Ti3C2Tx MXene-modified domestic high-modulus high-strength carbon fibers based on electrophoretic deposition method

-

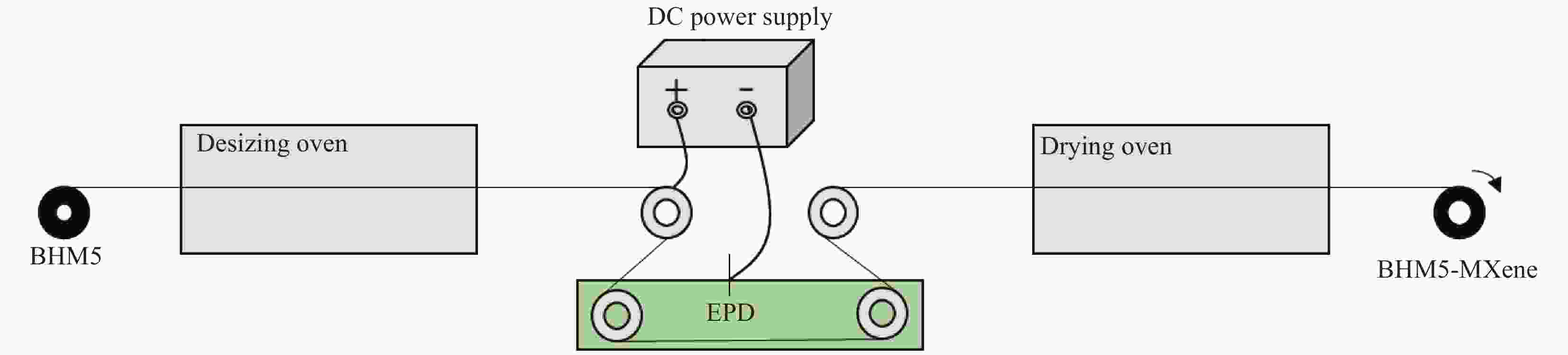

摘要: 为提升国产高模高强碳纤维的表面特性及其复合材料的界面性能,采用连续化电泳沉积工艺,在国产高模高强碳纤维(BHM5碳纤维)表面构筑Ti3C2Tx MXene纳米片层。通过SEM、XPS、动态接触角、INSTRON万能材料试验机对改性前、后BHM5碳纤维的表面形态、表面元素含量、表面润湿性及其复合材料的力学性能和断面形貌进行了表征,探讨了Ti3C2Tx MXene改性BHM5碳纤维复合材料的界面增强机制。结果表明,经Ti3C2Tx MXene改性后的BHM5碳纤维表面粗糙度和比表面积增加,具备了与环氧树脂基体良好的机械互锁能力。碳纤维表面极性基团的含量明显上升,表面润湿性得以增强。在15 V电压下对BHM5碳纤维处理2 min后,其复合材料的层间剪切强度达到82.54 MPa,相较于未处理的碳纤维制成的复合材料,提升了28.2%。

-

关键词:

- 高模高强碳纤维 /

- 电泳沉积 /

- 复合材料 /

- Ti3C2Tx MXene /

- 界面性能

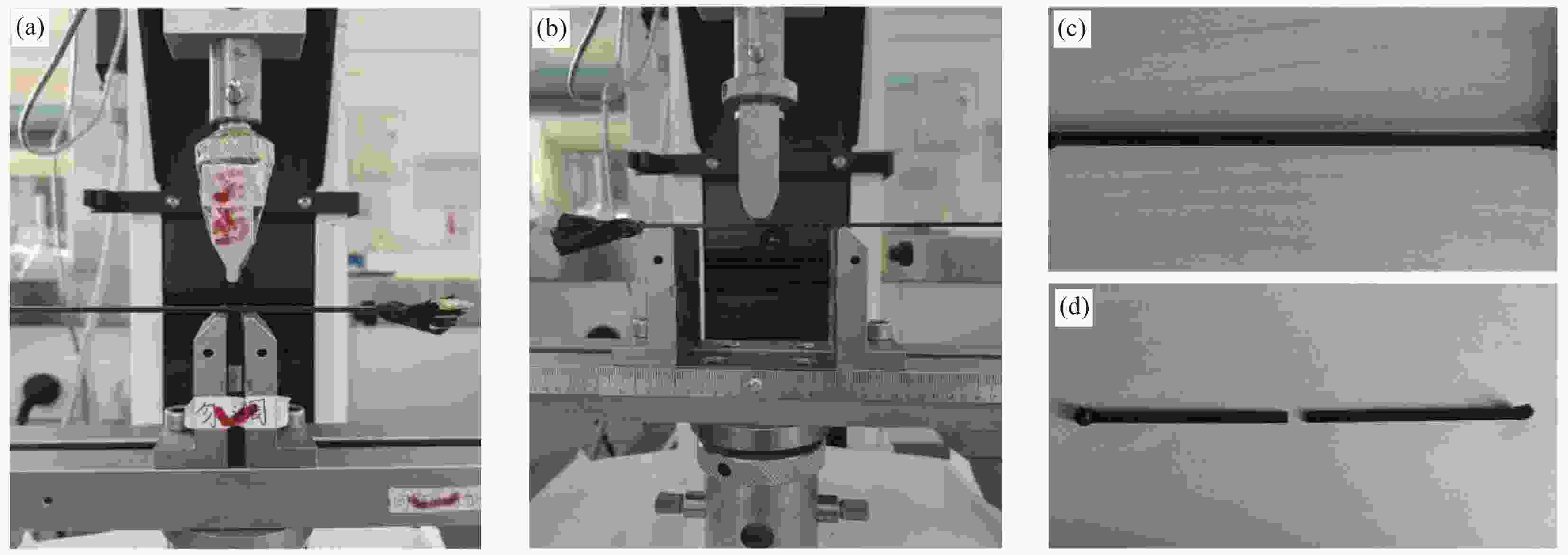

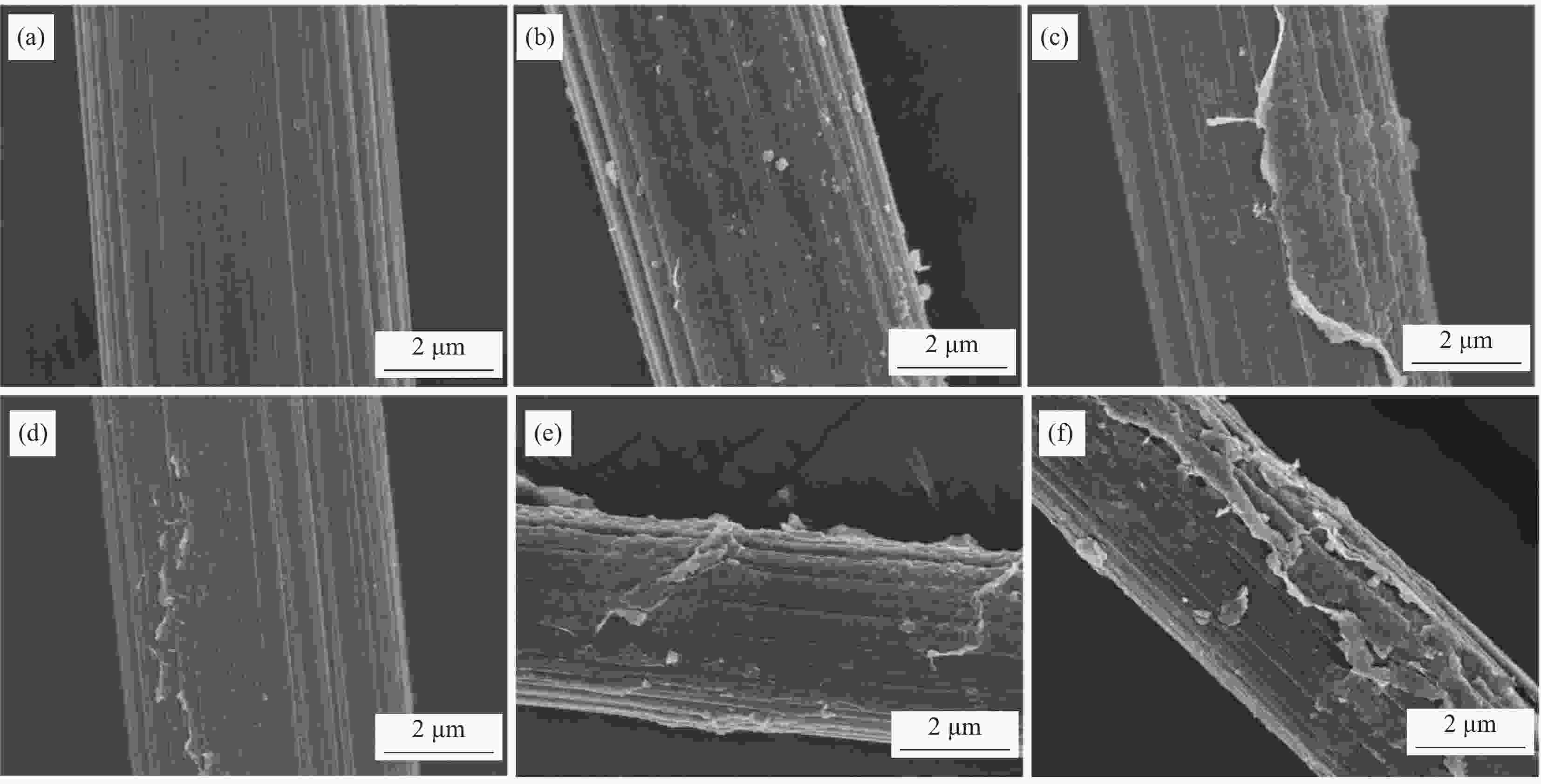

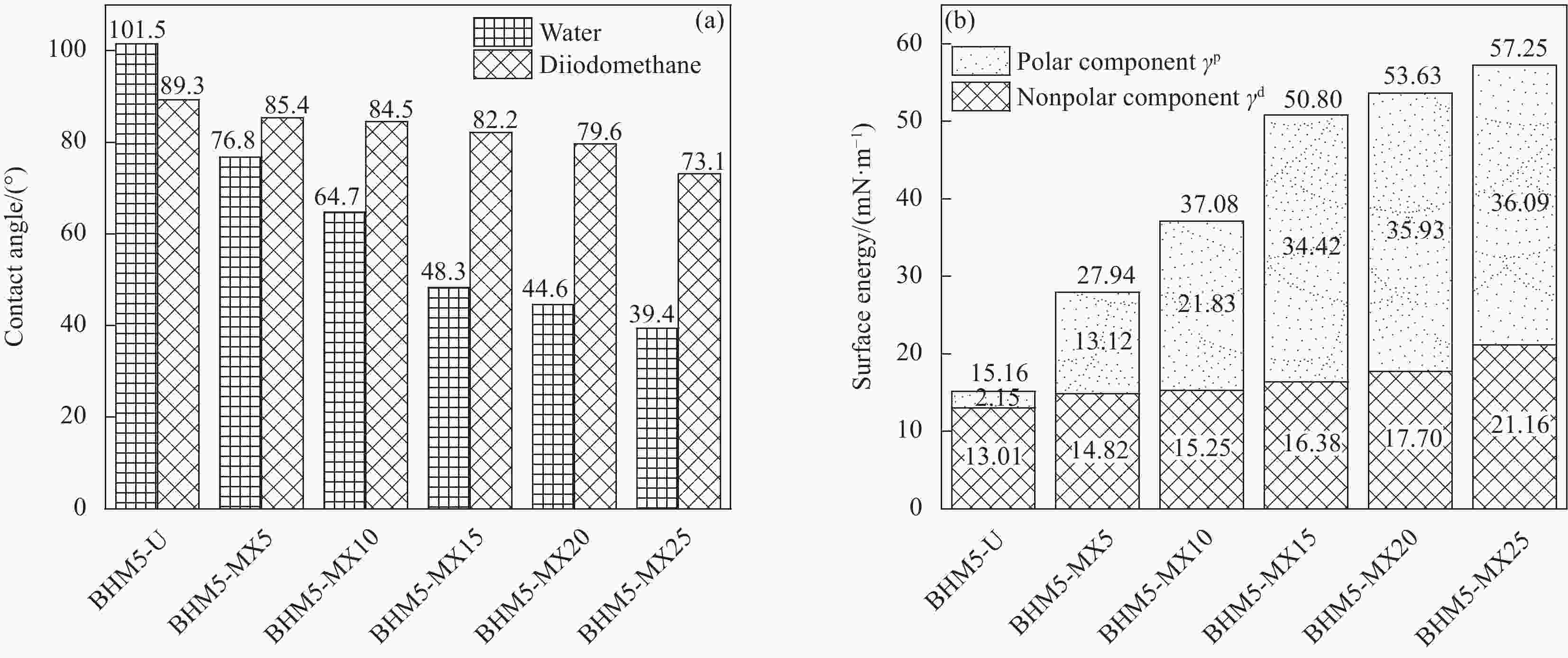

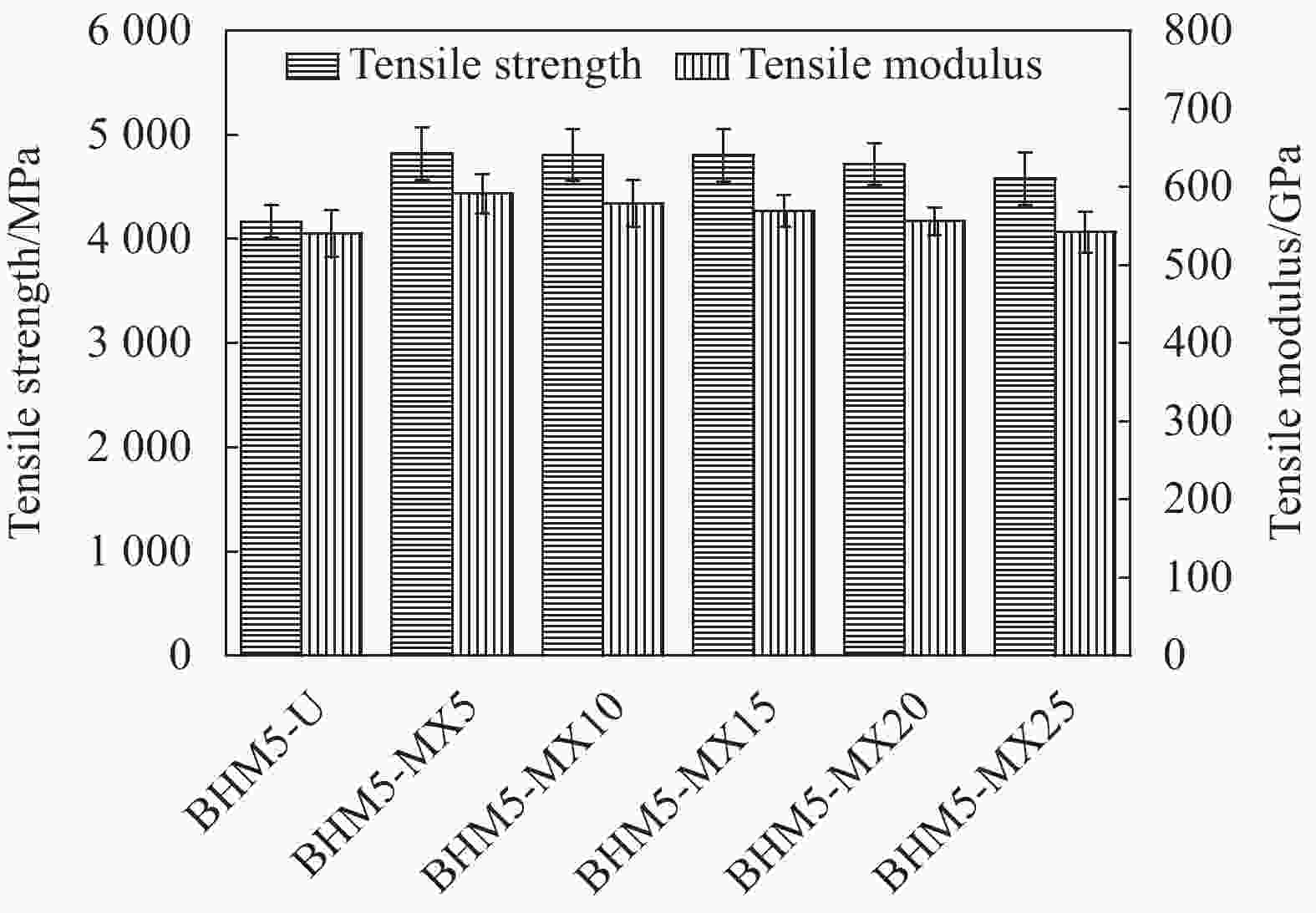

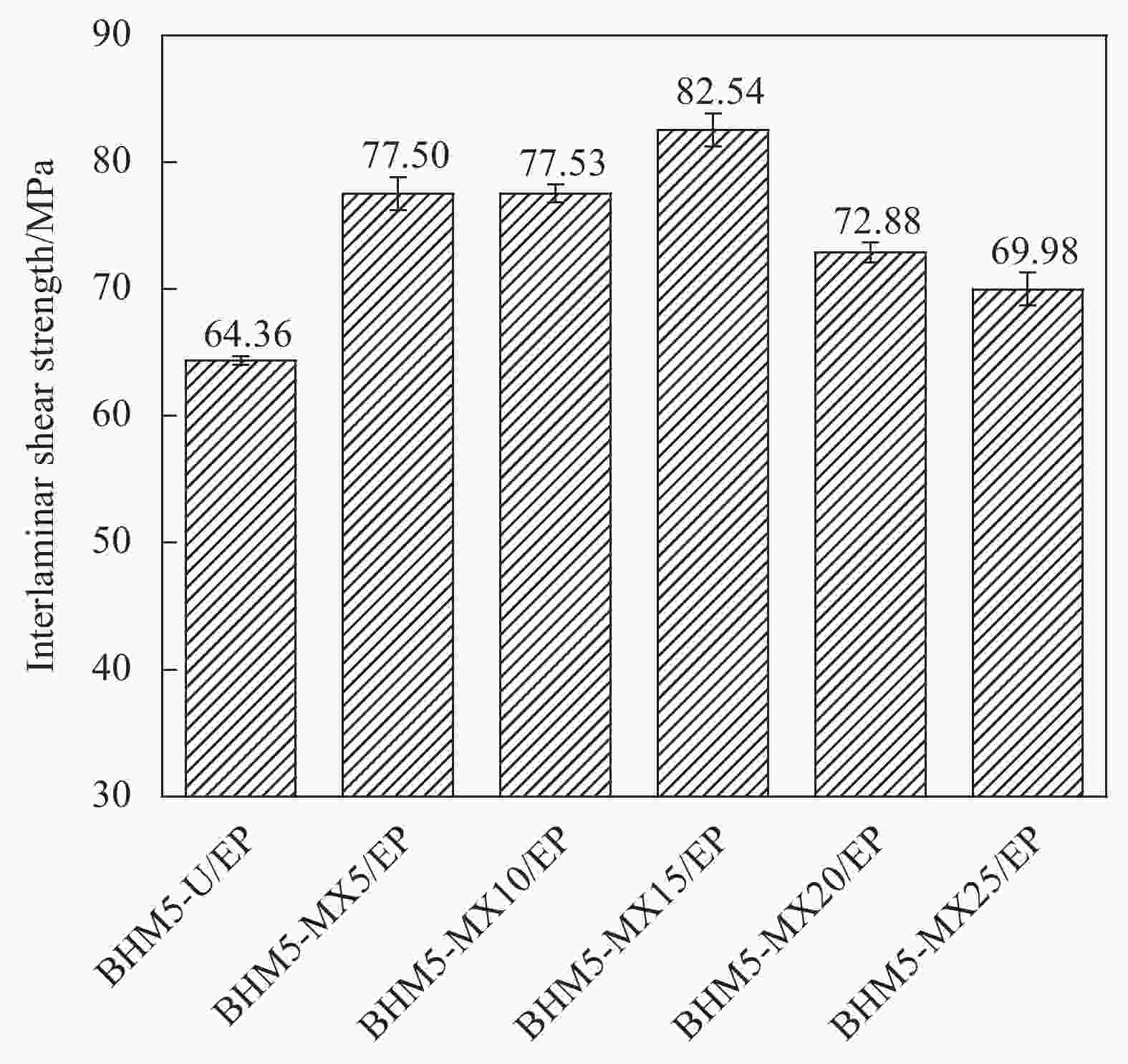

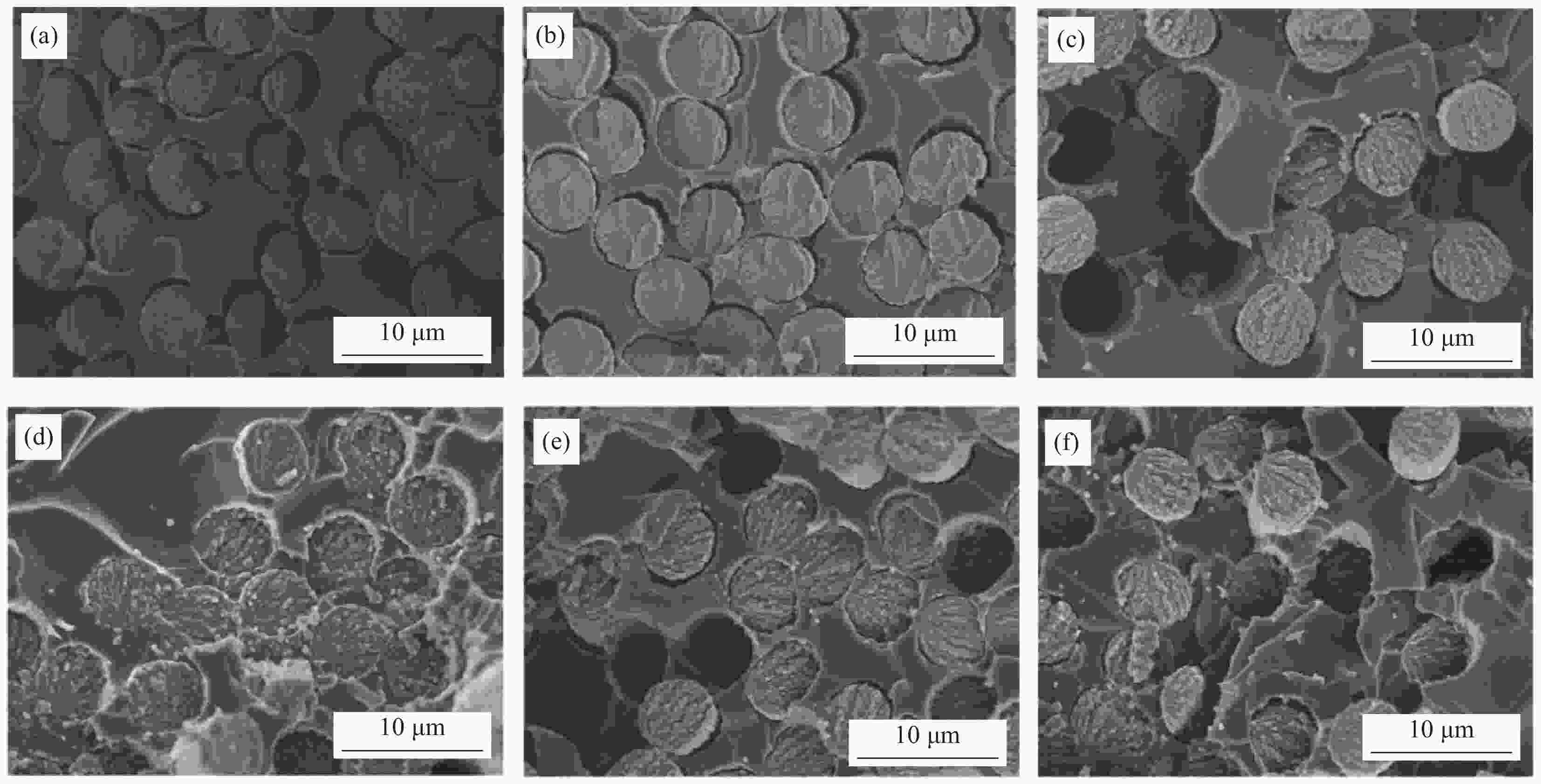

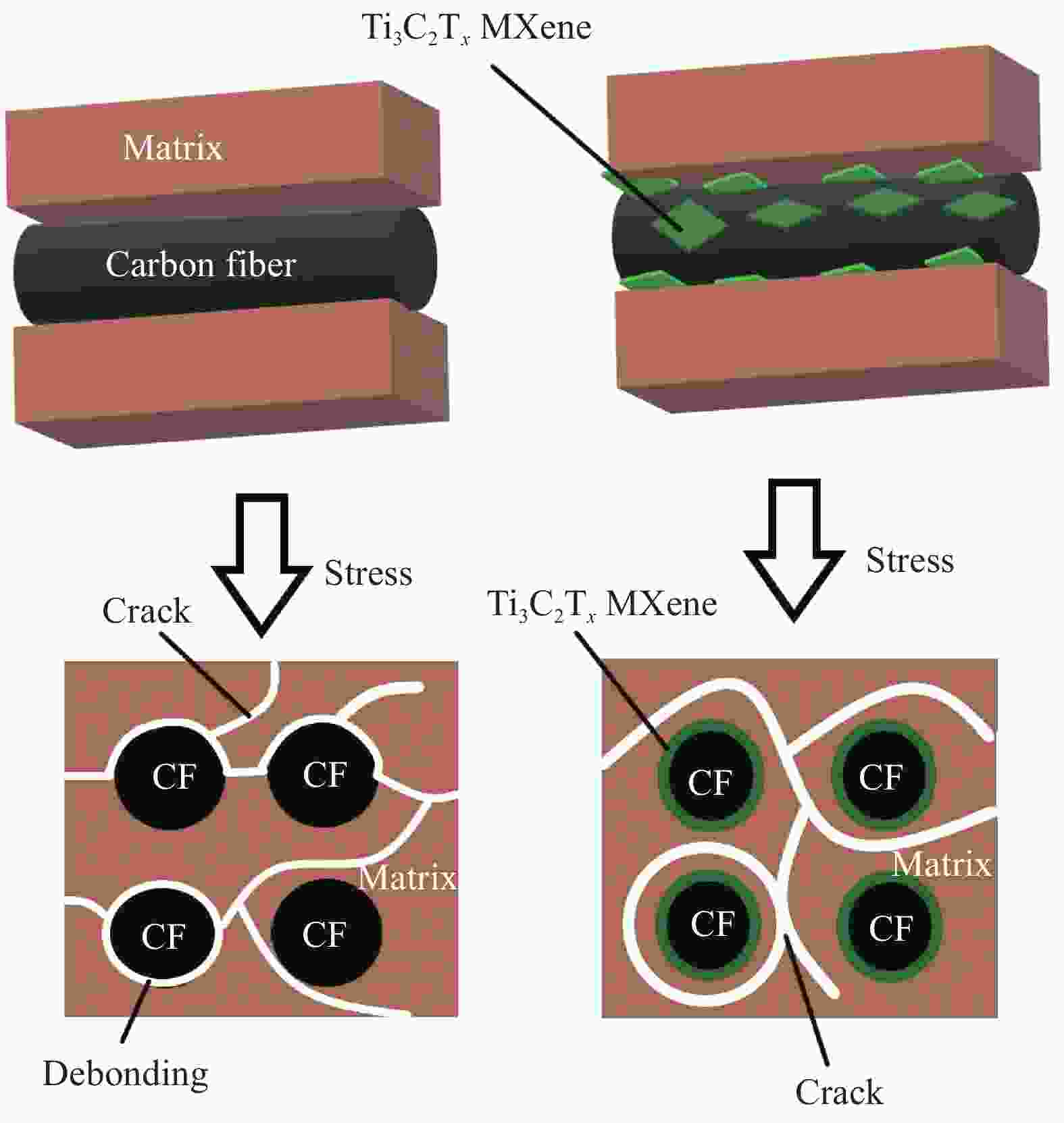

Abstract: In order to improve the surface properties of domestic high-modulus high-strength carbon fibers and the interfacial properties of their composites, Ti3C2Tx MXene nanosheets were constructed on the surface of domestic high-modulus high-strength carbon fibers (BHM5 carbon fibers) using a continuous electrophoretic deposition process. The surface morphology, surface element content, surface wettability of BHM5 carbon fibers and the mechanical properties and cross-section morphology of their composites before and after modification were characterized by SEM, XPS, dynamic contact angle, and INSTRON universal material tester, and the interfacial enhancement mechanism of the Ti3C2Tx MXene-modified BHM5 carbon fiber composites was investigated. The results show that the surface roughness and specific surface area of the Ti3C2Tx MXene-modified BHM5 carbon fibers increase, possessing a good mechanical interlocking ability with the epoxy resin matrix. The content of polar groups on the surface of the carbon fiber increases significantly, and the surface wettability is enhanced. After treating the BHM5 carbon fibers at 15 V for 2 min, the interlaminar shear strength of the composites reaches 82.54 MPa, which is enhanced by 28.2% compared with the composites made of untreated carbon fibers. -

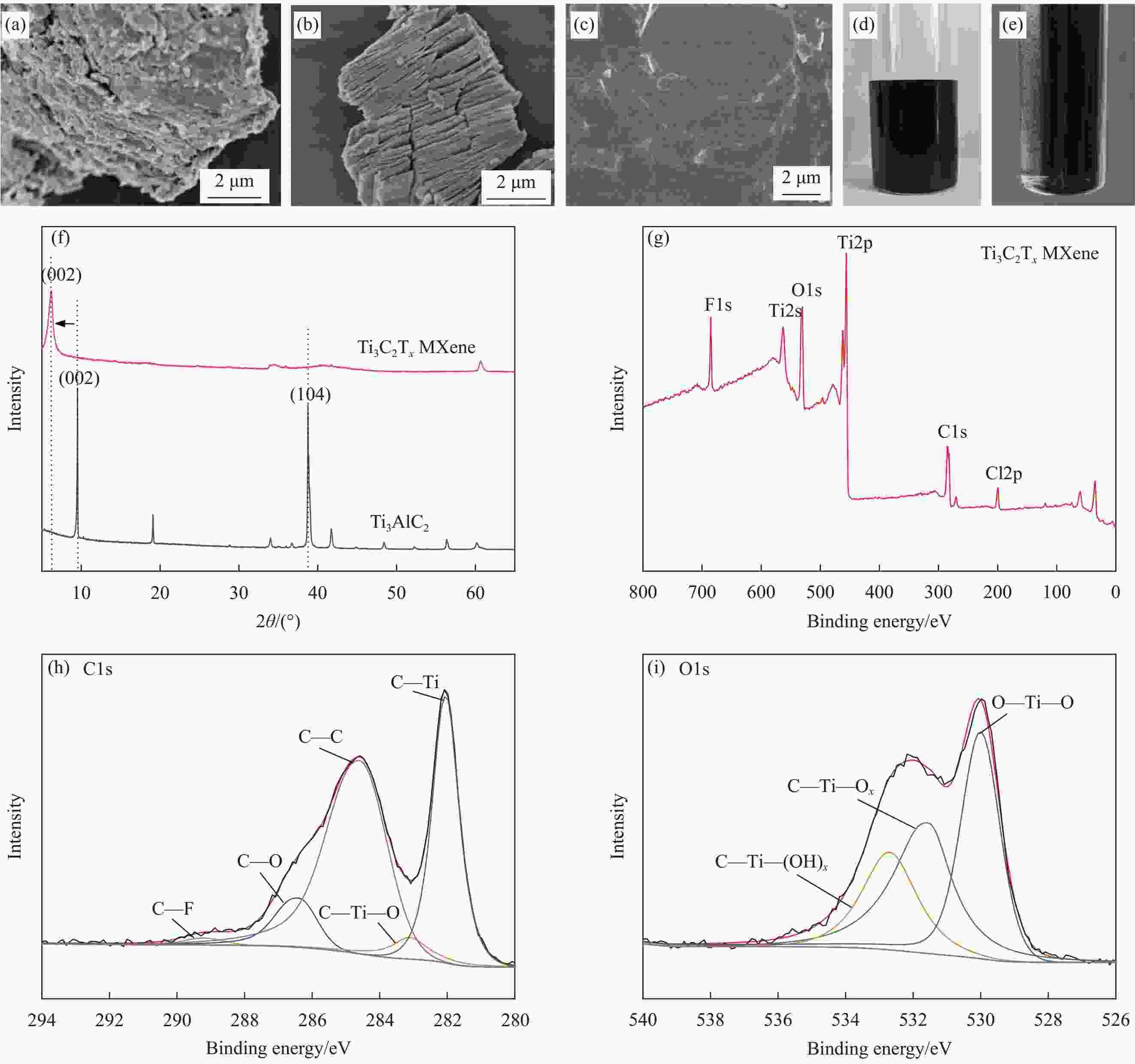

图 3 Ti3AlC2 MAX (a)、多层Ti3C2Tx MXene (b)、少层Ti3C2Tx MXene (c)的SEM图像;较高浓度Ti3C2Tx MXene溶液(d)、较低浓度Ti3C2Tx MXene溶液(e)的实物图;Ti3AlC2 MAX 和Ti3C2Tx MXene的XRD图谱(f);Ti3C2Tx MXene的XPS广谱图(g)、C1s分峰拟合图谱(h)、O1s分峰拟合图谱(i)

Figure 3. SEM images of Ti3AlC2 MAX (a), multilayer Ti3C2Tx MXene (b), few-layer Ti3C2Tx MXene (c); Physical photos of higher concentration Ti3C2Tx MXene solution (d), lower concentration Ti3C2Tx MXene solution (e); XRD pattern of Ti3AlC2 MAX and Ti3C2Tx MXene (f); XPS broad spectrum of Ti3C2Tx MXene (g), C1s split peak fitting pattern (h), O1s split peak fitting pattern (i)

表 1 样品命名

Table 1. Naming of sample

Sample Deposition voltage/V BHM5-U/EP 0 BHM5-MX5/EP 5 BHM5-MX10/EP 10 BHM5-MX15/EP 15 BHM5-MX20/EP 20 BHM5-MX25/EP 25 表 2 不同电压下碳纤维负载MXene质量

Table 2. Mass of carbon fiber loaded MXene at different voltages

Deposition voltage/V Carbon fiber initial mass/mg Modified carbon fiber mass/mg Load MXene mass/mg 5 159.7 163.4 3.7 10 160.2 166.5 6.3 15 160.1 168.2 8.1 20 160.3 170.1 9.8 25 160.6 171.1 10.5 表 3 BHM5-U 和 BHM5-MX15表面活性官能团的相对含量

Table 3. Relative content of surface-active functional groups of BHM5-U and BHM5-MX15

BHM5 C—O at 286.1 eV C=O at 287.6 eV O—C=O/C—F at 289.1 eV BHM5-U 12.50wt% 2.18wt% 0.09wt% BHM5-MX15 11.17wt% 22.92wt% 0.02wt% -

[1] YANG S, CHENG Y, XIAO X, et al. Development and application of carbon fiber in batteries[J]. Chemical Engineering Journal, 2020, 384: 123294. doi: 10.1016/j.cej.2019.123294 [2] LUO L, WANG Y, LIU L, et al. Ablation behavior of C/SiC composites in plasma wind tunnel[J]. Carbon, 2016, 103: 73-83. doi: 10.1016/j.carbon.2016.02.085 [3] KAFI A, HUSON M, CREIGHTON C, et al. Effect of surface functionality of PAN-based carbon fibres on the mechanical performance of carbon/epoxy composites[J]. Composites Science and Technology, 2014, 94: 89-95. doi: 10.1016/j.compscitech.2014.01.011 [4] 钱伯章. 国产M55J级高强高模碳纤维制备取得突破[J]. 合成纤维, 2018, 47(6): 55.QIAN Bozhang. Breakthrough in the preparation of domestically produced M55J-grade high-strength and high-modulus carbon fibers[J]. Synthetic Fiber in China, 2018, 47(6): 55(in Chinese). [5] 钱伯章. “863”计划高强高模碳纤维项目验收[J]. 合成纤维工业, 2018, 41(4): 70.QIAN Bozhang. Acceptance of high strength and high modulus carbon fiber project of "863" program[J]. China Synthetic Fiber Industry, 2018, 41(4): 70(in Chinese). [6] 王清清, 王飘飘, 钱鑫, 等. 水溶性热塑性聚酰亚胺上浆剂对国产高强高模碳纤维复合材料界面性能的影响[J]. 材料工程, 2023, 51(5): 174-182.WANG Qingqing, WANG Piaopiao, QIAN Xin, et al. Effect of water-soluble thermoplastic polyimide sizing agent on interfacial properties of domestic high strength and high modulus carbon fiber reinforced composites[J]. Journal of Materials Engineering, 2023, 51(5): 174-182(in Chinese). [7] BARAL N, DAVIES P, BALEY C, et al. Delamination behaviour of very high modulus carbon/epoxy marine composites[J]. Composites Science and Technology, 2008, 68(3): 995-1007. [8] 孙宇航, 张月义, 杨小平, 等. 高强/高模碳纤维复合材料界面影响机制及界面相构筑研究进展[J]. 航空制造技术, 2020, 63(15): 22-31.SUN Yuhang, ZHANG Yueyi, YANG Xiaoping, et al. Research progress on influence mechanism of interface and construction of interphase of high-strength/high-modulus carbon fiber composites[J]. Aeronautical Manufacturing Technology, 2020, 63(15): 22-31(in Chinese). [9] ALLIX O, LÉVÊQUE D, PERRET L. Identification and forecast of delamination in composite laminates by an interlaminar interface model[J]. Composites Science and Technology, 1998, 58(5): 671-678. doi: 10.1016/S0266-3538(97)00144-9 [10] WU G, MA L, LIU L, et al. Interface enhancement of carbon fiber reinforced methylphenylsilicone resin composites modified with silanized carbon nanotubes[J]. Materials & Design, 2016, 89: 1343-1349. [11] QIU B, SUN T, YUAN M, et al. Effect of different lateral dimension graphene oxide sheets on the interface of carbon fiber reinforced polymer composites[J]. Composites Science and Technology, 2021, 213: 108939. doi: 10.1016/j.compscitech.2021.108939 [12] YAO X, GAO X, JIANG J, et al. Comparison of carbon nanotubes and graphene oxide coated carbon fiber for improving the interfacial properties of carbon fiber/epoxy composites[J]. Composites Part B: Engineering, 2018, 132: 170-177. doi: 10.1016/j.compositesb.2017.09.012 [13] YANG G, CHENG F, ZUO S, et al. Growing carbon nano-tubes in situ surrounding carbon fiber surface via chemical vapor deposition to reinforce flexural strength of carbon fiber composites[J]. Polymers. 2023, 15(10): 2309. [14] MA Y, YAN C, XU H, et al. Enhanced interfacial properties of carbon fiber reinforced polyamide 6 composites by grafting graphene oxide onto fiber surface[J]. Applied Surface Science, 2018, 452: 286-298. doi: 10.1016/j.apsusc.2018.04.274 [15] YUAN X, ZHU B, CAI X, et al. Influence of different surface treatments on the interfacial adhesion of graphene oxide/carbon fiber/epoxy composites[J]. Applied Surface Science, 2018, 458: 996-1005. doi: 10.1016/j.apsusc.2018.06.161 [16] HU Y, PANG S, YANG G, et al. MXene modified carbon fiber composites with improved mechanical properties based on electrophoretic deposition[J]. Materials Research Bulletin, 2022, 150: 111761. doi: 10.1016/j.materresbull.2022.111761 [17] ZHAO X, QI S, LIU J, et al. Preparation and mechanical performances of carbon fiber reinforced epoxy composites by Mxene nanosheets coating[J]. Journal of Materials Science: Materials in Electronics, 2019, 30(11): 10516-10523. doi: 10.1007/s10854-019-01395-w [18] 董玉双, 张学军, 田艳红, 等. Ti3C2T x -MXene上浆剂表面改性高模量碳纤维及其环氧树脂基复合材料界面性能[J]. 复合材料学报, 2022, 39(8): 3712-3722.DONG Yushuang, ZHANG Xuejun, TIAN Yanhong, et al. Ti3C2T x -MXene sizing agent surface modified high modulus carbon fiber and its epoxy resin matrix composites interface properties[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 3712-3722(in Chinese). [19] HUANG L, DONG Y, TIAN Y, et al. Electrophoretic deposition of Ti3C2T x MXene nanosheets onto high modulus carbon fiber enhances their composites interfacial properties[J]. Materials Today Communications, 2023, 34: 105429. doi: 10.1016/j.mtcomm.2023.105429 [20] GHIDIU M, LUKATSKAYA M R, ZHAO M Q, et al. Conductive two-dimensional titanium carbide 'clay' with high volumetric capacitance[J]. Nature, 2014, 516(7529): 78-81. doi: 10.1038/nature13970 [21] ALHABEB M, MALESKI K, ANASORI B, et al. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2T x MXene)[J]. Chemistry of Materials, 2017, 29(18): 7633-7644. doi: 10.1021/acs.chemmater.7b02847 [22] TIAN S, CHENG G, TANG Z, et al. Fabrication of two-dimensional Ti3C2T x MXenes by ball milling pretreatment and mild etchant and their microstructure[J]. Ceramics International, 2020, 46(18): 28949-28954. [23] 中国建筑材料联合会. 纤维增强塑料层间剪切强度试验方法: GB/T 1450.1—2005[S]. 北京: 中国标准出版社, 2005.China Building Materials Federation. Fibre-reinforced plastic composites—Determination of interlaminar shear strength: GB/T 1450.1—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [24] 中国建筑材料工业协会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.China Building Materials Federation. Test method for flexural properties of fiber reinforced plastics: GB/T 1449—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [25] 全国碳纤维标准化技术委员会. 碳纤维 单丝拉伸性能的测定: GB/T 31290—2022[S]. 北京: 中国标准出版社, 2022.National Technical Committee for Carbon Fiber Standardization. Determination of tensile properties of carbon fiber monofilaments: GB/T 31290—2022[S]. Beijing: Standards Press of China, 2022(in Chinese). [26] SHEKHIREV M, SHUCK C E, SARYCHEVA A, et al. Characterization of MXenes at every step, from their precursors to single flakes and assembled films[J]. Progress in Materials Science, 2021, 120: 100757. doi: 10.1016/j.pmatsci.2020.100757 [27] WANG W, CAI T, CHENG Z, et al. A shape programmable MXene-based supermolecular nanocomposite film[J]. Composites Part A: Applied Science and Manufacturing, 2022, 159: 106997. doi: 10.1016/j.compositesa.2022.106997 [28] YIN L, KANG H, MA H, et al. Sunshine foaming of compact Ti3C2T x MXene film for highly efficient electromagnetic interference shielding and energy storage[J]. Carbon, 2021, 182: 124-133. doi: 10.1016/j.carbon.2021.05.048 [29] DESIMONI E, CASELLA G I, MORONE A, et al. XPS determination of oxygen-containing functional groups on carbon-fibre surfaces and the cleaning of these surfaces[J]. Surface and Interface Analysis, 1990, 15(10): 627-634. doi: 10.1002/sia.740151011 [30] KHAN S U M, AL-SHAHRY M, INGLER W B. Efficient photochemical water splitting by a chemically modified n-TiO2[J]. Science, 2002, 297(5590): 2243-2245. doi: 10.1126/science.1075035 [31] TRAN M Q, HO K K C, KALINKA G, et al. Carbon fibre reinforced poly(vinylidene fluoride): Impact of matrix modification on fibre/polymer adhesion[J]. Composites Science and Technology, 2008, 68(7): 1766-1776. [32] ZHANG R L, WANG C G, LIU L, et al. Polyhedral oligomeric silsesquioxanes/carbon nanotube/carbon fiber multiscale composite: Influence of a novel hierarchical reinforcement on the interfacial properties[J]. Applied Surface Science, 2015, 353: 224-231. doi: 10.1016/j.apsusc.2015.06.156 [33] KHAN S U, KIM J K. Improved interlaminar shear properties of multiscale carbon fiber composites with bucky paper interleaves made from carbon nanofibers[J]. Carbon, 2012, 50(14): 5265-5277. doi: 10.1016/j.carbon.2012.07.011 [34] MA L, ZHU Y, FENG P, et al. Reinforcing carbon fiber epoxy composites with triazine derivatives functionalized graphene oxide modified sizing agent[J]. Composites Part B: Engineering, 2019, 176: 107078. doi: 10.1016/j.compositesb.2019.107078 [35] ZHANG X, FAN X, YAN C, et al. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide[J]. ACS Applied Materials & Interfaces, 2012, 4(3): 1543-1552. [36] HU Y, PANG S, LI J, et al. Enhanced interfacial properties of hierarchical MXene/CF composites via low content electrophoretic deposition[J]. Composites Part B: Engineering, 2022, 237: 109871. doi: 10.1016/j.compositesb.2022.109871 [37] CHEN W, YU Y, LI P, et al. Effect of new epoxy matrix for T800 carbon fiber/epoxy filament wound composites[J]. Composites Science and Technology, 2007, 67(11): 2261-2270. [38] HE X, WANG C, TONG L, et al. Direct measurement of grafting strength between an individual carbon nanotube and a carbon fiber[J]. Carbon, 2012, 50(10): 3782-3788. doi: 10.1016/j.carbon.2012.03.053 [39] ZHANG R L, LIU Y, HUANG Y D, et al. Effect of particle size and distribution of the sizing agent on the carbon fibers surface and interfacial shear strength (IFSS) of its composites[J]. Applied Surface Science, 2013, 287: 423-427. doi: 10.1016/j.apsusc.2013.09.174 -

下载:

下载: