Research progress of bacterial cellulose and its composites for electrochemical energy storage and sensing

-

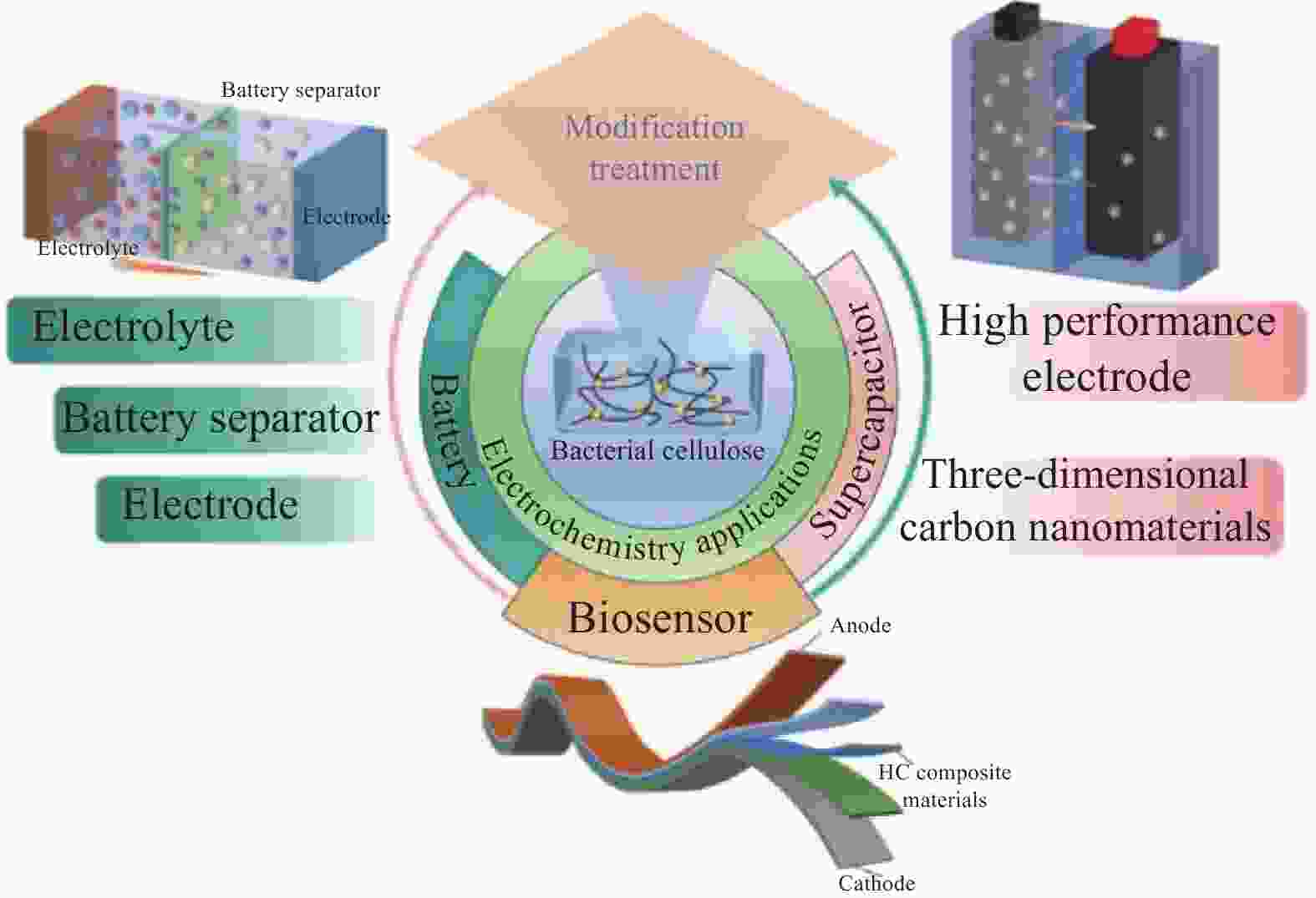

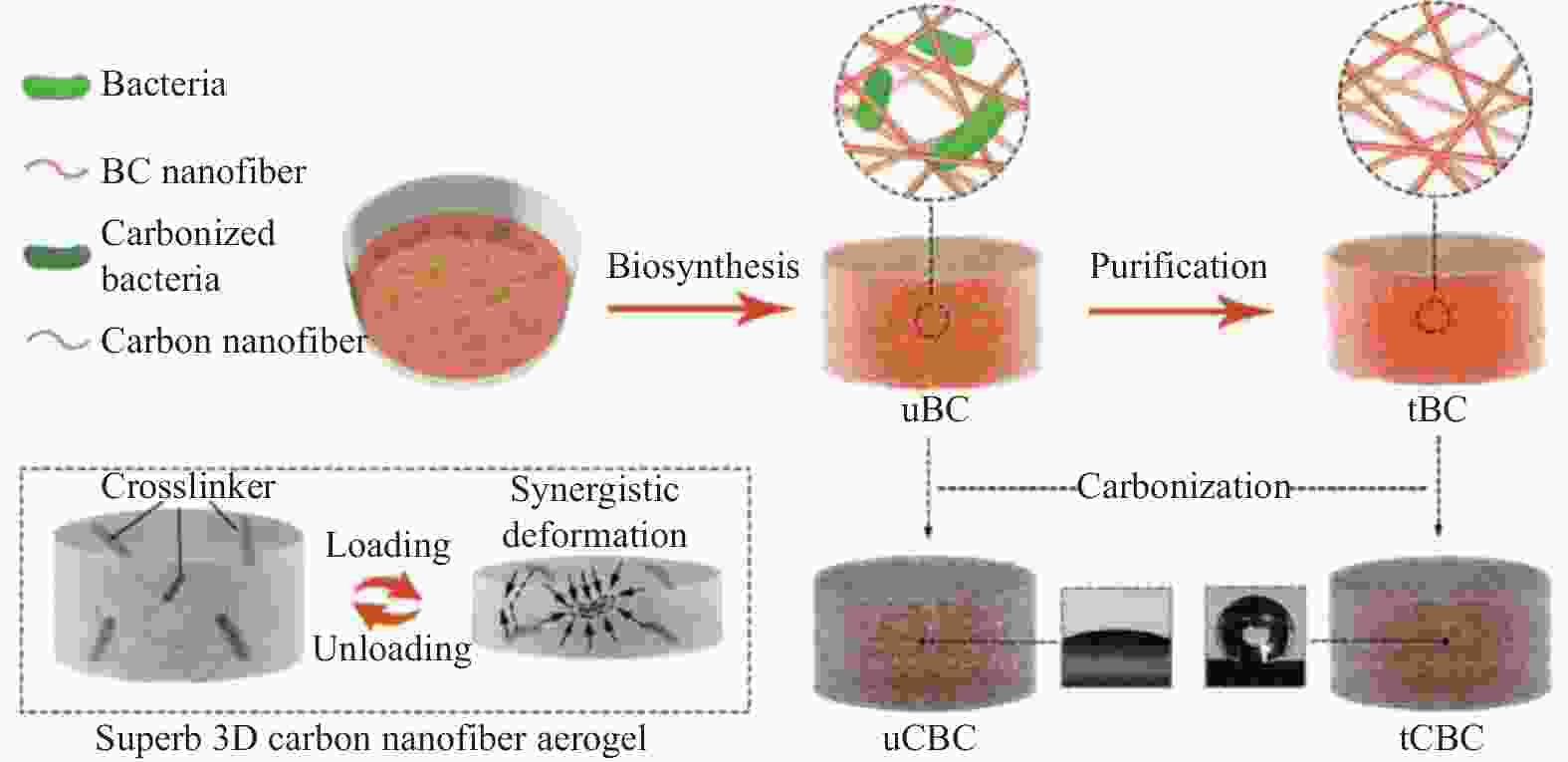

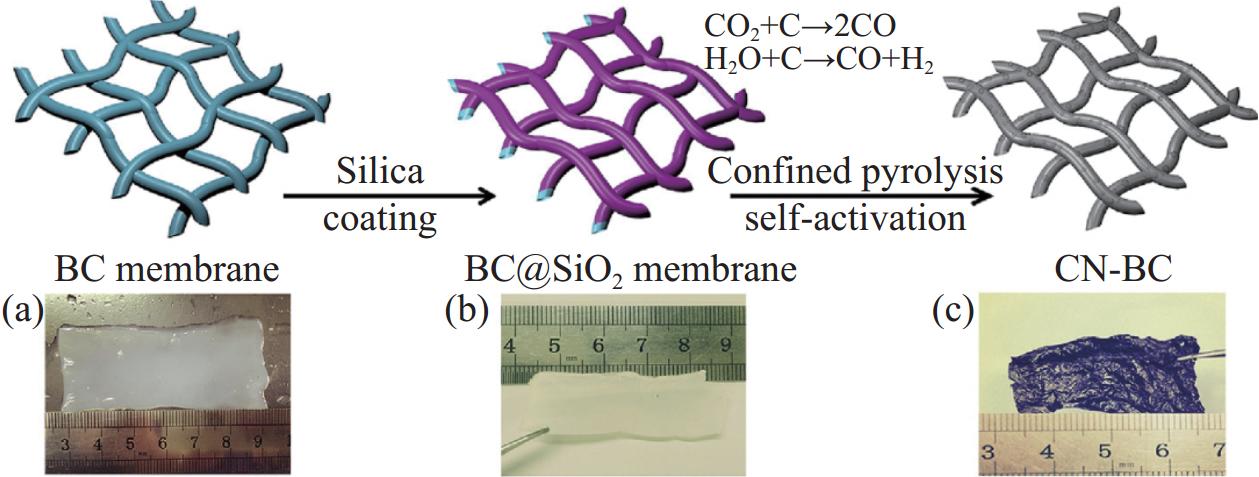

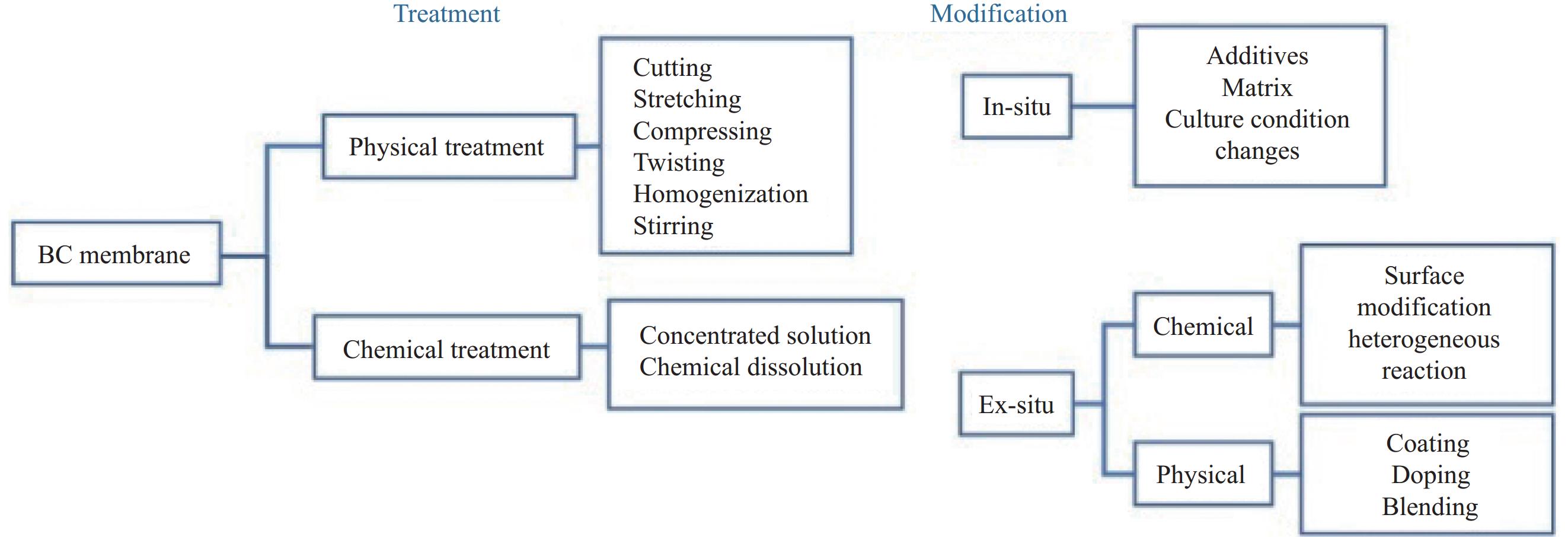

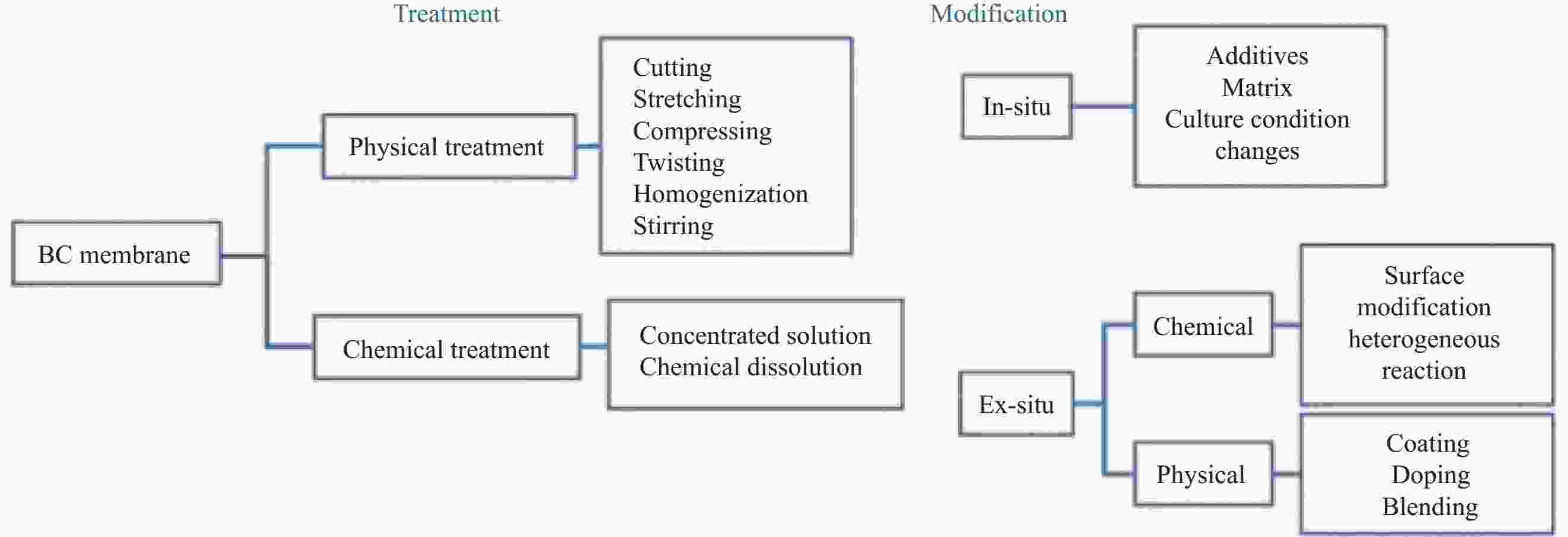

摘要: 细菌纤维素(Bacterial cellulose,BC)来源丰富,是一种绿色环保的可再生材料。BC具有优异的物理化学特性,被认为是具有多样性应用潜力的生物聚合物材料,随着能源和生态环境的持续恶化,对于开发先进储能技术亟待实现,BC在电化学储能、传感及能源转换领域展现出广阔的应用前景,受到诸多关注。本文对BC做了简要介绍,以BC及其复合材料在电化学储能及传感领域的种类、不同处理及改性手段对BC结构与性能的影响为线索,系统地对BC在电化学储能及传感领域的应用进展进行了概述,对其在新型电子器件及能源转换领域的发展也有所涉及,最后对BC在电化学储能及传感材料的研究进展及发展方向进行了总结和展望。Abstract: Bacterial cellulose (BC) is a green and renewable material with abundant sources. BC has outstanding physical and chemical properties and is considered to be a biopolymer material with diverse application potential. With the continuous deterioration of energy and ecological environment, it is urgent to develop advanced energy storage technology. BC shows broad application prospects in the fields of electrochemical energy storage, sensing and energy conversion, and has gained a lot of attention. In this review, BC is briefly introduced. Based on the types of BC and its composites in the field of electrochemical energy storage and sensing, as well as the effects of different treatments and modification methods on the structure and properties of BC, the application progress of BC in the field of electrochemical energy storage and sensing is systematically summarized. In addition, in terms of the composite matrix and reinforcement concept, the construction process of BC and its composites was systematically introduced. The application status of BC in the field of electrochemical energy storage and sensing is mainly reviewed, and the strengths and weaknesses of its application are analyzed and summarized. Meantime, the different applications of BC in new electronic devices and energy conversion are also involved. Finally, the existing challenges and prospects of BC in electrochemical energy storage and sensing are summarized.

-

Key words:

- bacterial cellulose /

- composite /

- energy storage /

- sensing /

- application progress

-

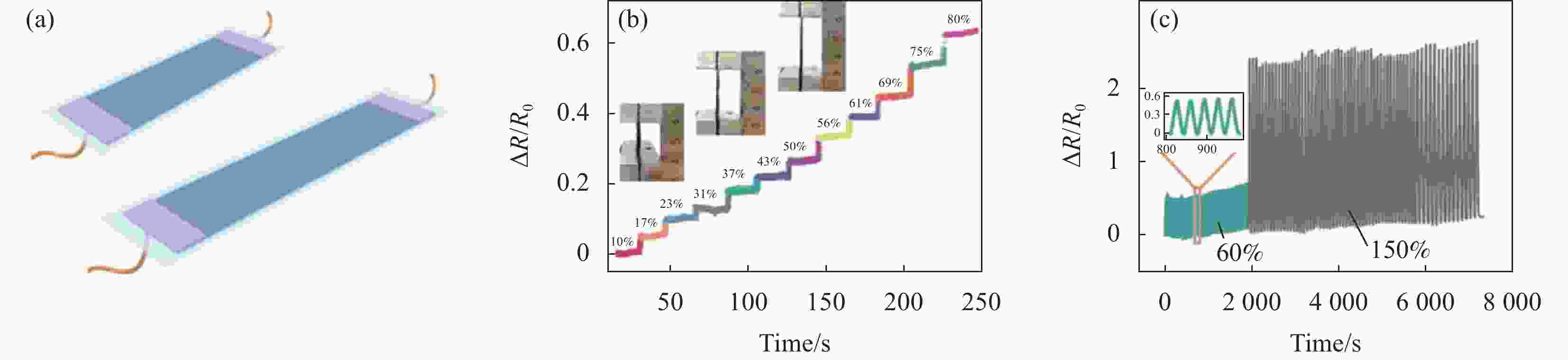

图 6 聚乙烯醇/海藻酸钠/BC/羧基化改性碳纳米管(PVA/SA/BC/MCC)水凝胶作为应变传感器 :(a)拉伸前后组装成压阻应变传感器的水凝胶示意图;(b)拉伸应变范围为10%至80%的相对电阻变化(ΔR/R0)(插图显示了拉伸过程中的压阻应变传感器的不同状态);(c)在60%和150%应变下重复拉伸/释放循环的传感器的相对电阻变化[75]

Figure 6. Polyvinyl alcohol/Sodium alginate/BC/Carboxylated modified carbon nanotubes (PVA/SA/BC/MCC) hydrogels as strain sensors: (a) Schematic of hydrogels assembled into piezoresistive strain sensors before and after stretching; (b) Relative resistance changes (ΔR/R0) within the stretching strain range of 10% to 80% (Illustrations showing different states of the piezoresistive strain sensors during stretching); (c) Relative resistance changes of the sensors during repeated stretching/releasing cycles at 60% and 150% strain[75]

-

[1] ARSERIM-UÇAR D K, KOREL F, LIU L, et al. Characterization of bacterial cellulose nanocrystals: Effect of acid treatments and neutralization[J]. Food Chemistry, 2021, 336: 127597. doi: 10.1016/j.foodchem.2020.127597 [2] DE AMORIM J D P, DE SOUZA K C, DUARTE C R, et al. Plant and bacterial nanocellulose: Production, properties and applications in medicine, food, cosmetics, electronics and engineering: A review[J]. Environmental Chemistry Letters, 2020, 18(3): 851-869. doi: 10.1007/s10311-020-00989-9 [3] HUANG J, ZHAO M, HAO Y, et al. Recent advances in functional bacterial cellulose for wearable physical sensing applications[J]. Advanced Materials Technologies, 2021, 7(1): 2100617. [4] DE ASSIS S C, MORGADO D L, SCHEIDT D T, et al. Review of bacterial nanocellulose-based electrochemical biosensors: Functionalization, challenges, and future perspectives[J]. Biosensors, 2023, 13(1): 142. doi: 10.3390/bios13010142 [5] 张艳, 孙怡然, 于飞, 等. 细菌纤维素及其复合材料在环境领域应用的研究进展[J]. 复合材料学报, 2021, 38(8): 2418-2427.ZHANG Yan, SUN Yiran, YU Fei, et al. Research progress on the application of bacterial cellulose and its composites in environmental field[J]. Acta Materiae Compositae Sinica, 2021, 38(8): 2418-2427(in Chinese). [6] 陈少杰, 徐海兵, 张雪辉, 等. 复合材料结构超级电容器碳纤维电极的制备与改性方法研究进展[J]. 复合材料学报, 2023, 40(11): 6010-6028.CHEN Shaojie, XU Haibing, ZHANG Xuehui, et al. Recent progress in carbon fiber electrodes for structural supercapacitors composites[J]. Acta Materiae Compositae Sinica, 2023, 40(11): 6010-6028 (in Chinese). [7] MAUREIRA D, ROMERO O, ILLANES A, et al. Industrial bioelectrochemistry for waste valorization: State of the art and challenges[J]. Biotechnology Advances, 2023, 64: 108123. doi: 10.1016/j.biotechadv.2023.108123 [8] LIU N, LI W, PASTA M, et al. Nanomaterials for electrochemical energy storage[J]. Frontiers of Physics, 2014, 9(3): 323-350. doi: 10.1007/s11467-013-0408-7 [9] SHAH N, UL-ISLAM M, KHATTAK W A, et al. Overview of bacterial cellulose composites: A multipurpose advanced material[J]. Carbohydrate Polymers, 2013, 98(2): 1585-1598. doi: 10.1016/j.carbpol.2013.08.018 [10] WANG J, TAVAKOLI J, TANG Y. Bacterial cellulose production, properties and applications with different culture methods - A review[J]. Carbohydrate Polymers, 2019, 219: 63-76. doi: 10.1016/j.carbpol.2019.05.008 [11] SRIPLAI N, PINITSOONTORN S. Bacterial cellulose-based magnetic nanocomposites: A review[J]. Carbohydrate Polymers, 2021, 254: 117228. doi: 10.1016/j.carbpol.2020.117228 [12] PANAITESCU D M, FRONE A N, CHIULAN I, et al. Structural and morphological characterization of bacterial cellulose nano-reinforcements prepared by mechanical route[J]. Materials & Design, 2016, 110: 790-801. [13] SWINGLER S, GUPTA A, GIBSON H, et al. Recent advances and applications of bacterial cellulose in biomedicine[J]. Polymers, 2021, 13(3): 412. doi: 10.3390/polym13030412 [14] COSTA A F S, ALMEIDA F C G, VINHAS G M, et al. Production of bacterial cellulose by gluconacetobacter hansenii using corn steep liquor as nutrient sources[J]. Frontiers in Microbiology, 2017, 8. [15] CHEN J, CHEN C, LIANG G, et al. In situ preparation of bacterial cellulose with antimicrobial properties from bioconversion of mulberry leaves[J]. Carbohydrate Polymers, 2019, 220: 170-175. doi: 10.1016/j.carbpol.2019.05.062 [16] HAMSAN M H, HALIM N A, DEMON S Z N, et al. Multifunction web-like polymeric network bacterial cellulose derived from SCOBY as both electrodes and electrolytes for pliable and low-cost supercapacitor[J]. Polymers, 2022, 14(15): 3196. doi: 10.3390/polym14153196 [17] 朱晓东, 杜昀怡, 原续波, 等. 细菌纤维素的最新研究进展[J]. 高分子通报, 2022(5): 17-26.ZHU Xiaodong, DU Yunyi, YUAN Xubo, et al. Recent progress on bacterial cellulose[J]. Polymer Bulletin, 2022(5): 17-26(in Chinese). [18] TAJIMA K, IMAI T, YUI T, et al. Cellulose-synthesizing machinery in bacteria[J]. Cellulose, 2022, 29(5): 2755-2777. doi: 10.1007/s10570-021-04225-7 [19] KAWEE N, LAM N T, SUKYAI P. Homogenous isolation of individualized bacterial nanofibrillated cellulose by high pressure homogenization[J]. Carbohydrate Polymers, 2018, 179: 394-401. doi: 10.1016/j.carbpol.2017.09.101 [20] 梁琳. 低维功能纳米材料的合成及其在电化学领域的应用 [D]. 合肥: 中国科学技术大学, 2014.LIANG Lin. Synthesis and electrochemical applications of low-dimensional functional nanometerials [D]. Hefei: University of Science and Technology of China, 2014(in Chinese). [21] 董丽攀, 李政, 王福迎, 等. 细菌纤维素@聚吡咯-单壁碳纳米管导电膜的制备与表征[J]. 复合材料学报, 2019, 36(3): 723-724.DONG Lipan, LI Zheng, WANC Fuying, et al, Preparation and characterization of bacterial cellulose@polypyrrole-single wall carbon nanotube conductive films[J]. Acta Materiae Compositae Sinica, 2019, 36(3): 723-729 (in Chinese). [22] TORRES F G, DE-LA-TORRE G E, GONZALES K N, et al. Bacterial-polymer-based electrolytes: Recent progress and applications[J]. ACS Applied Energy Materials, 2020, 3(12): 11500-11515. doi: 10.1021/acsaem.0c02195 [23] MA L, BI Z, XUE Y, et al. Bacterial cellulose: An encouraging eco-friendly nano-candidate for energy storage and energy conversion[J]. Journal of Materials Chemistry A, 2020, 8(12): 5812-5842. doi: 10.1039/C9TA12536A [24] BHARTI V K, SHARMA C S, KHANDELWAL M. Carbonized bacterial cellulose as free-standing cathode host and protective interlayer for high-performance potassium-sulfur batteries with enhanced kinetics and stable operation[J]. Carbon, 2023, 212: 118173. doi: 10.1016/j.carbon.2023.118173 [25] RAMÍREZ-CARMONA M, GÁLVEZ-GÓMEZ M P, GONZÁLEZ-PEREZ L, et al. Production of bacterial cellulose hydrogel and its evaluation as a proton exchange membrane[J]. Journal of Polymers and the Environment, 2023, 31(6): 2462-2472. doi: 10.1007/s10924-023-02759-4 [26] XIA Y, GUAN J, DU X. Bacterial cellulose derived carbon nanofiber aerogel assembled with redox active hydrogel and alpha-MoO3 nanoplate for high-performance supercapacitors[J]. Journal of Energy Storage, 2023, 72(Part E): 108776. [27] MASHKOUR M, RAHIMNEJAD M, MASHKOUR M, et al. Electro-polymerized polyaniline modified conductive bacterial cellulose anode for supercapacitive microbial fuel cells and studying the role of anodic biofilm in the capacitive behavior[J]. Journal of Power Sources, 2020, 478: 228822. doi: 10.1016/j.jpowsour.2020.228822 [28] DURSUN B, SAR T, ATA A, et al. Pyrolyzed bacterial cellulose-supported SnO2 nanocomposites as high-capacity anode materials for sodium-ion batteries[J]. Cellulose, 2016, 23(4): 2597-2607. doi: 10.1007/s10570-016-0966-2 [29] WANG W, KHABAZIAN S, CASAS-PAPIOL M, et al. Nanoarchitectonics of bacterial cellulose with nickel-phosphorous alloy as a binder-free electrode for efficient hydrogen evolution reaction in neutral solution[J]. International Journal of Hydrogen Energy, 2022, 47(69): 29753-29761. doi: 10.1016/j.ijhydene.2022.06.298 [30] WANG W, BLACK A P, LIU C, et al. High performance N-doped carbon nanosheet/MnO2 cathode derived from bacterial cellulose for aqueous Zn-ion batteries[J]. Journal of Materials Chemistry A, 2023, 11(32): 17272-17281. doi: 10.1039/D3TA01487H [31] ZHANG Z, LI Y, CUI X, et al. Understanding the advantageous features of bacterial cellulose-based separator in Li-S battery[J]. Advanced Materials Interfaces, 2022, 10(1): 2201730. [32] 边文杰, 钟宇光, 钟春燕, 等. 细菌纤维素在电池应用中的研究进展[J]. 纤维素科学与技术, 2021, 29(2): 48-54.BIAN Wenjie, ZHONG Yuguang, ZHONG Chunyan, et al. Progress of bacterial cellulose in battery application[J]. Journal of Cellulose Science and Technology, 2021, 29(2): 48-54(in Chinese). [33] TAFETE G A, ABERA M K, THOTHADRI G. Review on nanocellulose-based materials for supercapacitors applications[J]. Journal of Energy Storage, 2022, 48: 103938. doi: 10.1016/j.est.2021.103938 [34] JIANG F, YIN L, YU Q, et al. Bacterial cellulose nanofibrous membrane as thermal stable separator for lithium-ion batteries[J]. Journal of Power Sources, 2015, 279: 21-27. doi: 10.1016/j.jpowsour.2014.12.090 [35] CHENG C, YANG R, WANG Y, et al. A bacterial cellulose-based separator with tunable pore size for lithium-ion batteries[J]. Carbohydrate Polymers, 2023, 304: 120489. doi: 10.1016/j.carbpol.2022.120489 [36] YANG Y, HUANG C, GAO G, et al. Aramid nanofiber/bacterial cellulose composite separators for lithium-ion batteries[J]. Carbohydrate Polymers, 2020, 247: 116702. doi: 10.1016/j.carbpol.2020.116702 [37] STUMPF T R, YANG X, ZHANG J, et al. In situ and ex situ modifications of bacterial cellulose for applications in tissue engineering[J]. Material Science and Engineering: C, 2018, 82: 372-383. doi: 10.1016/j.msec.2016.11.121 [38] YUE L, XIE Y, ZHENG Y, et al. Sulfonated bacterial cellulose/polyaniline composite membrane for use as gel polymer electrolyte[J]. Composites Science and Technology, 2017, 145: 122-131. doi: 10.1016/j.compscitech.2017.04.002 [39] YUAN B, CONG Z, CHENG Z, et al. Bacteria cellulose framework-supported solid composite polymer electrolytes for ambient-temperature lithium metal batteries[J]. Nanotechnology, 2022, 33(41): 415401. doi: 10.1088/1361-6528/ac64ab [40] YAN M, QU W, SU Q, et al. Biodegradable bacterial cellulose-supported quasi-solid electrolyte for lithium batteries[J]. ACS Applied Materials & Interfaces, 2020, 12(12): 13950-13958. [41] XU D, WANG B, WANG Q, et al. High-strength internal cross-linking bacterial cellulose-network-based gel polymer electrolyte for dendrite-suppressing and high-rate lithium batteries[J]. ACS Applied Materials & Interfaces, 2018, 10(21): 17809-17819. [42] LI X, YUAN L, LIU R, et al. Engineering textile electrode and bacterial cellulose nanofiber reinforced hydrogel electrolyte to enable high-performance flexible all-solid-state supercapacitors[J]. Advanced Energy Materials, 2021, 11(12): 2003010. doi: 10.1002/aenm.202003010 [43] 杨敬轩, 陈仕艳, 王华平. 细菌纤维素制备技术与应用[J]. 高分子通报, 2013(10): 115-128.YANG Jingxuan, CHEN Shiyan, WANG Huaping. Progress on bacterial cellulose fermentation technology and application[J]. Polymer Bulletin, 2013(10): 115-128(in Chinese). [44] LI S, HUANG D, YANG J, et al. Freestanding bacterial cellulose-polypyrrole nanofibres paper electrodes for advanced energy storage devices[J]. Nano Energy, 2014, 9: 309-317. doi: 10.1016/j.nanoen.2014.08.004 [45] 马丽娜, 石川, 赵宁, 等. 细菌纤维素基纳米生物材料在储能领域的应用[J]. 无机材料学报, 2019, 35(2): 145-157.MA Lina, SHI Chuan, ZHAO Ning, et al. Bacterial cellulose based nano-biomaterials for energy storage applications[J]. Journal of Inorganic Materials, 2019, 35(2): 145-157(in Chinese). [46] LEI W, JIN D, LIU H, et al. An overview of bacterial cellulose in flexible electrochemical energy storage[J]. ChemSusChem, 2020, 13(15): 3731-3753. doi: 10.1002/cssc.202001019 [47] PRILEPSKII A, NIKOLAEV V, KLAVING A. Conductive bacterial cellulose: From drug delivery to flexible electronics[J]. Carbohydrate Polymers, 2023, 313: 120850. doi: 10.1016/j.carbpol.2023.120850 [48] HUANG Y, HUANG X, MA M, et al. Recent advances on the bacterial cellulose-derived carbon aerogels[J]. Journal of Materials Chemistry C, 2021, 9(3): 818-828. doi: 10.1039/D0TC05433J [49] 夏文, 李政, 徐银莉, 等. 超级电容器用细菌纤维素基电极材料[J]. 化学进展, 2016, 28(11): 1682-1688.XIA Wen, LI Zheng, XU Yinli, et al. Bacterial cellulose based electrode material for supercapacitors[J]. Progress in Chemistry, 2016, 28(11): 1682-1688(in Chinese). [50] WU H, ZHANG Y, YUAN W, et al. Highly flexible, foldable and stretchable Ni-Co layered double hydroxide/polyaniline/bacterial cellulose electrodes for high-performance all-solid-state supercapacitors[J]. Journal of Materials Chemistry A, 2018, 6(34): 16617-16626. doi: 10.1039/C8TA05673K [51] JIANG Q, KACICA C, SOUNDAPPAN T, et al. An in situ grown bacterial nanocellulose/graphene oxide composite for flexible supercapacitors[J]. Journal of Materials Chemistry A, 2017, 5(27): 13976-13982. doi: 10.1039/C7TA03824K [52] WANG W, YANG Y, CHEN Z, et al. High-performance yarn supercapacitor based on directly twisted carbon nanotube@bacterial cellulose membrane[J]. Cellulose, 2020, 27(13): 7649-7661. doi: 10.1007/s10570-020-03307-2 [53] NOPPARUT K, THANAKORN W, SRIKULKIT K. Multilayered bacterial cellulose/reduced graphene oxide composite films for self-standing and binder-free electrode application[J]. Heliyon, 2022, 8(8): e10327. doi: 10.1016/j.heliyon.2022.e10327 [54] ZHENG W F, FAN L L, MENG Z H, et al. Flexible quasi-solid-state supercapacitors for anti-freezing power sources based on polypyrrole@cation-grafted bacterial cellulose[J]. Carbohydrate Polymers, 2024, 324: 121502. doi: 10.1016/j.carbpol.2023.121502 [55] BU Y, CAO M, JIANG Y, et al. Ultra-thin bacterial cellulose/poly(ethylenedioxythiophene) nanofibers paper electrodes for all-solid-state flexible supercapacitors[J]. Electrochimica Acta, 2018, 271: 624-631. doi: 10.1016/j.electacta.2018.03.155 [56] LI Q, TANG R, ZHOU H, et al. A high-performance and flexible electrode film based on bacterial cellulose/polypyrrole/nitrogen-doped graphene for supercapacitors[J]. Carbohydrate Polymers, 2023, 311: 120754. doi: 10.1016/j.carbpol.2023.120754 [57] ZHENG W F, FAN L L, ZHOU J G, et al. Flexible, ultrathin and integrated nanopaper supercapacitor based on cationic bacterial cellulose[J]. International Journal of Biological Macromolecules, 2024, 256(Part 2): 128497. [58] RANA A K, SCARPA F, THAKUR V K. Cellulose/polyaniline hybrid nanocomposites: Design, fabrication, and emerging multidimensional applications[J]. Industrial Crops and Products, 2022, 187(Part A): 115356. [59] HOU L, ZHI X, ZHANG W, et al. Boosting the electrochemical properties of polyaniline by one-step co-doped electrodeposition for high performance flexible supercapacitor applications[J]. Journal of Electroanalytical Chemistry, 2020, 863: 114064. doi: 10.1016/j.jelechem.2020.114064 [60] LYU Z, WANG C, WAN C, et al. Strain-driven auto-detachable patterning of flexible electrodes[J]. Advanced Materials, 2022, 34(30): 2202877. doi: 10.1002/adma.202202877 [61] LUO H, DONG J, ZHANG Y, et al. Constructing 3D bacterial cellulose/graphene/polyaniline nanocomposites by novel layer-by-layer in situ culture toward mechanically robust and highly flexible freestanding electrodes for supercapacitors[J]. Chemical Engineering Journal, 2018, 334: 1148-1158. doi: 10.1016/j.cej.2017.11.065 [62] LIANG Q, WAN J, JI P, et al. Continuous and integrated PEDOT@bacterial cellulose/CNT hybrid helical fiber with “reinforced cement-sand” structure for self-stretchable solid supercapacitor[J]. Chemical Engineering Journal, 2022, 427: 131904. doi: 10.1016/j.cej.2021.131904 [63] JIAJIA W, ZHANWEN D, PING X, et al. Fabrication of flexible polyindole/carbon nanotube/bacterial cellulose nanofiber nonwoven electrode doped by D-tartaric acid with high electrochemical performance[J]. Cellulose, 2020, 27(11): 6353-6366. doi: 10.1007/s10570-020-03199-2 [64] WU Z Y, LIANG H W, CHEN L F, et al. Bacterial cellulose: A robust platform for design of three dimensional carbon-based functional nanomaterials[J]. Accounts of Chemical Research, 2015, 49(1): 96-105. [65] KONG D, QIN C, CAO L, et al. Synthesis of biomass-based porous carbon nanofibre/polyaniline composites for supercapacitor electrode materials[J]. International Journal of Electrochemical Science, 2020, 15(1): 265-279. doi: 10.20964/2020.01.02 [66] BAI Q, XIONG Q, LI C, et al. Hierarchical porous carbons from a sodium alginate/bacterial cellulose composite for high-performance supercapacitor electrodes[J]. Applied Surface Science, 2018, 455: 795-807. doi: 10.1016/j.apsusc.2018.05.006 [67] WANG J, WAN Y, XUN X, et al. Engineering bacteria for high-performance three-dimensional carbon nanofiber aerogel[J]. Carbon, 2021, 183: 267-276. doi: 10.1016/j.carbon.2021.07.021 [68] WANG F, ZHANG T, RAN F. Insights into sodium-ion batteries through plateau and slope regions in cyclic voltammetry by tailoring bacterial cellulose precursors[J]. Electrochimica Acta, 2023, 441: 141770. doi: 10.1016/j.electacta.2022.141770 [69] CHEN L F, HUANG Z H, LIANG H W, et al. Bacterial-cellulose-derived carbon nanofiber@MnO2 and nitrogen-doped carbon nanofiber electrode materials: An asymmetric supercapacitor with high energy and power density[J]. Advanced Materials, 2013, 25(34): 4746-4752. doi: 10.1002/adma.201204949 [70] HAO X, WANG J, DING B, et al. Bacterial-cellulose-derived interconnected meso-microporous carbon nanofiber networks as binder-free electrodes for high-performance supercapacitors[J]. Journal of Power Sources, 2017, 352: 34-41. doi: 10.1016/j.jpowsour.2017.03.088 [71] LIU Z, YUE L, WANG C, et al. Free-standing carbon nanofiber composite networks derived from bacterial cellulose and polypyrrole for ultrastable potassium-ion batteries[J]. ACS Applied Materials & Interfaces, 2023, 15(11): 14865-14873. [72] ZHANG M, CHEN S, SHENG N, et al. Spinning continuous high-strength bacterial cellulose hydrogel fibers for multifunctional bioelectronic interfaces[J]. Journal of Materials Chemistry A, 2021, 9(21): 12574-12583. doi: 10.1039/D1TA01606G [73] SHI Z, GAO X, ULLAH M W, et al. Electroconductive natural polymer-based hydrogels[J]. Biomaterials, 2016, 111: 40-54. doi: 10.1016/j.biomaterials.2016.09.020 [74] PAN X, LI J, MA N, et al. Bacterial cellulose hydrogel for sensors[J]. Chemical Engineering Journal, 2023, 461: 142062. doi: 10.1016/j.cej.2023.142062 [75] HUANG J, ZHAO M, CAI Y, et al. A dual-mode wearable sensor based on bacterial cellulose reinforced hydrogels for highly sensitive strain/pressure sensing[J]. Advanced Electronic Materials, 2019, 6(1): 1900934. [76] WANG W, ZHANG T J, ZHANG D W, et al. Amperometric hydrogen peroxide biosensor based on the immobilization of heme proteins on gold nanoparticles-bacteria cellulose nanofibers nanocomposite[J]. Talanta, 2011, 84(1): 71-77. doi: 10.1016/j.talanta.2010.12.015 [77] 胡伟立. 细菌纤维素的表面修饰及功能化 [D]. 上海: 东华大学, 2013.HU Weili. Surface modification and functionalization of bacterial cellulose [D]. Shanghai: Donghua University, 2013(in Chinese). [78] WANG B, YIN X, CHENG R, et al. Compressible, superelastic and fatigue resistant carbon nanofiber aerogels derived from bacterial cellulose for multifunctional piezoresistive sensors[J]. Carbon, 2022, 199: 318-328. doi: 10.1016/j.carbon.2022.08.006 [79] MA H, LI X, LOU J, et al. Strong bacterial cellulose-based films with natural laminar alignment for highly sensitive humidity sensors[J]. ACS Applied Materials & Interfaces, 2022, 14(2): 3165-3175. [80] FAROOQ U, ULLAH M W, YANG Q, et al. High-density phage particles immobilization in surface-modified bacterial cellulose for ultra-sensitive and selective electrochemical detection of Staphylococcus aureus[J]. Biosensors and Bioelectronics, 2020, 157: 112163. doi: 10.1016/j.bios.2020.112163 [81] XIANG Q, ZHANG H, LIU Z, et al. Engineered structural carbon aerogel based on bacterial cellulose/chitosan and graphene oxide/graphene for multifunctional piezoresistive sensor[J]. Chemical Engineering Journal, 2024, 480: 147825. doi: 10.1016/j.cej.2023.147825 [82] DE SOUZA T C, AMORIM J D P D, SILVA JUNIOR C J G D, et al. Magnetic bacterial cellulose biopolymers: Production and potential applications in the electronics sector[J]. Polymers, 2023, 15(4). [83] SALIDKUL N, MONGKOLTHANARUK W, FAUNGNAWAKIJ K, et al. Hard magnetic membrane based on bacterial cellulose - Barium ferrite nanocomposites[J]. Carbohydrate Polymers, 2021, 264. [84] 张艳, 马忠雷, 李桢, 等. 轻质高强 MXene/细菌纤维素复合气凝胶的制备及其电磁屏蔽性能[J]. 复合材料学报, 2023, 40(11): 6407-6415.ZHANG Yan, MA Zhonglei, LI Zhen, et al. Preparation and EMl shielding properties of light weight and mechanically strong MXene/bacterial cellulose composite aerogels[J]. Acta Materiae Compositae Sinica, 2023, 40(11): 6407-6415 (in Chinese). [85] ZONG Y, LOU J, LI H, et al. Bacterial cellulose-based dual chemical reaction coupled hydrogel thermocells for efficient heat harvesting[J]. Carbohydrate Polymers, 2022, 294: 119789. doi: 10.1016/j.carbpol.2022.119789 [86] LIU K, LYU J, FAN G, et al. Flexible and robust bacterial cellulose-based ionogels with high thermoelectric properties for low-grade heat harvesting[J]. Advanced Functional Materials, 2021, 32(6): 2107105. [87] LI H, ZONG Y, LI X, et al. Biodegradable CuI/BCNF composite thermoelectric film for wearable energy harvesting[J]. Cellulose, 2021, 28(17): 10707-10714. doi: 10.1007/s10570-021-04244-4 -

下载:

下载: