Recent progress in the preparation, properties and applications of superhydrophobic coatings

-

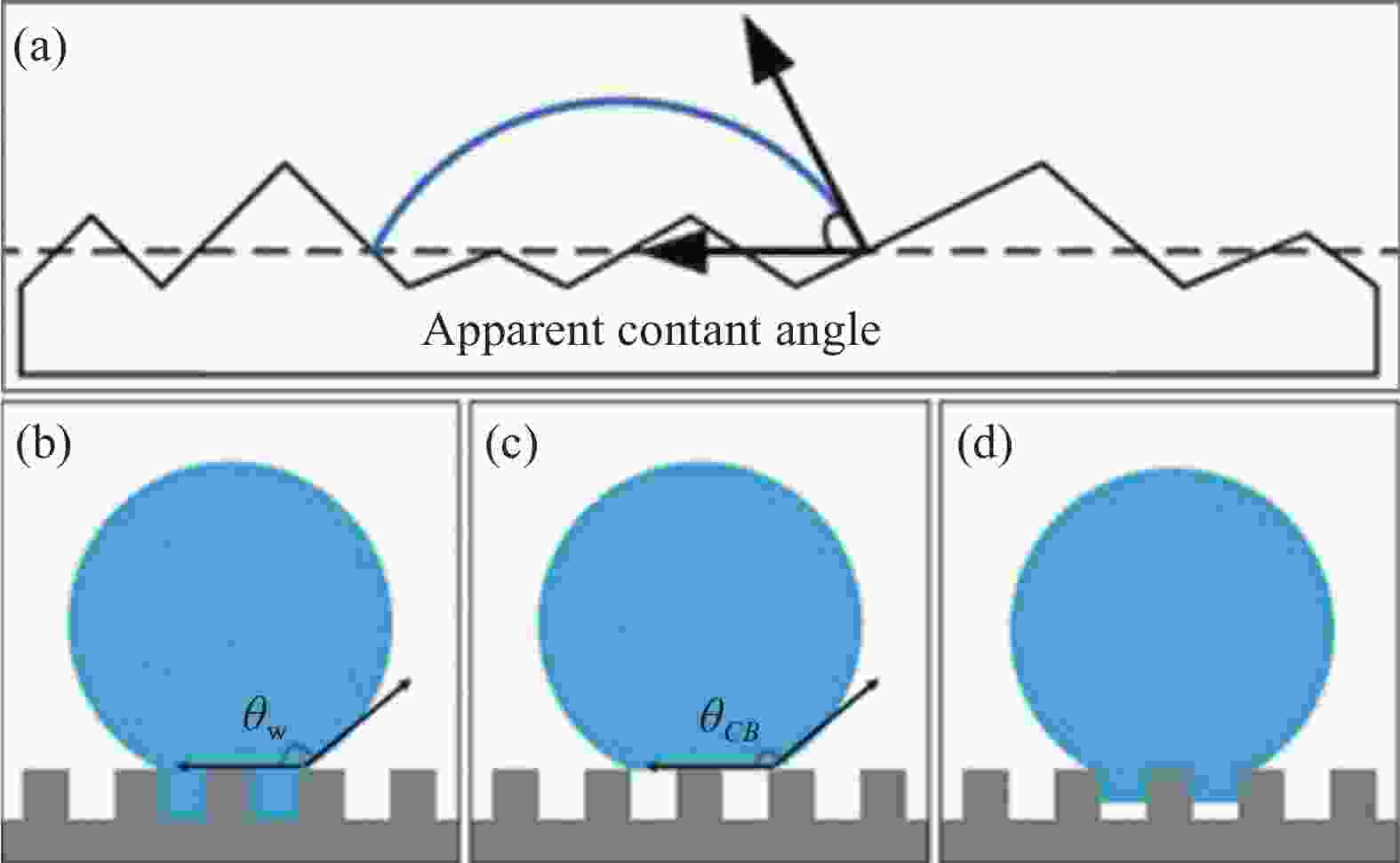

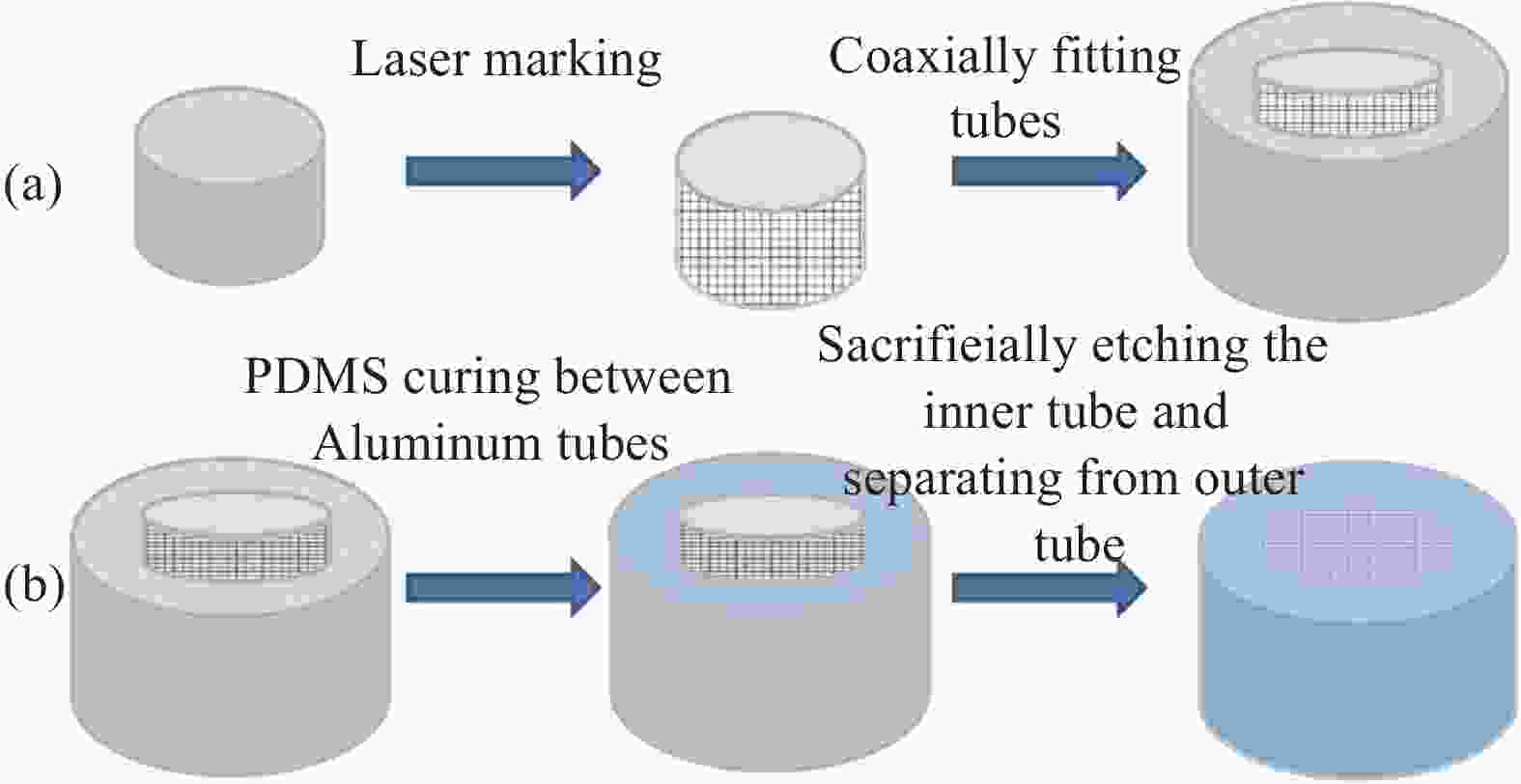

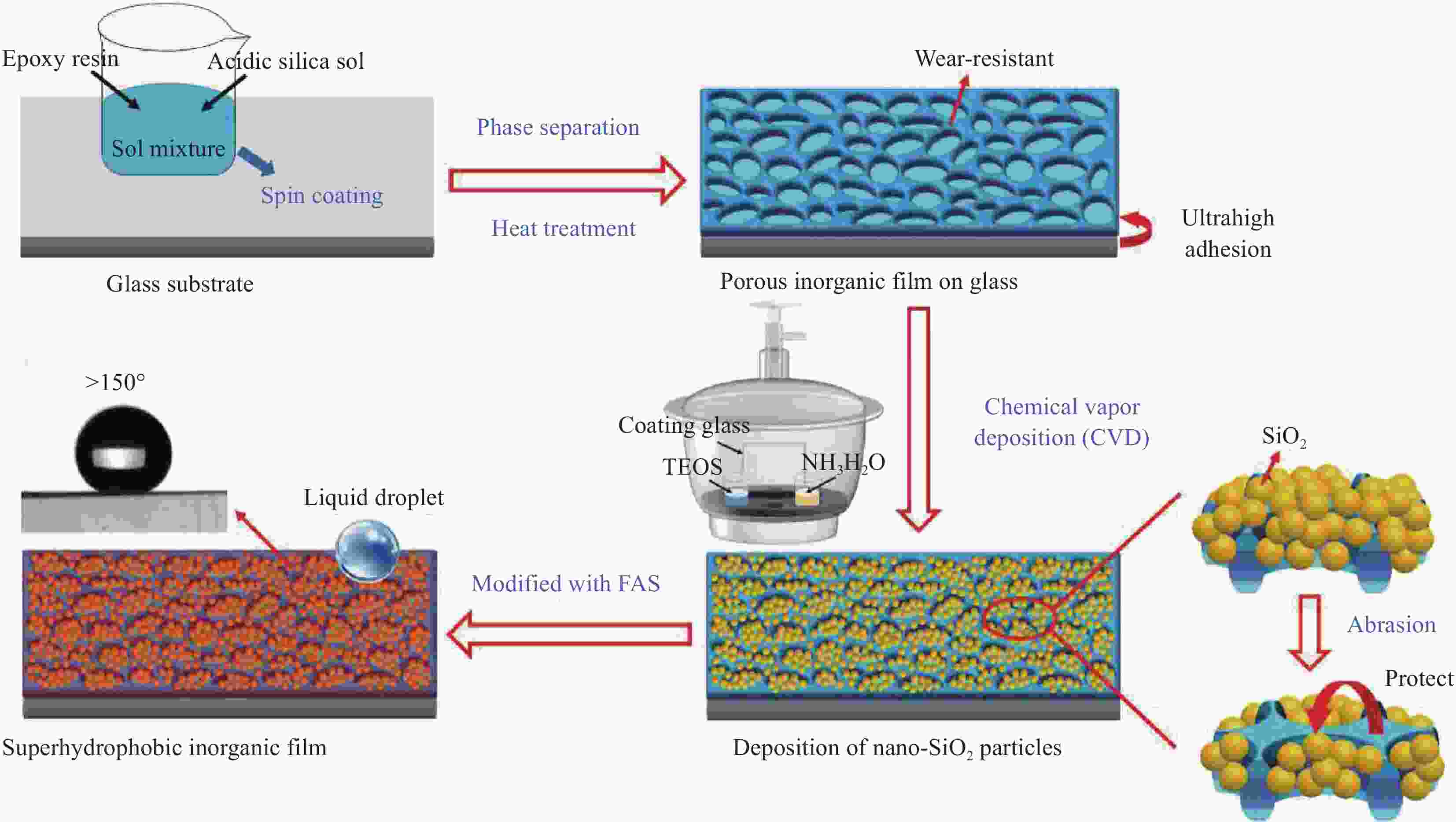

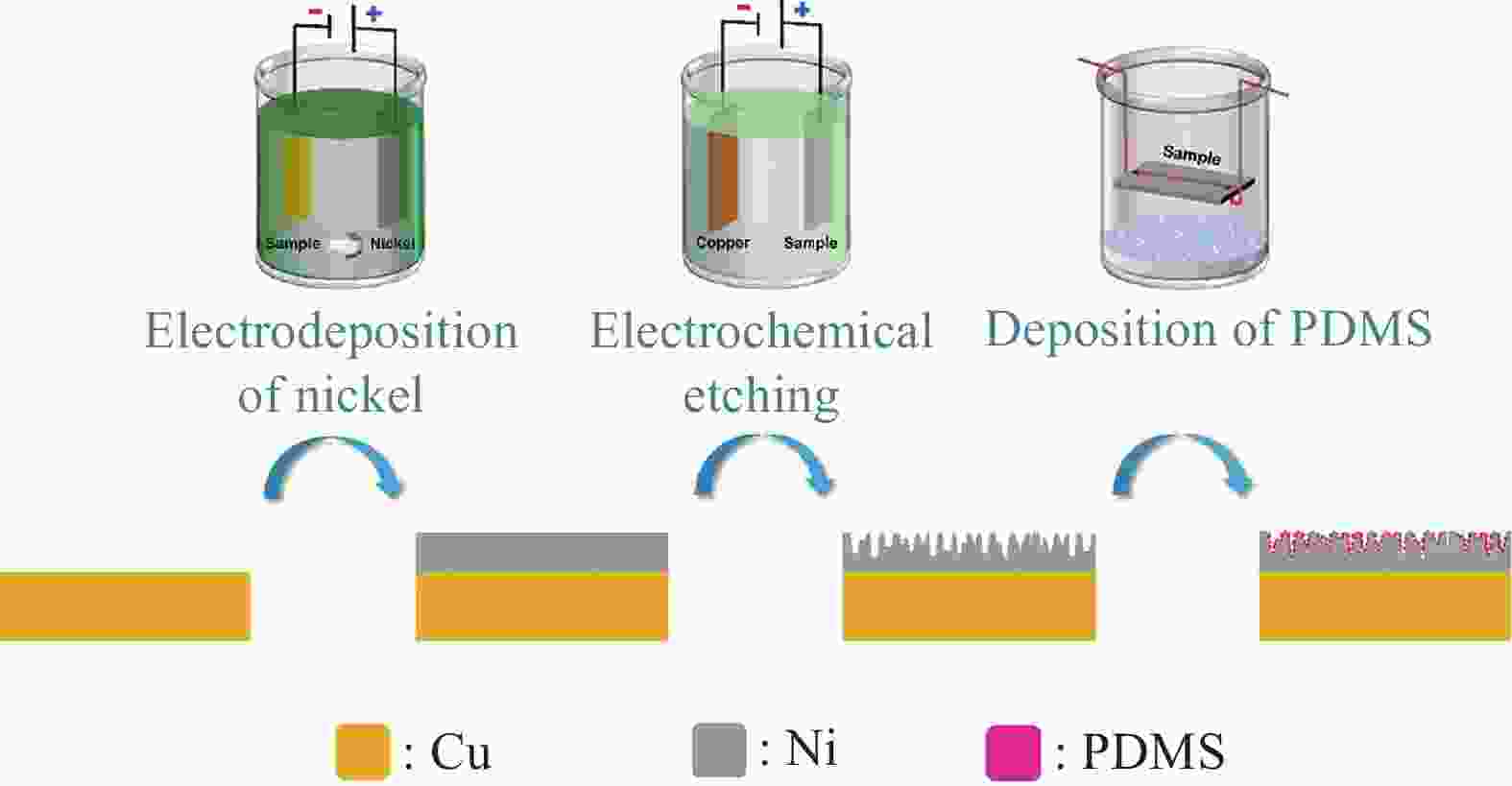

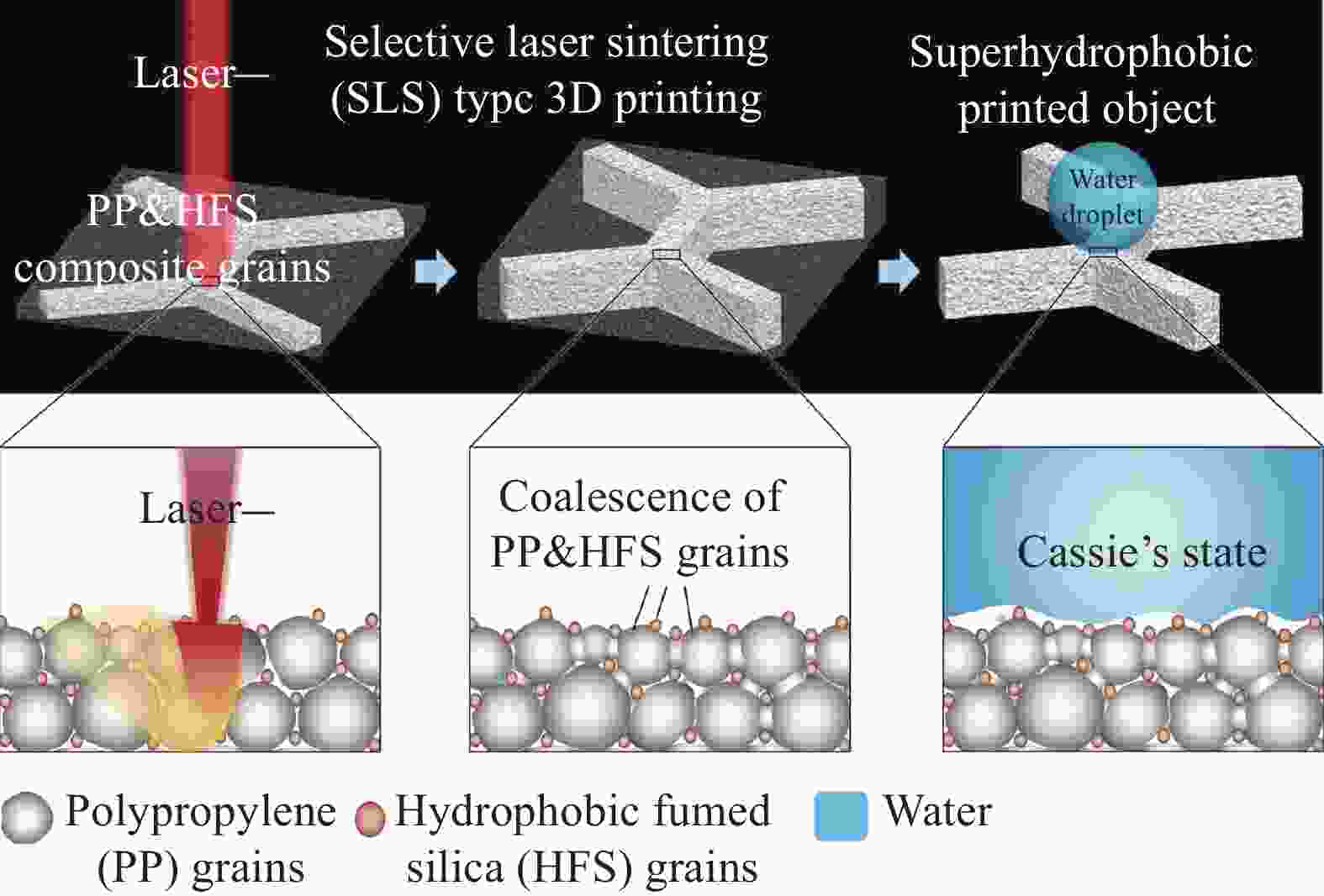

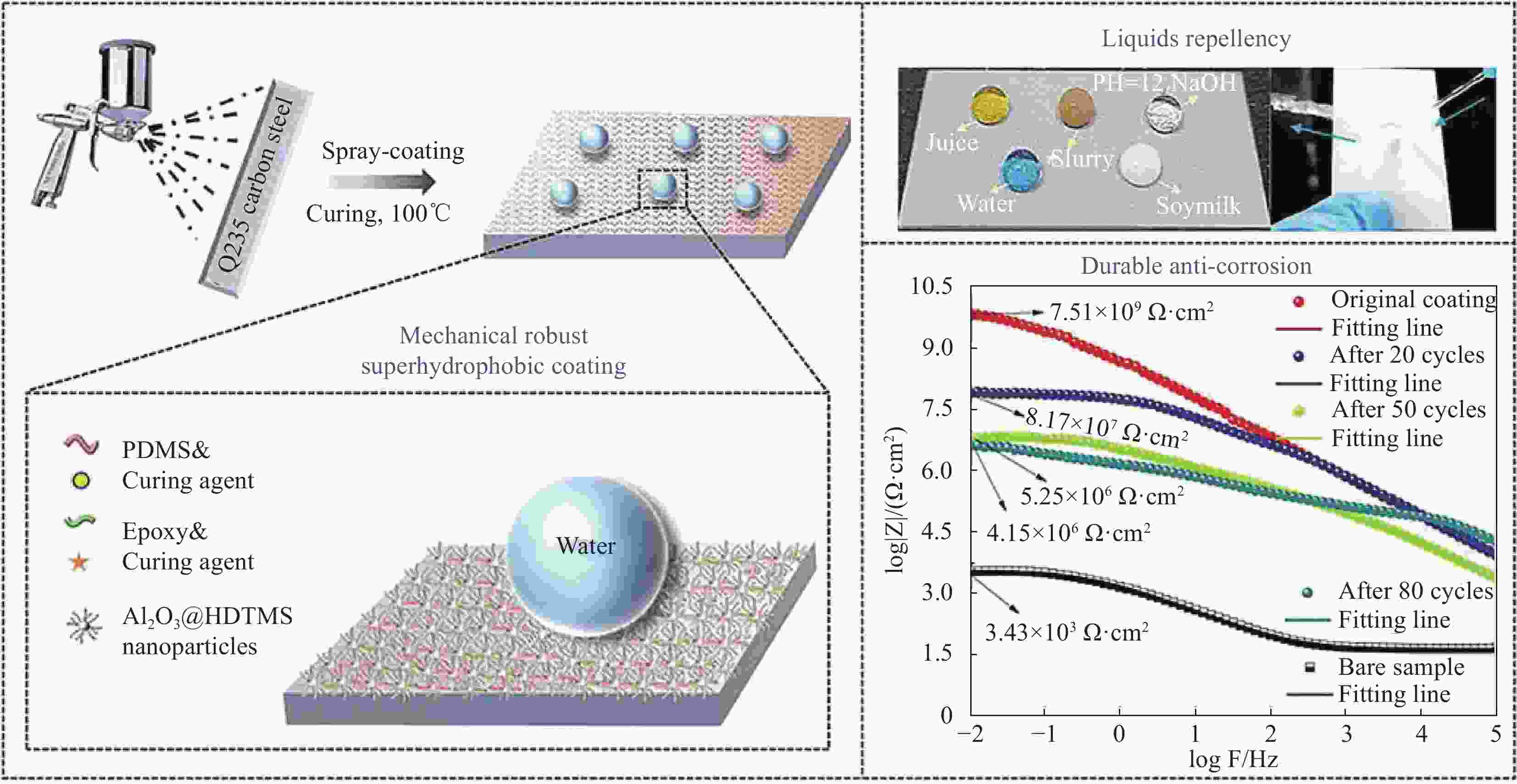

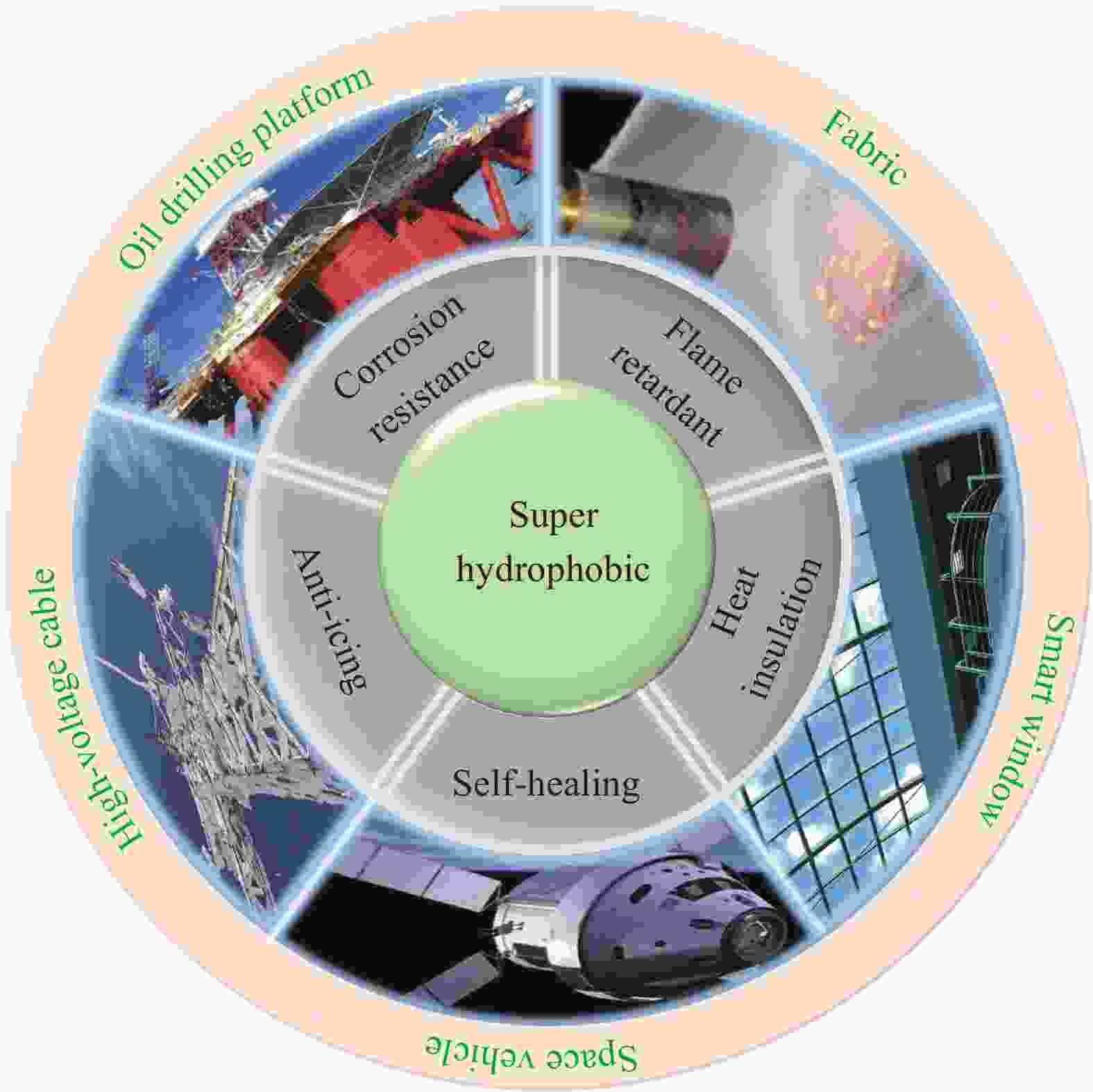

摘要: 随着材料工程和涂料工业的发展,具有耐腐蚀、自清洁、防雾、减阻或抗结冰等性能的超疏水涂层由于能够满足不同应用领域的功能需求,越来越受到研究人员的关注。此外,通过进一步在涂层内部引入隔热、防冰、阻燃、防腐等功能填料可赋予其多功能性,极大地拓宽了超疏水涂层的应用领域。本文首先对超疏水涂层的原理进行了梳理;进一步阐述了超疏水涂层的经典润湿理论,包括杨氏模型、Wenzel模型和Cassie-Baxter模型;随后分析了超疏水涂层不同制备方法的特点,并对各方法的优缺点进行了对比;最后通过介绍掺杂功能填料的多功能超疏水涂层研究进展,指出超疏水涂层存在的主要问题,并对其发展方向进行了展望。Abstract: Superhydrophobic coatings with excellent corrosion resistance, self-cleaning, anti-fog, drag reduction, or icing resistance have been paid more and more attention due to their applications in the engineering and coatings industry. In addition, the application of superhydrophobic coatings can be greatly expanded by introducing functional fillers such as heat insulation, anti-icing, flame retardant, and anti-corrosion into the coating. In this paper, the mechanism of superhydrophobic coating is first reviewed, and the classical wetting theory of superhydrophobic coating is further described, including Young's model, Wenzel model, and Cassie-Baxter model. The characteristics of different preparation methods of superhydrophobic coatings are compared, subsequently. Finally, the main problems existing in the development of superhydrophobic coatings are pointed out by introducing the research progress of multifunctional superhydrophobic coatings, and the development direction of superhydrophobic coatings is proposed.

-

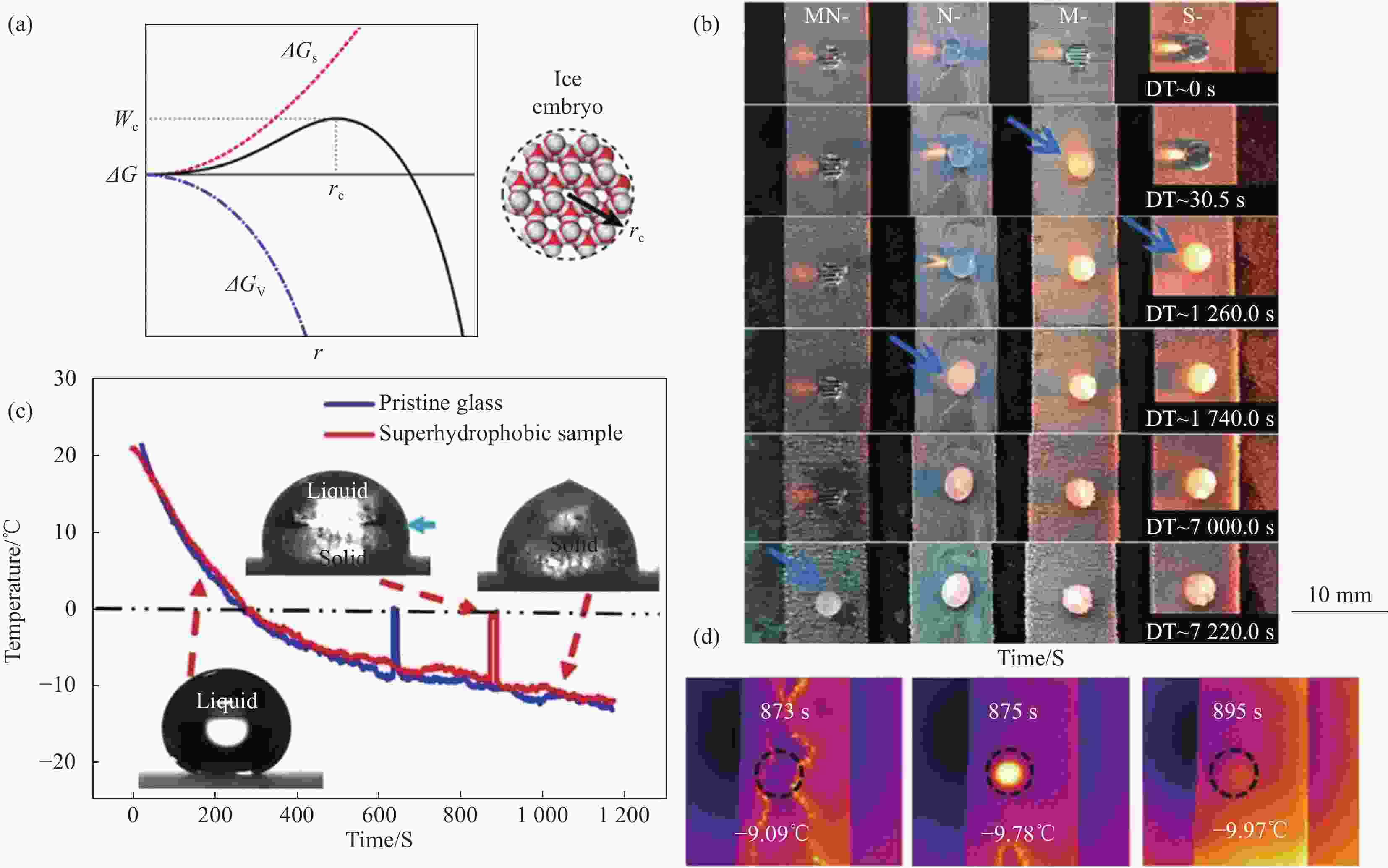

图 9 (a) ∆G与ri关系图; (b) 临界半径为(ri,c)的冰胚示意图[70]; (c) 液滴温度(20 μL)随时间变化及不同状态下(冷冻过程之前、期间和之后)对应的液滴图片; (d) 在不同状态下(冷冻过程之前、期间和之后)捕获的红外图像[71]

Figure 9. (a) ∆G and ri relationship diagram[70]; (b) Schematic diagram of an ice embryo with a critical radius of (ri,c); (c) Droplet (20 μL) temperature changes over time and corresponding droplet pictures under different states (before, during and after the freezing process); (d) Infrared images captured in different states (before, during and after the freezing process)[71]

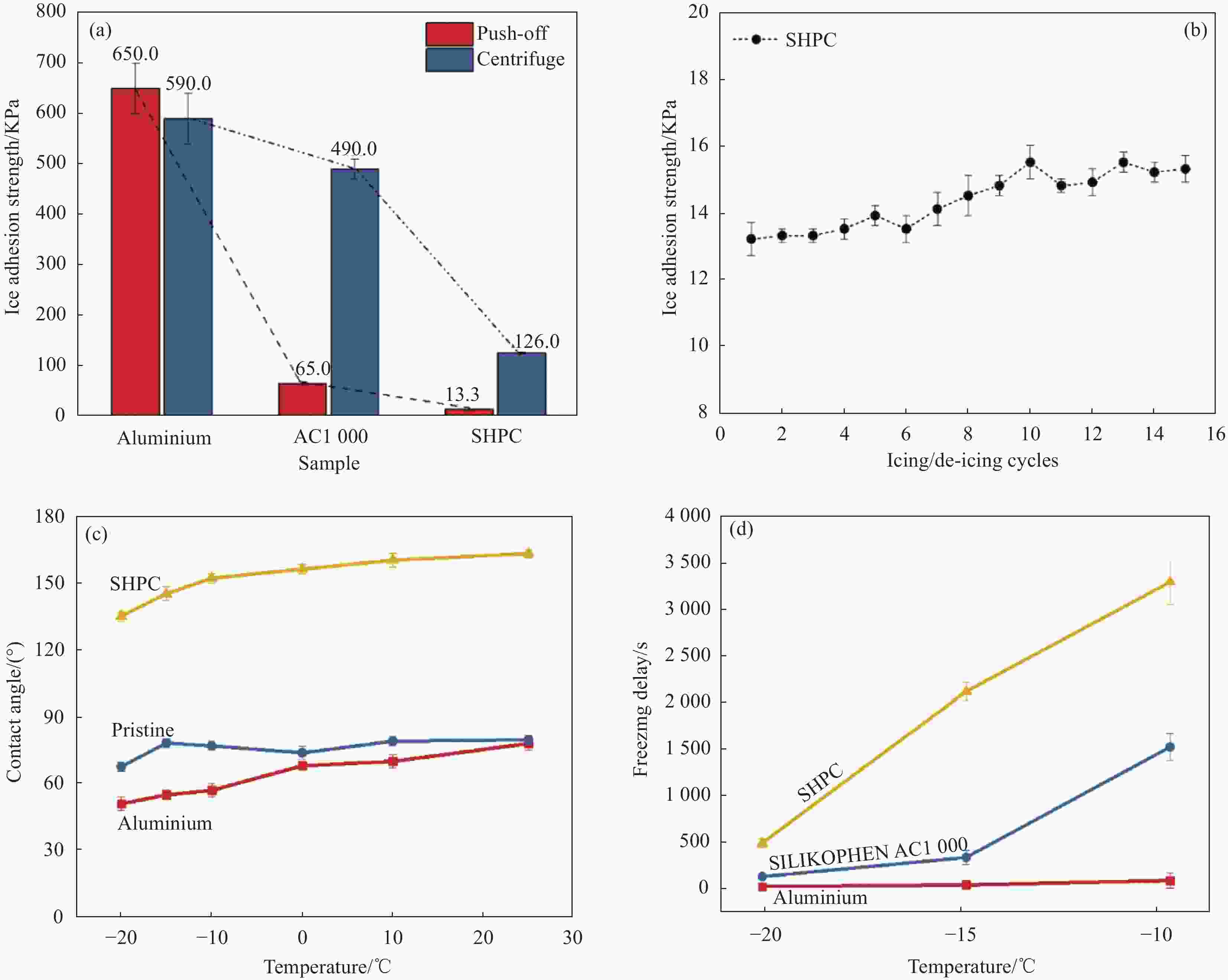

图 10 (a) 空白铝基材、SILIKOPHEN AC1000和超疏水(SHP)涂层的冰粘附强度; (b) SHP涂层的结冰/除冰耐久性; (c) 不同温度下样品表面的水接触角; (d) 不同亚冰点温度下样品表面水滴的冻结时间[72]

Figure 10. (a) Ice adhesion strength measurements by push-off and centrifuge tests on bare aluminium, SILIKOPHEN AC1000, and SHP coating; (b) icing/de-icing durability test results for the SHP coating; (c) CA of water droplets on the samples at different temperatures; (d) the freezing time of water droplets on different samples at different sub-freezing temperatures[72]

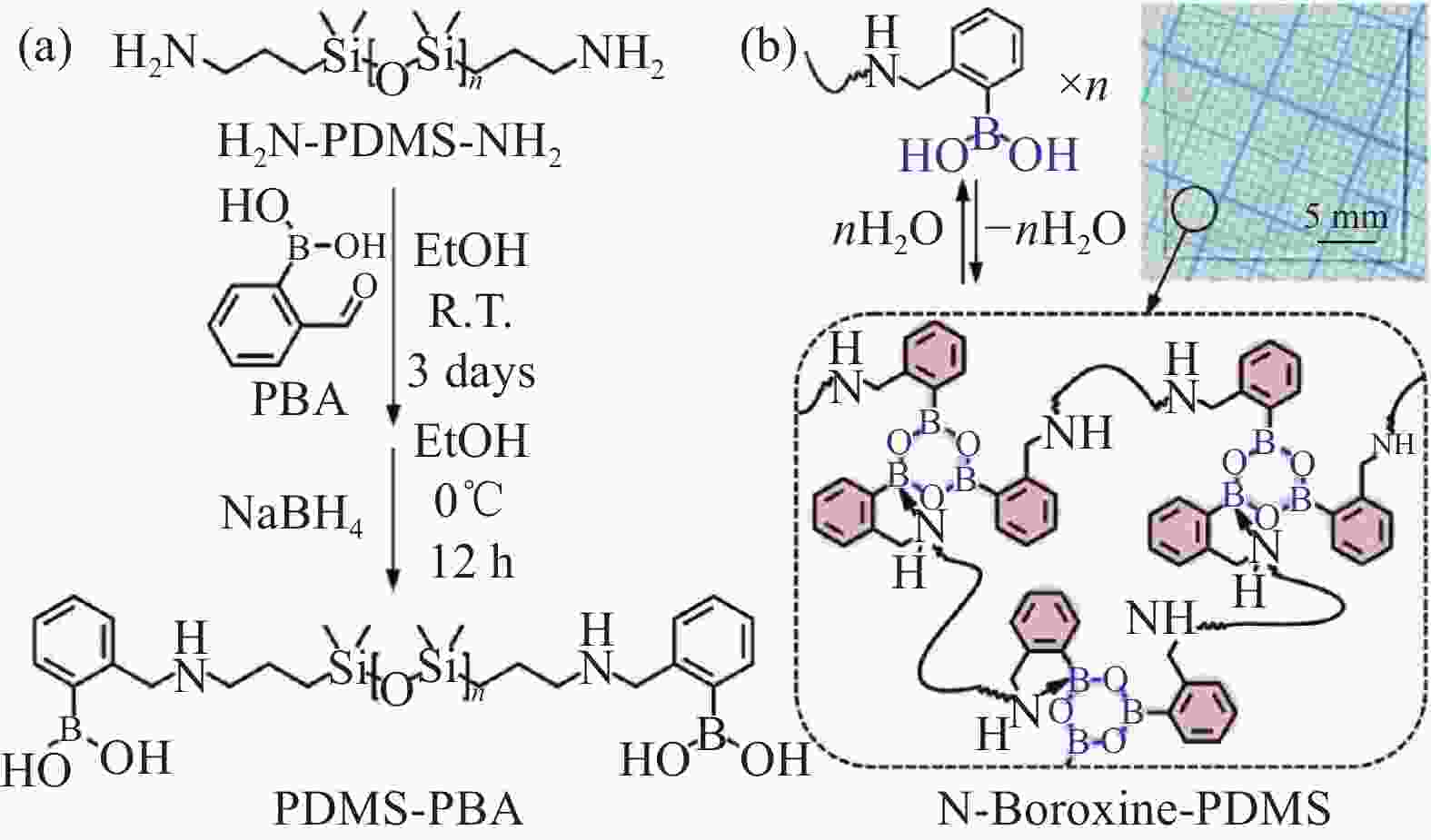

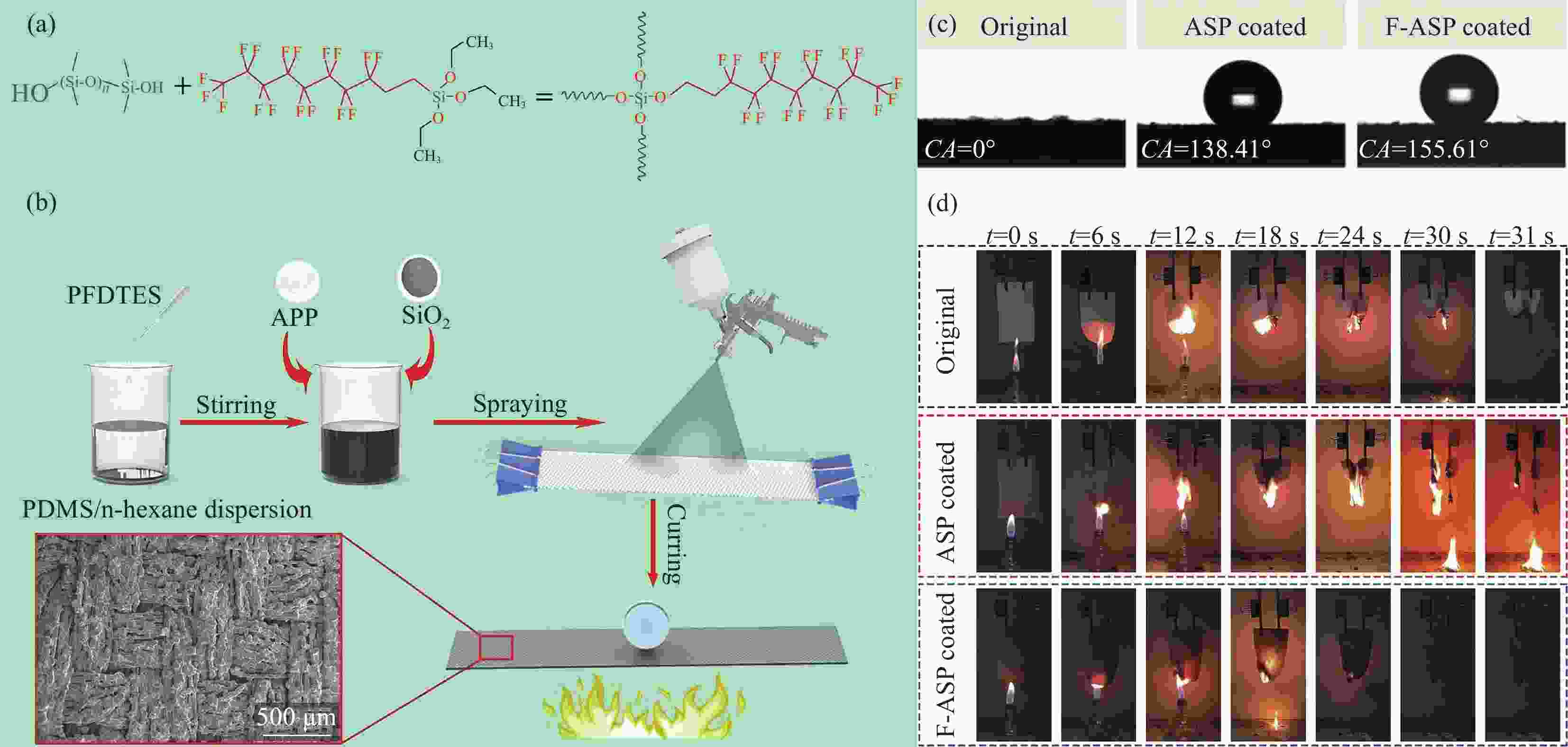

图 13 (a,b) 超疏水阻燃织物的制备工艺; (c) 未改性PET织物、ASP涂层织物和F-ASP涂层织物的接触角照片; (d) 未改性PET织物, ASP涂层织物和F-ASP涂层织物的垂直燃烧实验照片[86]

Figure 13. (a,b) Preparation process of super hydrophobic flame retardant fabric; (c) Contact Angle photos of unmodified PET fabric, ASP coated fabric and F-ASP coated fabric; (d) Photographs of vertical burning experiments of unmodified PET fabrics, ASP coated fabrics and F-ASP coated fabrics[86]

表 1 超疏水表面制备方法、性能及应用

Table 1. Preparation methods, properties and applications of superhydrophobic surface

Method Process Advantages Disadvantages Substrates Reference Templating method The low surface energy template was prepared, the rough structure of which was replicated, and subsequently removed Easy to process

Low costingStencil removal difficulty Glass

Metal[45-47] Sol-gel method Preparation of homogeneous sol, the sol into gel, remove the solvent in the gel, further solidification gel forming a superhydrophobic material with a specific structure Easy to process

Easy to controllong processing time

Easy to shrinkGlass

Fabric[48-52] Coating method Prepare coating solution and dry after spraying Low costing

Wide application rangePoor adhesion Glass

Metal

Wood

Fabric[53,54] Chemical deposition Through chemical reaction, low surface energy nanoparticles are deposited on the surface of the substrate to form fine and high-performance thin films Easy to process

Strong acid and alkaline resistanceSlow deposition rate

Air pollutionGlass

Wood

Fabric[55-57] Electro-chemical deposition Ions undergo a REDOX reaction under an applied electric field and attach other metal coatings to the surface of one metal by electrodeposition High efficiency

Corrosion resistancePoor adhesion

poor abrasion

Limited in applicationMetal [58-60] Laser etching High energy laser is used to ablate the substrate, which causes a series of reactions under photoelectric or photothermal action and changes the surface roughness of the substrate Easy to control and manipulate

Pollution-freeHigh cost, Glass

Metal[61-65] Chemical etching The glass or metal parts are immersed in an etching solution to obtain the desired etching structure and roughness Easy to process

Low costingPoor uniformity Glass

Metal[66-68] 表 2 多功能超疏水涂层

Table 2. Multifunctional superhydrophobic coating

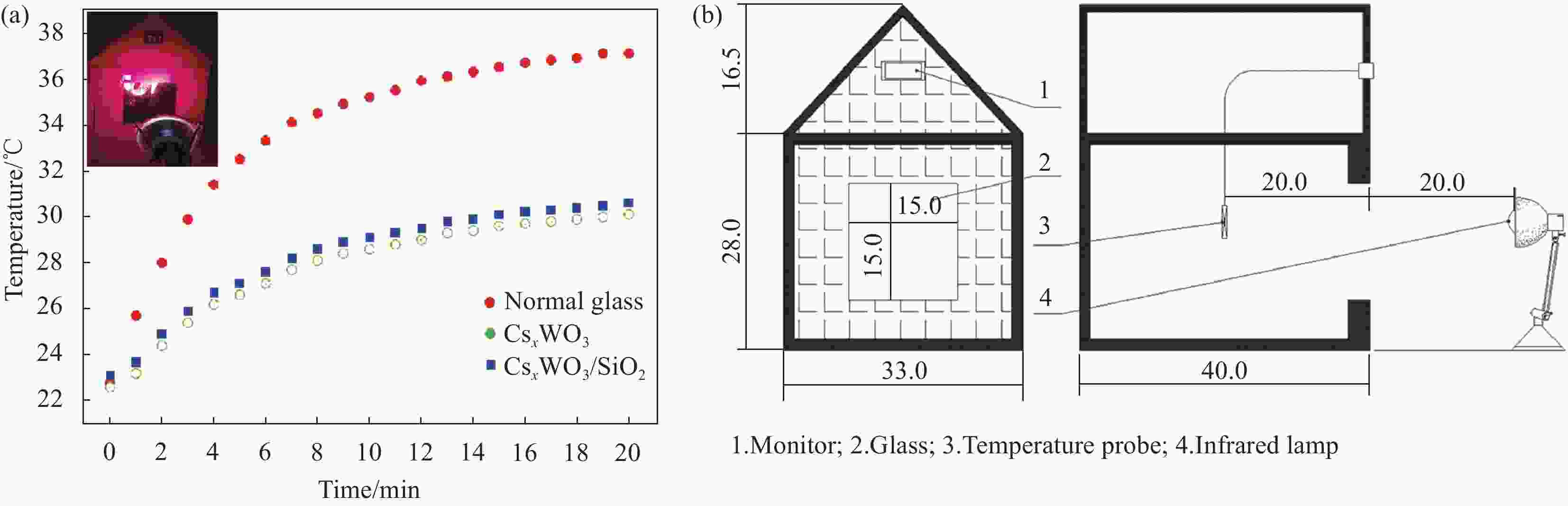

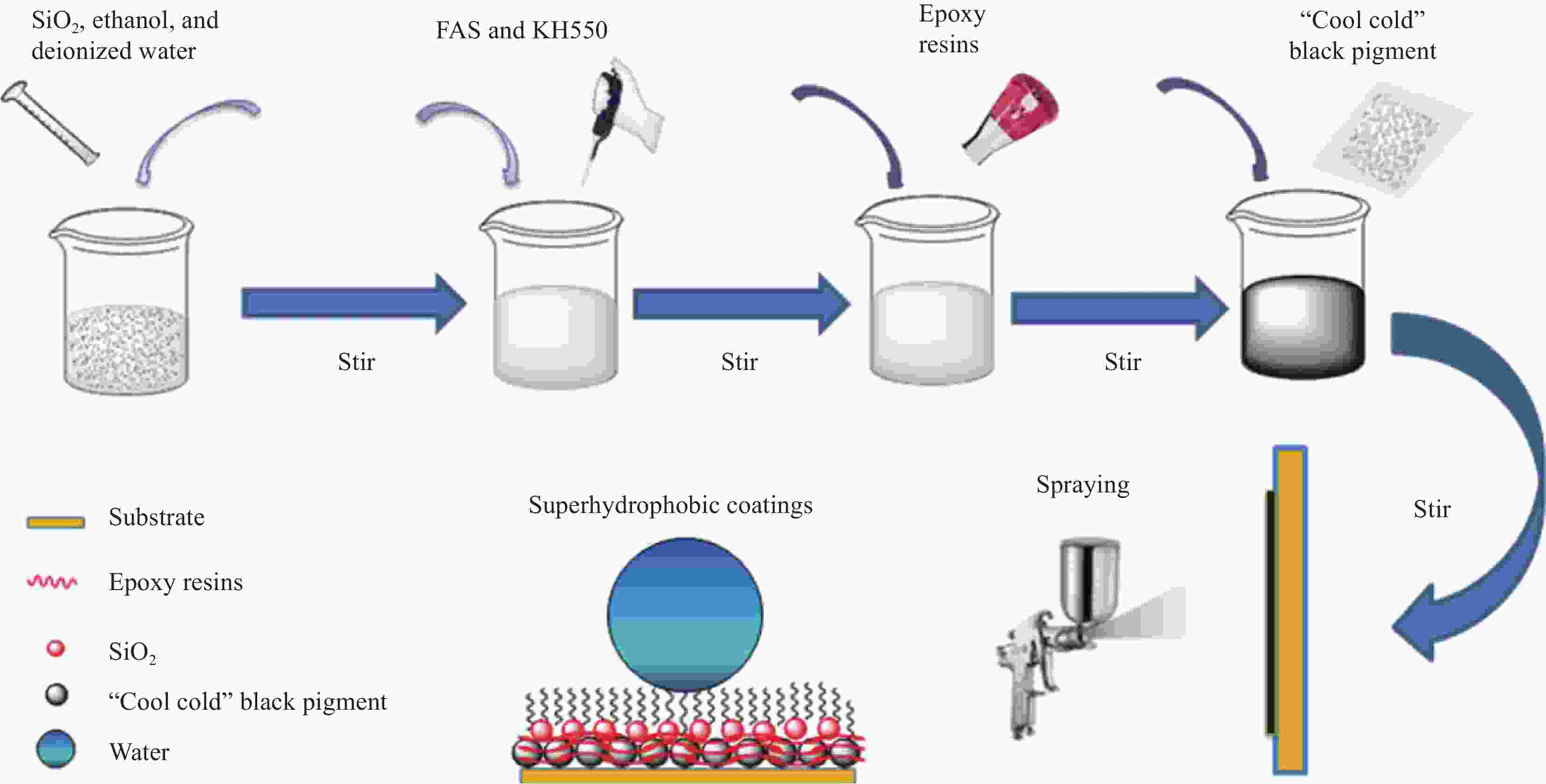

Function Principle Function and application Substrates Reference Anti-icing Inhibit ice cores, prevent frost formation, and reduce ice adhesion Reduce solid surface ice accumulation

Delayed icingSolar panels, cables [69-73] Anticorrosion A physical barrier is constructed between the substrate and the corrosive medium to inhibit interfacial corrosion Improve corrosion resistance of the substrate Ship shell, pipeline [74-76] Self-healing Regeneration of roughness structures, storage and release of healing agents Extended coating life Glass, wood, fabric [77-80] Flame retardant The coating forms a dense coke layer that causes the coated fabric to self-extinguishes during vertical combustion tests Enhance the flame retardancy of the substrate Fabrics, protective materials, furniture [81-86] Thermal insulation Near infrared reflection/shielding Heat insulation and cooling Window glass, outdoor cabinet [87-90] -

[1] TIAN D L, SONG Y L, JIANG L. Patterning of controllable surface wettability for printing techniques[J]. Chemical Society Reviews, 2013, 42(12): 5184-5209. doi: 10.1039/c3cs35501b [2] SU B, TIAN Y, JIANG L. Bioinspired interfaces with superwettability: from materials to chemistry[J]. Journal of the American Chemical Society, 2016, 138(6): 1727-1748. doi: 10.1021/jacs.5b12728 [3] PéREZ-GONZáLEZ C, ALERT R, BLANCH-MERCADER C, et al. Active wetting of epithelial tissues[J]. Nature Physics, 2018, 15(1): 79-88. [4] ZHAO C, ZHANG P, ZHOU J, et al. Layered nanocomposites by shear-flow-induced alignment of nanosheets[J]. Nature, 2020, 580(7802): 210-215. doi: 10.1038/s41586-020-2161-8 [5] FENG L B, ZHANG H X, WANG Z L, et al. Superhydrophobic aluminum alloy surface: Fabrication, structure, and corrosion resistance[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2014, 441: 319-325. doi: 10.1016/j.colsurfa.2013.09.014 [6] 赵美蓉, 周惠言, 康文倩, 等. 超疏水表面制备方法的比较[J]. 复合材料学报, 2021, 38(2): 361-379.ZHAO Meirong, ZHOU Huiyan, KANG Wenqian, et al. Comparison of methods for fabricating superhydrophobic surface[J]. Acta Materiae Compositae Sinica, 2021, 38(2): 361-379(in Chinese). [7] OLLIVIER H. Recherches sur la capillarité[J]. Journal de Physique Théorique et Appliquée, 1907, 6(1): 757-782. [8] WENZEL R N. Resistance of solid surfaces to wetting by water[J]. Industrial & Engineering Chemistry, 2002, 28(8): 988-994. [9] CASSIE A B D, BAXTER S. Wettability of porous surfaces[J]. Transactions of the Faraday Society, 1944, 40: 546-551. doi: 10.1039/tf9444000546 [10] BARTHLOTT W, NEINHUIS C. Purity of the sacred lotus, or escape from contamination in biological surfaces[J]. Planta, 1997, 202(1): 1-8. doi: 10.1007/s004250050096 [11] NEINHUIS C. Characterization and distribution of water-repellent, self-cleaning plant surfaces[J]. Annals of Botany, 1997, 79(6): 667-677. doi: 10.1006/anbo.1997.0400 [12] 武壮壮, 马国佳, 崔向中, 等. 微纳结构超疏水表面的浸润性及防冰性能[J]. 复合材料学报, 2020, 37(11): 2769-2775.WU Zhuangzhuang, MA Guojia, CUI Xiangzhong, et al. Wettability and anti-icing performance of micro-nano structure superhydrophobic surface[J]. Acta Materiae Compositae Sinica, 2020, 37(11): 2769-2775(in Chinese). [13] QIAN Z Q, WANG S D, YE X S, et al. Corrosion resistance and wetting properties of silica-based superhydrophobic coatings on AZ31B Mg alloy surfaces[J]. Applied Surface Science, 2018, 453: 1-10. doi: 10.1016/j.apsusc.2018.05.086 [14] CAO Y Z, LU Y M, LIU N, et al. Multi-applicable, durable superhydrophobic anti-icing coating through template-method and chemical vapor deposition[J]. Surfaces and Interfaces, 2022, 32: 102100. doi: 10.1016/j.surfin.2022.102100 [15] TANG J B, ZOU R Q, ZHANG X, et al. Combination of universal chemical deposition and unique liquid etching for the design of superhydrophobic aramid paper with bioinspired multiscale hierarchical dendritic structure[J]. ACS Applied Materials & Interfaces, 2022, 14(3): 4791-4807. [16] PANG B, ZHENG H P, JIN Z Q, et al. Inner superhydrophobic materials based on waste fly ash: Microstructural morphology of microetching effects[J]. Composites Part B:Engineering, 2024, 268: 111089. doi: 10.1016/j.compositesb.2023.111089 [17] LI S Y, XIANG X G, MA B H, et al. Facile preparation of diverse alumina surface structures by anodization and superhydrophobic surfaces with tunable water droplet adhesion[J]. Journal of Alloys and Compounds, 2019, 779(30): 219-228. [18] CHEN Y L, LI Z Q, CHENG W W, et al. A two-step laser-jet electrodeposition for the preparation of superhydrophobic surfaces on SUS304[J]. Surfaces and Interfaces, 2024, 45: 103907. doi: 10.1016/j.surfin.2024.103907 [19] TANG S W, WU Z G, FENG G X, et al. Multifunctional sandwich-like composite film based on superhydrophobic MXene for self-cleaning, photodynamic and antimicrobial applications[J]. Chemical Engineering Journal, 2023, 454(3): 140457. [20] GUZMáN E, RUBIO R G, ORTEGA F. A closer physico-chemical look to the Layer-by-Layer electrostatic self-assembly of polyelectrolyte multilayers[J]. Advances in Colloid and Interface Science, 2020, 282: 102197. doi: 10.1016/j.cis.2020.102197 [21] XIONG Z, HUANG J, WU Y Z, et al. Robust multifunctional fluorine-free superhydrophobic fabrics for high-efficiency oil-water separation with ultrahigh flux[J]. Nanoscale, 2022, 14: 5840. doi: 10.1039/D2NR00337F [22] SUTAR R S, LATTHE S S, BHOSALE A K, et al. Durable self-cleaning superhydrophobic coating of SiO2-cyanoacrylate adhesive via facile dip coat technique[J]. Macromolecular Symposia, 2019, 387(1): 1800218. doi: 10.1002/masy.201800218 [23] ZHANG X G, LIU Z J, LI Y, et al. Robust superhydrophobic epoxy composite coating prepared by dual interfacial enhancement[J]. Chemical Engineering Journal, 2019, 371: 276-285. doi: 10.1016/j.cej.2019.04.040 [24] LI D W, WANG H Y, LIU Y, et al. Large-scale fabrication of durable and robust super-hydrophobic spray coatings with excellent repairable and anti-corrosion performance[J]. Chemical Engineering Journal, 2019, 367: 169-179. doi: 10.1016/j.cej.2019.02.093 [25] NGUYEN-TRI P, TRAN H N, PLAMONDON C O, et al. Recent progress in the preparation, properties and applications of superhydrophobic nano-based coatings and surfaces: A review[J]. Progress in Organic Coatings, 2019, 132: 235-256. doi: 10.1016/j.porgcoat.2019.03.042 [26] 徐达, 肖振, 余新泉, 等. 多功能疏水/超疏水复合涂层的制备及其防覆冰性[J]. 复合材料学报, 2022, 39(3): 1102-1109.XU Da, XIAO Zhen, YU Xinquan, et al. Preparation and anti-icing characteristics of multifunctional hydrophobic/superhydrophobic composite coating[J]. Acta Materiae Compositae Sinica, 2022, 39(3): 1102-1109(in Chinese). [27] SVINTERIKOS E, ZUBURTIKUDIS I, ABU K H, et al. Multifunctional polymer-based coatings for outdoor glass surfaces: A state of the art[J]. Advanced Industrial and Engineering Polymer Research, 2023, 6(3): 310-332. doi: 10.1016/j.aiepr.2023.04.001 [28] ROWELL R L. Physical chemistry of surfaces, 6th ed[J]. Journal of Colloid & Interface Science, 1998, 208(2): 582. [29] WONG T S, KANG S H, TANG S K Y, et al. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity[J]. Nature, 2011, 477(7365): 443-447. doi: 10.1038/nature10447 [30] GOOD R J. Contact angle, wetting, and adhesion: a critical review[J]. Journal of Adhesion Science and Technology, 1992, 6(12): 1269-1302. doi: 10.1163/156856192X00629 [31] ROURA P. Thermodynamic derivations of the mechanical equilibrium conditions for fluid surfaces: Young’s and Laplace’s equations[J]. American Journal of Physics, 2005, 73(12): 1139-1147. doi: 10.1119/1.2117127 [32] CHEN F Z, WANG Y Q, TIAN Y L, et al. Robust and durable liquid-repellent surfaces[J]. Chemical Society Reviews, 2022, 51(20): 8476-8583. doi: 10.1039/D0CS01033B [33] K C G. The scientific papers of J. Willard Gibbs[J]. Nature, 1907, 75: 361-362. doi: 10.1038/075361a0 [34] DRELICH J W. Contact angles: From past mistakes to new developments through liquid-solid adhesion measurements[J]. Advances in Colloid and Interface Science, 2019, 267: 1-14. doi: 10.1016/j.cis.2019.02.002 [35] RAZIYEH A, CARLO A, Contact angle measurements: From existing methods to an open-source tool[J]. Advances in Colloid and Interface Science, 2021, 294: 102470. [36] WANG T, SHI L P, LV L, et al, Homogeneous surface hydrophilization on the inner walls of polymer tubes using a flexible atmospheric cold microplasma jet[J]. Plasma Process and Polymers, 2020, 17: 202000056. [37] HUHTAMäKI T, TIAN X, KORHONEN J T, et al. Surface-wetting characterization using contact-angle measurements[J]. Nature Protocols, 2018, 13: 1521-1538. doi: 10.1038/s41596-018-0003-z [38] ZHU M Y, HUANG L Y, ZHANG B, et al. Recent progress in optimal design of superhydrophobic surfaces[J]. APL Materials, 2022, 10(11): 110701. doi: 10.1063/5.0096796 [39] MARMUR A, DELLA VOLPE C, SIBONI S, et al. Contact angles and wettability: towards common and accurate terminology[J]. Surface Innovations, 2017, 5(1): 3-8. doi: 10.1680/jsuin.17.00002 [40] CLAUDIO D P. Formulas for data-driven control: Stabilization, optimality, and robustness[J]. IEEE Transactions on Automatic Control, 2020, 65: 909-924. doi: 10.1109/TAC.2019.2959924 [41] LIU P, LIU S Q, YU X Q, et al. Silane-triggered fabrication of stable waterborne superamphiphobic coatings[J]. Chemical Engineering Journal, 2021, 406(15): 127153. [42] ZHANG Q H, JIM B Y, WANG B, et al. Fabrication of a highly stable superhydrophobic surface with dual-scale structure and its antifrosting Properties[J]. Industrial & Engineering Chemistry Research, 2017, 56(10): 2754-2763. [43] LIN D, ZHANG X G, YUAN S C, et al, Robust waterborne superhydrophobic coatings with reinforced composite interfaces[J]. ACS Applied Materials & Interfaces, 2022, 12(42): 48216-48224. [44] XUE C H, LI M, GUO X J, et al. Fabrication of superhydrophobic textiles with high water pressure resistance[J]. Surface & Coatings Technology, 2017, 310: 134-142. [45] HE Q, MA Y W, WANG X S, et al. Superhydrophobic flexible silicone rubber with stable performance, anti-icing, and multilevel rough structure[J]. ACS Applied Polymer Materials, 2023, 5(7): 4729-4737. doi: 10.1021/acsapm.3c00273 [46] WANG J P, WU Y L, ZHANG D G, et al. Preparation of superhydrophobic flexible tubes with water and blood repellency based on template method[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2020, 587: 124331. doi: 10.1016/j.colsurfa.2019.124331 [47] TAO C Y, YAN H W, YUAN X D, et al. Synthesis of shape-controlled hollow silica nanostructures with a simple soft-templating method and their application as superhydrophobic antireflective coatings with ultralow refractive indices[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2016, 501: 17-23. [48] 王焆, 李晨, 徐博. 溶胶-凝胶法的基本原理、发展及应用现状[J]. 化学工业与工程, 2009, 26(3): 273-277.WANG Juan, LI Chen, XU Bo. Basic Principle, Advance and current application situation of sol-gel method[J]. Chemical Industry and Engineering, 2009, 26(3): 273-277(in Chinese). [49] RODRIGUEZ J E, ANDERSON A M, CARROLL M K. Hydrophobicity and drag reduction properties of surfaces coated with silica aerogels and xerogels[J]. Journal of Sol-Gel Science and Technology, 2014, 71(3): 490-500. doi: 10.1007/s10971-014-3388-3 [50] ZHENG K, ZHU J, LIU H, et al. Study on the superhydrophobic properties of an epoxy resin-hydrogenated silicone oil bulk material prepared by sol-gel methods[J]. Materials, 2021, 14(4): 988. doi: 10.3390/ma14040988 [51] LI Y, MEN X, ZHU X, et al. One-step spraying to fabricate nonfluorinated superhydrophobic coatings with high transparency[J]. Journal of Materials Science, 2015, 51(5): 2411-2419. [52] FENG J H, XIN J B, FENG Q G, et al. Facile fabrication of a low-cost, room-temperature curable superhydrophobic coating with excellent stability[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2023, 668: 131477. doi: 10.1016/j.colsurfa.2023.131477 [53] ZHU P, ZHU L J, GE F F, et al. Robust and transparent superamphiphobic coating prepared via layer-by-layer spraying[J]. Surface & Coatings Technology, 2021, 426: 127793. [54] DANESHMAND H, SAZGAR A, ARAGHCHI M. Fabrication of robust and versatile superhydrophobic coating by two-step spray method: An experimental and molecular dynamics simulation study[J]. Applied Surface Science, 2021, 567: 150825. doi: 10.1016/j.apsusc.2021.150825 [55] TAN R X, XIE H Y, SHE J Q, et al. A new approach to fabricate superhydrophobic and antibacterial low density isotropic pyrocarbon by using catalyst free chemical vapor deposition[J]. Carbon, 2019, 145: 359-366. doi: 10.1016/j.carbon.2019.01.041 [56] ZHENG J W, YANG J C, CAO W, et al. Fabrication of transparent wear-resistant superhydrophobic SiO2 film via phase separation and chemical vapor deposition methods[J]. Ceramics International, 2022, 48(21): 32143-32151. doi: 10.1016/j.ceramint.2022.07.154 [57] HUANG X, SUN M, SHI X, et al. Chemical vapor deposition of transparent superhydrophobic anti-icing coatings with tailored polymer nanoarray architecture[J]. Chemical Engineering Journal, 2023, 454: 139981. doi: 10.1016/j.cej.2022.139981 [58] ATUANYA C U, EKWEGHIARIRI D I, OBELE C M. Experimental study on the microstructural and anti-corrosion behaviour of Co-deposition Ni-Co-SiO2 composite coating on mild steel[J]. Defence Technology, 2018, 14(1): 64-69. doi: 10.1016/j.dt.2017.10.001 [59] WANG S, XUE Y, XUE Y, et al. Long-term durability of robust super-hydrophobic Co-Ni-Based coatings produced by electrochemical deposition[J]. Coatings, 2022, 12(2): 222. doi: 10.3390/coatings12020222 [60] YE Y, KANG Z, WANG F, et al. Achieving hierarchical structure with superhydrophobicity and enhanced anti-corrosion via electrochemical etching and chemical vapor deposition[J]. Applied Surface Science, 2023, 610: 155362. doi: 10.1016/j.apsusc.2022.155362 [61] CHEN L, HUANG G Q, HU T, et al. Fabrication of robust superhydrophobic surface on silicone rubber[J]. Composites Science and Technology, 2024, 247(1): 110401. [62] SONG Y X, WANG C, DONG X R, et al. Controllable superhydrophobic aluminum surfaces with tunable adhesion fabricated by femtosecond laser[J]. Optics and Laser Technology, 2018, 102: 25-31. doi: 10.1016/j.optlastec.2017.12.024 [63] JING X, XIA Y, CHEN F, et al. Preparation of superhydrophobic glass surface with high adhesion[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2022, 633(2): 127861. [64] WU Z, SHI C, CHEN A, et al. Large-scale, abrasion-resistant, and solvent-free superhydrophobic objects fabricated by a selective laser sintering 3D printing strategy[J]. Advanced Science, 2023, 10(9): 2207183. doi: 10.1002/advs.202207183 [65] LIN Y, HAN J P, CAI M Y, et al. Durable and robust transparent superhydrophobic glass surfaces fabricated by a femtosecond laser with exceptional water repellency and thermostability[J]. Journal of Materials Chemistry A, 2018, 6(19): 9049-9056. doi: 10.1039/C8TA01965G [66] ZHANG Y F, ZHANG L Q, XIAO Z, et al. Fabrication of robust and repairable superhydrophobic coatings by an immersion method[J]. Chemical Engineering Journal, 2019, 369: 1-7. doi: 10.1016/j.cej.2019.03.021 [67] KUMAR A, GOGOI B. Development of durable self-cleaning superhydrophobic coatings for aluminium surfaces via chemical etching method[J]. Tribology International, 2018, 122: 114-118. doi: 10.1016/j.triboint.2018.02.032 [68] WANG S, LIU M, FENG Y, et al. Bioinspired hierarchical copper oxide surfaces for rapid dropwise condensation[J]. Journal of Materials Chemistry A, 2017, 5(40): 21422-21428. doi: 10.1039/C7TA05087A [69] BOINOVICH L B, EMELYANENKO A M, EMELYANENKO K A, et al. Modus operandi of protective and anti-icing mechanisms underlying the design of longstanding outdoor icephobic coatings[J]. ACS Nano, 2019, 13(4): 4335-4346. doi: 10.1021/acsnano.8b09549 [70] SCHUTZIUS T M, JUNG S, MAITRA T, et al. Physics of icing and rational design of surfaces with extraordinary icephobicity[J]. Langmuir, 2015, 31(17): 4807-4821. doi: 10.1021/la502586a [71] ZHU T X, CHENG Y, HUANG J Y, et al. A transparent superhydrophobic coating with mechano-chemical robustness for anti-icing, photocatalysis and self-cleaning[J]. Chemical Engineering Journal, 2020, 399: 125746. doi: 10.1016/j.cej.2020.125746 [72] ALLAHDINI A, JAFARI R, MOMEN G. Transparent non-fluorinated superhydrophobic coating with enhanced anti-icing performance[J]. Progress in Organic Coatings, 2022, 165: 106758. doi: 10.1016/j.porgcoat.2022.106758 [73] ZHOU P, WANG Y, ZHANG X. Bi2Se3 nanosheets-based photothermal composites with hydrophobic surface for synergistic anti-/de-icing[J]. Composites Science and Technology, 2023, 233: 109916. doi: 10.1016/j.compscitech.2023.109916 [74] DENG R, SHEN T, CHEN H, et al. Slippery liquid-infused porous surfaces (SLIPSs): a perfect solution to both marine fouling and corrosion?[J]. Journal of Materials Chemistry A, 2020, 8(16): 7536-7547. doi: 10.1039/D0TA02000A [75] LI L J, HUANG T, LEI J L, et al. Robust biomimetic-structural superhydrophobic surface on aluminum alloy[J]. ACS Applied Materials & Interfaces, 2015, 7(3): 1449-1457. [76] QIAO M Y, JI G J, LU Y, et al. Sustainable corrosion-resistant superhydrophobic composite coating with strengthened robustness[J]. Journal of Industrial and Engineering Chemistry, 2023, 121: 215-227. doi: 10.1016/j.jiec.2023.01.025 [77] SAM P C, JUN K H, ANNA W, et al. Life and death of liquid-infused surfaces: a review on the choice, analysis and fate of the infused liquid layer[J]. Chemical Society Reviews, 2022, 49: 3688-3715. [78] LI Y, LI L, SUN J. Bioinspired self-healing superhydrophobic coatings[J]. Angewandte Chemie-International Edition, 2010, 49(35): 6129-6133. doi: 10.1002/anie.201001258 [79] WANG H X, XUE Y H, DING J, et al. Durable, self-healing superhydrophobic and superoleophobic surfaces from fluorinated-decyl polyhedral oligomeric silsesquioxane and hydrolyzed fluorinated alkyl silane[J]. Angewandte Chemie-International Edition, 2011, 50(48): 11433-11436. doi: 10.1002/anie.201105069 [80] LI X, LI B, LI Y, et al. Nonfluorinated, transparent, and spontaneous self-healing superhydrophobic coatings enabled by supramolecular polymers[J]. Chemical Engineering Journal, 2021, 404: 126504. doi: 10.1016/j.cej.2020.126504 [81] 李豫伟. 极限氧指数的测试及影响因素探究[J]. 科技资讯, 2014, 12(20): 224. doi: 10.3969/j.issn.1672-3791.2014.20.179LI Yuwei. The test of limiting oxygen index and its influencing factors[J]. Science & Technology Information, 2014, 12(20): 224(in Chinese). doi: 10.3969/j.issn.1672-3791.2014.20.179 [82] LIU J, SUN Y L, MA R, et al. Mechanically robust and flame-retardant superhydrophobic textiles with anti-biofouling performance[J]. Langmuir, 2022, 38(42): 12961-12967. doi: 10.1021/acs.langmuir.2c02248 [83] XUE C H, WU Y, GUO X J, et al. Superhydrophobic, flame-retardant and conductive cotton fabrics via layer-by-layer assembly of carbon nanotubes for flexible sensing electronics[J]. Cellulose, 2020, 27(6): 3455-3468. doi: 10.1007/s10570-020-03013-z [84] ALONGI J, CAROSIO F, MALUCELLI G. Current emerging techniques to impart flame retardancy to fabrics: An overview[J]. Polymer Degradation and Stability, 2014, 106: 138-149. doi: 10.1016/j.polymdegradstab.2013.07.012 [85] BADDAM Y, IJAOLA A O, ASMATULU E. Fabrication of flame-retardant and superhydrophobic electrospun nanofibers[J]. Surfaces and Interfaces, 2021, 23: 101017. doi: 10.1016/j.surfin.2021.101017 [86] HE Q, WANG J W, WANG G F, et al. Construction of a durable superhydrophobic flame-retardant coating on the PET fabrics[J]. Materials & Design, 2023, 233: 112258. [87] KE Y J, ZHOU C Z, ZHOU Y, et al. Emerging thermal-responsive materials and integrated techniques targeting the energy-efficient smart window application[J]. Advanced Functional Materials, 2018, 28: 1800113. doi: 10.1002/adfm.201800113 [88] SUN Z Q, XIE X M, XU W L, et al. Chameleon-inspired energy-saving smart window responding to natural weather[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(38): 12949-12959. [89] QI S, XIAO X, LU Y, et al. Preparation and energy consumption evaluation of bifunctional energy-efficient glass with superior superhydrophobic and heat shielding properties[J]. Energy and Buildings, 2020, 215: 109913. doi: 10.1016/j.enbuild.2020.109913 [90] ZHANG J, LIN W Q, ZHU C X, et al. Dark, infrared reflective, and superhydrophobic coatings by waterborne resins[J]. Langmuir, 2018, 34(19): 5600-5605. doi: 10.1021/acs.langmuir.8b00929 -

点击查看大图

点击查看大图

计量

- 文章访问数: 132

- HTML全文浏览量: 64

- 被引次数: 0

下载:

下载: