Compressive performance of bamboo scrimber and concrete-filled steel tube columns

-

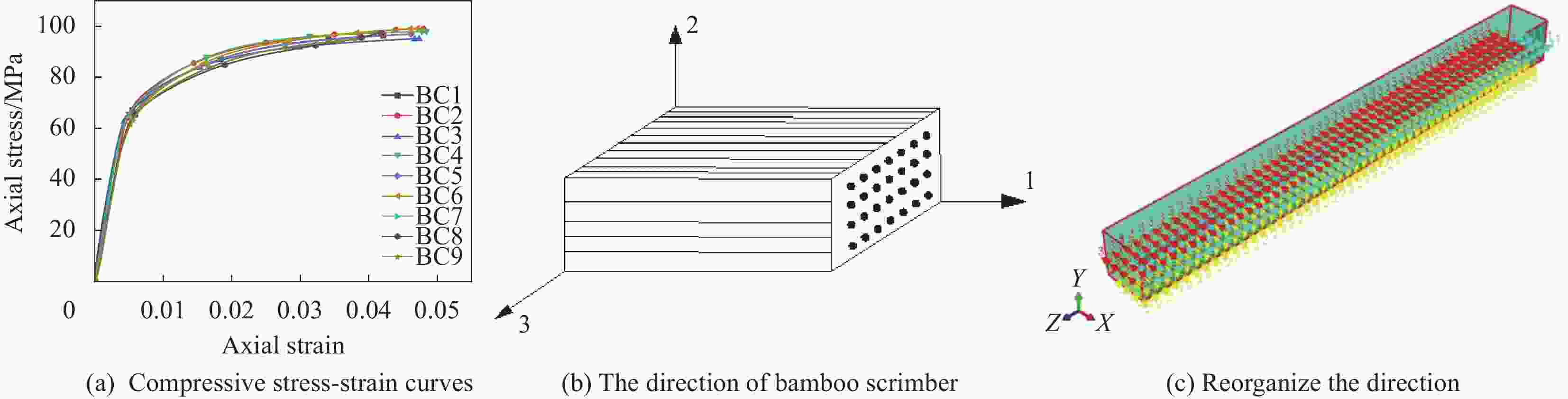

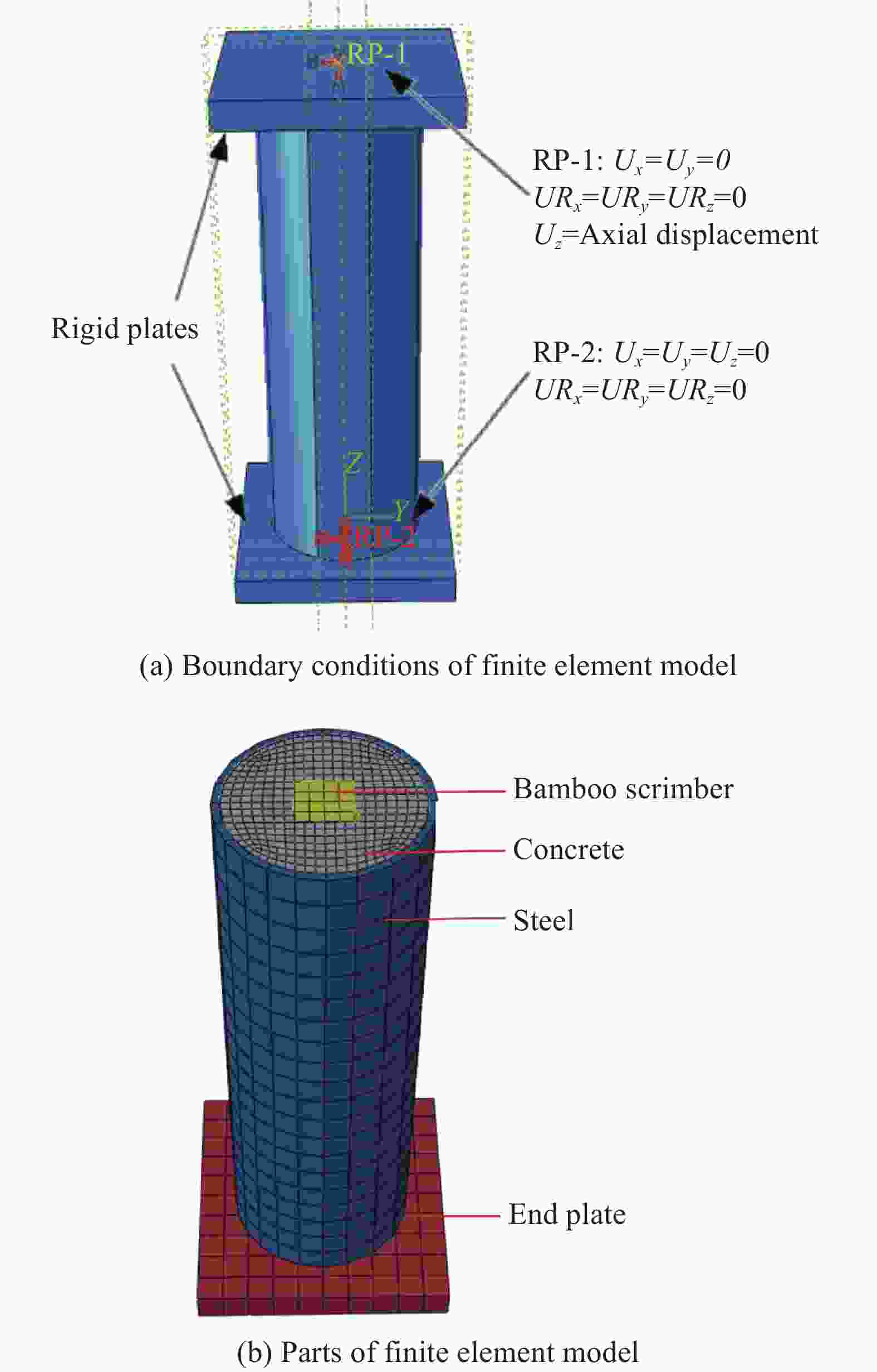

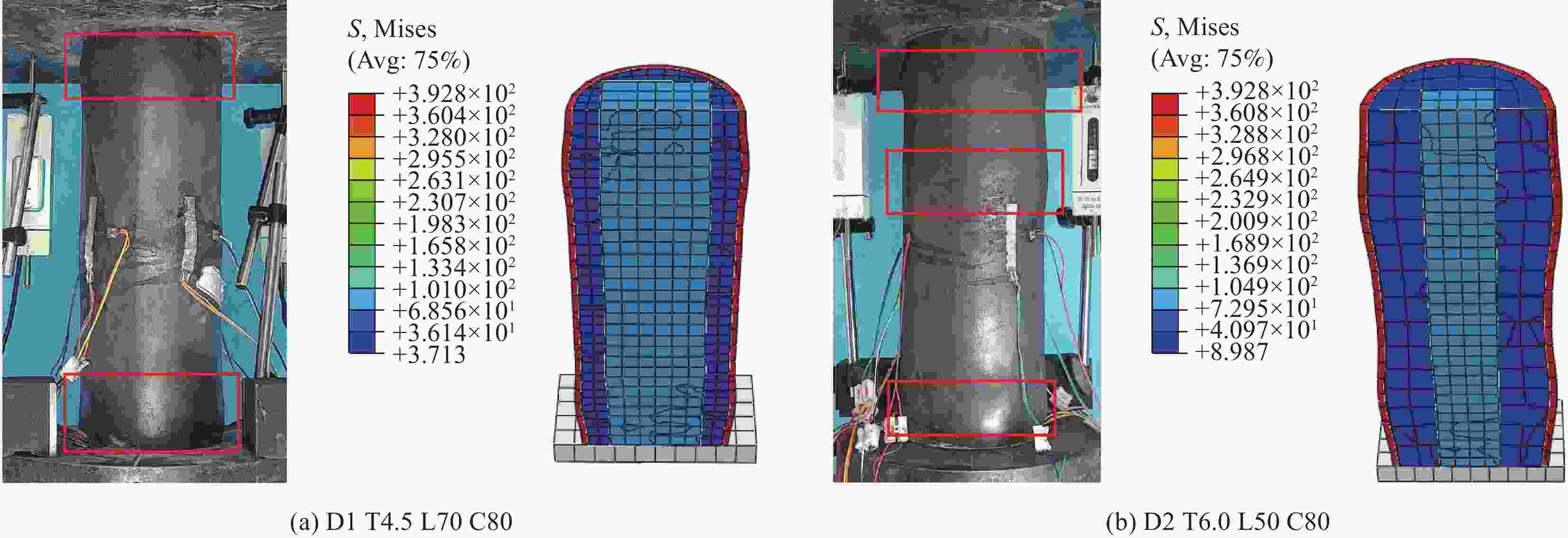

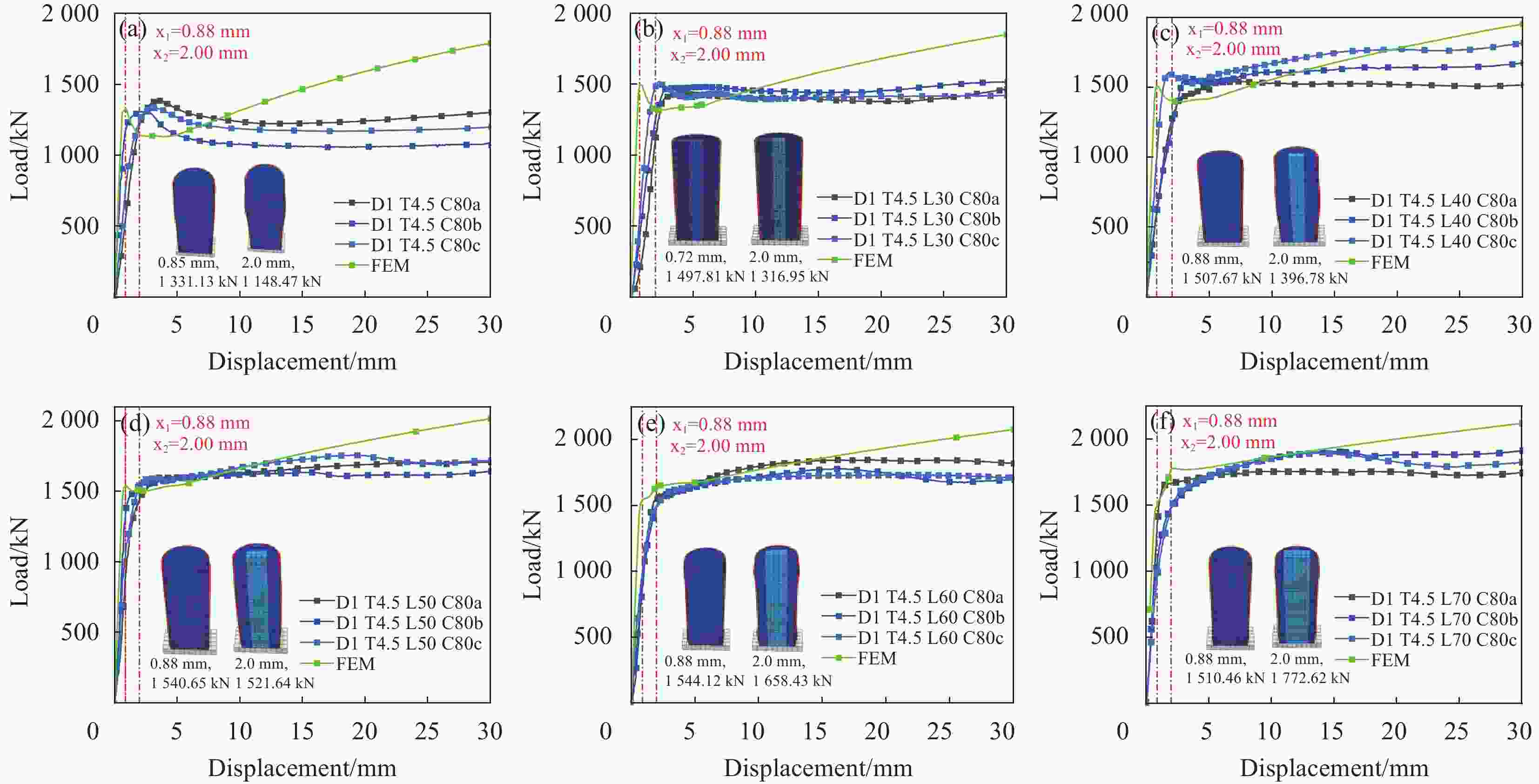

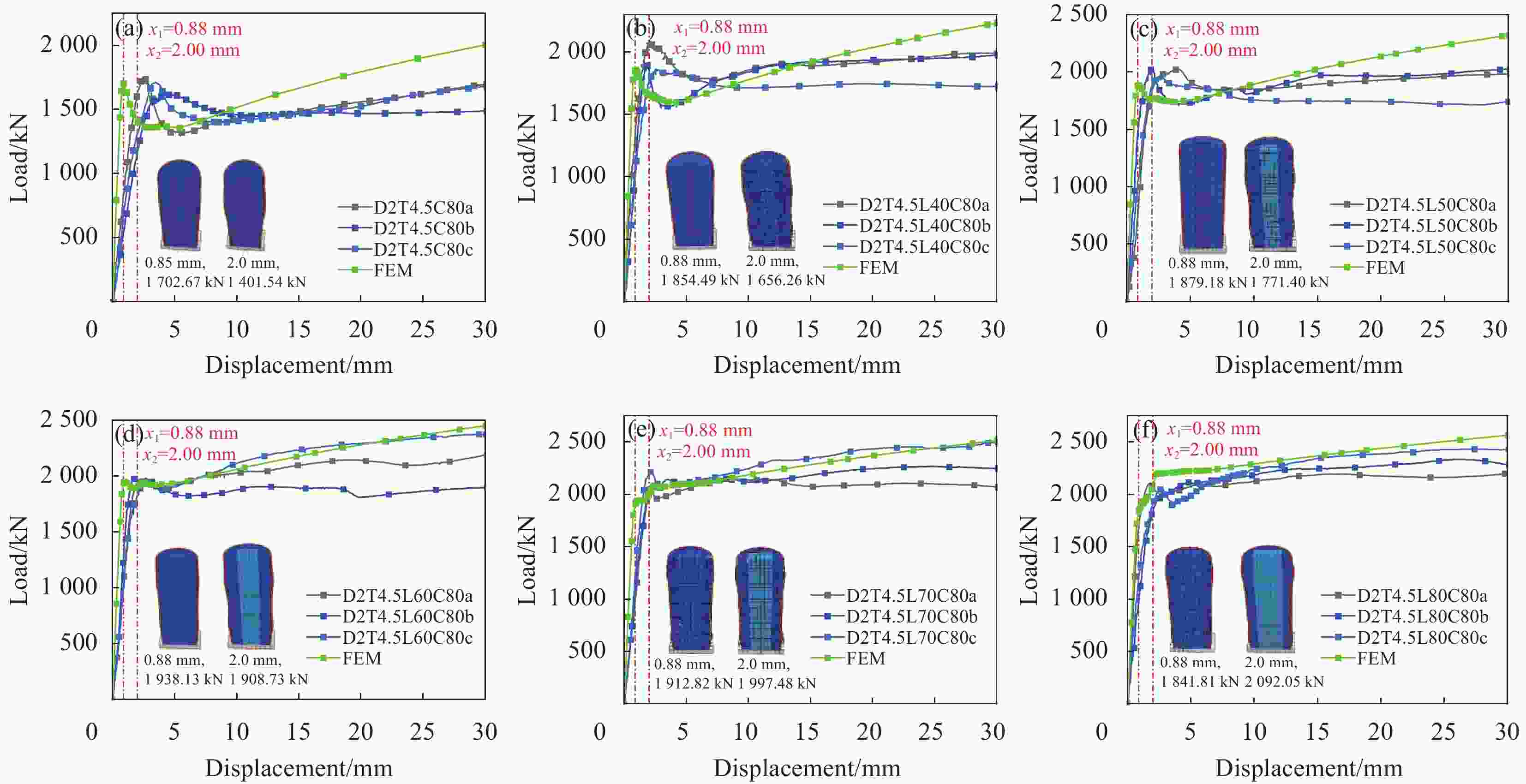

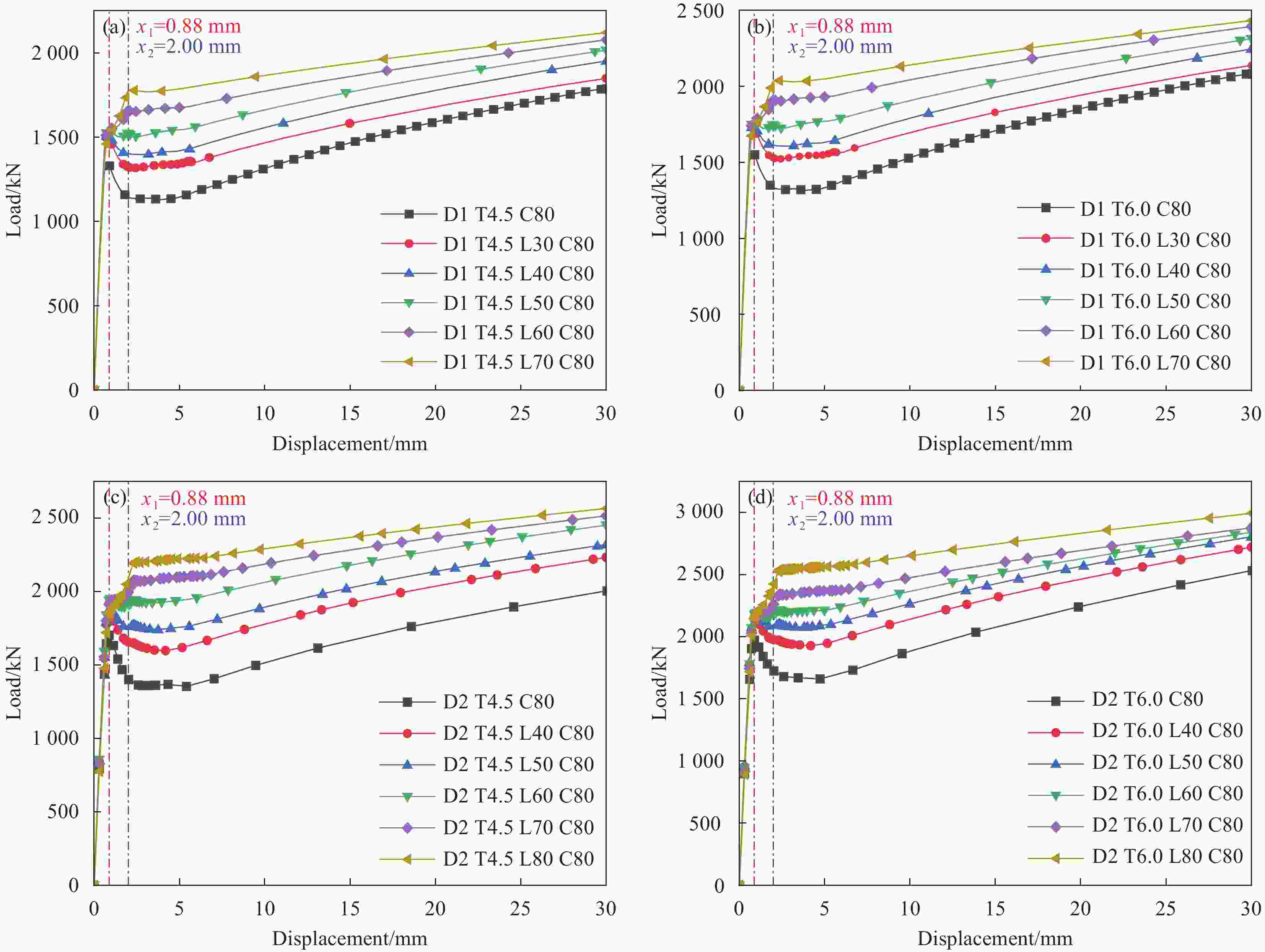

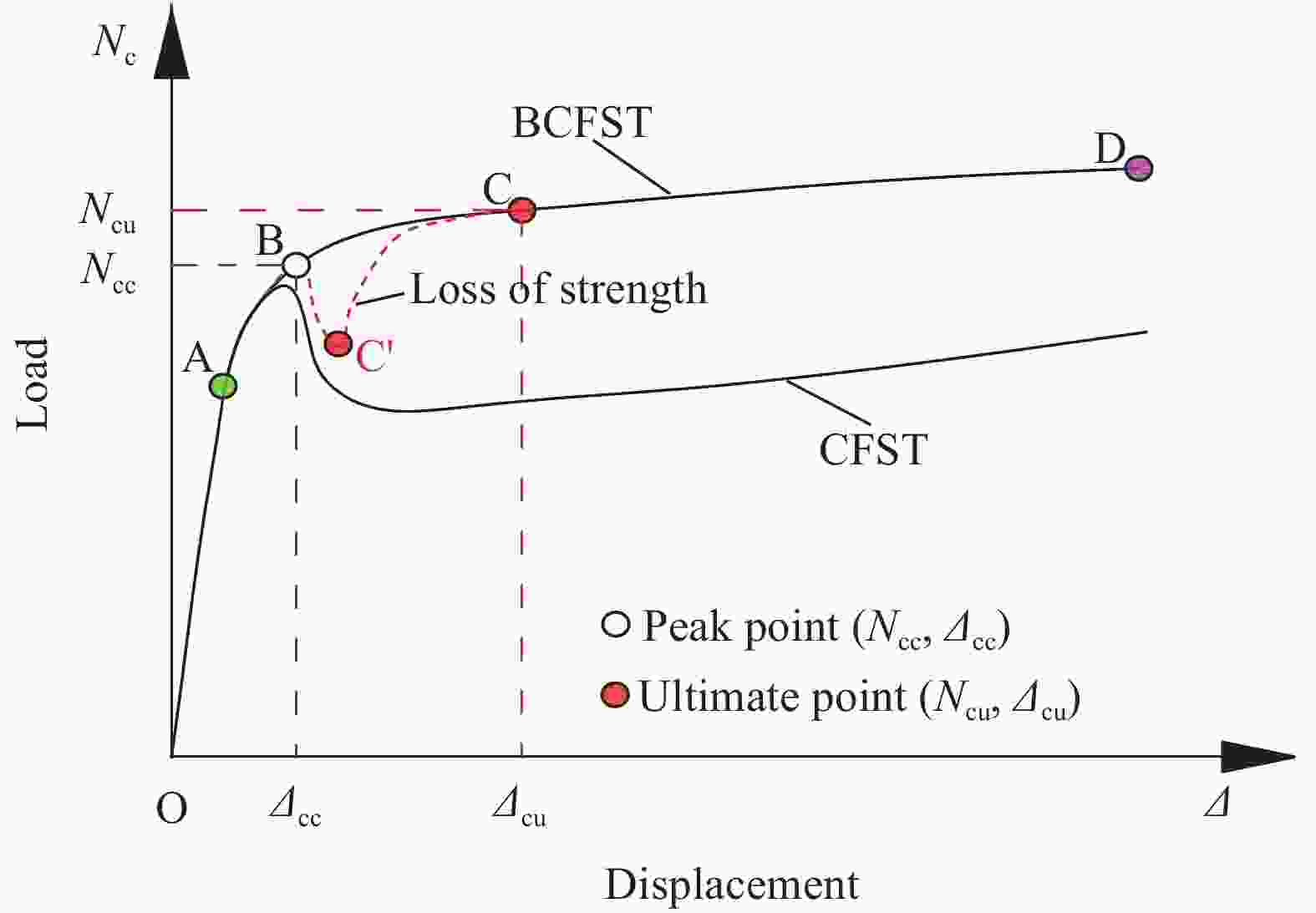

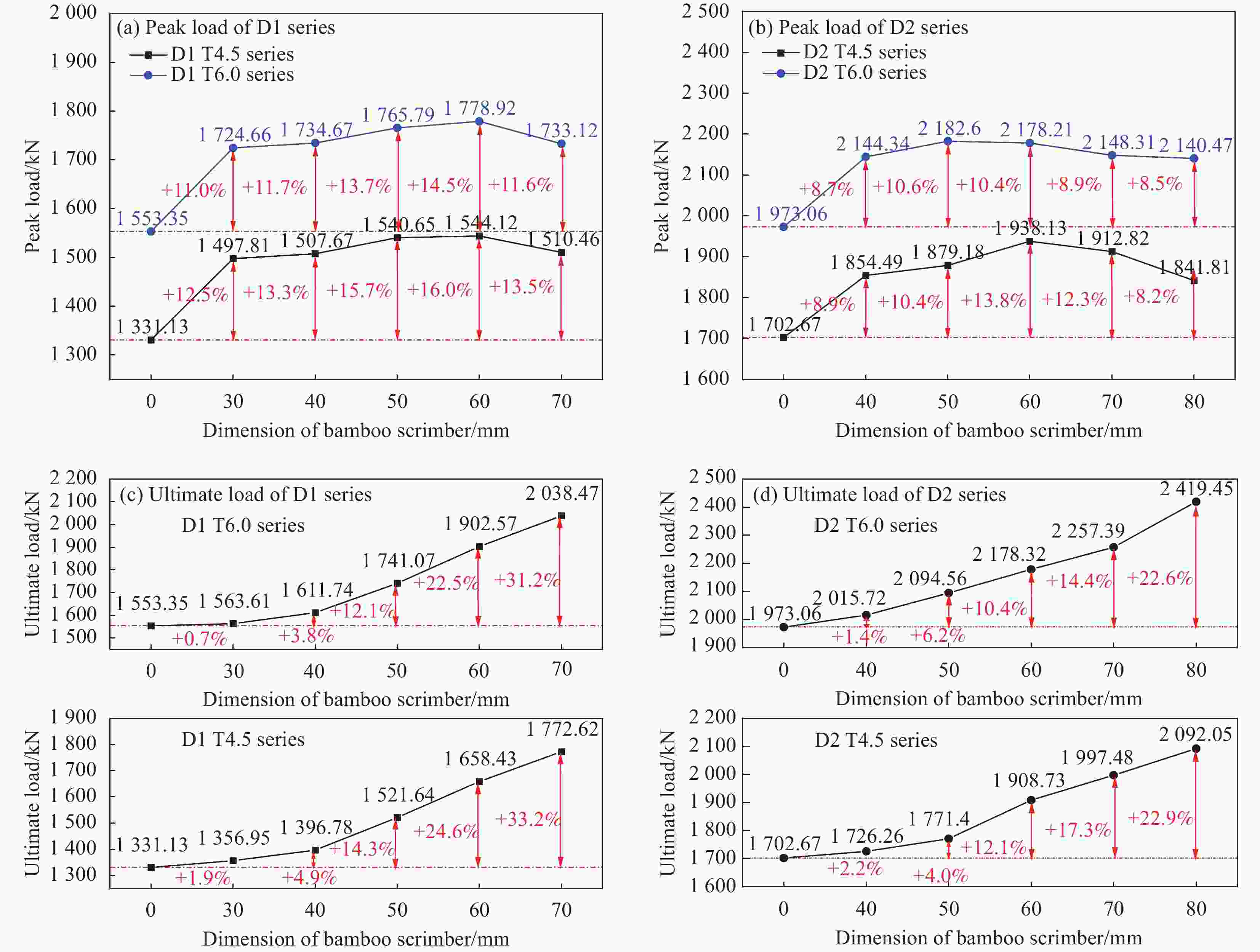

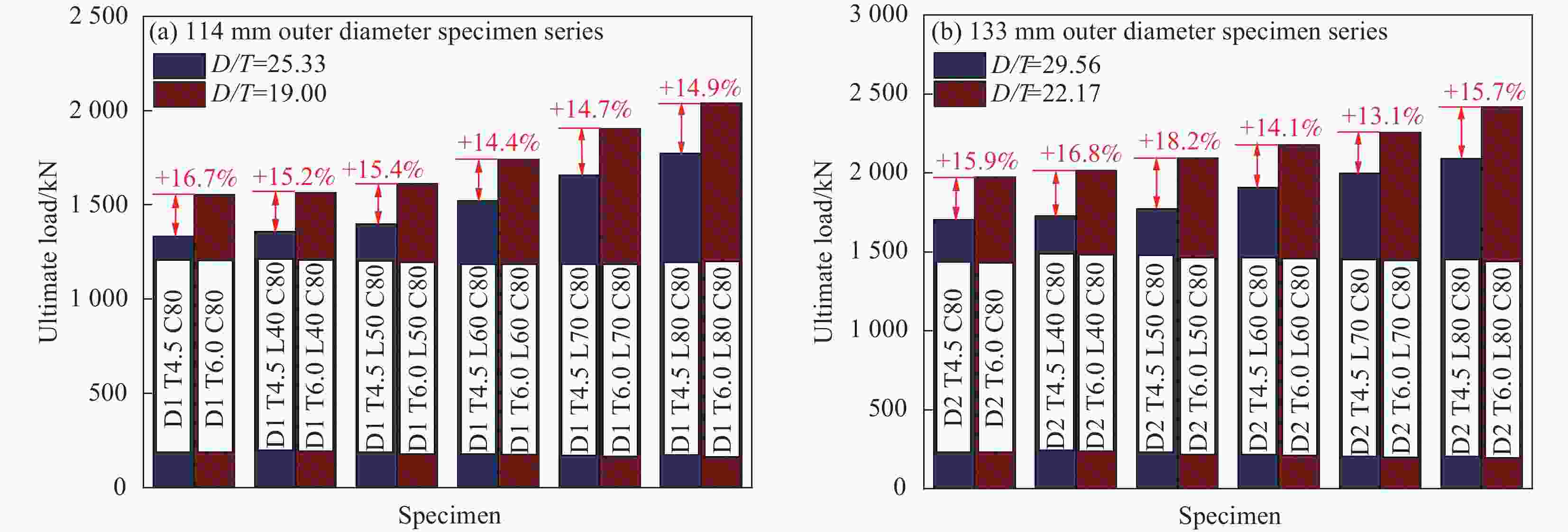

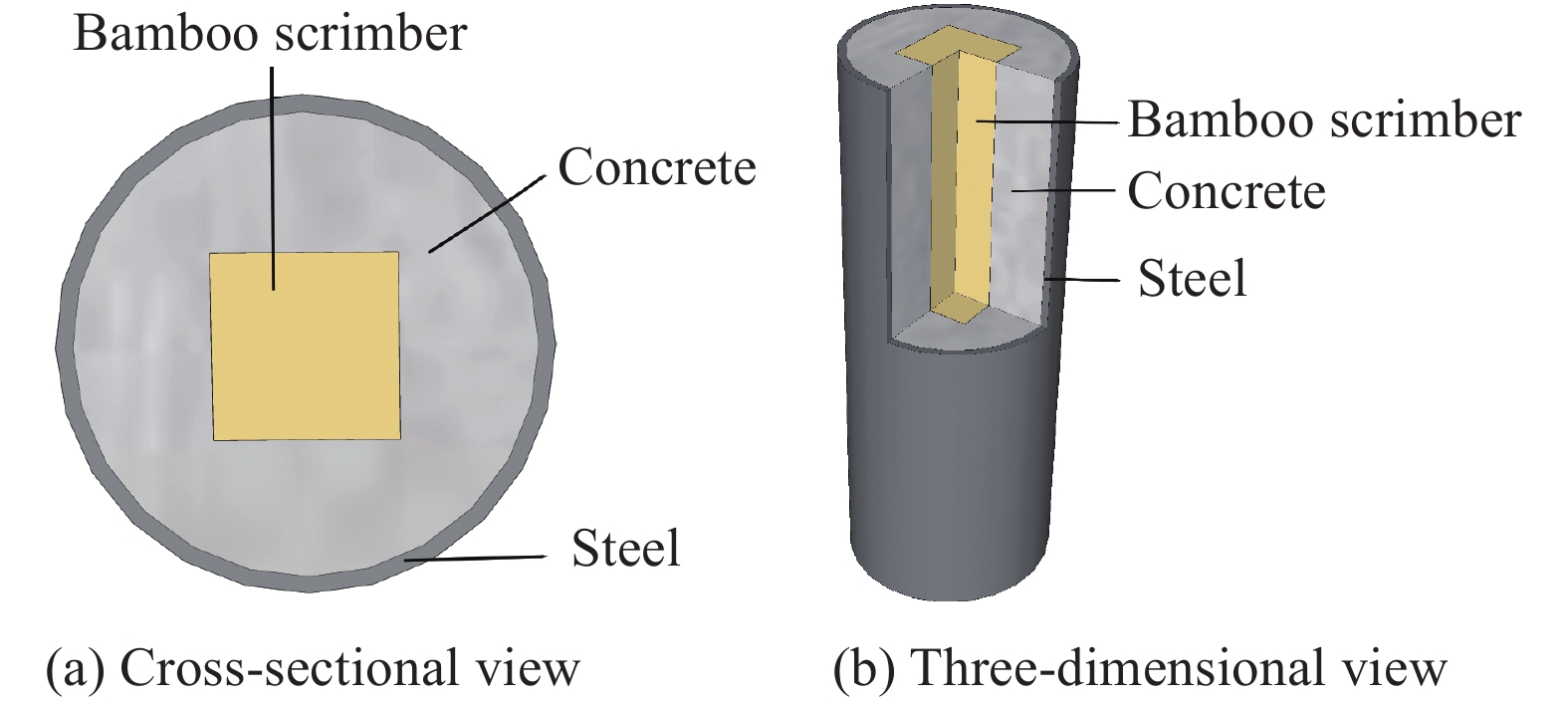

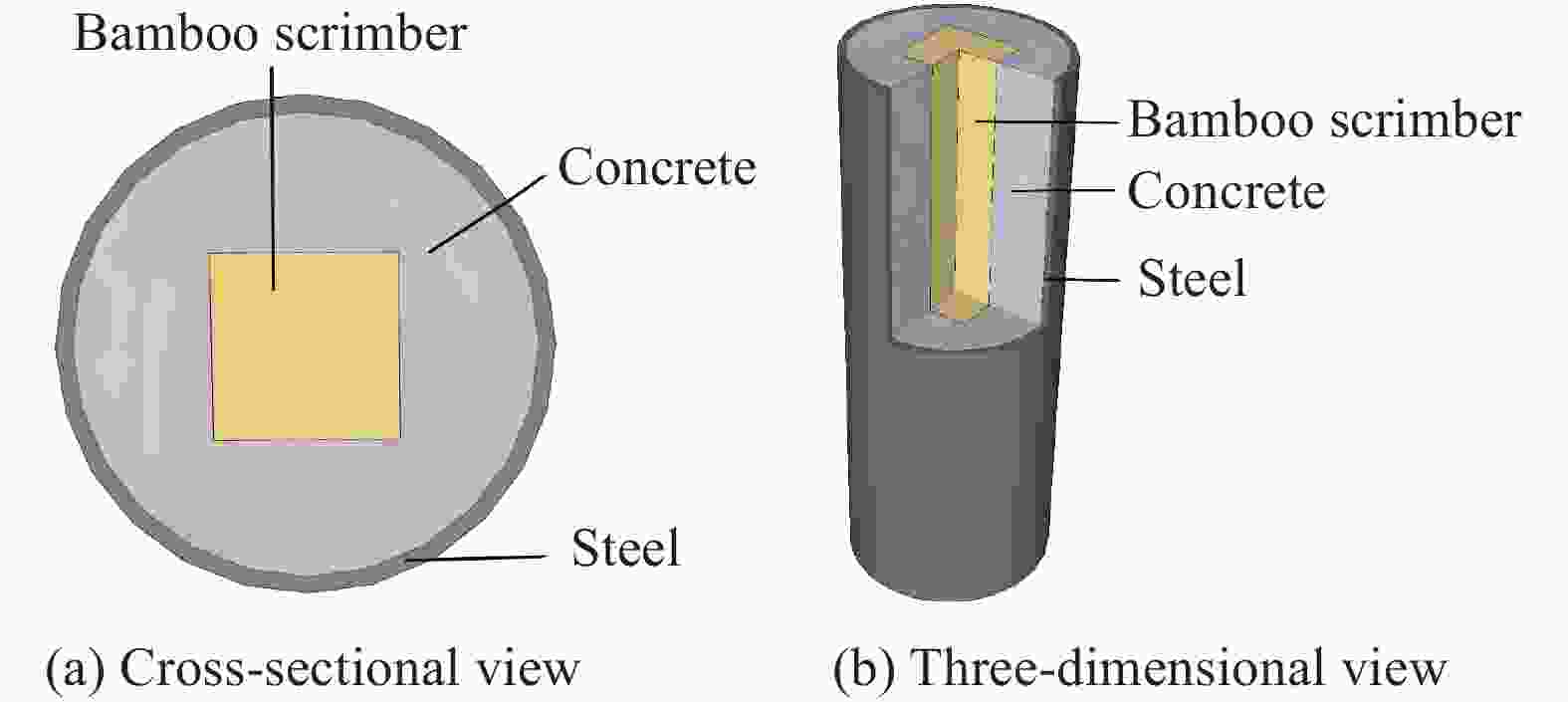

摘要: 将轻质高强的重组竹埋入钢管混凝土柱(CFST)的核心形成钢管约束竹-混凝土组合柱(BCFSTs),期望利用钢管的约束作用充分发挥重组竹的抗压强度并延缓其劈裂破坏。为研究BCFSTs的轴压性能,在3组BCFSTs轴压试验的基础上,采用ABAQUS有限元软件建立了相应的模型进行了非线性有限元分析。通过比对试件的破坏形式、荷载-位移曲线等结果,验证了有限元模型的可靠性与适用性;基于验证后的有限元模型,对重组竹尺寸和钢管径厚比两个关键设计变量进行参数化分析。结果表明:在相同钢管壁厚的钢管混凝土柱中,增大重组竹截面尺寸可以抑制荷载-位移曲线峰值点后的下降过程,BCFSTs的峰值承载力相较于CFST的提升范围均在8%以上,最大提升16%;试件的极限荷载呈现明显增长趋势,BCFSTs的极限承载力相较于CFST的最大提升可达到33.2%。钢管壁厚的增加使得重组竹和混凝土受到的环向约束增强,核心截面强度得以提高,钢管壁厚由4.5 mm变化为6.0 mm时,试件极限荷载最大提升18.2%。Abstract: The light and high strength bamboo scrimber was buried in the core of concrete-filled steel tube (CFST) to form bamboo scrimber and concrete-filled steel tube columns (BCFSTs), which was expected to give full play to the compressive strength of the bamboo scrimber and delay its crushing and splitting. In order to study the axial compression performance of BCFSTs, on the basis of three groups of axial compression tests, the corresponding model was established by using ABAQUS finite element software and the nonlinear finite element analysis was carried out. The reliability and applicability of the finite element model were verified by comparing the failure forms and load-displacement curves of the specimens. Based on the verified finite element model, the two key design variables of bamboo scrimber dimension and diameter to thickness ratio of steel tube were parameterized. The analysis results show that: for CFSTs with the same wall thickness, increasing the dimension of bamboo scrimber can inhibit the decline of load-displacement curve after peak point. Compared with CFSTs, the peak load of BCFSTs is increased by more than 8%, and the maximum increase is 16%. The ultimate load of the specimens show a clear growth trend, and the ultimate bearing capacity of the specimens with built-in bamboo scrimber could reach 33.2% compared with that of the CFSTs. With the increase of wall thickness of steel tube, the circumferential constraint of bamboo scrimber and concrete is strengthened, and the core section strength is improved. When the wall thickness of steel tube changes from 4.5 mm to 6.0 mm, the ultimate load of the specimen is increased by 18.2%.

-

表 3 重组竹各向异性弹性常数

Table 3. Anisotropic elastic constant of bamboo scrimber

E1/MPa E2/MPa E3/MPa v12 v13 v23 G12/MPa G13/MPa G23/MPa 16880 2688.12 2193.42 0.42 0.41 0.45 558.64 569.31 155.62 Notes: E1, E2 and E3 are the compressive elastic modulus of the material in the x, y and z directions, respectively; v12, v13 and v23 are the Poisson's ratio of the material in the x, y and z planes, respectively; G12, G13 and G23 are the shear modulus of the material in the x, y and z planes, respectively. 表 1 试件基本参数

Table 1. Basic parameters of specimens

Working condition Specimens D T D/T L Working condition Specimens D T D/T L W1 D1 T4.5 C80 114 4.5 25.33 - W3 D2 T6.0 C80 133 6.0 22.17 - D1 T4.5 L30 C80 114 4.5 25.33 30 D2 T6.0 L40 C80 133 6.0 22.17 40 D1 T4.5 L40 C80 114 4.5 25.33 40 D2 T6.0 L50 C80 133 6.0 22.17 50 D1 T4.5 L50 C80 114 4.5 25.33 50 D2 T6.0 L60 C80 133 6.0 22.17 60 D1 T4.5 L60 C80 114 4.5 25.33 60 D2 T6.0 L70 C80 133 6.0 22.17 70 D1 T4.5 L70 C80 114 4.5 25.33 70 D2 T6.0 L80 C80 133 6.0 22.17 80 W2 D2 T4.5 C80 133 4.5 29.56 - W4 D1 T6.0 C80 114 6.0 19.00 - D2 T4.5 L40 C80 133 4.5 29.56 40 D1 T6.0 L30 C80 114 6.0 19.00 30 D2 T4.5 L50 C80 133 4.5 29.56 50 D1 T6.0 L40 C80 114 6.0 19.00 40 D2 T4.5 L60 C80 133 4.5 29.56 60 D1 T6.0 L50 C80 114 6.0 19.00 50 D2 T4.5 L70 C80 133 4.5 29.56 70 D1 T6.0 L60 C80 114 6.0 19.00 60 D2 T4.5 L80 C80 133 4.5 29.56 80 D1 T6.0 L70 C80 114 6.0 19.00 70 Notes: D is the outer diameter of the steel tube; T is the thickness of the steel tube; D/T is the ratio of diameter to thickness of steel tube; L is the dimension of the bamboo scrimber. 表 2 材料基本性能

Table 2. Basic properties of materials

Materials Properties Compressive

strength/MPaElastic

modulus /MPaYield

stress/MPaUltimate

stress/MPaPoisson’s

ratioUltimate

compressive strainPeak

compressive strainDensity/

(kg·m−3)Steel — 205000 381 501.7 0.30 0.047 — 7850 Concrete 85.78 43530 — — 0.20 — 0.002 2427 Bamboo scrimber 98.62 16880 — 99.36 0.41 0.043 — 1301 表 4 BCFSTs试件有限元计算荷载与试验荷载对比

Table 4. Comparison of peak and ultimate load of simulation and test of BCFSTs specimens

Specimens Peak load ρb/% Ultimate load Ncc/kN Ncc'/kN Error value/% Ncu/kN Ncu'/kN Error value/% D1 T4.5 C80 1387.75 1331.13 4.25 0 1387.75 1331.13 4.25 D1 T4.5 L30 C80 1487.32 1497.81 0.70 10.4 1442.22 1356.95 5.91 D1 T4.5 L40 C80 1522.14 1507.67 0.96 18.5 1472.49 1396.78 5.42 D1 T4.5 L50 C80 1547.35 1540.65 0.43 28.9 1602.06 1521.64 5.29 D1 T4.5 L60 C80 1536.52 1544.12 0.49 41.6 1666.13 1658.43 0.46 D1 T4.5 L70 C80 1519.21 1510.46 0.58 56.6 1739.48 1772.62 1.87 D2 T4.5 C80 1677.61 1702.67 1.47 0 1677.61 1702.67 1.47 D2 T4.5 L40 C80 1860.21 1854.49 0.31 13.3 1765.60 1726.26 2.22 D2 T4.5 L50 C80 1921.13 1879.18 2.23 20.7 1827.75 1771.40 3.18 D2 T4.5 L60 C80 1989.02 1938.13 2.62 29.8 1970.29 1908.73 3.23 D2 T4.5 L70 C80 2021.10 1912.82 5.66 40.6 2120.71 1997.48 6.17 D2 T4.5 L80 C80 2006.17 1841.81 8.92 53.0 2167.53 2092.05 3.61 D2 T6.0 C80 2005.17 1973.06 1.63 0 2005.17 1973.06 1.63 D2 T6.0 L40 C80 2137.14 2144.34 0.34 13.9 2087.78 2015.72 3.45 D2 T6.0 L50 C80 2188.63 2182.60 0.28 21.7 2165.67 2094.56 3.39 D2 T6.0 L60 C80 2165.07 2178.21 0.61 31.3 2231.11 2178.32 2.52 D2 T6.0 L70 C80 2143.55 2148.31 0.22 42.6 2409.91 2257.39 6.76 D2 T6.0 L80 C80 2196.31 2140.47 2.61 55.7 2486.18 2419.45 2.76 Notes: Ncc is the test peak load, Ncc' is the numerical simulation peak load; Ncu is the test ultimate load, Ncu' is the numerical simulation ultimate load; Error value=│(test value − simulated value)/simulated value│×100%, ρb = Ab/ (Ac+ Ab), and ρb is the ratio of bamboo scrimber. -

[1] HAN L H, Yao G H, Tao Z. Performance of concrete-filled thin-walled steel tubes under pure torsion[J]. Thin-Walled Structures, 2007, 45(1): 24-36. doi: 10.1016/j.tws.2007.01.008 [2] WEI Y, JIANG C, WU Y F. Confinement effectiveness of circular concrete-filled steel tubular columns under axial compression[J]. Journal of Constructional Steel Research, 2019, 158: 15-27. doi: 10.1016/j.jcsr.2019.03.012 [3] 刘威. 钢管混凝土局部受压时的工作机理研究[D]. 福州大学, 2006.LIU W. Study on working mechanism of concrete filled steel tubular under local compression[D]. Fuzhou University, 2006. (in Chinese) [4] AHEMD M, LIANG Q Q, PATEL V I, et al. Experimental and numerical studies of square concrete-filled double steel tubular short columns under eccentric loading[J]. Engineering Structures, 2019, 197: 109419. doi: 10.1016/j.engstruct.2019.109419 [5] AHEMD M, LIANG Q Q, PATEL V I, et al. Experimental and numerical investigations of eccentrically loaded rectangular concrete-filled double steel tubular columns[J]. Journal of Constructional Steel Research, 2020, 167: 105949. doi: 10.1016/j.jcsr.2020.105949 [6] AHEMD M, LIANG Q Q, PATEL V I, et al. Nonlinear analysis of rectangular concrete-filled double steel tubular short columns incorporating local buckling[J]. Engineering Structures, 2018, 175: 13-26. doi: 10.1016/j.engstruct.2018.08.032 [7] HASSANEIN M F, ELCHALAKANI M, KARRECH A, et al. Finite element modelling of concrete-filled double-skin short compression members with CHS outer and SHS inner tubes[J]. Marine Structures, 2018, 61: 85-99. doi: 10.1016/j.marstruc.2018.05.002 [8] HASSANEIN M F, ELCHALAKANI M, KARRECH A, et al. Behaviour of concrete-filled double-skin short columns under compression through finite element modelling: SHS outer and SHS inner tubes[J]. Structures. Elsevier, 2018, 14: 358-375. [9] LIANG Q Q. Nonlinear analysis of circular double-skin concrete-filled steel tubular columns under axial compression[J]. Engineering Structures, 2017, 131: 639-650. doi: 10.1016/j.engstruct.2016.10.019 [10] LIANG Q Q. Numerical simulation of high strength circular double-skin concrete-filled steel tubular slender columns[J]. Engineering Structures, 2018, 168: 205-217. doi: 10.1016/j.engstruct.2018.04.062 [11] AYOUGH P, SULONG N H R, IBRAHIM Z, et al. Nonlinear analysis of square concrete-filled double-skin steel tubular columns under axial compression[J]. Engineering Structures, 2020, 216: 110678. doi: 10.1016/j.engstruct.2020.110678 [12] CI J, JIA H, CHEN S, et al. Performance analysis and bearing capacity calculation on circular concrete-filled double steel tubular stub columns under axial compression[J]. Structures. Elsevier, 2020, 25: 554-565. [13] CI J, JIA H, AHMED M, et al. Experimental and numerical analysis of circular concrete-filled double steel tubular stub columns with inner square hollow section[J]. Engineering Structures, 2021, 227: 111400. doi: 10.1016/j.engstruct.2020.111400 [14] 谢菁, 叶勇, 刘阳, 等. 内填料石钢管混凝土短柱轴压性能研究及承载力计算[J]. 建筑结构学报, 2022, 43(6): 43-52. doi: 10.14006/j.jzjgxb.2020.0440XIE Jing, LIU Yang, YE Yong, et al. Experimental study on axial load carrying performance and design method of stone prism and concrete-filled steel tubular stub columns[J]. Journal of Building Structures, 2022, 43(6): 43-52(in Chinese). doi: 10.14006/j.jzjgxb.2020.0440 [15] 谢菁, 叶勇, 刘阳, 等. 内填料石钢管混凝土中长柱轴压性能试验研究[J]. 建筑结构学报, 2023, 44(2): 27-36. doi: 10.14006/j.jzjgxb.2021.0584XIE Jing, YE Yong, LIU Yang, et al. Experimental study on axial compressive performance of stone prism and concrete-filled steel tubular slender columns[J]. Journal of Building Structures, 2023, 44(2): 27-36(in Chinese). doi: 10.14006/j.jzjgxb.2021.0584 [16] YE Y, LIU Y, GUO Z X, et al. Stone prism encased concrete-filled steel tube columns subjected to axial compression[J]. Structures. Elsevier, 2021, 33: 1853-1867. [17] NABATI A, GHANBARI T G, NG C T. CFRP-reinforced concrete-filled steel tubes with timber core under axial loading[J]. Composite Structures, 2019, 217: 37-49. doi: 10.1016/j.compstruct.2019.02.075 [18] GHANBARI T G, MAGSI G A, GU D, et al. Double-skin concrete-timber-filled steel columns under compression[J]. Engineering Structures, 2019, 200: 109537(1-14). [19] GHANBARI T G, JIAO H, HOLLOWAY D. Concrete-filled circular steel tubes with a timber infill under axial compression[J]. Journal of Structural engineering, 2017, 143(7): 04017037. doi: 10.1061/(ASCE)ST.1943-541X.0001757 [20] AZANDARIANI M G, GHANBARI-GHAZIJAHANI T, MOHEBKHA A, et al. Concrete-and timber-filled tubes under axial compression-Numerical and theoretical study[J]. Journal of Building Engineering, 2021, 44: 103231. doi: 10.1016/j.jobe.2021.103231 [21] 李帼昌, 岳祥虎, 杨志坚. 钢管-木-混凝土轴压短柱有限元分析[J]. 沈阳建筑大学学报(自然科学版), 2021, 37(2): 193-201.LI G C, YUE X H, YANG Z J. Finite element analysis of steel tube-wood-concrete short columns under axial compression[J]. Journal of Shenyang Jianzhu University (Natural Science), 2021, 37(2): 193-201(in Chinese). [22] 李帼昌, 夏秀斌, 邱增美. 方钢管-木-混凝土中长柱轴压性能有限元分析[J]. 沈阳建筑大学学报(自然科学版), 2022, 38(6): 961-969.LI G C, XIA X B, QIU Z M. Finite element analysis of axial compression performance on square steel tube-timber-concrete medium long column[J]. Journal of Shenyang Jianzhu University (Natural Science), 2022, 38(6): 961-969(in Chinese). [23] 荣秀强, 凌志彬. 内填木芯钢管混凝土短柱轴压性能有限元分析[J]. 建筑钢结构进展, 2022, 24(05): 8-17. doi: 10.13969/j.cnki.cn31-1893.2022.05.002RONG X Q, LING Z B. Finite Element Analysis of Concrete-Filled Steel Tubular Short Columns with Timber Core Under Axial Compression[J]. Progress in Steel Building Structures, 2022, 24(05): 8-17(in Chinese). doi: 10.13969/j.cnki.cn31-1893.2022.05.002 [24] 刘永军, 王紫怡, 佟舟. 钢管-再生混凝土-拼接木复合长柱轴压性能有限元分析[J]. 沈阳建筑大学学报(自然科学版), 2022, 38(06): 1020-1028.LIU Y J, WANG Z Y, TONG Z. Finite element analysis of axial compression performance on steel tube-recycled concrete-cpliced wood composite long columns[J]. Journal of Shenyang Jianzhu University (Natural Science), 2022, 38(06): 1020-1028(in Chinese). [25] ZHANG F, XIE S, XIAO J, et al. Mechanical behavior of Glass fiber-reinforced polymer-timber-steel tube-concrete composite columns under axial compression[J]. Structural Concrete, 2023, 24(1): 1296-1312. doi: 10.1002/suco.202200138 [26] GAN D, LI Z, ZHANG T, et al. Axial compressive behaviour of circular concrete-filled steel tubular columns with an inner bamboo culm[J]. Structures. Elsevier, 2020, 26: 156-168. [27] 陈思, 魏洋, 赵鲲鹏, 等. 重组竹顺纹受压蠕变性能及预测模型[J]. 复合材料学报, 2021, 38(3): 944-952. doi: 10.13801/j.cnki.fhclxb.20200615.002CHEN S, WEI Y, ZHAO K P, et al. Creep performance and prediction model of bamboo scrimber under compression[J]. Acta Materiae Compositae Sinica, 2021, 38(3): 944-952(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200615.002 [28] CHEN S, Wei Y, ZHU J, et al. Experimental investigation of the shear performance of bamboo scrimber beams reinforced with bamboo pins[J]. Construction and Building Materials, 2023, 365: 130044. doi: 10.1016/j.conbuildmat.2022.130044 [29] WEI Y, JI X, DUAN M, et al. Flexural performance of bamboo scrimber beams strengthened with fiber-reinforced polymer[J]. Construction and Building Materials, 2017, 142: 66-82. doi: 10.1016/j.conbuildmat.2017.03.054 [30] 魏洋, 纪雪微, 端茂军, 等. 重组竹轴向应力-应变关系模型[J]. 复合材料学报, 2018, 35(3): 572-579. doi: 10.13801/j.cnki.fhclxb.20170608.002WEI Y, JI X W, DUAN M J, et al. Model for axial stress strain relationship of bamboo scrimber[J]. Acta Materiac Compositae Sinica, 2018, 35(3): 572-579 (in Chinese). doi: 10.13801/j.cnki.fhclxb.20170608.002 [31] WU F, WEI Y, LIN Y, et al. Experimental study of bamboo scrimber-filled steel tube columns under axial compression[J]. Engineering Structures, 2023, 280: 115669. doi: 10.1016/j.engstruct.2023.115669 [32] 吴凤贻, 魏洋, 王高飞, 等. 不同加载模式下钢管约束重组竹轴压力学行为[J/OL]. 复合材料学报: 1-132023-08-27]. WU F Y, WEI Y, WANG G F, et al. Mechanical behavior of bamboo scrimber filled steel tube under different loading modes [J/OL]. Acta Materiae Compositae Sinica: 1-13[2023-08-27]. (in Chinese) [33] 刘明西, 刘承阳, 刘问, 等. 重组竹-混凝土界面粘结-滑移本构模型[J]. 复合材料学报, 2022, 39(05): 2299-2307. doi: 10.13801/j.cnki.fhclxb.20210804.002LIU M X, LIU C Y, LIU W, et al. Bond-slip constitutive model of bamboo scrimber-concrete interface[J]. Acta Materiae Compositae Sinica, 2022, 39(05): 2299-2307(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210804.002 [34] 中华人民共和国住房和城乡建设部. 混凝土结构试验方法标准: GB/T50152-2012[S]. 北京: 中国建筑工业出版社, 2012.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test method of concrete structures: GB/T50152-2012[S]. Beijing: China Architecture & Building Press2012. (in Chinese) -

下载:

下载: