Flame retardant and mechanical properties of wood-plastic composites with multi-layer sandwich structures

-

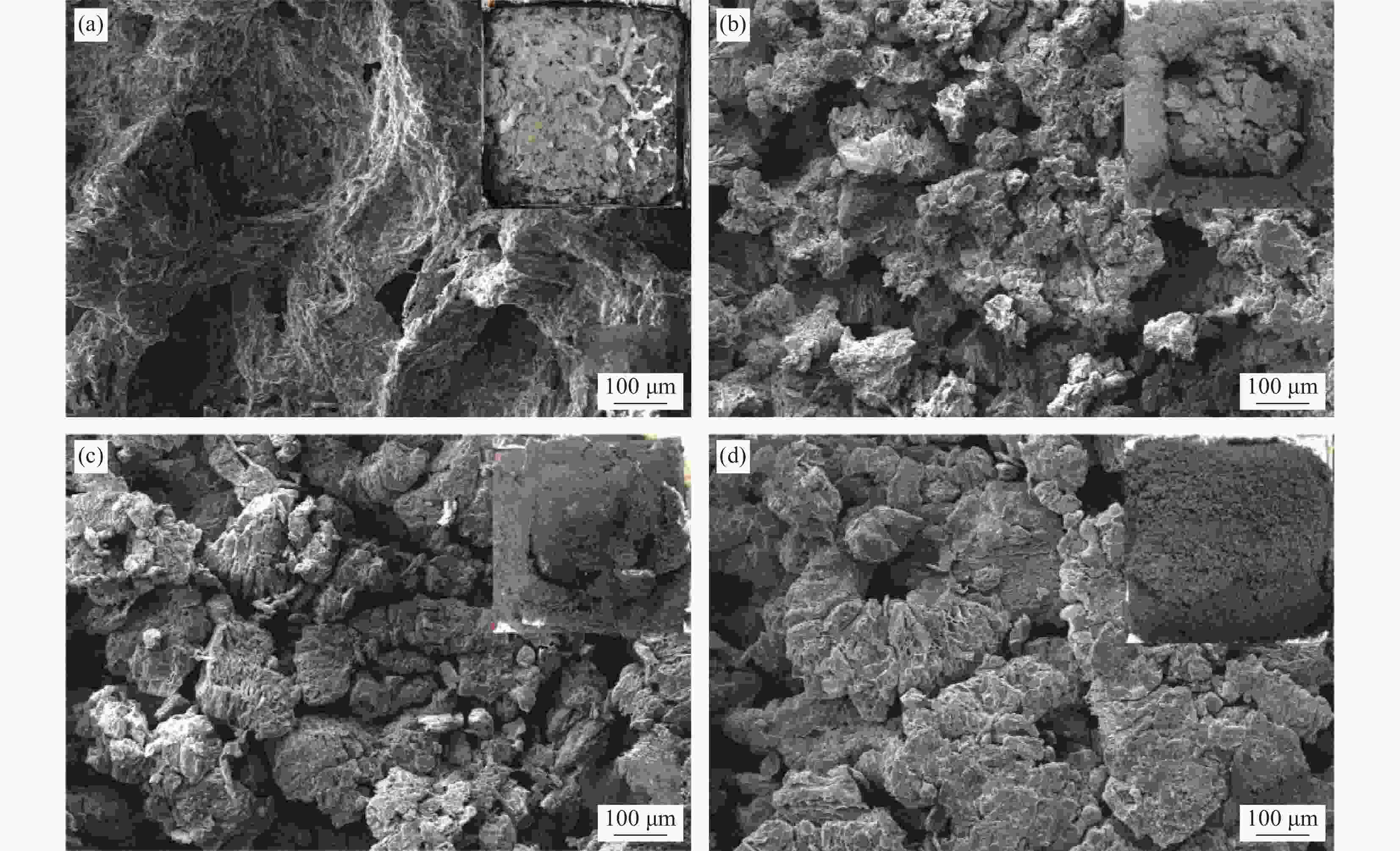

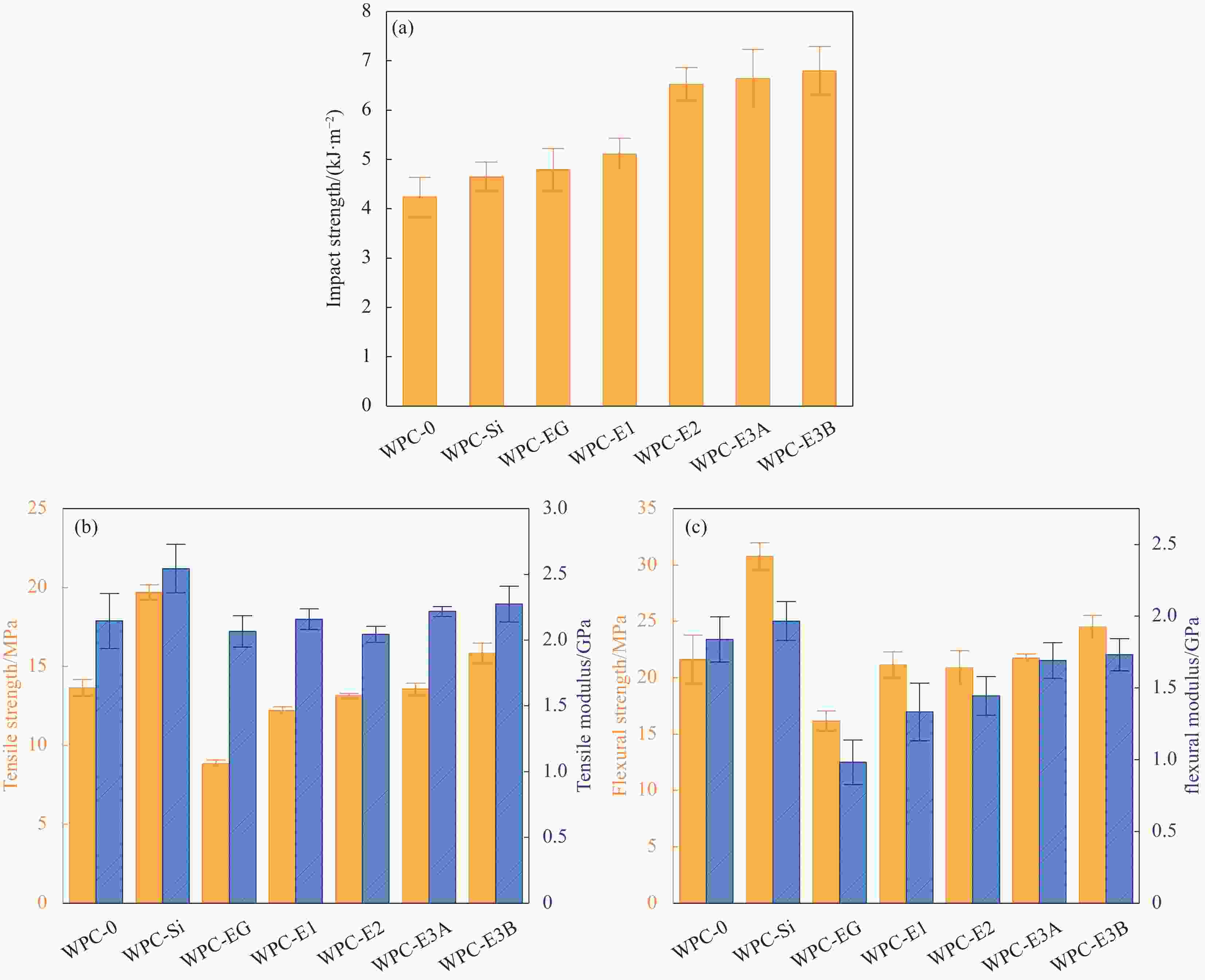

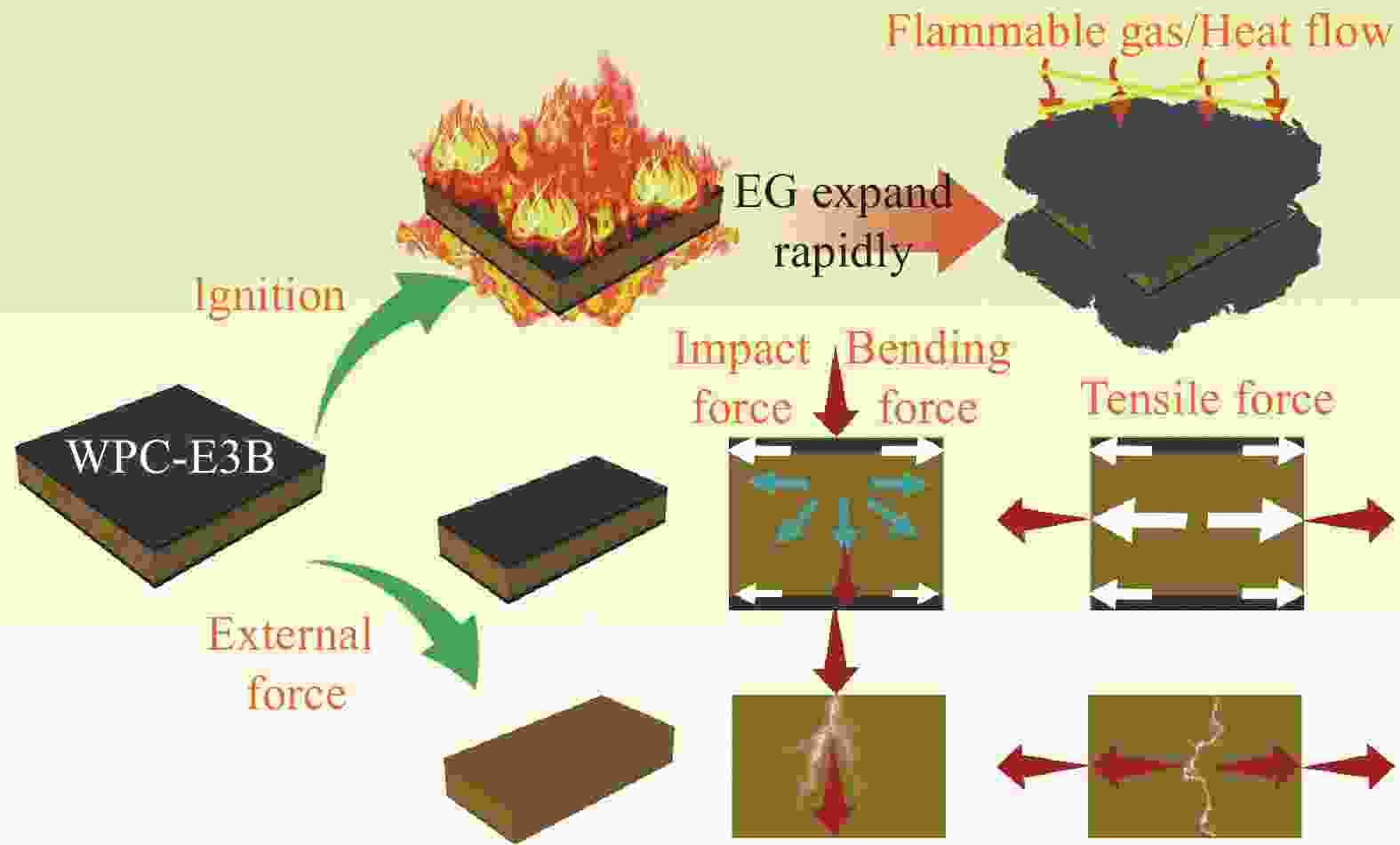

摘要: 针对传统膨胀石墨阻燃木塑复合材料(WPCs)阻燃剂添加量高、力学性能变差的问题,本研究以杨木木粉(WF)、高密度聚乙烯(HDPE)、膨胀石墨(EG)与纳米二氧化硅(n-SiO2)为主要原料,通过层积热压工艺和结构优化设计制备了具有多层夹芯结构的阻燃增强木塑复合材料。采用锥形量热仪、垂直燃烧测试仪、极限氧指数仪和万能力学试验机分别探究了单层、双层和三层夹芯结构对木塑复合材料阻燃和力学性能的影响。结果表明,相比于对照组(WPC-0),阻燃层中EG和增强层中n-SiO2的含量分别为10%和5%时,双层和三层夹芯结构木塑复合材料的热释放速率和总热释放、烟释放速率和总烟释放均有显著降低,残余物质量明显提升。其中三层夹芯结构木塑复合材料(WPC-E3B)的LOI值由20.8%提高至30.6%,UL-94达到V-0级。此外,相较于WPC-0,三层夹芯结构木塑复合材料(WPC-E3B)的冲击强度提升了61.9%,拉伸与弯曲强度分别提高了16.2%和13.4%。Abstract: In order to solve the problems of high flame-retardant addition and deterioration of mechanical properties in the modification of wood-plastic composites (WPCs) by traditional expandable graphite, flame-retardant reinforced wood-plastic composites with a multilayered sandwich structure were prepared by laminated hot pressing process and structure optimization design using poplar wood flour (WF), high-density polyethylene (HDPE), expandable graphite (EG) and nano-silicon dioxide (n-SiO2) as the main raw materials. And the appropriate characterization and equipment such as cone calorimeter, vertical burner, limiting oxygen index tester and mechanical testing machine were used to investigate the effects of single layer, double layer and triple layer sandwich structures on the flame retardant and mechanical properties of wood-plastic composites, respectively. The experimental results showed that compared with the control wood-plastic composite (WPC-0), the multilayer structure wood-plastic composites exhibited significant reduction of peak heat release rate, total heat release rate, smoke production rate and total smoke production, and remarkable improvement of residue yield in the cone test when the contents of EG in the flame-retardant layer and n-SiO2 in the reinforcement layer were 10% and 5%, respectively. Among all the multilayer wood-plastic composites, WPC-E3B with a triple layer sandwich structure improved its LOI from 20.8% to 30.6% and passed the UL-94 test with a V-0 rating. Moreover, it also showed better mechanical properties compared with WPC-0, such as a 61.9% increase in impact strength and 16.2% and 13.4% increases in tensile and flexural strength, respectively.

-

表 1 单层木塑复合材料各组分配方

Table 1. Formulation for the preparation of single-layer wood-plastic composites

Sample HDPE /wt.% WF /wt.% EG /wt.% n-SiO2 /wt.% MAPE /wt.% 530 D /wt.% Role in multilayer WPCs #0 45 50 0 0 3 2 - #1 45 35 10 5 3 2 - #2 45 40 10 0 3 2 - #3 45 45 0 5 3 2 Core layer #4 45 30 20 0 3 2 Surface layer #5 45 10 40 0 3 2 Surface layer 表 2 多层夹芯木塑复合材料的组成

Table 2. Composition of multilayer sandwich wood-plastic composites

Sample Core-layered Surface-layered WPC-E2 #3 (2 mm) *1 #4 (2 mm) *1 WPC-E3A #3 (2 mm) *1 #4 (1 mm) *2 WPC-E3B #3 (3 mm) *1 #5 (0.5 mm) *2 Note: The type, thickness and quantity of boards required for multilayer wood-plastic composites are shown in the table. For example, #5 (0.5 mm) *2 represents two samples of #5 with a thickness of 0.5 mm. 表 3 不同结构的木塑复合材料在CONE试验所得燃烧数据

Table 3. Combustion data of wood-plastic composites with different structures in the cone calorimeter.

Sample TTI/s PHRR1/(kW·m−2) PHRR2/(kW·m−2) THR/(MJ·m−2) TSP/m2 MR/% WPC-0 15 510.3 553.8 129.8 11.3 15.2 WPC-Si 16 419.6 415.3 119.1 11.9 23.5 WPC-E1 25 361.2 488.1 107.1 11.0 35.6 WPC-E2 26 161.1 213.0 77.7 6.5 53.0 WPC-E3A 26 154.1 485.3 92.0 7.4 44.7 WPC-E3B 27 74.8 338.7 78.1 7.1 52.5 Note: TTI is the time to ignition; PHRR1 is the peak first heat release rate; PHRR2 is the peak second heat release rate; THR is the total heat release; TSP is the total smoke production; and MR is the mass of residue. 表 4 不同结构的木塑复合材料的极限氧指数与垂直燃烧等级

Table 4. LOI values and UL94 rating of wood-plastic composites with different structures

Sample Vertical flame test LOI /% WPC-0 N-R 20.8 WPC-E1 N-R 25.7 WPC-E2 V-1 27.3 WPC-E3A V-0 29.1 WPC-E3B V-0 30.6 -

[1] 郭辰星, 朱震锋, 刘嘉琦. 新时期中国木材资源供需: 现状、问题及方略[J]. 中国林业经济, 2019, 05: 66-69.GUO Chenxing, ZHU Zhenfeng, LIU Jiaqi. Supply and demand of timber resources in China in the new era: current situation, problems and strategies[J]. China Forestry Economics, 2019, 05: 66-69(in Chinese). [2] BALLA V K, KATE K H, SATYAVOULU J, et al. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects[J]. Composites Part B:Engineering, 2019, 174: 106956. doi: 10.1016/j.compositesb.2019.106956 [3] MOHANTY A K, VIVEKANANDAN S, PIN J M, et al. Composites from renewable and sustainable resources: Challenges and innovations[J]. Scinence, 2018, 362(6414): 536-542. doi: 10.1126/science.aat9072 [4] 劳万里, 段新芳, 吕斌. 木材工业助力“双碳”目标大有可为[EB/OL]. (2022-01-07). https://www.forestry.gov.cn/main/586/20220107/090254715222376.htmlLAO Wanli, DUAN Xinfang, LV Bin. Wood industry has great potential to contribute to the "double carbon" target [EB/OL]. (2022-01-07). https://www.forestry.gov.cn/main/586/20220107/090254715222376.html (in Chinese). [5] 王清文, 易欣, 沈静. 木塑复合材料在家具制造领域的发展机遇[J]. 林业工程学报, 2016, 1(3): 1-8.WANG Qingwen, YI Xing, SHEN Jing. Tailoring wood-plastic composites for furniture production: possibilities and opportunities[J]. Journal of Forestry Engineering, 2016, 1(3): 1-8 (in Chinese). [6] 徐俊杰, 郝笑龙, 周海洋, 等. 超高填充聚丙烯基木塑复合材料高低温性能[J]. 复合材料学报, 2021, 38(12): 4106-4122. doi: 10.13801/j.cnki.fhclxb.20210317.002XU Junjie, HAO Xiaolong, ZHOU Haiyang, et al. High- and low-temperature performance of ultra-highly filled polypropylene-based wood plastic composite[J]. Acta Materiae Compositae Sinica, 2021, 38(12): 4106-4122(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210317.002 [7] 苍琼, 朱一丞, 张鑫, 等. 高性能木塑复合材料的制备[J]. 工业技术与职业教育, 2022, 20(05): 7-10. doi: 10.16825/j.cnki.cn13-1400/tb.2022.05.003CANG Qiong, ZHU Yicheng, ZHANG Xin, et al. Preparation of high performance wood-plastic composites[J]. Industrial Technology & Vocational Education, 2022, 20(05): 7-10(in Chinese). doi: 10.16825/j.cnki.cn13-1400/tb.2022.05.003 [8] SHAO Z B, DENG C, TAN Y, et al. An Efficient Mono-Component Polymeric Intumescent Flame Retardant for Polypropylene: Preparation and Application[J]. ACS Applied Materials & Interfaces, 2014, 6(10): 7363-7370. [9] 张爱丽, 林梅. 阻燃型室内用木塑复合材料制备与性能[J]. 工程塑料应用, 2021, 49(10): 148-152. doi: 10.3969/j.issn.1001-3539.2021.10.027ZHANG Aili, LIN Mei. Preparation and performance of flame-retardant indoor wood-plastic composite materials[J]. Engineering Plastics Applications, 2021, 49(10): 148-152(in Chinese). doi: 10.3969/j.issn.1001-3539.2021.10.027 [10] 梁兵. 利用膨胀型阻燃剂制备无卤阻燃木塑复合材料及其制备方法 [D]. 沈阳: 沈阳化工大学, 2012.LIANG Bing. Preparation of halogen-free flame-retardant wood-plastic composites using intumescent flame retardant and its preparation method [D]. Shenyang: Shenyang University of Chemical Technology, 2012(in Chinese). [11] 郭垂根, 陈永祥, 白钢, 等. 改性炭黑/膨胀石墨/聚磷酸铵阻燃木塑复合材料的性能研究[J]. 材料导报, 2015, 29(08): 68-73.GUO Chuigen, CHEN Yongxiang, BAI Gang, et al. Study on performance of flame retarded wood plastic composites with modified carbon black (M-CB) / expandable graphite (EG) / ammonium polyphosphate (APP)[J]. Materials Reports, 2015, 29(08): 68-73(in Chinese). [12] HU X C, ZHU X. J, SUN Z Q. Fireproof performance of the intumescent fire retardant coatings with layered double hydroxides additives[J]. Construction and Building Materials, 2020, 256: 119445. doi: 10.1016/j.conbuildmat.2020.119445 [13] SCHARTEL B, BRANU U, SCHWARZ U, et al. Fire retardancy of polypropylene / flax blends[J]. Polymer, 2003, 44(20): 6241-6250. doi: 10.1016/S0032-3861(03)00692-X [14] 王迪. 可膨胀聚苯乙烯基木塑复合材料的阻燃性能研究 [D]. 北京: 北京化工大学, 2020.WANG Di. Study on flame retardant properties of expandable polystyrene wood-plastic composites [D]. Beijing: Beijing University of Chemical Technology, 2020(in Chinese). [15] ZHENG J Q, LI B, Guo C G, et al. Flame- Retardant Properties of Acrylonitrile Butadiene Styrene/Wood Flour Composites Filled with Expandable Graphite and Ammonium Polyphosphate[J]. Journal of Applied Polymer Science, 2014, 131: 40281. doi: 10.1002/app.40281 [16] TURKU I, KARKI T. The influence of carbon-based fillers on the flammability of polypropylene-based co-extruded wood-plastic composite[J]. Fire and Materials, 2016, 40: 498-506. doi: 10.1002/fam.2306 [17] MOKHENA T C, SADIKU E R, MOCAHANE M J, et al. Mechanical properties of fire retardant wood-plastic composites: A review[J]. Express Polymer Letters, 2021, 15(8): 744-780. doi: 10.3144/expresspolymlett.2021.61 [18] HUANG Y P, ZHANG S, CHEN H, et al. A Branched Polyelectrolyte Complex Enables Efficient Flame Retardant and Excellent Robustness for Wood/Polymer Composites[J]. Polymers, 2020, 12(11): 2438. doi: 10.3390/polym12112438 [19] 申辉. 改性氢氧化镁/可膨胀石墨复配阻燃研究 [D]. 成都: 成都理工大学, 2013.SHEN Hui. The research on multiplexing of modified magnesium hydroxide / expandable graphite [D]. Chengdu: Chengdu University of Technology, 2013(in Chinese). [20] 周海洋. 无机纳米粒子网络结构功能化木粉-HDPE复合材料 [D]. 哈尔滨: 东北林业大学, 2019.ZHUO Haiyang. Inorganic nano-particle network structure functionalized wood flour-HDPE composites [D]. Harbin: Northeast Forestry University, 2019(in Chinese). [21] BUDDI T, RAO B N, SINGH S K, et al. Development and analysis of high density poly ethylene (HDPE) nano SiO2 and wood powder reinforced polymer matrix hybrid nano composites[J]. Journal of Experimental Nanoscience, 2018, 13: S24-S30. doi: 10.1080/17458080.2018.1426895 [22] SUN L C, XIE Y J, OU R X, et al. The influence of double-layered distribution of fire retardants on the fire retardancy and mechanical properties of wood fiber polypropylene composites[J]. Construction and Building Materials, 2020, 242: 118047. doi: 10.1016/j.conbuildmat.2020.118047 [23] 中国国家标准化管理委员. 塑料用氧指数测定燃烧行为 第1部分: GB/T 2406.1-2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Plastics - Determination of combustion behaviour by oxygen index - Part 1: GB/T 2406.1-2008[S]. Beijing: China Stand-ards Press, 2008(in Chinese). [24] 中国国家标准化管理委员会. 塑料 燃烧性能的测定 水平法和垂直法: GB/T 2408-2021[S]. 北京: 中国标准出版社, 2021.Standardization Administration of the People’s Republic of China. Determination of combustion properties of plastics - horizontal method and vertical method: GB/T 2408-2021[S]. Beijing: China Stand-ards Press, 2021(in Chinese). [25] International Organization for Standardization. ISO 5660-1: 2015: Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement)[S]. England: International Organization for Standardization, 2015. [26] American Society of Testing Materials. ASTM D638-22: Standard Test Method for Tensile Properties of Plastics[S]. Ameriaca: American Society of Testing Materials, 2022. [27] American Society of Testing Materials. ASTM D790-17: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials[S]. Ameriaca: American Society of Testing Materials, 2017. [28] American Society of Testing Materials. ASTM D256-23e1: Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics[S]. Ameriaca: American Society of Testing Materials, 2022. [29] 霍玉娜, 魏童, 周雪莲, 等. 以石塑为表层的WF/HDPE夹层结构复合材料的性能[J]. 林业工程学报, 2023, 8(04): 27-34.HUO Yuna, WEI Tong, ZHOU Xuelian, et al. Performance of sandwiched WF / HDPE composites with stone-flour/HDPE surface layer[J]. Journal of Forest Engineering, 2023, 8(04): 27-34(in Chinese). [30] CHEN B, MONTANARI C, POPOV S, et al. A distortion-map-based method for morphology generation in multi-phase materials - application to wood[J]. Composites Science and Technology, 2023, 224: 110262. [31] OSVALDOVA L M, KOSUTOVA K, LEE S H, et al. Ignition and burning of selected tree species from tropical and northern temperate zones[J]. Advanced Industrial and Engineering Polymer Research, 2023, 6(2): 195-202. doi: 10.1016/j.aiepr.2023.01.006 [32] 郑建强. EG/APP膨胀阻燃ABS基木塑复合材的制备与性能研究 [D]. 哈尔滨: 东北林业大学, 2013.ZHENG Jianqiang. Study on preparation and performance of EG / APP IFR flame retardanting ABS-based WPC [D]. Harbin: Northeast Forestry University, 2013(in Chinese). [33] 董倩倩, 李凯夫, 蔡奇龙, 等. 3D打印用聚乳酸/松木粉/纳米二氧化硅木塑复合材料性能研究[J]. 塑料科技, 2019, 47(01): 85-89. doi: 10.15925/j.cnki.issn1005-3360.2019.01.013DONG Qianqian, LI Kaifu, CAI Qilong, et al. Properties of PLA / PWF / nano-SiO2 wood-plastic composites for 3D printing[J]. Plastics Science and Technology, 2019, 47(01): 85-89(in Chinese). doi: 10.15925/j.cnki.issn1005-3360.2019.01.013 [34] 周松, 王静怡, 张再昌, 等. 纳米SiO2/竹纤维/环氧树脂复合材料性能研究[J]. 塑料助剂, 2009, 02: 47-50. doi: 10.3969/j.issn.1672-6294.2009.01.012ZHOU Song, WANG Jingyi, ZHANG Zaichang, et al. Study on properties of nano-SiO2 / bamboo fiber / epoxy resin ternary composites[J]. Plastic Additives, 2009, 02: 47-50(in Chinese). doi: 10.3969/j.issn.1672-6294.2009.01.012 [35] KIM B J, Yao F, HAN G P, et al. Mechanical and physical properties of core–shell structured wood plastic composites: Effect of shells with hybrid mineral and wood fillers[J]. Composites Part B:Engineering, 2013, 45(1): 1040-1048. doi: 10.1016/j.compositesb.2012.07.031 -

下载:

下载: