Preparation and properties of high specific strength carbon/carbon composites based on carbon fiber/carbon foam preforms

-

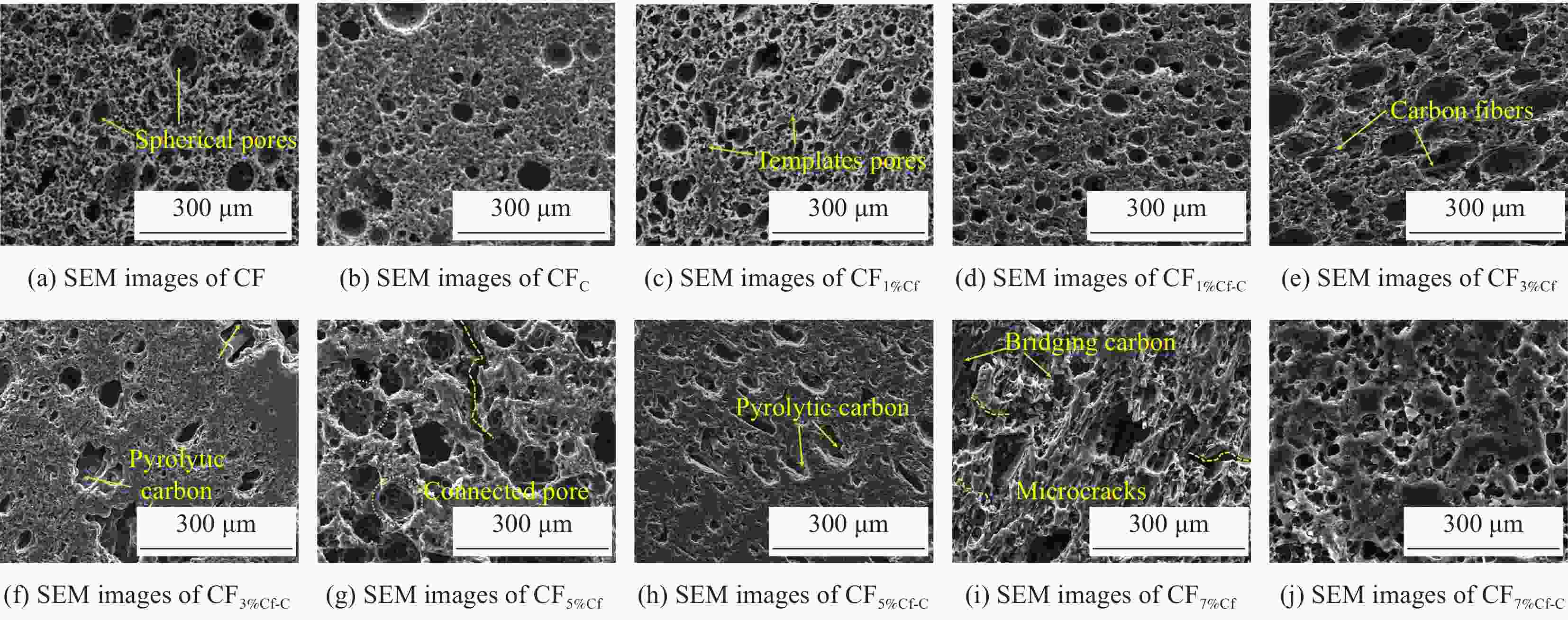

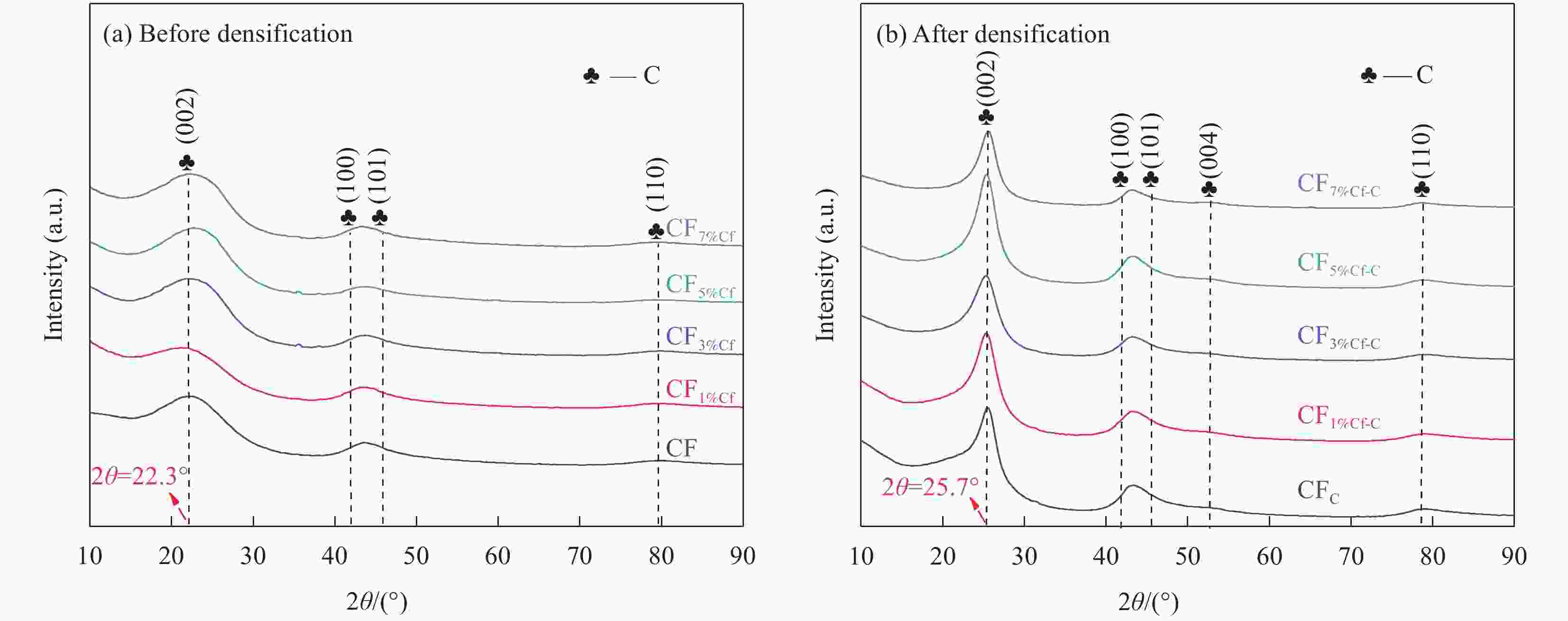

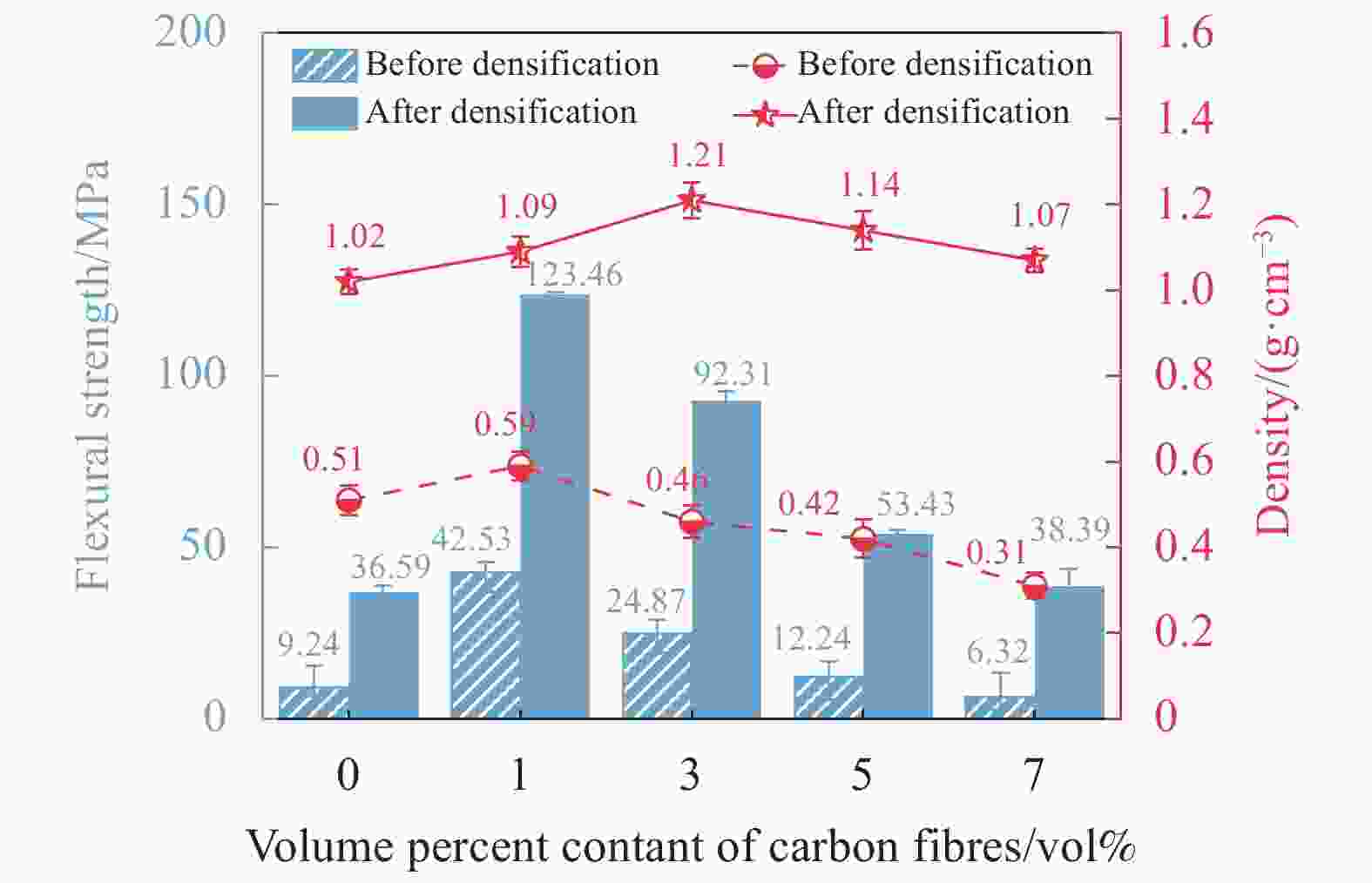

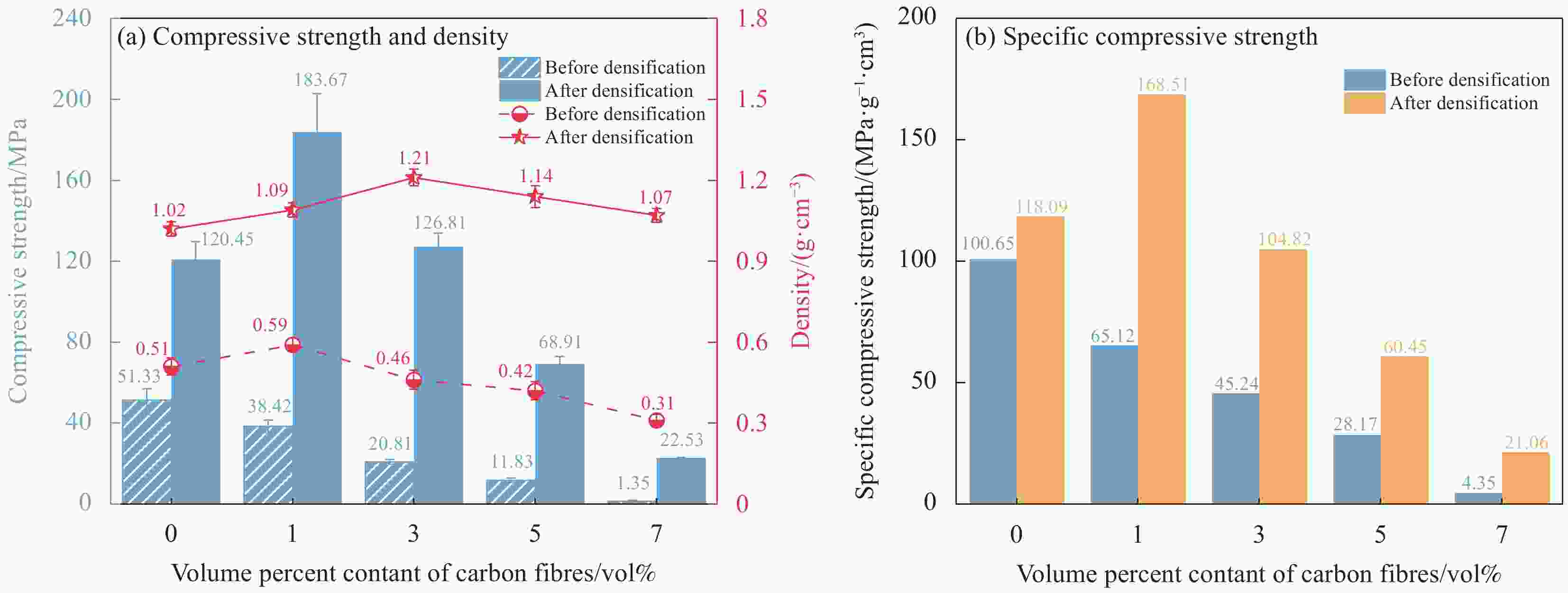

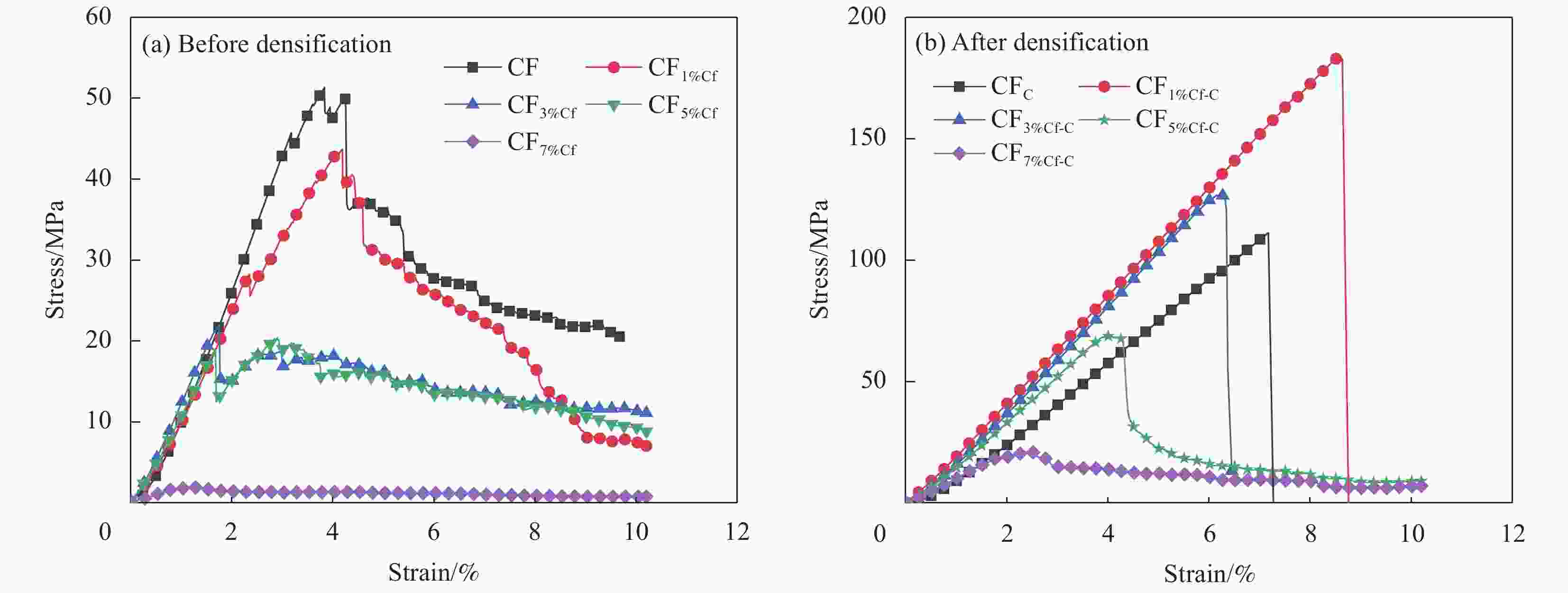

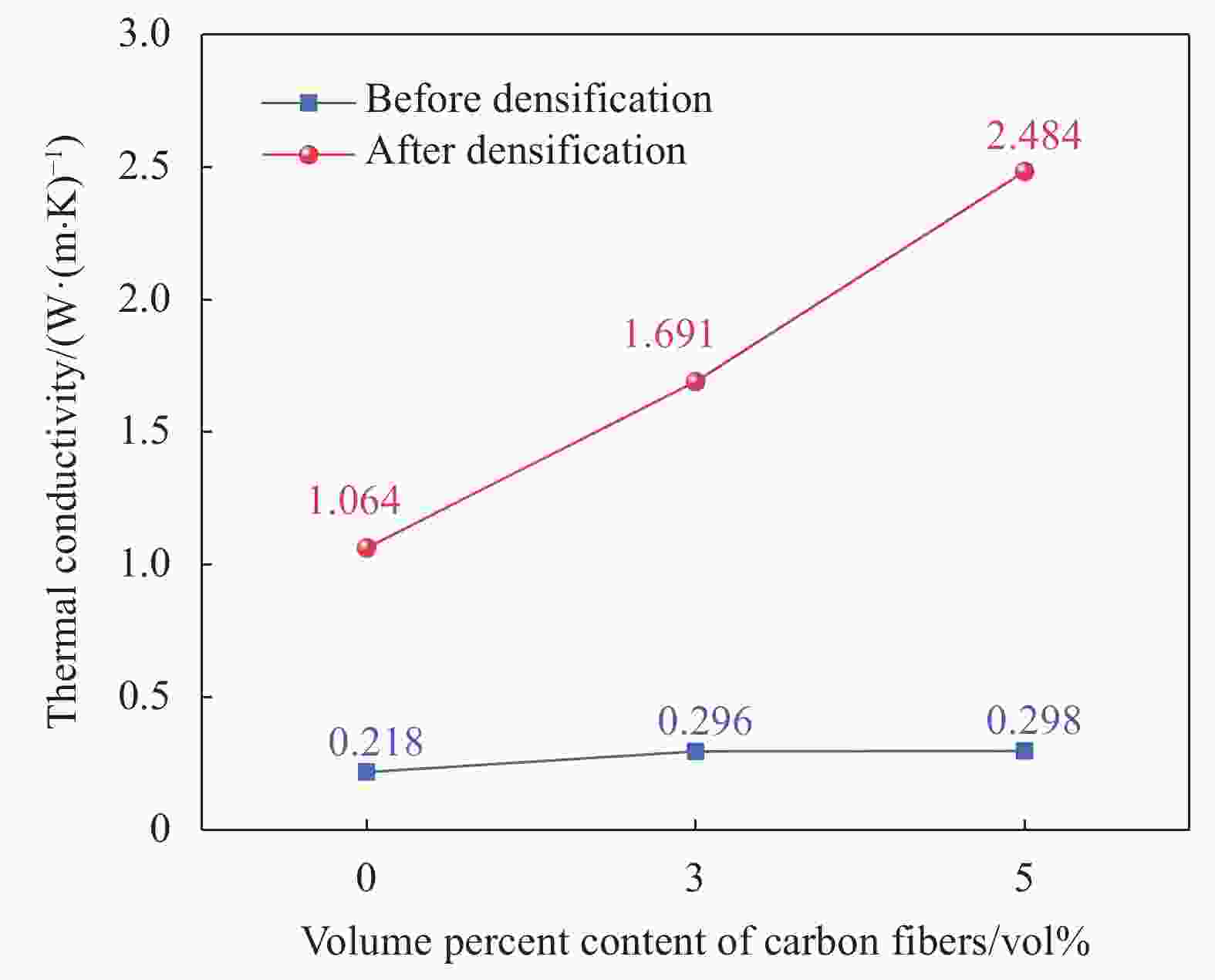

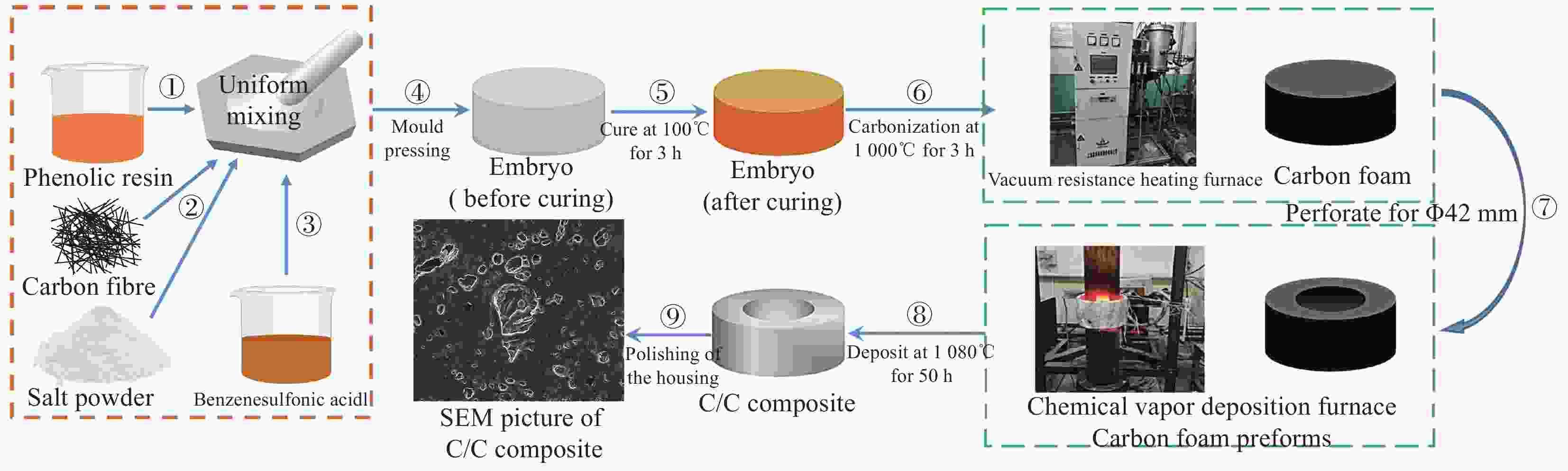

摘要: 碳/碳复合材料以其优异的性能广泛应用于航空航天、武器装备等领域,但碳纤维预制体成本高等因素限制了碳/碳复合材料的发展。碳泡沫具有三维网状结构,其韧带表现出与碳纤维相似的性质,可以作为增强相制备新型碳/碳复合材料。本文以酚醛树脂作为碳源,NaCl作为造孔剂,制备出不同碳纤维体积含量(0vol%、1vol%、3vol%、5vol%、7vol%)的碳泡沫作为碳/碳复合材料预制体,利用热梯度化学气相渗积(TG-CVI)快速致密化技术制备碳/碳复合材料,考察了碳纤维含量对碳纤维/碳泡沫预制体及其致密化后密度、微观结构和力学性能的影响。结果表明,随着碳纤维含量的增加,碳纤维/碳泡沫预制体中的微裂纹数量显增加,密度由0.51 g/cm3逐渐降低至0.31 g/cm3,抗压强度由51.30 MPa下降至1.30 MPa,抗弯强度由42.53 MPa下降至6.32 MPa。致密化之后碳/碳复合材料抗压强度与抗弯强度显著提升,最高分别为183.67 MPa和123.46 MPa,其密度为1.09 g/cm3,因此具有高比强度。致密化后复合材料的热导率从0.298 W/(m·K)(致密化前)增大到2.484 W/(m·K),提升了734%,这是由于致密化后碳纤维与热解碳形成了三维导热网络。Abstract: Carbon/carbon composites has been widely used in aerospace, weaponry and other fields with their excellent properties. However, the development of carbon/carbon composites has been limited by the high cost of carbon fiber preforms. Carbon foam has a three-dimensional network structure, and its ligaments show similar properties to carbon fibers, which can be used as the reinforcing phase to prepare carbon/carbon composites. In this paper, carbon foams with different carbon fiber volume contents (0vol%, 1vol%, 3vol%, 5vol%, 7vol%) were prepared as carbon/carbon composites preforms by using phenolic resin as the carbon source and NaCl as the pore-forming agent, and the carbon/carbon composites were prepared by using the rapid densification technique of thermal gradient chemical vapour infiltration (TG-CVI), which investigated the effects of carbon fiber content on the carbon fiber/carbon foam preform and its density, microstructure and mechanical properties after densification. The effects of carbon fiber content on the density, microstructure and mechanical properties of the carbon fiber/carbon foam preform and its densification were investigated. The results showed that with the increase of carbon fiber content, the number of microcracks in the carbon fiber/carbon foam precast body increased significantly, the density gradually decreased from 0.51 g/cm3 to 0.31 g/cm3, and the compressive strength decreased from 51.30 MPa to 1.30 MPa, flexural strength decreased from 42.53 MPa to 6.32 MPa. The compressive and flexural strengths of the carbon/carbon composites were significantly increased after densification, up to 183.67 MPa and 123.46 MPa, respectively, while the density was 1.09 g/cm3, resulting in high specific strength. The thermal conductivity of the composites increased from 0.298 W/(m·K) (before densification) to 2.484 W/(m·K), an increase of 734%, which was attributed to the formation of a three-dimensional thermal conductivity network between the carbon fibers and pyrolytic carbon after densification.

-

表 1 碳纤维/碳泡沫致密化前的密度、残碳率与体积收缩率

Table 1. Density, residual carbon rate and volume shrinkage of carbon fiber/carbon foam before deposition

Sample CF CF1%Cf CF3%Cf CF5%Cf CF7%Cf Density/(g·cm−3) 0.51 0.59 0.46 0.42 0.31 Residual carbon rate/% 49.1 50.3 52.1 54.7 56.8 Volume shrinkage/% 46.3 42.1 22.8 18.4 13.7 -

[1] LI B, HUANG D, LI T, et al. The positive role of mesophase-pitch-based carbon fibers in enhancing thermal response behavior in Carbon/Carbon composites[J]. Materials Characterization, 2023, 196: 112630. doi: 10.1016/j.matchar.2022.112630 [2] 王德文, 渠聚鑫, 孟东容. 碳/碳复合材料在再入弹头上的应用研究[J]. 真空科学与技术学报, 2018, 38(01): 65-70.WANG Dewen, DU Juxin, MENG Dongrong. Application study of carbon/carbon composites on reentry warheads[J]. Journal of Vacuum Science and Technology, 2018, 38(01): 65-70(in Chinese). [3] 隋金玲, 李木森, 吕宇鹏. 人体承重骨替换用碳/碳复合材料的研究现状[J]. 生物医学工程学杂志, 2004, (04): 686-689.SUI Jinling, LI Musen, LU Yupeng. Current status of carbon/carbon composites for human load-bearing bone replacement[J]. Journal of Biomedical Engineering, 2004, (04): 686-689(in Chinese). [4] XU M, GUO L, ZHANG P, et al. Effect of pyrolytic carbon texture on ablation behavior of carbon/carbon composites coated with SiC by pack cementation[J]. Ceramics International, 2022, 48(7): 10261-10270. doi: 10.1016/j.ceramint.2021.12.244 [5] CAO M, FENG Y, TIAN R, et al. Free-standing porous carbon foam as the ultralight and flexible supercapacitor electrode[J]. Carbon, 2020, 161: 224-230. doi: 10.1016/j.carbon.2020.01.093 [6] LIU Y, WANG Y, SHI C, et al. Co-ZIF derived porous NiCo-LDH nanosheets/N doped carbon foam for high-performance supercapacitor[J]. Carbon, 2020, 165: 129-138. doi: 10.1016/j.carbon.2020.04.084 [7] ZHANG P, CAO M, FENG Y, et al. Uniformly growing Co9S8 nanoparticles on flexible carbon foam as a free-standing anode for lithium-ion storage devices[J]. Carbon, 2021, 182: 404-412. doi: 10.1016/j.carbon.2021.06.032 [8] OLA O, CHEN Y, ZHU Y. Three-dimensional carbon foam nanocomposites for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2019, 191: 297-305. doi: 10.1016/j.solmat.2018.11.037 [9] XU Y, ZHANG Z, GENG X, et al. Smart carbon foams with switchable wettability for fast oil recovery[J]. Carbon, 2019, 149: 242-247. doi: 10.1016/j.carbon.2019.04.039 [10] XIONG W, LIU M, GAN L, et al. Preparation of nitrogen-doped macro-/mesoporous carbon foams as electrode material for supercapacitors[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2012, 411: 34-39. doi: 10.1016/j.colsurfa.2012.06.042 [11] LI X, LI X, DONG Y, et al. Porous cobalt oxides/carbon foam hybrid materials for high supercapacitive performance[J]. Journal of Colloid and Interface Science, 2019, 542: 102-111. doi: 10.1016/j.jcis.2019.01.128 [12] AGRAWAL P R, KUMAR R, UPPAL H, et al. Novel 3D lightweight carbon foam as an effective adsorbent for arsenic( v ) removal from contaminated water[J]. RSC Advances, 2016, 6(36): 29899-29908. doi: 10.1039/C6RA02208A [13] CAO Z, ZHANG J, DING Y, et al. In situ synthesis of flexible elastic N-doped carbon foam as a carbon current collector and interlayer for high-performance lithium sulfur batteries[J]. Journal of Materials Chemistry A, 2016, 4(22): 8636-8644. doi: 10.1039/C6TA01855F [14] KUMAR R, DHAKATE S R, SAINI P, et al. Improved electromagnetic interference shielding effectiveness of light weight carbon foam by ferrocene accumulation[J]. RSC Advances, 2013, 3(13): 4145. doi: 10.1039/c3ra00121k [15] 田辞. 碳泡沫的发泡法和模板法制备及其表征[D]. 同济大学, 2008.TIAN Ci. Preparation and characterization of carbon foams by foaming and template methods[D]. Tongji University, 2008. [16] ANDERSON D P, KEARNS K M, KLETT J W, et al. Microcellular graphitic carbon foams for next generation structures and thermal management[C/OL]//2000 IEEE Aerospace Conference. Proceedings (Cat. No. 00TH8484). Big Sky, MT, USA: IEEE, 2000: 193-200[2023-09-24 [17] COVACIU M, RAMOS-MOORE E, ROJAS S, et al. A novel one-pot method to synthesize hierarchical mesoporous carbon foams with ZnO coating[J]. Ceramics International, 2019, 45(17): 21475-21482. doi: 10.1016/j.ceramint.2019.07.138 [18] WU Y, BAO W, XIE Y, et al. Preparation and electrochemical performance of chemical-activated carbon foam[J]. Micro & Nano Letters, 2021, 16(2): 164-170. [19] DING J, ZHONG L, HUANG Q, et al. Chitosan hydrogel derived carbon foam with typical transition-metal catalysts for efficient water splitting[J]. Carbon, 2021, 177: 160-170. doi: 10.1016/j.carbon.2021.01.160 [20] MARX J, ROTH S, BROUSCHKIN A, et al. Tailored crystalline width and wall thickness of an annealed 3D carbon foam composites and their mechanical properties[J]. Carbon, 2019, 142: 60-67. doi: 10.1016/j.carbon.2018.10.004 [21] PATLE V K, KUMAR R, SHARMA A, et al. Three dimension phenolic resin derived carbon-CNTs hybrid foam for fire retardant and effective electromagnetic interference shielding[J]. Composites Part C:Open Access, 2020, 2: 100020. doi: 10.1016/j.jcomc.2020.100020 [22] CHUANG W, LEI P, ZHEN-HAI S, et al. Preparation, thermal stability and deflection of a density gradient thermally-conductive carbon foam material derived from phenolic resin[J]. Results in Physics, 2019, 14: 102448. doi: 10.1016/j.rinp.2019.102448 [23] WANG B, LUO X, KANG Y, et al. Preparation and Properties of Glass Fiber Reinforced Carbon Foam Composites[J]. Applied Composite Materials, 2022, 29(2): 845-853. doi: 10.1007/s10443-021-09993-w [24] FARHAN S, WANG R-M. Thermal, mechanical and self-destruction properties of aluminum reinforced carbon foam[J]. Journal of Porous Materials, 2015, 22(4): 897-906. doi: 10.1007/s10934-015-9963-3 [25] MEI H, ZHAO G, LIU G, et al. Effect of pore size distribution on the mechanical performance of carbon foams reinforced by in situ grown Si 3 N 4 whiskers[J]. Journal of the European Ceramic Society, 2015, 35(16): 4431-4435. doi: 10.1016/j.jeurceramsoc.2015.08.001 [26] 中国国家标准化管理委员会(标准制定单位). 碳/碳复合材料压缩性能试验方法: GB/T 34559-2017 [S]. 北京: 中国标准出版社, 2017.Standardization Administration of the People’s Republic of China. Test Method for Compressive Properties of Carbon/Carbon Composites: GB/T 34559-2017 [S]. Beijing: China Standards Press, 2017(in Chinese). [27] World Trade Organization Technical Barriers to Trade (TBT) Committee. Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature1: ASTM-C1161 − 18 (Reapproved 2023) [S] American Society for Testing and Materials, 2023. [28] WANG Y, HE Z, ZHAN L, et al. Coal tar pitch based carbon foam for thermal insulating material[J]. Materials Letters, 2016, 169: 95-98. doi: 10.1016/j.matlet.2016.01.081 [29] LI S, CHEN F, ZHANG B, et al. Structure and improved thermal stability of phenolic resin containing silicon and boron elements[J]. Polymer Degradation and Stability, 2016, 133: 321-329. doi: 10.1016/j.polymdegradstab.2016.07.020 [30] JORIO A, SAITO R, DRESSELHAUS G, et al. Raman Spectroscopy in Graphene Related Systems[M/OL]. 1 edition. Wiley, 2011[2023-08-13 [31] WANG X, LUO R, NI Y, et al. Properties of chopped carbon fiber reinforced carbon foam composites[J]. Materials Letters, 2009, 63(1): 25-27. doi: 10.1016/j.matlet.2008.08.036 [32] AGARI Y, UNO T. Estimation on thermal conductivities of filled polymers[J]. Journal of Applied Polymer Science, 2010, 32(7): 5705-5712. [33] 史青, 彭勃, 朱爱萍. 膨胀石墨-碳纤维/尼龙三元导热复合材料制备[J]. 复合材料学报, 2019, 36(3): 555-562.SHI Qing, PENG Bo, ZHU Aiping. Preparation of expanded graphite-carbon fiber/nylon ternary thermally conductive composites[J]. Acta Materiae Compositae Sinica, 2010, 32(7): 5705-5712. (in Chinese) -

点击查看大图

点击查看大图

计量

- 文章访问数: 131

- HTML全文浏览量: 77

- 被引次数: 0

下载:

下载: