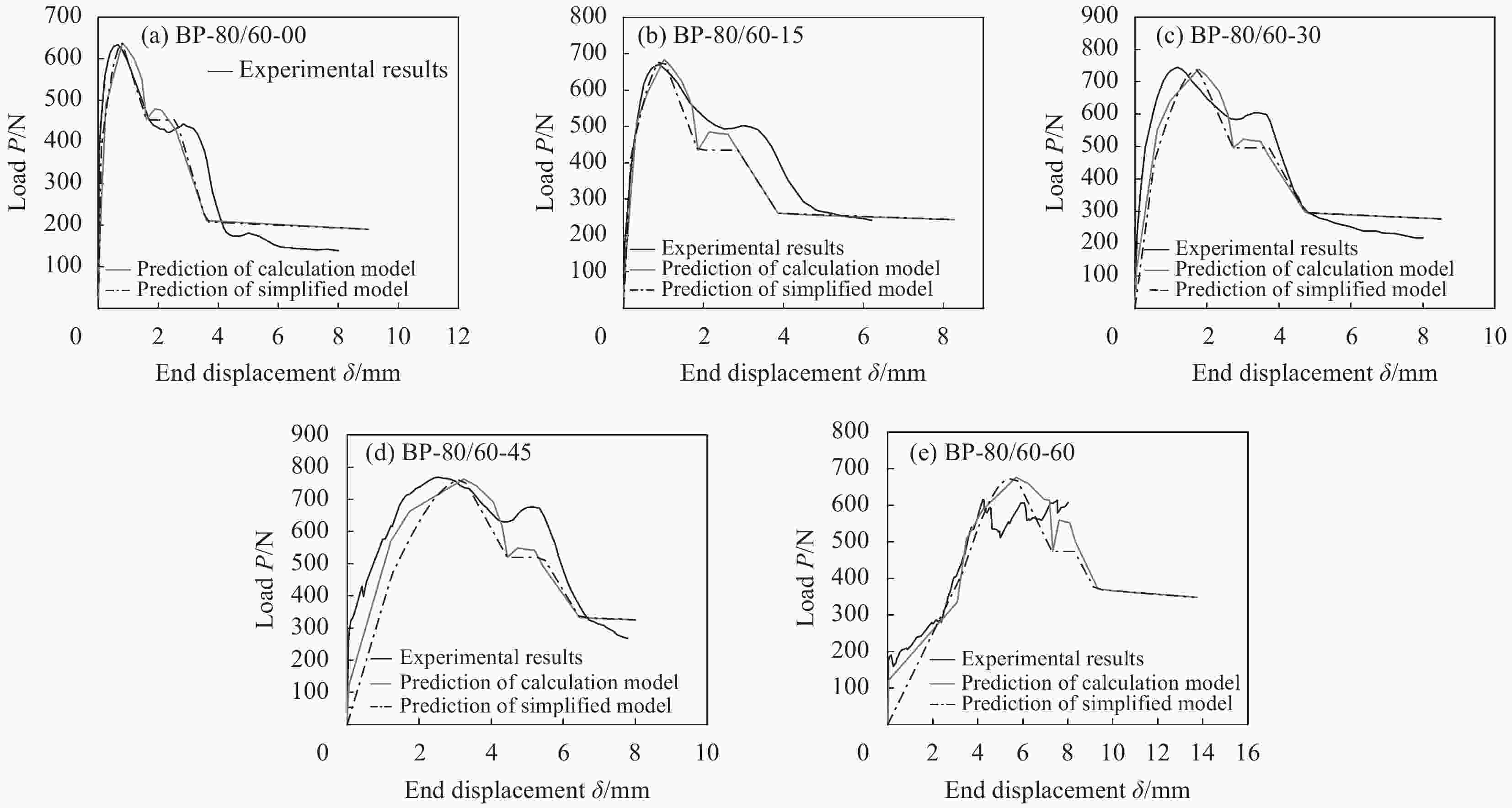

摘要: 端钩型钢纤维是结构工程中应用最广泛的钢纤维品类之一,单根钢纤维拔出力学性能对于确定钢纤维混凝土的受拉本构及受拉韧性具有重要意义。为了得到能够有效预测倾斜端钩型钢纤维拔出荷载-端部位移曲线的理论模型,首先将倾斜端钩型钢纤维拔出过程分为完全黏结、脱黏和拔出滑移阶段三种受力状态,考虑不同拔出阶段及基体孔道损伤,建立了钢纤维黏结应力与纤维端部位移之间的关系,同时考虑钢纤维塑性变形、附加摩擦力及纤维拔出角度导致的基体剥落和挤压摩擦效应,建立了一种可以预测倾斜端钩型钢纤维拔出全过程的理论计算模型,在此基础上提出形式简单的简化模型,选取已有试验数据对提出的计算模型进行验证,结果表明:本文提出的两种模型均能够有效预测端钩型钢纤维拔出全过程,具有较高的计算精度且变异系数小,为进一步分析钢纤维对水泥基材料受拉性能的增强作用提供了理论依据。Abstract: It is well-known that the hooked-end steel fiber is one of the most widely-used type of steel fiber in structural engineering, and the pullout behavior of a single steel fiber is significant for determining the tensile constitutive and the tensile toughness of steel fiber reinforced concrete. In order to obtain a theoretical analysis method which can effectively predict the pullout load-end displacement curves of inclined hooked-end steel fiber, the inclined pullout process of the hooked-end steel fiber was divided into three states: fully bonding stage, debonding stage and pullout slipping stage. A novel bond shear stresses-end displacement model was established considering the different steel fiber pullout stages and the damage of the matrix hole. A theoretical analysis model that can predict the load-slip curve of the pullout behavior of inclined hooked-end steel fiber was proposed by considering the plastic deformation of the steel fiber, the additional friction, spalling and snubbing effects of the matrix caused by the fiber pullout inclination. A simplified model was also proposed based on the theoretical model. The existing experimental data were selected to verify and evaluate the proposed calculation model. The results show that the two models proposed in this paper can effectively predict the process of hooked-end steel fiber inclined pullout. And the two models have high calculation accuracy and low coefficient of variation, which provide a theoretical reference for further analysis of the effect of steel fiber on the enhancement of tensile properties of cement-based materials.

-

Key words:

- hooked-end steel fiber /

- pullout behavior /

- inclined fiber /

- additional friction /

- spalling of matrix /

- snubbing effect

-

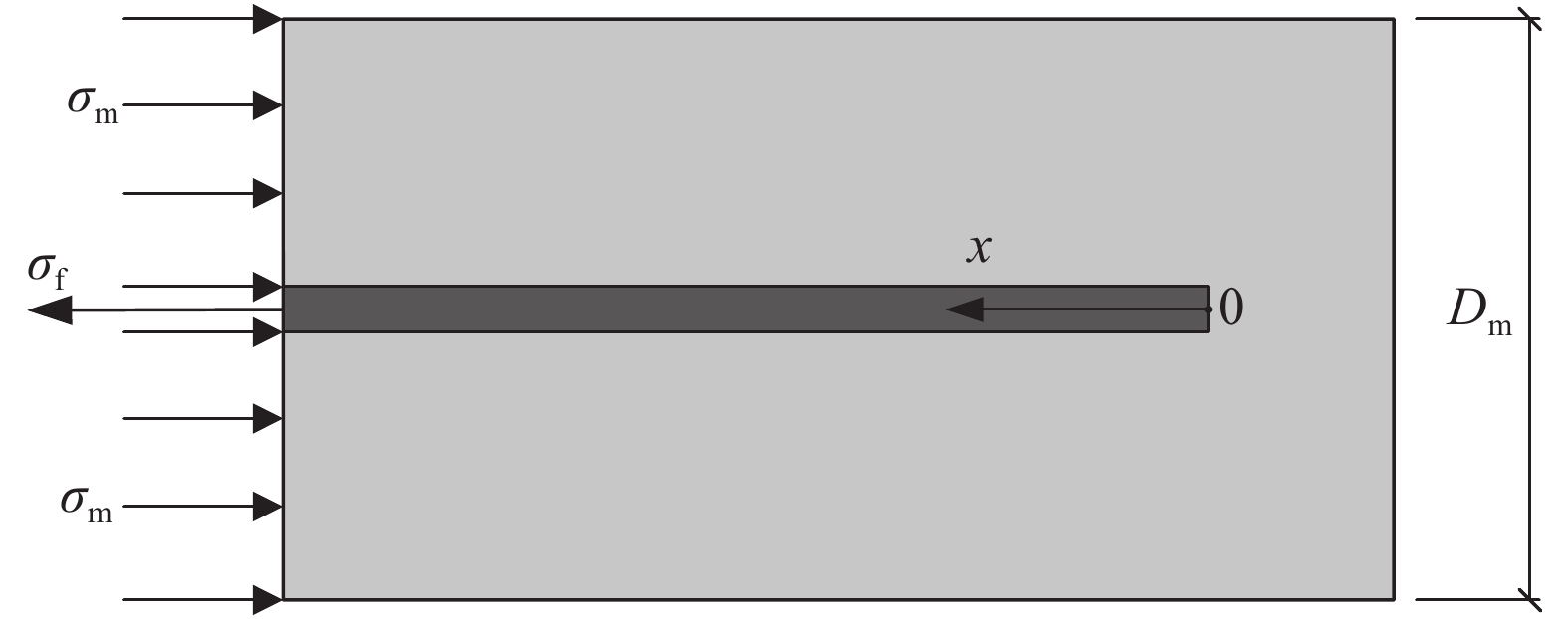

图 3 钢纤维黏结应力-端部位移关系

Figure 3. Relationship between fiber bond stress and end displacement

δ1, δ2—Maximum end-displacement in the completely bonding stage and debonding stage, respectively; τmax—Bond shear strength; τs—Bond shear stress corresponding to the end of the debongding stage; gf—Interfacial shear fracture energy

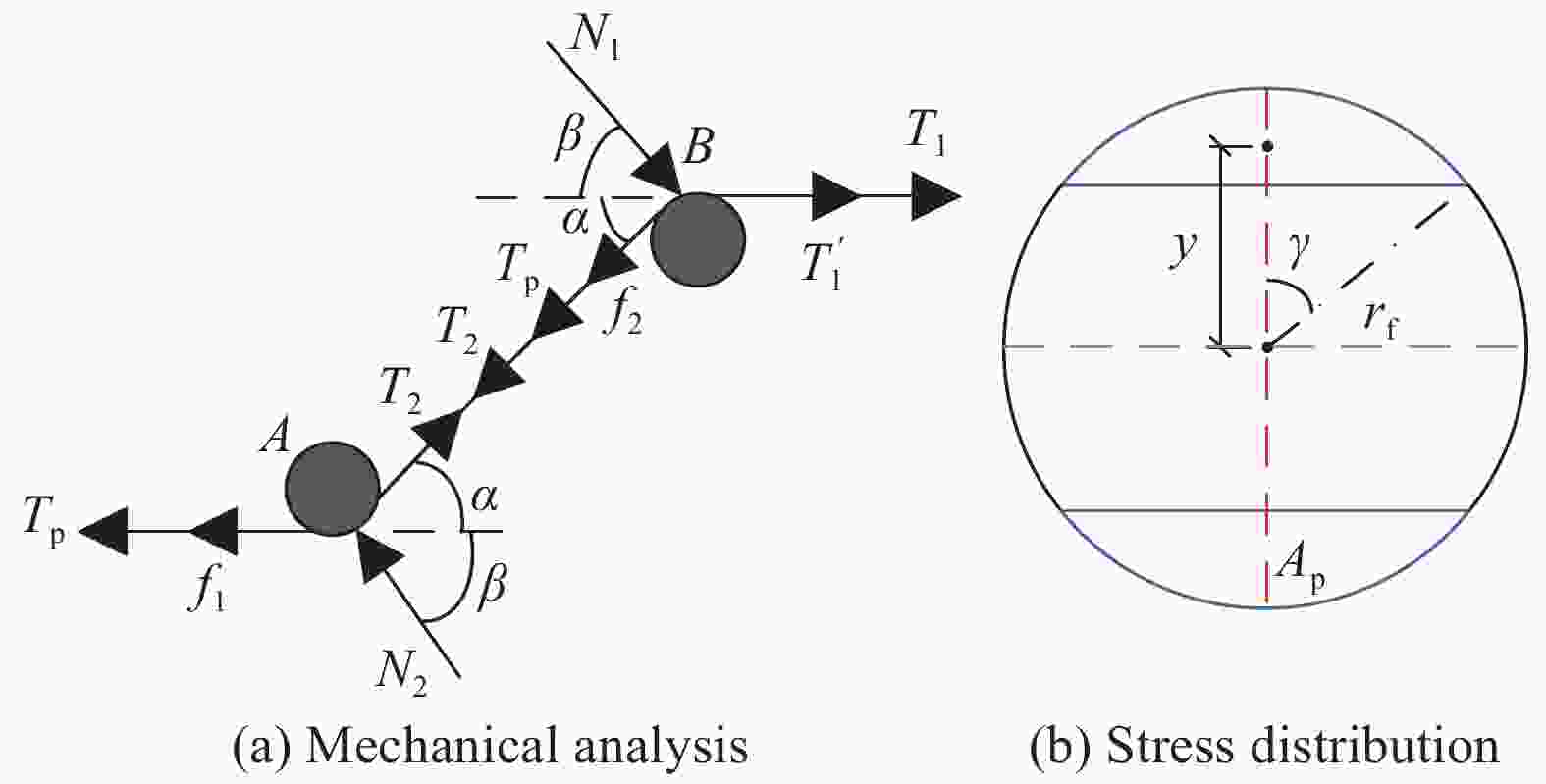

图 7 钢纤维端钩部分受力分析及截面应力分布

Figure 7. Mechanical analysis and stress distribution of hooked-end of steel fiber

T1, T2 and T1'—Tensile force for the end-hook; f1 and f2—Bond force of the end-hook; Tp—Tensile force required for plastic deformation; β—Angle of the normal force; N1 and N2—Normal force; rf—Radius of steel fiber; Ap—Area of the plastic region; y—Distance between the neutral axis and the plastic zone centroid; γ—Angle between the plastic zone and the vertical axis

表 1 用于预测端钩型钢纤维拔出力学性能的参数取值

Table 1. Parameters used to predict the pullout behavior of hooked-end steel fiber

Parameter Value Elastic modulus of matrix Em/MPa 3.2×104 Elastic modulus of fiber Ef/MPa 2×105 Diameter of matrix Dm 10df Fiber Poisson's ratio vf 0.3 Matrix Poisson's ratio vm 0.2 Curvature radius of hooked fiber ρ 2df End hook angle α/(°) 50 表 2 钢纤维拔出峰值荷载预测值与试验值对比

Table 2. Comparison between predicted and experimental values of steel fiber pullout peak load

Reference Specimen Ppre/N Pex/N Ppre/Pex Soetens et al[12] HHH-80-30-00 725.91 736.63 0.98 HHH-80-30-15 810.56 818.18 0.99 HHH-80-30-30 838.71 885.96 1.07 HHH-80-30-45 796.03 869.45 1.08 Breitenbücher et al[29] BP-80/60-00 637.51 633.88 1.01 BP-80/60-15 684.43 670.84 1.02 BP-80/60-30 739.01 744.76 0.99 BP-80/60-45 753.37 768.79 0.97 BP-80/60-60 675.96 615.40 1.10 μ 1.02 COV 0.05 Notes: Ppre and Pex—Predicted and the experimental value of the peak load, respectively; μ—Ratio of Ppre and Pex; COV—Coefficient of variation; “HHH” in notation system of the first series of tests represents the high strength matrix and hooked-end fiber with high carbon content. Figures in the second, third and fourth symbol represent fiber diameter (mm/100), embedded length (mm) and pullout inclination (°), respectively. For example, the notation of “HHH-80-30-30”—Pullout specimen with high strength matrix, 0.8 mm of fiber diameter, 30 mm of embedded length and 30° of pullout inclination. “BP” in notation system of the second series of tests represents a type of hooked-end fiber with tensile yield strength 2600 MPa. Figures in the second, third and fourth symbol represent fiber aspect ratio (-), fiber length (mm) and pullout inclination (°), respectively. For example, the notation of “BP-80/60-15”—Pullout specimen with 80 of fiber aspect ratio, 60 mm of fiber length and 15° of pullout inclination. -

[1] 韩嵘, 赵顺波, 曲福来. 钢纤维混凝土抗拉性能试验研究[J]. 土木工程学报, 2006, 39(11):63-67. doi: 10.3321/j.issn:1000-131X.2006.11.010HAN Rong, ZHAO Shunbo, QU Fulai. Experimental study on the tensile performance of steel flber reinforced concrete[J]. China Civil Engineering Journal,2006,39(11):63-67(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.11.010 [2] 卿龙邦, 聂雅彤, 慕儒. 钢纤维对水泥基复合材料抗起裂特性的影响[J]. 复合材料学报, 2017, 34(8):1862-1869.QING Longbang, NIE Yatong, MU Ru. Influence of steel fibres on the resistance to crack initiation of cementitious composites[J]. Acta Materiae Compositae Sinica,2017,34(8):1862-1869(in Chinese). [3] 梁兴文, 胡翱翔, 于婧, 等. 钢纤维对超高性能混凝土抗弯力学性能的影响[J]. 复合材料学报, 2018, 35(3):722-731.LIANG Xingwen, HU Aoxiang, YU Jing, et al. Effect of steel fibers on the flexural response of ultra-high performance concrete[J]. Acta Materiae Compositae Sinica,2018,35(3):722-731(in Chinese). [4] NAAMAN A E. Engineered steel fibers with optimal properties for reinforcement of cement composites[J]. Journal of Advanced Concrete Technology,2003,1(3):241-252. doi: 10.3151/jact.1.241 [5] 秦鸿根, 刘斯凤, 孙伟, 等. 钢纤维掺量和类型对混凝土性能的影响[J]. 建筑材料学报, 2003(4):364-368. doi: 10.3969/j.issn.1007-9629.2003.04.005QIN Honggen, LIU Sifeng, SUN Wei, et al. Effect of types and volume percentage of steel fiber on properties of concrete[J]. Journal of Building Materials,2003(4):364-368(in Chinese). doi: 10.3969/j.issn.1007-9629.2003.04.005 [6] 许碧莞, 施惠生, JU Jiannwen Woody. 水泥基体中弓形钢纤维拔出耗能模型[J]. 同济大学学报(自然科学版), 2010, 38(8):1194-1199. doi: 10.3969/j.issn.0253-374x.2010.08.017XU Biwan, SHI Huisheng, JU Jiannwen Woody. Modeling pullout energy of hooked end steel fiber in cementitious matrices[J]. Journal of Tongji University (Natural Science),2010,38(8):1194-1199(in Chinese). doi: 10.3969/j.issn.0253-374x.2010.08.017 [7] 朱德举, 李向阳, 史才军, 等. 水泥基体中仿生钢纤维的拔出试验[J]. 湖南大学学报(自然科学版), 2018, 45(1):84-89.ZHU Deju, LI Xiangyang, SHI Caijun, et al. Pullout test of bio-inspired steel fiber from cementitious matrix[J]. Journal of Hunan University (Natural Sciences),2018,45(1):84-89(in Chinese). [8] ROBINS P, AUSTIN S, JONES P. Pull-out behaviour of hooked steel fibres[J]. Materials and Structures,2002,35:434-442. doi: 10.1007/BF02483148 [9] NAAMAN A E, NAMUR G G, ALWAN J M, et al. Fiber pullout and bond slip. I: Analytical study[J]. Journal of Structural Engineering,1991,117:2769-2790. doi: 10.1061/(ASCE)0733-9445(1991)117:9(2769) [10] SHANNAG M J, BRINCKER R, HANSEN W. Pullout behavior of steel fibers from cement-based composites[J]. Cement and Concrete Research,1997,27(6):925-936. doi: 10.1016/S0008-8846(97)00061-6 [11] GHODDOUSI P, AHMADI R, SHARIFI M. Fiber pullout model for aligned hooked-end steel fiber[J]. Canadian Journal of Civil Engineering,2010,37:1179-1188. doi: 10.1139/L10-053 [12] SOETENS T, VAN-GYSEL A, MATTHYS S, et al. A semi-analytical model to predict the pull-out behaviour of inclined hooked-end steel fibres[J]. Construction and Building Materials,2013,43(2):253-265. [13] LARANJEIRA F, MOLINS C, AGUADO A. Predicting the pullout response of inclined hooked steel fibers[J]. Cement and Concrete Research,2010(40):1471-1487. [14] KULLAA J. Dimensional analysis of bond modulus in fiber pullout[J]. Journal of Structural Engineering,1996,122(7):783-787. doi: 10.1061/(ASCE)0733-9445(1996)122:7(783) [15] GAO Y, MAI Y, COTTERELL B. Fracture of fiber-reinforced materials[J]. Journal of Applied Mathematics and Physics,1988,39(4):550-572. [16] YANG S, HU X, LENG K, et al. Correlation between cohesive crack-tip local fracture energy and peak load in mortar beams[J]. Journal of Materials in Civil Engineering,2014,26(10):1-8. [17] CHANVILLARD G. Modeling the pullout of wire-drawn steel fibers[J]. Cement and Concrete Research,1999,29(7):1027-1037. doi: 10.1016/S0008-8846(99)00081-2 [18] GEORGIADIS-STEFANIDI K, MISTAKIDIS E, PANTOUSA D, et al. Numerical modelling of the pull-out of hooked steel fibers form high-strength cementitious matrix, supplemented by experimental results[J]. Construction and Building Materials,2010,24:2489-2506. doi: 10.1016/j.conbuildmat.2010.06.007 [19] CAILLEUX E, CUTARD T, BERNHART G. Pullout of steel fibers from a refractory castable: Experiment and modelling[J]. Mechanics of Materials,2005,37(4):427-445. doi: 10.1016/j.mechmat.2004.02.001 [20] LEUNG C K Y, SHAPIRO N. Optimal steel fiber strength for reinforcement of cementitious materials[J]. Journal of Materials in Civil Engineering,1999,11(2):116-123. doi: 10.1061/(ASCE)0899-1561(1999)11:2(116) [21] LI V C, WANG Y, BACKER S. Effect of inclining angle, bundling and surface treatment on synthetic fibre pull-out from a cement matrix[J]. Composites,1990,21(2):132-140. doi: 10.1016/0010-4361(90)90005-H [22] XU B W, JU J W, SHI H S. Progressive micromechanical modeling for pullout energy of hooked-end steel fiber in cement-based composites[J]. International Journal of Damage Mechanics,2011,20(6):922-938. doi: 10.1177/1056789510385260 [23] PARK J K, NGO T T, KIM D J. Interfacial bond characteristics of steel fibers embedded in cementitious composites at high rates[J]. Cement and Concrete Research,2019,123:1-17. [24] OUYANG C, PACIOS A, SHAH S P. Pullout of inclined fibers from cementitious matrix[J]. Journal of Engineering Mechanics,1994,120(12):2641-2659. doi: 10.1061/(ASCE)0733-9399(1994)120:12(2641) [25] ZHANG C, SHI C, WU Z, et al. Numerical and analytical modeling of fiber-matrix bond behaviors of high perfor-mance cement composite[J]. Cement and Concrete Research,2019,125:1-14. [26] FENG J, SUN W, WANG X, et al. Mechanical analyses of hooked fiber pullout performance in ultra-high-perfor-mance concrete[J]. Construction and Building Materials,2014,69:403-410. doi: 10.1016/j.conbuildmat.2014.07.049 [27] ABU-LEBDEH T, HAMOUSH S, HEARD W, et al. Effect of matrix strength on pullout behavior of steel fiber reinforced very-high strength concrete composites[J]. Construction and Building Materials,2011,25(1):39-46. doi: 10.1016/j.conbuildmat.2010.06.059 [28] GENG Y P, LEUNG C K Y. Damage-based modeling of fiber pullout under variable compressive stress[J]. Journal of Engineering Mechanics,1997,123(4):342-349. doi: 10.1061/(ASCE)0733-9399(1997)123:4(342) [29] BREITENBUECHER R, MESCHKE G, SONG F, et al. Experimental, analytical and numerical analysis of the pullout behaviour of steel fibres considering different fibre types, inclinations and concrete strengths[J]. Structural Concrete,2014,15(2):126-135. doi: 10.1002/suco.201300058 -

下载:

下载: