Preparation and properties of artificial auricles based on PVA/BNC composites

-

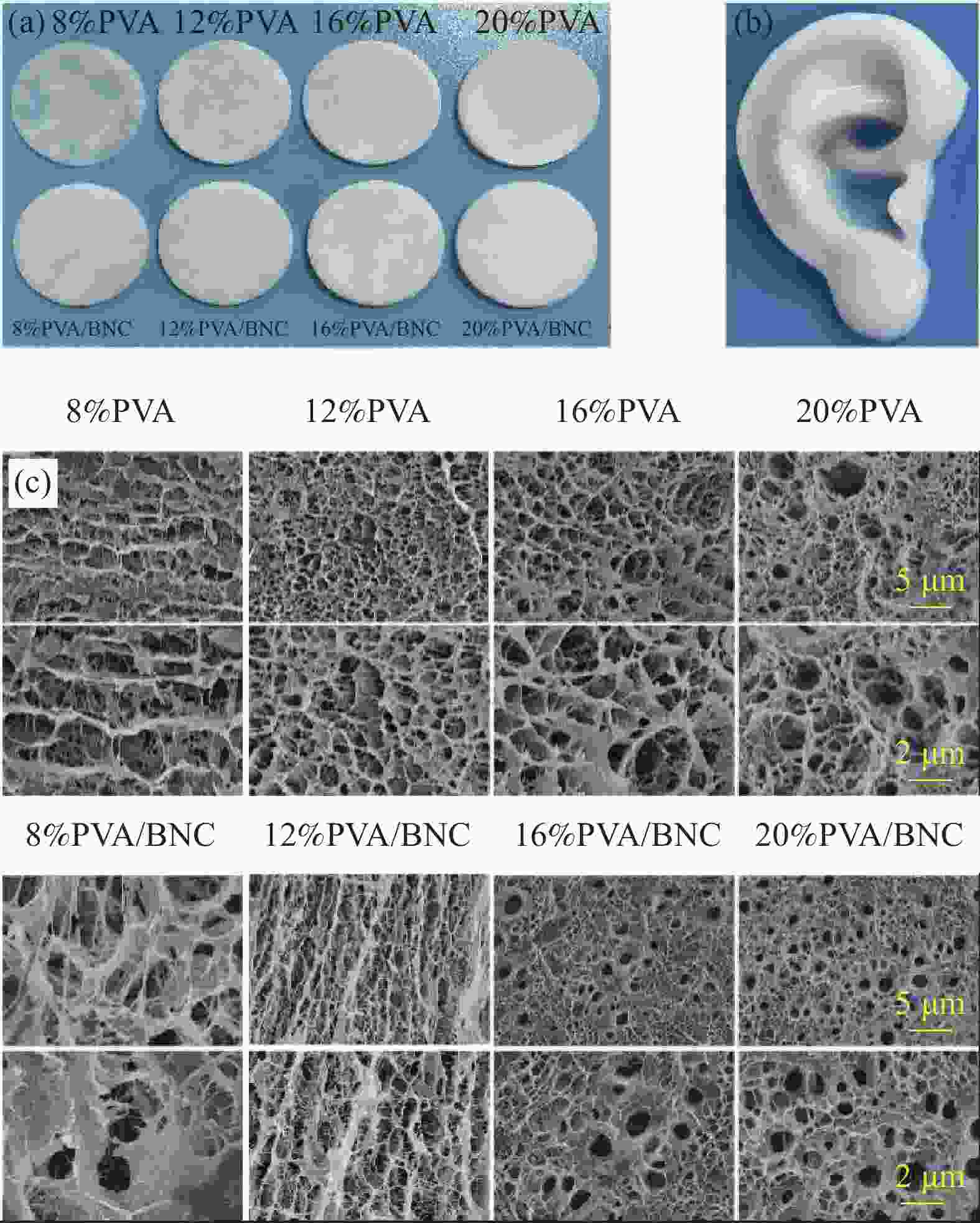

摘要: 耳廓再造的关键是实现植入材料与天然组织间的生物力学适配,然而迄今尚未找到一种理想的耳廓替代物。本研究将细菌纳米纤维素(Bacterial nanocellulose, BNC)匀浆加至不同浓度的聚乙烯醇(Polyvinyl alcohol, PVA)水溶液中,通过冻融法使两者物理交联形成兼具高弹柔韧性和高力学强度的PVA/BNC复合材料,并对其理化性能和细胞相容性进行表征。结果表明:该材料具有高吸水性、低溶胀比,较高的韧性、弹性和缝合强度等特点,最大压缩模量可达到6.98 ± 0.49 MPa,与天然耳廓组织的生物力学相适配。最大缝合强度可达7.06 ± 0.33 N,完全满足临床缝合需求。BNC的加入促进了细胞在材料表面的粘附、生长和增殖,使PVA/BNC复合材料具有更高的细胞密度和活力,是一种很有潜力的人工耳廓材料。Abstract: The key to auricle reconstruction is to achieve a biomechanical fit between the implanted material and the natural tissue. So far, an ideal auricle substitute has not been found. In this study, bacterial nanocellulose (BNC) homogenate was added into polyvinyl alcohol (PVA) aqueous solutions of different concentrations, and the freeze-thaw method was used to form PVA/BNC composite materials with both high elastic flexibility and high mechanical strength via physically cross-linking. The physical and chemical properties and cytocompatibility of the composites were characterized. The results show that the material has the characteristics of high water absorption, low swelling ratio, as well as high toughness, elasticity and suture strength. The maximum compressive modulus reaches 6.98 ± 0.49 MPa, which matches the biomechanics of natural auricle tissue. The maximum suture strength reaches 7.06 ± 0.33 N, which fully meets the needs of clinical suture. Addition of BNC promotes the adhesion, growth and proliferation of cells on the surface of the material, giving the PVA/BNC composite material higher cell density and vitality. All the results show that the PVA/BNC composite is a promising biomaterial for artificial auricles.

-

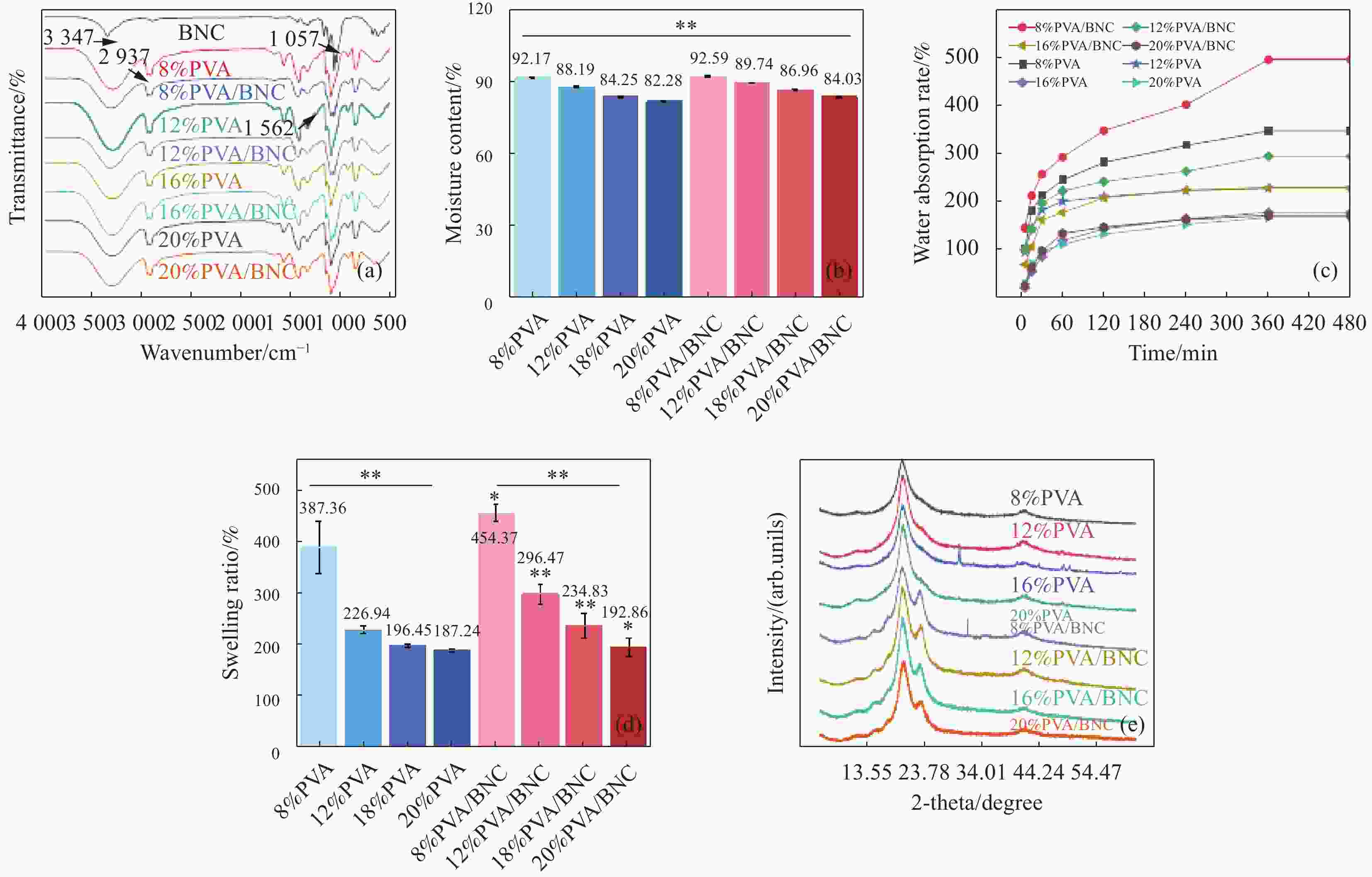

图 2 材料的基本理化性质

(a)不同浓度PVA、PVA/BNC材料的红外光谱图;(b)含水率;(c)吸水率;(d)饱和溶胀率;(e)X射线衍射图谱

Figure 2. Basic physical and chemical properties of materials

(a) Fourier transform infrared spectra of PVA and PVA/BNC materials with different concentrations;(b) Moisture content; (c) Water absorption rate;(d) Saturated swelling rate; (e) X-ray diffraction pattern

图 3 PVA和PVA/BNC材料的压缩力学性能与缝合强度

(a)不同浓度PVA、PVA/BNC材料的压缩强度;(b)压缩模量;(c)压缩应力-应变曲线;(d)16%PVA和PVA/BNC循环压缩应力-应变曲线;(e)循环压缩能量耗散与能量损耗系数;(f)缝合强度

Figure 3. Compressive mechanical properties and suture strength of PVA and PVA/BNC materials

(a) Compressive strength of PVA and PVA/BNC materials with different concentrations; (b) Compressive modulus; (c) Compressive stress-strain curves; (d) 16% PVA and PVA/BNC cyclic compressive stress-strain curves; (e) Cyclic compression energy dissipation and energy dissipation coefficient;(f) Suture retention

图 4 PVA、PVA/BNC材料的拉伸力学性能

(a)各PVA、PVA/BNC材料的拉伸强度;(b)拉伸模量;(c)断裂伸长率;(d)拉伸应力-应变曲线;(e)16%PVA和PVA/BNC循环拉伸应力-应变曲线;(f)循环拉伸韧性与能量损耗系数

Figure 4. Tensile mechanical properties of PVA and PVA/BNC materials

(a) Tensile strength of PVA and PVA/BNC materials; (b) Tensile modulus; (c) Elongation at break; (d) Tensile stress-strain curve; (e) 16% PVA and PVA/BNC cyclic tensile stress-strain curves; (f) Cyclic tensile toughness and energy dissipation coefficient

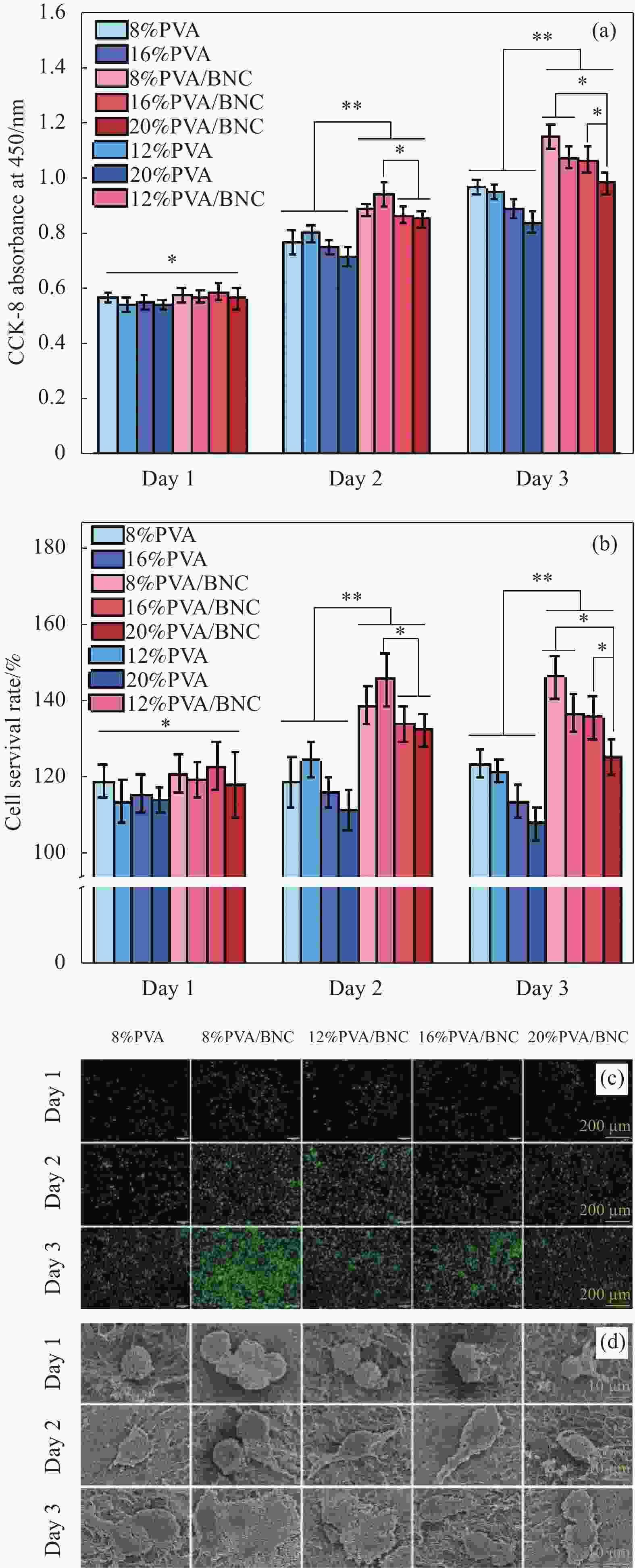

图 5 小鼠成纤维细胞的相容性

(a) CCK-8实验结果;(b)浸提液培养的细胞存活率;(c)浸提液培养L929细胞1、2、3天后细胞荧光图;(d)电镜显示细胞在材料上生长1、3、5天后的形态图

Figure 5. Cytocompatibility of mouse fibroblasts

(a) CCK-8 experimental results; (b) Cell viability of extract culture; (c) Cell fluorescence pattern of L929 cells after culture in extract for 1, 2 and 3 days; (d) Electron microscopy showing morphology of cells after 1, 3, and 5 days of growth on the material

表 1 孔隙率与比表面积测试结果

Table 1. Porosity and specific surface area test results

Sample Skeletal density/(g·cm−3) Apparent density/(g·cm−3) Porosity/% Specific surface area/(m2·g−1) BNC

16%PVA

16%PVA/BNC1.056 ± 0.017

1.219 ± 0.006

1.207 ± 0.0050.009

0.909

0.45599.17

25.47

62.2758.98

24.96

26.48Notes: BNC—Bacterial nanocellulose; PVA—Polyvinyl alcohol 表 2 材料的结晶度

Table 2. Crystallinity of materials

Sample Crystallinity/% BNC 44.73 ± 5.07 8%PVA 34.08 ± 4.36 12%PVA 34.66 ± 9.87 16%PVA 35.80 ± 8.60 20%PVA 36.15 ± 6.28 8%PVA/BNC 37.38 ± 7.52 12%PVA/BNC 38.39 ± 7.88 16%PVA/BNC 45.68 ± 3.94 20%PVA/BNC 40.07 ± 1.47 -

[1] JIANG C, ZHAO C, CHEN B, et al. Auricular reconstruction using Medpor combined with different hearing rehabilitation approaches for microtia[J]. Acta Otolaryngol, 2021, 141(6): 572-578. doi: 10.1080/00016489.2021.1900601 [2] SHIEH S J, TERADA S, VACANTI J P. Tissue engineering auricular reconstruction: in vitro and in vivo studies[J]. Biomaterials, 2004, 25(9): 1545-1557. doi: 10.1016/S0142-9612(03)00501-5 [3] PARK J Y, CHOI Y J, SHIM J H, et al. Development of a 3D cell printed structure as an alternative to autologs cartilage for auricular reconstruction[J]. J Biomed Mater Res B Appl Biomater, 2017, 105(5): 1016-1028. doi: 10.1002/jbm.b.33639 [4] 王艺蒙. 力学仿生耳软骨组织工程支架的3D打印及应用基础研究 [D]. 北京: 北京协和医学院, 2022.WANG Yimeng. Basic research on 3D printing and application of mechanical bionic ear cartilage tissue engineering scaffold [D]. Beijing: Peking Union Medical College, 2022(in Chinese). [5] FENG P, ZHAO R, TANG W, et al. Structural and Functional Adaptive Artificial Bone: Materials, Fabrications, and Properties[J]. Advanced Functional Materials, 2023, 33: 2214726. doi: 10.1002/adfm.202214726 [6] 张如鸿, 曹谊林. 全耳再造的过去、现在和将来[J]. 组织工程与重建外科, 2005, (02): 109-114.ZHANG Ruhong, CAO Yilin. The past, present and future of whole ear reconstruction[J]. Journal of Tissue Engineering and Reconstructive Surgery, 2005, (02): 109-114(in Chinese). [7] HAN Y, LI C, CAI Q, et al. Studies on bacterial cellulose/poly(vinyl alcohol) hydrogel composites as tissue-engineered corneal stroma[J]. Biomed Mater, 2020, 15: 035022. doi: 10.1088/1748-605X/ab56ca [8] SVENSSON A, NICKLASSON E, HARRAH T, et al. Bacterial cellulose as a potential scaffold for tissue engineering of cartilage[J]. Biomaterials, 2005, 26(4): 419-431. doi: 10.1016/j.biomaterials.2004.02.049 [9] 唐敬玉, 包露涵, 李雪, 等. 细菌纳米纤维素与聚乙烯醇复合水凝胶管的生物相容性表征[J]. 中国组织工程研究, 2017, 21(34): 5474-5480.TANG Jingyu, BAO Luhan, LI Xue, et al. Biocompatibility Characterization of Bacterial Nanocellulose and Polyvinyl Alcohol Composite Hydrogel Tubes[J]. Chinese Journal of Tissue Engineering Research, 2017, 21(34): 5474-5480(in Chinese). [10] HU G Q, CHEN L, ZHAO S, et al. Mercerization of tubular bacterial nanocellulose for control of the size and performance of small-caliber vascular grafts[J]. Chemical Engineering Journal, 2022, 428: 131104. doi: 10.1016/j.cej.2021.131104 [11] NIMESKERN L, MARTINEZ A H, SUNDBERG J, et al. Mechanical evaluation of bacterial nanocellulose as an implant material for ear cartilage replacement[J]. J Mech Behav Biomed Mater, 2013, 22: 12-21. doi: 10.1016/j.jmbbm.2013.03.005 [12] HU G Q, LI G L, CHEN L, et al. Production of novel elastic bacterial nanocellulose/polyvinyl alcohol conduits via mercerization and phase separation for small-caliber vascular grafts application[J]. International Journal of Biological Macromolecules, 2023, 239. [13] WANG J, GAO C, ZHANG Y, et al. Preparation and in vitro characterization of BC/PVA hydrogel composite for its potential use as artificial cornea biomaterial[J]. Materials Science and Engineering:C, 2010, 30(1): 214-218. doi: 10.1016/j.msec.2009.10.006 [14] ZHAO J, TONG H, KIRILLOVA A, et al. A Synthetic Hydrogel Composite with a Strength and Wear Resistance Greater than Cartilage[J]. Advanced Functional Materials, 2022, 32: 2205662. doi: 10.1002/adfm.202205662 [15] MILLON L E, WAN W K. The polyvinyl alcohol–bacterial cellulose system as a new nanocomposite for biomedical applications[J]. Journal of Biomedical Materials Research Part B:Applied Biomaterials, 2006, 79B(2): 245-253. doi: 10.1002/jbm.b.30535 [16] CHEN G, CHEN L, WANG W, et al. Manufacture of a novel anisotropic bacterial nanocellulose hydrogel membrane by using a rotary drum bioreactor[J]. Carbohydrate Polymers, 2019, 211: 281-288. doi: 10.1016/j.carbpol.2019.01.072 [17] YANG G, WANG C, HONG F, et al. Preparation and characterization of BC/PAM-AgNPs nanocomposites for antibacterial applications[J]. Carbohydrate Polymers, 2015, 115: 636-642. doi: 10.1016/j.carbpol.2014.09.042 [18] WAN W K, CAMPBELL G, ZHANG Z F, et al. Optimizing the tensile properties of polyvinyl alcohol hydrogel for the construction of a bioprosthetic heart valve stent[J]. J Biomed Mater Res, 2002, 63(6): 854-861. doi: 10.1002/jbm.10333 [19] GROULT S, BUDTOVA T. Thermal conductivity/structure correlations in thermal super-insulating pectin aerogels[J]. Carbohydrate Polymers, 2018, 196: 73-81. doi: 10.1016/j.carbpol.2018.05.026 [20] CHEN Q, ZHANG X, CHEN K, et al. Bilayer Hydrogels with Low Friction and High Load-Bearing Capacity by Mimicking the Oriented Hierarchical Structure of Cartilage[J]. ACS Applied Materials & Interfaces, 2022, 14(46): 52347-52358. [21] 郭佩佩, 蒋海越. 颞浅筋膜瓣在整形修复外科领域的临床应用进展[J]. 中华整形外科杂志, 2019, 35(12): 1271-1274. doi: 10.3760/cma.j.issn.1009-4598.2019.12.022GUO Peipei, JIANG Haiyue. Clinical application of temporal superficial fascia flap in plastic surgery[J]. Chinese Journal of Plastic Surgery, 2019, 35(12): 1271-1274 (in Chinese). doi: 10.3760/cma.j.issn.1009-4598.2019.12.022 [22] LUO Y H, LI G L, CHEN L, et al. Preparation and Evaluation of Bacterial Nanocellulose/Hyaluronic Acid Composite Artificial Cornea for Application of Corneal Transplantation[J]. Biomacromolecules, 2023, 24(1): 201-212. doi: 10.1021/acs.biomac.2c01052 [23] 王森. 高强度大孔聚乙烯醇水凝胶的制备和机理分析 [D]. 大连: 大连理工大学, 2020.WANG Sen. Preparation and mechanism analysis of high-strength macroporous polyvinyl alcohol hydrogel [D]. Dalian: Dalian University of Technology, 2020(in Chinese). [24] PAN Y S, XIONG D, CHEN X L. Mechanical properties of nanohydroxyapatite reinforced poly(vinyl alcohol) gel composites as biomaterial[J]. Journal of Materials Science, 2007, 42(13): 5129-5134. doi: 10.1007/s10853-006-1264-4 [25] GRIFFIN M F, PREMAKUMAR Y, SEIFALIAN A M, et al. Biomechanical Characterisation of the Human Auricular Cartilages; Implications for Tissue Engineering[J]. Annals of Biomedical Engineering, 2016, 44(12): 3460-3467. doi: 10.1007/s10439-016-1688-1 [26] KOSHUT W J, RUMMEL C, SMOOT D, et al. Flaw Sensitivity and Tensile Fatigue of Poly(Vinyl Alcohol) Hydrogels[J]. Macromolecular Materials and Engineering, 2021, 306: 200679. [27] NAYYER L, BIECHALL M, SEIFALIAN A M, et al. Design and development of nanocomposite scaffolds for auricular reconstruction[J]. Nanomedicine: Nanotechnology, Biology and Medicine, 2014, 10(1): 235-246. [28] TANG S, CHI K, XU H, et al. A covalently cross-linked hyaluronic acid/bacterial cellulose composite hydrogel for potential biological applications[J]. Carbohydr Polym, 2021, 252: 117123. doi: 10.1016/j.carbpol.2020.117123 -

点击查看大图

点击查看大图

计量

- 文章访问数: 53

- HTML全文浏览量: 45

- 被引次数: 0

下载:

下载: