Highly efficient flame-retardant epoxy resin with a novel compound containing phosphaphenanthrene and triazole groups

-

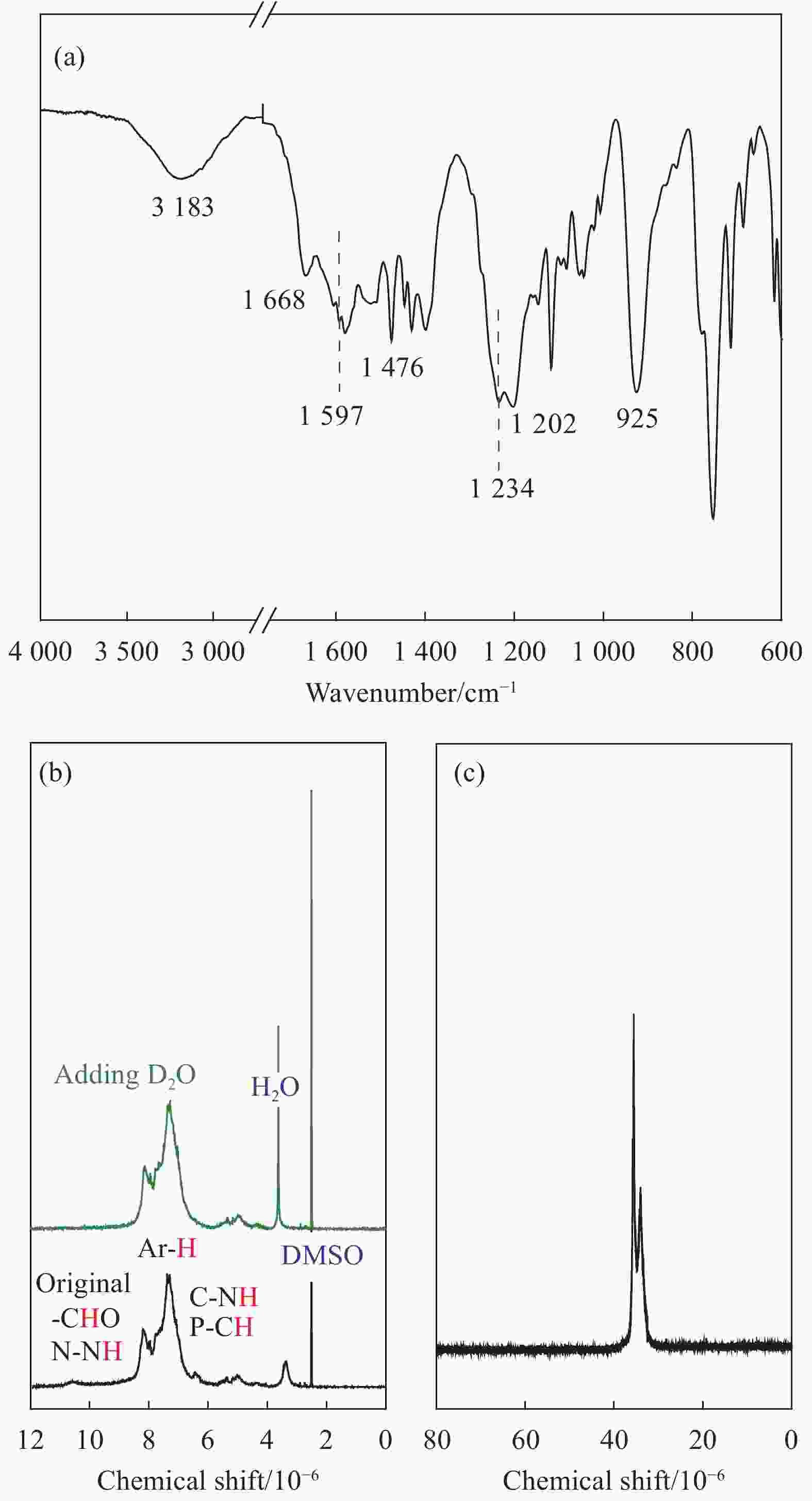

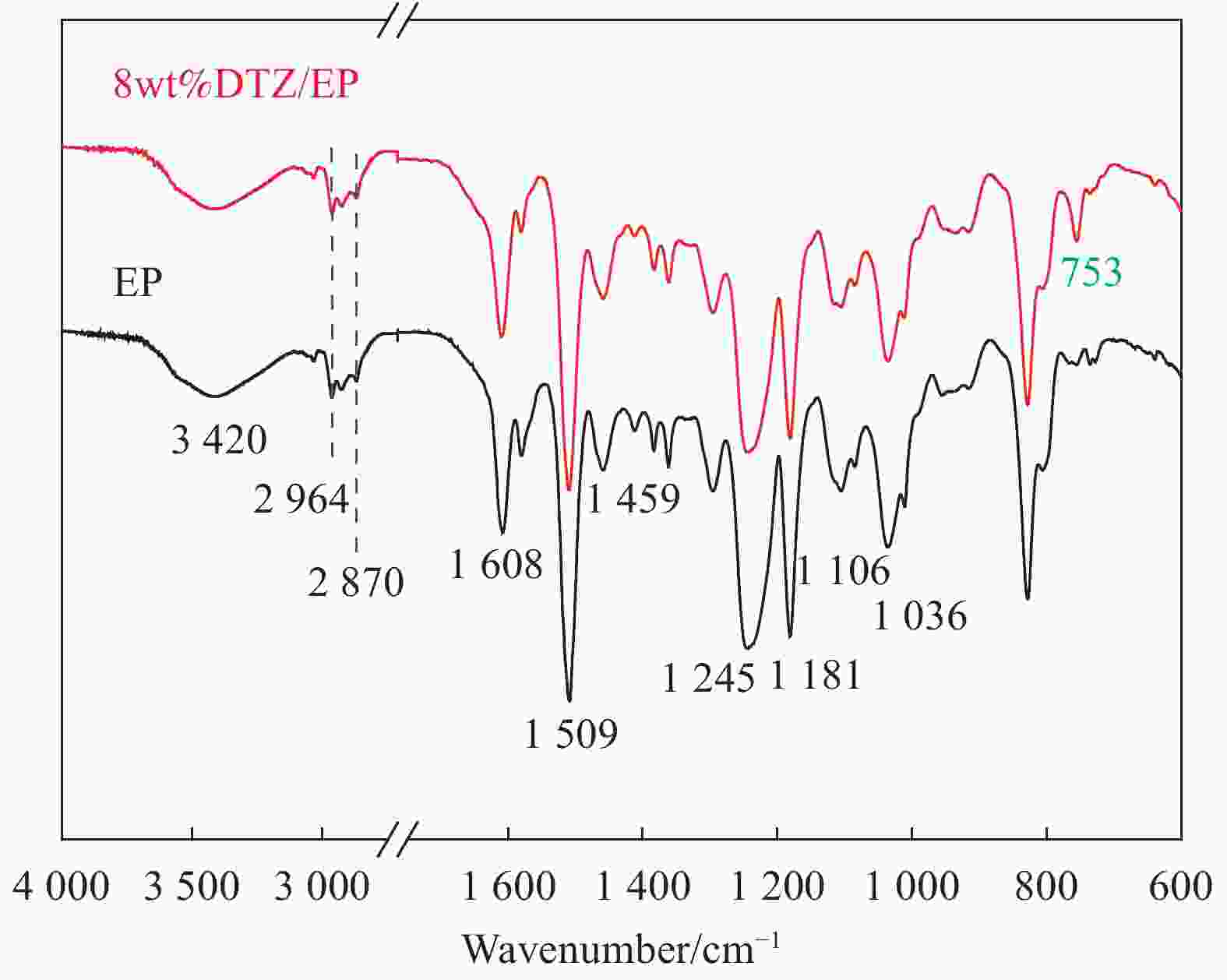

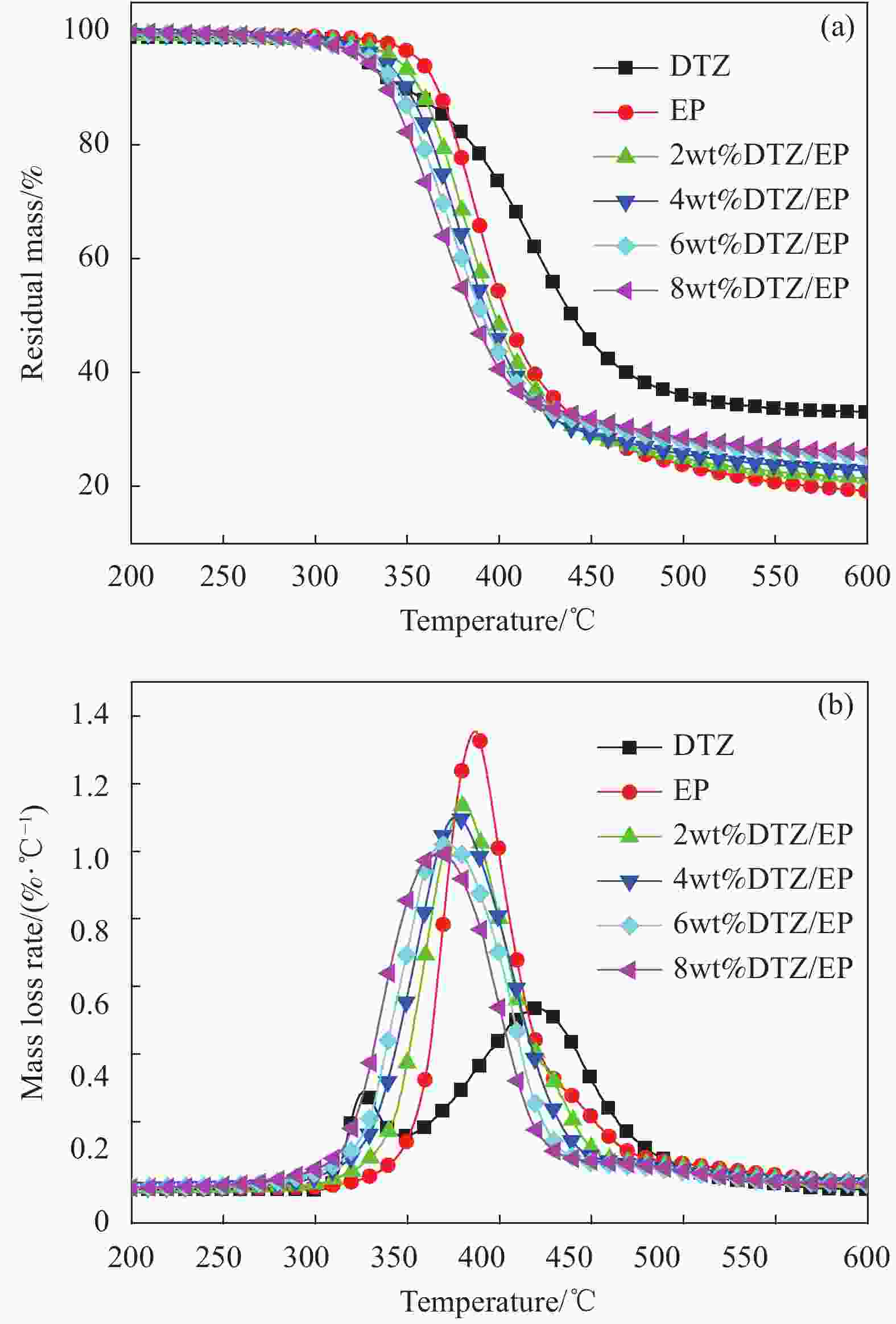

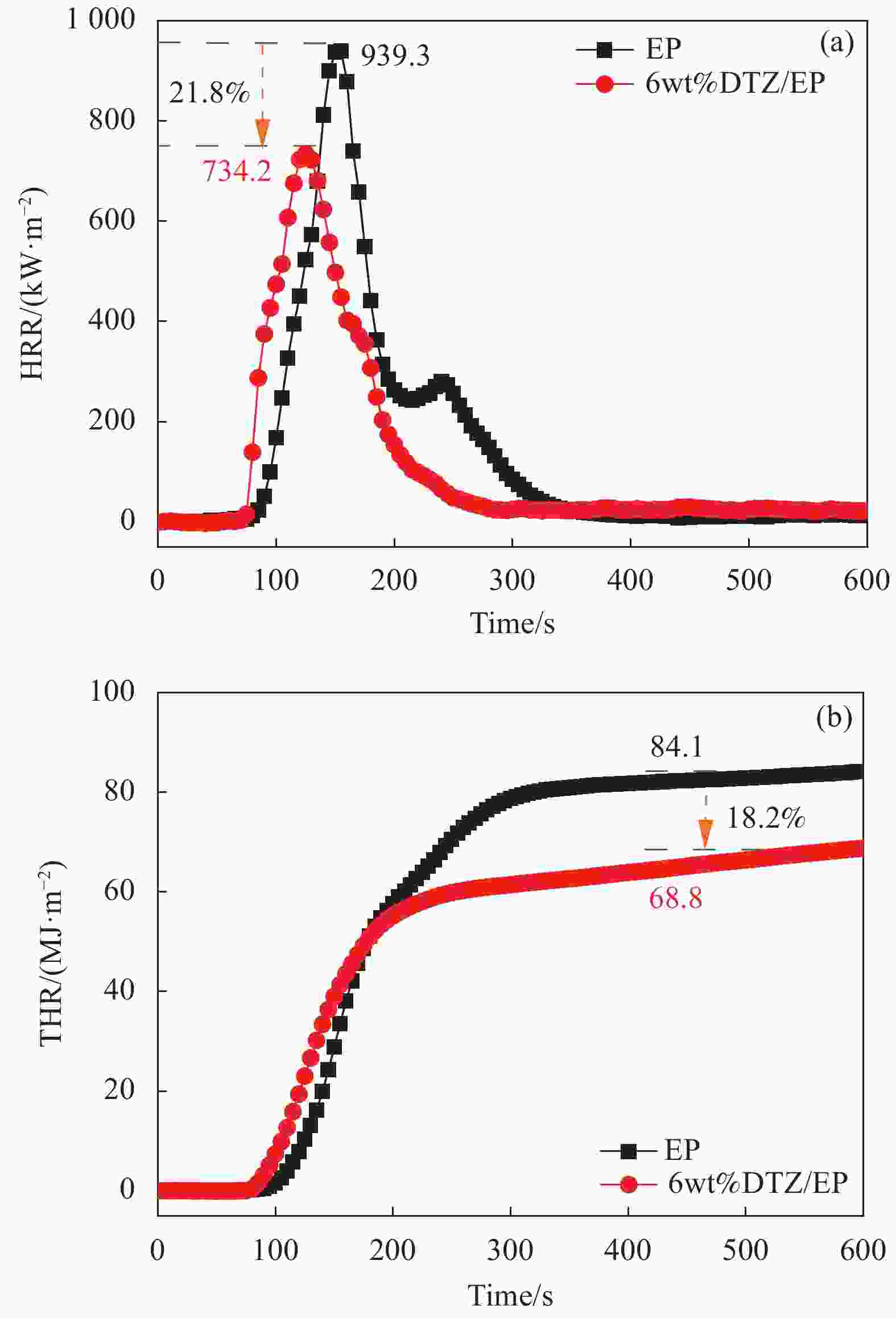

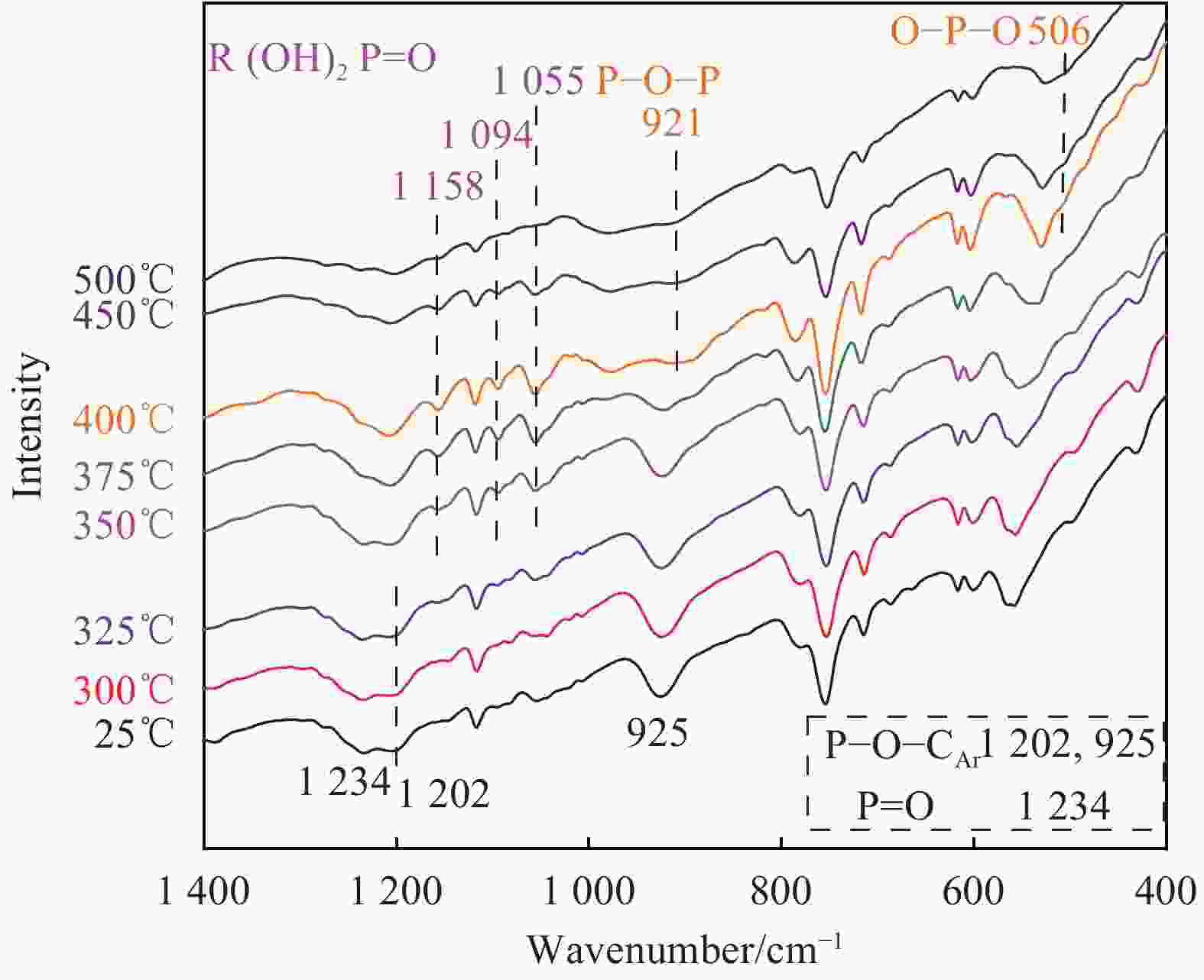

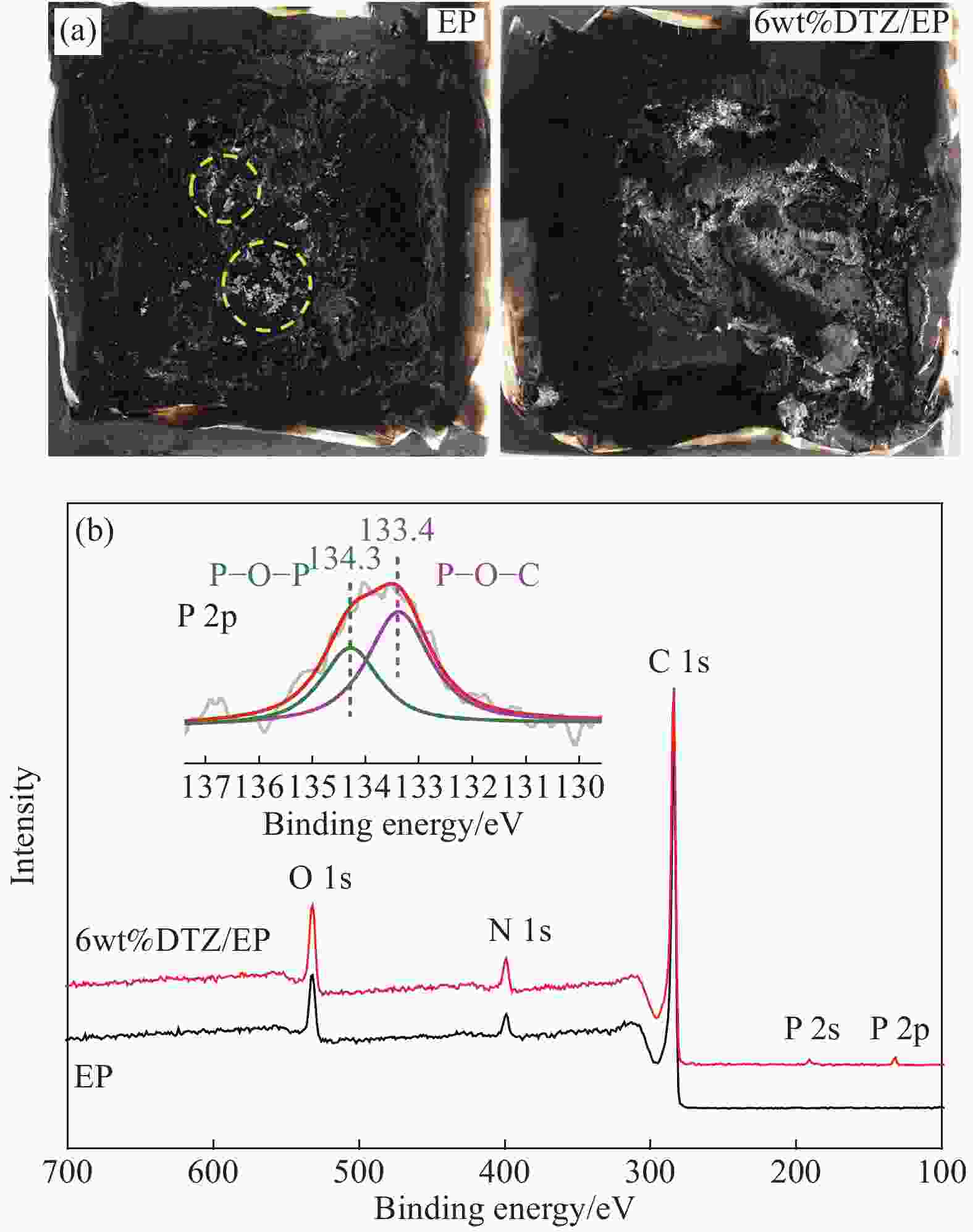

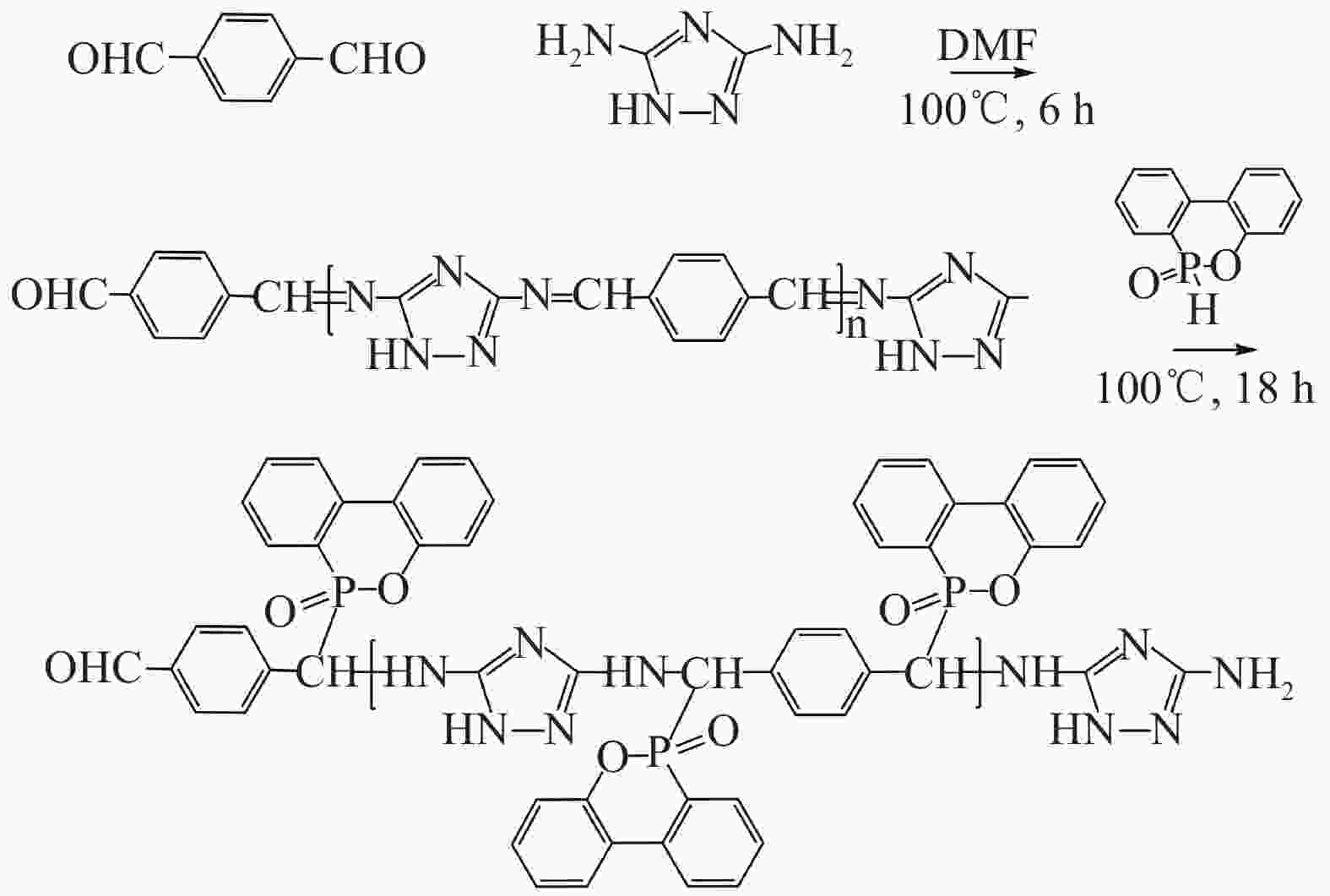

摘要: 以对苯二甲醛、3,5-二氨基-1,2,4-三氮唑和9,10-二氢-9-氧杂-10-磷杂菲-10-氧化物(DOPO)为原料合成了一种磷杂菲三氮唑双基化合物(DTZ),将其用于高效阻燃环氧树脂。利用FTIR、NMR、GPC和元素分析表征了其分子结构,采用TG和DSC研究了环氧固化物的热性能,利用极限氧指数、垂直燃烧、锥形量热、拉伸性能测试仪探究了环氧固化物的阻燃和力学性能,通过分析DTZ的热裂解行为、热氧化降解行为及炭层的形貌和结构研究了其阻燃机制。结果表明,DTZ的引入会降低环氧固化物的起始降解温度和玻璃化温度,但会提高其高温残炭率和拉伸强力。DTZ可显著提升环氧固化物的阻燃性能,当添加量为6wt%时,所得固化物的极限氧指数(LOI)值为33.5%,UL-94测试等级达到V-0级,热释放速率峰值和总热释放量分别降低21.8%和18.2%。DTZ可通过猝灭自由基、稀释可燃气体、促进基体成炭,在气相和凝聚相同时发挥阻燃作用。Abstract: A novel compound with phosphaphenanthrene and triazole groups (DTZ) for highly efficient flame-retardant epoxy resin was synthesized with p-phthalaldehyde, 3,5-diamino-1,2,4-triazole and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO). Its chemical structure was characterized by FTIR, NMR, GPC and elemental analysis. The thermal properties of epoxy thermosets were investigated by TGA and DSC analyses. The flame-retardant and mechanical properties were evaluated by limiting oxygen index, UL-94, cone calorimeter and tensile tests. Moreover, the flame-retardant mechanism of DTZ was particularly investigated by analyzing the pyrolysis and thermo-oxidative degradation behaviors, along with the morphology and structure of residual char of epoxy thermoset. It reveals that the incorporation of DTZ decreases the initial degradation temperature and glass transition temperature, while increases the char yield at elevated temperature and tensile strength for thermoset. DTZ remarkably improves the flame retardancy of epoxy thermoset. With the incorporation of 6wt% DTZ, the modified epoxy thermoset achieves an limit oxygen index (LOI) value of 33.5% and passes UL-94 V-0 rating. Moreover, the peak heat release rate and total heat release in cone calorimetry test decrease by 21.8% and 18.2%, respectively. DTZ shows high flame-retardant activity not only by diluting combustible volatiles and quenching active radicals in the gas phase, but also by promoting the char formation in the condensed phase.

-

Key words:

- epoxy resin /

- phosphaphenanthrene /

- triazole /

- flame retardancy /

- mechanism

-

表 1 环氧固化物的组成

Table 1. Formulations of epoxy thermosets

Sample Composition/g DTZ/wt% DGEBA DDM DTZ EP 100 21.82 0 0 2wt%DTZ/EP 100 21.82 2.49 2 4wt%DTZ/EP 100 21.82 5.08 4 6wt%DTZ/EP 100 21.82 7.78 6 8wt%DTZ/EP 100 21.82 10.59 8 Notes: EP—Epoxy resin; DGEBA—Bisphenol A epoxy resin; DDM—4,4 '-diaminodiphenylmethane. 表 2 DTZ和环氧固化物在N2中的热数据

Table 2. Thermal data of DTZ and thermosets in N2

Sample T5%/℃ Tmax /℃ Vmax/(%·℃−1) Y600/% Tg/℃ DTZ 325.2 420.5 0.54 33.1 — EP 356.3 386.3 1.36 19.2 154.6 2wt%DTZ/EP 344.1 380.7 1.14 21.4 153.7 4wt%DTZ/EP 335.8 376.0 1.10 22.8 152.3 6wt%DTZ/EP 330.9 370.3 1.02 25.3 150.6 8wt%DTZ/EP 327.5 367.9 0.99 26.0 148.5 Notes: T5%—Temperature at 5% mass loss; Vmax—Maximum mass loss rate; Tmax—Temperature at Vmax; Y600—Char yield at 600℃; Tg—Glass transition temperature. 表 3 环氧固化物的极限氧指数(LOI)值和UL-94等级

Table 3. Limit oxygen index (LOI) values and UL-94 ratings of epoxy thermosets

Sample LOI/% UL-94, 3.0 mm bar t1 +t2/s Dripping Rating EP 25.5 BC Yes No 2wt%DTZ/EP 29.7 11.5+5.2 No V-1 4wt%DTZ/EP 31.2 6.3+7.2 No V-1 6wt%DTZ/EP 33.5 4.2+2.6 No V-0 8wt%DTZ/EP 34.7 2.3+3.1 No V-0 Notes: t1,t2—Average combustion times after the first and second applications of the flame; BC—Burn to clamp. 表 4 EP和6wt%DTZ/EP的锥形量热数据

Table 4. Cone calorimetry data of EP and 6wt%DTZ/EP

Sample TTI/s av-EHC/

(MJ·kg−1)TSP/m2 RM/% EP 58 23.1 34.4 10.8 6wt%DTZ/EP 64 19.5 29.7 15.3 Notes: TTI—Time to ignition; av-EHC—Average effective heat combustion; TSP—Total smoke production; RM—Residual mass. -

[1] ZHANG Q R, LI Z W, LI X H, et al. Zinc ferrite nanoparticle decorated boron nitride nanosheet: Preparation, magnetic field arrangement, and flame retardancy[J]. Chemical Engineering Journal,2019,356:680-692. doi: 10.1016/j.cej.2018.09.053 [2] JIAN X Y, AN X P, LI Y D, et al. All plant oil derived epoxy thermosets with excellent comprehensive properties[J]. Macromolecules,2017,50(15):5729-5738. doi: 10.1021/acs.macromol.7b01068 [3] YANG G, WU W H, WANG Y H, et al. Synthesis of a novel phosphazene-based flame retardant with active amine groups and its application in reducing the fire hazard of epoxy resin[J]. Journal of Hazardous Materials,2019,366:78-87. doi: 10.1016/j.jhazmat.2018.11.093 [4] 贺梦, 张冲, 郭晓东, 等. 含硫功能聚磷腈微纳米球的合成及其在环氧树脂阻燃中的应用[J]. 复合材料学报, 2019, 36(3):584-591.HE Meng, ZHANG Chong, GUO Xiaodong, et al. Synthesis of sulfur containing polyphosphazene micro-nano sphere and its application in flame retarded epxoy resin[J]. Acta Materiae Compositae Sinica,2019,36(3):584-591(in Chinese). [5] QU L J, SUI Y L, ZHANG C L, et al. Improved flame retardancy of epoxy resin composites modified with a low additive content of silica-microencapsulated phosphazene flame retardant[J]. Reactive & Functional Polymers,2020,148:104485. [6] 魏柯, 张道海, 秦舒浩, 等. 反应型和添加型磷杂菲类阻燃剂在聚合物中的应用进展[J]. 高分子材料科学与工程, 2019, 35(5):184-190.WEI Ke, ZHANG Daohai, QIN Shuhao, et al. Application progress of reactive and additive phosphine-based flame retardants in polymers[J]. Polymeric Materials Science and Engineering,2019,35(5):184-190(in Chinese). [7] 刘建华, 史铁钧, 李明, 等. 含双DOPO的双酚A-单苯并嗪合成、表征及其与环氧树脂共聚物的阻燃性能[J]. 化工学报, 2015, 66(2):820-826. doi: 10.11949/j.issn.0438-1157.20141028LIU Jianhua, SHI Tiejun, LI Ming, et al. Synthesis, characterization of single benzoxazine contained bis-DOPO based on bisphenol A and flame retardant performance of its copolymer with epoxy[J]. Journal of Chemical Industry and Engineering(China),2015,66(2):820-826(in Chinese). doi: 10.11949/j.issn.0438-1157.20141028 [8] WANG J L, MA C, WANG P L, et al. Ultra-low phosphorus loading to achieve the superior flame retardancy of epoxy resin[J]. Polymer Degradation and Stability,2018,149:119-128. doi: 10.1016/j.polymdegradstab.2018.01.024 [9] ZHANG Y, YU B, WANG B B, et al. Highly effective P-P synergy of a novel DOPO-based flame retardant for epoxy resin[J]. Industrial & Engineering Chemistry Research,2017,56(5):1245-1255. [10] LI S N, ZHAO X J, LIU X H, et al. Cage-ladder-structure, phosphorus-containing polyhedral oligomeric silsesquinoxanes as promising reactive-type flame retardants for epoxy resin[J]. Journal of Applied Polymer Science,2019,136(23):47607. doi: 10.1002/app.47607 [11] ZHANG W C, LI X M, YANG R J. Novel flame retardancy effects of DOPO-POSS on epoxy resins[J]. Polymer Degradation and Stability,2011,96(12):2167-2173. doi: 10.1016/j.polymdegradstab.2011.09.016 [12] SHEN D, XU Y J, LONG J W, et al. Epoxy resin flame-retarded via a novel melamine-organophosphinic acid salt: Thermal stability, flame retardance and pyrolysis behavior[J]. Journal of Analytical and Applied Pyrolysis,2017,128:54-63. doi: 10.1016/j.jaap.2017.10.025 [13] WANG P, CHEN L, XIAO H. Flame retardant effect and mechanism of a novel DOPO based tetrazole derivative on epoxy resin[J]. Journal of Analytical and Applied Pyrolysis,2019,139:104-113. doi: 10.1016/j.jaap.2019.01.015 [14] QIAN L J, QIU Y, WANG J Y, et al. High-performance flame retardancy by char-cage hindering and free radical quenching effects in epoxy thermosets[J]. Polymer,2015,107:262-269. [15] American Society for Testing Material International. Standard test method for tensile properties of plastic: ASTM D638—08[S]. West Conshohocken: ASTM International, 2008. [16] American Society for Testing Material International. Standard test method for measuring the minimum oxygen concentration to support candle-like combustion of plastics (oxygen index): ASTM D2863—06[S]. West Conshohocken: ASTM International, 2006. [17] 中国国家标准化管理委员会. 塑料燃烧性能的测定 水平法和垂直法: GB/T 2408—2008[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the people’s Republic of China. Plastics: Determination of burning characteristics: Horizontal and vertical test: GB/T 2408—2008[S]. Beijing: China Standards Press, 2009(in Chinese). [18] International Organization for Standardization. Reactionto-fire tests: Heat release, smoke production and mass loss rate Part 1: Heat release rate (cone calorimeter method): ISO 5660−1: 2002[S]. Geneva: International Organization for Standardization, 2002. [19] ZHANG W C, LI X M, YANG R J. Pyrolysis and fire behaviour of epoxy resin composites based on a phosphorus-containing polyhedral oligomeric silsesquioxane (DOPO-POSS)[J]. Polymer Degradation and Stability,2011,96(10):1821-1832. doi: 10.1016/j.polymdegradstab.2011.07.014 [20] WIRASAPUTRA A, YAO X H, ZHU Y M, et al. Flame-retarded epoxy resins with a curing agent of DOPO-triazine based anhydride[J]. Macromolecular Materials and Engineering,2016,301:982-991. doi: 10.1002/mame.201600094 [21] XU W H, WIRASAPUTRA A, LIU S M, et al. Highly effective flame retarded epoxy resin cured by DOPO-based co-curing agent[J]. Polymer Degradation and Stability,2015,122:44-51. doi: 10.1016/j.polymdegradstab.2015.10.012 [22] LIU J K, DAI J Y, WANG S P, et al. Facile synthesis of bio-based reactive flame retardant from vanillin and guaiacol for epoxy resin[J]. Composites Part B: Engineering,2020,190:107926. doi: 10.1016/j.compositesb.2020.107926 [23] ZHANG Q Q, WANG J, YANG S, et al. Synthesis of a P/N/S-based flame retardant and its flame retardant effect on epoxy resin[J]. Fire Safety Journal,2020,113:102994. doi: 10.1016/j.firesaf.2020.102994 [24] SUN Z Z, HOU Y B, HU Y, et al. Effect of additive phosphorus-nitrogen containing flame retardant on char formation and flame retardancy of epoxy resin[J]. Materials Chemistry and Physics,2018,214:154-164. doi: 10.1016/j.matchemphys.2018.04.065 [25] JIAN R K, AI Y F, XIA L, et al. Organophosphorus heteroaromatic compound towards mechanically reinforced and low-flammability epoxy resin[J]. Composites Part B: Engineering,2019,168:458-466. doi: 10.1016/j.compositesb.2019.03.052 [26] LUO Q Q, SUN Y L, YU B, et al. Synthesis of a novel reactive type flame retardant composed of phenophosphazine ring and maleimide for epoxy resin[J]. Polymer Degradation and Stability,2019,165:137-144. doi: 10.1016/j.polymdegradstab.2019.05.008 [27] XU Y J, CHEN L, RAO W H, et al. Latent curing epoxy system with excellent thermal stability, flame retardance and dielectric property[J]. Chemical Engineering Journal,2018,347:223-232. doi: 10.1016/j.cej.2018.04.097 [28] 卢林刚, 程哲, 丘新铭, 等. 星型绿色磷腈阻燃剂的制备及阻燃环氧树脂性能[J]. 高等学校化学学报, 2018, 39(12):2789-2796. doi: 10.7503/cjcu20180339LU Lingang, CHENG Zhe, QIU Xinming, et al. Preparation of green star-topology phosphazene flame retardant andproperties of flame-retardant epoxyresin[J]. Chemical Journal of Chinese Universities,2018,39(12):2789-2796(in Chinese). doi: 10.7503/cjcu20180339 [29] WANG P, CHEN L, XIAO H, et al. Nitrogen/sulfur-containing DOPO based oligomer for highly efficient flame-retardant epoxy resin[J]. Polymer Degradation and Stability,2020,171:109023. doi: 10.1016/j.polymdegradstab.2019.109023 [30] JIN S L, LIU Z, QIAN L J, et al. Epoxy thermoset with enhanced flame retardancy and physical-mechanical properties based on reactive phosphaphenanthrene compound[J]. Polymer Degradation and Stability,2020,172:109063. doi: 10.1016/j.polymdegradstab.2019.109063 [31] QIU Y, QIAN L J, WANG X. Flame-retardant effect of a novel phosphaphenanthrene/triazine-trione bi-group compound on an epoxy thermoset and its pyrolysis behaviour[J]. RSC Advances,2016,6(61):56018-56027. doi: 10.1039/C6RA10752D [32] WANG P, XIAO H, DUAN C, et al. Sulfathiazole derivative with phosphaphenanthrene group: Synthesis, characterization and its high flame-retardant activity on epoxy resin[J]. Polymer Degradation and Stability,2020,173:109078. doi: 10.1016/j.polymdegradstab.2020.109078 [33] LIU D Y, JI P F, ZHANG T L. A bi-DOPO type of flame retardancy epoxy prepolymer: Synthesis, properties and flame-retardant mechanism[J]. Polymer Degradation and Stability,2021,190:109629. [34] QIAN L J, QIU Y, SUN N, et al. Pyrolysis route of a novel, flame retardant constructed by phosphaphenanthrene and triazine-trione groups and its flame-retardant effect on epoxy resin[J]. Polymer Degradation and Stability,2014,107:98-105. doi: 10.1016/j.polymdegradstab.2014.05.007 [35] SCHARTEL B, PERRET B, DITTRICH B, et al. Flame retardancy of polymers: The role of specific reactions in the condensed phase[J]. Macromolecular Materials and Engineering,2016,301(1):9-35. doi: 10.1002/mame.201500250 [36] ZHAO J J, DONG X, HUANG S, et al. Performance comparison of flame retardant epoxy resins modified by DPO-PHE and DOPO-PHE[J]. Polymer Degradation and Stability,2018,156:89-99. doi: 10.1016/j.polymdegradstab.2018.08.007 [37] LIANG W J, ZHAO B, ZHAO P H, et al. Bisphenol-S bridged penta(anilino)cyclotriphosphazene and its application in epoxy resins: Synthesis, thermal degradation, and flame retardancy[J]. Polymer Degradation and Stability,2017,135:140-151. doi: 10.1016/j.polymdegradstab.2016.11.023 [38] GAO Y Y, DENG C, DU Y Y, et al. A novel bio-based flame retardant for polypropylene from phytic acid[J]. Polymer Degradation and Stability,2019,161:298-308. doi: 10.1016/j.polymdegradstab.2019.02.005 -

下载:

下载: