Preparation and anisotropic conduction behavior of polyethylene/carbonfiber composites

-

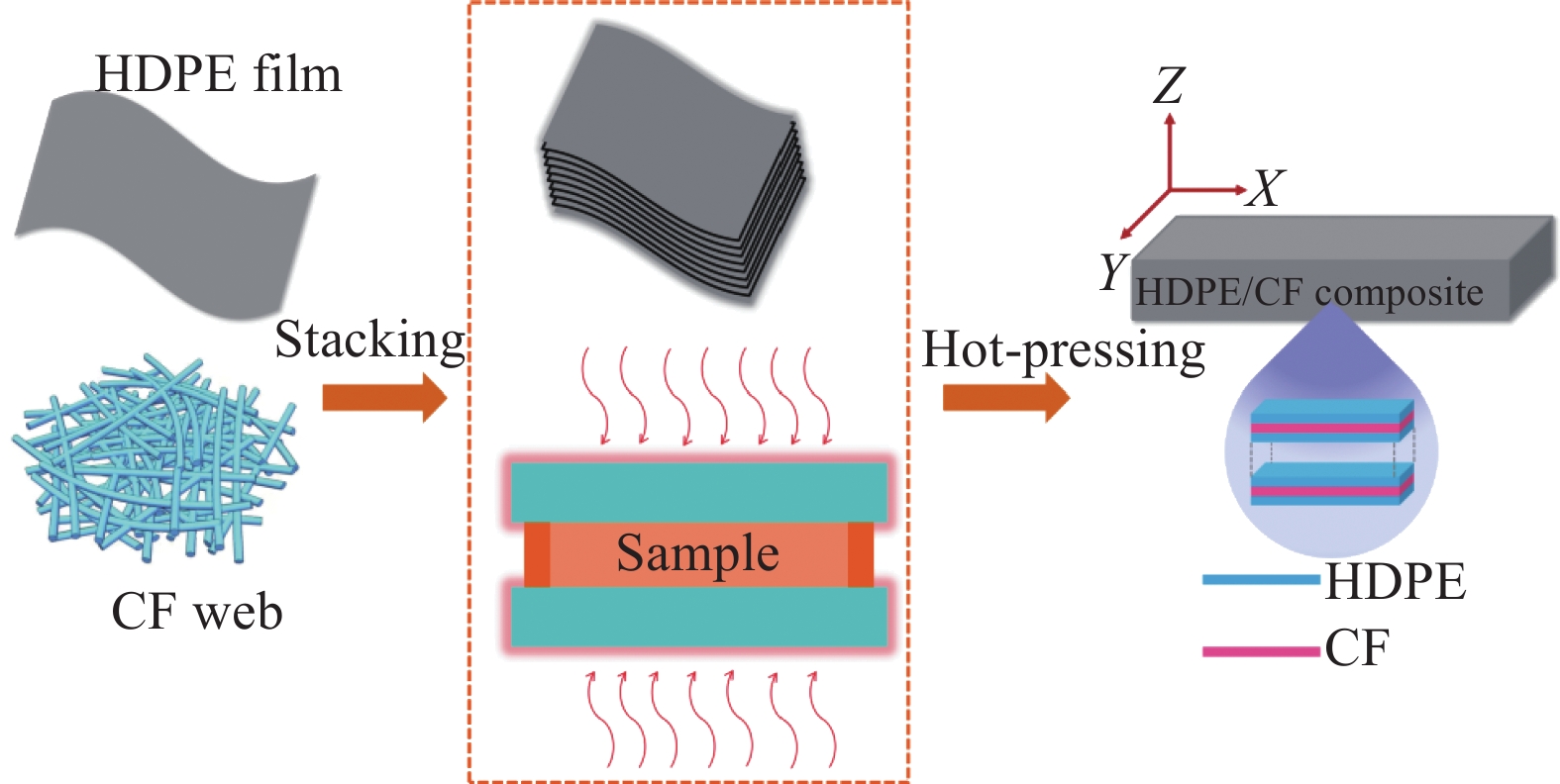

摘要: 各向异性传导高分子复合材料(ACPC)因其独特的各向异性导电、导热等特性在集成电路、传感器件、热管理等领域具有巨大的应用潜力。本文以碳纤维(CF)和高密度聚乙烯(HDPE)膜为原料,碳纤维经高温预处理后,通过超声分散和真空抽滤工艺制备三维碳纤维网络,再采用热压成型技术将其与聚乙烯膜复合制备具有各向异性传导行为的HDPE/CF复合材料。通过DSC、SEM、TG及导电性能测试研究了复合材料的微结构、热性质和电性能,采用集成电路和红外热像仪对复合材料的各向异性传导行为进行监测。聚乙烯层与碳纤维网层交替排列且结合紧密;这种交替多层结构赋予了HDPE/CF复合材料层内导电、层间绝缘特性,呈现典型的各向异性传导行为。HDPE/CF复合材料在X方向和Y方向具有优异的导电性能(电导率高达85.71 S/m),高出Z方向5~7个数量级。交替多层结构和碳纤维网的引入显著提高了HDPE/CF复合材料的热稳定性能,其初始热分解温度相对HDPE膜提高了约35℃。该复合材料具有优异的电子载流能力和定向传导能力,在电路连接、定向导电、热管理等领域具有巨大的应用潜力。Abstract: The anisotropic conductive polymer composites (ACPCs) have great application potential in integrated circuits, sensors, thermal management and other fields because of their unique anisotropic conductive and thermal properties. In this experiment, the carbon fiber (CF) and high-density polyethylene (HDPE) films were used as raw materials. The CF was pretreated at high temperature firstly and then used to make a carbon fiber network by ultrasonic dispersion and vacuum filtration technology. Subsequently, the HDPE/CF composites with anisotropic conductivity were fabricated by hot-pressing molding technique. DSC, SEM, TG and conductivity tests were performed to analyze the microstructure, thermal and conductive properties of composites. Then the anisotropic conduction behavior of HDPE/CF was monitored by the integrated circuits and IR thermal camera. HDPE layer and CF web layer are arranged alternately and closely combined. The alternating multilayer structure endows HDPE/CF composites with special intra layer conductivity and interlayer insulation, showing typical anisotropic conductivity. HDPE/CF composites exhibit excellent electrical conductivity in the X and Y directions (with conductivity up to 85.71 S/m), which is 5-7 orders of magnitude higher than the Z direction. The introduction of alternating multilayer structure and CF web significantly improves the thermal stability of HDPE/CF composite, and its initial thermal decomposition temperature is increased by about 35℃ compared with that of HDPE film. It exhibits excellent current-carrying capability and remarkable conductive anisotropy, exhibiting great application potential in circuit connection, directional conduction, thermal management and other fields.

-

图 6 3-HDPE/CF复合材料的各向异性导热应用:(a)样品测试热传导示意图;(b) X和Z方向的温度分布曲线图;(c) X和Z方向的红外热成像图

Figure 6. Demonstration of anisotropic thermal property of HDPE/CF composites: (a) Heat-transfer schematic of sample; (b) Temperature distributions curves in X and Z directions; (c) Thermographic images in X and Z directions

-

[1] WAN J Y, SONG J W, YANG Z, et al. Highly anisotropic conductors[J]. Advanced Materials, 2017, 29(41): 1703331. doi: 10.1002/adma.201703331 [2] ZENG Z H, JIN H, CHEN M J, et al. Lightweight and anisotropic porous MWCNT/WPU composites for ultrahigh performance electromagnetic interference shielding[J]. Advanced Functional Materials, 2016, 26(2): 303-310. doi: 10.1002/adfm.201503579 [3] 赵康. 交替微层PP/MWCNTs导电复合材料制备及性能研究[D]. 郑州: 郑州大学, 2019.ZHAO Kang. Preparation and properties of PP/MWCNTs conductive composites with alternating microlayers[D]. Zhengzhou: Zhengzhou University, 2019(in Chinese). [4] HAN J, DU G, GAO W, et al. An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network[J]. Advanced Functional Materials, 2019, 29(13): 1900412. doi: 10.1002/adfm.201900412 [5] MENONA A V, MADRASB G, BOSE S. Shape memory polyurethane nanocomposites with porous architectures for enhanced microwave shielding[J]. Chemical Engineering Journal, 2018, 352: 590-600. doi: 10.1016/j.cej.2018.07.048 [6] MARTIN C A, SANDLER J K W, WINDLE A H, et al. Electric field-induced aligned multi-wall carbon nanotube networks in epoxy composites[J]. Polymer, 2005, 46(3): 877-886. doi: 10.1016/j.polymer.2004.11.081 [7] WU S Y, LADANI R B, ZHANG J, et al. Aligning multilayer graphene flakes with an external electric field to improve multifunctional properties of epoxy nanocomposites[J]. Carbon, 2015, 94: 607-618. doi: 10.1016/j.carbon.2015.07.026 [8] SHI Y D, YU H O, LI J, et al. Low magnetic field-induced alignment of nickel particles in segregated poly(L-lactide)/poly(ε-caprolactone)/multi-walled carbon nanotube nanocomposites: Towards remarkable and tunable conductive anisotropy[J]. Chemical Engineering Journal, 2018, 347: 472-482. doi: 10.1016/j.cej.2018.04.147 [9] KIM I T, TANNENBAUM A, TANNENBAUM R. Anisotropic conductivity of magnetic carbon nanotubes embedded in epoxy matrices[J]. Carbon, 2011, 49(1): 54-61. doi: 10.1016/j.carbon.2010.08.041 [10] MA Q L, WANG J X, DONG X T, et al. Flexible Janus nanoribbons array: A new strategy to achieve excellent electrically conductive anisotropy, magnetism, and photoluminescence[J]. Advanced Functional Materials, 2015, 25(16): 2436-2443. doi: 10.1002/adfm.201500348 [11] LIU M K, DU Y F, MIAO Y E, et al. Anisotropic conductive films based on highly aligned polyimide fibers containing hybrid materials of graphene nanoribbons and carbon nanotubes[J]. Nanoscale, 2015, 7: 1037-1046. doi: 10.1039/C4NR06117A [12] YIN K Z, ZHOU Z, SCHUELE D E, et al. Effects of interphase modification and biaxial orientation on dielectric properties of poly(ethylene terephthalate)/poly(vinylidene fluoride-co-hexafluoropropylene) multilayer films[J]. ACS Applied & Materials Interfaces, 2016, 8(21): 13555-13566. [13] GAO W L, ZHENG Y, SHEN J B, et al. Electrical properties of polypropylene-based composites controlled by multilayered distribution of conductive particles[J]. ACS Applied & Materials Interfaces, 2015, 7(3): 1541-1549. doi: 10.1021/am506773c [14] LU J R, WENG W G, CHEN X F, et al. Piezoresistive materials from directed shear-induced assembly of graphite nanosheets in polyethylene[J]. Advanced Functional Materials, 2010, 15(8): 1358-1363. [15] HUANG J R, ZHU Y T, JIANG W, et al. Parallel carbon nanotube stripes in polymer thin film with remarkable conductive anisotropy[J]. ACS Applied & Materials Interfaces, 2014, 6(3): 1754-1758. doi: 10.1021/am404758d [16] JIANG K, YU F L, BAI H W, et al. Alternating multilayer structure of polyethylene/polypropylene blends obtained through injection molding[J]. Journal of Applied Polymer Science, 2012, 124(6): 4452-4456. doi: 10.1002/app.35451 [17] WANG J, WANG C, ZHANG X, et al. Morphological evolution and toughening mechanism of polypropylene and polypropylene/poly(ethylene-co-octene) alternating multilayered materials with enhanced low-temperature toughness[J]. RSC Advances, 2014, 4(39): 20297-20307. doi: 10.1039/C3RA48036D [18] XU S, WEN M, LI J, et al. Structure and properties of electrically conducting composites consisting of alternating layers of pure polypropylene and polypropylene with a carbon black filler[J]. Polymer, 2008, 49(22): 4861-4870. doi: 10.1016/j.polymer.2008.08.056 [19] BAI H, HUANG C, XIU H, et al. Significantly improving oxygen barrier properties of polylactide via constructing parallel-aligned shish-kebab-like crystals with well-interlocked boundaries[J]. Biomacromolecules, 2014, 15(4): 1507-1514. doi: 10.1021/bm500167u [20] PANDE S, SINGH B P, MATHUR R B, et al. Improved electromagnetic interference shielding properties of MWCNT-PMMA composites using layered structures[J]. Nanoscale Research Letters, 2009, 4: 327-334. doi: 10.1007/s11671-008-9246-x [21] 孔之奇, 张梦, 刘蓓, 等. 碱预处理对碳纤维分散及碳纸原纸性能的研究[J]. 中国造纸, 2022, 41(11): 29-36.KONG Zhiqi, ZHANG Meng, LIU Bei, et al. Study of alkali pretreatment on the dispersion of carbon fiber and the performance of carbon paper-base paper[J]. China Pulp & Paper, 2022, 41(11): 29-36(in Chinese). [22] 陈伟明, 王成忠, 周同悦, 等. 高性能T800碳纤维复合材料树脂基体[J]. 复合材料学报, 2006, 4(23): 29-35. doi: 10.13801/j.cnki.fhclxb.2006.04.006CHEN Weiming, WANG Chengzhong, ZHOU Tongyue, et al. High-performance resin matrix for T800 carbon fiber composites[J]. Acta Materiae Compositae Sinica, 2006, 4(23): 29-35(in Chinese). doi: 10.13801/j.cnki.fhclxb.2006.04.006 [23] SHI S Y, PAN Y M, LU B, et al. Realizing the simultaneously improved toughness and strength of ultra-thin LLDPE parts through annealing[J]. Polymer, 2013, 54(25): 6843-6852. [24] QIN Y J, XU Y H, ZHANG L Y, et al. Interfacial interaction enhancement by shear-induced β-cylindrite in isotactic polypropylene/glass fiber composites[J]. Polymer, 2016, 100: 111-118. doi: 10.1016/j.polymer.2016.08.016 [25] LI H, ZHANG X M, WANG J F, et al. The mechanism for the temperature-dependency of the interfacial interaction in polyamide/tin-fluoro-phosphate glass composites[J]. Composites Science and Technology, 2018, 159: 273-282. doi: 10.1016/j.compscitech.2018.03.011 [26] WU D F, WU L, ZHANG M, et al. Viscoelasticity and thermal stability of polylactide composites with various functionalized carbon nanotubes[J]. Polymer Degradation and Stability, 2008, 93(8): 1577-1584. doi: 10.1016/j.polymdegradstab.2008.05.001 [27] 石素宇, 赵康, 张笑源, 等. 各向异性导电PP-MWCNTs/HDPE 复合材料的结构及性能[J]. 复合材料学报, 2022, 39(10): 4694-4700.SHI Suyu, ZHAO Kang, ZHANG Xiaoyuan, et al. Structure and properties of PP-MWCNTs/HDPE composites with anisotropic conductivity[J]. Acta Materiae Compositae Sinica, 2022, 39(10): 4694-4700(in Chinese). -

下载:

下载: