Failure mechanisms and residual compression performance of carbon fiber reinforced epoxy composite shaft tubes subjected to low velocity impact

-

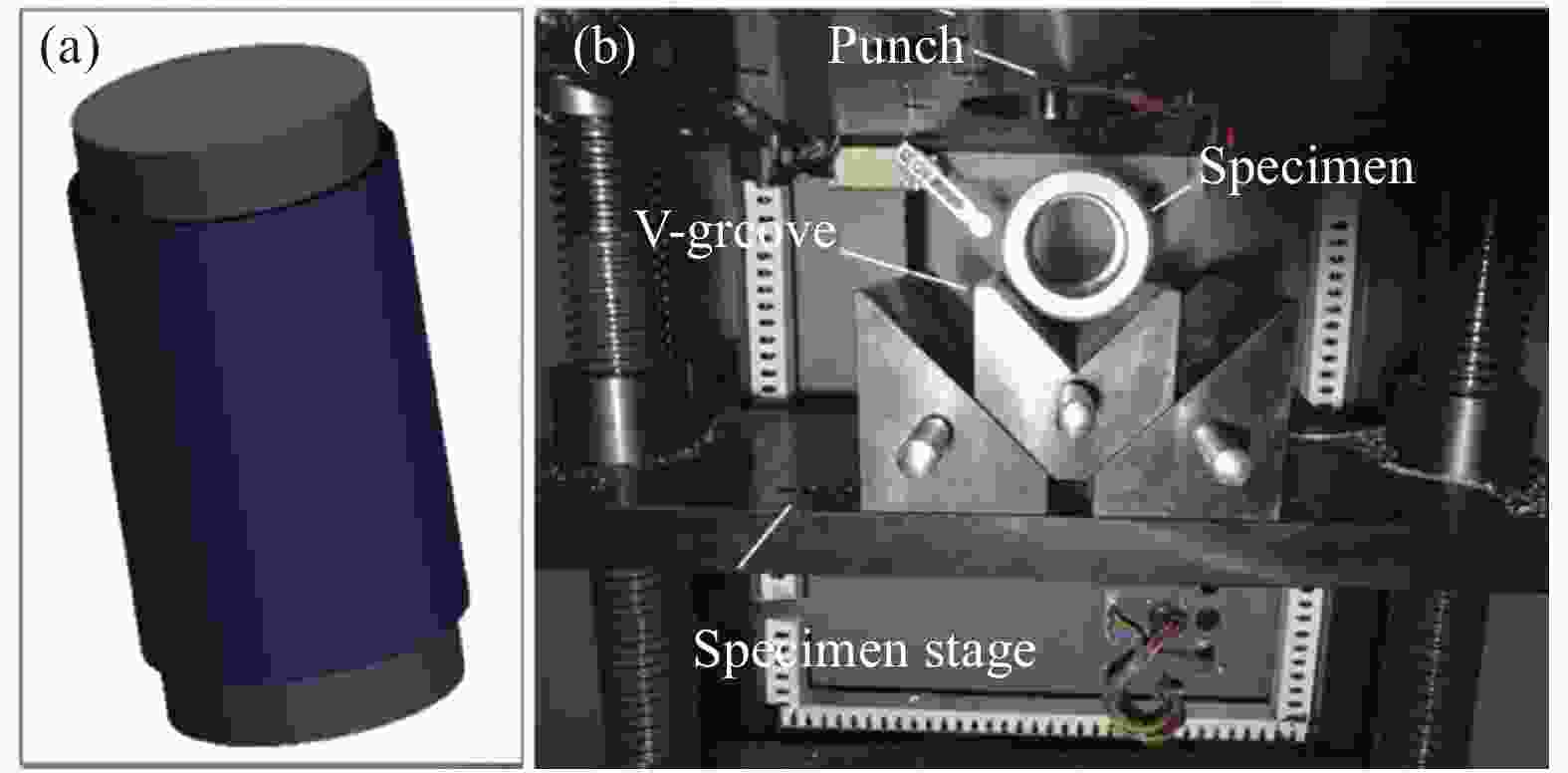

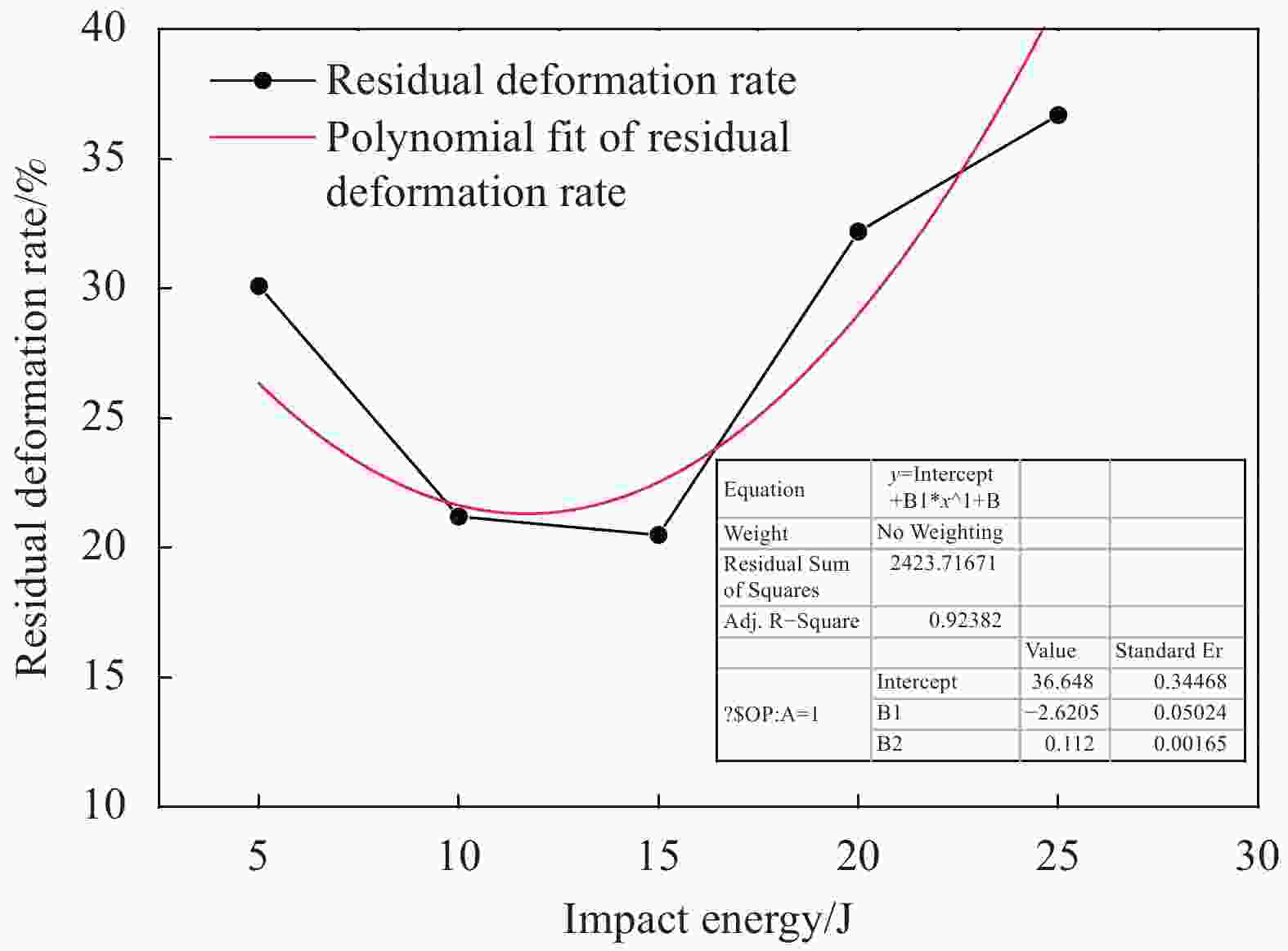

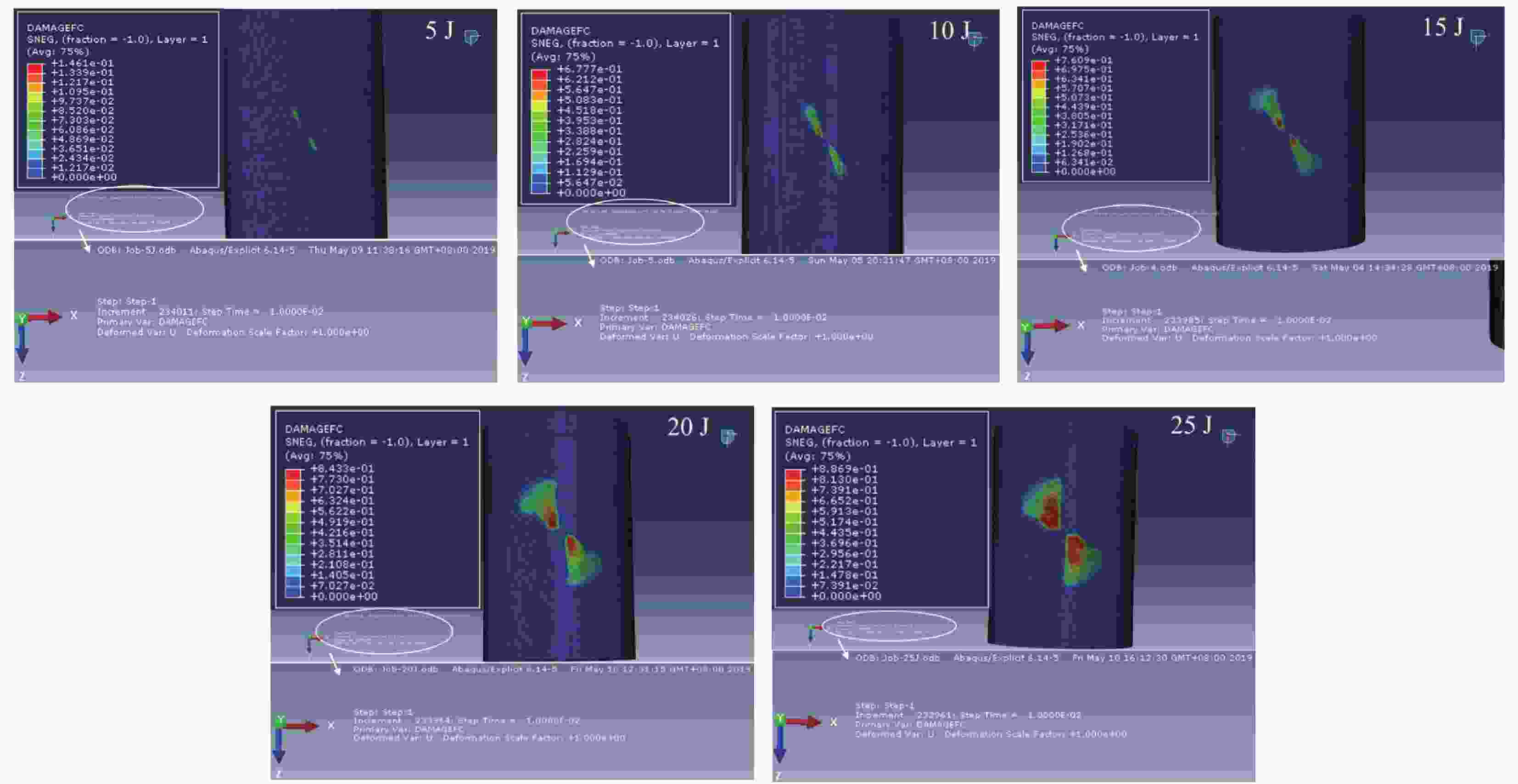

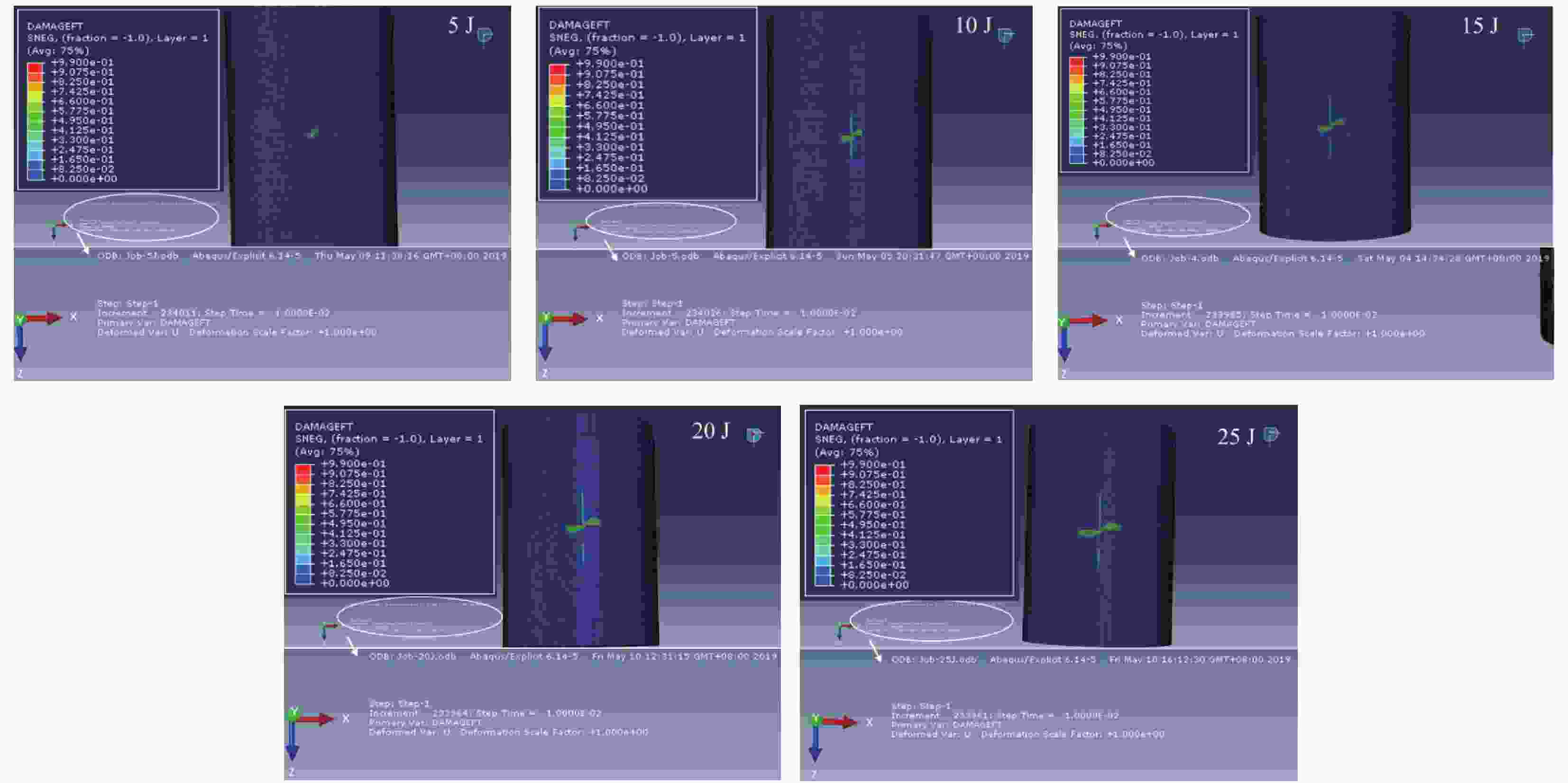

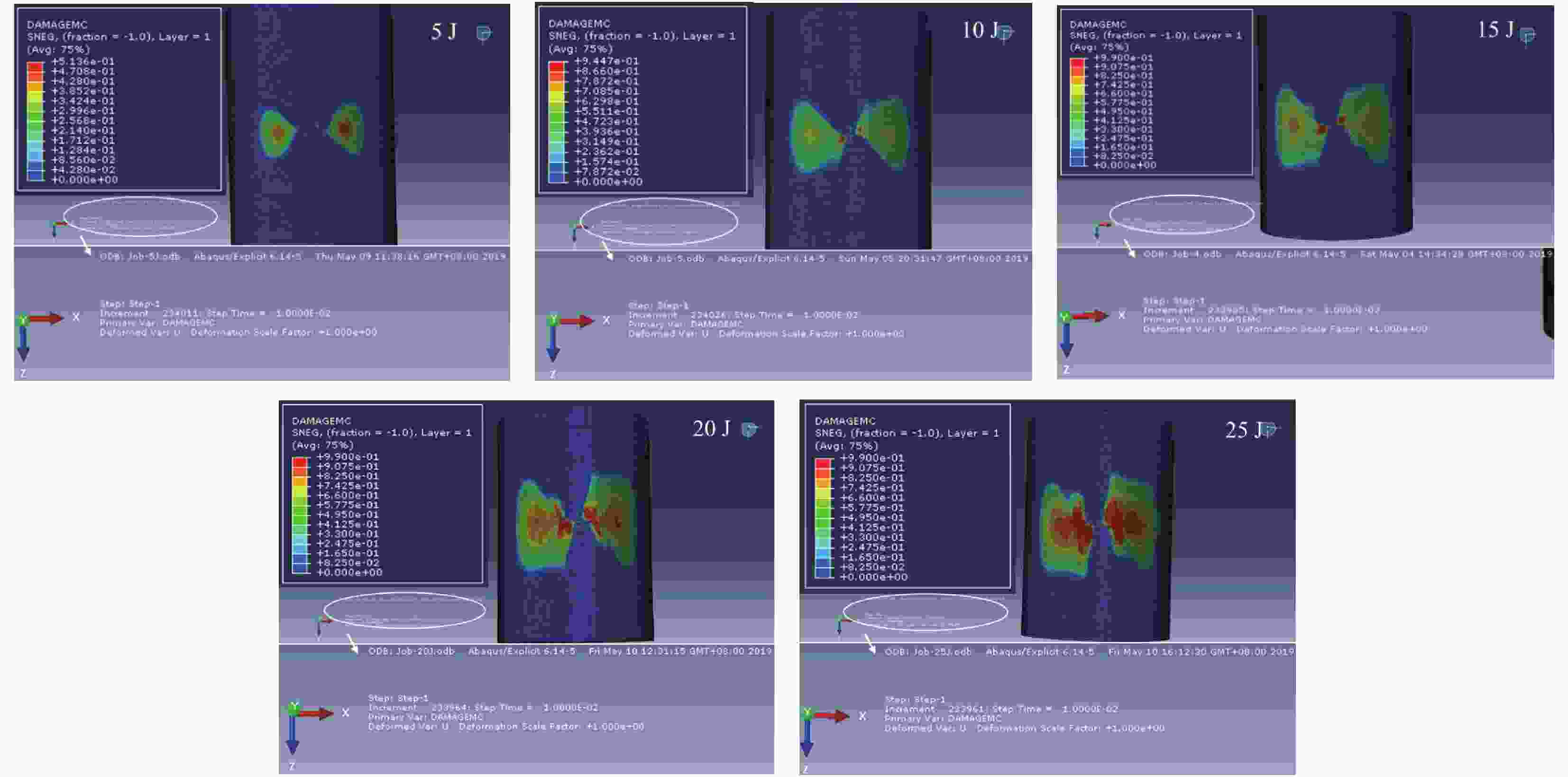

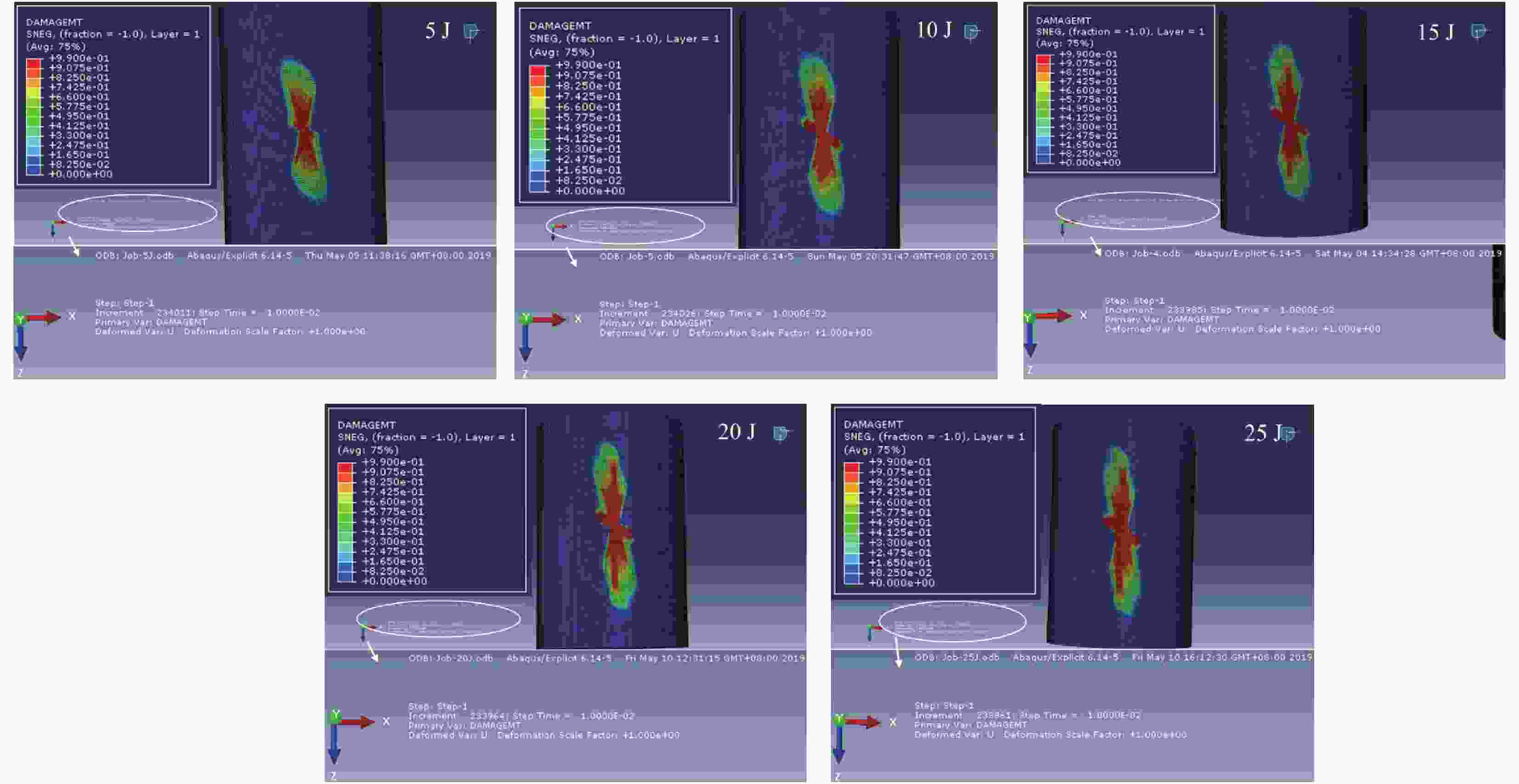

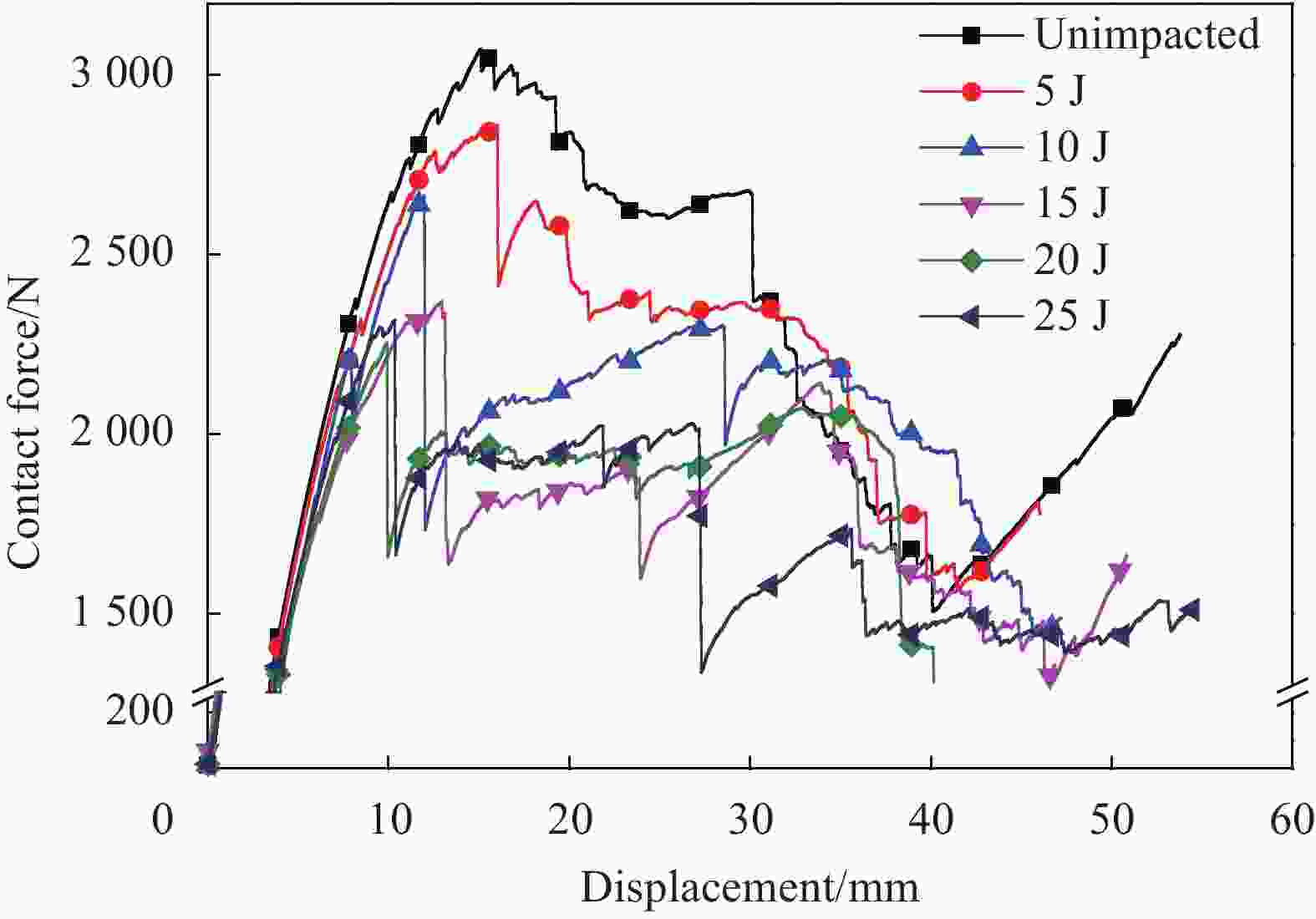

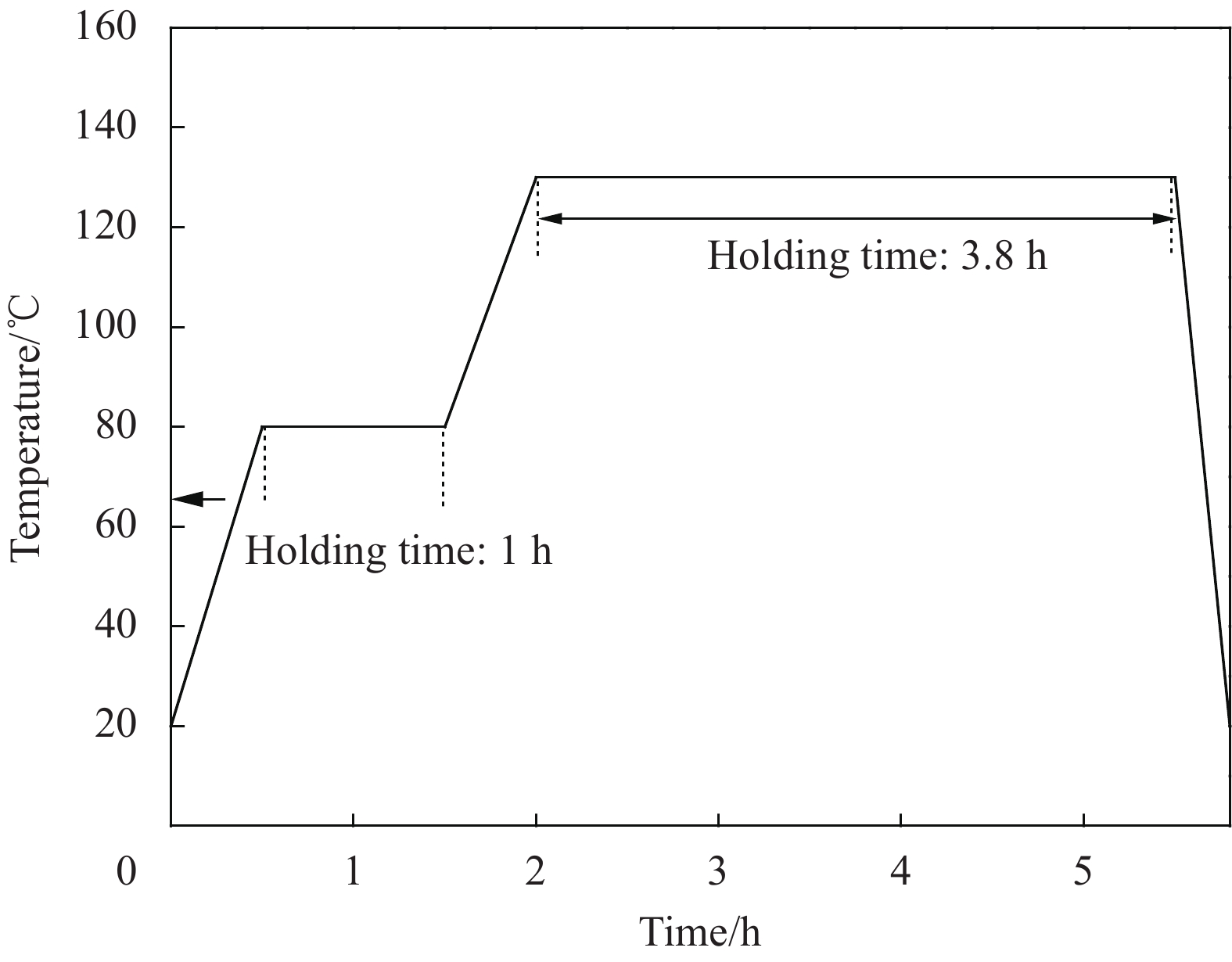

摘要: 采用落锤冲击试验模拟低速冲击过程,对碳纤维增强环氧树脂基复合材料传动轴的轴管在不同能级冲击下的损伤行为以及冲击后的剩余压缩性能进行了研究;通过ABQUAS有限元分析软件和X射线断层扫描技术(CT)相结合的方法观察了复合材料轴管在受到低速冲击时的损伤形式,研究其内部损伤规律。结果表明,复合材料轴管的抗冲击形变能力随着冲击能量的增加先增强后减弱,在冲击能量为10 ~20 J之间出现最大值。CT无损检测结果显示复合材料轴管的失效形式包括分层损伤、树脂开裂和纤维破裂(断裂)。在低能量冲击时,复合材料轴管主要产生分层损伤和树脂的开裂,而纤维断裂损伤只出现在冲击位置,且随着冲击能量的增加纤维断裂现象愈加显著。有限元仿真结果显示复合材料轴管中的碳纤维在拉伸方向的失效明显小于压缩失效,压缩失效沿纤维排布方向扩散,拉伸失效沿轴向和横向呈十字扩散,轴向失效的程度大于横向失效的程度;而树脂的压缩失效沿轴向从冲击位置向横向扩散,扩散形状近似圆形,越靠近圆心失效越明显,拉伸失效范围呈十字,整体失效沿十字边缘扩散。

-

关键词:

- 碳纤维增强环氧树脂基复合材料 /

- 轴管 /

- 低速冲击损伤 /

- ABQUAS有限元分析 /

- 剩余压缩性能

Abstract: Drop hammer impact test was used to study the failure mechanism and the compression after impact (CAI) of carbon fiber reinforced epoxy composite shaft tubes when subjected to different impact energy levels to simulate the low-velocity impact (LVI) process. ABQUAS finite element analysis technology and X-ray tomography (CT) techniques were used to investigate the internal failure mechanisms. Results show that, with the increase of impact energy, the deformation resistance of the composite tubes first increases and then decreases, and reaches a maximum value when the impact energy falls between 10 J and 20 J. The accuracy of the test results is confirmed by the fact that the energy absorption rates of the shaft tube with different energy levels differ little. CT results show that the composite shaft tube after LVI mainly fails in forms of delamination and resin cracking. Fiber fracture mainly occurs at the impact location, and the fiber fracture becomes more and more significant with the increase of impact energy. The finite element simulation results show that the fiber failure of composite shaft tube in the tensile direction is significantly less than the compression failure. The compression failure mainly diffuses along the fiber layout direction. The tensile failure mainly spreads along the axial direction and transverse direction, and the axial failure degree is greater than the transverse failure degree. The compression failure of the resin mainly diffuses from the impact position to the transverse along the axial direction. The diffusion shape is nearly round, the closer to the center, the failure is more obvious. The stretching failure range is a cross; the overall failure diffuses along the cross edge. -

表 1 碳纤维/环氧树脂复合材料参数

Table 1. Materials’ parameters of carbon fiber/epoxy composites

Elastic parameter of composites Failure parameter of Hashin criterion E11= 123.3 GPa XT= 1632 MPa;

YC=ZT=34 MPaE22=E33=7.78 GPa XC= 704 MPa;

YC=ZC=68 MPaυ12=υ13=0.27 S12=80 MPa;

S13= S23=55 MPaυ23=0.42 Gft=90 kJ/m2;

Gfc=80 kJ/m2G12= G13=5 GPa Gmt=520 J/m2;

Gmc=1580 J/m2G23=3.1 GPa Notes:E11, E22, E33—Elasticity modulus in the fiber direction, perpendicular to the fiber direction and normal direction, respectively; υ—Poisson's ratio; XT, YT, ZT—Tensile strength in the fiber direction, perpendicular to the fiber direction and normal direction, respectively; XC, YC, ZC—Compressive strength in the fiber direction, perpendicular to the fiber direction and normal direction, respectively; S12, S13, S23 —Sheer strength of the plane in the normal direction, perpendicular to the fiber direction and fiber direction, respectively; G12, G13, G23—Shear modulus of the plane in the normal direction, perpendicular to the fiber direction and fiber direction, respectively; Gft, Gfc, Gmt, Gmc—Fracture energy density generated from the fiber tensile stress, fiber compression stress, matrix tensile stress and matrix compression stress, respectively. -

[1] YAN X P, LIANG X X, OUYANG W, et al. A review of progress and applications of ship shaft-less rim-driven thrusters[J]. Ocean Engineering,2017,144:142-156. doi: 10.1016/j.oceaneng.2017.08.045 [2] 赵云峰. 先进纤维增强树脂基复合材料在航空航天工业中的应用[J]. 军民两用技术与产品, 2010(1):4-6. doi: 10.3969/j.issn.1009-8119.2010.01.002ZHAO Y F. Application of advanced fiber Reinforced resin matrix composites in aerospace industry[J]. Dual-use Technologies and Products,2010(1):4-6(in Chinese). doi: 10.3969/j.issn.1009-8119.2010.01.002 [3] 潘鼎, 曾凡龙, 荣海琴. 中国复合材料的发展与展望[J]. 玻璃钢, 2006(3):16-26.PAN D, ZENG F L, RONG H Q. Development and prospect of composite materials in China[J]. Glass Fiber Reinforced Plastics,2006(3):16-26(in Chinese). [4] HETHERINGTON P L, KRAUS R F, DARLOW M S. Demonstration of a supercritical composite helicopter power transmission shaft[J]. Journal of the American Helicopter Society, 1990, 35(1): 23-28. [5] LI H C, WANG J, BAKER A. Rapid composite bonded repair for helicopter tail drive shafts[J]. Composites Part B: Engineering,2012,43(3):1579-1585. doi: 10.1016/j.compositesb.2011.08.012 [6] NADEEM S S, GIRIDHARA G, RANGAVITTAL H K. A Review on the design and analysis of composite drive shaft[J]. Materials Today: Proceedings,2018,5(1):2738-2741. doi: 10.1016/j.matpr.2018.01.058 [7] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU S Y. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [8] KHALID Y A, MUTASHER S A, SAHARI B B, et al. Bending fatigue behavior of hybrid aluminum/composite drive shafts[J]. Materials & Design,2007,28(1):329-334. doi: 10.1016/j.matdes.2005.05.021 [9] SINO R, BARANGER T N, CHATELET E, et al. Dynamic analysis of a rotating composite shaft [J]. Composites Science and Technology, 2008, 68 (2): 337-345. [10] 赵玉飞, 袁剑民, 费又庆. 碳纤维网络增强环氧树脂基复合材料的制备与表征[J]. 复合材料学报, 2015, 32(6):1611-1617.ZHAO Y F, YUAN J M, FEI Y Q. Fabrication and characteri-zation of carbon fiber network reinforced epoxy matrix composites[J]. Acta Materiae Compositae Sinica,2015,32(6):1611-1617(in Chinese). [11] 陈燕, 葛恩德, 傅玉灿, 等. 碳纤维增强树脂基复合材料制孔技术研究现状与展望[J]. 复合材料学报, 2015, 32(2):301-316.CHEN Y, GE E D, FU Y C. Review and prospect of drilling technologies for carbon fiber reinforced polymer[J]. Acta Materiae Compositae Sinica,2015,32(2):301-316(in Chinese). [12] DING Z, WEEGER O, QI H J, et al. 4D rods: 3D structures via programmable 1D composite rods[J]. Materials & Design,2018,137:256-265. doi: 10.1016/j.matdes.2017.10.004 [13] MUTASHER S A. Prediction of the torsional strength of the hybrid aluminum/composite drive shaft[J]. Materials & Design,2009,30(2):215-220. doi: 10.1016/j.matdes.2008.05.024 [14] 徐坚, 王亚会, 李林洁, 等. 2019年先进纤维复合材料研发热点回眸[J]. 科技导报, 2020, 38(1):82-92.XU J, WANG Y H, LI L J, et al. Hot topics of advanced fiber reinforced composites in 2019[J]. Science and Technology Review,2020,38(1):82-92(in Chinese). [15] 杨斌, 章继峰, 周利民. 玻璃纤维-碳纤维混杂增强PCBT复合材料层合板的制备及低速冲击性能[J]. 复合材料学报, 2015, 32(2):435-443.YANG B, ZHANG J F, ZHOU L M. Preparation and low-velocity impact properties of glass fiber-carbon fiber hybrid reinforced PCBT composite laminate[J]. Acta Materiae Compositae Sinica,2015,32(2):435-443(in Chinese). [16] 张彦, 朱平, 来新民, 等. 低速冲击作用下碳纤维复合材料铺层板的损伤分析[J]. 复合材料学报, 2006, 23(2):150-157. doi: 10.3321/j.issn:1000-3851.2006.02.026ZHANG Y, ZHU P, LAI X M. Low-velocity impact damage analysis in carbon fiber reinforced composite laminated plates[J]. Acta Materiae Compositae Sinica,2006,23(2):150-157(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.02.026 [17] 张辰, 饶云飞, 李倩倩, 等. 碳纤维-玻璃纤维混杂增强环氧树脂复合材料低速冲击性能及其模拟[J]. 复合材料学报, 2021, 38 (1): 165 - 176.ZHANG C, RAO Y Y, LI Q Q, et al. Low-velocity impact behavior and numerical simulation of carbon fiber-glass fiber hybrid reinforced epoxy composites[J]. Acta Materiae Compositae Sinica, 2021, 38 (1): 165 - 176(in Chinese). [18] 李春晓. 碳纤维及其复合材料在汽车领域的应用[J]. 新材料产业, 2019(1):5-7.LI C X. Application of carbon fiber and composite ma-terials in automotive industry[J]. New Materials Industry,2019(1):5-7(in Chinese). [19] AP C A, GUIMARAES T A M, DA SILVA B R, et al. Analysis of the dynamic behavior of a rotating composite hollow shaft[J]. Latin American Journal of Solids and Structures,2017,14(1):1-16. doi: 10.1590/1679-78253168 [20] GNING P B, TARFAOUI M, COLLOMBET F, et al. Damage development in thick composite tubes under impact loading and influence on implosion pressure: experimental observations[J]. Composites Part B: Engineering,2005,36(4):306-318. doi: 10.1016/j.compositesb.2004.11.004 [21] LIN Q H, LI B M. Numerical simulation of dynamic large deformation and fracture damage for solid armature in electromagnetic railgun[J]. Technology Definition,2020,16(2):348-353. doi: 10.1016/j.dt.2019.05.020 [22] KARA M, KIRICI M, TATAR A C, et al. Impact behavior of carbon fiber/epoxy composite tubes reinforced with multi-walled carbon nanotubes at cryogenic environment[J]. Composites Part B: Engineering,2018,145:145-154. doi: 10.1016/j.compositesb.2018.03.027 [23] MOKHTAR I, YAHYA M Y, KADER A S A, et al. Transverse impact response of filament wound basalt composite tubes[J]. Composites Part B: Engineering,2017,128:134-145. doi: 10.1016/j.compositesb.2017.01.005 [24] 林智育, 许希武, 朱伟垚. 复合材料层板冲击损伤特性及冲击后压缩强度研究[J]. 航空材料学报, 2011, 31(1):73-80. doi: 10.3969/j.issn.1005-5053.2011.1.014LIN Z Y, XU X W, ZHU W Y. Experimental study on impact damage characteristics and residual compressive strength of composite laminates[J]. Journal of Aeronautical Ma-terials,2011,31(1):73-80(in Chinese). doi: 10.3969/j.issn.1005-5053.2011.1.014 [25] ZHANG C, TAN K T. Low-velocity impact response and compression after impact behavior of tubular composite sandwich structures[J]. Composites Part B: Engineering,2020,193:108026. [26] CHRISTENSEN R M. Tensor transfor-mations and failure criteria for the analysis of fiber composite materials[J]. Journal of Composite Materials, 1988, 22 (9): 874-897. [27] CHRISTENSEN R M. Failure criteria for fiber composite materials, the astonishing sixty year search, definitive usable results[J]. Composites Science and Technology, 2019, 182: 107718. [28] GU J F, CHEN P H. Some modifications of Hashin’s failure criteria for unidirectional composite materials[J]. Composite Structures, 2017, 182: 143-152 [29] MACEDO R Q D, FERREIRA R, GUEDESET J M, et al. Intraply failure criterion for unidirectional fiber reinforced composites by means of asymptotic homogenization[J]. Composite Structures, 2017, 159, 335-349. [30] MURTY A V K, NAIK G N, GOPALAKRISHNAN S. Towards a rational failure criterion for unidirectional composite laminae[J]. Mechanics of Advanced Materials and Structures, 2005, 12(2): 147-157. [31] ZHAO H W, LIU X G, KENT A. Mechanical properties research of carbon fiber composite laminates[J]. Materials Science Forum,2020,980:107-116. [32] FENG D, AYMERICH F. Damage prediction in composite sandwich panels subjected to low-velocity impact[J]. Composites Part A: Applied Science and Manufacturing,2013,52:12-22. doi: 10.1016/j.compositesa.2013.04.010 [33] PIECZONKA L, UKOWSKI P, KLEPKA A, et al. Impact da-mage detection in light composite sandwich panels using piezo-based nonlinear vibro-acoustic modulations[J]. Smart Materials and Structures,2014,23(10):105021. doi: 10.1088/0964-1726/23/10/105021 [34] 中国国家标准化管理委员会. 纤维增强热固性塑料管平行板外载性能试验方法: GB/T 5352—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of China. Test Method for external Load performance of fiber-reinforced thermo-setting plastic pipe Andante: GB/T 5352—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). -

下载:

下载: